Page 1

CPS2500D +/-190V

Downstream System

Product Manual

Select Code 167-102-106

Comcode 848755265

Issue 4

January 2008

Page 2

Page 3

Product Manual

Select Code 167-102-106

Comcode 848755265

Issue 4

January 2008

CPS2500D +/-190V

Downstream System

Notice:

The information, specifications, and procedures in this manual are

subject to change without notice. Lineage Power assumes no

responsibility for any errors that may appear in this document.

© 2008 Lineage Power

All International Rights Reserved

Printed in U.S.A.

Page 4

Page 5

CPS2500D +/-190V Downstream System

Table of Contents

1 Introduction

CPS2500D Downstream System 1-1

Overview 1-1

Applications 1-1

Web Site 1-1

Customer Service Contacts 1-2

Customer Service, Technical Support,

Product Repair and Return, and Warranty Service 1-2

Customer Training 1-2

On-Line Power Systems Product Manuals 1-2

EasyView software 1-2

2 Product Description

Physical Description 2-1

Block Diagram 2-1

Operation 2-2

Specifications 2-3

Electrical 2-4

Maximum Output Power 2-5

Installation category: 2-5

3 Engineering and Ordering

Ordering Information 3-1

Engineering 3-2

4 Safety

Safety Statements 4-1

Warning Statements and Safety Symbols 4-4

Deutsch 4-6

Espanol 4-6

5 Installation

CPS2500D Installation 5-1

Purpose 5-1

Precautions 5-1

Safety 5-1

Installation Tools 5-1

Issue 4 January 2008 Table of Contents - 1

Page 6

CPS2500D +/-190V Downstream System

Unpack the CPS2500D Shelf 5-2

CPS2500D Unpack 5-2

Ground Configuration 5-3

Ground Jumper 5-3

Inspect the Network 5-4

Check and Mark Wiring Compliance 5-4

Install the CPS2500D Shelf 5-5

CPS2500D Frame Install 5-5

CPS2500 Cable Install 5-6

Installing the Converters 5-7

QS882A Converter Installation 5-7

Install the QS882A Converters 5-7

Recognizing Normal States 5-8

Recognize Normal States 5-8

Diagnosing Abnormal States 5-9

Diagnosing Abnormal States 5-9

6 Electrical Interface Reference Information

Shelf Electrical Interfaces 6-1

Connector Details 6-1

Connector Pinouts 6-2

7 Reference Information

CPS2500D Shelf 7-1

QS882A Converter 7-3

8 Product Warranty

Appendix A Operating Temperature and Vertical Spacing

Overview A-1

Operating Temperature A-1

Revision History

2 - Table of Contents Issue 4 January 2008

Page 7

CPS2500D +/-190V Downstream System

List of Figures

Figure 1-1: CPS2500D Downstream System 1-1

Figure 2-1: QS800A Shelf Block Diagram 2-1

Figure 2-2: Unit Maximum Output Power vs. Input Voltage 2-5

Figure 3-1: Constant Delivered Power Curves

(normal range of operation) 3-2

Figure 5-1: Ground Jumper 5-3

Figure 5-2: QS800A Frame Mounting 5-5

Figure 5-3: ESD Ground Jack 5-6

Figure 5-4: QS800A with All Cables Attached 5-6

Figure 5-5: Align the QS882A Converter 5-7

Figure 5-6: QS800A with All Cables Attached 5-7

Figure 5-7: Recognizing Normal States

(with associated LED display definitions) 5-8

Figure 5-8: Output Voltage Low - Additional Circuits Required 5-9

Figure 5-9: Converter Internal Fault 5-10

Figure 5-10: Remove Converter 5-10

Figure 5-11: Network Wiring Fault 5-11

Figure 5-12: Network Wiring Faulty on Circuit 6B 5-11

Figure 5-13: Relay Identification for Replacement 5-13

Figure 7-1: QS800A Shelf Mounting Hole Dimensions 7-1

Figure 7-2: Depth and Height Dimensions 7-1

Figure 7-3: 12-Inch Shelf Mounting Hole

Dimensions (CC109139853) 7-2

Figure 7-4: Shelf Equipped with 19-Inch Adapter Bracket

(CC848828525) 7-2

Figure 7-5: Q882A Size 7-3

Issue 4 January 2008 List of Figures - 1

Page 8

Page 9

CPS2500D +/-190V Downstream System

List of Tables

Table 2-A: Absolute Maximum Ratings 2-3

Table 2-B: Electrical Specifications 2-4

Table 7-A: LED Truth Table 7-4

Issue 4 January 2008 List of Tables - 1

Page 10

Page 11

CPS2500D +/-190V Downstream System

1 Introduction

CPS2500D Downstream System

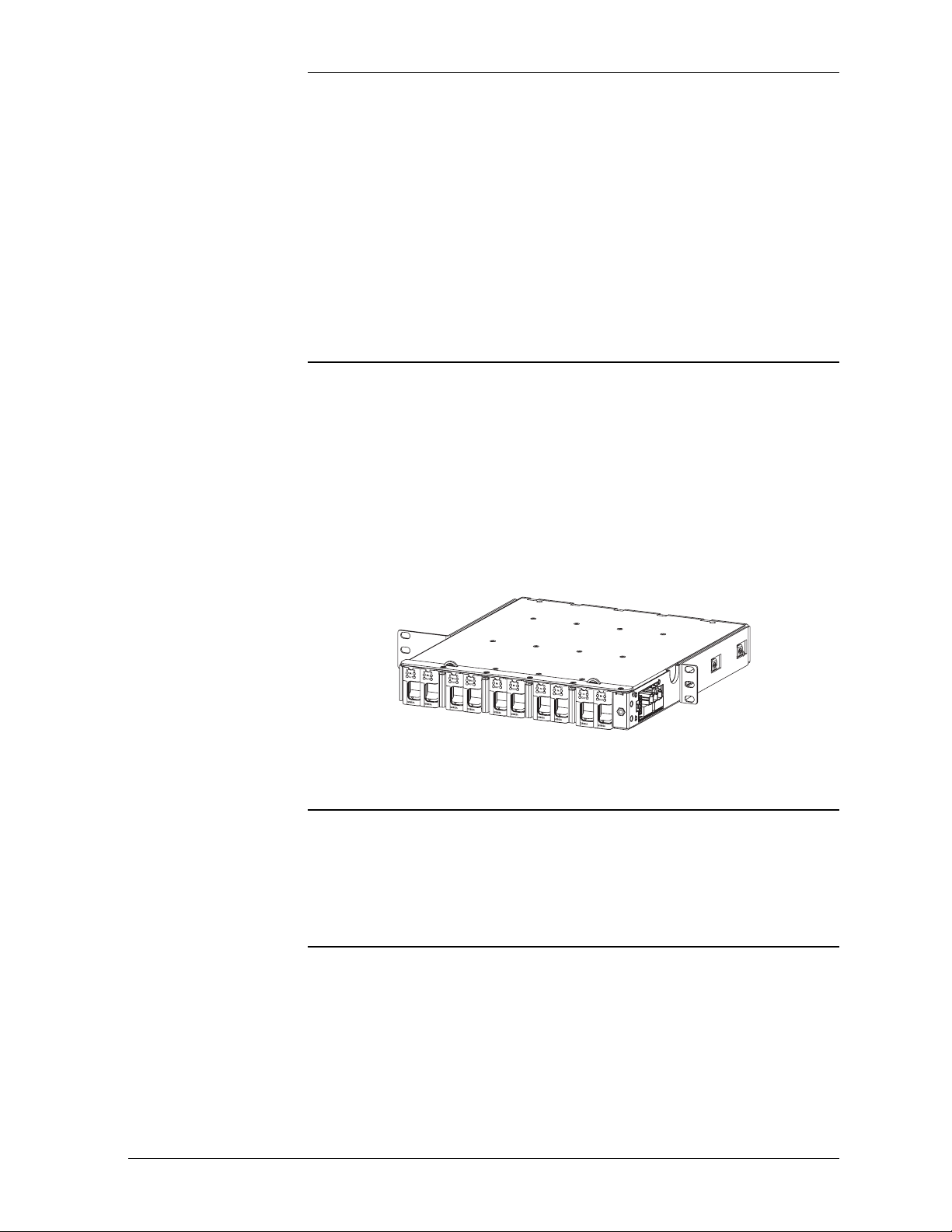

Overview The CPS 2500D System consists of up to ten QS882A dual converter cards in

a shelf with input and output wiring and an alarm and connector card on the

right side. Each converter on the QS882A card:

• Accepts 100VA limited source voltage in a range of 190 to 395 volts.

