Page 1

H569-445 Battery Distribution Fuse/ Circuit

Breaker Bay (BDFB/BDCBB)

Product Manual

Comcode 850018552

Issue 3

June 2012

Page 2

Table of Contents

Customer Service Contacts ............................................................................................. 3

BDFB Overview ................................................................................................................ 4

Specifications .............................................................................................................. 5

Safety ......................................................................................................................... 6

Getting Started ........................................................................................................... 9

Floor Mounting ......................................................................................................... 12

Cabinet Extensions .................................................................................................... 13

Cabinet Top Cover ..................................................................................................... 14

Frame Ground ........................................................................................................... 15

Panel Positions and Labeling ..................................................................................... 17

Load Bus Arrangements ............................................................................................ 19

Distribution Panels ................................................................................................... 20

VIM1C Meter ............................................................................................................ 23

Alarm Connections and ABS Power ........................................................................... 27

Discharge Return Bus Options ................................................................................... 29

Adding/Moving Load Shunt Bus Details ..................................................................... 31

Wiring Schematics .................................................................................................... 35

Product Warranty ..................................................................................................... 37

Revision History ........................................................................................................ 39

Notice:

The information, specifications, and procedures in this manual are subject to change without

notice. Lineage Power assumes no responsibility for any errors that may appear in this

document.

© 2012 Lineage Power

All International Rights Reserved

Printed in U.S.A.

Page 3

Secondary DC Power Distribution Bay H569-445

Customer Service Contacts

For customers in the United States, Canada, Puerto Rico, and the US Virgin Islands, call

1-800-THE-1PWR (1-800-843-1797). This number is staffed from 7:00 am to 5:00 pm

Central Time (zone 6), Monday through Friday, on normal business days. At other times

this number contacts an answering service with on-call personnel for out of service

emergencies.

Customer Training

Lineage Power offers customer training on many Power Systems products. For

information call 1-877-LINEAGE (1-877-546-3243). This number is answered from 8:00

a.m. until 4:30 p.m., Central Time Zone (Zone 6), Monday through Friday.

Downloads and Software

To download the latest product information, visit our web site at

http://www.lineagepower.com/

Issue 3 June 2012 3

Page 4

Secondary DC Power Distribution Bay H569-445

BDFB Overview

This manual describes the H569-445 Secondary DC Power Distribution Bay. This Battery

Distribution Fuse Bay (BDFB) or Battery Distribution Circuit Breaker Bay (BDCCB) serves

as a secondary fuse or circuit breaker distribution center for -48V dc power delivered

from a central office battery plant.

Cabinet:

• 7-foot tall

• seismic zone 4

• extensions available for 9 and 11-1/2 foot applications

Load Buses

• up to six, 800A each

• each fed by a battery plant fuse or circuit breaker

• each feeding one or more Distribution Panels

Distribution Panels

• up to six, 28 positions each

• one or more Distribution Panels per Load Bus

• alarm lights and signals individual to each panel

Protectors

• Fuses or Circuit Breakers

• No position or spacing restrictions

• Fuses: TPS or TLS up to 125A

• Circuit Breakers up to 250A

Cabling

• Top or Bottom fed Input and Output cabling without reconfiguring the

cabinet.

Return Bars

• Optional internal 2-hole ground bars

• Optional external ground bars

mounted to overhead framing or cable rack

Monitoring - VIM1 Smart Monitor (standard)

• Voltage and Current of each load bus

or combined current of entire BDFB

• Alarm Status – Red backlight and LED

• Alarm Contacts: Fuse Alarm, Power Loss, Overload

• Redundantly Powered – Load Bus A and Load Bus B and ABS input

• Configurable for numerous BDFB applications

Issue 3 June 2012 4

Page 5

Secondary DC Power Distribution Bay H569-445

Specifications

Output Voltage: -48Volts DC

Output Capacity: 800A per Distribution Panel

6 Load BDFB: 2400A per Side, 4800A Maximum per Bay

4 Load BDFB: 1600A per Side, 3200A Maximum per Bay

2 Load BDFB: 800A per Side, 1600A Maximum per Bay

Agency Approval: UL Listed (cULus), NEBs

Environment: 0C to +40C (+32F to +104F)

Cabinet: Seismic Zone 4 Box Framework

Color: Central Office Soft Blue

Width: 26 inches (660mm) or 34 inches (864mm)

Height: 84 inches (2134mm)

Depth: 15 inches (381mm)

Weight: Approx. 375 pounds (6 panels)

Access: Front Fuse/Breaker and Alarm Access, Rear Wiring Access

Distribution: 28-Position Panel for Bullet-Style Protectors

Protectors:

• Bullet-Style Fuse Holders, TPS or TLS Fuses through 125A

• Single Pole LEL Bullet-Style Circuit Breakers through 100A

• Two-Pole LEL Bullet-Style Circuit Breakers through 150A

• Three-Pole LEL Bullet-Style Circuit Breakers through 250A

• No Protector Spacing Restrictions

• Maximum Loading

• 64% of protector rating - Continuous (List 1)

• 80% of protector rating - Maximum Load (List 2 - typically end of

discharge)

Accessories: External Ground Bar Assembly

Seismic Anchor Kits

Bullet-Style Fuse Holders, Fuses

Bullet-Style Circuit Breakers

2 ft Extension Cabinet for 9-ft application

4-1/2 ft Extension Cabinet for 11-1/2 ft applications

Top Cover for Bottom Feed Applications.

Issue 3 June 2012 5

Page 6

Secondary DC Power Distribution Bay H569-445

Safety

Safety Statements

Read and follow all safety instructions, warnings, and precautions in this manual and the manuals of all

equipment before installing, maintaining, or repairing the power system. Equipment manuals contain

additional safety statements, warnings, and precautions specific to the equipment.

• The H569-445 Secondary DC Power Distribution Bay is Underwriters Laboratories (UL) Listed per

Subject Letter 1801 (DC Power Distribution Centers for Telecommunications Equipment) for use

in the USA.

• Install only in restricted access areas (dedicated equipment rooms, equipment closets, or the like).

• Use this equipment in a controlled environment (an area where the humidity is maintained at levels

that cannot cause condensation on the equipment, the contaminating dust is controlled, and the

steady-state ambient temperature is within the range specified). Evaluated maximum ambient

temperature: 104°F (40°C).

• Do not install this equipment over combustible surfaces.

