Page 1

gg

GENERAL

Pulsing Current High Resistance Neutral Grounding

System

GEI-72116 Installation/Operation Instructions

TYPE AKD-8

Low-Voltage Switchgear

High Resistance Pulsing Ground Detection

System

General Applications, Vol. IGA- 1 No. 5, Sept./Oct. 1965

under High Resistance Grounding.

The following paragraphs describe a high resistance neutral

grounding system supplied with GE AKD-8 Low voltage

Switchgear. The system features an alarm system and utilizes

a pulsing current to locate the first ground fault. The system

has the following basic features:

1. Grounds the neutral of an ungrounded 3-phase power

system, utilizing the "high resistance" method. This

allows the system to operate as an "ungrounded" system

but eliminates the danger of high transient over-voltage

during certain types of ground faults.

2. Gives an immediate warning when the first ground fault

occurs.

3. Provides a method for quickly locating and removing the

fault before another fault develops on another phase,

thereby preventing circuit outages due to double line to

ground faults.

Reference: The high resistance grounding method is fully

described in IEEE Transactions on Industry and

EQUIPMENT DESCRIPTION AND

GROUNDING SYSTEM OPERATION

During normal conditions, with no ground fault on the

system, no voltage appears across the system and no voltage

appears across the grounding resistors. (Refer to Fig. 1).

When a ground fault occurs, the resistors limit the ground

current to a low value, adjustable between 0.9 and 3.6

amperes.

The voltage appearing across the resistors will be sensed by

the voltage coil of the meter relay. Auxiliary contacts

Fault Locating

The success of operating a high resistance grounded system

relies heavily on a dependable method of searching out the

ground fault location to allow the faulty system member to be

removed with the least delay.

The two important innovations introduced in this equipment

to take the uncertainty out of signal tracing include:

1. Use of repeating, cyclic, switching sequence by which the

tracer current can be rhythmically switched to a slightly

higher value. This gives unique character to the tracer

signal by which it can be distinguished from steady state

background noise.

2. Use of an extremely sensitive ground-fault-current

sensing transformer such that extraneous noise will be

ignored and only the current-carrying member which

passes through the window will be registered on the

meter.

of the meter relay, operated by the voltage coil, may be used

for remote indications and annunciation.

A green indicating light on the equipment indicates that

control voltage is available and that the system is normal.

When a fault develops, a red indicating light on the

equipment will remain lighted until the ground fault is

removed. If no remote annunciator is available to notify the

operator, an audible signal may be added to the equipment as

an option. A rotating red signal beacon may be used in noisy

or remote installations.

Page 2

EQUIPMENT DESCRIPTION AND

GROUNDING SYSTEM OPERATION

(CONT.)

To trace the ground fault, the operator turns the selector

switch to the "pulse" position. This initiates cycle timing

alternately energizing and deenergizing a shorting contactor

at the secondary resistor, resulting in a rhythmic fluctuation

in the magnitude of the ground current.

An optional current transformer and ammeter at the panel

will allow the operator to determine the current fluctuations

on the system. A portable hook-on detector is then used to

trace the fluctuations in ground current through the system to

the point of fault. After the ground point has been located

and removed from the system, the operator then resets the

selector switch to deenergize pulse cycle timing circuits, and

depresses a reset button to reset indicating lights and

annunciators.

Taps are provided on the resistor to adjust the magnitude of

the ground current in the range of 0.9 to 7.3A., depending on

the size of the system, so that the current through the resistor

to a ground fault will be slightly , greater than the system's

natural capacitance charging current.

The capacitance charging current of most 480 volt systems is

below one ampere, so that the resistor is usually set at 0.9

ampere, with an increase to 3.6 ampere during pulsing. For

unusually large systems, taps are available for an initial

ground current of 3.6 amps with pulsing to 7.3 amperes.