• Delivers up to 65W at nominal -48 volts.

A fully configured shelf delivers a maximum load power of 1300 Watts in an

outdoor cabinet. If converter card redundancy is desired the maximum power

that can be delivered is 1170 Watts.

Figure 1-1: CPS2500D Downstream System

Applications The CPS2500D is the part of a telephone line powered system that is located

with the video switching equipment at a site not served by batteries - typically

a cross connect cabinet. It is designed to operate most optimally from a

CPS3200U source on the other end of the telephone lines near a battery

reserve, but works with other upstream vendor equipment.

Web Site For further information about CPS6000 systems visit the CPS6000 Web site at

http://www.lineagepower.com/

Issue 4 January 2008 Introduction 1 - 1

Page 12

CPS2500D +/-190V Downstream System

Customer Service Contacts

Customer Service, Technical Support, Product Repair and Return, and Warranty Serv ice

Customer Training Lineage Power offers customer training on many Power Systems products. For

Downloads and Software

For customers in the United States, Canada, Puerto Rico, and the US Virgin

Islands, call 1-800-THE-1PWR (1-800-843-1797). This number is staffed

from 7:00 am to 5:00 pm Central Time (zone 6), Monday through Friday, on

normal business days. At other times this number is still available, but for

emergencies only. Services provided through this contact include initiating the

spare parts procurement process, ordering documents, product warranty

administration, and providing other product and service information.

For other customers worldwide the 800 number may be accessed after first

dialing the AT&T Direct country code for the country where the call is

originating, or you may contact your local field support center or your sales

representative to discuss your specific needs.

information call 1-972-284-2163. This number is answered from 8:00 a.m.

until 4:30 p.m., Central Time Zone (Zone 6), Monday through Friday.

To download the latest product information, product software and software

upgrades, visit our web site at

http://www.lineagepower.com/

1 - 2 Introduction Issue 4 January 2008

Page 13

CPS2500D +/-190V Downstream System

)

2 Product Description

Physical Description

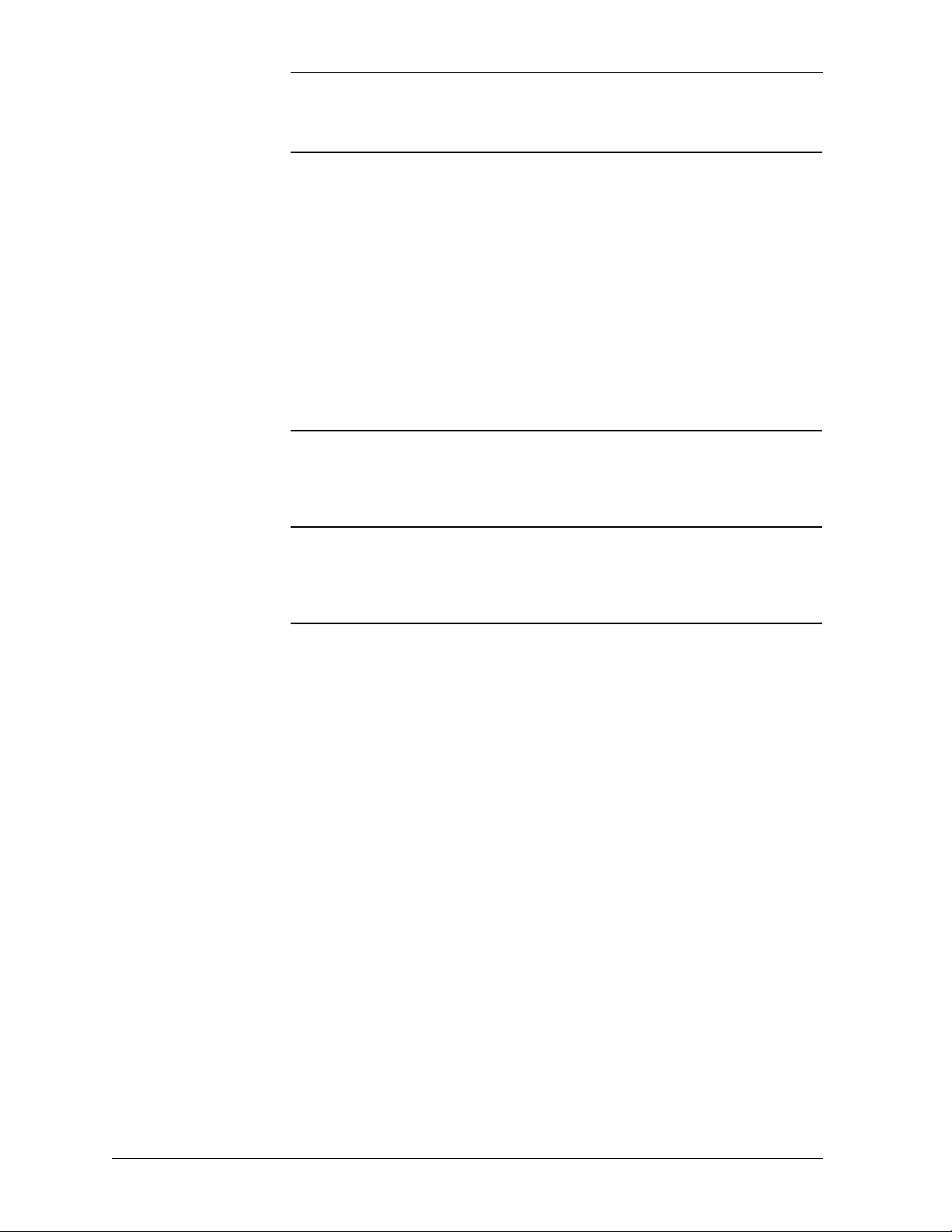

Block Diagram

QS882A Dual Converter

QS882A Dual Converter

QS882A Dual Converter

P321

Signal Output

Cable

QS800A Shelf

Slot 1

Slot 2

Slot 10

Alarm Card

P700

-48V Output

Power Cable

P800

+/-190V Input

Power Cable

(20 Telephone Pairs

Figure 2-1: QS800A Shelf Block Diagram

Issue 4 January 2008 Product Description 2 - 1

Page 14

Operation

CPS2500D +/-190V Downstream System

Power comes in on P800 from up to 20 independent 100VA +/- 190V circuits.

Power comes out on P700 at -54 volts. Maximum current for a fully

provisioned shelf is 24 Amps or 1300 Watts. Major and minor alarms are

available on P321. The alarms are configured as Form C closures. A major

indicates circuit or input failure on 2 or more circuits. A minor alarm indicates

circuit or input failure of one circuit.

Section 5 has a step by step installation and trouble shooting process using the

Display LEDs as a primary guide to next actions.