• Compression Connectors

• For installations in the U. S. or Canada, use Listed/Certified compression connectors to terminate

Listed/Certified field-wire conductors where required.

• For all installations, apply the appropriate connector to the correct size conductor as specified by

the connector manufacturer, using only the connector manufacturer’s recommended tooling or

tooling approved for that connector.

• If the proper connector for the country of installation is not provided, obtain appropriate

connectors and follow manufacturer’s and all local requirements for proper connections.

• The field wiring connections have been evaluated for connection of minimum 90°C conductors sized

per the U.S. National Electrical Code using 75°C ampacity tables.

• Torque electrical connections to the values specified on labels or in the product documentation.

• The short circuit current capability of the battery input to the distribution panel must not exceed

10,000 amperes.

• Use only fuses and circuit breakers specified in the product documentation to avoid possible in injury

to service personnel or equipment damage. They may not be provided with the equipment.

• Size fuses and circuit breakers as required by the National Electric Code (NEC) and/or local codes.

Refer to the equipment ratings to assure current does not exceed:

• Continuous Load (List 1) - 64% of protector rating

• Maximum Load (List 2 - typically end of discharge) - 80% of protector rating.

• Field-wired Conductors - Follow all National Electric Code (NEC) and local rules and regulations when

making field connections.

• Size field-wired conductors based on listed recommendations, National Electric Code (NEC)

and/or local codes based on 70°C ampacity.

• Insulation rating (minimum): 90°C; 105°C if internal to enclosed equipment cabinets.

• Dress cables to avoid undue stress on the connectors and damage to the conductors caused by

routing around sharp edges or routing in areas where wires could get pinched.

Issue 3 June 2012 6

Page 7

Secondary DC Power Distribution Bay H569-445

One of these two symbols (or equivalent) may be used to identify the

conductors with uninsulated metal objects. Follow safety precautions.”

One of these two symbols may be used to identify the presence of a hot

means that the part is or could be at hazardous voltage levels.

This symbol is used to identify the need for safety glasses and may

safety glasses.”

Warning and Safety Symbols

The symbols may sometimes be accompanied by some type of statement; e.g., “Hazardous

voltage/energy inside. Risk of injury. This unit must be accessed only by qualified

personnel.” Signal words as described below may also be used to indicate the level of

hazard

DANGER

WARNING

CAUTION

Indicates the presence of a hazard that will cause death or severe

personal injury if the hazard is not avoided.

Indicates the presence of a hazard that can cause death or severe

personal injury if the hazard is not avoided.

Indicates the presence of a hazard that will or can cause minor personal

injury or property damage if the hazard is not avoided.

This symbol identifies the need to refer to the equipment instructions

for important information.

These symbols (or equivalent) are used to identify the presence of

hazardous ac mains voltage.

This symbol is used to identify the presence of hazardous ac or dc

voltages. It may also be used to warn of hazardous energy levels.

presence of rectifier and battery voltages. The symbol may sometimes

be accompanied by some type of statement, for example: “Battery

voltage present. Risk of injury due to high current. Avoid contacting

surface. It may also be accompanied by a statement explaining the

hazard. A symbol like this with a lightning bolt through the hand also

This symbol is used to identify the protective safety earth ground for

the equipment.

This symbol is used to identify other bonding points within the

equipment.

sometimes be accompanied by some type of statement, for example:

“Fuses can cause arcing and sparks. Risk of eye injury. Always wear

Issue 3 June 2012 7

Page 8

Secondary DC Power Distribution Bay H569-445

Precautions

Read and follow these precautions.

• General precautions:

• Use only properly insulated tools.

• Remove all metallic objects (key chains, glasses, rings, watches, other jewelry, etc.).

• Wear safety glasses.

• Test circuits before touching.

• Lock out and tag circuit breakers/fuses when possible to prevent accidental turn on.

• Be aware of potential hazards before servicing equipment.

• Identify exposed hazardous electrical potentials on connectors, wiring, etc. (note the condition

of these circuits, especially wiring).

• Use care when removing or replacing covers; avoid contacting circuits.

• Use a personal ESD strap when accessing or removing electronic components.

• The equipment must be installed, serviced, and operated only by skilled, qualified personnel who

have the necessary knowledge and practical experience with electrical equipment and who

understand the hazards that can arise when working on this type of equipment.

• Exercise care and follow all safety warnings and practices when servicing this equipment. Hazardous

energy and voltages are present in the unit and on the interface cables that can shock or cause

serious injury.

• Batteries may be connected in parallel with the output of the rectifiers. Turning off the rectifiers will

not necessarily remove power from the bus. Make sure the battery power is also disconnected

and/or follow safety procedures while working on any equipment that contains hazardous

energy/voltage.

• Electricity produces magnetic fields that can affect implanted medical electronic devices, such as

pacemakers. The strength of the magnetic field depends on the amount of current in the circuit, as

well as other conditions (such as number of conductors, placement, and distance from the

conductor). DC power and distribution systems, including batteries, can operate at high current

levels. Personnel with electronic medical devices need to be aware of their restrictions when

working around electricity.

Issue 3 June 2012 8

Page 9

Secondary DC Power Distribution Bay H569-445

English

Screw Size

Torque (N-m)

Torque (in-lb)

6-32

1.1

10

10-32

2.8

30

1/4”-20

7.3

65

5/16-18

15

135

3/8”-16

27

240

Getting Started

Tools and Hardware

You will need the following tools and hardware to install the BDFB:

• Material-handling equipment to unload the cabinet at the installation site,

remove from shipping container, and set in final position [minimum lifting

capacity: 500 lbs. (227Kg)] Note: Use the equipment weights and dimensions as a

guideline for choosing material-handling equipment.