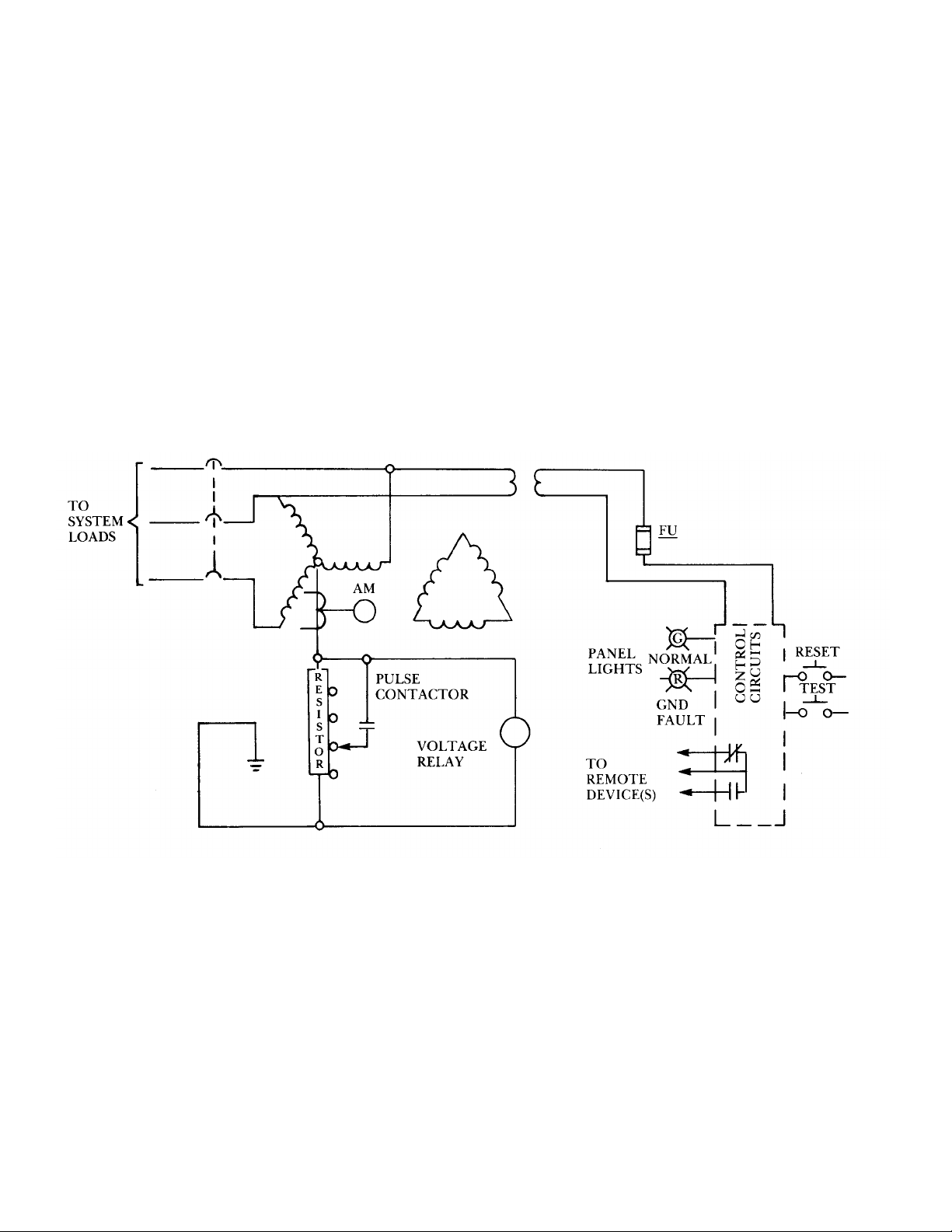

Refer to Fig. 2 for typical system circuit elementary.

CONTROL

TRANSFORMER

2

EQUIPMENT DESCRIPTION AND

Figure 1. Basic System Operation

Page 3

GROUNDING SYSTEM OPERATION

(CONT.)

Grounding Resistors

Since ground current is limited by the resistors, the last

section must never be shorted out by the shorting con-tactor

during pulsing.

The resistor must be adjusted at installation so that the

ground current with one ground fault is equal to or slightly

greater than the maximum system capacitance charging

current. (The value obtained with maximum connected load

of the system). If maximum system capacitance current is not

known, refer to "System Capacitance Charging Current"

below for methods to determine the value.

Operation of Equipment

The following instructions will appear on an engraved

nameplate on the equipment door:

Normal

1 - Green light indicates normal condition and equip-ment

energized.

2 - Red light indicates ground fault on system.

Ground Detection

1 - Press reset button. If red light goes out, there is no

ground.

2 - Plug in portable pulsing unit.

3 - Trace pulsing ground current with portable de-

tector.

1 - Press test button to simulate ground and to operate alarm

and control circuits. Hold for five seconds or until red

light is lit.

2 - Press reset button after test to return to normal.

Equipment Included In Standard 480V WYE

System With System Neutral Available

1 - Neutral current transformer (optional) (CT)

1 - Meter relay (MR)

1 - Pulsing contactor, set to produce approx. 40 cur-

rent pulsations per minute (fixed or portable) (PC)

1 - Neutral grounding resistors. (RES)

1 - Relay for pulsing contactor. (PCR)

1 - Holding relay, with extra interlocks for remote

alarm. (HR)

1 - Neutral ammeter (optional). (AM)

1 - "Ground Fault" red indicating light. (LT/GRD FLT)

1 - "Normal" green indicating light. (LT/NORM)

1 - "Reset" pushbutton. (PB/RESET)

1 - "Test" pushbutton. (PB/TEST)

1 - Instruction plate on door.