2 - 2 Product Description Issue 4 January 2008

Page 15

Specifications

CPS2500D +/-190V Downstream System

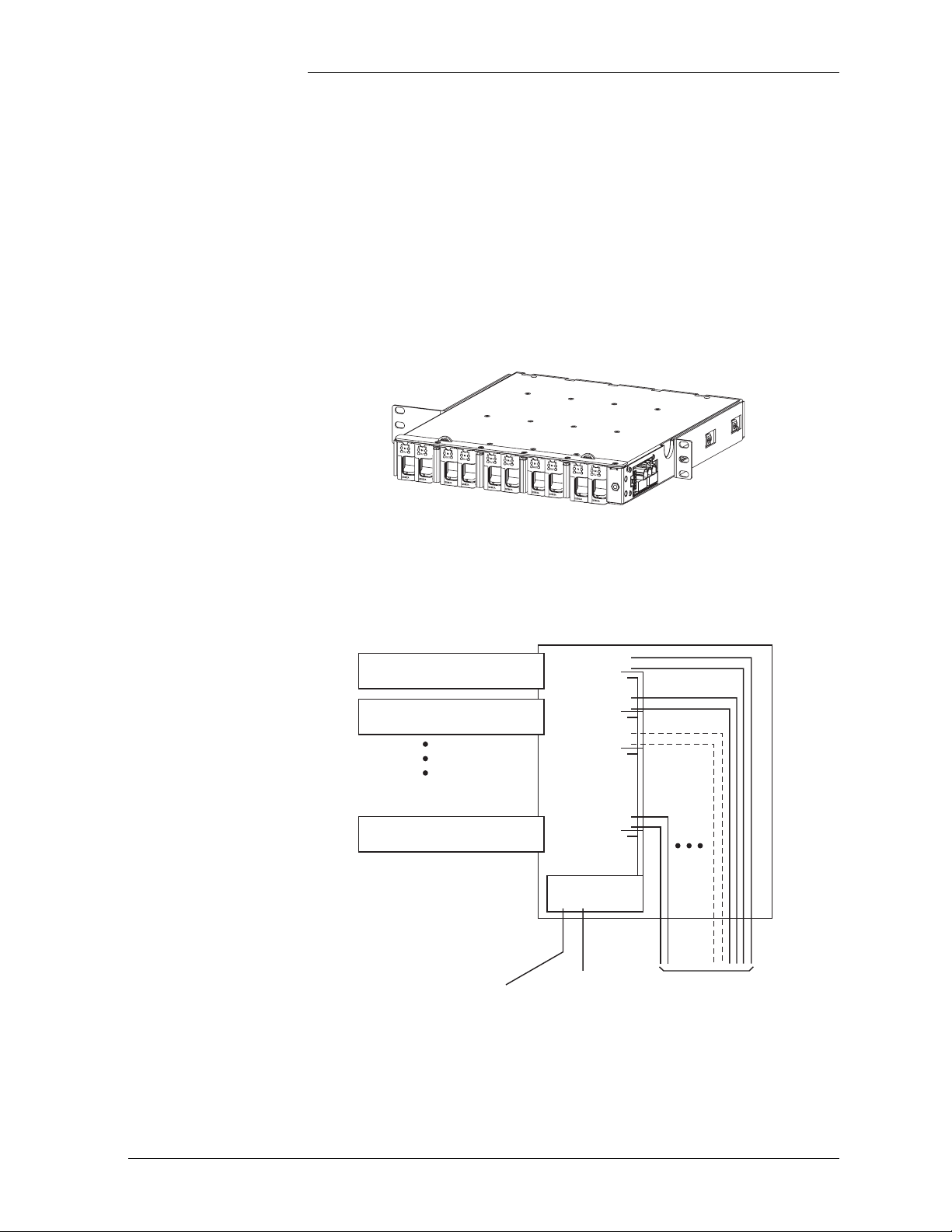

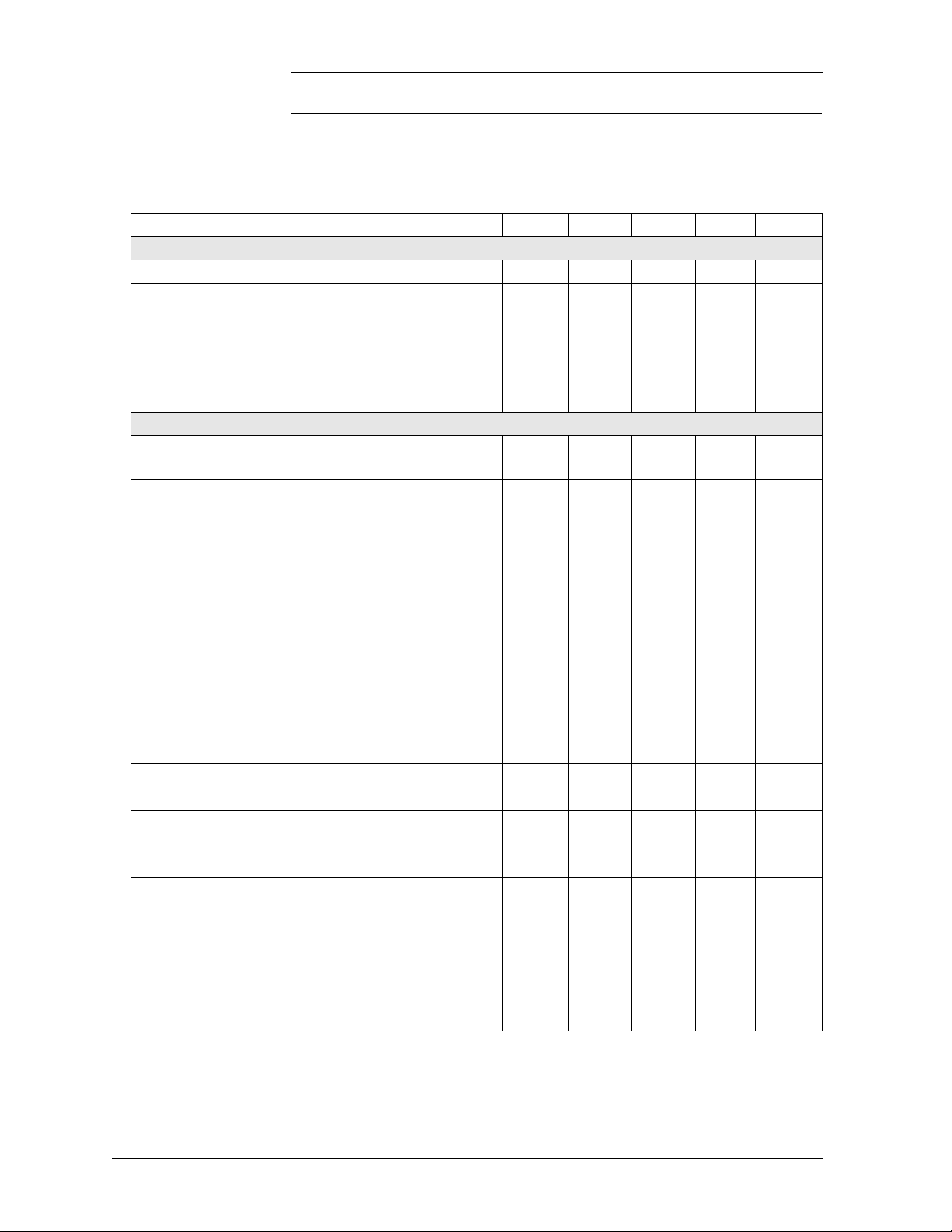

Table 2-A: Absolute Maximum Ratings

Parameter Symbol Min Typ Max Unit

Input Voltage

Continuous VI 0 380 400 Vdc

TransientDuration = 10ms Vtr 400 TBD Vdc

Te mp er at ur e

Normal Operating Ambient

Temperature at 150 lfm airflow

Operating Ambient Temperature at

higher (TBD) airflow

(See Thermal Considerations section)

Storage Temperature Tstg -55 125 °C

Power

Input Power (per Power unit) Pin 200 W

Power Dissipation (Power unit

Dissipation)

Output Power (per Power unit) Pout 130 TBD W

Isolation

Input to Output Voltage 1500 Vdc

TA -40 65 °C

TA -40 75 °C

Pdiss 27 TBD W

Issue 4 January 2008 Product Description 2 - 3

Page 16

CPS2500D +/-190V Downstream System

Electrical Unless otherwise specified, specifications apply over all operating input

voltage, output load current and temperature conditions.

Table 2-B: Electrical Specifications

Parameter Symbol Min Typ Max Unit

Input

Operating Input Voltage Vi 130 391.1 400 Vdc

Maximum Input Current

0.233

0.241

0.250

(±190 Vdc: Vioc=320 Vdc to 398 Vdc, Io=Io, max)

Future Code:

Iin max

0.314

0.33

0.347

(±130 Vdc: Vioc=250 Vdc to 278 Vdc, Io=Io, max)

Inrush Transient (Duration: <= 1.0 ms) Ipk 0.25 Adc

Output (per Power Unit, 2 Circuits)

Output Voltage Set-point

(Vin=Vin min, Io=1.47A, Ta =25°C)

Vo , s e t -54.5 Vdc

Output Voltage

(Over all operating input voltage, resistive load, and

Vo -52.0 -- -55.0 Vdc

temperature conditions until end of life)

Output Regulation

Line (Vin=Vin min to Vin max)

Load* (Io=Io min to Io max)

--

--

0.5

TBD

--

3.5

%Vo

%Vo

*Output voltage droops as load current

increases to provide system current sharing.