• Digital multimeter (DMM) with 0.05% accuracy on dc scale

• Insulated hand tools

• Screwdrivers (flat-blade and Phillips)

• Wire cutters and stripper

• Crimp Tools

• Drill and Drill Bits to install floor anchors

• Torque wrenches 25-720 in-lb

• Sockets: 5/16”, 7/16”, 9/16”, 3/4”, 15/16”, 19mm

Torque Setting for Hardware

Issue 3 June 2012 9

Page 10

Secondary DC Power Distribution Bay H569-445

Unpacking BDFB

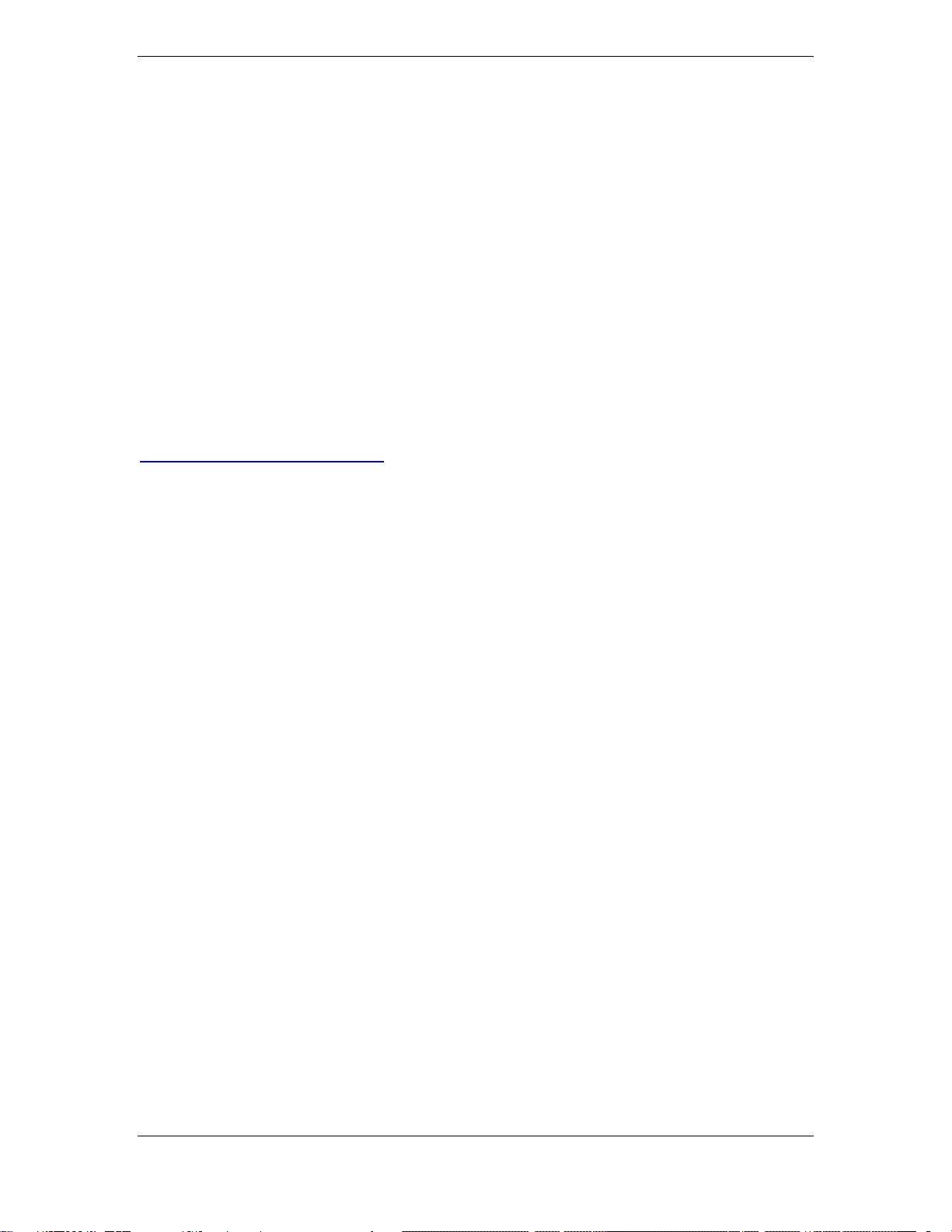

BDFB’s ship on a 42 by 42 inch skid as shown below. A 15/16 inch wrench or socket is

required to remove 5/8 inch diameter shipping bolts from skid. Before opening the

packaging, carefully inspect the outside in the presence of shipping personnel for signs

of damage. Carefully open the packaging to verify that the contents are complete and

undamaged. If damaged, follow the shipping carrier’s procedure for filing a damage

claim. If the equipment must be returned, repack in the original shipping packaging.

Before continuing, verify that the following conditions exist at the installation site:

• Floor is conditioned and clean (refers to removal of any combustible flooring, e.g.,

carpet, wood, etc.).

• Job Site Documentation details cabinet locations.

