Page 1

GE Energy

ACE184 Series Power Shelf

Main Output: 600A; Standby output: 8A

Applications

12Vdc distributed power architectures

Mid-End Servers

Blade Servers

Network Equipment

Network Attached Storage

Storage Area Networks

Preliminary Data Sheet

Features

Fits in a 19” wide rack system

Designed for ETS300 rack mounting.

Supported by a retracted side ‘runner’

1U high

Accommodates hot swap capability

Accepts up to 4 modules

Proved in with the CAR1812 and CAR1612

rectifiers

Active current sharing

Hot insertion/removal (hot plug)

UL, CSA and VDE certified

EMI: class A FCC docket 20780 part 15, EN55022

System meets EN6100 immunity and transient

standards

Shock & vibration: IPC-9592A, Class II

Routers/Switches

Enterprise Networks

Advanced workstations

Description

The ACE184 series of Power Shelves are designed for the Datacom and Server market segments. These shelves are

designed to minimize installation and maintenance time with easy access warm-swap insertion, accommodating, up

to 4 modules, rectifiers or converters, with output voltages as high as 60Vdc, in a 19” wide enclosure compliant to

ETS300 rack mounting standards. All the necessary interfacing for output and signaling needs are provided. The

signaling pins of each module are separately brought out for maximum flexibility.

October 29, 2012 ©2012 General Electric Company. All rights reserved.