Temperature (TA = -40°C to +85°C)

--

150

--

Output Ripple and Noise on nominal output

(Vin=Vin nom and Io=Io min to Io max)

RMS (5Hz to 20MHz bandwidth)

Peak-to-Peak (5Hz to 20MHz bandwidth)

--

--

140

200

--

mVrms

--

mVpk

External Capacitance Co max -- -- 3,000 µF

Output Power (per circuit pair, Vo=Vo min) Io 0 2.5 Adc

Efficiency (Io=Io max, Vo=Vo set, Ta=25°C)

Vin=260V

Vin=380V

η 86

83

%

Dynamic Load Response

(ΔIo/Δt=1A/10µs, Vin=Vin nom, Ta=25°C)

Load Change from Io=50% to 75% of Io max

Peak Deviation

Load Change from Io=75% to 50% of Io max

Peak Deviation

Vpk

ts

Vpk

ts

%Vo set

%Vo set

Settling Time (Vo<10% peak deviation)

Adc

mV

µs

µs

2 - 4 Product Description Issue 4 January 2008

Page 17

CPS2500D +/-190V Downstream System

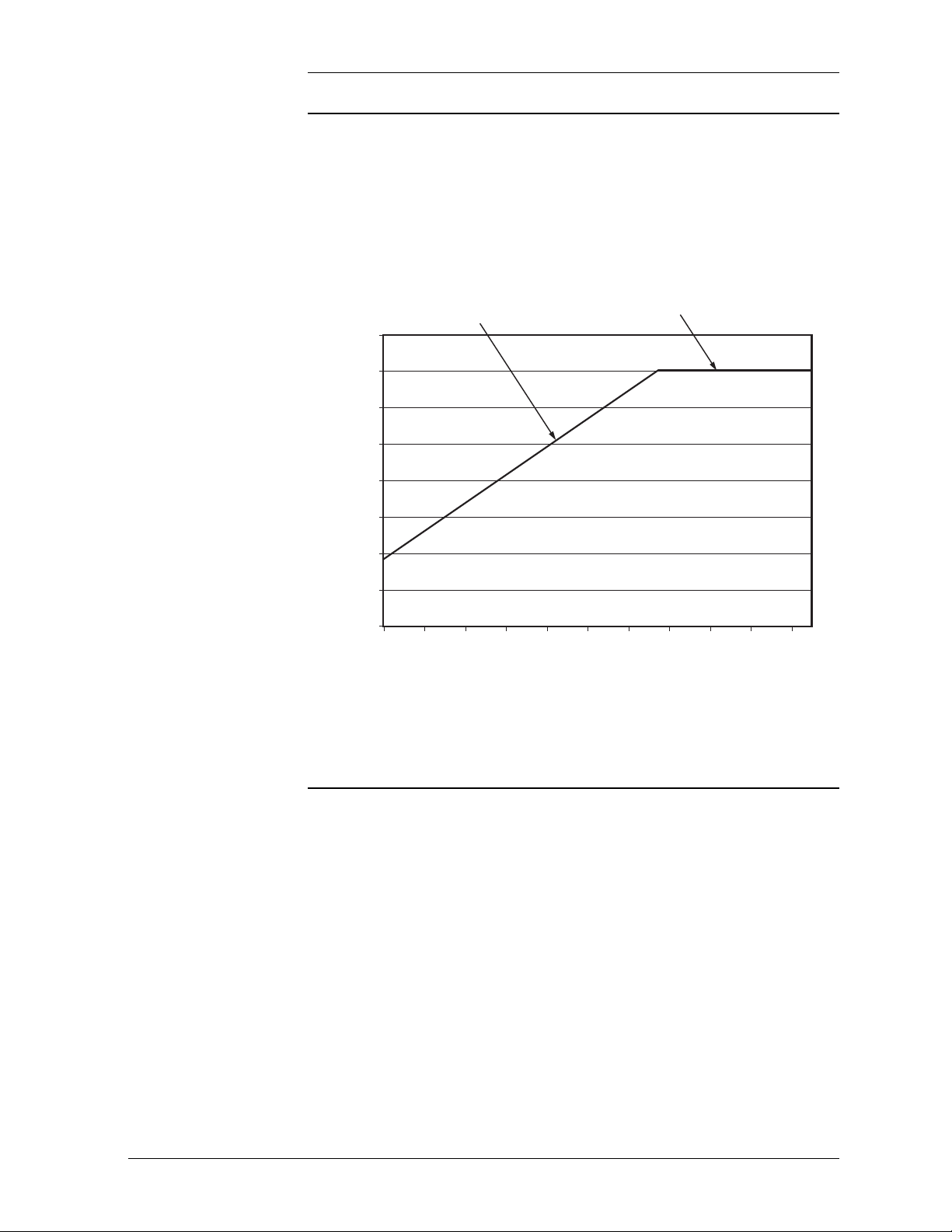

Maximum Output Power

The following graph shows the low side tolerance output power from the pair

of dc/dc circuits on each unit, as input voltage delivered to the unit varies due

to losses in the copper feeder pairs. Efficiency is assumed to be linear with 84%

at Vin minimum of 190V (Pin =2 x (190 x 0.239) = 2 x 45.41W = 90.82W),

and 83% at Vin maximum of 380V; maximum input current is limited to 0.239

Amps at all input voltages.

Output power limited by

thermal dissipation

Watts

Output power limited by

maximum input current

140.0

130.0

120.0

110.0

100.0

90.0

80.0

Installation category:

Unit Output Power (per circuit pair)

70.0

60.0

190 210 230 250 270 290 310 330 350 370 390

Input Voltage

Figure 2-2: Unit Maximum Output Power vs. Input Voltage

Unit Maximum Output Power vs. Input Voltage when fed from +/-190V

upstream source.

Input power shall be provided by up to 20 telephone wire pairs. The host

system must protect each pair to a level corresponding to a CommScope

3C*EW Gas tube primary protector. This protector has a voltage breakdown

range of 265-465 Volts and an impulse spark over range of <265-700 Volts.

Issue 4 January 2008 Product Description 2 - 5

Page 18

Page 19

CPS2500D +/-190V Downstream System

3 Engineering and Ordering

Ordering Information

Shelf Description Comcode

QS882A Converter Unit 108994918

QS800A Shelf 108994926

QS800B 12-Inch Complete Shelf (requires

external ground connection)

19-Inch Adapter Bracket CC848828525

CC109139853

Issue 4 January 2008 Engineering and Ordering 3 - 1

Page 20

Engineering

CPS2500D +/-190V Downstream System

Engineering a telephone line powered system requires knowledge about the

resistance of the input wires feeding each circuit. To make a rough estimate

follow these steps. An example follows each step in [ ] brackets.

1. Assess the total resistance of the loop feeding each circuit. [ 600Ω ]

2. Decide how much power your load requires. [ 600W ]

3. Choose the highest power curve available for circuits with the input

resistance provided by your network. [ For 600Ω, the 60Watt line almost

works. This looks like about 58 Watts.]

Figure 3-1: Constant Delivered Power Curves

(normal range of operation)

3 - 2 Engineering and Ordering Issue 4 January 2008

Page 21

CPS2500D +/-190V Downstream System

4. Use the 80% efficiency factor to determine how much power is delivered

per circuit. [58 Watts * .8 = 46.4 Watts]

5. Divide your total load by the power delivered per circuit to determine the

minimum number of circuits required to support the load. [ 600 Watts / 46.4

Watts = 12. 93 circuits or 13 circuits.]

6. Add cards to reach the level of redundancy desired. [ One card redundancy

so 16 circuits or 8 cards.]

Issue 4 January 2008 Engineering and Ordering 3 - 3

Page 22

Page 23

CPS2500D +/-190V Downstream System

4 Safety

Safety Statements

Please read and follow all safety instructions and warnings before installing,

maintaining, or repairing the system:

• The system is Underwriters Laboratories (UL) Recognized per the

applicable requirements of UL60950-1 and UL60950-21.

• For the product to be safe the chassis must be grounded by a permanent

means.

• The return conductor of the -48V shall be earthed.

• Install only in restricted access areas (dedicated equipment rooms,

equipment closets, or the like) in accordance with articles 110-31, 110-32,

and 110-33 of the U.S. National Electric Code (NEC), ANSI/NFPA No.

70, and pursuant to applicable local codes.

• The telecommunication line cable, carrying the +/-190V, shall be

minimum 26 AWG, and rated minimum 200V. Consideration shall be

taken at the time of installation to verify cable rating.

• Primary protection must be provided on all the telecommunication line

cable consistent with UL 497.

• Airflow must be provided at a rate of 150 lfm across the entire cross

section of the shelf for operation in environments from -40°C to 65°C.

• This equipment is to be used in controlled environments (an area where

the humidity is maintained at levels that cannot cause condensation on the

equipment, the contaminating dust is controlled, and the steady-state

ambient temperature is within the range specified).

• This equipment must not be installed over combustible surfaces.

• For installations in the United States, Listed compression connectors are

to be used to terminate Listed field-wired conductors where required.

For all installations, the appropriate connector is to be applied only to the

correct size conductor as specified by the connector manufacturer, using

only the connector manufacturer's recommended tooling or tooling

approved for that connector.