Figure 1 Cabinet Shipping Pallet

Issue 3 June 2012 10

Page 11

Secondary DC Power Distribution Bay H569-445

Unpacking Mounting Hardware

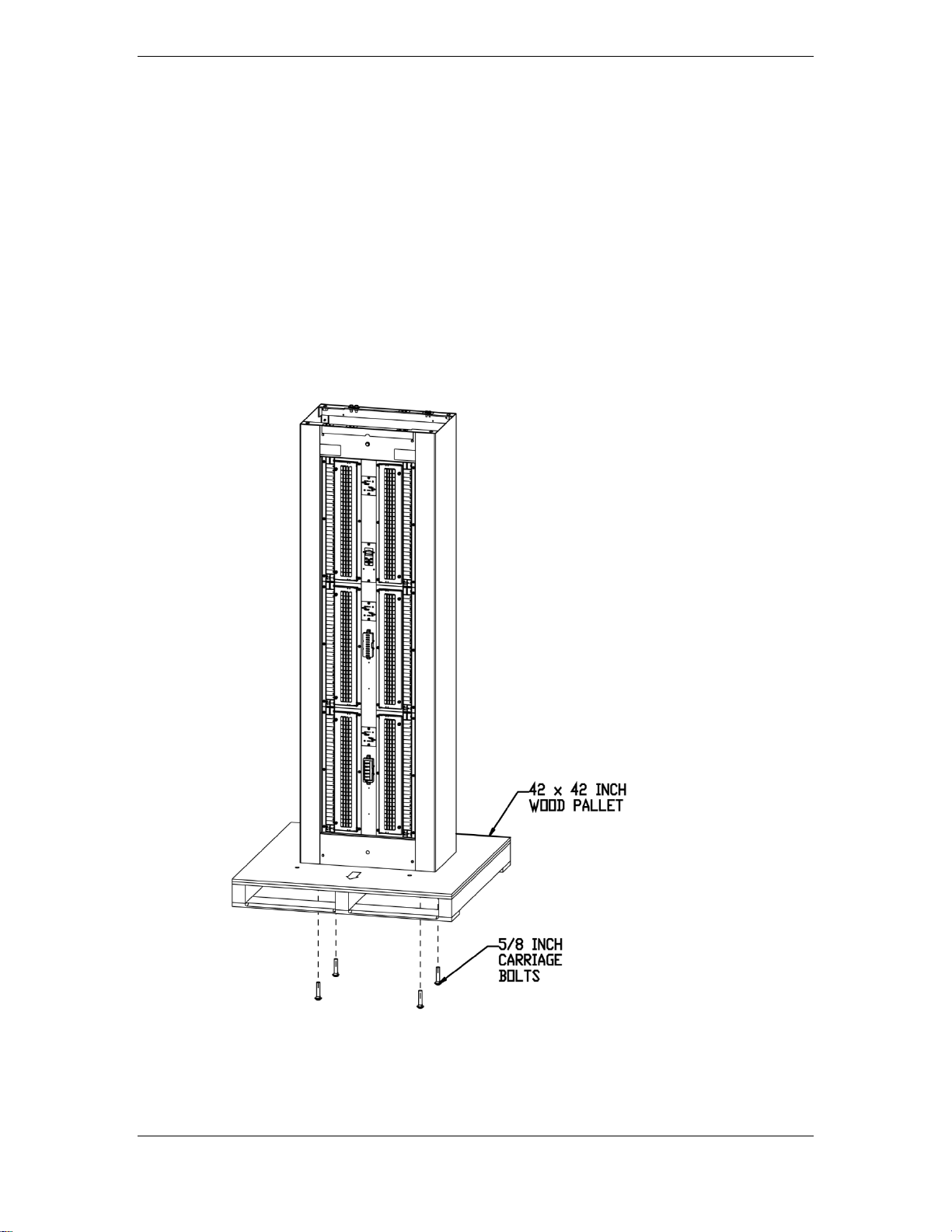

Hardware for making all cabled connections is included with the BDFB. 3/8 inch

hardware for Input Load Bus connections is installed on the Load Shunt and Load Return

Bus Details as shown in section 9. CC408576210 ¼ inch conical nuts are provided for all

output load and return connections. These nuts are located in the hardware box as

shown below.

Figure 2 Hardware Box Location

Issue 3 June 2012 11

Page 12

Secondary DC Power Distribution Bay H569-445

2” deep

(18 ft·lbs)

100mm deep

(60 ft·lbs)

Ordering Code

Description

Floor Mounting

When installing the BDFB cabinet to the floor, the following mounting hardware may be

required depending on customer requirements.

• Drill anchor holes to depth specified in table below.

• Place floor insulation pad and/or use insulation bushings provided with anchors

if required.

• Shim under cabinet corners as necessary to level.

• Torque anchors as specified in table below.

Anchor Kits

Seismic

Zone

Ordering

Code

Anchor Type

(Hilti)

Hole

Size

Wrench Torque

0,1,2 847135662

0,1,2,3,4 847135688

Isolation and Leveling Kits

408520408 Floor Insulation Kit (16 in x 24 ¼ in)

CC109121588 Shim Kit

(4) 1/2 inch

drop-in

(4) 12 mm

cap bolts

5/8 inch bit

18mm bit

3/4 inch

19 mm

216 in·lbs

720 in·lbs

24.5

N·m

81.6

N·m

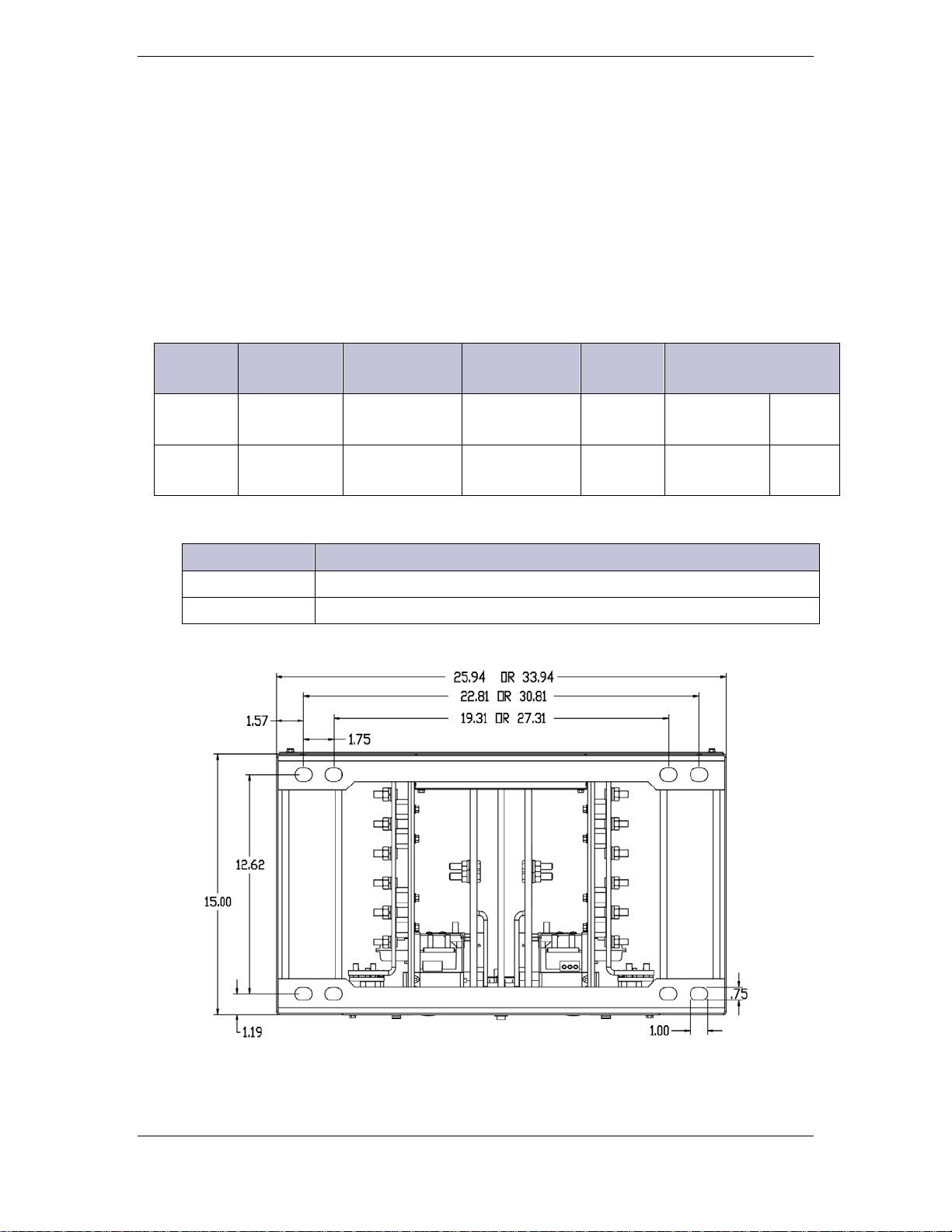

Figure 3 Footprint of Cabinets

Issue 3 June 2012 12

Page 13

Secondary DC Power Distribution Bay H569-445

Cabinet Extension Kits for 26-inch Wide Cabinet

848258588

4 -1/2 ft

11-1/5 ft

848258570

2 ft

9 ft

Frame

Ground

2’

