Page 1

Critical Power

Product Manual

CPS3200U Upstream System

Remote Power System

48 Vdc Input, ±190 Vdc Output

Converter/Limiter System

Service and Assistance - +1 877 546 3243 or +1 972 244 9288 PE.TechSupport@ge.com

© 2013 General Electric Company. All rights reserved. http://www.ge.com/powerelectronics

CC848779826 Issue 09 December 2013 1

Page 2

CPS3200U Upstream System – 23” Product Manual CPS3200U

Table of Contents

Table of Contents ...............................................................................................................................................................................................................................2

Table of Figures ..................................................................................................................................................................................................................................3

Table of Tables ....................................................................................................................................................................................................................................4

1 Introduction ......................................................................................................................................................................................................................................5

Reference Documents ............................................................................................................................................................................................................5

Customer Service Contacts ..................................................................................................................................................................................................6

On-Line Power Systems Product Manuals and Software .......................................................................................................................................6

2 Product Description .......................................................................................................................................................................................................................7

Operation .....................................................................................................................................................................................................................................7

Configurations ...........................................................................................................................................................................................................................7

Specifications .............................................................................................................................................................................................................................8

3 Ordering .............................................................................................................................................................................................................................................9

Ordering Codes ..........................................................................................................................................................................................................................9

Lugs ................................................................................................................................................................................................................................................9

4 Safety................................................................................................................................................................................................................................................ 10

Safety Statements ................................................................................................................................................................................................................. 10

Warning Statements and Safety Symbols .................................................................................................................................................................. 13

Precautions .............................................................................................................................................................................................................................. 14

5 Pre-Installation ............................................................................................................................................................................................................................. 15

Purpose ...................................................................................................................................................................................................................................... 15

Audience .................................................................................................................................................................................................................................... 15

Precautions .............................................................................................................................................................................................................................. 15

Safety .......................................................................................................................................................................................................................................... 15

Installation Tools .................................................................................................................................................................................................................... 15

System Identification ........................................................................................................................................................................................................... 15

6 Installing the Shelf Level Upstream Product ................................................................................................................................................................... 16

Unpacking Shelf Level Upstream Product .................................................................................................................................................................. 16

Installing and Powering the CP3200U Converter Shelf ......................................................................................................................................... 16

Ground the Shelf .................................................................................................................................................................................................................... 18

Attach the Load Wiring ....................................................................................................................................................................................................... 18

Set Shelf ID and Attach Alarm Wiring ........................................................................................................................................................................... 20

Installing the Baffle ............................................................................................................................................................................................................... 22

Installing the Fan Shelf ........................................................................................................................................................................................................ 22

Installing the Filter Bracket and Filter ........................................................................................................................................................................... 26

7 Inspect the Network - Check and Mark Wiring Compliance .................................................................................................................................... 28

8 Final Installation........................................................................................................................................................................................................................... 29

Installing the Converters .................................................................................................................................................................................................... 29

Apply DC Power ...................................................................................................................................................................................................................... 30

Recognizing Normal States ............................................................................................................................................................................................... 30

QS982A LED Information Map ......................................................................................................................................................................................... 31

Confirm Operation of Alarm Wiring ............................................................................................................................................................................... 32

Installing the QS941A Ethernet Module ....................................................................................................................................................................... 32

Installing the Office Alarm Connector ........................................................................................................................................................................... 36

9 Reference Information .............................................................................................................................................................................................................. 37

QS982A Converter LED Information Map .................................................................................................................................................................... 37

QS982A LED Information Map (visual) .......................................................................................................................................................................... 38

Alarm Card Information ...................................................................................................................................................................................................... 39

QS912A Converter Shelf ..................................................................................................................................................................................................... 40

QS930A Fan Shelf .................................................................................................................................................................................................................. 42

10 Maintenance ............................................................................................................................................................................................................................... 43

Filter Cleaning ......................................................................................................................................................................................................................... 43

11 Product Warranty ..................................................................................................................................................................................................................... 44

Appendix A: Operating Temperature Measurement and Vertical Spacing........................................................................................................... 46

Operating Temperature ...................................................................................................................................................................................................... 46

Baffles and Fan Trays .......................................................................................................................................................................................................... 46

Appendix B: Alarm Reference Table ....................................................................................................................................................................................... 47

Appendix C: Operation without a Controller - Alarm Wiring ....................................................................................................................................... 49

CPS3200U Shelf Alarm Card State Table ..................................................................................................................................................................... 50

Alarm Card Logical Operation of LEDs and Alarm Relays .................................................................................................................................... 50

Revision History ............................................................................................................................................................................................................................... 51

CC848779826 r09 December 2013 2

Page 3

CPS3200U Upstream System – 23” Product Manual CPS3200U

Table of Figures

Figure 1 Block Diagram -48V Fed CPS3200U Shelf ............................................................................................................................................................ 7

Figure 2 Capacitance Safety Limits......................................................................................................................................................................................... 12

Figure 3 QS912A Converter Shelf ............................................................................................................................................................................................. 16

Figure 4 Mounting the Converter Shelf .................................................................................................................................................................................. 16

Figure 5 Preparing to Make DC Connections to Converter Shelf ................................................................................................................................ 17

Figure 6 Making DC Connections to Converter Shelf ...................................................................................................................................................... 17

Figure 7 Grounding Converter Shelf ....................................................................................................................................................................................... 18

Figure 8 Output Wiring for Converter Shelves .................................................................................................................................................................... 19

Figure 9 Accessing Alarm Cards ............................................................................................................................................................................................... 20

Figure 10 Removing Alarm Card .............................................................................................................................................................................................. 20

Figure 11 Setting Shelf ID ............................................................................................................................................................................................................ 21

Figure 12 Signal Wiring between Converter Shelves....................................................................................................................................................... 21

Figure 13 Installing a Baffle ........................................................................................................................................................................................................ 22

Figure 14 Mounting the Fan Shelf ............................................................................................................................................................................................ 22

Figure 15 Inserting Fan Trays .................................................................................................................................................................................................... 23

Figure 16 Open the Wiring Region of the Fan Shelf ......................................................................................................................................................... 23

Figure 17 Alarm Wiring for Fan Shelf ..................................................................................................................................................................................... 24

Figure 18 DC Cabling Fan Trays in CPS3200U Systems ................................................................................................................................................. 24

Figure 19 Cover the Wiring Region of the Fan Shelf ........................................................................................................................................................ 25

Figure 20 Fan Tray LEDs .............................................................................................................................................................................................................. 25

Figure 21 Mounting the Filter Bracket.................................................................................................................................................................................... 26

Figure 22 Filter Retention Bracket ........................................................................................................................................................................................... 26

Figure 23 Install Filter .................................................................................................................................................................................................................... 27

Figure 24 Secure Filter Retention Bracket ............................................................................................................................................................................ 27

Figure 25 Shelf Level ESD Jack .................................................................................................................................................................................................. 29

Figure 26 Installing Converters ................................................................................................................................................................................................. 29

Figure 27 QS982A Faceplate and LEDs ................................................................................................................................................................................. 30

Figure 28 Fan Shelf Right Hand Cover ................................................................................................................................................................................... 32

Figure 29 Fan Shelf Controller Jumper .................................................................................................................................................................................. 32

Figure 30 Preparing a Fan Shelf for a CPS Controller ...................................................................................................................................................... 33

Figure 31 Installing the Controller ........................................................................................................................................................................................... 33

Figure 32 Controller Wiring ......................................................................................................................................................................................................... 34

Figure 33 Fan Shelf RS-485 Jacks ............................................................................................................................................................................................ 35

Figure 34 Signal Cables - System ............................................................................................................................................................................................. 35

Figure 35 Office Alarm Cable Pinout ....................................................................................................................................................................................... 36

Figure 36 QS982 LEDs and Test Points .................................................................................................................................................................................. 37

Figure 37 Alarm Card Faceplate ............................................................................................................................................................................................... 39

Figure 38 Shelf ID Rotary Switches.......................................................................................................................................................................................... 39

Figure 39 QS912A Dimensions .................................................................................................................................................................................................. 40

Figure 40 Output Connectors .................................................................................................................................................................................................... 41

Figure 41 QS930 Fan Shelf Dimensions ................................................................................................................................................................................ 42

Figure 42 QS930 Fan Shelf Connections and Fuses ........................................................................................................................................................ 42

Figure 43 Converter Shelf with Slot Fillers ............................................................................................................................................................................ 46

Figure 44 Alarm Card Office Alarm Pinout and Shelf ID ................................................................................................................................................. 49

Figure 45 Alarm Card Office Alarm Cables .......................................................................................................................................................................... 49