Issue 4 January 2008 Safety 4 - 1

Page 24

CPS2500D +/-190V Downstream System

• If the proper connector for the country of installation is not provided,

obtain appropriate connectors and follow manufacturer’s and all local

requirements for proper connections. All national and local rules and

regulations should be followed when making field connections.

• A bulk output option is provided; load connections should be made in

close proximity to the power shelf.

• The main input voltage (+/-190V) shall meet UL60950-21 RFT-V

requirements. DO NOT CONNECT TO RFT-C CIRCUITS.

• The main output voltage (48V) meets SELV requirements.

• Insulation on field-wired conductors should be rated no less than 90°

Celsius. Wire conductor size should be sized per electrical codes for 75°

Celsius wire, and based on the ampacity of the associated protection

device. Wiring internal to enclosed equipment cabinets should be rated at

105° Celsius (minimum).

• Torque electrical connections to the values specified on labels or in the

product documentation.

• Cables must be dressed to avoid damage to the conductors (caused by

routing around sharp edges or routing in areas where wires could get

pinched) and undue stress on the connectors.

• Alarm contacts are not fused in the shelf; therefore, current limiting

protection for these contacts must be provided by external circuits.

Maximum ratings for alarm connections are 60Vdc and 0.5 amperes.

Exceeding these maximum ratings could result in fire or damage to the

unit.

• For applications in cabinets, huts, vaults, and central offices, the system

mounting framework must be connected to the system integrated ground

grid.

• The designed capacitance between +/-190V RFT-V conductors is 1uF and

the measured capacitance between +/-190V and earth is 1uF. DO NOT

add capacitance to the system to reach values that exceed safety limits per

the following figure:

4 - 2 Safety Issue 4 January 2008

Page 25

CPS2500D +/-190V Downstream System

Issue 4 January 2008 Safety 4 - 3

Page 26

CPS2500D +/-190V Downstream System

Warning Statements and Safety Symbols

The symbols may sometimes be accompanied by some type of statement; e.g., “Hazardous voltage/energy

inside. Risk of injury. This unit must be accessed only by qualified personnel.” Signal words as described

below may also be used to indicate the level of hazard

DANGER

WARNING

CAUTION

Indicates the presence of a hazard that will cause death or severe personal injury if the

hazard is not avoided.

Indicates the presence of a hazard that can cause death or severe personal injury if the

hazard is not avoided.

Indicates the presence of a hazard that will or can cause minor personal injury or

property damage if the hazard is not avoided.

This symbol identifies the need to refer to the equipment instructions for important

information.

These symbols (or equivalent) are used to identify the presence of hazardous ac mains

voltage.

This symbol is used to identify the presence of hazardous ac or dc voltages. It may

also be used to warn of hazardous energy levels.

One of these two symbols (or equivalent) may be used to identify the presence of

rectifier and battery voltages. The symbol may sometimes be accompanied by some

type of statement, for example: “Battery voltage present. Risk of injury due to high

current. Avoid contacting conductors with uninsulated metal objects. Follow safety

precautions.”

One of these two symbols may be used to identify the presence of a hot surface. It

may also be accompanied by a statement explaining the hazard. A symbol like this

with a lightning bolt through the hand also means that the part is or could be at

hazardous voltage levels.

This symbol is used to identify the protective safety earth ground for the equipment.

This symbol is used to identify other bonding points within the equipment.

This symbol is used to identify the need for safety glasses and may sometimes be

accompanied by some type of statement, for example: “Fuses can cause arcing and

sparks. Risk of eye injury. Always wear safety glasses.”

4 - 4 Safety Issue 4 January 2008

Page 27

Precautions

CPS2500D +/-190V Downstream System

When working on or using this type of equipment, the following precautions

should be noted:

• This unit must be installed, serviced, and operated only by skilled

and qualified personnel who have the necessary knowledge and

practical experience with electrical equipment and who understand

the hazards that can arise when working on this type of equipment.

• The equipment could be powered by multiple ac inputs. Ensure that

the appropriate circuit protection device for each ac input being

serviced is disconnected before servicing the equipment. Do not

disconnect permanent bonding provisions unless all ac inputs are

disconnected.

• Batteries may be connected in parallel with the output of the

rectifiers. Turning off the rectifiers will not necessarily remove

power from the bus. Make sure the battery power is also

disconnected and/or follow safety procedures while working on any

equipment that contains hazardous energy/voltage.

• Hazardous energy and voltages are present in the unit and on the

interface cables that can shock or cause serious injury. Follow all

safety warnings and practices when servicing this equipment. When

equipped with ringer modules, hazardous voltages will be present

on the ringer output connectors.

• In addition to proper job training and safety procedures, the

following are some basic precautions that should always be used:

–Use only properly insulated tools.

– Remove all metallic objects (key chains, glasses, rings,

watches, or other jewelry).

– Wear safety glasses. Fuses can produce sparks. High energy

levels on buses and distribution components can produce severe

arcing.

– Test circuits before touching.

– Lock out and tag circuit breakers/fuses when possible to

prevent accidental turn on.

– Be aware of potential hazards before servicing equipment.

– Identify exposed hazardous electrical potentials on connectors,

wiring, etc. (note the condition of these circuits, especially

wiring).

– Use care when removing or replacing covers; avoid contacting

circuits.

Issue 4 January 2008 Safety 4 - 5

Page 28

CPS2500D +/-190V Downstream System

Special Installation Notes

Deutsch Installationsanleitung

Espanol Notas especiales para instalaciones en países de habla hispana

4 - 6 Safety Issue 4 January 2008

Page 29

CPS2500D +/-190V Downstream System

5 Installation

CPS2500D Installation

Purpose CPS 2500D Shelf Installation

Precautions Observe ESD protection while installing circuit packs

Safety • Always consider personal safety.

• Make sure the system is properly grounded per the National Electrical

Code and local building codes.

• Remove all metal jewelry before beginning the installation.

Installation Tools • Wire cutters and strippers

• Heat shrink gun

• Torque wrench (0-240 inch-lb or 28 Nm)

• 5/16 inch (8mm) hex driver

• 10 mm hex driver

• 48 Volt test load

• Digital meter with an accuracy of +/- 0.02%

• Screw Drivers (flat-blade and Phillips)

•ESD wrist strap

Issue 4 January 2008 Installation 5 - 1

Page 30

CPS2500D +/-190V Downstream System

Unpack the CPS2500D Shelf

CPS2500D Unpack The box contains:

• One QS800A Shelf

• One 848744961 Power Cable

• One 848745547 Alarm Signal Cable

• Product documentation

Step Action

Unpack the box.

1

Inspect the shipping container for any signs of damage. If damage

exists, have the carrier’s representative sign a note acknowledging

the damage.

Carefully cut the sealing tape and remove the shelf, cables and

2

documentation from the carton.

Save the shipping package until all parts are operating within

3

specifications.

5 - 2 Installation Issue 4 January 2008

Page 31

CPS2500D +/-190V Downstream System

Ground Configuration

Ground Jumper

Step Action Action

1

Is Ground to RTN connection made on a fuse or distribution panel?

Yes - If Ground Jumper is

present, remove Ground Jumper

as shown below.

No - If Ground Jumper is not

present, install Ground Jumper as

shown below.

Figure 5-1: Ground Jumper

Issue 4 January 2008 Installation 5 - 3

Page 32

CPS2500D +/-190V Downstream System

Inspect the Network

Check and Mark Wiring Compliance

Each location in the network where the input is available to be touched must

be protected and marked as an A2 voltage.

Step Action

Is accessibility to the circuit throughout the network consistent with A2

1

requirements?

Voltage

Class General Public Employees Craftspersons

A1 Restricted

A2 Inaccessible Restricted

A3 Inaccessible Inaccessible Restricted

Is the 5-pin protector marked as a special circuit?

2

Does the 5-pin protector protect each pair to a level corresponding to a CommScope

3

3C*EW Gas tube primary protector? This protector has a voltage breakdown range

of 265-465 Volts and an impulse spark over range of <265-700 Volts. Protectors

with a lower voltage breakdown rating will be problematic.

Access

Exposed Exposed

Exposed

Access

Access

(Excsptions)

To meet UL60950-21 specific procedural steps must be taken at the time of

installation. This section goes through those steps. These steps should be

performed before power is distributed in the network. Normally the final step

is performed by closing the circuit using a 5-pin protector after DC power is

applied to the system.

Step Action

Recognize that the Remote Feed Telecommunication Voltage limited (RFT-V)

1

circuit is voltage limited to +190V and -190V from ground.

Is the total capacitance to ground on each line of the circuit less than 10 µF?