4-1/2’

Frame

Ground

7’ Cabinet

7’ Cabinet

Cabinet Extensions

Optional cabinet extensions, constructed in the same manner as the 7 foot cabinet,

mount on top of the 26-inch wide cabinet to match the height of adjacent cabinets.

Kit Comcode Height Extension Height with Extension

Secure the cabinets together with four 5/8” bolts, lock washers and flat washers

(provided). Use a 15/16” socket.

Secure the interframe ground cable with two 7/16” bolts, lock washers, flat washers and

nuts (provided). Use 7/16” socket and wrench. This provides a continuous frame ground

to the top of the cabinet.

Mounting

Hardware

Figure 4 2-Foot or 4-1/2-Foot Extension Cabinet

Issue 3 June 2012 13

Strap

Mounting

Hardware

Strap

Page 14

Secondary DC Power Distribution Bay H569-445

848556908

5/8" x 1" Bolt (4 places)

Washer (4 places)

Cabinet Top Cover

When cabinets are used in bottom feed applications, an optional 848429288 top cover

kit may be installed on top of the 26-inch wide cabinet as shown below. Secure cover

with four 5/8” bolts and flat washers using a 15/16” socket.

802105304

Top Cover

802841759

Figure 5 Top Cover for Bottom-Feed Applications

Issue 3 June 2012 14

Page 15

Secondary DC Power Distribution Bay H569-445

Frame Ground

Frame ground connections are located on top of the cabinet. Connection is made using

either a 1/4 inch double-hole terminal lug on 0.625 inch centers or a 3/8 inch doublehole terminal lug on 1 inch centers. Landings are provided on both the front and rear

rails of the cabinet. Hardware is factory installed for these connections. Local grounding

practices will determine the grounding method and size of cable connected to the

cabinet.

Figure 6 Top View of 26-inch Wide Cabinet

Issue 3 June 2012 15

Page 16

Secondary DC Power Distribution Bay H569-445

Figure 7 Top View of 34-inch Wide Cabinet

Issue 3 June 2012 16

Page 17

Secondary DC Power Distribution Bay H569-445

Panel Positions and Labeling

The cabinet is configured for either top or bottom cable entry. The following figures

show the default labeling orientation used for top and bottom fed BDFB’s. Load Bus

designations (A, B, C, D, etc.) are stamped on the labels and the VIM1C meter is

programmed to reflect the Load Bus designations.

Some customers require a different labeling scheme so an extra set of 850018546 labels

is included to relabel the BDFB per local customer requirements. If the Load Bus

designations change, the VIM1C meter must identify the new location.

Menu ►Load Pa ram et er s ►First Load locates Load Bus A as upper-left, upper-

right, lower-left or lower-right. .

Menu ►Load Pa ram et er s ►Number of Loads identifies the number of load shunts

in the BDFB.

Figure 8 Top Feed BDFB

Issue 3 June 2012 17

Page 18

Secondary DC Power Distribution Bay H569-445

Figure 9 Bottom Feed BDFB

Issue 3 June 2012 18

Page 19

Secondary DC Power Distribution Bay H569-445

All bus bars are copper with a bright tin finish. Bus bars do not require buffing or

Load Bus Arrangements

A load bus is defined as one or more panels protected by a single circuit breaker or fuse

at the battery plant. Cable from the battery plant is terminated at Load Shunt Bus

Details rated for 800 amperes. (Two 750 kcmil feeder cables are required per shunt for

currents larger than 500 amps per shunt.) 3/8 inch hardware is provided for this

connection. The cabinet may be equipped for 2, 4 or 6 loads. In 2 or 4 load

configurations a bus bar link connects some panels together vertically. The 800 ampere

capacity per load bus applies even if multiple fuse panels are connected together.

When internal return buses are ordered, load return bus details will be located either at

the top or the bottom of the cabinet as shown depending on if a top cable feed or

bottom cable feed was ordered. These may easily be unbolted and moved if the

application requires. 3/8 inch hardware is provided for load return cables.

Note

the application of NO-OX before connection to terminal lugs or other bus bars.

Figure 10 Load Connection Points

Issue 3 June 2012 19

Page 20

Secondary DC Power Distribution Bay H569-445

Distribution Panels

Each 28-position distribution panel accepts bullet-style circuit breakers and fuseholders.

Single-pole breakers through 100A, two-pole breakers through 150A, three-pole

breakers through 250A and fuses to 125A may be installed in any position with no

spacing restrictions. Panels come with hinged front doors equipped with plastic slot

fillers. As circuit breakers or fuseholders are installed, un-snap the plastic slot filler and

replace with a circuit breaker or fuseholder. Store the excess plastic slot fillers in the

hardware bin in the back of the cabinet. Note: breakers/fuseholders can only be

installed one way or the front hinged door will not close properly. Each distribution

position has three alarm pin openings. The outer alarm opening is the alarm output.

Alarm pin of protector should insert into this opening. The inner two openings are

provided because some breaker styles have additional pins that require alarm power to

generate the output alarm.

Figure 11 Installing Breakers/Fuseholders

Issue 3 June 2012 20

Page 21

Secondary DC Power Distribution Bay H569-445

Figure 12 Distribution Connections

Issue 3 June 2012 21

Page 22

Secondary DC Power Distribution Bay H569-445

Two-pole breakers require two 850019325 2-pole adapter bus kits. Three-pole breakers

require two 850025679 3-pole adapter bus kits. They attach to the distribution panel as

shown below. The bus has 3/8-16 studs on 1 inch centers. Hardware is included.

Terminal lugs are sold separately.

