Page 1

USER MANUAL

Ethernet Option

OPC-G11S-ETN

For

GE Fuji AF-300G11/P11

Firmware Version 1.XXX

Document SDM-7583-006

Version 1.0 - Dec 19, 2003

HMS Industrial Networks

Germany

Japan

Sweden

U.S.A

℡

+ 49 - 721 - 96472 - 0 sales-ge@hms-networks.com

+ 81 – 45 - 478 -5340 sales-jp@hms-networks.com

+ 46 - 35 - 17 29 20 sales@hms-networks.com

+ 1 - 773 - 404 - 2271 sales-us@hms-networks.com

!

Page 2

Table of Contents

Table of Contents

Table of Contents.................................................................................................................. I

About This Manual ............................................................................................................ IV

How To Use This Manual.........................................................................................................................................................IV

Important User Information.....................................................................................................................................................IV

Related Documentation.............................................................................................................................................................IV

Revision List................................................................................................................................................................................IV

Conventions Used in This Manual............................................................................................................................................ V

About the OPC-G11S-ETN...................................................................................................1

Key Features.................................................................................................................................................................................. 1

General........................................................................................................................................................................................ 1

Ethernet Global Data (EGD)..................................................................................................................................................... 1

EtherNet/IP............................................................................................................................................................................... 1

Modbus/TCP ............................................................................................................................................................................. 1

EtherNet/IP Network Overview............................................................................................................................................... 2

Ethernet Global Data (EGD) Network Overview.................................................................................................................. 2

Modbus/TCP Network Overview............................................................................................................................................. 3

Applicable Inverters..................................................................................................................................................................... 4

I

Installation ............................................................................................................................5

Receiving Inspection.................................................................................................................................................................... 5

Installation of Option Card......................................................................................................................................................... 6

Installation Checklist.................................................................................................................................................................... 7

Installation and Configuration .............................................................................................8

Module Overview......................................................................................................................................................................... 8

Network Connection ................................................................................................................................................................... 8

Status Indicators ........................................................................................................................................................................... 9

LED 1 – Ethernet Link/Activity.............................................................................................................................................. 9

LED 2 – Module Status............................................................................................................................................................. 9

LED 3 – Network Status .......................................................................................................................................................... 9

Assigning a Network Address................................................................................................................................................... 10

Example Using HICP .............................................................................................................................................................. 11

Bus Configuration Parameters.................................................................................................................................................. 12

Operation Configuration Parameters....................................................................................................................................... 12

Fault Detection and Action....................................................................................................................................................... 13

EGD .................................................................................................................................... 14

Configuration .............................................................................................................................................................................. 14

Data Messages............................................................................................................................................................................. 15

Command Messages................................................................................................................................................................... 15

Configuration Messages............................................................................................................................................................. 16

Modbus/TCP......................................................................................................................17

Page 3

Table of Contents

Addressing................................................................................................................................................................................... 17

Commands .................................................................................................................................................................................. 17

Exception Codes......................................................................................................................................................................... 17

Timeout........................................................................................................................................................................................ 18

EtherNet/IP ....................................................................................................................... 19

IO Connection............................................................................................................................................................................ 19

Idle action .................................................................................................................................................................................. 19

Example PLC configuration ...................................................................................................................................................... 19

Explicit Messaging...................................................................................................................................................................... 21

Get Attribute Single Example................................................................................................................................................... 21

Set Attribute Single Example.................................................................................................................................................... 23

Electronic Data Sheet (EDS) File ............................................................................................................................................24

Appendix A - EGD, EtherNet/IP IO Format.................................................................... 25

Data Consumed by the Drive................................................................................................................................................... 25

Run Command Word ................................................................................................................................................................ 25

Frequency Setting (S01) ............................................................................................................................................................. 25

Data Produced by the Drive..................................................................................................................................................... 26

Operation Status Monitor 1 ....................................................................................................................................................... 26

Operation Status Monitor 2 ....................................................................................................................................................... 26

Output Frequency Monitor (M06).............................................................................................................................................. 27

II

Appendix B - Drive Parameters.......................................................................................... 28

Parameter List............................................................................................................................................................................. 28

Data Format Specification......................................................................................................................................................... 33

Data Format [1]: Integer Data (Positive): Min. Unit 1 ............................................................................................................ 33

Data Format [2]: Integer Data (Positive, Negative): Min. Unit 1............................................................................................. 33

Data Format [3]: Decimal Data (Positive): Min. Unit 0.1....................................................................................................... 33

Data Format [4]: Decimal Data (Positive, Negative): Min. Unit 0.1........................................................................................ 33

Data Format [5]: Decimal Data (Positive): Min. Unit 0.01..................................................................................................... 33

Data Format [6]: Decimal Data (Positive, Negative): Min. Unit 0.01 ..................................................................................... 33

Data Format [7]: Decimal Data (Positive): Min. Unit 0.001................................................................................................... 33

Data Format [8]: Decimal Data (Positive, Negative): Min. Unit 0.001 ................................................................................... 34

Data Format [10]: Alarm Code............................................................................................................................................... 34

Data Format [11]: Capacity Code............................................................................................................................................ 34

Data Format [12]: Index Data (ACC/DEC Time, Display Coefficient).................................................................................. 35

Data Format [14]: Operation Command................................................................................................................................... 35

Data Format [15]: Universal Output Terminal......................................................................................................................... 35

Data Format [16]: Operating State........................................................................................................................................... 36

Data Format [17]: Type Code.................................................................................................................................................. 36

Data Format [18]: Code Setting (1 – 4 Figures)........................................................................................................................36

Data Format [19]: Amperage Value Decimal Data (Positive)................................................................................................... 37

Data Format [20]: Transmission Error Code............................................................................................................................ 37

Data Format [21]: Auto Tuning............................................................................................................................................... 37

Appendix C – Ethernet/IP Objects.................................................................................... 38

Identity Object, Class 0x01 ....................................................................................................................................................... 39

Services ...................................................................................................................................................................................... 39

Class Attributes......................................................................................................................................................................... 39

Instance Attributes..................................................................................................................................................................... 39

Assembly Object (Class 0x04) ..................................................................................................................................................40

Services ...................................................................................................................................................................................... 40

Class Attributes......................................................................................................................................................................... 40

Instance Attributes, Instance/Connection Point 0x03 (3d).......................................................................................................... 40

Page 4

Table of Contents

III

Instance Attributes, Instance/Connection Point 0x64 (100d) .....................................................................................................40

Instance Attributes, Instance/Connection Point 0x65 (101d) .....................................................................................................40

Instance Attributes, Instance/Connection Point 0x96 (150d) .....................................................................................................40

Fuji Vendor Specific Object (Class 0x64) ............................................................................................................................... 41

Services ...................................................................................................................................................................................... 41

Class Attributes......................................................................................................................................................................... 41

Instance Attributes..................................................................................................................................................................... 41

TCP/IP Interface Object (Class 0xF5).................................................................................................................................... 42

Services ...................................................................................................................................................................................... 42

Class Attributes......................................................................................................................................................................... 42

Instance Attributes..................................................................................................................................................................... 42

Ethernet Link Object (Class 0xF6).......................................................................................................................................... 43

Services ...................................................................................................................................................................................... 43

Class Attributes......................................................................................................................................................................... 43

Instance Attributes..................................................................................................................................................................... 43

Appendix D - EGD Exchanges ..........................................................................................44

Exchange C1 ............................................................................................................................................................................... 44

Exchange P1................................................................................................................................................................................ 44

Exchange P2................................................................................................................................................................................ 44

Exchange P3................................................................................................................................................................................ 45

Page 5

About This Manual

About This Manual

How To Use This Manual

This manual is intended to provide a good understanding of the functionality of the OPC-G11S-ETN

module. This manual only covers the Ethernet communication module, for more info about the drive’s

capabilities refer to the drive manual. For more information about a specific fieldbus contact the respective

fieldbus organization.

Important User Information

The data and illustrations found in this document are not binding. We reserve the right to modify our

products in line with our policy of continuous product development. The information in this document is

subject to change without notice and should not be considered as a commitment by HMS Industrial Networks

AB. HMS Industrial Networks AB assumes no responsibility for any errors that may appear in this document.

AnyBus® is a registered trademark of HMS Industrial Networks AB. All other trademarks are the property of

their respective holders.

IV

Related Documentation

Document Author

EtherNet/IP specification ODVA

Open Modbus/TCP specification Schneider Electric

Ethernet Global Data, Protocol specification GE Fanuc / GE Industrial Systems

AF-300G11 Instruction Manual GE Fuji

AF-300P11 Instruction Manual GE Fuji

Revision List

Revision Date Author Chapter Description

1.0 Dec 19, 2003 MaH All Document created

Page 6

About This Manual

Conventions Used in This Manual

The following conventions are used throughout this manual:

• Numbered lists provide sequential steps

• Bulleted lists provide information, not procedural steps

• The term ‘module’ is used when referring to the OPC-G11S-ETN

• Hexadecimal values are written in the format NNNNh or 0xNNNN, where NNNN is the

hexadecimal value.

V

Page 7

About the OPC-G11S-ETN

About the OPC-G11S-ETN

The OPC-G11S-ETN Ethernet adapter interfaces the G11 or P11 drive to an Ethernet network. The module

support three different communication protocols: EtherNet/IP, Ethernet Global Data (EGD), and

Modbus/TCP. It is not recommended that more than one protocol is used for controlling the drive at the

same time.

Key Features

General

• 10/100 Mbps operation

• DHCP support

• Supports HICP (Host IP Configuration Protocol)

• FTP server for configuration and firmware upgrade

1

Ethernet Global Data (EGD)

• Implements EGD class 3 functionality

• Data messages (Exchanges)

• Command messages

• Configuration messages

EtherNet/IP

• IO data connection

• EtherNet/IP explicit messaging

Modbus/TCP

• Supports 8 simultaneously connections

• Configurable time-out

Page 8

About the OPC-G11S-ETN

EtherNet/IP Network Overview

EtherNet/IP is an industrial networking standard that takes advantage of commercial off-the-shelf Ethernet

communication chips and physical media. IP, stands for 'industrial protocol' and is what distinguishes this

network. Unlike many options in the industrial Ethernet crowd, EtherNet/IP uses an open protocol at the

application layer. Further, more than one vendor or organization backs EtherNet/IP. It is the only standard

supported by three networking organizations: ControlNet International (CI), the Industrial Ethernet

Association (IEA) and the Open DeviceNet Vendor Association (ODVA)

For further information:

ODVA

1099 Highland Drive, Suite A

Ann Arbor, Michigan 48108

Phone: 1-734-975-8840

Fax: 1-734-922-0027

Email: odva@odva.org

http://www.odva.org

2

Ethernet Global Data (EGD) Network Overview

Ethernet Global Data (EGD) supports the ability to share information between controllers (nodes) in a

networked environment. EGD allows one controller, referred to as the producer of the data, to simultaneously

send information to any number of peer controllers (consumers) at a fixed periodic rate.