2

The QS882A introduces less than 1 µF. The sourcing electronics and line must

introduce less than 9 µF of capacitance.

Is the total capacitance line to line of the circuit less than 40 µF?

3

The QS882A introduces less than 1 µF. The sourcing electronics and line must

introduce less than 39 µF of capacitance from tip to ring.

Is the remote equipment also a RFT-V voltage limited circuit?

4

Both ends of the circuit must be designed to the same standard. This must be

verified before the equipment is connected together.

Is the voltage rating of the Network Wiring sufficient to support 190V to ground?

5

Is the chassis of the system bonded to ground?

6

Verify by both observation and measurement before powering the system.

5 - 4 Installation Issue 4 January 2008

Page 33

CPS2500D +/-190V Downstream System

Install the CPS2500D Shelf

CPS2500D Frame Install

Use the following procedure to mount the CPS 2500D shelf into a frame with

mounting holes located on 12.9 inch (328 mm) centers.

Step Action

Locate the 2 mounting brackets, one on each side of the QS800A

1

shelf; align the holes in the shelf-mounting bracket with the holes in

the mounting frame. See Figure 5-2.

Attach the CPS shelf to the frame using 6 screws threaded to match

2

the holes in the equipment frame. Refer to the table below for Torque

Specifications.

Torque

Hardware Nm in-lb

Metric M5 4 35

12-24 4 35

Metric M6 7.3 65

12 34 56 7 910

AB

IN

OUT

AB

IN

OUT

AB

IN

OUT

AB

IN

OUT

AB

IN

OUT

AB

IN

OUT

AB

IN

OUT

8

AB

IN

OUT

AB

IN

OUT

AB

IN

OUT

QS882A

QS882A

Frame Mounting

Screws Go Here

Figure 5-2: QS800A Frame Mounting

QS882A

QS882A

QS882A

QS882A

QS882A

QS882A

QS882A

ESD

QS882A

And Here

Issue 4 January 2008 Installation 5 - 5

Page 34

CPS2500D +/-190V Downstream System

Install the CPS2500D Shelf (continued)

CPS2500 Cable Install

Follow the steps below to route cables to and from the QS800A shelf.

Step Action

Insert ESD wrist strap pin into ESD jack shown in Figure 5-3.

1

Connect the ground lug to the shelf as shown in Figure 5-3. Use two

2

10-32 by 5/8 inch or shorter threaded fasteners and a double hole lug

with holes on 5/8 inch centers to secure a 6 AWG ground lead to the

location on the right of the shelf just in front of the power output

connectors. Torque to 30 inch –lbs.

Locate the 2 included cable sets that came with the shelf and the

3

pigtailed 50 pin connector that is permanently attached to the shelf.

Attach the 2 included cable sets, 848744961 and 848745547, to the

4

QS800A Shelf as shown in Figure 5-4. The connectors are keyed so

that they only fit in the correct way.

Attach the terminal ends of each cable, labeled P800 for input +/-

5

190V, P700 for -48V out, and P321 for signals out, to the using

equipment according the Figure 5-4 and documentation for the using

equipment.

Figure 5-3: ESD Ground Jack

848744961

P800

848745547

P321

P700

Figure 5-4: QS800A with All Cables Attached

5 - 6 Installation Issue 4 January 2008

Page 35

CPS2500D +/-190V Downstream System

Installing the Converters

QS882A Converter Installation

Install the QS882A Converters

QS882A Converters mount in the QS800 shelf. Note that numbering starts

from the left and is correlated to the marking on the 5-pin protector block

cabinet input wiring panels.

Warning: You must properly protect yourself against ESD discharge prior

to installing the QS882A Controller.

Note: There is an ESD cord connection located on the right side of the shelf.

This procedure is used to install each QS882A Converter.

Step Action

Remove the QS882A converter from its shipping container.

1

Align the plastic converter housing on the right and insulated

2

circuit board on the left.

Guide the converter into the first available slot by positioning the

3

plastic converter housing in the notch on the top right edge of the

opening. See Figure 5-5.

Slide the converter into the shelf until it is fully seated in the

4

connector on the rear of the CPS shelf.

Push the display faceplate into the shelf until the latch on the top of

5

the converter housing catches. See Figure 5-6.

Repeat this process as needed for your application.

6

A

B

IN

OUT

Push in until

latch clicks

QS882A

Figure 5-5: Align the QS882A Converter

Issue 4 January 2008 Installation 5 - 7

Figure 5-6: QS800A with All Cables Attached

Page 36

CPS2500D +/-190V Downstream System

Recognizing Normal States

Recognize Normal States

Once power is provided to the CPS 2500D system the LEDs on the converters

will illuminate. Understanding what the LEDs mean allows one to recognize

normal states and diagnose abnormal states. The top row of LEDs show the

state of the input to the converters. The bottom row of LEDs show the state of

the output from the converters.

Step Action

Observe the LEDs.

1

Does the display look like a combination of the states shown in

2

Figure 5-7: Normal States?

Yes - The system is operating

3

normally. Proceed to the next

No - Continue to Diagnosing

Abnormal States.

task.

111

AB

Green GreenGreen

Green Green

Both Pairs

Powered

IN

OUT

QS882A

Green

A Pair

Powered

B Pair

Never

Powered

AB

IN

OUT

QS882A

Neither Pair

Ever

Powered

AB

IN

OUT

QS882A

Figure 5-7: Recognizing Normal States

(with associated LED display definitions)

5 - 8 Installation Issue 4 January 2008

Page 37

CPS2500D +/-190V Downstream System

Diagnosing Abnormal States

Diagnosing Abnormal States

Abnormal states are presented in order of increasing difficulty to repair:

a) Output Voltage Low - Additional Circuits Required

b) One converter fault or two converter faults

c) Network Wiring Fault

Step Action

Observe the LEDs.

1

Does the display look like a combination of the states shown in

2

Figure 5-8: Normal States?

Yes - The system load exceeds

3

the sourcing capability of the

No - Continue to the next step

Diagnosing Abnormal States.

CPS2500D shelf. Add

additional converters following

the procedure described as

QS882A Converter Installation.

1

AB

Green

IN

OUT

Additional Circuits Required

Output Voltage Low

QS882A

Figure 5-8: Output Voltage Low - Additional Circuits Required

Issue 4 January 2008 Installation 5 - 9

Page 38

CPS2500D +/-190V Downstream System

Diagnosing Abnormal States (continued)

Diagnosing

Abnormal States

Abnormal state:

One converter fault and two converter faults.

Step Action

Observe the LEDs.

1

Does the display look like a combination of the states shown in

2

Figure 5-9: Converter Internal Fault?

Yes - Replace the faulty

3

converter by first removing it as

No - Continue to the next step of

Diagnosing Abnormal States.

shown in Figure 5-10 and then

installing a replacement

converter following the

procedure described as QS882A

Converter Installation.

11

AB

Green GreenGreen Green

One Converter

Internal Fault

IN

OUT

Red RedGreen Red

Two Converters

Internal Faults

AB

IN

OUT

QS882A

Figure 5-9: Converter Internal Fault

2. Pull forward with

latch depressed

Figure 5-10: Remove Converter

A

IN

OUT

QS882A

QS882A

B

1. Press down to

unlatch module

5 - 10 Installation Issue 4 January 2008

Page 39

CPS2500D +/-190V Downstream System

Diagnosing Abnormal States (continued)

Diagnosing

Abnormal States

Abnormal state:

Network Wiring Fault

Step Action

Observe the LEDs.

1

Does the display look like a combination of the states shown in

2

Figure 5-11: Network Wiring Fault?

Yes - Trace the fault back to the

3

5 pin protector and circuit where

it enters the cabinet using the

slot identifiers and circuit

identifiers as shown in example

Figure 5-12: Network Wiring

Faulty on Circuit 6B. The

problem resides outside the

CPS2500D system. Resolve the

wiring problem using the

standard procedures provided by

the network service provider.

No - Continue to the next step of

Diagnosing Abnormal States.

Input Voltage

Interrupted on

Green

Green

11

AB

Green RedRed Red

Green

B Pair

IN

OUT

Input Voltage

Interrupted on

Both Pairs

QS882A

AB

IN

OUT

QS882A

Figure 5-11: Network Wiring Fault

1

AB

IN

OUT

QS882A

2

AB

IN

OUT

QS882A

3

AB

IN

OUT

QS882A

4

AB

IN

OUT

QS882A

5

AB

IN

OUT

QS882A

6

AB

IN

OUT

QS882A

Figure 5-12: Network Wiring Faulty on Circuit 6B

Red

Issue 4 January 2008 Installation 5 - 11

Page 40

CPS2500D +/-190V Downstream System

Diagnosing Abnormal States (continued)

Diagnosing

Abnormal States

Resolving Abnormal states starting from the office alarms. The CPS2500D

provides Power Major and Power Minor office alarms according to this logic:

one converter circuit output out of limits is a minor; two converter circuits out

of limits is a major.