1 - Portable clamp on detector (optional)

System Capacitance Charging Current

The maximum system capacitance charging current must be

known before the high resistance grounding system resistors

can be set for the correct ground current during a fault. If the

maximum system charging current is not known, the value

may be established by the procedures detailed on pages 5 or 6,

whichever is appropriate.

4 - Remove ground.

5 · Press reset button to remove fault indication.

6 - Unplug portable pulser.

Test

3

Page 4

Figure 2 Typical High Resistance Pulsing Ground Detection Elementary

4

Page 5

(Using Accepted Normal Values of System

Capacitance Charging Current)

High Resistance Pulsing Ground Detector

480 Volt WYE

1. Familiarize yourself with this instruction and with the

grounding circuit.

2. Adjust the neutral ground resistance by moving jumpers

on resistor terminal board such that the ground current

with one ground fault is greater than the System

Capacitance Charging Current (Ic)

TABLE 5.1

Neutral Ground Resistor Data

Ic-

Maximum

Primary On Resistor Terminal Board Resistance (OHMS) Data Data

0.8

1.1

2.3

3.5

Jumper Connection Ground Fault Pulsing

(See Note 2) Normal Pulsing Amps Watts Amps Watts

3-4

1-2, 3-4

1-2, 3-5, 4-6

1-3, 2-5, 4-6

304

228

114

76

76

76

38

38

0.91

1.21

2.43

3.65

252

334

672

1010

3.65

3.65

7.3

7.3

556

605

1213

1417

3. Maximum normal expected ground fault for system

kVA: kVA shown:

TOTAL SYSTEM MAX NORMAL

SIZE (kVA) GROUND FAULT AMPS

1000 0.9

1500 1.2

2000 2.4

3000 3.6

4. Set the meter relay (MR) such that the high-set pointer,

"RED" is the maximum setting and the low-set pointer,

"BLUE" is just higher than the voltage across the neutral

ground resistor due to the system capacitance charging

current.

NOTE: 1. The control voltage must be within 107-127

Volts, otherwise meter relay will not operate.

2. Refer to ground system elementary for resistor

terminal board. Never short out resistors by

connecting terminal 5 to 4 or 6.

5

Page 6

Testing For System Capacitance Charging

Current, 480 Volt WYE

WARNING: Testing for capacitance charging cur-

rent requires that the entire system be energized;

hence, take all the necessary safety measures and

employ all safety codes and practices.

The following instruction describes a high resistance

neutral ground system supplied with Type AKD-8

Low Voltage Switchgear. The system features an

alarm, and utilizes a pulsing current to locate the first

ground fault.

quality clamp-on ammeter may be used if

portable signal detector is not supplied).

6. With maximum operating load equipment

connected on system, re-energize the grounding

equipment by re-connecting hard wire connection

to neutral bus and closing main breaker. (Do Not

reinstall neutral-ground link, if supplied).

7. Energize the variable voltage auto transformer

from an ungrounded, 110V, 60 Hz. single-phase

test source. (Use 1:1 isolation transformer rated

(5) amps or more to obtain ungrounded voltage).

This system is designed to:

1. De-energize grounding equipment by opening

main circuit breaker, and by disconnecting hard

wire connection to neutral bus. Be sure no other

ground is connected to system. Remove neutral

ground link, if supplied.

2. Disconnect or open-circuit the resistors during

test, and insert a 6-amp, 600V current limiting

fuse as shown in Figure 1.

3. Connect a Variable Voltage Auto Transformer

rated five (5) amps or more between equipment

and ground as shown. Initially set at zero volts.

4. Connect a voltmeter as shown.

5. Use portable signal detector if furnished to read

ground current. (1-amp scale for most systems.)

Wire can be passed through detector window

several times to produce greater sensitivity. (Test

8. With maximum operating load equipment

connected on the system, bring the voltage up

slowly, recording neutral displacement voltage

and current at selected test points until a linear

variation of current with voltage is obtained.

9. Calculate system capacitance charging current,

IC, at rated voltage by extrapolation as follows:

Ic = E x Ia = Amps system charging

√3 V

current, where

E = Rated system voltage, line to line

(usually 480V)

V =Measured test voltage. (Neutral

displacement).

Ia = Measured ground current corresponding to

V.

10. Plot various test values to verify that linear

relationship of current to voltage is being

attained as system neutral is gradually displaced

from ground potential.

Page 7

6

Figure 3. Testing Schematic

7

Page 8

g

GE Electrical Distribution & Control

_____________________________________

General Electric Company

41 Woodford Ave., Plainville, CT 06062

GEI 72116 0889 BLA 1989 General Electric Company

Loading...

Loading...