In addition, EGD supports a set of commands for accessing data and protocol information on EGD nodes.

EGD also defines a mechanism for sharing configuration information among nodes.

EGD protocol messages are categorized as command, data, or configuration messages.

Command messages can be used to monitor and control the operation of EGD on the destination node.

Data messages are individually configured to send a sample of data at a fixed periodic rate. Each data message

that a node sends or receives is associated with a specific identifier, which uniquely defines the configuration

of the data sample. This configuration is referred to as an exchange. EGD allows the configuration of

exchanges that are sent to a single destination address (IP Unicast addressing), a group of addresses (IP

Multicast addressing), or to all EGD nodes (IP Broadcast addressing). An assigned set of 32 IP Multicast

addresses has been defined for use by applications requiring the transmission of data exchanges to a group of

nodes.

EGD configuration messages are transferred using HTTP on the connection based TCP/IP transport layer,

utilizing XML as a data abstraction layer.

Page 9

About the OPC-G11S-ETN

Modbus/TCP Network Overview

Modbus/TCP was invented by Modicon/Group Schneider and is today is one of the most popular protocols

embedded inside the TCP/IP frames of Ethernet.

The Modbus protocol was first published back in the 1970's and has been adopted by users and vendors alike

in the industrial automation world. No changes have been made to the protocol itself but changes have been

made in the way or the rate that messages are sent in order to fulfill the real-time needs of industrial

applications. This has given us Modbus/TCP.

Modbus/TCP basically embeds a Modbus frame into a TCP frame in a simple manner. This is a connectionoriented transaction, which means every query expects a response.

This query/response technique fits well with the master/slave nature of Modbus, adding to the deterministic

advantage that Switched Ethernet offers industrial users.

For further information:

The Modbus Organization

PO Box 628

Hopkinton, MA 01748-0628

3

Phone: 508-435-7170

http://www.modbus.org

Page 10

About the OPC-G11S-ETN

Applicable Inverters

Item Description

Inverter type AF-300G11/P11

Compatible inverter Model number The two last digits of the model number should be B1 or later

Example: 6KG1123X1B1

Up to 22kW (30HP) S08000 Minimum inverter ROM version

30 kW (40HP) and above H08004

Note: This product can only be used for Inverters with ROM version numbers greater than or equal to the versions

shown above.

1. Check the ROM number of your Inverter as follows, using the inverter keypad.

2. Check that the Inverter Operation monitor (Operation mode) screen is displayed.

3. Press the [PRG] key of the Inverter once.

4. Select the "5. MAINTENANC" with the cursor and press the [FUNC/DATA] key.

5. Press the down cursor key to increment the display at the MAINTENANC screen. Finally, the ROM

number is shown in the maintenance information, as indicated by the display "INV=Hxxxxx or

Sxxxxx".

4

The maintenance and inspection items are similar to the Inverter unit, for detail refer to the Inverter

Instruction Manual.

Page 11

Installation

Receiving Inspection

Confirm the following items upon a receipt.

1. The model number matches your purchase order?

2. Check the model number printed on the circuit board.

Model: OPC – G11S – ETN

Inverter type

G11S = AF-300 G11/P11 Series

Installation

5

Option Type

ETN = Ethernet Interface Option

3. Inspection for damage during transportation. Report damage to transportation carrier.

Page 12

Installation

yp

p

p

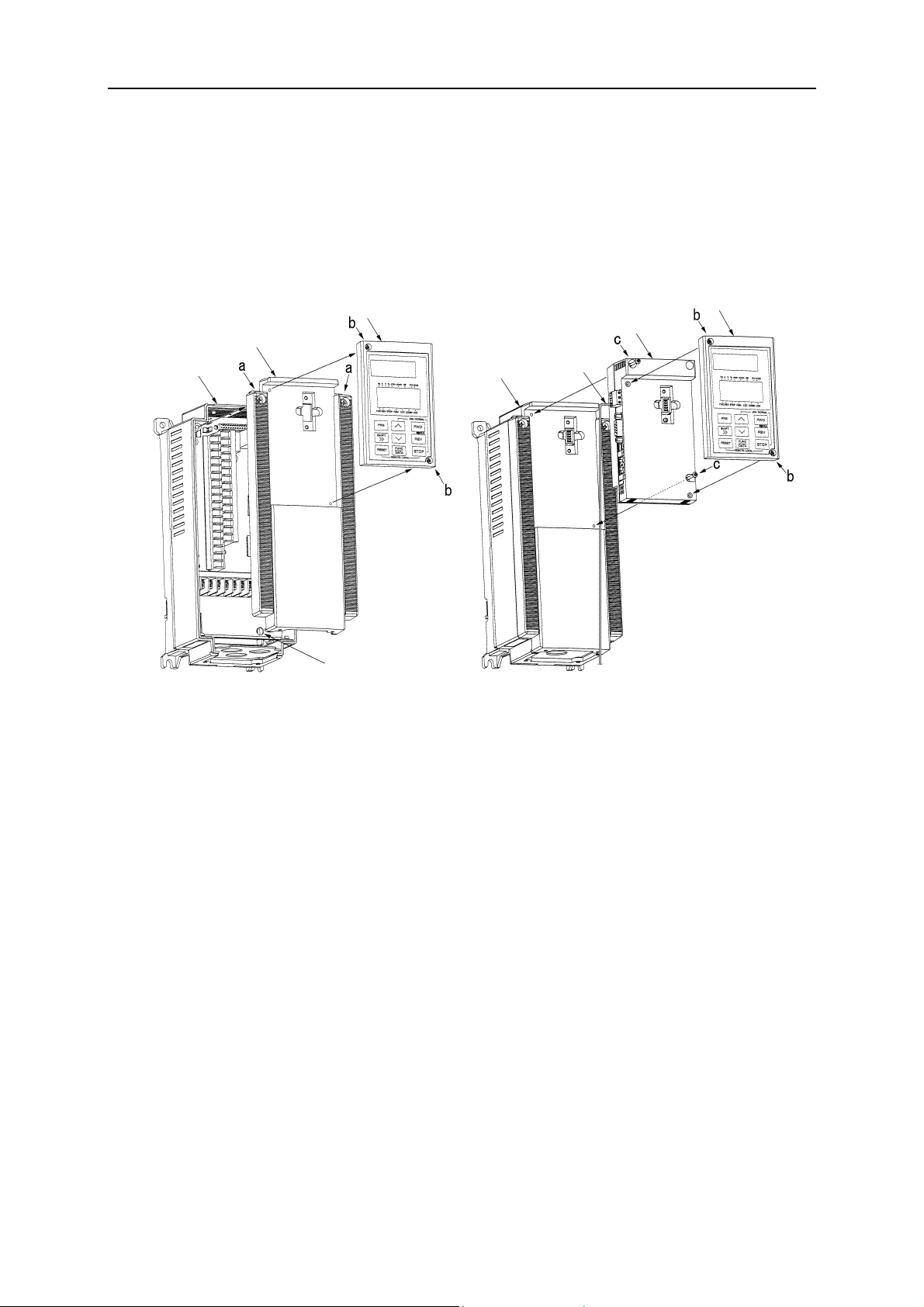

Installation of Option Card

Please follow the installation procedure described as follows. Please install or detach the option after turning

off the input power supply of the inverter and confirming the charge lamp (CHARGE or CRG) is gone out.

The shape, the dimensions and the position of the charge lamp of the inverter are different by each capacity.

Ke

To

Inverter Unit

Cover

Keypad

Inverter Unit

PE Line

tion Unit

O

6

ad

Charge Lamp

Step 1 Step 2 to 4

Step 1

Loosen two screws (M4) at a and remove the top cover. Loosen two screws (M3) at b and detach the keypad

panel. (For the 30kW[40HP] and above inverters, the keypad panel can be detached if the front cover is

removed and the screws loosened at b.)

Step 2

Reassemble the top cover, push-in the option unit and secure it with two screws (M3) at c.

Step 3

Secure the keypad panel to the option unit with two screws at b.

Step 4

Connect the ground cable to the PE terminal of the option unit (The rightmost screw terminal, besides the

RJ45 Ethernet connector).

Page 13

Installation Checklist

After installation and wiring, check the following items.

• The wiring is correct.

• No loose wires or screws remain inside the Inverter.

• The screws and terminals are all tight.

• There are no loose threads of wires at terminals that may contact other terminals.

• Inverter parameters such as H30, o27, o28, o31 to o40, are set correctly. (H30: Link Active/Inactive,

o27 and o28: for network loss action, o31 to o40: for fieldbus specific options)