Step Action

Observe the office alarm contact closure states. Do you have a

1

Power Major or a Power Minor Alarm?

For Power Major Alarms,

2

a)Observe the LEDs on the

module in position 1.

b)Use the Diagnosing

Abnormal States using

LEDs above to resolve the

state of the first QS882A

module to a normal state.

c)Work across the shelf

position by position until all

QS882A converters are

displaying a normal state.

For Power Minor Alarms,

a)Observe the LEDs on the

module in position 1.

b)Work across the shelf position

by position until the QS882A

displaying an abnormal state

is found.

c)Use the Diagnosing Abnormal

States using LEDs above to

resolve the state of that

QS882A module to a normal

state.

d)If all the modules are

displaying a normal state

and a Power Major is still

being issued the Power

Major Relay should be

replaced. The power Major

Relay is marked K1 and

located closer to the back of

the shelf in Figure 5-13.

e)Replace the Socketed Relay

with Lineage Power Part

Number 406789586.

f) Confirm that the alarms

have been successfully

retired.

d)If all the modules are

displaying a normal state and

a Power Minor is still being

issued the Power Minor Relay

should be replaced. The power

Minor Relay is marked K2

and located closer to the front

of the shelf in Figure 5-13.

e)Replace the Socketed Relay

with Lineage Power Part

Number 406789586.

f) Confirm that the alarms have

been successfully retired.

5 - 12 Installation Issue 4 January 2008

Page 41

CPS2500D +/-190V Downstream System

Diagnosing Abnormal States (continued)

Diagnosing

Abnormal States

(continued)

Figure 5-13: Relay Identification for Replacement

Issue 4 January 2008 Installation 5 - 13

Page 42

Page 43

CPS2500D +/-190V Downstream System

6 Electrical Interface Reference

Information

Shelf Electrical Interfaces

Interface

+/- 190V DC Input 12 P800

-48V DC Output 24 P700 Use 8 AWG stranded THHN wire.

Alarm Output 24 P321

Cable Length

(inches)

Connector

Label

Comments

Connector Details The following parts are used on QS800A wiresets. Choose the appropriate

mating connector for your specific application.

Connector Description Manufacturer Part Number

P800 50-position plug assembly (1/26 side entry) Cinch KS21997L1

P700 3-position receptacle Molex Receptacle 42816-0312

with 42815-0031 (8 AWG wire)

P321 16-position receptacle Molex Receptacle 39-01-2165

with 39-00-0059 sockets (24-18

AWG wire)

Issue 4 January 2008 Electrical Interface Reference Information 6 - 1

Page 44

CPS2500D +/-190V Downstream System

Connector Pinouts P800

P800

-190V Pin +190V Pin Pair

1 26 1

2 27 2

3 28 3

4 29 4

5 30 5

6 31 6

7 32 7

8 33 8

9 34 9

10 35 10

11 36 11

12 37 12

13 38 13

14 39 14

15 40 15

16 41 16

17 42 17

18 43 18

19 44 19

20 45 20

Pins 20-25 and 46-50 are not connected.

Mate for P800 can be constructed using AMP Kit part number 1-229913-1.

This 50 pin “Cable to Cable Receptacle with Tapered Cover and Screw Kit”

accepts 24 AWG solid or stranded wire. The cable housing should be dressed

away from pins 1 and 26 with the bundle exiting over pins 25 and 50.

P700

P700

Pin With jumper in place (default) With jumper removed

1 Not Used No Connection

2 -48V -48V

3 RTN / Frame Ground RTN

To create a custom wireset that connects directly to the shelf, mate for P700

can be constructed using:

• Molex Mini-Fit SR. 3 position housing: 42816-0312

• Molex Mini-Fit SR 8 AWG contact 42815-0031

• 8 AWG stranded UL1028 MTW 600V wire

Our stock cable uses black for -48 and white for return

6 - 2 Electrical Interface Reference Information Issue 4 January 2008

Page 45

CPS2500D +/-190V Downstream System

P321

P321

Pin Function

1 Power Major Alarm NC

2 Power Major Alarm Common

3 Power Major Alarm NO

4 Power Minor Alarm NC

5 Power Minor Alarm Common

6 Power Minor Alarm NO

7-16 No Connection

Notes:Both alarms are fail-safe isolated Form C contact closures

NC = Normally Closed, NO = Normally Open

Use same ratings for relays as CPS4000 alarm relays

Alternate Alarm Wireset

Alarm Output Connector

Pin Function

1 Power Major Alarm NC

2 Power Major Alarm Common

3 Power Major Alarm NO

4 Power Minor Alarm NC

5 Power Minor Alarm Common

6 Power Minor Alarm NO

Notes:Both alarms are fail-safe isolated Form C contact closures

NC = Normally Closed, NO = Normally Open

Use same ratings for relays as CPS4000 alarm relays

To create a custom wireset that connects directly to the shelf, mate for the

Alarm Output Connector can be constructed using:

• AMP 6 Position Housing 1445022-6

• AMP Socket Contact 794606-1

• 22 AWG Stranded Wire

Issue 4 January 2008 Electrical Interface Reference Information 6 - 3

Page 46

Page 47

CPS2500D +/-190V Downstream System

7 Reference Information

CPS2500D Shelf

13.6 in. (345.4 mm)

12.9 in. (327.7 mm)

1.25 in.

(37.8 mm)

Front View

Figure 7-1: QS800A Shelf Mounting Hole Dimensions

Figure 7-2: Depth and Height Dimensions

0.625 in.

(15.9 mm)

Issue 4 January 2008 Reference Information 7 - 1

Page 48

CPS2500D +/-190V Downstream System

Figure 7-3: 12-Inch Shelf Mounting Hole Dimensions (CC109139853)

Figure 7-4: Shelf Equipped with 19-Inch Adapter Bracket (CC848828525)

7 - 2 Reference Information Issue 4 January 2008

Page 49

QS882A Converter

CPS2500D +/-190V Downstream System

A

B

IN

OUT

1.6 in.

(41 mm)

QS882A

11 in.

280 mm

0.8 in.

(20 mm)