Figure 13 Two-Pole and Three-Pole Adapter Bus Kits

Figure 14 Distribution Cable Routing

Issue 3 June 2012 22

Page 23

Secondary DC Power Distribution Bay H569-445

VIM1C Meter

Each load bus is equipped with a 1500 ampere shunt. The VIM1C monitors these shunts

to determine actual currents and the remaining capacity of each load bus.

VIM1C features include fuse/breaker alarms, power loss alarms, individually

configurable overload thresholds, individually configurable power loss, audible, and

remote form-C output alarms. The VIM1 receives redundant power from the A and B

panels and external ABS.

Voltage and Current - VIM1C displays voltage, current, and identifies each monitored load

1

.

bus

Alarm Indication - When an alarm occurs, the backlight on the display changes color from

green (normal) to red (alarm

Alarms” to “Alarms.”

Menus and Keys – Menus are structured with three main menu items: System

Parameters, Load Parameters, and Control/Operations - . Each key menu item has sub

items as shown in the menu map below. Left and Right keys are used to navigate the

menu. Up and Down keys are used to adjust the parameters. The VIM1C includes an

audible alarm with a user configurable on/off feature.

active) and the front panel text also changes from “No

Figure 15 VIM1 Smart Meter

1

The default VIM1 screen displays the label “Panel”, rather than “Load Bus”, before the Load Bus

identifier.

Issue 3 June 2012 23

Page 24

Secondary DC Power Distribution Bay H569-445

Figure 16 Meter Menu Map

Issue 3 June 2012 24

Page 25

Secondary DC Power Distribution Bay H569-445

measurement capability. These circuits are pre-wired with fixed positions in the BDFB. If

Programming the Meter

VIM1C parameters like shunt size and number of load buses are preconfigured when it is factory

installed in a BDFB. Only customer specific preferences need to be adjusted in the field. As a

replacement or meter upgrade, the factory default settings may need to be adjusted for the

application. Listed below are the configurable parameters and their associated factory defaults

available through the front panel. Following the table are the typical items that need to be

configured or verified in a retrofit or replacement application.

Item

1 System Voltage Factory default is 48V.

2 Local Buzzer Allows audible alarm to be Enabled or Disabled. Factory default is Disabled.

3

4 Software Version Displays the version of the application code running in the meter.

System

Parameters

Display Contrast

Description

Allows the display contrast to be adjusted for the local ambient lighting. Adjustable from 0100% in 1% increments. Factory default is 50%.

Load Parameters Description

5 Number Of Loads

6 Meter Type

7 Load ID Format

8 First Load (location)

9 Shunt Rating

10 Overload Latch

11 Combined Load

12 Load Available

13 Load Power Loss

14 Load Overload Type

15 Load Overload

16 Load Overload Delay

17 Assigned Circuits

Used to identify the number of individual loads/buses in the BDFB. Factory set from 1-8

depending on BDFB configuration.

Configures meter to display individual monitored bus voltages (voltage), voltages and

currents (volt_curr), or only currents (current). Factory default is Voltage and Current

(volt_curr).

Configures display format used in referencing individual DC loads/buses. Allowable

formats: A1, A, and 1. “A1” identifies loads using an A1, B1; A2, B2; … format. “A”

identifies loads using an A, B, C, D ... format. “1” identifies loads using a 1, 2, 3, 4 …

format. Factor Default is A format.

Used to indicate where the first load in the distribution is located. Allowable configurations

are: top-left, top-right, btm-left (bott om -l e ft), btm-right (bottom-right). Every monitored shunt

is considered a load. Factory default is determined by BDFB configuration.

Used to define the current rating of the shunt in the load bus. All shunts in the load must be

of the same size. A 50mV shunt is assumed. Allowable range is 1-4000A. The factory

default is 1500A in the BDFB.

A single configuration for all panels/buses that allows a temporary Over Load event to be

latched. Factory default is “Disabled”.

Displays the load value as one combined sum by adding up all shunts in the system and

presenting it as values for a single load. Factory default is disabled.

Indicates if the load is available or in use. Allowable configurations are “installed” and “not

installed”. “Installed” loads imply that the load is in use. “Not Installed” loads imply that the

load may be present, but it is not in use. Information obtained from the load should not be

relevant. Factor default is set to be “installed”.

The Power Loss (PL) alarm is triggered upon loss of the primary DC or when the

individual’s panels’ DC input has reached the configured low voltage threshold. This Power

Loss voltage threshold is configurable between 40.00-60.00V. Factory default is 40.00V.

The Power Overload Type defines whether the smart meter is to treat the Overload alarm

event for a “Single Bus” or for a “Redundant Bus” configuration. The “Single Bus”

configuration is based on straight Overload threshold being exceeded. The “Redundant

Bus” configuration causes the VIM1 to sum the two respective left and right load shunt

measurements and compare it to the individual overload thresholds configured for the each

of the respective panels in the pairing. The lowest Overload value threshold configured for

the Redundant loads shall take priority and be used in the comparison. Once the

“Redundant Bus” measurement exceeds this threshold, the controller asserts the Over

Load (OVL) alarm. Factor default is “Single Bus” configuration”.

The Load Overload (OVL) alarm event is triggered when any measured panel currents

exceed their respective configured thresholds. These OVL thresholds can be configured

from 1-4000A. Factory default is 800A.

An Overload Delay can be set to prevent nuisance alarms. This delay is configurable

between 0-300 seconds. Factory default is 0 seconds.

The VIM1 has eight individual load circuits with each circuit having voltage and shunt

Issue 3 June 2012 25

Page 26

Secondary DC Power Distribution Bay H569-445

circuit wiring from the VIM is redressed in the field this feature can be used to assign the

appropriate circuit to the new load location.

Control and

Item

Operations

Description

Parameters

18 Start Lamp Test

19 Clear Latched Events

20 Start Alarm Test

Cycles the illumination of the front panel LED and Backlight through Red, Amber, and

Green

Clears a latched Overload Alarm event. Note the Overload Latched Event must be enabled

to have a latched alarm.

Asserts Form-C alarms available at connector J3 in a fixed sequence: Fuse Alarm (FA),

Power Loss (PL), and Overload (OVL). Alarm asserted is displayed on the front panel.

Feature can be used to test the site’s remote monitoring systems and wiring.