Installation

7

Page 14

Installation and Configuration

Installation and Configuration

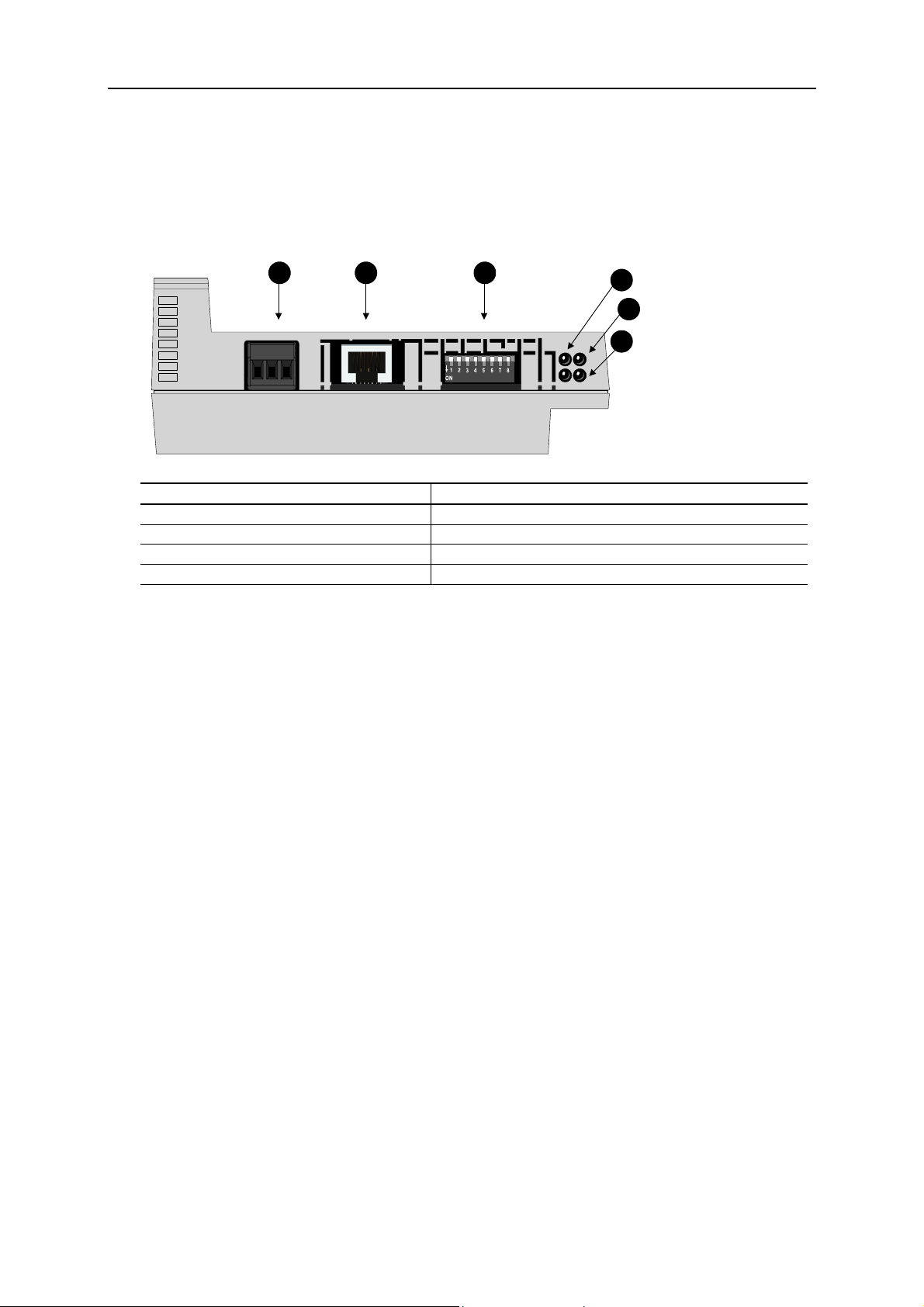

Module Overview

8

A B C

1

2

3

Figure Description

A PE Connector

B RJ45 Ethernet connector

C Network address switch

1-3 LED indicators

Network Connection

Connect the module to a 10 or 100 Mbps Ethernet network.

LED 1 lit green when the module detects link, the LED will flash when the module is receiving/transmitting

data on the network.

Default, auto negotiation will be used for speed and duplex. If speed and duplex settings need to be

configured manually, i.e., no link is established, see the bus configuration parameters.

Page 15

Installation and Configuration

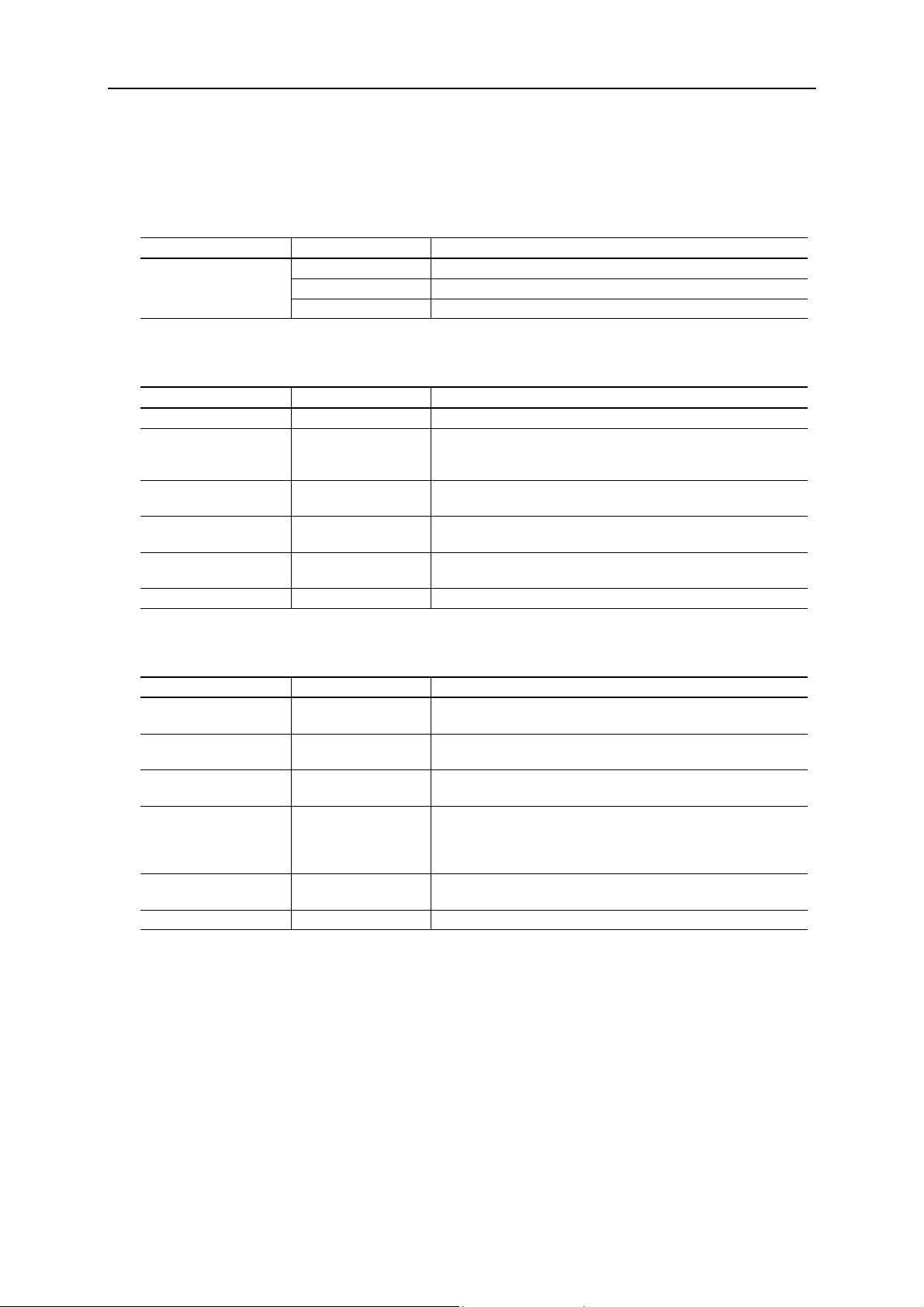

Status Indicators

LED 1 – Ethernet Link/Activity

Color LED state Description

Green

LED 2 – Module Status

LED state Device State Description

Steady Off No power Steady Green Device operational

Flashing Green Standby

Flashing Red Minor fault

Steady Red Major fault

Flashing Green/Red Self-test The module is performing its power up testing.

On The module sense link

Off The module does not sense link

Flash The module is receiving/transmitting data on Ethernet

The module has an Ethernet/IP connection OR has a

healthy EGD exchange OR has a Modbus/TCP

connection.

The module has no active data exchange but is ready to

be controlled.

A recoverable minor fault has been detected. E.g., a

connection time out or EGD exchange in unhealthy state.

A major internal error has been detected. E.g., hardware

fault or invalid drive type detected.

9

LED 3 – Network Status

LED state Network State Description

Steady Off

Flashing Green No connections

Steady Green Connected

Flashing Red Connection timeout

Steady Red Duplicate IP

Flashing Green/Red Self-test The module is performing its power up testing.

No power or

no IP address

The module has no power or no IP address is configured.

There are no Ethernet/IP connections established to the

module.

The module has at least one established Ethernet/IP

connection.

One or more of the EtherNet/IP connections, where this

module is the target, has timed out. This state is only left if

all timed out connections are re-established or if the

module is reset.

The module has detected that its IP address is already in

use.

Page 16

Installation and Configuration

Assigning a Network Address

When the module is connected to the network it must me assigned a unique IP address on the network. There

are four methods available for setting the IP address:

Method Description Comment

Network address switch

DHCP

HICP

(Windows program)

EtherNet/IP

The module will use the IP address

192.168.0.X where X is set with the

network address switch. The address

is set binary with DIP1 as MSB.

The module will automatically receive

the configuration from a DHCP server.

Use “Anybus IPconfig” software to find

the module on the network and

configure it.

Send IP parameters to the TCP/IP

interface object-

Must be set before power-on. This

configuration can only be used in a

private network.

DHCP is enabled by default.

HICP can be disable, see bus config

parameters.

Module needs to be restarted before

new configuration will be used.