Figure 7-5: Q882A Size

Issue 4 January 2008 Reference Information 7 - 3

Page 50

CPS2500D +/-190V Downstream System

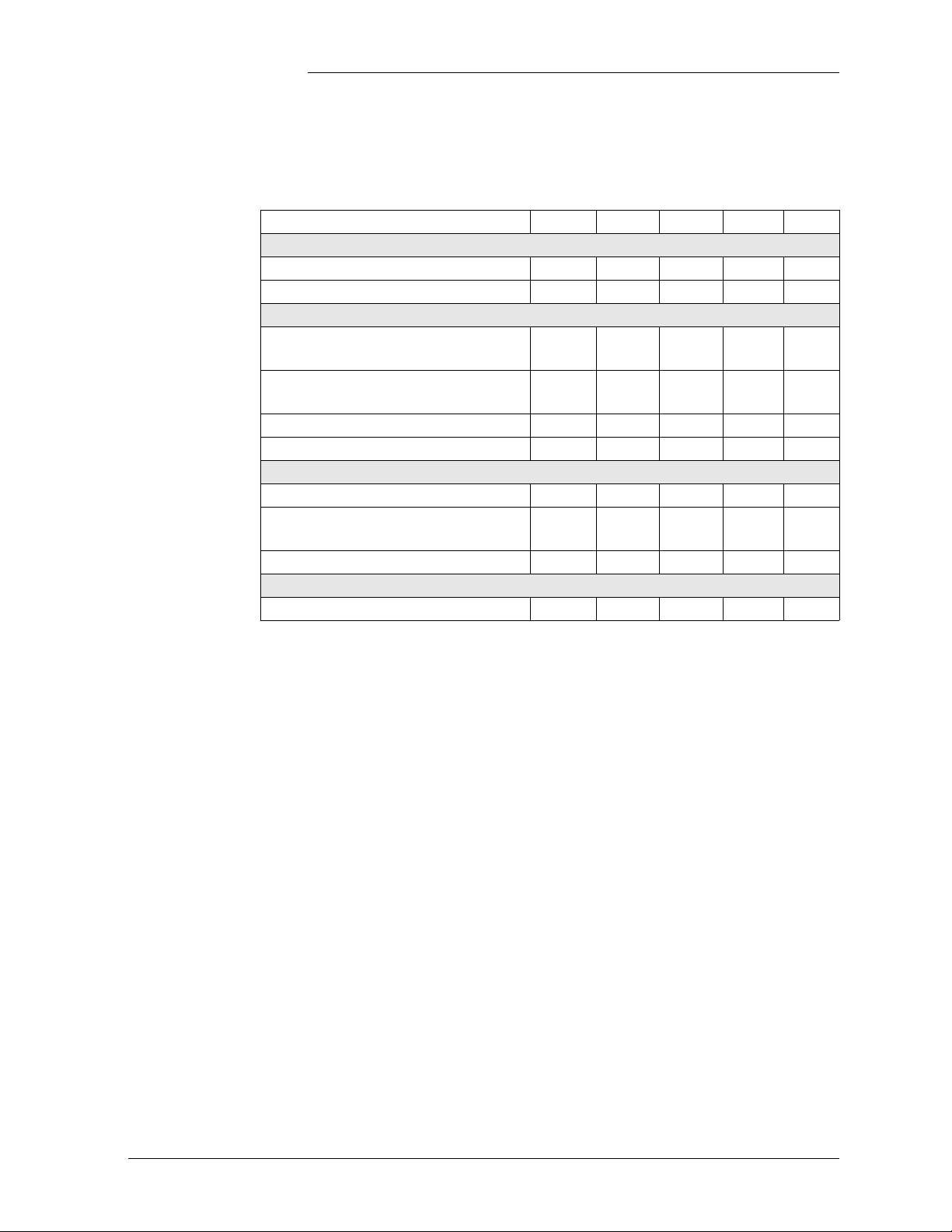

Table 7-A: LED Truth Table

LED Indicators Condition Shelf Alarm

1

AB

Green Green

Green

IN

OUT

Green

Both circuits receiving input voltage

within acceptable range with input current

below maximum input value, and

delivering acceptable output.

None

1

AB

Green

Green

Green Red

Green

Red Red

Green

Green

IN

OUT

1

AB

IN

OUT

1

AB

IN

OUT

1

AB

IN

OUT

1

AB

IN

OUT

Green

Red

Circuit A receiving input voltage within

acceptable range with input current below

maximum input value and delivering

acceptable output.

Circuit B has never received power.

Neither circuit has received acceptable

input voltage since insertion into powered

shelf.

Input voltage has been interrupted to

circuit B. Occurs after circuit B has been

powered acceptably.

Input voltage has been interrupted to both

circuits A and B. Occurs after both

circuits have been powered acceptably.

Circuit B has internal failure but

acceptable input power.

Circuit A has acceptable input and output

power.

None

None

MIN

MAJ

MIN

1

AB

Green Green

Red

Green Green

IN

OUT

1

AB

IN

OUT

Red

Both circuit A and circuit B have internal

faults while input power is acceptable.

Load power exceeds source powere

delivery capability. Both circuits in input

MAJ

MAJ

limit mode.

Note: Minor and Major alarms are mutually exclusive. Only one can be

asserted at a time.

7 - 4 Reference Information Issue 4 January 2008

Page 51

CPS2500D +/-190V Downstream System

8 Product Warranty

A. Seller warrants to Customer only, that:

1. As of the date title to Products passes, Seller will have the right to sell,

transfer, and assign such Products and the title conveyed by Seller shall be

good;

2. During the warranty period stated in Sub-Article B below, Seller’s

Manufactured Products (products manufactured by Seller), which have been

paid for by Customer, will conform to industry standards and Seller’s

specifications and shall be free from material defects;

3. With respect to Vendor items (items not manufactured by Seller), Seller

warrants that such Vendor items, which have been paid for by Customer, will

be free from material defects for a period of sixty (60) days commencing

from the date of shipment from Seller’s facility.

B. The Warranty Period listed below is applicable to Seller’s Manufactured

Products furnished pursuant to this Agreement, commencing from date of

shipment from Seller’s facility, unless otherwise agreed to in writing:

Warranty Period

Product Type New Product Repaired Product*

Central Office

Power Equipment

*The Warranty Period for a repaired Product or part thereof is six (6) months

or, the remainder of the unexpired term of the new Product Warranty Period,

whichever is longer.

C. If, under normal and proper use during the applicable Warranty Period, a defect

or nonconformity is identified in a Product and Customer notifies Seller in

writing of such defect or nonconformity promptly after Customer discovers such

defect or nonconformity, and follows Seller's instructions regarding return of

defective or nonconforming Products, Seller shall, at its option attempt first to

repair or replace such Product without charge at its facility or, if not feasible,

provide a refund or credit based on the original purchase price and installation

charges if installed by Seller. Where Seller has elected to repair a Seller’s

Manufactured Product (other than Cable and Wire Products) which has been

installed by Seller and Seller ascertains that the Product is not readily returnable

for repair, Seller will repair the Product at Customer’s site.

With respect to Cable and Wire Products manufactured by Seller which Seller

elects to repair but which are not readily returnable for repair, whether or not

24 Months 6 Months

Issue 4 January 2008 Product Warranty 8 - 1

Page 52

CPS2500D +/-190V Downstream System

installed by Seller, Seller at its option, may repair the cable and Wire Products at

Customer’s site.

D. If Seller has elected to repair or replace a defective Product, Customer shall have

the option of removing and reinstalling or having Seller remove and reinstall the

defective or nonconforming Product. The cost of the removal and the

reinstallation shall be borne by Customer. With respect to Cable and Wire

Products, Customer has the further responsibility, at its expense, to make the

Cable and Wire Products accessible for repair or replacement and to restore the

site. Products returned for repair or replacement will be accepted by Seller only

in accordance with its instructions and procedures for such returns. The

transportation expense associated with returning such Product to Seller shall be

borne by Customer. Seller shall pay the cost of transportation of the repaired or

replacing Product to the destination designated by Customer.

E. Except for batteries, the defective or nonconforming Products or parts which are

replaced shall become Seller's property. Customer shall be solely responsible for

the disposition of any batteries.

F. If Seller determines that a Product for which warranty service is claimed is not

defective or nonconforming, Customer shall pay Seller all costs of handling,

inspecting, testing, and transportation and, if applicable, traveling and related

expenses.

G. Seller makes no warranty with respect to defective conditions or nonconformities

resulting from actions of anyone other than Seller or its subcontractors, caused by

any of the following: modifications, misuse, neglect, accident, or abuse;

improper wiring, repairing, splicing, alteration, installation, storage, or

maintenance; use in a manner not in accordance with Seller’s or Vendor’s

specifications or operating instructions, or failure of Customer to apply

previously applicable Seller modifications and corrections. In addition, Seller

makes no warranty with respect to Products which have had their serial numbers

or month and year of manufacture removed, altered, or experimental products or

prototypes or with respect to expendable items, including, without limitation,

fuses, light bulbs, motor brushes, and the like. Seller’s warranty does not extend

to any system into which the Product is incorporated. This warranty applies to

Customer only and may not be assigned or extended by Customer to any of its

customers or other users of the Product.

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND ARE IN LIEU OF

ALL OTHER EXPRESS AND IMPLIED WARRANTIES, INCLUDING BUT NOT

LIMITED TO WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE. CUSTOMER’S SOLE AND EXCLUSIVE REMEDY

SHALL BE SELLER’S OBLIGATION TO REPAIR, REPLACE, CREDIT, OR

REFUND AS SET FORTH ABOVE IN THIS WARRANTY.

8 - 2 Product Warranty Issue 4 January 2008

Page 53

CPS2500D +/-190V Downstream System

Appendix

A

Operating Temperature and Vertical Spacing

Overview The CPS2500 System has been designed for mounting in cabinets where

-48Vdc is required. It is designed for use with other equipment that requires

vertical airflow cooling. To operate in 65°C environments, 150 linear feet per

minute (Lfm) airflow must be provided.

Operating Temperature

75°C operation is possible with additional airflow. Confirmation testing is

required.

Issue 4 January 2008 Operating Temperature and Vertical Spacing Appendix A - 1

Page 54

Page 55

CPS2500D +/-190V Downstream System

Revision History

Issue 4 Rebranding.

Issue 3 Added safety, grounding, jumper, and connector information. Added QS800B

shelf and 19-inch adapter bracket.

Issue 2 Formatting issues only.

Issue 4 January 2008 Revision History - 1

Page 56

CPS2500D +/-190V Downstream System

2 - Revision History Issue 4 January 2008

Loading...

Loading...