Basic items to configure in a -48V meter retrofit or replacement

Use the previous VIM1C menu map and table as a reference to configure the basic items

listed below:

• Configure the Number Of Loads present in the BDFB (Item 5)

• Set the display Meter Type (Item 6)

• Configure the Load ID Format presented on the display (Item 7)

• Set the position of the First Load Location (Item 8)

• Configure the Shunt Rating of each monitored load in amps (Item 9)

• Set the state of each load as installed or not installed at Load Available (Item

12)

• Set the local audible alarm indicator capability at Local Buzzer (Item 2)

Issue 3 June 2012 26

Page 27

Secondary DC Power Distribution Bay H569-445

Alarm Connections and ABS Power

At the top of the cabinet is a Customer Interface Board for connecting Output Alarms

and Alarm Battery Supply (ABS) to redundantly power the alarms and the VIM1C meter.

The VIM1C receives redundant power from panels 1 and 2 as well as an external ABS

connection, so the ABS connection is not mandatory for proper operation but some

customers require its use. A Return connection is required for operation of the meter

and alarms. The Return connection on the Customer Interface Board is factory wired

when internal return buses are ordered, otherwise it must be field wired to the external

return bus. Alarm Outputs consist of one form-C contact for power loss, one form-C for

current overload and one form-C contact for fuse/breaker alarms (Note: there are two

connection points for FAJ/CB but they are connected to the same form-C contact).

Contacts are rated for 60V, 1/2A. Maximum wire size to the terminal blocks is 12 gage.

Figure 17 Accessing Customer Interface Board

Issue 3 June 2012 27

Page 28

Secondary DC Power Distribution Bay H569-445

Figure 18 Customer Interface Board

Issue 3 June 2012 28

Page 29

Secondary DC Power Distribution Bay H569-445

Discharge Return Bus Options

Discharge return bus options for terminating fuse or circuit breaker return leads may

either be internally mounted in the cabinet or externally mounted outside the

distribution bay on a cable rack.

Internal

The internal discharge return bus bar option terminates return cables from the battery

plant at the top (or bottom) of the cabinet as shown in Figure 12. There is a left-side bus

that interconnects to return bars mounted on the three left mounted fuse or circuit

breaker panels and a right-side bus for the right mounted panels. The bus at the top of

the cabinet is designed for terminating six 3/8 inch double-hole terminal lugs on 1 inch

centers with a tongue width up to 1.7 inches wide. Each panel mounted discharge

return bus is designed for terminating up to 2 gage cable with 1/4 inch double-hole

terminal lugs on 5/8 inch centers.

The advantage of internal returns is that load leads are paired at the fuse or circuit

breaker and eliminates the need for identification tags on each return lead. The

drawback to this cabling scheme is that you are limited to 1200 amps per side so for

multi-load BDFB’s requiring from 1200A-2400A capacity per side requires that input

returns must be located at the top and bottom of the cabinet with returns from the

battery plant split between the top and bottom bus bars. A second concern is the

potential cable congestion resulting from twice the number of leads in the distribution

bay. For these reasons, the internal discharge return option is recommended only for

applications with smaller ultimate capacities. For most applications, the external return

bus option is recommended.

External

The external discharge return bus bar options are shown in Figure 19 and Figure 20. The

external bus is mounted on a standard 15 or 20 inch ladder type cable rack. ED83019-50

Group 13 (150021156) and Group 13A (150021157) are rated for 2400 amperes of

current. Option 150021156 provides the first bus bar and the cable rack mounting

hardware. Option 150021157 provides a bus bar, the connecting bus bar and insulating

standoffs for stacking additional tiers as required. Refer to ED83019-50 drawing for

other ground bar options.

Issue 3 June 2012 29

Page 30

Secondary DC Power Distribution Bay H569-445

Figure 19 External Discharge Return Bus Options on Cable Rack

Figure 20 Bus Bar Hole Pattern and Numbering Schemes

Issue 3 June 2012 30

Page 31

Secondary DC Power Distribution Bay H569-445

Adding/Moving Load Shunt Bus Details

Sometimes it may be necessary to reconfigure a BDFB in the field. Two common

changes are converting two load BDFB’s from top feed configurations to bottom feed

configurations and changing from a 2-load to a 4 or 6-load BDFB. Additional Load Shunt

Bus Kits as shown on Figure 10 may be purchased separately.

Converting Top-Feed to Bottom-Feed

The following steps describe how to convert a top-feed cabinet to a bottom-feed

cabinet. Reverse this procedure to convert a bottom-feed to a top-feed cabinet.

1. Disconnect wires from the shunts on the load shunt assembly. Note the wire

colors and location. These same colors are used when moving the shunts from

panel position 1 to panel 5 position and panel position 2 to panel position 6. The

solid color (blue or slate) is closest to the input cables.

2. Disconnect the hardware securing the shunt assembly at the top of the cabinet.

3. Remove 6-32 screw securing shunt wires to the charge bus bar at the bottom of

the cabinet where the shunt assembly will be placed.

4. Relocate load shunt assembly and mount it in the bottom of the cabinet.

5. Connect shunt wires in same location and color as in previous location.

6. Connect shunt wires to the charge bus bar at the top of the cabinet where the

shunt assembly was removed using same 6-32 screw.

7. Move the internal return bus bar from the top to the bottom of the cabinet.

Note: Internal return bus bars may not be present.

8. The VIM1 meter needs to be reconfigured. Navigate to Menu ►Lo ad Paramet ers

►First Load

lower-right depending on which side you want to be side A and side B.

9. Relabeling might also be required as discussed in the Panel Positions and

Labeling section.

and change Load Bus A location from upper-left to lower-left or

Issue 3 June 2012 31

Page 32

Secondary DC Power Distribution Bay H569-445

Figure 21 Top-Feed to Bottom-Feed Cabinet Conversion

Issue 3 June 2012 32

Page 33

Secondary DC Power Distribution Bay H569-445

Converting from 2-Load to 4 or 6-Load

This requires that new load shunt bus kits be added to existing panels in the cabinet and

linking bus bars between panels be removed or “split” to create the additional loads.

The following steps describe this procedure.

Caution: Live potentials are present within a working BDFB/ BDCBB cabinet! Take

proper precautions to insulate all tools and prohibit any live surface from contacting

framework or any other grounded surface.

Note: If splitting existing loads within the BDFB/BDCBB, the load shunt assembly

will be at a live potential as soon as it comes into contact with a distribution panel

bus and must not be allowed to contact framework or any grounded surface during

or following this step!

1. Remove 6-32 screw securing shunt wires to the charge bus bar where the new

load shunt bus assembly will be installed. Note color of shunt wires at each

position.