10

Page 17

Installation and Configuration

11

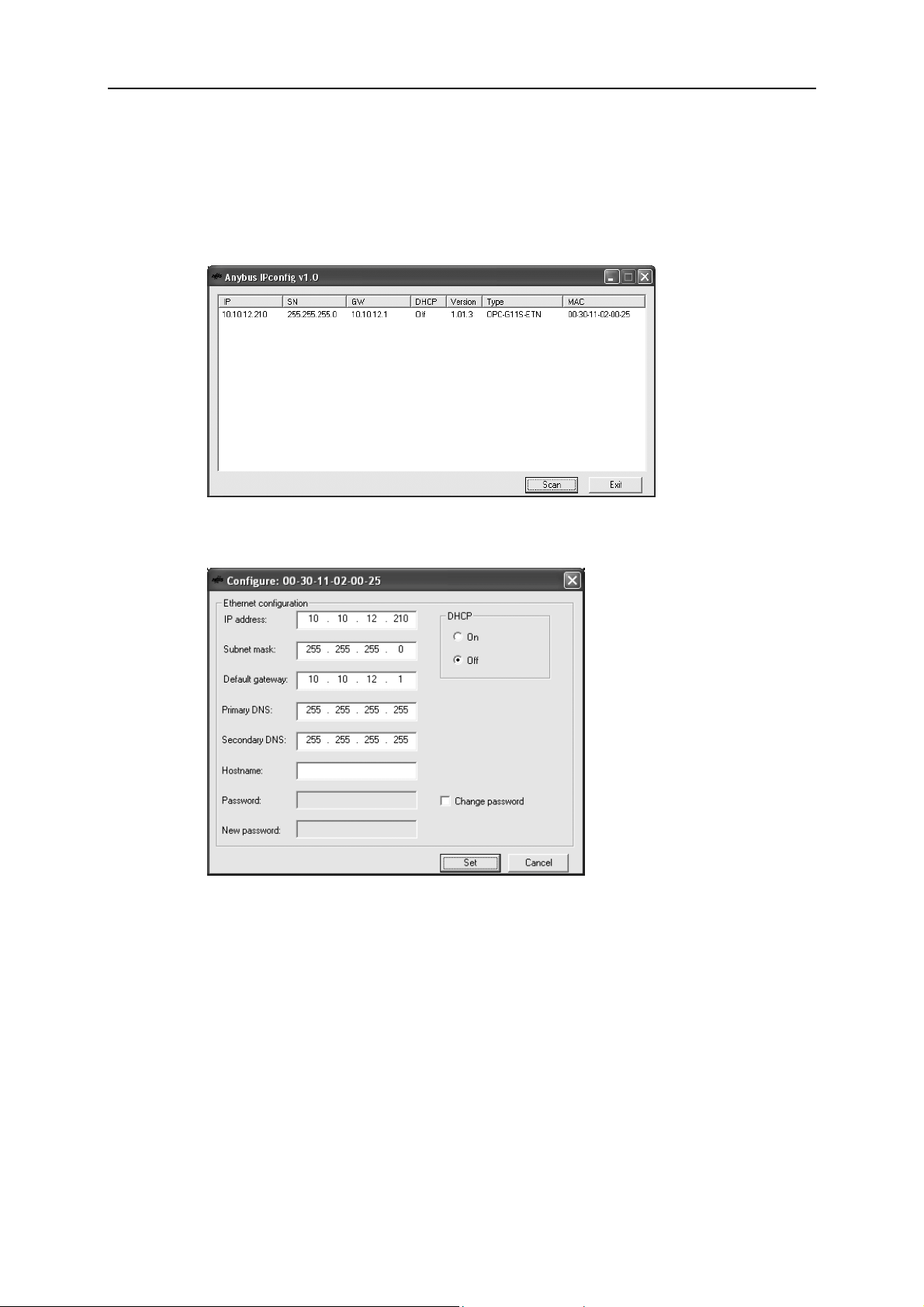

Example Using HICP

Install “Anybus IPconfig” software on a PC with MS Windows. The software is located on the diskette

delivered with the module and can also be downloaded from the web at http://www.hms-networks.com.

1. Start the configuration program and hit the Scan button, the module(s) shall appear in the window: If

the module does not appear, make sure that it is connected to the same network and that it has link.

2. Double click on the line with the module you want to configure. If you have several nodes connected

to the network, the MAC address shall match the MAC address that is printed on the side of the

module. The following window will open:

3. Enter the desired settings and turn DHCP off. The settings can optionally be protected by a

password. Hit set and the module is configured. The DNS settings are not used in this product.

Page 18

Installation and Configuration

Bus Configuration Parameters

Some basic settings can be accessed via the keypad. For instructions how to use the keypad, see the drive’s

user manual.

Drive

parameter

o30 Communication rate

o31 Disable FTP

o32 Reserved o33 IDLE action

o34 Modbus/TCP timeout

Name Description

0 = Auto negotiate

1 = 100 Mbps, Full duplex

2 = 100 Mbps, half duplex

3 = 10 Mbps, Full duplex

4 = 10 Mbps, half duplex

0 = Enable FTP server

1 = Disable FTP server

0 = If the EtherNet/IP header indicates idle, an error is sent to

the drive

1 = The run/idle bit is ignored

Sets the maximum time between Modbus/TCP commands

before a time-out is detected.

The value is multiplied with 100 ms to give the timeout from

100ms-25.5s.

12

Operation Configuration Parameters

These parameters configure the link option control and set the drive’s reaction upon a network loss event.

Drive

parameter

H30 Link function

o27

o28

Name Description

0 = Command and freq. from drive

1 = Command from drive, freq. from option card

2 = Command from option card, freq. from drive

3 = Command and freq. from option card

Loss of network

behaviour

ERR5 timer setting

(used with o27)

0 = Immediate trip (ERR5)

1 = Trip after timer setting, o28

2 = Re-check after timer setting o28

3 = Ignore communication error

ERR5 timer setting, 0.0 – 60s

Page 19

Installation and Configuration

Fault Detection and Action

A network loss event will be generated to the drive from the Ethernet option board when any of the following

events occur:

Event Source Condition Fault cleared when

Link lost Hardware Link was established. Network cable connected

Connection time-out -

Connection Idle

A consumed data exchange

enters the UNHEALTY

state.

The time from last

Modbus/TCP message has

exceeded the configured

Modbus time-out action.

EtherNet/IP

EGD

Modus/TCP

Configured to set error

on IDLE. See drive

parameter o33.

The configured

consumption time must

not be set to zero.

Configured Modbus

timeout action must not

be set to zero.

See drive parameter

o34.

Connection is deleted or

module receives information

on connection again.

Master is set in run mode

Exchange enters the

HEALTHY state

A new Modbus/TCP

message is received.

13

After an error is cleared, the error must be acknowledged to the drive before drive control will start again. The

drive’s reaction to a network loss event can be set, see the “Operation Configuration Parameters” section.

Page 20

EGD

EGD

Configuration

The EGD configuration is stored in a file called “egd.cfg” in the module’s file system. Altering this file

configures the EGD protocol.

To configure the module follow these steps:

1. Make sure that the module’s FTP server is enabled (default). See the “Bus Configuration Parameters”

section.

2. Connect to the module from an FTP client, such as Internet Explorer, by typing ftp://[IP address]

3. Open/download the file called “egd.cfg”

4. Alter the file to reflect your configuration

5. Store/Download the file to the module again

6. Restart the drive

14

The file contains settings in a format where the configuration parameter name, e.g., [Producer ID], is defined

on the first line and next line contains the value for that parameter.

The following configuration parameters are located in the file:

Parameter Description

[Producer ID]

[Network Name]

[Multicast TTL]

[Production 1 Address] Destination address of produced exchange 1

[Production 1 Period]

[Production 2 Address] Destination address of produced exchange 2

[Production 2 Period]

[Consumption 1 Address]

[Consumption 1 ProducerID]

[Consumption 1 ExchangeID]

[Consumption 1 Timeout]

[Consumption 1 Signature]

[Consumption 1 CfgTime]

ID number that uniquely identifies the EGD node. Format should be

either a dotted decimal IP address (e.g., 10.10.12.210) or an unsigned

decimal integer value. If set to zero, the module’s IP address will be

used for ProducerID.

A symbolic name of the network that the device is connected to

(Optional)

Time to live setting of multicast packages. Need normally not be

changed from default value = 1

Produce rate of exchange 1. Set between 20-65535 ms. A value of 0

disables the production of this exchange.

Produce rate of exchange 2. Set between 1000-65535 ms. A value of 0

disables the production of this exchange.

Consumes messages sent to this IP address, e.g., modules configured

IP address or a multicast address.

Must match the ProducerID of the consumed exchange, formatted as

either a dotted decimal IP address (e.g., 10.10.12.63) or an unsigned

decimal integer value. A value of zero disables consumption of this

exchange.

Must match the ExchangeID of the consumed exchange A value of zero

disables consumption of this exchange.

Specifies the maximum time between consumed exchanges before the

exchange state transits to UNHEALTHY state. The UNHEALTHY state

generates a network loss event. Set between 20 – 65535 ms. A value

of zero disables consumption of this exchange.

For the consumed exchange to be used, the major number of the

configured signature must match the major number of the signature in

the consumed exchange. If set to 0, the signature is not checked.

For the consumed exchange to be used, this value must match the

CfgTime in the consumed exchange. If set to 0, the CfgTime is not

checked.

Page 21

EGD

15

[Consumption 1 DataOffset]

The number of 16-bit words into the data portion of the exchange from

which consumed data is copied. Using different offsets on different

devices allows a single exchange to be sent to a group of devices,

improving network bandwidth utilization and coordination among

devices.

To set the configuration to default, delete the file and restart the drive.

Data Messages

This product defines four EGD exchanges:

Exchange Description

Exchange C1

Exchange P1

Exchange P2

Exchange P3

Consumed exchange 1, this exchange contains control information to the

drive. Data format is described in “Appendix A - EGD, EtherNet/IP IO

Format”.

Produced exchange 1, this exchange contains operation status monitor

words and frequency output monitor. Data format is described in

“Appendix A - EGD, EtherNet/IP IO Format”.

Produced exchange 2, this exchange contains control and monitor values

from the drive. The values in this exchange is updated at low priority, e.g.,

other protocols, like Modbus/TCP, are prioritized when requesting data.

Data format is described in “Appendix D - EGD Exchanges”.

Produced exchange 3, this exchange is used for accessing drive registers

with Command messages and cannot be set up for cyclic production.

Data format is described in “Appendix D - EGD Exchanges”.

Command Messages

Command messages are used for monitoring and control of the module.

The following commands are used for this product:

Command Description

Retrieve Configuration Returns configuration information for an exchange

Summary Returns a summary of the exchanges

Capabilities Returns the supported capabilities of the module

Statistics Returns the operating statistics of a specified exchange

Read Returns the contents of one or more continuous groups of memory

Write Changes the contents of one or more continuous groups of memory

Page 22

EGD

Configuration Messages

EGD configuration messages are sent using the HTTP protocol on TCP port 7937, a message request have

the following format:

http://[IP Address]:7937/EGD?Action=[Action]&Type=[Type]&ProducerID=[Producer ID]

The brackets shall be substituted as:

Field Description

IP Address The modules assigned IP address

Action GetVersion - Get version information

GetDoc - Retrieve specified configuration document

Type Specifies document to be retrieved. Used for GetDoc

ProducerID Producer ID of module. Used for GetDoc

The following documents can be retrieved:

Document Description

ProducedData Describes the produced data exchanges

ConsumedData Describes the needs for consumed data exchanges

EGDProfile Describes the EGD capabilities

SymbolTable Describes the contents of the exchanges

16

Examples:

http://10.10.12.210:7937/EGD?Action=GetDoc&Type=SymbolTable&ProducerID=10.10.12.210

http://10.10.12.210:7937/EGD?Action=GetVersion

Page 23

Modbus/TCP

Modbus/TCP

This product incorporates a Modbus/TCP server according to version 1.0 of the Modbus/TCP specification.