CC848779826 r09 December 2013 3

Page 4

CPS3200U Upstream System – 23” Product Manual CPS3200U

Table of Tables

Table 1 Specifications ..................................................................................................................................................................................................................... 8

Table 2 Ordering Codes .................................................................................................................................................................................................................. 9

Table 3 Output Connector Pinout ............................................................................................................................................................................................ 19

Table 4 QS982A LED Information Map ................................................................................................................................................................................... 31

Table 5 QS982A Converter LED Information Map ............................................................................................................................................................. 37

Table 6 QS982A Converter LED Information Map (visual) .............................................................................................................................................. 38

Table 7 Output Connector Pinout ............................................................................................................................................................................................ 41

Table 8 Alarm Reference .............................................................................................................................................................................................................. 47

Table 9 Shelf Alarm Card State ................................................................................................................................................................................................. 50

CC848779826 r09 December 2013 4

Page 5

CPS3200U Upstream System – 23” Product Manual CPS3200U

1 Introduction

Overview

The CPS3200U is the premier upstream dc/dc converter for line powering FTTN networks. The 3200U contains 16 dc/dc

converter/limiter cards in a dense 2 RU shelf. Each card contains a pair of independent -48 Vdc input to ±190 Vdc

output converters with each output safety limited to 100VA. In addition, each output terminal is safety Ground Fault

protected. The cards are fully connectorized and insulator shielded, inrush current protected and completely hot

swappable, making card addition to in-service shelves in the field an easy, one step process. The converter card shelf is

completely front access, with all -48V input and RJ21 output connections made on connectors in front of the midmount shelf brackets. The alarm and communications connections are also on the front of the shelf.

The CPS3200U converter shelf meets the applicable requirements of these North American product standards:

UL60950-21, UL60950-1, Telcordia GR-3108-CORE, GR-1089-CORE, GR-487-CORE (converter shelf), and GR-063-CORE.

Summary

The CPS3200U Upstream System delivers power over telephone lines. The primary application is enabling the delivery of

video bandwidth data rates to residences over twisted pairs by allowing placement of powered electronics at an

acceptable distance from the residence.

48 Vdc Input, ±190 Vdc Output Converter/Limiter System distributes battery backed up power from existing -48V

battery backed up sites like Central Offices and Remote terminals to reliably power electronics near the home. It does

this by converting the -48V to a UL60950-21 safety approved + and – 190V current limited and ground fault protected

source. Each front access shelf provides 32 channels.

Reference Documents

Document Title

CC848836981 Galaxy Pulsar Edge Product Manual

CC848853457 CPS3200U Technical Support Guide

Line Power Product Line Brochure – Specifications and Ordering Guide

CC848779826 r09 December 2013 5

Page 6

CPS3200U Upstream System – 23” Product Manual CPS3200U

Calling from

Phone Number

+1 877 546 3243

+1 972 244 9288

Or contact your local field support center or your sales representative to discuss your specific needs.

Customer Service Contacts

Customer Service, Customer Training, Technical Support,

Product Repair and Return, and Warranty Service

Services provided include initiating the spare parts procurement process, ordering documents, product warranty

administration, and providing other product and service information.

GE Energy phones are staffed from 7:00 am to 5:00 pm USA Central Time Zone (GMT -6), Monday through Friday, on

normal business days. At other times, this number is still available, but for emergencies only.

• United States, Canada, Puerto Rico, and the US Virgin

Islands

• All other countries

Or

1

USADCC

+ 877 546 3243

On-Line Power Systems Product Manuals and Software

Product manuals, technical support guides, product line brochures, and software are available on-line. Software

includes Easy View and SNMP MIB.

http://www.gecriticalpower.com

1

The USA direct country code for the country where the call is originating

CC848779826 r09 December 2013 6

Page 7

CPS3200U Upstream System – 23” Product Manual CPS3200U

2 Product Description

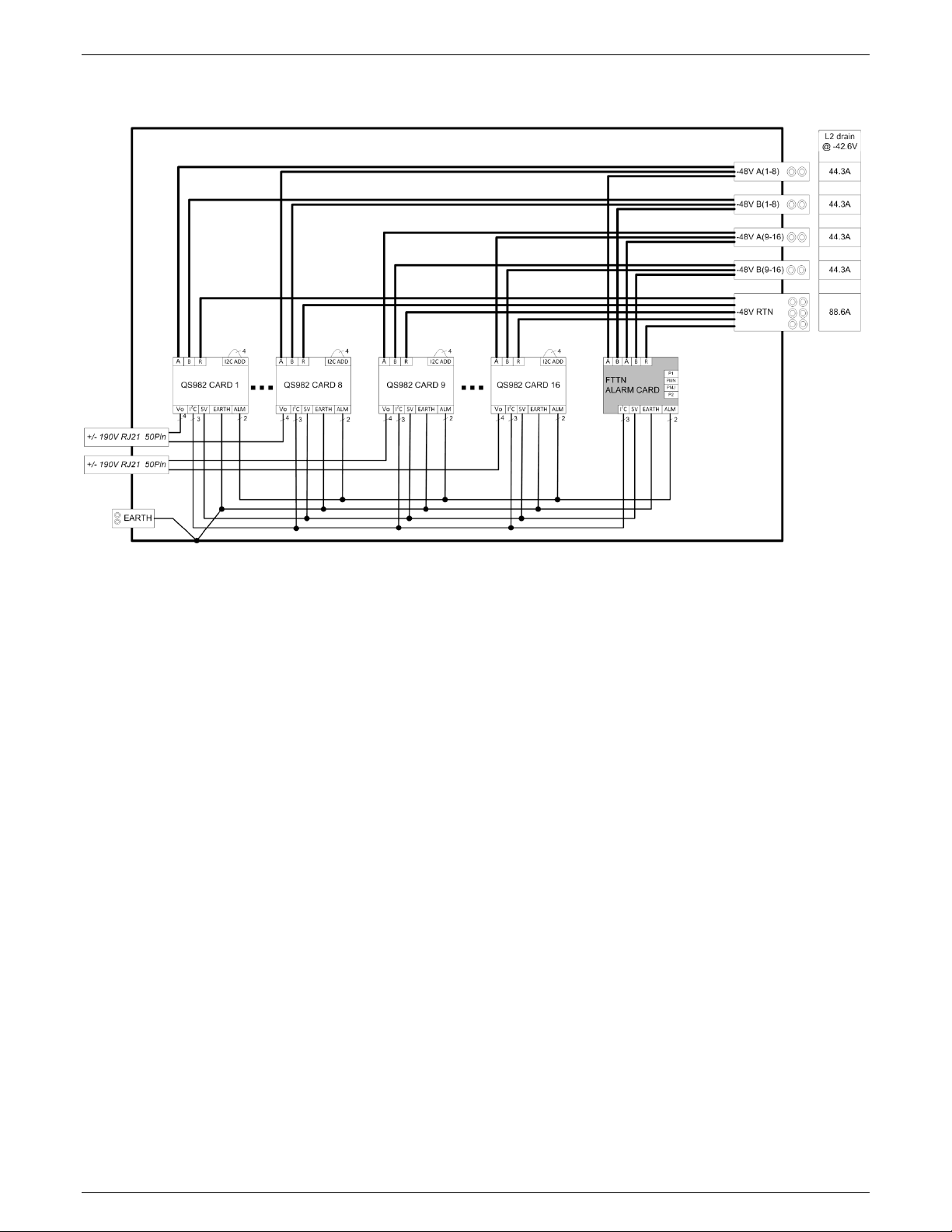

Figure 1 Block Diagram -48V Fed CPS3200U Shelf

Basic block diagram of single converter shelf System

Operation

Power comes in as -48V and is distributed in an A and B redundant fashion to each of the converter cards and the

alarm card. There are two +/-190V circuits on each converter card. The circuits both boost the voltage and limit the

current as prescribed by UL60950-21 and GR-1089-CORE.

Warning: Ground faults or short circuits on the output do not permanently disconnect the output. The converter circuit

tests the line every 4 seconds and will re-energize if the wiring fault is cleared.

A serial communication bus links each converter to an alarm card at the end of each shelf.

The alarm card provides major and minor form C contacts, manages the converters and relays information to a Lineage

Power CPS6000 family controller using Galaxy Protocol over an RS485 bus. Up to 24 shelves can be controlled and

monitored by one CPS6000 family controller. The CPS6000 controller is WEB and SNMP capable.

Configurations

32 circuit, front access +/-190V shelves come in two configurations - airflow from bottom to top and airflow from top to

bottom. A single IP drop can be used to manage up to 24 shelves or 768 circuits.