2. Install load shunt bus assembly to the charge bus as shown in Figure 22. Connect

(2) red glastic standoffs to panel. Attach shunt detail to panels charge bus with

5/16 hardware provided and ½” socket (Torque to 135 in-lb) and attach to

standoffs with 1/4-20 screws provided and 7/16” socket (Torque to 65 in-lb).

3. Connect shunt wires to shunt. There should be a solid color like Blue, Orange,

Gray or Brown and a striped color like White-Blue, White-Orange, White-Gray or

White-Brown. Attach solid color to back connection (it is connected to input

bus). Attach striped color to front connection (it is connected to panels charge

bus).

4. Remove Bus Bar Straps to “split off” these panels as individual load buses.

Remove 5/16” hardware with ½” socket. Store these links in hardware bin in

back of cabinet.

5. The VIM1 meter needs to be reconfigured. Navigate to

Menu ►Load Parameters ►Number of Loads and set the number of load shunts

in the BDFB.

6. Relabeling might also be required as discussed in Section 8. Stamp or Label new

load designations on the labels.

Issue 3 June 2012 33

Page 34

Secondary DC Power Distribution Bay H569-445

Figure 22 2-Load to 6-Load Cabinet Conversion

Issue 3 June 2012 34

Page 35

Secondary DC Power Distribution Bay H569-445

Wiring Schematics

Figure 23 Panel Wiring Schematic

Issue 3 June 2012 35

Page 36

Secondary DC Power Distribution Bay H569-445

Figure 24 Alarm Wiring Schematic

Issue 3 June 2012 36

Page 37

Secondary DC Power Distribution Bay H569-445

Warranty Period

Product Type

New Product

Repaired Product*

Central Office Power

Equipment**

* The Warranty Period for a repaired Product or part thereof is six (6) months or, the

longer.

Product Warranty

A. Seller warrants to Customer only, that:

1 As of the date title to Products passes, Seller will have the right to sell, transfer, and

assign such Products and the title conveyed by Seller shall be good;

2 During the warranty period stated in Sub-Article B below, Seller’s Manufactured

Products (products manufactured by Seller), which have been paid for by Customer,

will conform to industry standards and Seller’s specifications and shall be free from

material defects;

3 With respect to Vendor items (items not manufactured by Seller), Seller warrants

that such Vendor items, which have been paid for by Customer, will be free from

material defects for a period of sixty (60) days commencing from the date of

shipment from Seller’s facility.

B. The Warranty Period listed below is applicable to Seller’s Manufactured Products

furnished pursuant to this Agreement, commencing from date of shipment from

Seller’s facility, unless otherwise agreed to in writing:

24 Months 6 Months

remainder of the unexpired term of the new Product Warranty Period, whichever is

C. If, under normal and proper use during the applicable Warranty Period, a defect or

nonconformity is identified in a Product and Customer notifies Seller in writing of such

defect or nonconformity promptly after Customer discovers such defect or

nonconformity, and follows Seller's instructions regarding return of defective or

nonconforming Products, Seller shall, at its option attempt first to repair or replace

such Product without charge at its facility or, if not feasible, provide a refund or credit

based on the original purchase price and installation charges if installed by Seller.

Where Seller has elected to repair a Seller’s Manufactured Product (other than Cable

and Wire Products) which has been installed by Seller and Seller ascertains that the

Product is not readily returnable for repair, Seller will repair the Product at

Customer’s site.

With respect to Cable and Wire Products manufactured by Seller which Seller elects to

repair but which are not readily returnable for repair, whether or not installed by

Seller, Seller at its option, may repair the cable and Wire Products at Customer’s site.

Issue 3 June 2012 37

Page 38

Secondary DC Power Distribution Bay H569-445

D. If Seller has elected to repair or replace a defective Product, Customer shall have the

option of removing and reinstalling or having Seller remove and reinstall the defective

or nonconforming Product. The cost of the removal and the reinstallation shall be

borne by Customer. With respect to Cable and Wire Products, Customer has the

further responsibility, at its expense, to make the Cable and Wire Products accessible

for repair or replacement and to restore the site. Products returned for repair or

replacement will be accepted by Seller only in accordance with its instructions and

procedures for such returns. The transportation expense associated with returning

such Product to Seller shall be borne by Customer. Seller shall pay the cost of

transportation of the repaired or replacing Product to the destination designated by

Customer.

E. Except for batteries, the defective or nonconforming Products or parts which are

replaced shall become Seller's property. Customer shall be solely responsible for the

disposition of any batteries.

F. If Seller determines that a Product for which warranty service is claimed is not

defective or nonconforming, Customer shall pay Seller all costs of handling,

inspecting, testing, and transportation and, if applicable, traveling and related

expenses.

G. Seller makes no warranty with respect to defective conditions or nonconformities

resulting from actions of anyone other than Seller or its subcontractors, caused by any

of the following: modifications, misuse, neglect, accident, or abuse; improper wiring,

repairing, splicing, alteration, installation, storage, or maintenance; use in a manner

not in accordance with Seller’s or Vendor’s specifications or operating instructions, or

failure of Customer to apply previously applicable Seller modifications and

corrections. In addition, Seller makes no warranty with respect to Products which

have had their serial numbers or month and year of manufacture removed, altered, or

experimental products or prototypes or with respect to expendable items, including,

without limitation, fuses, light bulbs, motor brushes, and the like. Seller’s warranty

does not extend to any system into which the Product is incorporated. This warranty

applies to Customer only and may not be assigned or extended by Customer to any of

its customers or other users of the Product.

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND ARE IN LIEU OF ALL OTHER EXPRESS

AND IMPLIED WARRANTIES, INCLUDING BUT NOT LIMITED TO WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. CUSTOMER’S SOLE AND

EXCLUSIVE REMEDY SHALL BE SELLER’S OBLIGATION TO REPAIR, REPLACE, CREDIT, OR

REFUND AS SET FORTH ABOVE IN THIS WARRANTY.

Issue 3 June 2012 38

Page 39

Secondary DC Power Distribution Bay H569-445

Revision History

Issue 1 November 30, 2011

Initial release

Issue 2 December 15, 2011

Add External Return Bus Options 150021156 and 150021157.

Issue 3 June 7, 2011

Add References to 3-pole circuit breakers and 34-inch wide cabinet.

Issue 3 June 2012 39

Loading...

Loading...