The product listens for incoming connections on TCP port 502.

Up to 8 simultaneously connections can be set-up. A connection will be closed if no data has been exchanged

during 1 minute.

Addressing

This product supports the Modbus area for output/holding registers (4XXXX).

Register 40001-40255 corresponds to Communication No. 1-255.

Commands

The module supports the following Modbus/TCP commands:

17

Function

code

3 Read multiple registers Read one ore more registers in the drive

6 Write single register Write to a single register

16 Write multiple registers Write to multiple registers

23 Read/Write registers Read and write to multiple registers with one command

Function name Description

Exception Codes

If a command cannot be executed an exception code is returned. The following exception codes can be

returned:

Exception

code

01 Illegal function The function code in the query is not supported

02 Illegal data address

03 Illegal data value

06 Slave device busy

Exception name Description

The data address in the query is outside the valid address

range or the address is invalid.

This code will be returned if:

1. Trying to write to a read only register in the drive or

2. The requested register cannot be changed while the drive

is running.

This code will be returned if:

1. The inverter is busy or

2. There is a communication error between the drive and the

communication adapter.

Page 24

Modbus/TCP

18

Timeout

When a Modbus/TCP timeout value is configured, see the “Bus Configuration Parameters” chapter, a

network error will be generated to the drive if the time between two Modbus messages exceeds the configured

value.

Note: If the Modbus/TCP protocol is used for controlling the drive, a timeout value shall be configured so that the

drive trips if the connection with the master fails.

Page 25

EtherNet/IP

EtherNet/IP

IO Connection

An IO connection is used for data that is cyclically exchanged with the drive, i.e., Frequency command and

operation command. Other drive parameters can be exchanged by explicit messaging, see the “Explicit

Messaging” section.

Idle action

For security reasons, when the PLC is put into program/idle mode it defaults generates a network loss event

to stop the drive. This functionality can be disabled by bus configuration parameter IDLE action, see the “Bus

Configuration Parameters” section.

Example PLC configuration

In this example a connection is set up to a Rockwell Automation ControlLogix PLC, equipped with a 1756ENBT/A Ethernet bridge. The configuration program used is RSLogix 5000 from Rockwell Software.

19

1. Start RSLogix 5000

2. Right-click on the Ethernet bridge module and choose “New module”

Page 26

EtherNet/IP

20

3. Select type “ETHERNET MODULE” and click OK

4. Configure the IP address to the module and Input and Output instances. The configuration instance

is not used but requires a value. Input is set to three words and output is to two words, the data

format shall be set to “Data – INT”. Click Next>

5. Set the RPI value to 20ms or higher. Click Finish>>>

The module is now added to the PLC configuration and can be used in the PLC program. For example, to

access the drive speed, use the tag OPCG11SETN:I.Data[2].

Save the configuration and download to the PLC.

The format of the IO data is described in “Appendix A - EGD, EtherNet/IP IO Format”.

Page 27

EtherNet/IP

Explicit Messaging

Many of the drive’s parameters are mapped as Communication No:s, see “Appendix B - Drive Parameters”,

for EtherNet/IP the CommunicationNo:s are accessed via the Fuji Vendor Specific Object (Class 0x64).

Various configuration softwares or, for example, ControlLogix from Rockwell Automation can perform

EtherNet/IP explicit messaging. The examples in the chapter demonstrate how explicit read/writes can be

performed with the ControlLogix PLC. The PLC is configured in RSLogix 5000.

Get Attribute Single Example

This example shows how to get the “DC link circuit voltage” (M21) by explicit messaging.

1. In Controller tags, create a tag of MESSAGE type for the read instruction and create a tag of INT

type for storing the value.

21

2. Add the message instruction (MSG) to a rung and use the created tag as value for the “Message

Control” field.

Page 28

EtherNet/IP

3. Click the button with the three dots in the MSG instruction to bring up the MESSAGE

configuration window. Do the following settings:

Field Value Description

Message Type CIP Generic CIP Message

Service Type Get attribute single CIP Service

Class 64 Fuji Vendor Specific Object

Instance 1 Instance 1

Attribute 23

Destination DC_Voltage Name of created destination tag

Path OPCG11SETN

M21 – DC link circuit voltage = Communication No.

35 = 23 hex

Name of device. Click Browse and locate the module.

Must have been added as described in the IO

connection example chapter

22

When GetDcValue in the example is activated, DC voltage is read and stored in the DC_Voltage Tag.

Page 29

EtherNet/IP

23

Set Attribute Single Example

This example shows how to set the “LED Monitor (Function)” (E43) to show the output current on the LED

display, by explicit messaging.

In Controller tags, create a tag of MESSAGE type for the write instruction and create a tag of INT type for

the value to send.

1. In Controller tags, create a tag of MESSAGE type for the write instruction and create a tag of INT

type for the value to be sent. Set the value tag to 3 for “Output current”.

2. Add the message instruction (MSG) to a rung and use the created tag as value for the “Message

Control” field.

Page 30

EtherNet/IP

3. Click the button with the three dots in the MSG instruction to bring up the MESSAGE

configuration window. Do the following settings:

Field Value Description

Message Type CIP Generic CIP Message

Service Type Set attribute single CIP Service

Class 64 Fuji Vendor Specific Object

Instance 1 Instance 1

Attribute 8A

Source

Element

Source Length

Path OPCG11SETN

SetDisplayValue Name of created source tag

2 1 word

E43 – LED Monitor (Function) = Communication No.

138 = 8A hex

Name of device. Click Browse and locate the module.

Must have been added as described in the IO

connection example chapter

24

When SetDisplay in the example is activated, the value in the SetDisplayValue Tag is written to parameter E43

in the drive.

Electronic Data Sheet (EDS) File

An EtherNet/IP node needs an EDS file with information about the device, the EDS file is used by network

configuration tools. The EDS file for this product is located on the diskette supplied together with the module

or can be downloaded from http://www.hms-networks.com/private/fujilogin.asp. Username: fuji, Password:

400024.

Page 31

Appendix A - EGD, EtherNet/IP IO Format

Appendix A - EGD, EtherNet/IP IO Format

This chapter specifies the format of data that is cyclically exchange with the drive, here called IO data. This

format is used for the assembly instances on EtherNet/IP and for the exchanges P1 and C1 on EGD.

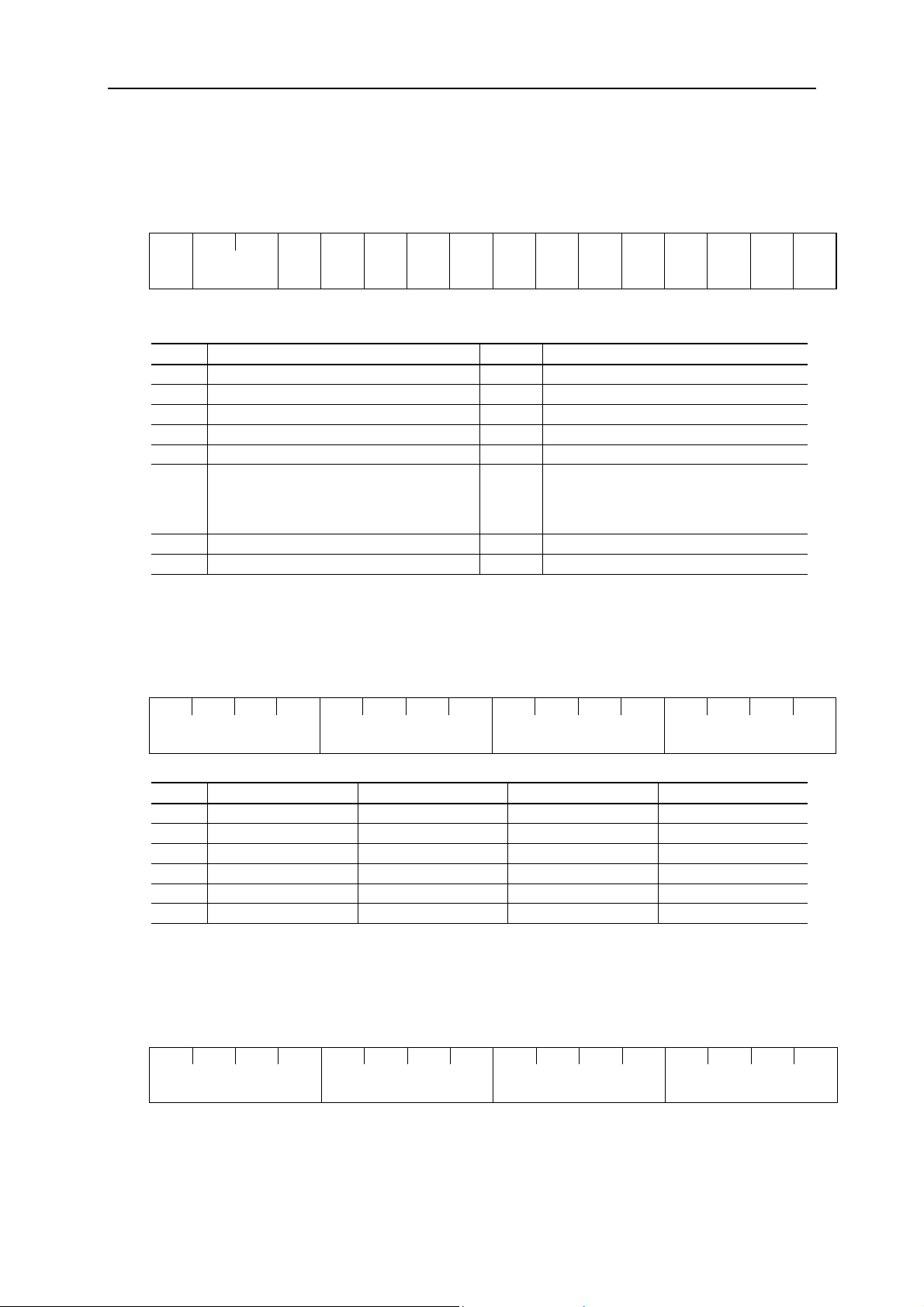

Data Consumed by the Drive

Consumed data is located in assembly instance 150 on EtherNet/IP and Produced Exchange 1(P1) on EGD.