Page 2

GE Energy

Preliminary Data Sheet

ACE184 Series Power Shelf

Main Output: 600A; Standby output: 8A

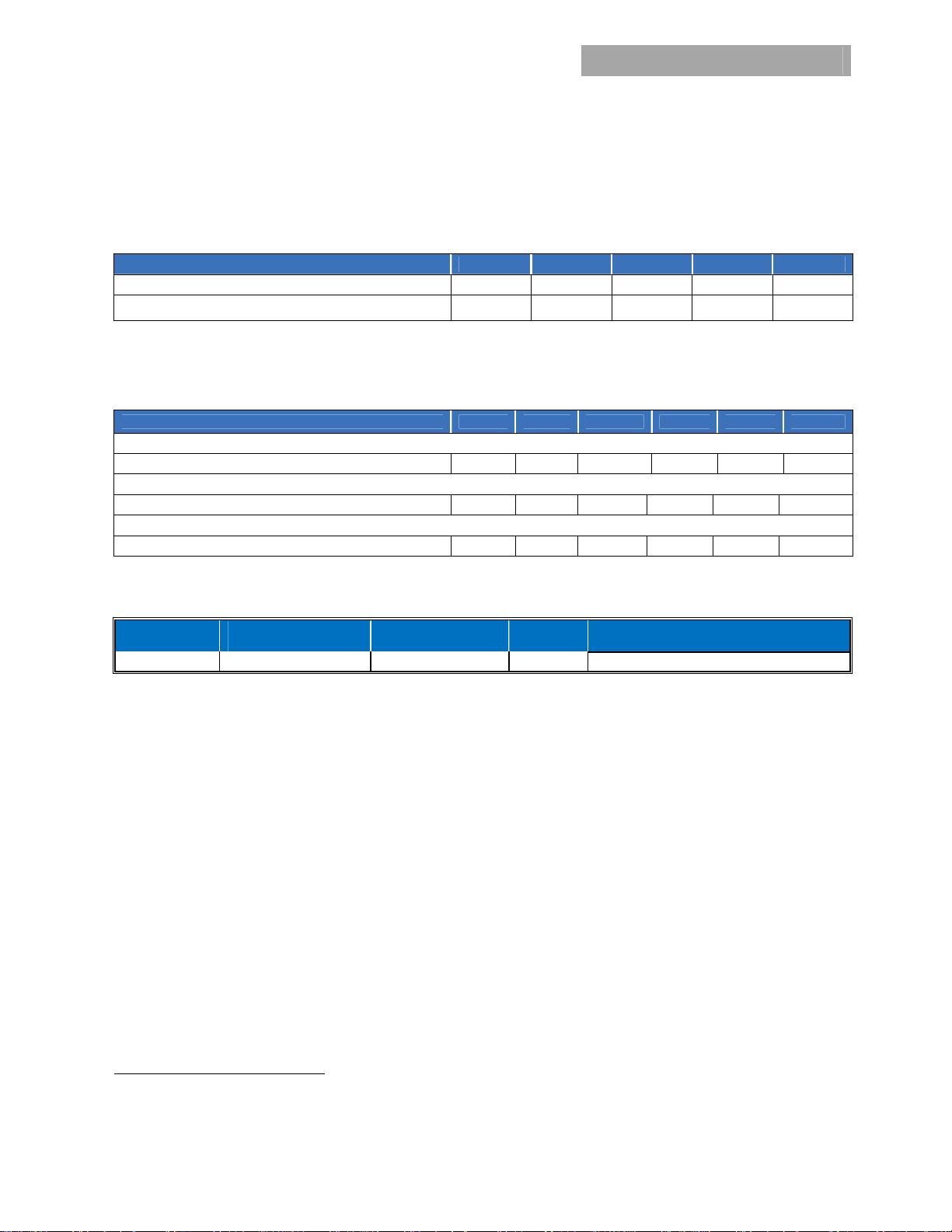

Absolute Maximum Ratings

Stresses in excess of the absolute maximum ratings can cause permanent damage to the device. These are absolute stress ratings

only, functional operation of the device is not implied at these or any other conditions in excess of those given in the operations

sections of the data sheet. Exposure to absolute maximum ratings for extended periods can adversely affect the device reliability.

Parameter Device Symbol Min Max Unit

Operating Ambient Temperature All TA -10 70 °C

Storage Temperature All Tstg -40 85 °C

Electrical Specifications

Unless otherwise indicated, specifications apply over all operating input voltage, resistive load, and temperature conditions.

Parameter Device Symbol Min Typ Max Unit

OUTPUT

Main output All I

Standby Output All I

Isolation1 Output - Ground All 500 Vdc

out

0 8 A

out

0 600 A

dc

dc

Port Phenomena test criteria Reference standard

Enclosure ESD (immunity) 8 kVair 4 kVcontact A EN 61000-4-2

1

Isolation in the context of this data sheet documents the capability of the shelf. Actual isolation capability may be further reduced by the isolation

capability of the utilized modules. Consult the module data sheet for actual capability.

October 29, 2012

©2012 General Electric Company. All rights reserved. Page 2

Page 3

GE Energy

ACE184 Series Power Shelf

Main Output: 600A; Standby output: 8A

Status and Control

Some features, such as programming of the output voltage,

may be controlled both by hardware and firmware.

Unless otherwise noted, control of the output voltage via the

signal pin (Vprog) is ‘active’ and overrides as long as the

signal voltage is ≤ 3Vdc. A firmware initiated command,

attempting to change the output voltage will be ignored as

long as the signal voltage (Vprog) is ≤ 3Vdc

Details of analog controls are provided in this data sheet

under Signal Definitions. GE Energy will provide separate

application notes for the I2C protocol ( Document

#97FS2855). Contact your local GE Energy sales

representative for details.

Note that most control and capability functions

Signal Definitions

All signals and outputs are referenced to Output return.

These include ‘Vstb return’ and ‘Signal return’.

Input Signals

Note: Refer to the individual rectifier data sheets for

supported features.

Voltage programming (V

signal can vary the output voltage of all modules.

If 12V output CAR1812 or CAR1612 rectifiers are used, the

output can vary ± 10% from 10.8Vdc to 13.2Vdc. The

equation of this signal is:

V

= 10.8 + (V

out

If 2.5 < Vprog < 3, the output is 13.2V. If Vprog is > 3V or left

open the programming signal is ignored and the unit output

is set at the setpoint of 12Vdc.

This signal is paralleled among the power supplies.

Load share (Ishare): This is a single wire analog signal that is

generated and acted upon automatically by power supplies

connected in parallel. The Ishare pins are tied together

among the power supplies in the shelf. No resistors or

capacitors should get connected to this pin.

Remote ON/OFF: Controls the presence of the main output

voltage. This is an open collector, TTL level control signal.

This signal needs to be pulled HI externally through a

resistor. Maximum collector voltage is 12Vdc and the

maximum sink current is 1mA. A Logic 1 (TTL HI level) turns

ON the main output, while a Logic 0 (TTL LO level) turns OFF

the main output.

This signal is not overwritten by the firmware ON/OFF

instruction. The default firmware setting is ON. An OFF

command either through this signal or firmware would turn

OFF the power supply.

The default state re-initializes if bias power is interrupted to

the processor.

These signals are brought out independently for each power

supply.

* 0.96) 0 < V

prog

): An analog voltage on this

prog

< 2.5

prog

Preliminary Data Sheet

Enable (ON/OFF): This is a short signal pin that controls the

presence of the main output. This pin should be connected

to ‘output return’ on the system side of the output

connector. The purpose of this pin is to ensure that the

output turns ON after engagement of the power blades and

turns OFF prior to disengagement of the power blades.

These signals are brought out independently for each power

supply.

Write protect (WP): This signal protects the contents of the

EEPROM from accidental over writing. When left open the

EEPROM is write protected. A LO (TTL compatible) permits

writing to the EEPROM. This signal is pulled HI internally by

the power supply. Note: only for factory programming.

This signal is interconnected among the power supplies

Output signals

Output current monitor (Imon): A voltage level proportional

to the delivered output current is present on this pin. The

signal level is 150A = 3V when the CAR182 or CAR1612

rectifiers are used.

These signals are brought out independently for each power

supply.

INPUT OK: A TTL compatible status signal representing

whether the input voltage is within the anticipated range.

This signal needs to be pulled HI externally through a

resistor.

These signals are brought out independently for each power

supply.

DC OK: A TTL compatible status signal representing

whether the output voltage is present. This signal needs to

be pulled HI externally through a resistor.

These signals are brought out independently for each power

supply.

Over temp warning: A TTL compatible status signal

representing whether an over temperature exists. This signal

needs to be pulled HI externally through a resistor.

These signals are brought out independently for each power

supply.

If an over temperature should occur, this signal would pull

LO for approximately 10 seconds prior to shutting down the

power supply. The unit would restart if internal temperatures

recover within normal operational levels. At that time the

signal reverts back to its open collector (HI) state.

Fault: A TTL compatible status signal representing whether

a Fault occurred. This signal needs to be pulled HI externally

through a resistor.

These signals are brought out independently for each power

supply.

This signal activates for OTP, OVP, OCP, AC fault or No

output.

Module Present: This pin is connected to ‘output return’

within the power supply. Its intent is to indicate to the

system that a power supply is present. This signal may need

to be pulled HI externally through a resistor.

October 29, 2012 ©2012 General Electric Company. All rights reserved. Page 3

Page 4

GE Energy

ACE184 Series Power Shelf

Main Output: 600A; Standby output: 8A

These signals are brought out independently for each power

supply.

Interrupt (SMBAlert): A TTL compatible status signal,

representing the SMBusAlert# feature of the PMBus

compatible i

needs to be pulled HI externally through a resistor.

Maximum sink current ≤ 4mA and the pull up resistor should

be tied to 3.3Vdc. Open collector (HI) on this signal indicates

that no Interrupt has been triggered.

This signal is paralleled among the power supplies.

Serial Bus Communications

The I²C interface facilitates the monitoring and control of

various operating parameters within the unit and transmits

these on demand over an industry standard I²C Serial bus.

All signals are referenced to ‘Signal Return’.

Device addressing: The microcontroller (MCU) and the

EEPROM have the following addresses:

Device Address Address Bit Assignments

MCU 0xBx 1 0 1 1 A2 A1 A0 R/W

EEPROM 0xAx 1 0 1 0 A2 A1 A0 R/W

Address lines (A1, A0): These signal pins allow up to four (4)

modules to be addressed on a single I²C bus. The pins are

configured automatically in the shelf. Rectifier addressing

increments from left to right as viewed from the front.

Address line (A2): This bit sets the address of the shelf. The

bit setting depends on the rear accessible dip switch and pin

51 of the signal connector. In order to set the address HI

(‘1’), the dip switch needs to be set to Mark 1 and the signal

pin needs to be left open. Setting the dip switch to Mark 0 or

grounding pin 51 will configure the shelf to address bit 0

(LO).

Serial Clock (SCL): The clock pulses on this line are generated

by the host that initiates communications across the I²C

Serial bus. This signal is pulled up internally to 3.3V [ 5V

a 10kΩ resistor. The end user should add additional pull up

resistance as necessary to ensure that rise and fall time

timing and the maximum sink current is in compliance to

the I²C specifications.

This signal is paralleled among the power supplies.

Serial Data (SDA): This line is a bi-directional data line. . This

signal is pulled up internally to 3.3V [ 5V ] by a 10kΩ resistor.

The end user should add additional pull up resistance as

necessary to ensure that rise and fall time timing and the

maximum sink current is in compliance to the I²C

specifications.

This signal is paralleled among the power supplies.

2

C protocol in the power supply. This signal

(Most to Least Significant)

2

] by

Preliminary Data Sheet

Another separate EEPROM IC will provide another 128 bytes

of memory with write protect feature. Minimum information

to be included in this separate EEPROM: model number,

revision, date code, serial number etc.

See the communications protocol for further information.

Communications Protocol

The I²C protocol is described in detail by the I2C and PMBus

Serial Communications Protocol for the CAR Family of

Power Supplies application note.( Document # 97FS2855)

EEPROM

The microcontroller has 96 bytes of EEPROM memory

available for the system host.

2

Module configured with 5V standby output

October 29, 2012

©2012 General Electric Company. All rights reserved. Page 4

Page 5

GE Energy

ACE184 Series Power Shelf

Main Output: 600A; Standby output: 8A

Outline Drawing

Preliminary Data Sheet

Perforated areas need to be

exposed for cooling purposes

Dip switch for Shelf Address:

Mark 0 – ‘A2 pin set to 0’

Mark 1 – ‘A2 pin set to 1’

(if Pin51 is not grounded)

Output Power Terminations

The outputs of the four power supplies are internally connected in parallel and brought out on the rear panel via four sets of

M6 studs with 5/8 inch center spacing, accommodati ng industry standard lugs. The lug terminations can e xit the sh e lf either

above or below the shelf, or to the rear when right angle lugs are utilized. An insulation cover is provided over the lug

terminations and it ca n be rotated to accommodate the cables exiting either upward or downward.

The maximum output current capacity of the lug/wire combination should be sized to carry 300 amperes per set when two

lugs are utilized.

October 29, 2012 ©2012 General Electric Company. All rights reserved. Page 5

Page 6

53

54

55

56

57

58

59

60

GE Energy

Preliminary Data Sheet

ACE184 Series Power Shelf

Main Output: 600A; Standby output: 8A

Connector Pin Assignments

Signal Connector: shelf end: Tyco AMP P/N 1-5499786-1

Mate: Tyco AMP P/N 1-1658621-1

Pin

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Ordering Information

Please contact your GE Energy Sales Representative for pricing, availability and optional features.

Signal Function Pin Signal Function Pin Signal Function

INPUT OK 1

DC OK 1

Mod present 1

Temp OK 1

On / Off 1

Imon 1

N.C.

Fault 1

INPUT OK 2

DC OK 2

Mod present 2

Temp OK 2

On / Off 2

Imon 2

N.C.

Fault 2

INPUTOK 3

DC OK 3

Mod present 3

Temp OK 3

PRODUCT DESCRIPTION PART NUMBER

600A Shelf Power Shelf capable of delivering 600A of main output and 8A of Standby power ACE184RUW12XZ01A

INPUT OK 1

DC OK 1

Module present 1

Temp OK 1 24

Remote On / Off 1 25

Current readout 1 26

27

Fault 1

INPUT OK 2

DC OK 2 30

Module present 2 31

OK 2

Temp

Remote On / Off 2

Current readout 2 34

35

Fault 2

INPUT OK 3

DC OK 3

Module present 3 39

Temp OK 3 40

21

22

23

28

29

32

33

36

37

38

On / Off 3

Imon 3

N.C.

Fault 3

INPUT OK 4

DC OK 4

Mod present 4

Temp OK 4

On / Off 4

Imon 4

N.C.

Fault 4

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

Remote On / Off 3

Current readout 3

Fault 3 44

INPUT OK 4 45

DC OK 4 46

Module present 4 47

Temp OK 4

Remote On / Off 4

Current readout 4 50

51

Fault 4

41

42

43

48

49

52

N.C.

I_share

V_prog Voltage Setting

INT

SCL

SDA

WP

RS +

RS -

RTN

Shelf Address

Vsb

Vsb

Vsb

Vsb

N.C.

Vsb_rtn

Vsb_rtn

Vsb_rtn

Vsb_rtn

Current sharing

I²C interrupt

I²C clock line

I²C data line

Write Protect

Positive sense

Negative sense

Signal return

A2 pin

output

standby

output

standby

output

standby

output

standby

standby return

standby return

standby return

return

standby

Contact Us

For more information, call us at

USA/Canada:

+1 888 546 3243, or +1 972 244 9288

Asia-Pacific:

+86.021.54279977*808

Europe, Middle-East and Africa:

+49.89.878067-280

India:

+91.80.28411633

October 29, 2012 ©2012 General Electric Company. All rights reserved. Page 6

www.ge.com/powerelectronics

Loading...

Loading...