CC848779826 r09 December 2013 7

Page 8

CPS3200U Upstream System – 23” Product Manual CPS3200U

Table 1 Specifications

Electrical

Parameter

Symbol

Min

Typical

Max2

Unit

Input Voltage

Operating Continuous

Non-operating, No Damage

V

-40 0 -52.8

-60

-40

Vdc

Transient (@ duration =)

1 µs

V

-200

Input Current - (per half shelf

at 97.7W on all circuits)

VIN = 54.4V

I

IN

34.7

Adc

VIN = 52.1V

I

IN

36.2

Adc

VIN = 42.6V

I

IN

44.3

Adc

VIN = 40.0V

I

47.2

Adc

Temperature

Normal Operating Ambient

Temperature at 150 lfm airflow

TA -40 50

°C

Operating Ambient Temperature

at higher (TBD) airflow

TA -40 75

°C

Cold Start Temperature

TA

-40

°C

Storage Temperature

T

stg

-55 85

°C

Power – per C/L Card

Input Power at -42.6 Vdc input

Pin

2403

W

Power Dissipation

Pdiss

21

40*

W

Output Power

Pout

200

W

Output

Voltage – line to line

VO 378

380

382

Vdc

Power – per C/L circuit

PO 95.0

97.7

100

W

Current – per C/L circuit

I

OUT

251

257

262

mA

Isolation

Input to Output Voltage

1500

Vdc

Physical

Height

in (mm)

Width

in (mm)

Depth

in (mm)

Weight

lb (kg)

23-Inch Shelf

3.5 (88.9)

21.4 (543.6)

12 (304)

30 (13.6)

Fan Shelf

3.5 (88.9)

21.4 (543.6)

12 (304)

20 (9.0)

1U Baffle

1.75 (44.4)

21.4 (543.6)

12 (304)

4 (1.8)

Specifications

I

5 Seconds

rise and fall rate of 10V/ms)

10 ms (

10 µs

V

tr

V

tr

V

tr

tr

IN

-65

-75

-100

Vdc

Installation Category

CPS3200U output circuits are suitable for connection to telephone lines that are equipped with primary lightning

protectors consistent with UL 497. The user must provide protection on each copper pair to a level corresponding to a

CommScope 3C*EW Gas tube primary protector or equivalent gas tube protector [For example: 3C3EW provides the

part in a red color]. This protector has a voltage breakdown range of 265-465 Volts and an impulse spark over range of

<265-700 Volts. The 5-Pin protector must be marked as a “special circuit” consistent with the marking protocol in the

users network. Protectors are provided by the telco customer.

Network equipment and components along the powering circuit shall have suitable insulation resistance at 200 Vdc

from each conductor to ground and a total insulation resistance suitable for 400 Vdc from line to line.

2

Max = Absolute Maximum Rating

3

These are maximum situations with each circuit loaded to 100W. No actual or engineered application would load

every circuit to this level. In the absence of detailed information about the network we would recommend using the

typical dissipation value of 21 Watts for most applications with 30W per card for highly loaded networks.

CC848779826 r09 December 2013 8

Page 9

CPS3200U Upstream System – 23” Product Manual CPS3200U

Table 2 Ordering Codes

CODE

COMCODE

DESCRIPTION

Items for new installation or growth of existing installations

QS912A

108996732

Converter Shelf with Alarm Module (provides landings for double-hole lugs)

QS982A

108996641

Converter Card (For first install on single shelf systems the sum of converters cards

Converter slot fillers)

CC109121992

Converter slot filler

QS930A

108996930

Fan Shelf with 2 redundant fan trays

QS941A

108996947

Controller with Display and Ethernet capabilities

CC848756577

Airflow baffle without bracket for air filter

CC109102638

Airflow baffle with bracket for air filter. Includes air filter.

Replacement air filter CC109121984 listed below.

Spares: Items for repair or maintenance of existing installation

CC109121984

Air filter to be used with Airflow baffle CC109102638 (Spare)

QS930B

108997623

Fan tray assembly (Spare)

QS920A

CC109102118

Alarm Module (Spare)

Expansion Items: Provide a 4 ft long wireset to transmit alarm signals past a baffle.

Use when adding a second fan shelf to an existing system.

H5694820G050

CC109122074

Fan Shelf w/2 fan trays, wireset, baffle, filter, controller cover

H5694820G051

CC109132271

Fan Shelf w/2 fan trays, wireset, baffle, controller cover

H5694820G012

CC109122082

Converter Shelf, RJ45 wireset, hardware, alarm board (same as QS912A above)

Similar Lugs

Panduit

T&B

3 Ordering

Ordering Codes

This is a short list of CPS3200 items that can be purchased. See Line Power Product Line Brochure for detail.

and converter slot fillers should be 16. For example: 14 Converter cards and 2

Note: A baffle must be placed above the topmost converter shelf for use in customer premise locations for UL safety

compliance. Baffles are not required in restricted access locations such as outside plant cabinet, CEV or hut locations.

The baffle can be ordered separately from the above list or in combination with a fan shelf by choosing an item from

this list.

Lugs

GA Description

2 Straight, STR 54 405348202 YA2CL-2TC14 LCD2-14A-Q 54207 (STR)

2 Straight, FLEX 8 405347683 YAV2C-L2TC14-FX LCDX2-14A-E 54208 (Flex)

2 45°, STR - - YA2CL-2TC14-45 LCD2-14AH-Q 54207UF (STR)

2 45°, FLEX 193 408210524 YAV2C-L2TC14-FX-45 LCDX2-14AH-E 54208UF (Flex)

4 Straight, STR / FLEX 5 405347576 YAV4C-L2TC14-FX LCDX4-14A-L (FLEX)

4 45°, STR / FLEX - - YAV4C-L2TC14-FX-45 LCDX4-14AH-L (FLEX)

6 Straight, STR / FLEX 3 405347519 YAV6C-L2TC14-FX LCDX6-14A-L (FLEX)

6 45°, STR / FLEX - - YAV6C-L2TC14-FX-45 LCDX6-14AH-L (FLEX)

8 Straight, STR / FLEX 75 406021626 YA8CL2TC14 LCDX8-14A-L (FLEX)

8 45°, STR / FLEX - - YA8CL2TC14-45 LCDX8-14AH-L (FLEX)

WP-91412

List Comcode Burndy Equivalent

NOTE: May have different dimensions.

54206 (STR)

LCD4-14A-L (STR)

LCD4-14AH-L (STR)

LCD6-14A-L (STR)

LCD6-14AH-L (STR)

LCD8-14A-L (STR)

LCD8-14AH-L (STR)

54206 (FLEX)

54206UF (STR)

54206UF (FLEX)

54205 (STR)

54205 (FLEX)

54205UF (STR)

54205UF (FLEX)

542040410 (STR)

542040410 (FLEX)

N/A

CC848779826 r09 December 2013 9

Page 10

CPS3200U Upstream System – 23” Product Manual CPS3200U

4 Safety

Safety Statements

Please read and follow all safety instructions and warnings before installing, maintaining, or repairing the CPS3200U

System:

• The CPS3200U platform is Underwriters Laboratories (UL) Listed per UL60950-21.

• CPS3200U shelves have high, current limited, voltages on the output connectors with ground fault protection.

• For the product to be safe the chassis must be grounded by a permanent means.

• The return conductor of the -48V shall be terminated in the ground window, (held at frame ground potential).

• Install only in restricted access areas (dedicated equipment rooms, equipment closets, or the like) in accordance

with articles 110-16, 110-17, and 110-18 of the U.S. National Electric Code (NEC), ANSI/NFPA No. 70, and

pursuant to applicable local codes.

• The telecommunication line cable, carrying the +/-190V inside the cabinet between the equipment and the

primary protectors, shall be minimum 26 AWG, and rated minimum 200V. Consideration shall be taken at the

time of installation to verify cable rating.

• Primary protection must be provided on all the telecommunication line cable consistent with UL 497.

• Airflow must be provided at a rate of 175 lfm across the entire cross section of the shelf for operation in

environments up to 65 C, when measured at the inlet of the warmest converter shelf.

• This equipment is to be used in controlled environments (an area where the humidity is maintained at levels that

cannot cause condensation on the equipment, the contaminating dust is controlled, and the steady-state

ambient temperature is within the range specified).

• For multi-shelf systems (up to 3), this equipment has been evaluated for continuous use in central office

environments with ambient temperatures from -40°C to 50°C when used with the QS982A converters. For multishelf systems (up to 2), this equipment has been evaluated for continuous use in outside plant cabinet, CEV, and

hut applications with ambient temperatures from -40°C to +75°C. Proper airflow is required in all cases to ensure

maximum performance.