Position Description

Word 0 (16 Bit) Run command word

Word 1 (16 Bit) Frequency setting (S01)

Run Command Word

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

25

RST - BX RT4 - X9 X8 X7 X6 X5 X4 X3 X2 X1 REV FWD

FWD 1: Run forward command

REV 1: Run reverse command

X1 – X9 1: Digital input

RT4 1: Acceleration/Deceleration time 4 (Has priority over the Acc/Dec time selection by X terminal)

BX 1: Coast-to-stop command

RST Alarm reset:

(Each function is set by inverter’s parameter E01-E09, See drive manual)

0 to 1 and 1 to 0

t

min

= 20ms

Frequency Setting (S01)

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Frequency command data

Frequency is set as: Output Frequency * 20000 / Max frequency

Max frequency = F03

Reverse direction is set with a negative value

Page 32

Appendix A - EGD, EtherNet/IP IO Format

Data Produced by the Drive

Produced data is located in assembly instance 100 on EtherNet/IP and Consumed Exchange 1(C1) on EGD.

Position Description

Word 0 (16 Bit) Operation status monitor 1

Word 1 (16 Bit) Operation status monitor 2

Word 2 (16 Bit) Output frequency monitor

Operation Status Monitor 1

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

- - WR RL ALM DEC ACC IL VL TL NUV BRK INT EXT REV FWD

FWD 1: In forward command

REV 1: In reverse command

EXT 1: In DC breaking or in preparatory excitation

INT 1: No output

BRK 1: In breaking

NUV 1: DC link voltage is establishment

(Under voltage condition at 0)

TL 1: In torque limiting

VL 1: In voltage limiting

IL 1: In current limiting

ACC 1: In acceleration

DEC 1: In deceleration

ALM 1: Alarm

RL 1: Remote (Run command or Frequency command is valid from link)

WR 1: Fieldbus writing right, 0: Keypad writing right

26

Operation Status Monitor 2

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

- - - - - - - - - - - - SWM2 RDY FDT FAR

FAR 1: Frequency (speed) arrival

FDT 1: Frequency (speed) detection

RDY 1: Ready for operation

SWM2 1: Motor 2 switching

Page 33

Appendix A - EGD, EtherNet/IP IO Format

Output Frequency Monitor (M06)

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Output frequency

27

Page 34

Appendix B - Drive Parameters

Appendix B - Drive Parameters

Parameter List

This table shows the mapping between Communication No. and drive parameter number. The

Communication No. is used when accessing parameters from the fieldbus.

G11/P11

Code

- 0 (0) - S01 1 (1) Frequency command 2

- 2 (2)

- 3 (3) - -

- 4 (4) - S05 5 (5) Frequency command 5

S06 6 (6) Operation command 14

S07 7 (7) Universal Do 15

S08 8 (8) Accel Time F07 3

S09 9 (9) Deccel Time F08 3

S10 10 (A) Driving Torque Limit F40 5

S11 11 (B) Braking Torque Limit F41 5

S12 12 (C) Universal Ao 2

- 13 (D) - -

- 14 (E) - M01 15 (F) Frequency command (final) 2

- 16 (10) - -

- 17 (11) - -

- 18 (12) - M05 19 (13) Frequency command (final) 5

M06 20 (14) Actual frequency 2

M07 21 (15) Actual value of torque 6

M08 22 (16) Torque current 6

M09 23 (17) Output frequency 5

M10 24 (18) Motor output 5

M11 25 (19) Output current (rms) 5

M12 26 (1A) Output voltage (rms) 3

M13 27 (1B) Operation (final) 14

M14 28 (1C) Operation state 16

M15 29 (1D) General-purpose output terminal 15

M16 30 (1E) Alarm content latest 10

M17 31 (1F) Alarm content 1st previous 10

M18 32 (20) Alarm content 2nd previous 10

M19 33 (21) Alarm content 3rd previous 10

M20 34 (22) Total operation time 1

M21 35 (23) DC link voltage 1

- 36 (24) - M23 37 (25) Type code 17

M24 38 (26) Capacity code 11

M25 39 (27) ROM version 1

M26 40 (28) Processing code in abnormal transmission 20

Communication

No. (Hex)

