Page 1

GE Industrial Systems

6KCV301DNET

DeviceNet interface board

for AV-300i Drives

INSTRUCTIONS

GE Industrial Systems

Page 2

Supersedes GEI-100435 Rev. 0.1 (10/99)

These instructions do not purport to cover all details or variations

in equipment, nor to provide every possible contingency to be met

during installation, operation, and maintenance. If further information is desired or if particular problems arise that are not covered

sufficiently for the purchaser’s purpose, the matter should be referred to GE Industrial Systems.

This document contains proprietary information of General Electric Company, USA and is furnished to its customer solely to assist that customer in the installation, testing, operation, and/or

maintenance of the equipment described. This document shall not

be reproduced in whole or in part nor shall its contents be disclosed to any third party without the written approval of GE Industrial Systems.

© 1999 by General Electric Company, USA. All rights reserved.

Page 3

6KCV301DNET

TABLE OF CONTENTS

1.0 INTRODUCTION ................................................................... 5

1.1 THE MANUAL ........................................................................................... 5

1.2 DEVICENET GENERAL DESCRIPTION ......................................................... 6

2.0 HARDWARE DESCRIPTION ................................................. 7

2.1 DIMENSIONS, WEIGHT, PROTECTION DEGREE........................................... 7

2.2 INSTALLATION ......................................................................................... 8

2.3 POWER SUPPLY ..................................................................................... 10

2.4 TERMINALS ........................................................................................... 10

2.5 LEDS ...................................................................................................... 10

2.6 TECHNICAL SPECIFICATION ................................................................... 11

2.7 INTERFACE ............................................................................................. 11

3.0 DEVICENET FUNCTION ...................................................... 12

3.1 OBJECT DESCRIPTION ........................................................................... 13

3.1.1 Object Model ................................................................................. 13

3.1.2 How Objects Affect Behavior. .......................................................... 14

3.1.3 Defining Object Interface ................................................................ 14

3.1.4 I/O Assembly Instances ................................................................... 15

3.1.5 I/O Assembly Data Attributes Format ............................................... 15

3.2 DATA TRANSFER VIA EXPLICIT MESSAGING .......................................... 15

3.2.1 Drive Parameter Access ................................................................. 16

3.2.1.1 Class code ...................................................................................... 16

3.2.1.2 Class attributes ............................................................................... 16

3.2.1.3 Instance Attributes ......................................................................... 16

3.2.1.4 Common Services ........................................................................... 16

3.2.1.5 Object Specific services .................................................................. 16

3.2.1.6 Behavior ......................................................................................... 17

3.2.1.6.1 Write Drive Parameter ................................................................ 17

3.2.1.6.1.1 Write Drive Parameter Request ............................................... 17

3.2.1.6.1.2 Write drive parameter - Reply OK ............................................ 18

3.2.1.6.1.3 Write drive parameter - Reply Error ........................................ 18

3.2.1.6.2 Read Drive Parameter ................................................................. 18

3.2.1.6.2.1 Read Drive Parameter Request ............................................... 18

3—————— TABLE OF CONTENTS ——————

Page 4

SIEI

3.2.1.6.2.2 Read drive parameter - Reply OK ............................................ 19

3.2.1.6.2.3 Read drive parameter - Reply Error ......................................... 19

3.2.2 DGF Option Parameter Access .......................................................... 19

3.2.2.1 Class code ...................................................................................... 20

3.2.2.2 Class attributes ............................................................................... 20

3.2.2.3 Instance Attributes ......................................................................... 20

3.2.2.4 Common Services ........................................................................... 20

3.2.2.5 Object Specific services .................................................................. 20

3.2.2.6 Behavior ......................................................................................... 20

3.2.2.6.1 Write DGF Parameter .................................................................. 21

3.2.2.6.1.1 Write DGF Parameter Request ................................................. 21

3.2.2.6.1.2 Write DGF parameter - Reply OK ............................................. 21

3.2.2.6.1.3 Write DGF parameter - Reply Error .......................................... 22

3.2.2.6.2 Read DGF Parameter .................................................................. 22

3.2.2.6.2.1 Read DGF Parameter Request ................................................. 22

3.2.2.6.2.2 Read DGF parameter - Reply OK .............................................. 23

3.2.2.6.2.3 Read DGF parameter - Reply Error .......................................... 23

4.0 POLLING FUNCTION ........................................................... 24

5.0 SETTING OF VIRTUAL DIGITAL I/O ..................................... 25

6.0 KEYBOARD INTERFACE...................................................... 26

6.1 MAIN MENU STRUCTURE ...................................................................... 26

6.1.2 Warning and error message handling ............................................. 26

6.2 SBI INFO MENU ...................................................................................... 27

6.2.1 Display node address (MAC ID) ...................................................... 28

6.2.2 Display Baud Rate .......................................................................... 28

6.2.3 Node status .................................................................................... 28

6.2.3.1 DeviceNet error types .................................................................... 29

6.2.4 Status of allocation ......................................................................... 31

6.2.5 CNXN status ................................................................................... 32

6.2.6 I/O CNXN status .............................................................................. 32

6.2.7 DUP MAC ID test (DMC) ................................................................. 33

6.2.8 Display Software version (Sotware version) ................................... 33

6.2.9 Display compatibility index(Compatib. index) .................................. 33

7.0 MISCELLANEOUS ............................................................... 34

7.1 DEFINITIONS ........................................................................................... 34

7.2 REFERENCES .......................................................................................... 34

—————— TABLE OF CONTENTS ——————4

Page 5

6KCV301DNET

1.0 INTRODUCTION

The manual describes the optional 6KCV301DNET card for connecting of

inverters and converters to DeviceNet networks.

A V300i drives can be connected in network through the 6KCV301DNET card.

This manual is intended for design engineeres and technicians responsible for

the maintenance, commissioning and operation of DeviceNet systems.

A basic knowledge of DeviceNet is assumed and may be found in the follow-

ing manuals:

- DeviceNet Specifications. Volume 1 - DeviceNet Communication Model

and Protocol (Issued by ODVA).

- DeviceNet Specifications. V olume 2 - DeviceNet Device Profiles and Object Library (Issued by ODV A).

1.1 THE MANUAL

Chapter 2 Dimensions, card mechanical installation, electric

connections and Dipswitch setting.

Chapter 3 DeviceNet functions: description of the objects

controlled by the card, data transfer via “Explicit

messaging”.

Chapter 4 “Polling” operations for the exchange of Drive pa-

rameters between the Master and the interface card

(M->S and S->M)

Chapter 5 Setting of virtual digital I/Os

Chapter 6 Keypad menus

Chapter 7 Definitions and references

—————— Interface card DeviceNet ——————

5

Page 6

GEI-100435A

1.2 DEVICENET GENERAL DESCRIPTION

DeviceNet is a profile of communication for industrial systems based on CAN.

As protocol CAN (ISO 11898) is used CAN2.0A with the 11 bit identifier .

The SBI card is developed as “Slave UCMM Capable Device” for operating

only in “Predefined Master/Slave Connection Set”.

The data transfer is carried out cyclically; the Master unit reads the data supplied by the Slaves and writes the Slave reference data; the Baud Rate supported by the SBI card are:

- 125 kbit

- 250 kbit

- 500 kbit .

The physical support is given by the RS485 serial line; a maximum of 64 Slaves

can be connected to the Bus.

6

—————— Interface card DeviceNet ——————

Page 7

6KCV301DNET

2.0 HARDWARE DESCRIPTION

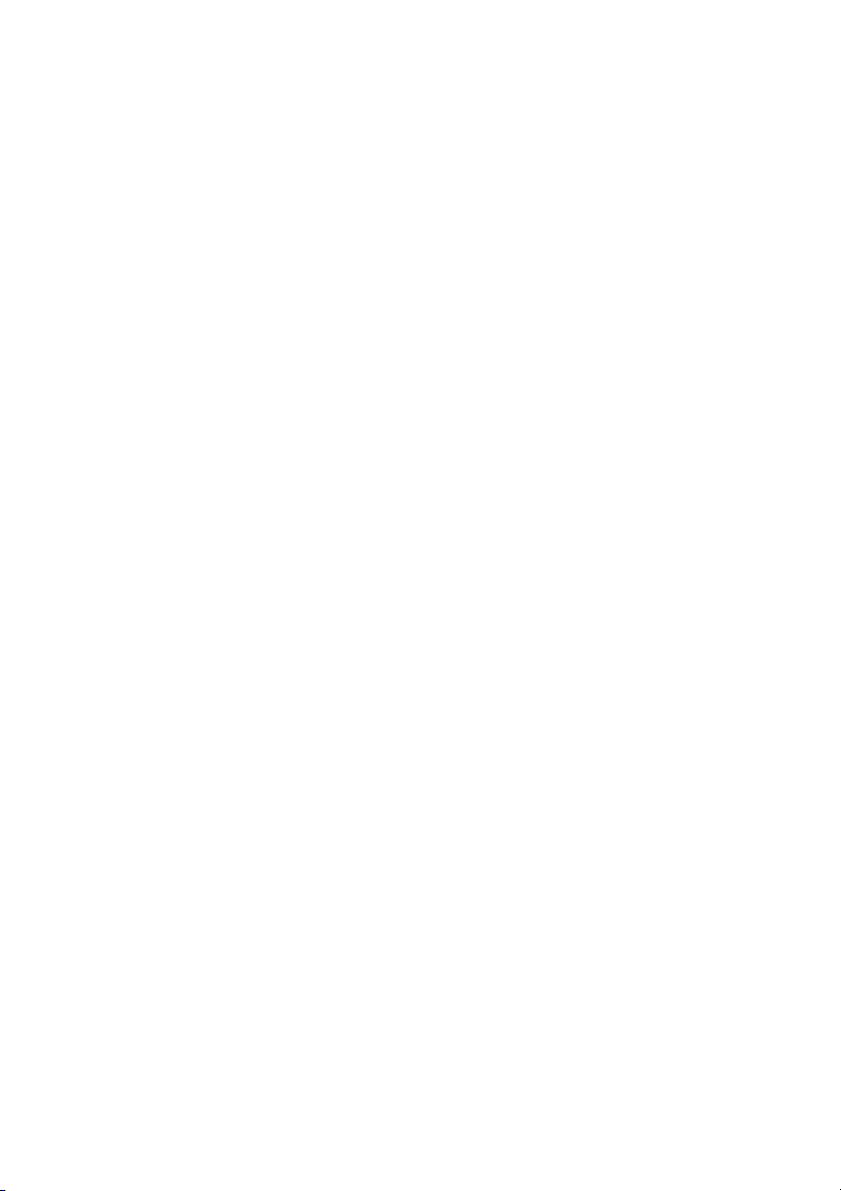

2.1 DIMENSIONS, WEIGHT, PROTECTION DEGREE

Component side Soldering side

SBI- /DN-33

145 mm [5,7“]

88 mm [3,4“]

BUS terminal Ground

Dimensions 145 [5.7”] x 88 [3.4”] x 30 [1.2]mm [in.] (H) x (W) x (D)

W eight 88 g [3.1 oz]

Protection degree IP00

—————— Interface card DeviceNet ——————

7

Page 8

GEI-100435A

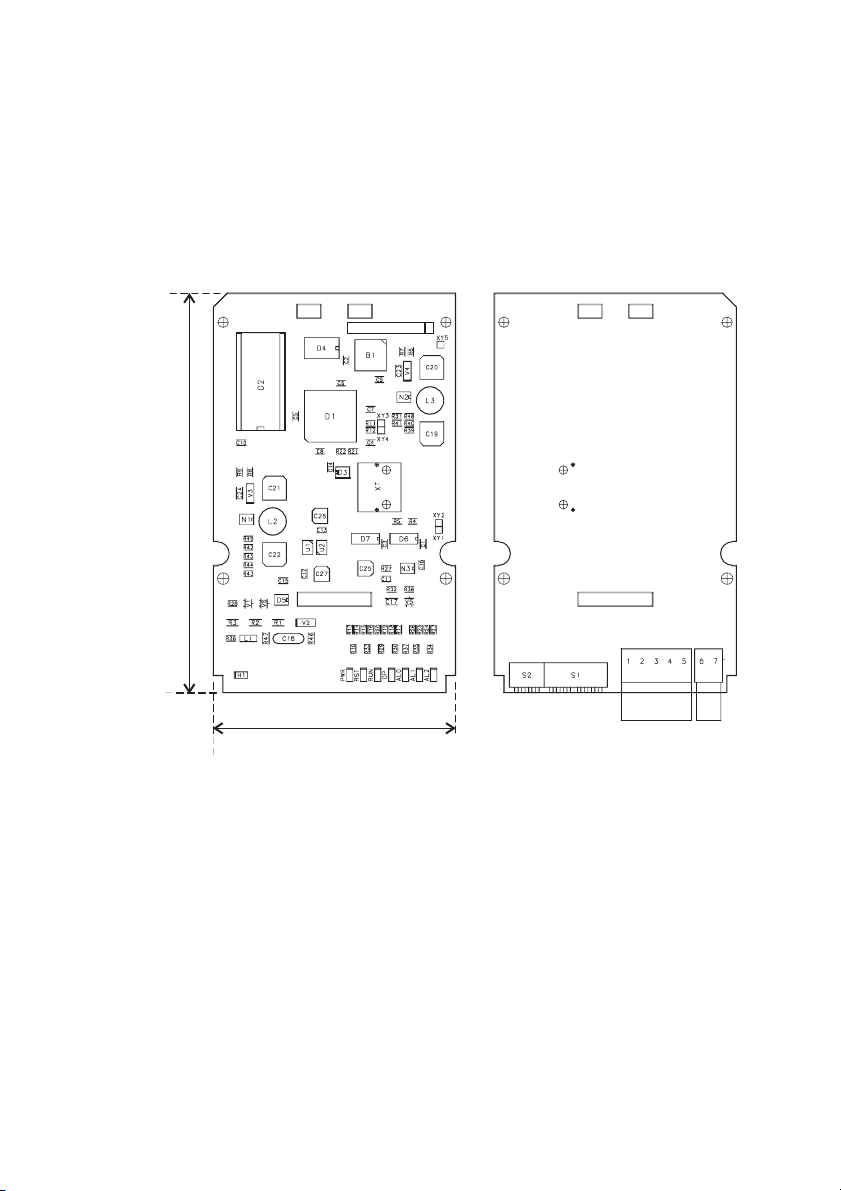

2.2 INSTALLATION

The SBI card is supplied with standoffs, screws, washers and a SBI-Drive link

cable provided with connectors.

1 . Switch the drive off.

2 . If the card is mounted inside the drive (see example below), fasten the SBI

card to the drive regulation card by means of screws (B) and standoffs

(A). The SBI-Drive link cable (C) must be connected between XT1 (on

Regulation card) and XT connector (on SBI card).

If the card is mounted outside the drive, the SBI card has to be fastened to

a DIN rail by using the external mounting kit; it is recommended to keep

the SBI card as close as possible to the drive. Do not put the SBI-Drive link

cable near power cables.

3. The SBI-Drive link cable is connected to the XT connector on the SBI-card.

8

—————— Interface card DeviceNet ——————

Page 9

6KCV301DNET

4. The Baud Rate of the SBI card is set via the Switches 7 and 8 of the

Dipswitch S1. The Baud Rate is detected only when the card is switched

on and it can be modified only by switching off and swtching on the card

again.Table 2 shows the relation between the DIP-Switches and the selectable Baud Rate value. The Default value is 125 Kbaud.

Switch 8 Switch 7 Baud Rate

OFF OFF 125 kBaud

OFF ON 250 kBaud

ON OFF 500 kBaud

ON ON 125 KBaud

DN21

.

5 . The switches 1..6 of the Dip-Switch S1 determine the address.

The address is only detected when the card is switched on. If the address

has been modified, the SBI card has first to be switched off and then on in

order assume the new address.

6. The Dip-Switch S2 determines the amount of words exchanged over the

Polling I/O. The table describes the relationship between the switches and

the number of Polling I/O words.

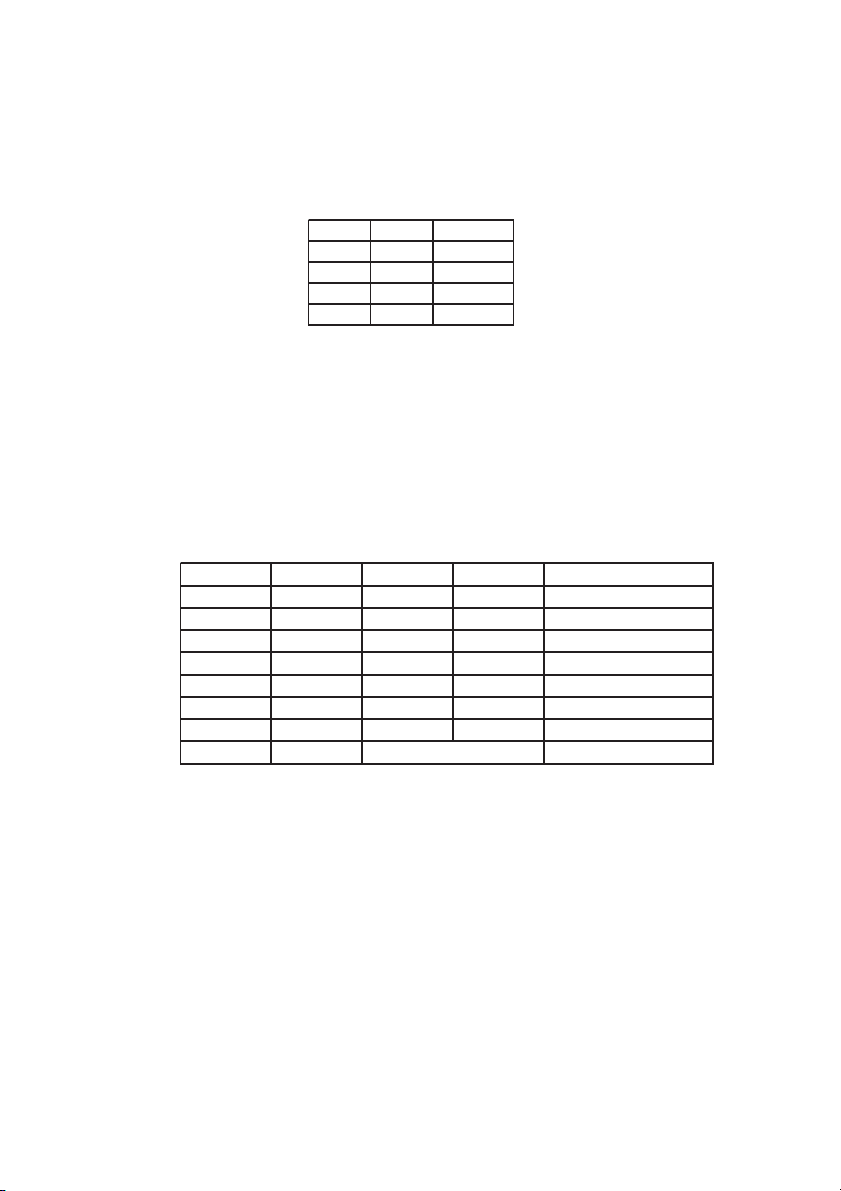

switch 4 switch 3 switch 2 switch 1 # of Polling I/O word

OFF OFF OFF OFF 1

OFF OFF OFF ON 1

OFF OFF ON OFF 2

OFF OFF ON ON 3

OFF ON OFF OFF 4

OFF ON OFF ON 5

OFF ON ON OFF 6

All Other 6

Combination

tdn0010

The Polling I/O word number is only detected when the card is switched on. If

the polling I/O word number has been modified, the SBI card has first to be

switched off and then on.

7 . Connect the Bus cable to the BUS terminal.

8 . Switch on the drive.

9 . The LEDS PWR and RUN light up.

10. Switch the Device Net power supply on; the LED H1 lights up.

11. The LED OP lights up when the Master/Slave connection has been established.

—————— Interface card DeviceNet ——————

9

Page 10

GEI-100435A

2.3 POWER SUPPLY

The power supply is provided by the XT connector which is also used to

transfer data between the SBI card and the drive regulation card.

Current draw: 350 mA

2.4 TERMINALS

Ground terminals (6-7) DeviceNet cable shield is connected to the ground

(PE) through these terminals.

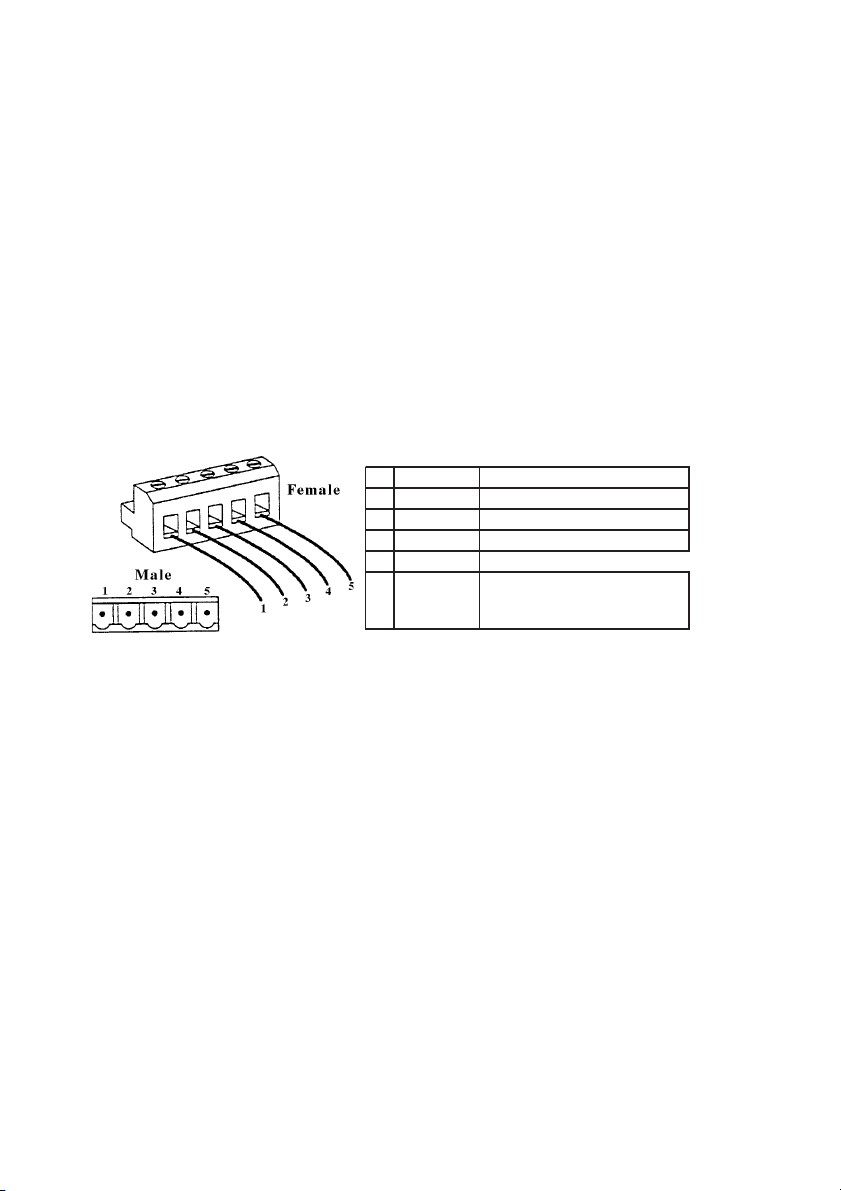

T erminal BUS See the figure below. It allows to connect the SBI

card to the DeviceNet network. The pins are the

following:

Pin Signal Description

1 CAN_GND Ground / 0V /V2 CAN_L Can_L bus line (dominant low)

3 CAN_SHLD CAN shield

4 CAN_H CAN_H bus line (dominant high)

5 CAN_V+

CAN external positive supply

(dedicated for supply of

transceiver and optocouplers)

dn22

2.5 LEDS

PWR +5V power supply .

RST Reset active.

H1 +5V power supply on the RS 485 driver side. It is

supplied by the Bus.

RUN It is on when the microcontroller is operating.

OP It is on when the Master/Slave connection is es-

tablished.

AL0 It blinks when the “Duplicate MAC ID” test has

not been passed.

AL1, AL2 Not used and are always off.

10

—————— Interface card DeviceNet ——————

Page 11

6KCV301DNET

2.6 TECHNICAL SPECIFICATION

Storage temperature: -20°... +70°C (-68...+158°F)

Operating temperature: 0°... +55°C (32...+131°F)

Such temperatures are suitable to be used with those of the drive, which they

are connected to.

2.7 INTERFACE

For the mechanical connection, according to the internal or external mounting,

please use the kit and the mounting instruction sheet supplied with the card.

For the electrical connection please use the SBI-Drive link cable, also supplied.

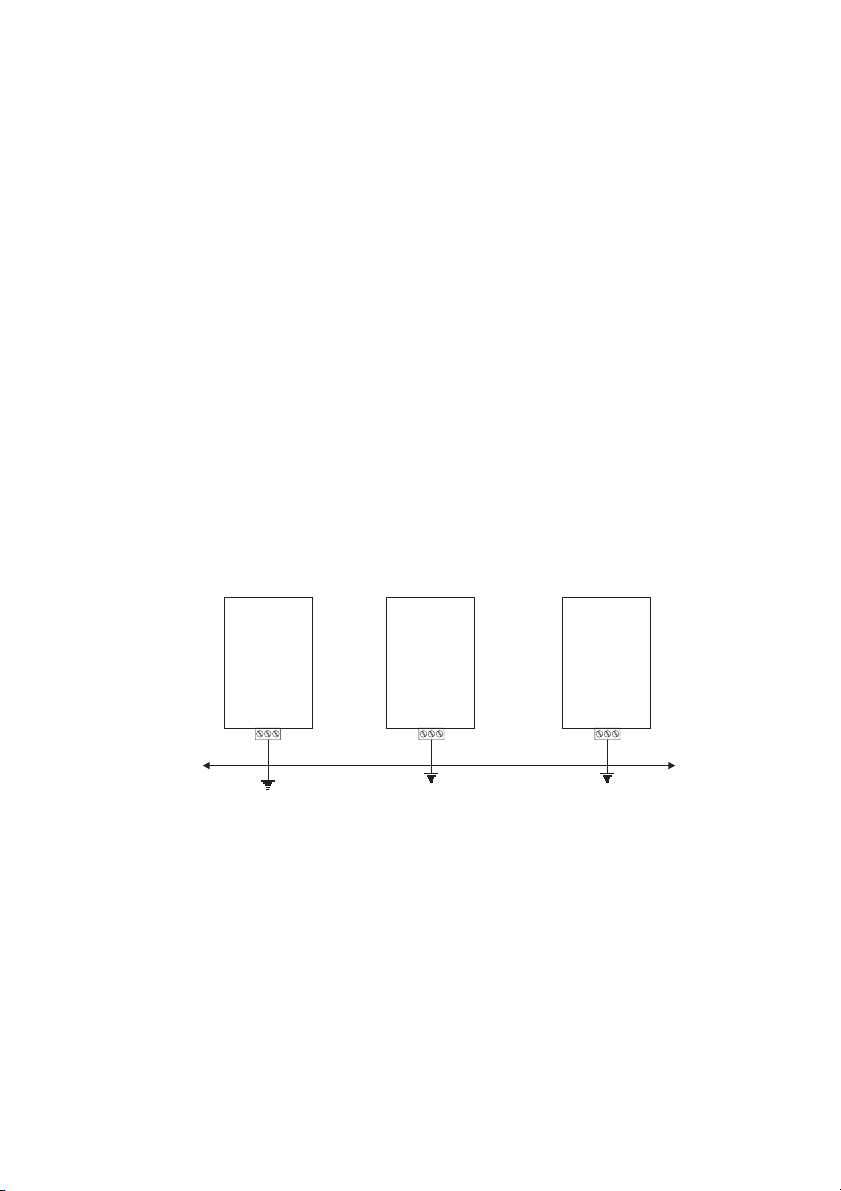

For the connection to the Bus please use a shielded twisted cable recom-

mended by DeviceNet specification.

The connection among the single cards is accomplished by a shielded cable as

shown in the following figure:

6KCV301DNET

6KCV301DNET 6KCV301DNET

—————— Interface card DeviceNet ——————

PE

Shield

11

Page 12

GEI-100435A

3.0 DEVICENET FUNCTION

In this chapter are described the functions of DeviceNet managed by the SBI

card. The main characteristics of the card are:

1 . The card operates only as Slave in “Predifined Master/Slave Connection

Set”.

2. W ithin the “Predefined Master/Slave Connection Set” the card is a “UCMM

Capable Device”.

3 . The “Explicit Messaging” is managed.

4. The “Polling” for the fast cyclical data exchange Master/Slave is managed.

5 . The detection mechanism of the “Duplicate MAC ID” is implemented.

Regarding the “Explicit Messaging” the fragmentation of the data frame, with

a total of max. 38 byte, is managed.

Connection sizes

CONNECTION INSTANCE PRODUCED CONSUMED

Polled I/O

Explicit messaging 38 38

12

—————— Interface card DeviceNet ——————

Dependent on frame setting

tdn30020

Page 13

6KCV301DNET

3.1 OBJECT DESCRIPTION

Hereafter you find the description of the objects managed by the SBI card.

3.1.1 Object Model

The Fig. 3.11 shows the SBI card “Object Model”.

Application Objects

DGF par

Assembly Class

I/OI/O

Drive par

Message

Router

Connection

ExplicitI/O

Figure 3.1: DeviceNet Object Model

The following table shows:

1 . The object classes of the SBI-card.

2 . If the class is mandatory.

3. The number of instances included in every class.

See “DeviceNet Specifications” for the Standard classes.

IDENTITY

DeviceNet

—————— Interface card DeviceNet ——————

13

Page 14

GEI-100435A

Object Optional/Required # of Instances

Identity Required 1

Message Router Required 1

DeviceNet Required 1

Connection Required at maximum one Explicit

Assembly Optional 0..2

Drive Parameter Access Optional many

DGF Parameter Access Optional many

tdn0030ge

3.1.2 How Objects Affect Behavior.

The “Affect Behaviour” of the objects is reported in the following table:

Object

Identity

Message Router

DeviceNet

Connection

Assembly

Drive Parameter Access

DGF Option Parameter Access

Effect on Behavior

Supports “Reset Service”.

No effect

Port attributes configuration

Contains the number of logical ports

internal or external to the SBI board

Defines the I/O data format

Drive parameters read/write

DGF parameters read/write

3.1.3 Defining Object Interface

The object interface of the SBI card is the following:

Object Interface

Identity Message router

Message Router

DeviceNet Message router

Connection Message router

Assembly

Drive Parameter Access Message router

DGF Parameter Access Message router

Explicit Messaging

Connection Instance

I/O Connection or

Message Router

tdn0040ge

tdn0050ge

14

—————— Interface card DeviceNet ——————

Page 15

6KCV301DNET

3.1.4 I/O Assembly Instances

The following table identifies the “I/O Assembly” instances of the SBI card:

Number Type Name

195 Input PMSCS Assembly Cons

194 Output PMSCS Assembly Prod

DN325

3.1.5 I/O Assembly Data Attributes Format

The “I/O Assembly” attributes format for the Input is the following:

PMSCS Assembly Cons:

Instance Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0

1

2

195

….

….

(n2)-1

n*2

(n) is the number of consumed Words; it depends on frame setting.

word #1 to consume, low byte

word #1 to consume, high byte

word #2 to consume, low byte

….

….

word #n to consume, low byte

word #n to consume, high byte

dn330

PMSCS Assembly Prod:

Instance Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

194

0

1

2

….

….

(n2)-1

n*2

word #1 to produce, low byte

word #1 to produce, high byte

word #2 to produce, low byte

….

….

word #n to produce, low byte

word #n to produce, high byte

dn335

(n) is the number of produced Words; it depends on frame setting.

3.2 DATA TRANSFER VIA EXPLICIT MESSAGING

The data transfer via Explicit Messaging is made through two new objects: one

for accessing the Drive parameters, the other to access the parameters of the

DGF option card.

—————— Interface card DeviceNet ——————

15

Page 16

GEI-100435A

3.2.1 Drive Parameter Access

For reading/writing the drive parameters the Drive Parameter Access object is

defined with the following characteristics:

- Class ID: 66h.

- Class Attribute: Revision

- Instance Attribute: This instance does not provide any attribute.

3.2.1.1 Class code

Class Code: 66hex

3.2.1.2 Class attributes

Number

1 Optional Get Revision UINT

Need in

implementation

Access Rule Name

3.2.1.3 Instance Attributes

Number

Need in

implementation

Access Rule Name

This instance does not provide attributes

3.2.1.4 Common Services

This object has no common services.

3.2.1.5 Object Specific services

Service

Code

32

hex

33

hex

Need in

implementation

Class Instance

n/a Required Get_Drive_Value Read drive parameter value

n/a Required Set_Drive_Value Writes drive parameter value

Service Name Description of Service

DeviceNet

Data Type

DeviceNet

Data Type

Description

of Attribute

Revision of

this object

Description

of Attribute

Semantics of

values

dn345

Semantics of

values

dn350

dn355

16

—————— Interface card DeviceNet ——————

Page 17

6KCV301DNET

3.2.1.6 Behavior

This object is the interface between the DeviceNet network and all Drive parameters. The access to the Drive parameter is carried out by the parameter

index; if the parameter does not exist or may not be accessed for any reason

(for example: try to write a read only parameter) an error code will be returned.

Drive parameters in text format cannot be accessed.

In the following are repeted patterns of how the data frame of data has to be

composed for reading/writing Drive parameters.

3.2.1.6.1 Write Drive Parameter

In this example the writing of a Drive parameter is shown; the cases of positive

or wrong writing are distinguished.

3.2.1.6.1.1 Write Drive Parameter Request

The data frame for writing a drive parameter is composed as follows:

DATA TYPE FIELD VALUE MEANING

Byte

See Note

Byte

1)

Byte or W ord depending on the type of allocation executed by the Master .

2)

The number of bytes of the “Value”-field depends on the length of the

Service

Code

Class ID 66hex

1)

Instance

2)

VA LU E

ID

33hex

XXXX

XX

XX

XX

XX

Set Drive Parameter -

Object Specific Service.

Drive Parameter Access

Class Object.

Drive Parameter Index in

format Low byte-High

byte.

Low byte-Low word drive

parameter value.

High byte-Low word drive

parameter value.

Low byte-High word drive

parameter value.

High byte-High word

drive parameter value.

dn360

Drive parameter; i.e.: if the Drive parameter type is “Integer” the length of

V ALUE is 2 bytes.

—————— Interface card DeviceNet ——————

17

Page 18

GEI-100435A

3.2.1.6.1.2 Write drive parameter - Reply OK

If the Drive parameter is written correctly, the response is:

DATA TYPE FIELD VALUE MEANING

Byte Service Code 33hex OR 80hex

Word Result 0000

Set Drive Parameter

Reply code- Object

Specific Service.

Result field equal to zero

means writing correctly

executed.

dn365

3.2.1.6.1.3 Write drive parameter - Reply Error

If the writing of the drive parameter has been rejected, the response is the

following:

DATA TYPE FIELD VALUE MEANING

Byte Service Code 33hex OR 80hex

Word Result

XXXX

Set Drive Parameter

Reply code- Object

1

Specific Service.

Drive specific error code.

dn370

1) For error codes see chapter 6.0

3.2.1.6.2 Read Drive Parameter

In this example is shown the reading of a Drive parameter; the cases of positive

or wrong reading are distinguished.

3.2.1.6.2.1 Read Drive Parameter Request

The data frame for the Drive parameter reading is composed as follows:

DATA

TYPE

Byte

See Note

See Note1)Instance

FIELD VALUE MEANING

1)

Service

Code

Class ID 66hex

ID

32hex

XXXX

Get Drive Parameter -

Object Specific Service.

Drive Parameter Access

Class Object.

Drive Parameter Index in

format Lowbyte-High

byte.

dn375

1) Byte or W ord depending on the type of allocation executed by the Master.

18

—————— Interface card DeviceNet ——————

Page 19

6KCV301DNET

3.2.1.6.2.2 Read drive parameter - Reply OK

If the Drive parameter is read correctly, the response is:

DATA TYPE FIELD VALUE MEANING

Byte

Word Result 0

Byte 1) XX

Byte 1) XX

Byte 1) XX

Byte 1) XX

Service

VA LU E

Code

32hex OR

80hex

Get Drive Parameter

Reply code- Object

Specific Service.

Result field equal to zero

means reading correctly

executed.

Low byte-Low word drive

parameter value.

High byte-Low word drive

parameter value.

Low byte-High word drive

parameter value.

High byte-High word

drive parameter value.

dn380

1) The number of bytes of the Value-field depends on the length of the Drive

parameter; i.e. if the Drive parameter type is “Integer” the length of V ALUE is 2

bytes.

3.2.1.6.2.3 Read drive parameter - Reply Error

If Drive parameter reading is rejected, the response is the following:

DATA TYPE FIELD VALUE MEANING

Byte

Word Result

Service

Code

32hex OR

80hex

XXXX

Get Drive Parameter

Reply code- Object

Specific Service.

1

Drive specific error code.

dn385

1) For error codes see chapter 6.0

3.2.2 DGF Option Parameter Access

For reading/writing the parameters of the DGF optional card the DGF Parameter

Access object is defined with the following characteristics:

- Class ID: 67h.

Class Attribute: - Revision

Instance Attribute: - This instance does not foresee any attribute.

—————— Interface card DeviceNet ——————

19

Page 20

3.2.2.1 Class code

3.2.2.2 Class attributes

GEI-100435A

Class Code: 67hex

Number

1 Optional Get Revision UINT

Need in

implementation

Access Rule Name

3.2.2.3 Instance Attributes

Number

Need in

implementation

Access Rule Name

This instance does not provide attributes

3.2.2.4 Common Services

This object has no common services.

3.2.2.5 Object Specific services

Service

Code

32

hex

33

hex

Need in

implementation

Class Instance

n/a

Required

n/a Required

Service

Name

Get_DGF_

Value

Set_DGF_

Value

3.2.2.6 Behavior

DeviceNet

Data Type

DeviceNet

Data Type

Description

of Attribute

Revision of

this object

Description

of Attribute

Description of Service

Read DGF option

parameter value

Writes DGF option

parameter value

Semantics of

values

dn345

Semantics of

values

dn350

Dn395ge

This object is the interface between the DeviceNet networkand all parameters

of the optional DGF card that can be mounted on the drive. The access to the

DGF parameter is made by the parameter index and the data type: if the parameter does not exist or cannot be accessed for any reason (i.e. try to write a read

only parameter) a specific DGF error code is returned.

Hereafter are reported patterns of how to compose the data frame for read/write

DGF parameters.

20

—————— Interface card DeviceNet ——————

Page 21

6KCV301DNET

3.2.2.6.1 Write DGF Parameter

In this example the writing of a DGF parameter is reported; cases of positive

and wrong writing are distinguished.

3.2.2.6.1.1 Write DGF Parameter Request

The data frame for writing a DGF parameter is composed as follows:

DATA TYPE FIELD VALUE MEANING

Byte

See Note

Byte

Service

Code

Class ID 67hex

1)

Instance

ID

Data Type

2)

N/U 00

VA LU E

33hex

XXXX

XX

XX

XX

XX

XX

Set DGF Parameter Object Specific Service.

DGF Parameter Access

Class Object.

DGF Parameter Index in

format Low byte-High

byte.

DGF specific data type

code.

Not used; has to be set to

zero.

Low byte-Low word DGF

parameter value.

High byte-Low word DGF

parameter value.

Low byte-High word DGF

parameter value.

High byte-High word

DGF parameter value.

dn3960ge

1) Byte or W ord depending on the type of allocation executed by the Master.

2) For codes see DGFC- manual.

3.2.2.6.1.2 Write DGF parameter - Reply OK

If the DGF parameter is written correctly, the response is:

DATA TYPE FIELD VALUE MEANING

Byte

Word Result 0

Service

Code

33hex OR

80hex

Set DGF Parameter

Reply code- Object

Specific Service.

Result field equal to zero

means writing correctly

executed.

—————— Interface card DeviceNet ——————

dn3970ge

21

Page 22

GEI-100435A

3.2.2.6.1.3 Write DGF parameter - Reply Error

If the writing of the DGF parameter is rejected, the response is:

DATA TYPE FIELD VALUE MEANING

Byte

Word Result

Service

Code

33hex OR

80hex

XXXX

Set DGF Parameter

Reply code- Object

Specific Service

1)

DGF specific error code

dn3975ge

1) For error codes see DGF-manual.

3.2.2.6.2 Read DGF Parameter

In this example the reading of a DGF-parameter is shown; the cases of positive

or wrong reading are distinguished.

3.2.2.6.2.1 Read DGF Parameter Request

The data frame for the reading of a DGF parameter is composed as follows:

DATA TYPE FIELD VALUE MEANING

Byte

See Note

Word

Byte

Byte N/U 0

Service

Code

1)

Class ID 67hex

Instance

ID

Data Type

2)

32hex

XXXX

XX

Get DGF Parameter -

Object Specific Service

DGF Parameter Access

Class Object

DGF Parameter Index in

format Low byte-High

byte

DGF specific data type

code

Not used; has to be set to

zero

dn3980ge

1) Byte or W ord depending on the type of allocation executed by the Master.

2) For data-type codes see DGF-manual.

22

—————— Interface card DeviceNet ——————

Page 23

6KCV301DNET

3.2.2.6.2.2 Read DGF parameter - Reply OK

If the DGF-parameter is read correctly, the response is:

DATA TYPE FIELD VALUE MEANING

Byte

Word Result 0000

Byte

Service

Data Type

VA LU E

32hex OR

Code

N/U 00

80hex

1)

XX

XX

XX

XX

XX

1) For data-type codes see DGF-manual.

Get DGF Parameter

Reply code- Object

Specific Service.

Result field equal to zero

means reading correctly

executed.

DGF specific data type

code.

Not used; has to be set to

zero.

Low byte-Low word DGF

parameter value.

High byte-Low word DGF

parameter value.

Low byte-High word DGF

parameter value.

High byte-High word

DGF parameter value.

dn3985ge

3.2.2.6.2.3 Read DGF parameter - Reply Error

If the reading of the DGF-parameter is rejected, the response is the following:

DATA TYPE FIELD VALUE MEANING

Byte

Word Result

Service

Code

32hex OR

80hex

XXXX

1) For error codes see DGF-manual.

—————— Interface card DeviceNet ——————

Get DGF Parameter

Reply code- Object

Specific Service

1)

DGF specific error code

dn3990ge

23

Page 24

GEI-100435A

4.0 POLLING FUNCTION

This type of DeviceNet-function is used for a fast cyclic exchange of Driveparameters between Master and SBI card.

The characteristics of the Polling-function are:

1. The data frame length is configurable through Dip-Switch and can vary

from 1 to 6 word for both directions (Slave->Master and Master->Slave).

From 1 up to 6 Drive parameters of one W ord each in Input and Output can

be transferred cyclically .

2. The card, as it is a Slave, during the Polling consumes Output data and

produces Input data as response.

The configuration of the Drive parameters transferred via Polling is set by

using configuration parameter allocated in the drive.

For the configuration of the Polling parameters, see the “OPTION 1” chapter of

the drive instruction manual.

24

—————— Interface card DeviceNet ——————

Page 25

6KCV301DNET

5.0 SETTING OF VIRTUAL DIGITAL I/O

The configuration of the Virtual Digital I/Os, is set by using configuration

parameter allocated in the drive.

For the configuration of the “Virtual Digital I/Os” see the “OPTION 1” chapter

of the drive instruction manual.

Remember that in this chapter the virtual digital inputs/outputs refer to the

Drive, it means that the Master can “write” the virtual digital inputs and

“read” the virtual digital outputs.

Virtual digital I/O are descrete signals which can be controlled by the master:

- 16 Input and 16 Output are available with the SBI card.

Virtual Dig I/O are thus an additional terminal strip:

Polling I/O Master>Slave Dig in

0

Enable

1

Start/stop

0

1

2

3

2

Jog+

3

Jog -

4

5

6

7

8

9

10

11

12

13

14

15

16

As for the digital terminals, before operating the virtual digital I/O, drive parameters must be assigned to the single terminal; in order to do this, please refer to

the “OPTION 1” chapter of the drive instruction manual.

Digital I/O value can be cyclically and fast transferred through the Polling I/O,

in order to do this, the virtual digit I/O value parameter must be assigned to one

of the Polling I/O words. Above picture shows that the virtual digital input has

been assigned to the Polling I/O Master>Slave Word 0. The example reports

also some drive signal assigned to the virtual digital input.

—————— Interface card DeviceNet ——————

25

Page 26

GEI-100435A

6.0 KEYBOARD INTERFACE

6.1 MAIN MENU STRUCTURE

This structure appears when the Enter key is pressed and “OPTION1” is displayed; in this case, keypad control passes to the SBI card.

OPTION 1

SBI INFO

SB3_8000

Move between the Menus by pressing the Cursor-Up/Cursor-Down keys and

use the Enter key to enter the currently displayed Menu. Pressing the Cancel

key in any displayed menu causes the “OPTION1” Menu to appear and keypad control returns to the Drive.

6.1.2 Warning and error message handling

Warning and error messages can be displayed on the first and second rows of

the keypad’s display; a maximum of 16 characters can be displayed per line.

The Cancel key must be pressed in order to clear these messages, at this point

the system automatically returns to the immediately superior Menu level.

26

—————— Interface card DeviceNet ——————

Page 27

6KCV301DNET

6.2 SBI INFO MENU

The keypad display shows either general purpose useful information (card

address, current Baud Rate, etc.) or information about the communication states

(node status, allocation status, etc.), in order to allow a fast troubleshooting if

the card can not be connected to the bus.

SBI INFO

MAC ID

XX

Baud Rate

XXX kBit

Node status

XX X

Status of alloc.

S:X A:X M:XXX

CNXN status

PE:X PP:X UE:X

IO CNXN status

XXX

DUP.MAC ID TEST

"text"

reserved - 1

XXXXXXXXXXXXX

Software version

V. X.XXX

Compatib. index

V XX.XX

DNM0040

By pressing the Cursor-Up/Cursor-Down keys it is possible to move through

the Menu items; the Cancel key allows to go back to the upper level Menus.

The first 8 information are automatically refreshed.

—————— Interface card DeviceNet ——————

27

Page 28

GEI-100435A

6.2.1 Display node address (MAC ID)

The node address (MAC ID), set by Dip-Switches, is displayed.

6.2.2 Display Baud Rate

The current Baud Rate of the node, set by Dip-Switches, is displayed.

6.2.3 Node status

The following node status are displayed:

· DNet Status.

· DNet StAux.

· DNet StUser.

By pressing the ENTER key , these three error-conditions are set to zero.

In normal conditions all must be set to zero; when pressing th ENTER key, all

error conditions are set to zero; if after this, the values are different from zero,

it means that an error occurred; even if these states are different from zero, the

PLC Master may be connected anyway.

28

—————— Interface card DeviceNet ——————

Page 29

6KCV301DNET

6.2.3.1 DeviceNet error types

DNetStatus Meaning

Code

0 No error exists

1 Resource not available

2 Value out of range

3 transportClass_trigger invalid

4 Invalid service for object state

5 Illegal message format

6 Invalid condition for transmission

7 Outstanding request exists

8 Object does not exist

9 Service not supported

1 0 Duplicate MacId check response received

1 1 Duplicate MacId check request received

1 2 Object not available

1 3 OpenAllIOCnxn failed

1 4 Duplicate MacId error

1 5 Time-out error

1 6 Software error

1 7 Message error

1 8 Hardware error

DnetStAux Meaning

Code

0 No additional information

1 All available group 2 message identifiers have been allocated

2 Invalid Ainitial_comm_characteristic@ attribute

3 All available group 1 message identifiers have been allocated

4 All available group 3 message identifiers have been allocated

5 Invalid value within the AtransportClass_trigger@ attribute

6 An Apply request is sent to a Connection instance when it is in

7 Illegal to send fragmented explicit Connection message

8 Connection object must be in Established state and must

9 Cannot send cnxn-based request since a request is outstanding

1 0 Invalid instance identifier specified in received explicit message

1 1 Explicit message request is directed at non-existent cnxn instance

1 2 A Create request can only be sent to the class, not a particular

1 3 ConfigCnxnndex already set

1 4 Unable to create cnxn class

1 5 Apply_attribute cannot be sent to the cnxn class, only a specific

1 6 Invalid service code received in explicit message request

1 7 Class specified in received Cnxn Based Explicit request message

the Established or Timed-out state

beMessaging type of Connection in order to send a cnxn-based

request

request

instance

instance

does not exist

—————— Interface card DeviceNet ——————

29

Page 30

GEI-100435A

1 8 More than 2 group 2 object have been created

1 9 Maximum number of allocatable group 3 identifiers already allo-

2 0 Group specified in open messaging connection is invalid

2 1 Invalid service code received in received ucmm request message

2 2 Duplicate MacId check response has been received

2 3 Duplicate MacId check request has been received

2 4 Cannot send open cnxn-based request since a request is outstanding

2 5 A connection within the client is not available

2 6 Timer Id not correct

2 7 expected_packet_rate not supported (is greater than maximum

2 8 No more Timer available

2 9 watchdog_timeout_action not correct

3 0 Watchdog time-out occured

3 1 UCMM time-out occured

3 2 Explicit time-out occured

3 3 Attempt to deallocate a CAN channel not allocated

3 4 No more CAN channel available

3 5 No more CAN channel available for transmission

3 6 CAN Interrupt register error

3 7 CAN is still in hardware reset

3 8 CAN status register error

3 9 Error on allocation

4 0 BusOff detected

4 1 Error on the-allocation

4 2 Too much data

4 3 Parameter object data type not correct

4 4 Connection path not correct

4 5 I/O length not correct

cated

allowed)

DnetStUser Meaning

Code

0 No error exists

1 No resource available

2 Duplicate MacId Check error

3 Illegal transmission

4 Illegal reception

5 Illegal action

6 Time-out error

7 Parameter error

8 DeviceNet is not enabled

9 DeviceNet module is not present or not ok

1 0 Hardware problem

0FFFFH General error

30

—————— Interface card DeviceNet ——————

Page 31

6KCV301DNET

6.2.4 Status of allocation

The following states of allocation are displayed:

1. S - Software state DNET ;1.the values, which this state can assume, are:

· 0 = initialization.

· 1 = Duplicate MAC ID Check in progress.

· 2 = Duplicate MAC ID Failed.

· 3 = Pre_Loop.

· 4 = Loop.

2. A - Bitmap of the allocations; the values are:

· 0 = No CNXN allocation.

· 1 = Explicit CNXN.

· 2 = Polled CNXN.

· 3 = Explicit + Polled CNXN.

3. M - MAC ID of the Master; the value is 255 if the Master has no allocation.

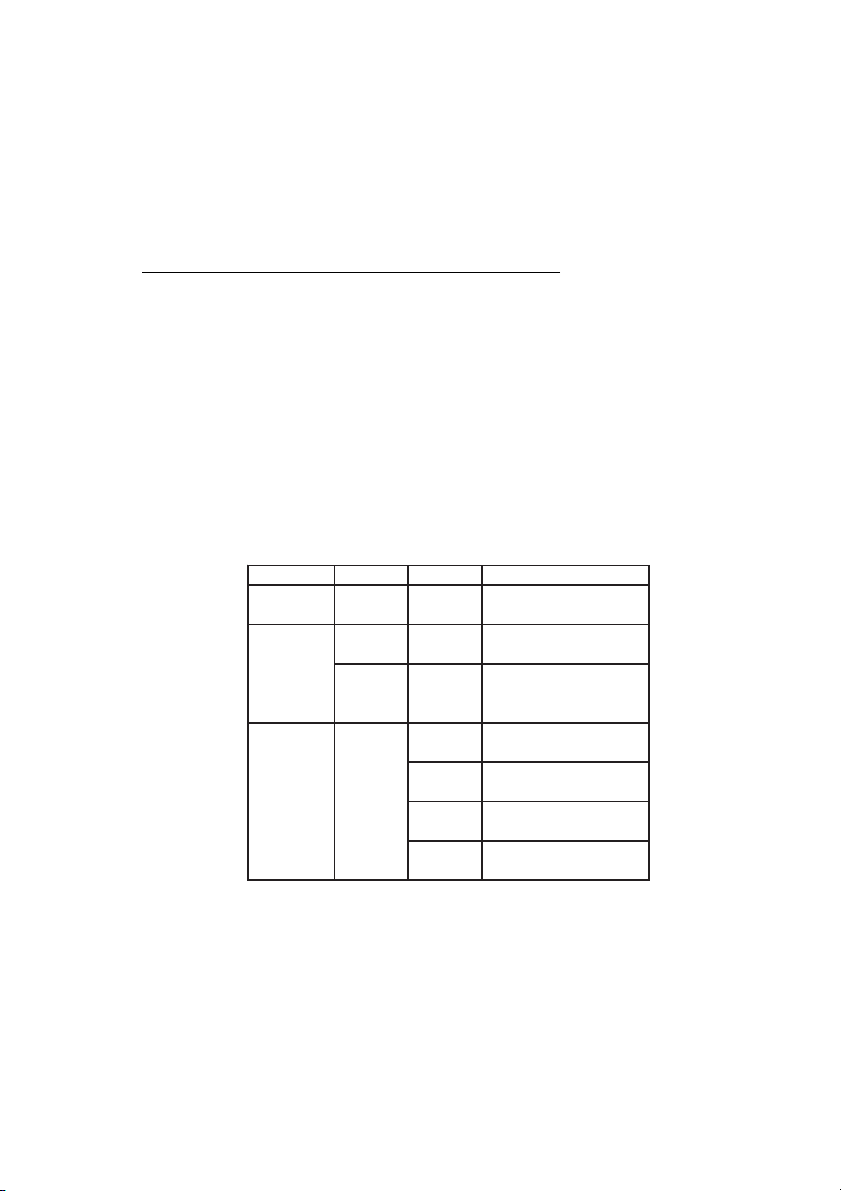

The following table shows the values of the single states corresponding to

specific operating conditions

TATUS ALLOCATION MAC ID

CONDITION

Normal functioning, the PLC

has not allocate connection yet

Normal functioning, the PLC

has allocate connections

Normal functioning, connections

goes on Timeout

Duplicate MAD ID Check in

Duplicate MAD ID failed

Pre_Loop (need some sec.) 3

1)

See DMC handling.

Progress

1)

S

0 255

4

1

1)

2

3

1

0 255

MasterMAC

—————— Interface card DeviceNet ——————

ID

dn6000

31

Page 32

GEI-100435A

6.2.5 CNXN status

The following states of the connections are displayed:

1. PE - Predefined Mode Explicit connection status .

2. PP - Predefined Mode Polled connection status .

3. UE - UCMM Explicit connection status.

Every single state can assume following values:

· 0 = does not exist.

· 1 = Configuring.

· 2 = W aiting for ID.

· 3 = Established.

· 4 = Timed-out.

· 5 = Deferred.

The following table shows the values of the single states corresponding to

specific operating conditions

CONDITION PE PP UE

Disconnected SBI card 0 0

Connected PLC 3 3

Disconnected PLC 3 4 or 0

1)

UE might have values different from zero occasionally for some seconds

1)

0

1)

0

1)

0

dn6010

from the allocation by PLC.

6.2.6 I/O CNXN status

The following states of the I/O connections are displayed:

1. E Expected Packet Rate; milliseconds indicating the Timeout, set by the

Master.

2. C Consuption Length; number of byte consumed (direction Master->Slave); set by the Master, for the card SBI depends on frame length.

3. P Produced Length; number of byte produced (direction Slave->Master) ;

set by the Master, for the card SBI depends on frame length.

32

—————— Interface card DeviceNet ——————

Page 33

6KCV301DNET

6.2.7 DUP MAC ID test (DMC)

The SBI card carries out a Test to check if there is another node with the same

address (Duplicate MAC ID) in the network; if there is a duplication of a node

address, the following message shows up:

DUP. MAC ID TEST

FAILED

In addition to this information, the red LED AL0 starts blinking.

In this case the address of the SBI card must be changed.

If the “Duplicate MAC ID” test is positive, the following message shows up:

DUP. MAC ID TEST

PASSED

This message means that the MAC ID is correct.

During the “Duplicate MAC ID” test, the following message shows up:

DUP. MAC ID TEST

IN PROGRESS - X

X is the current DMC state.

This test takes about two seconds; if the message remains, check cables,

connections and Baud Rate. See also the paragraph “Status of Allocation” to

display the Sw Dnet status.

6.2.8 Display Software version (Sotware version)

The Software version of the SBI card is shown.

6.2.9 Display compatibility index(Compatib. index)

The index of compatibility of the Software between the Drive and the SBI card

is shown.

—————— Interface card DeviceNet ——————

33

Page 34

GEI-100435A

7.0 MISCELLANEOUS

7.1 DEFINITIONS

- CAN Controller Area Network

- CNXN Connections

- C O S Change of State - DeviceNet operation mode

- DM C Duplicate Mac ID

- MAC ID Media Access Control Identifier (node address)

- ODVA Open DeviceNet Vendor Association

- UCMM Unconnected Message Manager

7.2 REFERENCES

- DeviceNet Specifications. Volume 1 - DeviceNet Communication Model

and Protocol (issued by ODVA)

- DeviceNet Specifications. Volume 2 - DeviceNet Device Profiles and Object Library (issued by ODV A )

- A V300i Instruction manual

- 6KCV301DGF Instruction manual

34

—————— Interface card DeviceNet ——————

Page 35

Page 36

6KCV301DNET 10/99

Rev. 0.2 - 21.8.2000

We bring good things to life.

GEI-100435A Rev. 0.2 (08/00)

GE Industrial Systems

Internet Address: http://www.ge.com

Loading...

Loading...