• This equipment must not be installed over combustible surfaces.

• For installations in the United States, Listed compression connectors are to be used to terminate Listed field-

wired conductors where required. For all installations, the appropriate connector is to be applied only to the

correct size conductor as specified by the connector manufacturer, using only the connector manufacturer's

recommended tooling or tooling approved for that connector.

• If the proper connector for the country of installation is not provided, obtain appropriate connectors and follow

manufacturer’s requirements and all local requirements for proper connections. All national and local rules and

regulations should be followed when making field connections.

• The subject product is not provided with a dc mains disconnect. Provision for mains disconnect such as branch

circuit breakers shall be provided by the end product installation.

• The main output voltage (+/-190V) meets UL60950-21RFT-V requirements. DO NOT CONNECT TO RFT-C

CIRCUITS.

• Insulation on field-wired conductors should be rated no less than 90° Celsius. Wire conductor size should be

sized per electrical codes for 75° Celsius wire, and based on the ampacity of the associated protection device.

Wiring internal to enclosed equipment cabinets should be rated at 105° Celsius (minimum).

• Torque electrical connections to the values specified on labels or in the product documentation.

• Input cables must be dressed to avoid damage to the conductors (caused by routing around sharp edges or

routing in areas where wires could get pinched) and undue stress on the connectors.

• Alarm contacts on the office alarm connector (TB1) are not fused within the distribution panel; therefore, current

limiting protection for these contacts must be provided by external circuits. Maximum ratings for alarm

CC848779826 r09 December 2013 10

Page 11

CPS3200U Upstream System – 23” Product Manual CPS3200U

connections are 60Vdc and 0.5 amperes. Exceeding these maximum ratings could result in fire or damage to the

unit.

• Fuse and/or circuit breaker loads must not exceed 80% of the fuse and/or circuit breaker current rating.

Distribute loads across the panel.

• The short circuit current capability of the battery input to the panel must not exceed 10,000A.

• DC branch circuits to this equipment must be protected with either fuses or circuit breakers. Refer to the

equipment ratings to assure rating of equipment will not exceed 80% of the value of the protector chosen.

• For applications in cabinets, huts, vaults, and central offices, the CPS3200U mounting framework must be

connected to the system integrated ground grid.

• Installing fuses or circuit breakers not specified for use in these modules may result in injury to service personnel

or equipment damage. Use only replacement parts listed in this manual and on the equipment drawings.

• The telecom-type (e.g., GMT type) fuses can produce sparks during interruption or clearing of a fault on a high

energy circuit. Use only fuses provided with safety caps for this type of circuit. Installing telecom-type fuses not

equipped with safety caps may result in injury to service personnel.

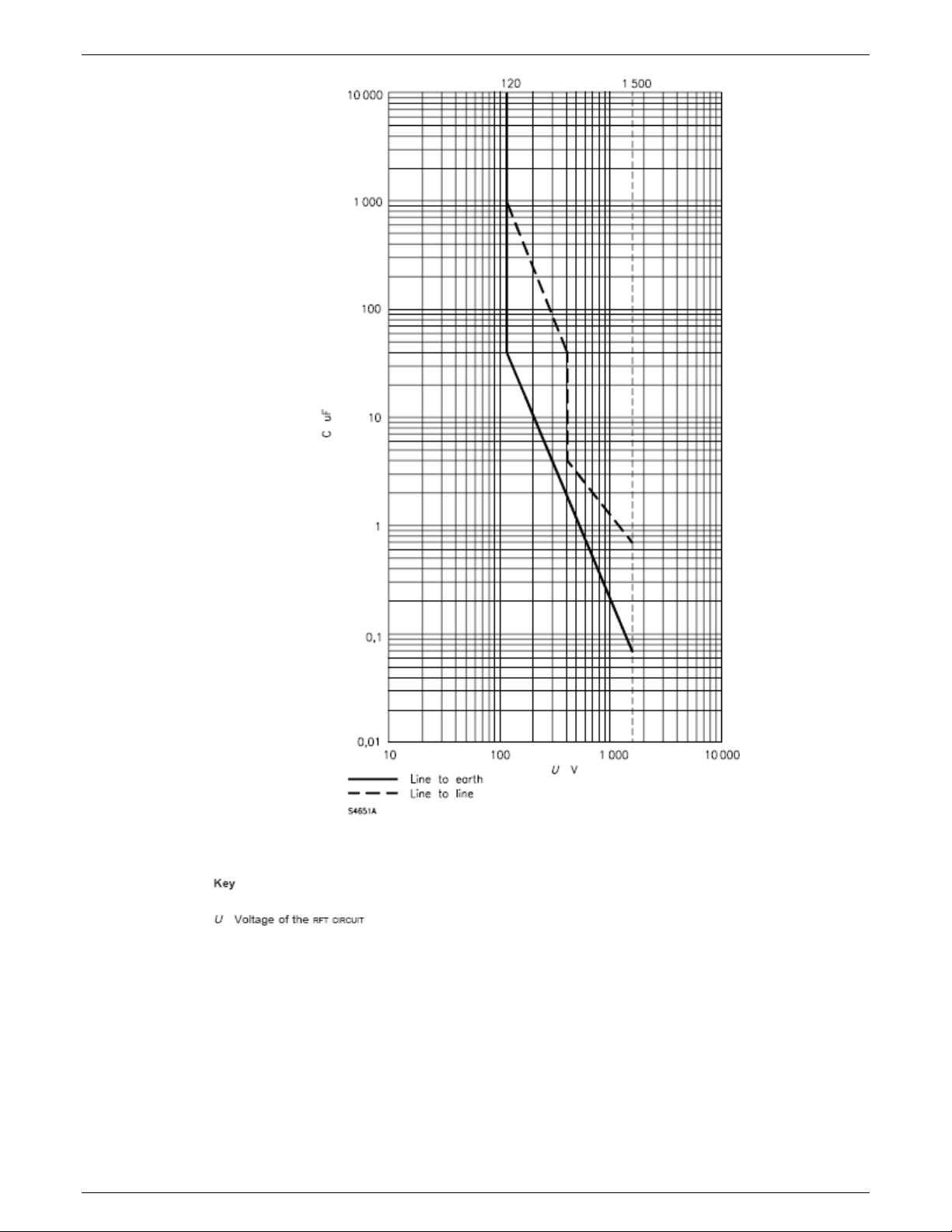

• The designed capacitance between +/-190V RFT-V conductors is 2.2uF and the measured capacitance between

+/-190V and earth is 4.4uF. DO NOT add capacitance to the system to reach values that exceed safety limits per

the following figure:

CC848779826 r09 December 2013 11

Page 12

CPS3200U Upstream System – 23” Product Manual CPS3200U

Figure 2 Capacitance Safety Limits

CC848779826 r09 December 2013 12

Page 13

CPS3200U Upstream System – 23” Product Manual CPS3200U

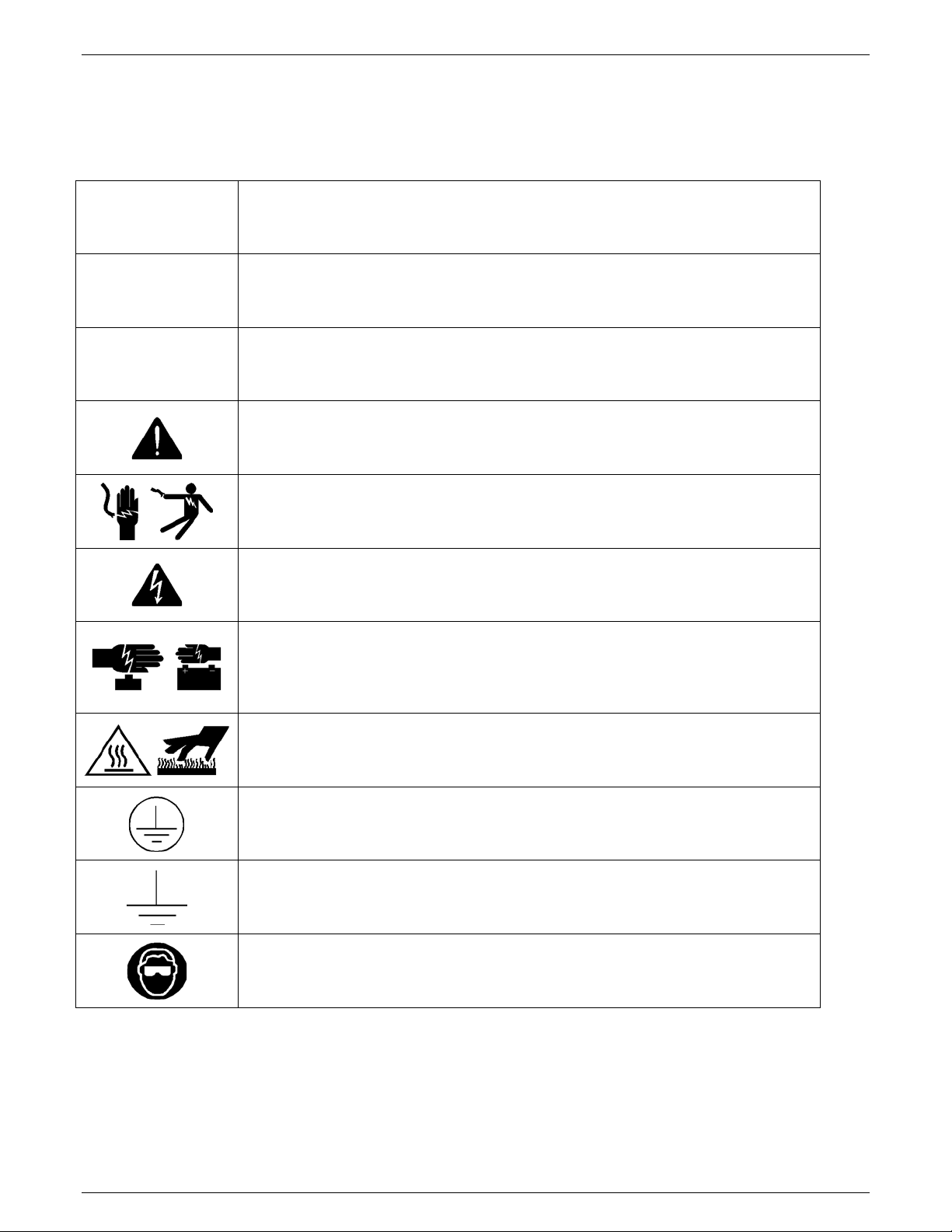

Indicates the presence of a hazard that will cause death or severe personal injury if

Indicates the presence of a hazard that can cause death or severe personal injury if

Indicates the presence of a hazard that will or can cause minor personal injury or

This symbol identifies the need to refer to the equipment instructions for important

These symbols (or equivalent) are used to identify the presence of hazardous ac mains

This symbol is used to identify the presence of hazardous ac or dc voltages. It may

One of these two symbols (or equivalent) may be used to identify the presence of

precautions.”

One of these two symbols may be used to identify the presence of a hot surface. It

hazardous voltage levels.

This symbol is used to identify the protective safety earth ground for the equipment.

This symbol is used to identify other bonding points within the equipment.

This symbol is used to identify the need for safety glasses and may sometimes be

Warning Statements and Safety Symbols

The symbols may sometimes be accompanied by some type of statement; e.g., “Hazardous voltage/energy inside. Risk

of injury. This unit must be accessed only by qualified personnel.” Signal words as described below may also be used to

indicate the level of hazard.

DANGER

WARNING

CAUTION

the hazard is not avoided.

the hazard is not avoided.

property damage if the hazard is not avoided.

information.

voltage.

also be used to warn of hazardous energy levels.

rectifier and battery voltages. The symbol may sometimes be accompanied by some

type of statement, for example: “Battery voltage present. Risk of injury due to high

current. Avoid contacting conductors with uninsulated metal objects. Follow safety

may also be accompanied by a statement explaining the hazard. A symbol like this

with a lightning bolt through the hand also means that the part is or could be at

accompanied by some type of statement, for example: “Fuses can cause arcing and

sparks. Risk of eye injury. Always wear safety glasses.”

CC848779826 r09 December 2013 13

Page 14

CPS3200U Upstream System – 23” Product Manual CPS3200U

Precautions

When working on or using this type of equipment, the following precautions should be noted:

• This unit must be installed, serviced, and operated only by skilled and qualified personnel who have the necessary

knowledge and practical experience with electrical equipment and who understand the hazards that can arise

when working on this type of equipment.

• The equipment could be powered by multiple dc inputs. Ensure that the appropriate circuit protection device for

each dc input is disconnected before servicing the equipment. Do not disconnect permanent bonding provisions

unless all dc inputs are disconnected.

• DC inputs may be connected in parallel to power the dc-dc converters. Disconnecting one dc input will not

necessarily remove power from the bus. Make sure all battery power sources are also disconnected and/or follow

safety procedures while working on any equipment that contains hazardous energy/voltage.

• Hazardous energy and voltages are present in the unit and on the interface cables that can shock or cause

serious injury. Follow all safety warnings and practices when servicing this equipment. When equipped with

QS982A modules, hazardous voltages (+/-190Vdc) will be present on the output connectors and associated

interconnection cables.

In addition to proper job training and safety procedures, the following are some basic precautions that should always

be used:

• Use only properly insulated tools.

• Remove all metallic objects (key chains, glasses, rings, watches, or other jewelry).

• Wear safety glasses. Fuses can produce sparks. High energy levels on buses and distribution components can

produce severe arcing.

• Do not rely on simple volt meter tests to determine if the +/-190V output circuit is off line. Physically break the

circuit by removing the associated QS982A converter before touching the +/-190V RFT-V circuit. Confirmationtest each circuit for 5 seconds before touching. In some line fault modes, power is cycled on every 4 seconds. The

presence of a fault may make it difficult to determine if the circuit is online. Always physically break the circuit.

• Lock out and tag circuit breakers/fuses when possible to prevent accidental turn on.

• Be aware of potential hazards before servicing equipment.

• Identify exposed hazardous electrical potentials on connectors, wiring, etc. (note the condition of these circuits,

especially wiring).

• Use care when removing or replacing covers; avoid contacting circuits.

CC848779826 r09 December 2013 14

Page 15

CPS3200U Upstream System – 23” Product Manual CPS3200U

•A Complete Standard Insulated tool set

•Wire cutters and strippers

•Digital meter, +/- 0.02%

•Heat shrink gun

•Screw Drivers (flat-blade and Phillips)

•Torque wrench (0-240 in-lb / 28 Nm)

•ESD wrist strap

•Sockets

5 Pre-Installation

CPS3200U Installation

Purpose

CPS3200U Shelf Installation guide for generic installations. Additional requirements are needed for application specific

installations. Refer to Appendix A for spacing requirements.

Audience

Field application personnel

Precautions

Read Safety section prior to installation.

Observe ESD protection while installing circuit packs

Safety

• Always consider personal safety.

• Make sure the system is properly grounded per the National Electrical Code, local building codes, and any specific

company requirements per standard practice.

• Remove all metal jewelry before beginning the installation.

Installation Tools

System Identification

Identify the product you have received. Make sure to select procedural steps to match the product you have.

CC848779826 r09 December 2013 15

Page 16

CPS3200U Upstream System – 23” Product Manual CPS3200U

Step

Action

1.

Before opening the packaging, carefully inspect the outside in the presence of shipping

personnel for signs of damage.

2.

Carefully open the packaging to verify that the contents are complete and undamaged.

3.

If damaged, follow the shipping carrier’s procedure for filing a damage claim.

4.

Save the shipping package until all parts are operating within specifications. If the equipment

must be returned, it should be repacked in the original shipping crate.

Step

Action

1.

Locate the 2 mounting brackets, one on each side of the CPS3200U shelf; align the holes in the shelf-

6 Installing the Shelf Level Upstream Product

Unpacking Shelf Level Upstream Product

Make sure the framework has the space and the airflow to provide an acceptable operating environment for the

CPS3200U shelf. Then unpack the equipment.

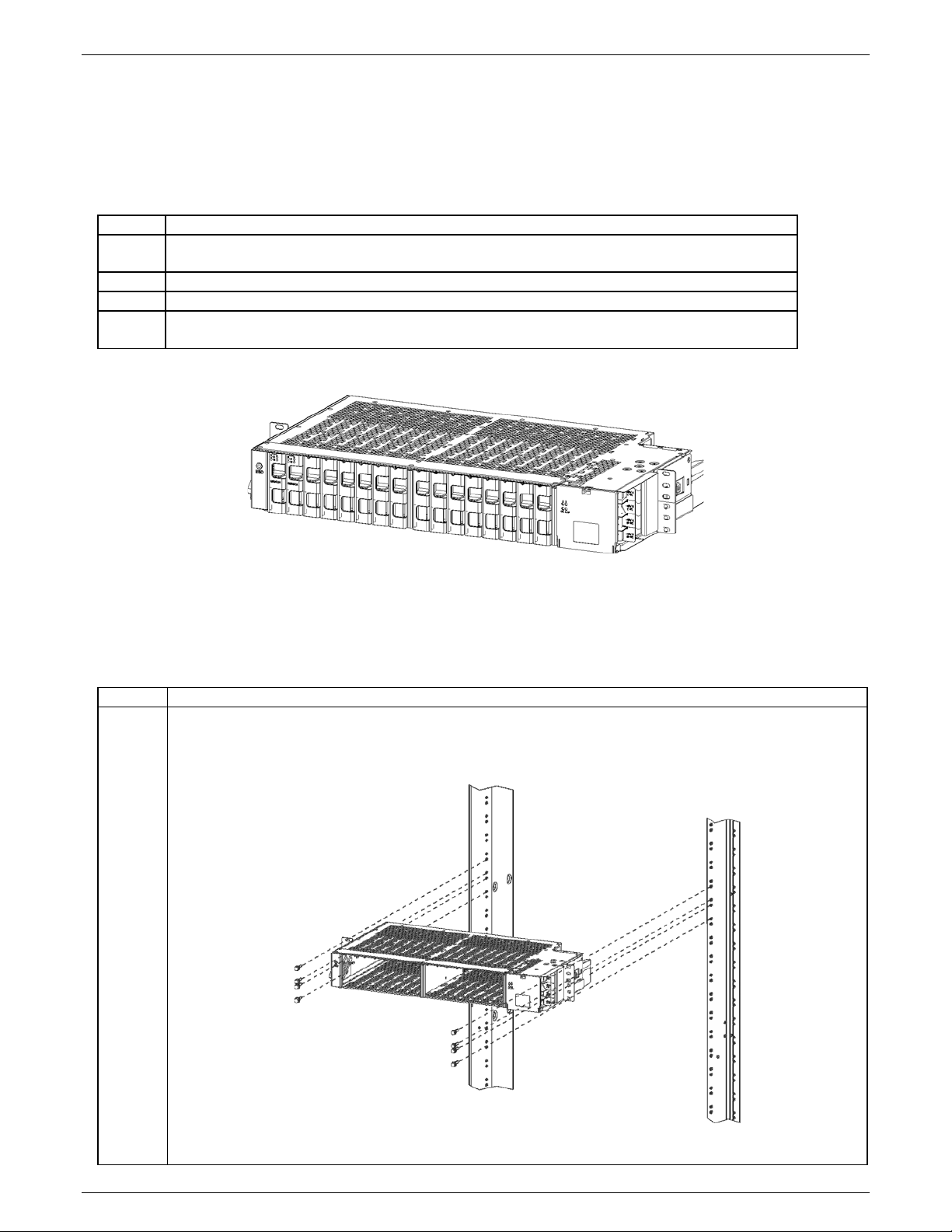

Figure 3 QS912A Converter Shelf

(Shown configured with 2 operational circuits and 14 slot fillers for airflow control)

Installing and Powering the CP3200U Converter Shelf

Position the Shelf and mechanically attach it to the frame

mounting bracket with the holes in the mounting frame. Attach the brackets to the frame using two

screws per frame as shown.

Figure 4 Mounting the Converter Shelf

CC848779826 r09 December 2013 16

Page 17

CPS3200U Upstream System – 23” Product Manual CPS3200U

2.

3.

4.

Open the distribution panel door on the right end of the shelf.

5.

Run 4 DC branch circuits back to the -48V source- Each feed supplies half of the shelf. A&B feeds for side

6.

Using the hardware supplied, attach the return wires for all 4 circuits.

7.

Using the hardware supplied, attach the A and B -48V conductors for side 1 (Slots 1-8).

8.

Using the hardware supplied, attach the A and B -48V conductors for side 2 (Slots 9-16).

9.

Torque each of the ¼ - 20 fasteners to 7 Nm or 65 in-lbs.

10.

Close the distribution door.

11.

Proceed to Grounding the Shelf.

Torque each of the fasteners to 4 Nm or 35 in-lbs.

Make sure the DC connections to be installed are not powered by turning off circuit breakers assigned to

this frame and checking with an Ohm meter.

Figure 5 Preparing to Make DC Connections to Converter Shelf

1 and A&B feeds for side 2.

Size each circuit to support 42 Amp List 2 Drains. Note: Lug landings are ¼ inch studs on 5/8 inch

centers. Use a minimum of 6 AWG conductor for environments up to +65°C (reference NEC Table 310-16

for applications of not more than three conductors in a raceway and correction factors for Ambient

Temperatures Over 30°C). Each installation will vary and the installer should review NEC cabling

requirements as well as local practice to ensure proper cable sizing is achieved for the local conditions.

Lugs for 6AWG conductor are as follows or available equivalent:

T&B 6STR30W

Burndy YAV6C-L2TC14-FX

Figure 6 Making DC Connections to Converter Shelf

CC848779826 r09 December 2013 17

Page 18

CPS3200U Upstream System – 23” Product Manual CPS3200U

Step

Action

1.

Run and connect the framework ground lead as shown.

2.

Use 6GA conductor minimum and connect to the safety grounding point

3.

Torque connections to 4 Nm or 35 in-lbs.

Step

Action

1.

The wiring assignment information in the following table provides the appropriate

terminate the J1 and J2 output connectors on the CPS3200U Shelf.

J2, 9-16

J1, 1-8

Ground the Shelf

The next step is to ground the shelf to earth ground. This is an important safety step since each converter relies on this

connection for proper ground fault detection.

(frame ground, or main ground bar) per local practice. Additionally apply

NO-OX ID to all bare metal connections if required by local practice. Lugs

are ¼ inch studs on 5/8 inch centers.

Lugs for 6AWG conductor are as follows or available equivalent:

T&B 6STR30W

Burndy YAV6C-L2TC14-FX

Attach the Load Wiring

Provide a circuit from each converter into the designated network telephone pairs. Follow the steps in the table below

to attach load wiring to the CPS3200U shelf.

connections for each circuit. A cable should be provided with this pinout configuration to

Figure 7 Grounding Converter Shelf

• Wireset Connector: RJ-21 type 50 pin plug:

• 22 AWG solid or stranded AMP 552173-1 or equivalent.

• 24 AWG solid or stranded or 26 AWG solid AMP 229974-1 or equivalent.

• The connector shall be arranged with a right angle housing such that the cable exits to the pin 1 side.

CC848779826 r09 December 2013 18

Page 19

CPS3200U Upstream System – 23” Product Manual CPS3200U

Table 3 Output Connector Pinout

Connector for Circuits 1-8 (Shelf J1)

Connector for Circuits 9-16 (Shelf J2)

Conv Out

Pos

Color

Conv Out

Pos

Color

Conv Out

Pos

Color

Conv Out

Pos

Color

1a-

1

BL / W 1a+

26

W / BL 9a-

1

BL / W 9a+

26

W / BL

1b-

2

O / W 1b+

27

W / O 9b-

2

O / W 9b+

27

W / O

2a-

3

G / W 2a+

28

W / G 10a-

3

G / W 10a+

28

W / G

2b-

4

BR / W 2b+

29

W / BR 10b-

4

BR / W 10b+

29

W / BR

3a-

5

SL / W 3a+

30

W / SL 11a-

5

SL / W 11a+

30

W / SL

3b-

6

BL / R 3b+

31

R / BL 11b-

6

BL / R 11b+

31

R / BL

4a-

7

O / R 4a+

32

R / O 12a-

7

O / R 12a+

32

R / O

4b-

8

G / R 4b+

33

R / G 12b-

8

G / R 12b+

33

R / G

5a-

9

BR / R 5a+

34

R / BR 13a-

9

BR / R 13a+

34

R / BR

5b-

10

SL / R 5b+

35

R / SL 13b-

10

SL / R 13b+

35

R / SL

6a-

11

BL / BK 6a+

36

BK / BL 14a-

11

BL / BK 14a+

36

BK / BL

6b-

12

O / BK 6b+

37

BK / O 14b-

12

O / BK 14b+

37

BK / O

7a-

13

G / BK 7a+

38

BK / G 15a-

13

G / BK 15a+

38

BK / G

7b-

14

BR / BK 7b+

39

BK / BR 15b-

14

BR / BK 15b+

39

BK / BR

8a-

15

SL / BK 8a+

40

BK / SL 16a-

15

SL / BK 16a+

40

BK / SL

8b-

16

BL / Y 8b+

41

Y / BL 16b-

16

BL / Y 16b+

41

Y / BL

spare

17

O / Y spare

42

Y / O spare

17

O / Y spare

42

Y / O

spare

18

G / Y spare

43

Y / G spare

18

G / Y spare

43

Y / G

spare

19

BR / Y spare

44

Y / BR spare

19

BR / Y spare

44

Y / BR

spare

20

SL / Y spare

45

Y / SL spare

20

SL / Y spare

45

Y / SL

spare

21

BL / V spare

46

V / BL spare

21

BL / V spare

46

V / BL

spare

22

O / V spare

47

V / O spare

22

O / V spare

47

V / O

spare

23

G / V spare

48

V / G spare

23

G / V spare

48

V / G

spare

24

BR / V spare

49

V / BR spare

24

BR / V spare

49

V / BR

*FR GRD

25

SL / V *FR GRD

50

V / SL *FR GRD

25

SL / V *FR GRD

50

V / SL

Step

Action

2.

Mark or tag the 25 pair cables on the unterminated end with J1 and J2 to

differentiate the two cables at the splice chamber.

3.

Run the cable down the frame and attach as shown.

4.

Use Screw and Cable tie to secure.

*EMI performance is enhanced when the output cable shield is grounded only at the CPS3200 end of the shield.

Attach output cabling as shown

Figure 8 Output Wiring for Converter Shelves

CC848779826 r09 December 2013 19

Page 20

CPS3200U Upstream System – 23” Product Manual CPS3200U

Step

Action

1.

Open the distribution door.

2.

Remove the alarm card.

Note: Door must be level to

Set Shelf ID and Attach Alarm Wiring

For systems where alarming is processed through a central controller using serial communications, each shelf must

have a unique address. Otherwise all alarm cards should be left in their factory default state of address 0, 0. Skip this

step if no QS941 will be present in the system.

Warning: You must properly protect yourself against ESD discharge prior to accessing the alarm card and setting shelf

IDs.

Figure 9 Accessing Alarm Cards

CC848779826 r09 December 2013 20

remove alarm card

Figure 10 Removing Alarm Card

Page 21

CPS3200U Upstream System – 23” Product Manual CPS3200U

3.

Use a Phillips Head screw driver to set the shelf address rotary switch to indicate a shelf

4.

If local contact closures are also desired continue with Attach Alarm Wiring, otherwise

reinstall alarm card and close door.

5.

Attach signal wiring between the Alarm Cards of adjacent Converter Shelves.

Included Communication Wiresets

Converter Shelf

ID. For most applications the only switch requiring adjustment will be on the far right

labeled ‘Units.’ Start with shelf 1 at the bottom and progress to higher numbers as one

goes up the frame. This figure shows settings for shelf 1 and shelf 6 as examples.

Figure 11 Setting Shelf ID

Doors not shown

Figure 12 Signal Wiring between Converter Shelves

CC848779826 r09 December 2013 21

Page 22

CPS3200U Upstream System – 23” Product Manual CPS3200U

Step

Action

1.

Install the baffle using as many fasteners as the frame will accept as shown:

Step

Action

1.

Install the Fan Shelf using as many fasteners as the frame will accept:

Installing the Baffle

Purpose: Redirect air coming into, and objects falling down toward, the FTTN shelf. Follow the steps in the table below to

attach a baffle above the FTTN shelves for all CO or customer premise applications. The baffle has two purposes: 1)

redirect air toward the back isle so that components located below the FTTN shelves will not over heat, and 2) Keep

objects from falling into the FTTN shelf. The baffle can either be fixed at a height above the Fan Shelf to allow for three

CPS3200U Shelves or be removed and reattached every time a CPS3200U shelf is added.

Note: There are two to airflow options provided for different applications: Airflow direction optimized for CO

deployments provided by the FTTN fan shelf is downward. Airflow direction for OSP applications is bottom to top. Baffles

should be oriented to direct cold air from the aisle through the converter shelf and out the back of the rack. A filter is

available and should be utilized in high contaminant areas with proper filter maintenance.

Figure 13 Installing a Baffle

Installing the Fan Shelf

CPS2300U shelves require external forced air. Follow the steps to install a fan shelf below each set of 3 CPS3200U

shelves.

Figure 14 Mounting the Fan Shelf

CC848779826 r09 December 2013 22

Page 23

CPS3200U Upstream System – 23” Product Manual CPS3200U

Step

Action

2.

Insert two fan trays operating the latches as shown:

3.

Remove the clear plastic cover from the wiring area:

Figure 15 Inserting Fan Trays

Figure 16 Open the Wiring Region of the Fan Shelf

CC848779826 r09 December 2013 23

Page 24

CPS3200U Upstream System – 23” Product Manual CPS3200U

Step

Action

3.

Attach signal wiring from the fan shelf to the alarm card in the converter shelf immediately

4.

Attach de-energized DC cabling (typically 14 AWG) as shown here. Use ring lugs or alternate

Included Communication Wireset

Converter Shelf

Fan Shelf

above the fan shelf.

(Door removed

for visibility)

Figure 17 Alarm Wiring for Fan Shelf

per local practice. Fuse externally at 5 Amps. Note: Returns for the A and B feeds are shared

on the -48Vdc RTN. The lowest position on the terminal block is to provide frame ground for

the fan shelf. Power feeds should be derived from a fuse or breaker panel using discrete

cabling which is independent from the converter shelf.

CC848779826 r09 December 2013 24

Figure 18 DC Cabling Fan Trays in CPS3200U Systems

Page 25

CPS3200U Upstream System – 23” Product Manual CPS3200U

Step

Action

5.

Replace the clear plastic (Lexan) cover and apply DC power.

6.

Check LED Display on each fan tray for proper operation.

7.

Resolve Alarm states by first assuring that DC power is being provided to both the A and the B

terminals on the shelf or Bay and then by replacing fan trays until the alarm clears.

Figure 19 Cover the Wiring Region of the Fan Shelf

Figure 20 Fan Tray LEDs

CC848779826 r09 December 2013 25

Page 26

CPS3200U Upstream System – 23” Product Manual CPS3200U

Step

Action

1.

Install the Filter Bracket directly below the fan shelf as shown.

2.

Loosen the filter retention screw and rotate retention bracket down.

Figure 22 Filter Retention Bracket

Retention Bracket

Installing the Filter Bracket and Filter

CPS3200U system has optional filters to provide a degree of protection from airborne particulate matter. Follow the

steps to install a filter bracket adjacent to the fan shelf. The example shown is for a separate filter bracket for bottom to

top airflow solutions. Top to bottom airflow applications require the filter to be above the system.

Figure 21 Mounting the Filter Bracket

CC848779826 r09 December 2013 26

Page 27

CPS3200U Upstream System – 23” Product Manual CPS3200U

Step

Action

3.

Slide the filter in to the filter bracket.

Figure 23 Install Filter

4.

Rotate retention bracket back into place and tighten screw.

Figure 24 Secure Filter Retention Bracket

Filter

Retention Bracket

CC848779826 r09 December 2013 27

Page 28

CPS3200U Upstream System – 23” Product Manual CPS3200U

Step

Action

1.

Is accessibility to the circuit throughout the network consistent with A2 requirements?

2.

Is the 5-pin protector marked as a special circuit?

3.

Does the 5-pin protector protect each pair to a level corresponding to a CommScope

lower voltage breakdown rating will be problematic.

Step

Action

1.

Recognize that the Remote Feed Telecommunication Voltage limited (RFT-V) circuit is

voltage limited to +190V and -190V from ground.

2.

Is the total capacitance to ground on each line of the circuit less than 10μF?

5.6 μF of capacitance.

3.

Is the total capacitance line to line of the circuit less than 40μF?

37.2 μF of capacitance from tip to ring.

4.

Is the remote equipment also a RFT-V voltage limited circuit? Both ends of the circuit

connected together.

5.

Is the voltage rating of the Network Wiring sufficient to support 190V to ground?

6.

Is the chassis of the system bonded to ground? Verify by both observation and

Many network providers use a value of 10 ohms.

7.

Test each circuit by powering an open circuit at the remote end of the wire with a QS982

If the FLT light does not blink yellow, there is no hard short between tip and ring.

7 Inspect the Network - Check and Mark Wiring Compliance

The CPS3200U +/-190V system is classified as an A2 circuit tested according to GR-1089-CORE Issue 3. As such, each

location in the network where the output is available to be touched must be protected and marked as an A2 voltage.

3C*EW Gas tube primary protector? This protector has a voltage breakdown range of

265-465 Volts and an impulse spark over range of <265-700 Volts. Protectors with a

To meet UL60950-21 specific procedural steps must be taken at the time of installation. This section goes through those

steps. These steps should be performed before power is distributed in the network. Normally the final step is performed

by closing the circuit using a 5-pin protector after DC power is applied to the system.

The QS982A introduces 4.4μF. The remote electronics and line must introduce less than

The QS982A introduces 2.2μF. The remote electronics and line must introduce less than

must be designed to the same standard. This must be verified before the equipment is

measurement before powering the system. Measurement from the exterior of the

CPS3200U shelf to the cabinet ground bus should indicate continuity as determined via a

meter providing an audible beep or the standard method of continuity verification used in

the network.

output. If red lights do not flash, there is no leakage path to ground at operating voltage.

CC848779826 r09 December 2013 28

Page 29

CPS3200U Upstream System – 23” Product Manual CPS3200U

Step

Action

1.

Warning: You must properly protect yourself against ESD discharge prior to installing the

QS982A Controller.

2.

Use the ESD jack on the left of each converter shelf to provide grounding before removing

3.

Remove the QS982A converter from its shipping container.

4.

Align the plastic converter housing on the right and insulated circuit board on the left.

5.

Guide the converter into the first available slot by positioning the plastic converter

6.

Slide the converter into the shelf until it is fully seated in the connector on the rear of the

CPS3200U shelf.

7.

Push the display faceplate into the shelf until the latch on the top of the converter

housing catches.

8.

Repeat this process as needed for your application.

9.

Insert empty slot fillers into all unused slots to control airflow in multi-shelf systems

ESD Jack

8 Final Installation

Installing the Converters

QS982A Converters mount in the CPS3200U shelf. Note that Converter Card numbering starts from the left and should

be correlated to the marking on the panel located on the other end of the load cable that plugs into J1 and J2. This may

be a cross connect panel or the 5-pin protector block near the building entrance.

the QS982A converters from their anti-static wrap:

Figure 25 Shelf Level ESD Jack

housing in the notch on the top right edge of the opening.

Figure 26 Installing Converters

CC848779826 r09 December 2013 29

Page 30

CPS3200U Upstream System – 23” Product Manual CPS3200U

Step

Action

1.

Observe the LEDs.

2.

Use the state table below to determine the state of the system and required corrective actions

if needed.

Apply DC Power

Apply DC power by turning on input fuses or circuit breakers. Power the fan shelf and the converter shelf

simultaneously. The system will operate from voltages between -40 and -60 volts with normal status at feed voltages

between -52 Volts and -54.5 Volts.

Fault LEDs will flash red until communications is established between the alarm card and each converter. The alarm

card will flash its fault LED until connection is confirmed to the QS941, if present. If no QS941 is present the alarm cards

will flash their red LED until they are set to address 0, 0 as described in the Set Shelf ID and Attach Alarm Wiring

section.

Complete UL 60950-21 step 7 under Inspect the Network to test each circuit after DC power is applied.

Recognizing Normal States

Once power is provided to the CPS3200U system the LEDs on the converters will illuminate. Understanding what the

LEDs mean allows one to recognize normal states and diagnose abnormal states.

Figure 27 QS982A Faceplate and LEDs

(Note: Test points work best if each voltage is measured with respect to ground)

CC848779826 r09 December 2013 30

Page 31

CPS3200U Upstream System – 23” Product Manual CPS3200U

Table 4 QS982A LED Information Map

LED Display

Conditions

(on b circuit)

Action Required

All OK

None

Circuit Placed in Standby

None depending on desired

Loss of comm.

Check seating on Alarm card

Ground fault

Check 5 pin protectors and

Overcurrent or under

Check output lines for shorts to

OV or internal failure

Replace unit

Thermal Alarm

Solve Thermal problem

card not powered or input

Check source voltage

Lamps test requested from

Observe Lamp Test

QS982A LED Information Map

Examples in the table are shown for conditions on the b circuit of the QS982A card. The same reasoning applies when

the "a" circuit LEDs are illuminated.

state of circuit b. Standby state

can be set using the QS941

controller or web browser.

and converter card

voltage

fuse failure

faults to ground

each other

CC848779826 r09 December 2013 31

controller

Page 32

CPS3200U Upstream System – 23” Product Manual CPS3200U

Figure 28 Fan Shelf Right Hand Cover

Figure 29 Fan Shelf Controller Jumper

Confirm Operation of Alarm Wiring

After the converters are recognized to be in a normal state, one should confirm the proper operation of the alarm

contact closures. If alarm wiring is correct:

1. The loss of A or B input power should result in the assertion of a Power Minor.

2. The loss of both A and B input power, which will result in a loss of service, should result in a Power Major and a

Power Minor.

3. If a controller is installed in the system then it will demonstrate an alarm state by turning the display red. Using

the buttons on the keypad the specific alarm can be retrieved by pressing the Back Arrow,. When the system

returns to normal function the display will be green.

Installing the QS941A Ethernet Module

To connect CPS2300U shelves to an IP Drop, follow these steps to install QS941A Ethernet module.

Step Action

1. Remove the cover from the right hand end of the fan shelf that will house the controller.

2. Move the controller jumper on the selected fan shelf into the leftmost position.

Warning: Controller may be damaged if this step is not

completed.

3. Replace the cover over the right hand end of the shelf.

CC848779826 r09 December 2013 32

Page 33

CPS3200U Upstream System – 23” Product Manual CPS3200U

Figure 30 Preparing a Fan Shelf for a CPS Controller

Figure 31 Installing the Controller

Step Action

4. Remove the faceplate on the left end of the fan shelf:

5. Install the controller into the fan shelf:

CC848779826 r09 December 2013 33

Page 34

CPS3200U Upstream System – 23” Product Manual CPS3200U

Figure 32 Controller Wiring

Step Action

6. Attach signal wiring to the controller at connector P6. The Ethernet connection to the local

network is made through the P6 RJ45 connector. Of the two RJ45s on the left side of the

controller, P6 is the one more toward the front labeled: P6 10/100 Base-T. Plug the local

network cable into P6. As shown here:

7. To check the network connection, use the controller display to determine what IP address has

been assigned to the QS941 controller. Press the square key,

of the keypad to display the menu.

■, on the upper right hand corner

8. Press the down arrow key, ▼, 2 times to scroll down to the “Status” item on the menu.

9.

Press the right arrow,

10. Press the down arrow key, ▼, 8 times to scroll down to the “Network Settings” item and select

by pressing the right arrow key.

11. Press the right arrow, ▼, to advance to the “Network Settings” menu.

12.

13. Read and record the network address for Port 1.

Press the right arrow,

When an IP address is listed connection to the server is confirmed.

, to advance to the “Status” menu.

, to select Port 1. The P6 connector is Port 1.

CC848779826 r09 December 2013 34

Page 35

CPS3200U Upstream System – 23” Product Manual CPS3200U

14.

Check the other end of the fan shelf to make sure the serial bus reaches all of the shelves in the

to Shelf above, if present

to Shelf below, if present

Step Action

system. RS-485 signals are Daisy Chained from all the elements in the system. The signal from

equipment located in the frame above the controller typically comes through the RJ45 jack on

the left. The jack shown here on the right will typically accept information from equipment

mounted below the fan shelf containing the controller:

Figure 33 Fan Shelf RS-485 Jacks

CC848779826 r09 December 2013 35

Figure 34 Signal Cables - System

Page 36

CPS3200U Upstream System – 23” Product Manual CPS3200U

Figure 35 Office Alarm Cable Pinout

CC848773671

10ft alarm cable - for QS941 controllers

848748558

25ft alarm cable - for QS941 controllers

CC848764448

50ft alarm cable - for QS941 controllers

848748566

150ft alarm cable - for QS941 controllers

Installing the Office Alarm Connector

Step Action

1. Plug appropriate length alarm cable into the socket on the side of the controller labeled J1.

Alarm cable options listed below.

2. Dress Cable out to alarm block and use the pinout below to appropriately route the alarms.

3. Available alarm cables are as follows:

CC848779826 r09 December 2013 36

Page 37

CPS3200U Upstream System – 23” Product Manual CPS3200U

Table 5 QS982A Converter LED Information Map

Action Required

OK LED

Fault LED

Conditions

Notes

None

Green

Off

All OK

Verify circuit

Off

Yellow

Standby

Standby can be set using the QS941

web browser.

Check seating on

converter card

Green

Blink Red On ½ second,

Loss of comm.

Check 5 pin

to ground

Red Blink

Red Blink

Ground fault

Check output lines for

shorts to each other

Green

Yellow Blink

Overcurrent or under

voltage

Replace unit

Red Blink

Off

OV or internal failure

Solve Thermal

problem

Off

Red Blink

Thermal Alarm

Latch off after 3 retry cycles

Check source voltage

Off

Off

card not powered or

input fuse failure

Observe Lamp Test

Bi-Color: 4.5 seconds

1 second off

Bi-Color: 4.5 seconds