Description

-

28

Data

format

-

Page 35

Appendix B - Drive Parameters

29

M27 41 (29) Frequency (Motor speed) setting at alarm final 2

- 42 (2A) - -

- 43 (2B) - -

- 44 (2C) - M31 45 (2D) Frequency setting at alarm final 5

M32 46 (2E) Actual frequency at alarm 2

M33 47 (2F) Actual value of torque at alarm 6

M34 48 (30) Torque current at alarm 6

M35 49 (31) Output frequency at alarm 5

M36 50 (32) Motor output at alarm 5

M37 51 (33) Output voltage (rms) at alarm 5

M38 52 (34) Output voltage effective value at alatm 3

M39 53 (35) Operation command at alarm 14

M40 54 (36) Operation state at alarm 16

M41 55 (37) General-purpose output terminal at alarm 15

M42 56 (38) Total operation time at alarm 1

M43 57 (39) DC link voltage at alarm 1

M44 58 (3A) Internal temperature of inverter at alarm 1

M45 59 (3B) Temperature of cooling fin at alarm 1

M46 60 (3C) Lifetime of main circuit capacitor 3

M47 61 (3D) Lifetime of capacitor on PCB 1

M48 62 (3E) Lifetime of cooling fan 1

- 63 (3F) - -

- 64 (40) - -

- 65 (41) - -

- 66 (42) - -

- 67 (43) - -

- 68 (44) - -

- 69 (45) - F00 70 (46) Data protection 1

F01 71 (47) Frequency command 1 1

F02 72 (48) Operation method 1

F03 73 (49) Maximum frequency 1 1

F04 74 (4A) Base frequency 1 1

F05 75 (4B) Rated voltage 1 1

F06 76 (4C) Maximum voltage 1 1

F07 77 (4D) Acceleration time 1 12

F08 78 (4E) Deceleration time 1 12

F09 79 (4F) Torque boost 1 12

F10 80 (50) Electronic Thermal 1 (Select) 3

F11 81 (51) Electronic Thermal 1 (Level) 1

F12 82 (52) Electronic Thermal 1 (Time constant) 16

F13 83 (53) Electronic thermal overload relay (for DB resistor) 3

F14 84 (54) Restart mode after momentary power failure 1

F15 85 (55) Frequency limiter (High) 1

F16 86 (56) Frequency limiter (Low) 1

F17 87 (57) Gain (for freq set signal) 1

F18 88 (58) Bias frequency 1

F20 89 (59) DC brake (Starting freq.) 3

F21 90 (5A) DC brake (Braking level) 1

F22 91 (5B) DC brake (Braking time) 3

F23 92 (5C) Starting frequency (Freq.) 3

F24 93 (5D) Starting frequency (Holding time) 3

F25 94 (5E) Stop frequency 1

Page 36

Appendix B - Drive Parameters

30

F26 95 (5F) Motor sound (Carrier freq.) 1

F27 96 (60) Motor sound (Sound tone) 1

F30 97 (61) FMA (Voltage adjust) 1

F31 98 (62) FMA (Function) 1

F33 99 (63) FMP (Pulse rate) 1

F34 100 (64) FMP (Voltage adjust) 1

F35 101 (65) FMP (Function) 1

F36 102 (66) 30RY operation mode 1

F40 103 (67) Torque limiter 1 (Driving) 1

F41 104 (68) Torque limiter 1 (braking) 1

F42 105 (69) Torque vector control 1 1

E01 106 (6A) X1 terminal function X1 1

E02 107 (6B) X2 terminal function X2 1

E03 108 (6C) X3 terminal function X3 1

E04 109 (6D) X4 terminal function X4 1

E05 110 (6E) X5 terminal function X5 1

E06 111 (6F) X6 terminal function X6 1

E07 112 (70) X7 terminal function X7 1

E08 113 (71) X8 terminal function X8 1

E09 114 (72) X9 terminal function X9 1

E10 115 (73) Acceleration time 2 12

E11 116 (74) Deceleration time 2 12

E12 117 (75) Acceleration time 3 12

E13 118 (76) Deceleration time 3 12

E14 119 (77) Acceleration time 4 12

E15 120 (78) Deceleration time 4 12

E16 121 (79) Torque limiter 2 (Driving) 1

E17 122 (7A) Torque limiter 2 (braking) 1

E20 123 (7B) Y1 terminal function 1

E21 124 (7C) Y2 terminal function 1

E22 125 (7D) Y3 terminal function 1

E23 126 (7E) Y4 terminal function 1

E24 127 (7F) Y5A, Y5C terminal func. 1

E30 128 (80) FAR function (Hysteresis) 3

E31 129 (81) FDT function (Level) 1

E32 130 (82) FDT signal (Hysteresis) 3

E33 131 (83) OL function (Mode select) 1

E34 132 (84) OL function signal (Level) 19

E35 133 (85) OL function signal (Timer) 3

E36 134 (86) FDT2 function (Level) 1

E37 135 (87) OL2 function (Level) 19

E40 136 (88) Display coefficient A 12

E41 137 (89) Display coefficient B 12

E43 138 (8A) LED Monitor (Function) 1

E44 139 (8B) LED Monitor (Display in STOP mode) 1

E45 140 (8C) LCD Monitor (Function) 1

C01 141 (8D) Jump frequency (Jump freq 1) 1

C02 142 (8E) Jump frequency (Jump freq 2) 1

C03 143 (8F) Jump frequency (Jump freq 3) 1

C04 144 (90) Jump frequency (Hysteresis) 1

C05 145 (91) Multistep frequency setting (Freq. 1) 5

C06 146 (92) Multistep frequency setting (Freq. 2) 5

C07 147 (93) Multistep frequency setting (Freq. 3) 5

C08 148 (94) Multistep frequency setting (Freq. 4) 5

Page 37

Appendix B - Drive Parameters

C09 149 (95) Multistep frequency setting (Freq. 5) 5

C10 150 (96) Multistep frequency setting (Freq. 6) 5

C11 151 (97) Multistep frequency setting (Freq. 7) 5

C20 152 (98) JOG frequency 5

C30 153 (99) Frequency command 2 1

C31 154 (9A) Offset adjust (terminal [12]) 4

C32 155 (9B) Offset adjust (terminal [C1]) 3

C33 156 (9C) Analog setting signal filter 5

P01 157 (9D) Number of motor 1 poles 1

P02 158 (9E) Motor 1 (Capacity) 5

P03 159 (9F) Motor 1 (Rated current) 19

P04 160 (A0) Motor 1 (Tuning) 21

P05 161 (A1) Motor 1 (On-line Tuning) 1

P06 162 (A2) Motor 1 (No-load current) 19

P07 163 (A3) Motor 1 (%R1 setting) 5

P08 164 (A4) Motor 1 (%X setting) 5

P09 165 (A5) Slip compensation control 5

H03 166 (A6) Data initializing 1

H04 167 (A7) Auto-reset (Times) 1

H05 168 (A8) Auto-reset (Reset interval) 1

H06 169 (A9) Fan stop operation 1

H07 170 (AA) ACC/DEC pattern (select) 1

H08 171 (AB) Rev. phase sequence lock 1

H09 172 (AC) Start mode 1

H10 173 (AD) Energy-saving operation 1

H11 174 (AE) DEC mode 1

H12 175 (AF) Instantaneous OC limiting 1

H13 176 (B0) Auto-restart (restart time) 3

H14 177 (B1) Auto-restart (freq. fall rate) 5

H15 178 (B2) Auto-restart (holding DC voltage) 1

H16 179 (B3) Auto-restart (OPR command self hold time) 3

H18 180 (B4) Torque control 1

H19 181 (B5) Active drive 1

H20 182 (B6) PID control (Mode select) 1

H21 183 (B7) PID control (Feedback signal) 1

H22 184 (B8) PID control (P-gain) 5

H23 185 (B9) PID control (I-gain) 3

H24 186 (BA) PID control (D-gain) 1

H25 187 (BB) PID control (Feedback filter) 5

H26 188 (BC) PTC thermistor (Mode select) 1

H27 189 (BD) PTC thermistor (Level) 5

H28 190 (BE) Droop operation 4

H30 191 (BF) Serial link (Function select) 1

H31 192 (C0) Modbus-RTU (Address) 1

H32 193 (C1) Modbus-RTU (Mode select on no response error) 1

H33 194 (C2) Modbus-RTU (Timer) 3

H34 195 (C3) Modbus-RTU (Baud rate) 1

H35 196 (C4) Modbus-RTU (Data length) 1

H36 197 (C5) Modbus-RTU (Parity check) 1

H37 198 (C6) Modbus-RTU (Stop bits) 1

H38 199 (C7) Modbus-RTU (No resp. error detection time) 1

H39 200 (C8) Modbus-RTU (Response interval) 5

A01 201 (C9) Maximum frequency 2 1

A02 202 (CA) Base frequency 2 1

31

Page 38

Appendix B - Drive Parameters

32

A03 203 (CB) Rated voltage 2 (at Base frequency 2)

A04 204 (CC) Maximum voltage 2

A05 205 (CD) Torque boost 2

A06 206 (CE) Electronic thermal 2 (Select)

A07 207 (CF) Electronic thermal 2 (Level)

A08 208 (D0) Electronic thermal 2 (Thermal time constant)

A09 209 (D1) Torque vector control 2

A10 210 (D2) Number of motor 2 poles

A11 211 (D3) Motor 2 (Capacity)

A12 212 (D4) Motor 2 (Rated current)

A13 213 (D5) Motor 2 (Tuning)

A14 214 (D6) Motor 2 (On-line Tuning)

A15 215 (D7) Motor 2 (No-load current)

A16 216 (D8) Motor 2 (%R1 setting)

A17

217 (D9) Motor 2 (%X setting) 5

1

1

1

1

19

3

1

1

5

19

21

1

19

5

A18 218 (DA) Motor 2 (Slip compensation control 2) 5

o01 219 (DB) Control method selection 1

o02 220 (DC) Speed filter time constant 1

o03 221 (DD) Number of feedback pulses 1

o04 222 (DE) P-gain of feedback 1

o05 I-gain of feedback 1

223 (DF)

o06 224 (E0) Feedback speed detection filter 1

o07 225 (E1) Feedback pulse correction coeff 1 1

o08 226 (E2) Feedback pulse correction coeff 2 1

o27 227 (E3) Bus loss behaviour 1

o28 228 (E4) Bus loss timer 1

o30 229 (E5) Communication rate 1

o31 230 (E6) Disable FTP 1

o32 231 (E7) Reserved 1

o33 232 (E8) Idle action 1

o34 233 (E9) Modbus/TCP timeout 1

o35 234 (EA) - 1

o36 235 (EB) - 1

o37 236 (EC) - 1

o38 237 (ED) - 1

o39 238 (EE) - 1

o40 239 (EF) - 1

o41 240 (F0) - 1

o42 241 (F1) - 1

o43 242 (F2) - 1

o44 243 (F3) - 1

o45 244 (F4) - 1

o46 245 (F5) - 1

o47 246 (F6) - 1

o48 247 (F7) - 1

o49 248 (F8) - 1

o50 249 (F9) - 1

o51 250 (FA) - 1

o52 251 (FB) - 1

o53 252 (FC) - 1

o54 253 (FD) - 1

o55 254 (FE) - 1

- 255 (FF) - -

Page 39

Appendix B - Drive Parameters

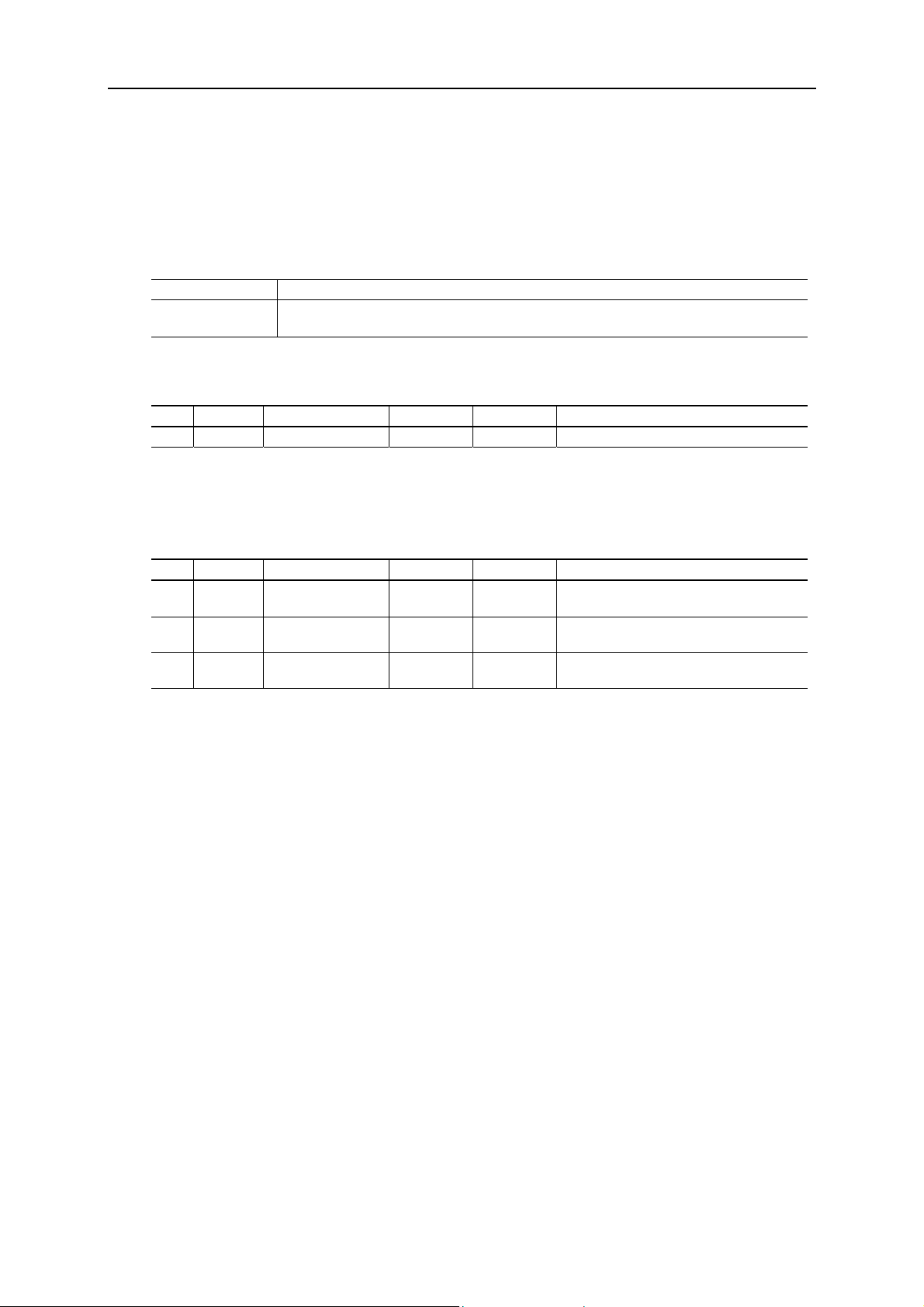

Data Format Specification

All data within the data field of the communication frame consist of 16 bits binary data.

(MSB) (LSB)

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

16-bits binary data

(Negative data is treated with two’s complement)

Data Format [1]: Integer Data (Positive): Min. Unit 1

Example) If F15 (Frequency limiter, high limit) = 60 Hz,

33

60 * 1 = 60 = 003C

H

Data Format [2]: Integer Data (Positive, Negative): Min. Unit 1

Example) If F18 (Bias frequency) = -20 Hz,

-20 * 1 = -20 = FFEC

(two’s complement)

H

Data Format [3]: Decimal Data (Positive): Min. Unit 0.1

Example) If F17 Gain (for frequency setting signal) = 100.0%,

100.0 * 10 = 1000 = 03E8

H

Data Format [4]: Decimal Data (Positive, Negative): Min. Unit 0.1

Example) If H28 (Droop operation) = -5.0Hz,

-5.0 * 10 = -50 = FFCE

(two’s complement)

H

Data Format [5]: Decimal Data (Positive): Min. Unit 0.01

Example) If C05 (Multi-step frequency 1) = 50.25 Hz,

50.25 * 100 = 5025 = 13A1

H

Data Format [6]: Decimal Data (Positive, Negative): Min. Unit 0.01

Example) If M07 (Actual torque value) = -85.38%,

-85.38 * 100 = -8538 = DEA6

(two’s complement)

H

Data Format [7]: Decimal Data (Positive): Min. Unit 0.001

Example) If o05 (Constant I of feedback speed controller) = 0.105s,

0.105 * 1000 = 105 = 0069

H

Page 40

Appendix B - Drive Parameters

Data Format [8]: Decimal Data (Positive, Negative): Min. Unit 0.001

Example) If value -1.234,

-1.234 * 1000 = -1234 = FB2EH(two’s complement)

Data Format [10]: Alarm Code

Code Description Code Description

0 No alarm 22 Overheat, DB resistor

1

2

3

5 Ground fault 27 Overspeed

6 Overvoltage, during acceleration 28 PG wire break

7 Over voltage, during deceleration 31 Memory error

8

10 DC undervoltage 33 CPU error

11 Power supply open phase 34 Option comm error

14 Blown DC fuse 35 Option error

16 Output wiring error 36 PL error

17 Overheat, heat sink, inverter 37 Output wiring error

18 Overheat, outside thermal 38 RS485 comm error

19 Overheat, unit inside temp - -

Overcurrent, during acceleration (INV

output)

Overcurrent, during deceleration (INV

output)

Overcurrent, during steady state

operation (INV output)

Overvoltage, during steady state

operation

23 Overload, motor 1

24 Overload, motor 2

25 Overload, drive

32 Keypad error

34

Data Format [11]: Capacity Code

Code Capacity (HP) Code Capacity (HP) Code Capacity (HP)

7 0.07 (spare) 2000 20 17500 175

15 0.15 (spare) 2500 25 20000 200

25 0.15 3000 30 25000 250

50 0.15 4000 40 30000 300

100 1 5000 50 35000 350

200 2 6000 60 40000 400

300 3 7500 75 45000 450

500 5 10000 100 50000 500

750 7.5 12500 125 60600 600

1000 10 15000 150 60700 700

1500 15 - - 60800 800

Page 41

Appendix B - Drive Parameters

35

Data Format [12]: Index Data (ACC/DEC Time, Display Coefficient)

(MSB) (LSB)

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Polarity 0 0 0 Index portion Data portion

Field Description

Polarity

0: Positive (+)

1: Negative (-)

Index portion 0: 0.01 * 001–999 (0.00 – 9.99)

1: 0.1 * 100–999 (10.0 – 99.9)

2: 1 * 100–999 (100 – 999)

3: 10 * 100–999 (1000 – 9990)

Data portion Value

Example) F07 (Acceleration time 1) = 20.0 s,

20.0 = 0.1 * 200 = 0400

+ 00C8H = 04C8H

H

Data Format [14]: Operation Command

(MSB) (LSB)

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

RST 0 0 0 0 X9 X8 X7 X6 X5 X4 X3 X2 X1 REV FWD

(All bits are ON or active by 1)

Field Description

RST Alarm

X9-X1 Multi function command

REV Reverse rotation command

FWD Forward rotation command

Example) If M13 (Operation command, Final command) = FWD, X1, X5 = ON

0000 0000 0100 0101b = 0045H

Data Format [15]: Universal Output Terminal

(MSB) (LSB)

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

0 0 0 0 0 0 0 0 0 0 0 Y5 Y4 Y3 Y2 Y1

Y5-Y1 = Universal command (All bits are ON by 1)

Example) If M15 (Universal output terminal) = Y1, Y5 = ON,

0000 0000 0001 0001

.= 0011H

b

Page 42

Appendix B - Drive Parameters

Data Format [16]: Operating State

36

(MSB)

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

BUSY WR RL ALM DEC ACC IL VL TL NUV BRK INT EXT REV FWD

(LSB)

(All bits are ON or active by 1)

Field Description Field Description

FWD In forward operation IL In current limiting

REV In reverse operation ACC In acceleration

EXT In DC braking (or in pre-excitation) DEC In deceleration

INT No output ALM Drive fault

BRK In braking RL Transmission valid

NUV

DC link voltage is establishment

(Under voltage at 0)

WR Function writing right

0: Keypad panel

1: RS485

2: Fieldbus (Option)

TL In torque limiting BUSY Processing data write

VL In voltage limiting - -

Data Format [17]: Type Code

(MSB) (LSB)

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Unit type Generation Series Voltage series

Code Type Generation Series Voltage series

1 VG 11th series For Japan 100V single phase

2 G 7 th series For Asia 200V single phase

3 P - For China 200V three phase

4 E - For Europe 400V three phase

5 C - For USA 575V three phase

6 S - - -

Data Format [18]: Code Setting (1 – 4 Figures)

(MSB) (LSB)

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Data 4 Data 3 Data 2 Data 1

Page 43

Appendix B - Drive Parameters

Data Format [19]: Amperage Value Decimal Data (Positive)

Min unit 0.01, inverter capacity 30HP or below

Min unit 0.1, for 40 HP and over

Example) If F11 (electronics thermal overload relay 1 level) 107.0 A (40 HP)

37

107.0 x 10 = 1070 =042E

H

If F11 (electronics thermal overload relay 1 level) 3.60A (1 HP)

3.60 x 100 = 360 =0168

H

Data Format [20]: Transmission Error Code

Field Description Code Description

1 FC (Function code) error 71 CRC error (no response)

2 Illegal address 72 Parity error (no response)

3 Illegal address (Data range error) 73

7

NAK

- Priority for comm.

- No privilege for writing error

- Forbidden writing error

- -

Other errors (no response)

- Framing error

- Overrun error

- Buffer full error

Data Format [21]: Auto Tuning

(MSB) (LSB)

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

0 0 0 0 0 0 REV FWD Data portion

0: Without forward rotation command

1: With forward rotation command

0: Without reverse rotation command

1: With reverse rotation command

Example) If P04 (Motor 1 auto tuning) = 1 : Forward rotation

0000 0001 0000 0001

= 0101H

B

Page 44

Appendix C – Ethernet/IP Objects

Appendix C – Ethernet/IP Objects

The following EtherNet/IP objects are implemented and can be accessed by EtherNet/IP explicit messaging.

For more information about these objects, see the EtherNet/IP specification.

• Identity object, Class 0x01

• Message router, Class 0x02

• Assembly object, Class 0x04

• Connection Manager, Class 0x06

• Fuji Vendor Specific Object, Class 0x64

• TCP/IP Interface object, Class 0xF5

• Ethernet Link object, Class 0xF6

38

Page 45

Appendix C – Ethernet/IP Objects

Identity Object, Class 0x01

Services

39

Class services

Instance services

Class Attributes

# Access Name Type Value Description

1 Get Revision UINT 0x0001 Revision 1

Instance Attributes

# Access Name Type Value Description

1 Get Vendor ID UINT 0x005A HMS Industrial Networks AB

2 Get Device type UINT 0x000C Communication Adapter

3 Get Product code UINT 0x012C OPC-G11S-ETN drive adapter

4 Get Revision

5 Get Status WORD -

6 Get Serial number UDINT

7 Get Product name

Get Attribute All

Get Attribute Single

Get Attribute All

Get Attribute Single

Reset

Struct of: - Version X.YY

USINT XX

USINT YY

SHORT_S

TRING

Serial

number

“OPCG11SETN”

Major product version of this

communication module.

Minor product version of this

communication module

Status of the device, see table

below.

This is the serial number of the

product, assigned when the module

is produced.

The module’s product name.

Status Attribute Extended Device Status (Bit 4-7)

Bit 0 Owned, shall be set when at least one

connection is configured.

Bit 1 Reserved, set to 0.

Bit 2 Configured, is always set to 1.

Bit 3 Reserved, set to 0.

Bit 4-7 See extended device status

0000 = Unknown

0010 = Faulted I/O connection

0011 = No I/O connection established

0100 = Non volatile configuration bad

0110 = Connection in run mode

0111 = Connection in idle mode

Bit 8 Is set for minor recoverable faults.

Bit 9 Is set for minor recoverable faults.

Bit 10 Is set for major recoverable faults.

Bit 11 Is set for major unrecoverable faults.

Bit 12-15 Reserved, set to 0.

Page 46

Appendix C – Ethernet/IP Objects

Assembly Object (Class 0x04)

The Assembly object uses static assemblies. The assembly instance IDs used are in the vendor specific range.

Services

Class services Get Attribute Single

Instance services

Class Attributes

# Access Name Type Value Description

1 Get Revision UINT 0x0002 Revision 2

2 Get Max Instance UINT 0x0096 The highest initiated instance number

Instance Attributes, Instance/Connection Point 0x03 (3d)

Get Attribute Single

Set Attribute Single

40

# Access Name Type Value Description

3 Get Data - - Heart beat instance

Instance Attributes, Instance/Connection Point 0x64 (100d)

# Access Name Type Value Description

3 Get Data

ARRAY of

BYTES

- Data produced by module

See “Appendix A - EGD, EtherNet/IP

IO Format”

Instance Attributes, Instance/Connection Point 0x65 (101d)

# Access Name Type Value Description

3 Get Data

ARRAY of

BYTES

-

Contains the same data as in EGD

exchange P2.

Instance Attributes, Instance/Connection Point 0x96 (150d)

# Access Name Type Value Description

3 Set Data

ARRAY of

BYTES

- Data consumed by module

See “Appendix A - EGD, EtherNet/IP

IO Format”

Page 47

Appendix C – Ethernet/IP Objects

Fuji Vendor Specific Object (Class 0x64)

This is a vendor specific object that makes it possible to read/write all Communication No. in the drive.

Services

Class services Get Attribute All

Instance services Get Attribute Single

Set Attribute Single

Class Attributes

# Access Name Type Value Description

1 Get Revision UINT 0x0001 Revision 1

Instance Attributes

41

If a Communication No is reporting ”Non existing error” the attribute does not exist.

# Access Name Type Value Description

1 Get/Set Parameter 1 UINT N/A

… Get/Set Parameter n UINT N/A

255 Get/Set Parameter 255 UINT N/A

Communication No 1 in the Fuji

Parameter List

Communication No n in the Fuji

Parameter List

Communication No 255 in the Fuji

Parameter List

Page 48

Appendix C – Ethernet/IP Objects

TCP/IP Interface Object (Class 0xF5)

Services

42

Class services

Instance services

Get Attribute All

Get Attribute Single

Get Attribute All

Get Attribute Single

Set Attribute Single

Class Attributes

# Access Name Type Value Description

1 Get Revision UINT 0x0001 Revision 1

Instance Attributes

# Access Name Type Value Description

1 Get Status DWORD 0x00000001

2 Get

3 Get/Set

4 Get

5 Get/Set

6 Get/Set Host Name STRING - Host name

Configuration

capability

Configuration

control

Physical Link

Object

Path size UINT 0x0002 2 words

Path

Interface

configuration

IP Address UDINT - Module’s IP address

Network Mask UDINT - Module’s Network mask

Gateway Address UDINT - Module’s Gateway address

Name Server UDINT - Not used

Name Server 2 UDINT - Not used

Domain Name STRING - Not used

DWORD 0x00000014

DWORD -

Struct of: