Page 1

6KCV301DGF

Digital General Function Card

for AV-300i Drives

INSTRUCTIONS

GE Industrial SystemsGE Industrial Systems

Page 2

These instructions do not purport to cover all details or variations in

equipment, nor to provide every possible contingency to be met during

installation, operation, and maintenance. If further information is desired

or if particular problems arise that are not covered sufficiently for the

purchaser’s purpose, the matter should be referred to GE Industrial

Systems.

This document contains proprietary information of General Electric

Company, USA and is furnished to its customer solely to assist that

customer in the installation, testing, operation, and/or maintenance of

the equipment described. This document shall not be reproduced in

whole or in part nor shall its contents be disclosed to any third party

without the written approval of GE Industrial Systems.

© 1999 by General Electric Company, USA. All rights reserved.

Page 3

Table of contents

1. GENERAL DESCRIPTION ..................................................................6

1.1 INTRODUCTION .................................................................................... 6

1.2 HARDWARE DESCRIPTION .................................................................. 7

1.2.1 MEMORY MAP .............................................................................................. 7

1.2.2 SERIAL LINE RS-485 ...................................................................................... 8

1.2.3 LEDS ............................................................................................................ 11

1.2.4 JUMPERS .................................................................................................... 12

1.2.5 CAN CONNECTOR ........................................................................................ 13

1.3 MECHANICAL LAYOUT ....................................................................... 14

2. DGF OVERVIEW ..............................................................................15

2.1 INTRODUCTION .................................................................................. 15

2.1.1 Firmware organization ................................................................................. 15

2.1.2 DGF application ............................................................................................ 16

2.1.2 Working of the DGF ..................................................................................... 17

2.1.3 Global organization of the DBASE ................................................................ 19

2.1.4 Parameters and variables ............................................................................ 22

2.1.4.1 Initialization of the General variables ............................................ 23

2.1.4.2 Data management inside the DBASE ............................................ 23

2.1.4.3 Access to a parameter from the external world ............................ 23

2.1.4.4 Storage of the parameter and of the associated record ................ 24

2.1.5 FVAR, IVAR and NUM .................................................................................. 26

2.1.6 DPRAM organization .................................................................................... 26

2.1.6.1 DPRAM hardware ......................................................................... 27

2.1.6.2 DPRAM software organization ...................................................... 27

2.2 DGF STATUS ....................................................................................... 29

2.2.1 Status commands ........................................................................................ 31

2.2.2 Alarms ......................................................................................................... 32

2.2.2.1 Alarm code from the drive ............................................................. 36

2.2.2.2 Severe alarm ................................................................................. 36

2.3 DATA FORMATS .................................................................................. 38

2.3.1 Description of base-10 floating point ........................................................... 38

2.3.1.1 Shreal format ................................................................................ 38

2.3.1.2 Slreal format ................................................................................. 39

Page 4

2.3.1.3 S3hreal format .............................................................................. 39

2.3.1.4 S3LREAL format ............................................................................ 39

2.4 INTERFACE.......................................................................................... 40

2.4.1 Drive keypad ................................................................................................ 40

2.4.2 DGF Serial line ............................................................................................. 47

2.4.2.1 HIBS .............................................................................................. 47

2.4.3 DRIVE SERIAL LINE ...................................................................................... 47

2.4.4 DeviceNet .................................................................................................... 47

2.4.5 Serial bus interface (SBI) ............................................................................. 47

2.5 DRIVE PARAMETERS .......................................................................... 48

2.6 PARAMETER DESCRIPTION ............................................................... 49

2.6.1 List of parameters ........................................................................................ 49

2.6.2 Description of parameters ........................................................................... 51

2.6.2.1 Identification parameters .............................................................. 51

2.6.2.2 DPRAM parameters ...................................................................... 52

2.6.2.3 I/O configuration ........................................................................... 53

2.6.2.4 Mode configuration ....................................................................... 53

2.6.2.5 Can controller parameters (DeviceNet) ........................................ 53

2.6.2.6 System parameters ....................................................................... 53

2.7 HOW TO CONFIGURE THE DGF........................................................... 57

2.7.1 Which method to use .................................................................................. 57

2.7.2 First configuration of DGF ............................................................................ 57

2.7.3 Mode configuration ...................................................................................... 57

2.7.4 Basic transition ............................................................................................ 57

2.7.5 Working mode ............................................................................................. 58

2.7.6 Serial address .............................................................................................. 59

2.7.7 DP-RAM ....................................................................................................... 59

2.7.8 I/O configuration .......................................................................................... 59

Page 5

List of tables and figures

1. GENERAL DESCRIPTION ..................................................................6

Figure 1.2.1: 6KCV301DGF connections ............................................................................ 7

Figure 1.2.1.1: 6KCV301DGF memory map........................................................................ 8

Figure1.2.1.2: 6KCV301DGF flash Eprom memory map ..................................................... 8

Figure 1.2.2.1: RS-485 interface ....................................................................................... 9

Figure 1.2.2.2: RS-485 single point comm. without signal isolation ................................ 10

Figure1.2.2.3: RS-485 communications with signal isolation .......................................... 10

Figure 1.2.4.1: 6KCV301DGF Jumper Locations .............................................................. 12

Figure 1.3.1: DGF Location .............................................................................................. 14

2. DGF OVERVIEW ..............................................................................15

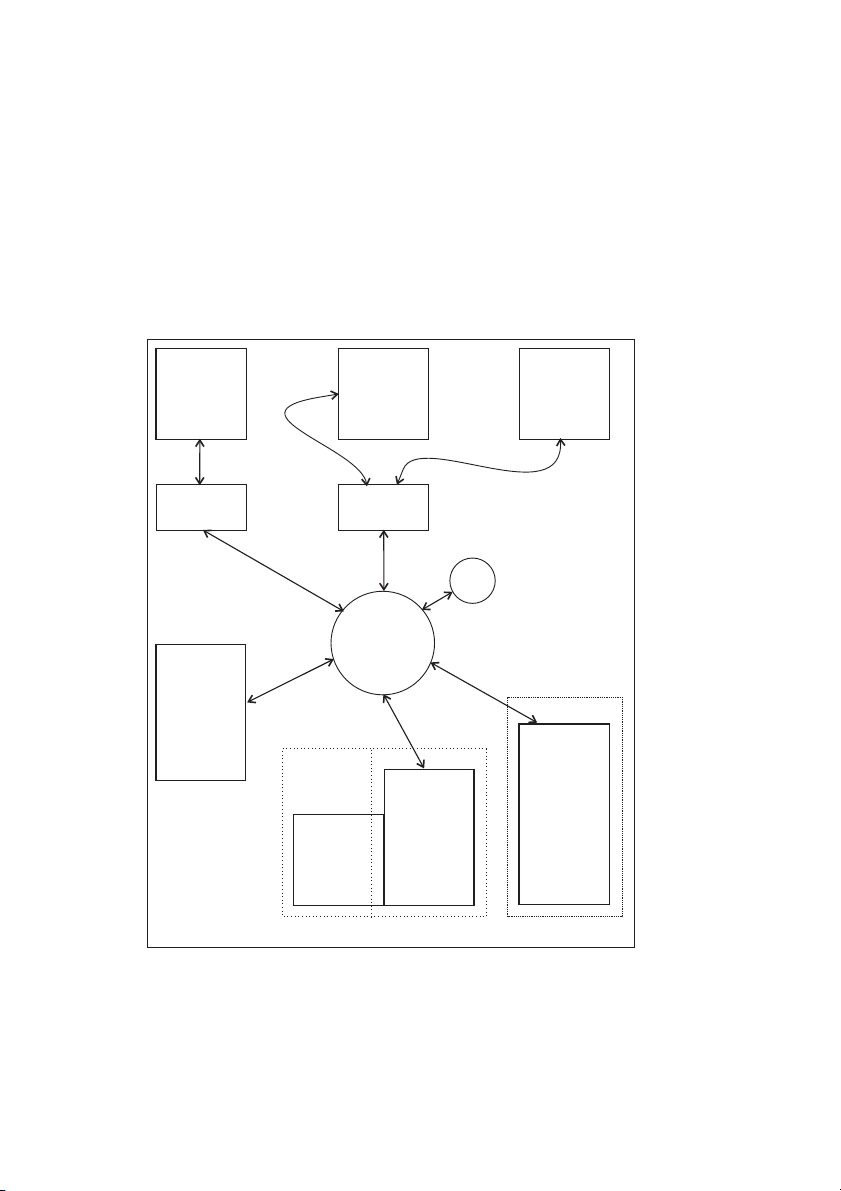

Figure 2.1.1: DGF block diagram ..................................................................................... 15

Figure 2.1.1.1: Logical structure ...................................................................................... 16

Figure 2.1.2.1: DGF Program Structure............................................................................ 19

Figure 2.1.7.1.1: DPRAM Hardware ................................................................................ 27

Figure 2.2.1: Logic of DGF status ..................................................................................... 29

Table 2.2.1: Leds status ................................................................................................... 31

Table 2.2.2.1: DGF alarm codes ....................................................................................... 33

Table 2.2.2.2: Alarm code 2 (AL_DPRAM)cause ............................................................. 33

Table 2.2.2.3: Alarm code 6 cause .................................................................................. 34

Table 2.2.2.4: Alarm code 14 (AL_BRICKS_DP) cause ................................................... 35

Table 2.2.2.5: Alarm code 15 (AL_REGISTER) cause ...................................................... 35

Table 2.2.2.6: Alarm code 16 (AL_CCZ) cause ............................................................... 35

Table 2.2.2.7: Alarm code 22 (AL_DNET) cause ............................................................. 36

Figure 2.4.1: DGF Communication ................................................................................... 40

Page 6

GEI-100430

1. GENERAL DESCRIPTION

1.1 INTRODUCTION

The optional Digital General Function Card (DGF) is mounted on the AV300i drives

for special functions such as winder/unwinder control, positioning, etc. It connects

with the drive regulation card via the connector for an optional card. The connection

with the drive also provides the power supply for the DGF.

The communication between the two cards uses a 2Kbytes dual-port ram (DPRAM).

The 6KCV301DGF card is based on an Intel 80C386EX-25 with a numerical processor

80C387SX-25.

The standard user communication on the card is RS-485 serial link.

It is possible to mount an option module with CAN controller for DeviceNet

communication.

It is also possible to read and write DGF parameters using all the drive communications

[serial link, local keypad and an additional optional communication card (e.g. GENIUS,

INTERBUS-S or PROFIBUS-DP)]. All these communications use the drive

microprocessor and DPRAM.

This manual comprises four chapters:

- Chapter 1 describes the DGF hardware. Its installation and configuration settings

are detailed. Settings for serial communications are explained.

- Chapter 2 details the software architecture of the DGF. It describes the MARTE

operating system, task organization, DGF parameters and variables, the five card

status states, and the DGF alarm conditions. Permissible data formats are described.

Drive keypad programmer operation is also described.

- Chapter 3 describes the HIBS software, which is used to download compiled user

programs to the DGF Card ; it is also used to load .BLK files (explained in chapter

4) to create supervision pages to monitor drive operation.

- Chapter 4 details .BLK file syntax. The .BLK file is an ASCII file which is used

to configure DGF DPRAM (Dual-Ported Random Access Memory) and create

supervision pages.

6

—————— Digital General Function Card ——————

Page 7

6KCV301DGF

1.2 HARDWARE DESCRIPTION

The power supply is external to the card and comes directly from the drive.

The DGF is defined as the option 2 card in the drive

A module with DNet interface can be mounted on the 6KCV301DGF card, if desired.

The main 6KCV301DGF hardware characteristics are:

- Intel “embedded” 80386EX 25MHz microprocessor

- Numerical processor 80387 SX 25MHz

- Two static RAM memories (128Kword)

- A FLASH-EPROM boot block memory (256Kword)

- 2 Kbytes serial EEPROM

- VPP signal 12V circuit generator for flash clear/programming

- Microprocessor supervisory circuit for supply surveillance and reset generation

- Serial link RS-485 with SLINK3 protocol.

- 2 Kbytes DPRAM (Dual Port Ram)

- CPU OK (Hardware Watchdog)

- Led for PWR, RST,VPP,CPU OK, CAN and status

The following picture shows the connections between 6KCV301DGF card and the

other cards.

AV-300i Regulation card DGF card

RV33-1

X0 X0

1

1

36

36

Dnet

DeviceNet

(optional)

RS485

(S-LINK3)

Figure 1.2.1: 6KCV301DGF connections

1.2.1 MEMORY MAP

The RAM address must start at 0:0 because the vector interrupts area is in the lowest

address. The flash EPROM must be mapped on the top area because the reset address

is FFFF:0. The DPRAM is mapped at the end address of RAM area.

—————— Digital General Function Card ——————

7

Page 8

GEI-100430

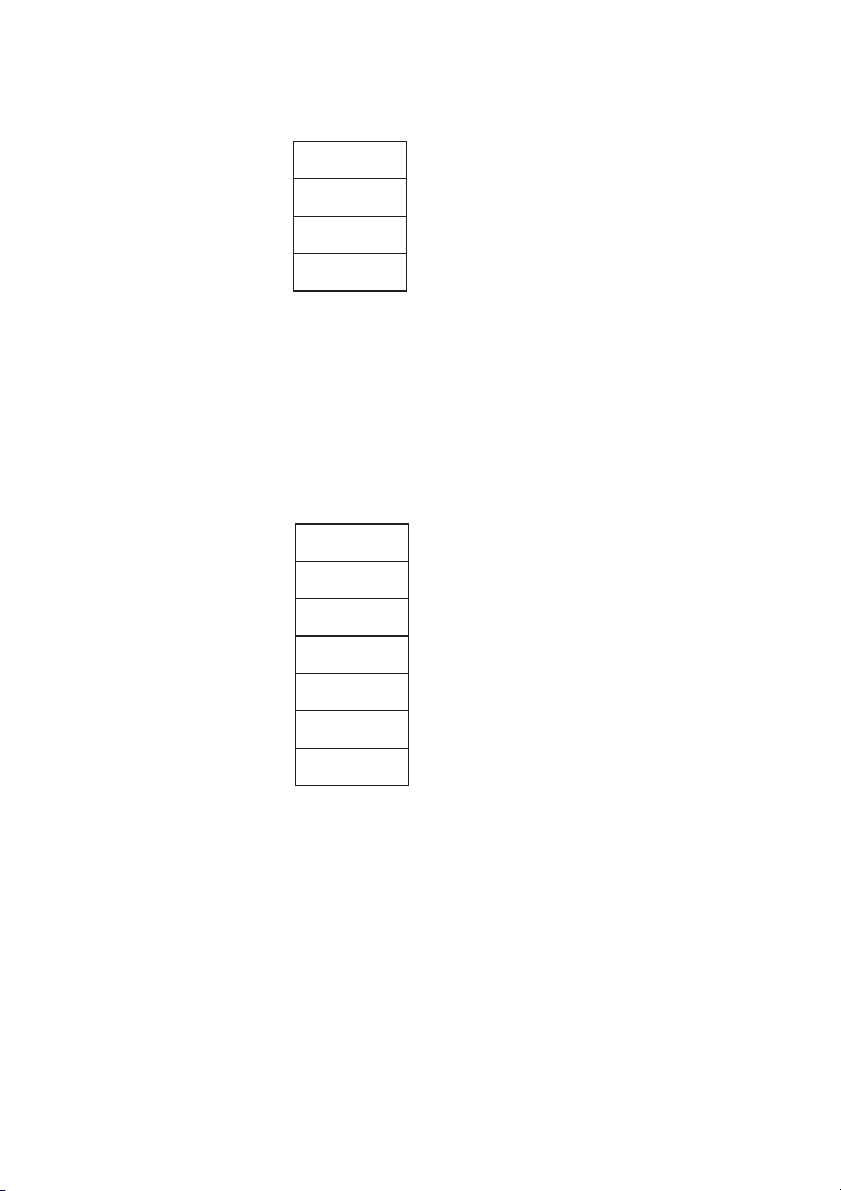

MEMORY MAP

FFFF:FH

FLASH EPROM

8000:0H

4800:0H

DPRAM

SRAM

Figure 1.2.1.1: 6KCV301DGF memory map

The flash EPROM boot-block programming is done once at time of manufacture.

Thereafter, all the software is downloaded using the boot code and the serial link.

The firmware is loaded starting from the first main block (8000:0H) while the data

block will be used to save parameters and block information.

DGFC-386: FLASH MEMORY MAP

4000:0H

0000:0H

FFFF:FH

BOOT BLOCK

DATA BLOCK 2

DATA BLOCK 1

MAIN BLOCK 3

MAIN BLOCK 2

MAIN BLOCK 1

MAIN BLOCK

FC00:0

FA00:0

F800:0

E000:0H

C000:0H

A000:0H

8000:0H

Figure1.2.1.2: 6KCV301DGF flash Eprom memory map

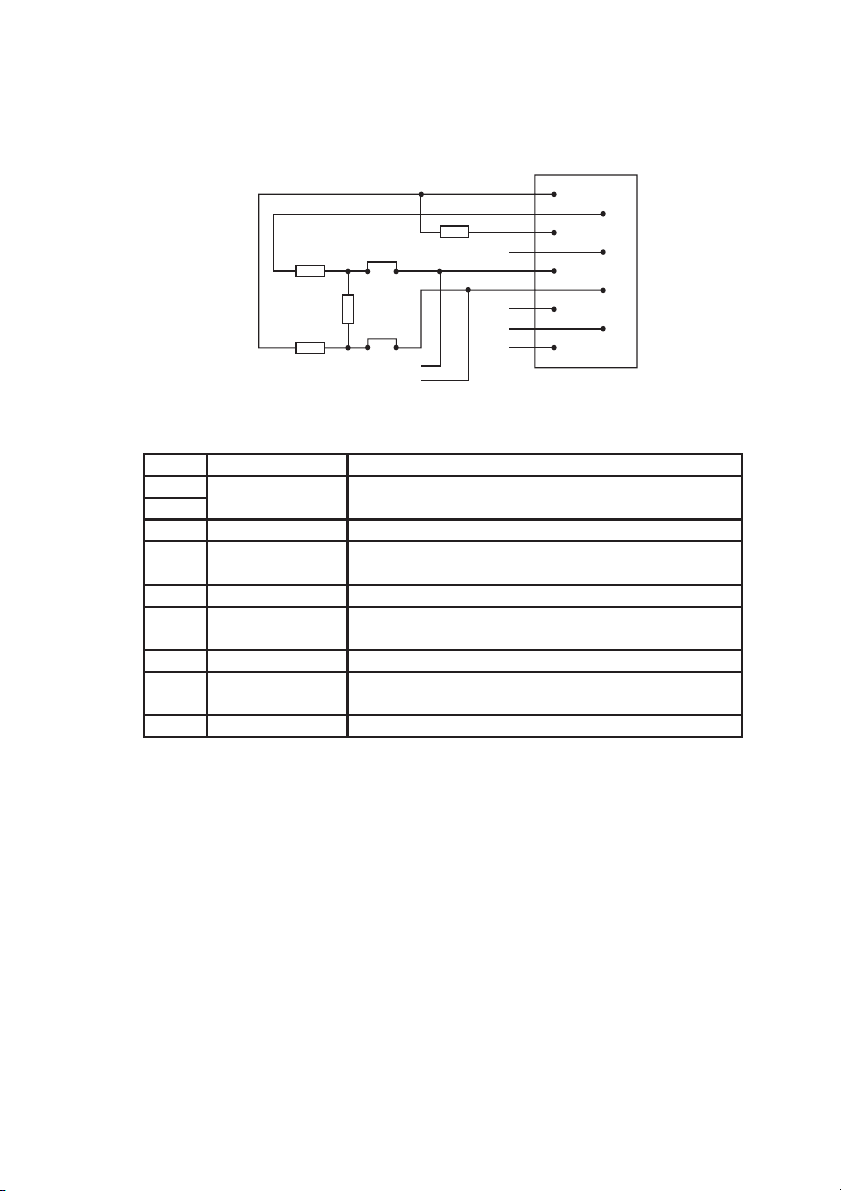

1.2.2 SERIAL LINE RS-485

The RS-485 interface allows data transfer using a two-wire twisted conductor with

shield. The transfer rate is 9.6 Kbaud. The serial link circuit is the same of the drive.

For download applications programs directly to the RS485 port, use a 6KCV300CTI

and a standard 9 pin m/f cable.A 9-socket female connector allows communication

with an external device in a multidrop configuration. The serial link may be used either

with or without signal isolation. When using signal isolation an external power supply

is necessary for 5V. This is the default configuration. The configuration without signal

isolation is possible only with short connections and with HIBS during the card

8

—————— Digital General Function Card ——————

Page 9

6KCV301DGF

configuration. When you use RS-485, the line terminator resistors are connected through

S23 and S24 jumpers and must be ON only on the line end device. The protocol used

is SLINK3, detail provided in separate manuals.

X3

470R

470R

0VS

+5VS

120R

S23

S24

TXB/RXB

TXA/RXA

100R

GND

+5V

5

9

4

8

3

7

2

6

1

Figure 1.2.2.1: RS-485 interface

Pin Signal Description

1

2

3 RXA/TXA (+) Positive differential I/O

4 GNDS

5 GNDS 0V External power supply

6 +5V

7 RXB/TXB (-) Negative differential I/O

8 GND

9 +5VS 5V External power supply Max 120 mA

- Reserved

Connected with pin 8 GNDS with 110 ohm for

equipotential connection

Internal +5V . You need to join with pin 9 for internal

supply

Internal GND. You need to join with pin 5 for internal

supply

d0010g

In this configuration you need to join pin 5 with pin 8 and pin 9 with pin 6 of X3

connector. DGF connectors are female connectors.

The configuration without signal isolation is possible only with short connections: for

example, with HIBS during the card configuration. On the drive, you need to use

signal isolation as described below.

Figure 1.2.2.2 shows a single-point connection between a PC or PLC RS-232 interface

and one 6KCV301DGF.

An adapter RS-232/485 is necessary to convert the PC RS-232 COM to an RS-485

signal. A simple two wire twisted cable is necessary to transmit the RS-485 differential

signals TXA/RXA - TXB/RXB.

—————— Digital General Function Card ——————

9

Page 10

DGFC

X3 RS485

59 6837

GEI-100430

S23=ON

S24=ON

RS485

RS232

RS232

PC/PLC

Figure 1.2.2.2: RS-485 single point comm. without signal isolation

The DGF jumpers are:

Name Default Function

S23 ON "ON" RS-485 line end device (for terminal resistor)

S24 ON "ON" RS-485 line end device (for terminal resistor)

d0020g

Figure 1.2.2.3 shows an RS-485 communications link with three 6KCV301DGF cards

with signal isolation.This is the recommended configuration for applications that use

the serial link. The card at the end of the line (both ends) must have the terminator

resistor inserted, and thus S23=S24=ON while the other two 6KCV301DGF cards

must have S23=S24=OFF.

DGFC DGFC DGFC

59 37 59 37 59 37

S23=OFF

S24=OFF

X3 RS485 X3 RS485 X3 RS485

S23=OFF

S24=OFF

S23=ON

S24=ON

+5V

RS485

COM

Figure1.2.2.3: RS-485 communications with signal isolation

DGF connectors are female connectors. In this configuration, all 6KCV301DGF cards

need external power supply for serial interface.

10

—————— Digital General Function Card ——————

Page 11

6KCV301DGF

1.2.3 LEDS

The LEDs on 6KCV301DGF card have the following meanings:

Name Color Function if LED ON

PWR Green Power 5V

RST Red Reset

OK Green Hardware watchdog = OK

VPP Green Flash eprom programming voltage

PRG Green Flash eprom programming voltage command

H1 Yellow Status LED 1 (see table 2.2.1)

H2 Red Status LED 2 (see table 2.2.1)

H3 Red Status LED 3 (see table 2.2.1)

H4 Red Status LED 4 (see table 2.2.1)

d0030g

PWR is on when 5V supply is present; this LED must be always on when the regulation

board of the drive is supplied.

RST led indicates that a hardware reset occurs. This LED is always OFF; the only

operation that puts the LED ON briefly is the power on and off operation

during the firmware download sequence.

OK is always ON during normal operation and indicates that the card is working

normally. If it is OFF during normal operation, this indicates a card malfunction;

this condition forces an alarm on the drive. The LED should be OFF only

during the firmware download sequence.

VPP indicates the presence of the flash eprom programming voltage (12V). This

LED must be ON only during the firmware download sequence or during the

archive operation (save parameters).

PRG indicates the enable of the flash eprom programming voltage generation. This

LED must be ON only during the firmware download sequence or during the

archive operation (save parameters).

H1 – H4 These LEDs are controlled by the software of the card. Refer to Chapter 2 for

additional information.

—————— Digital General Function Card ——————

11

Page 12

GEI-100430

1.2.4 JUMPERS

The following table shows the 6KCV301DGF jumpers:

Name Default Function

S7 OFF Reserved (NMI)

S17 OFF Reserved (hardware reset)

S23 ON

S24 ON

S27 A Reserved

S28 OFF Reserved

The only jumpers that it is possible to move are the RS-485 serial link jumpers. For

more information see section 1.2.2.

ON only on the RS-485 line end device (for terminal

resistor)

d0040ge

12

Figure 1.2.4.1: 6KCV301DGF Jumper Locations

—————— Digital General Function Card ——————

Page 13

6KCV301DGF

1.2.5 CAN CONNECTOR

The DNet (CAN) interface provides signal isolation and uses a 4- wire cable : two for

signals and two for external power supply. The 6KCV301DGF connectors have the

following meanings:

Pin Signal Description

1 V- Negative external power supply

2 CAN- Negative CAN signal

3 SHIELD Cable shield

4 CAN+ Positive CAN signal

5 V+ Positive external power supply

6

7

Note that the line terminator resistor is external to the card according to DeviceNet

specification.

GND Ground: connect to ground

d0050g

—————— Digital General Function Card ——————

13

Page 14

GEI-100430

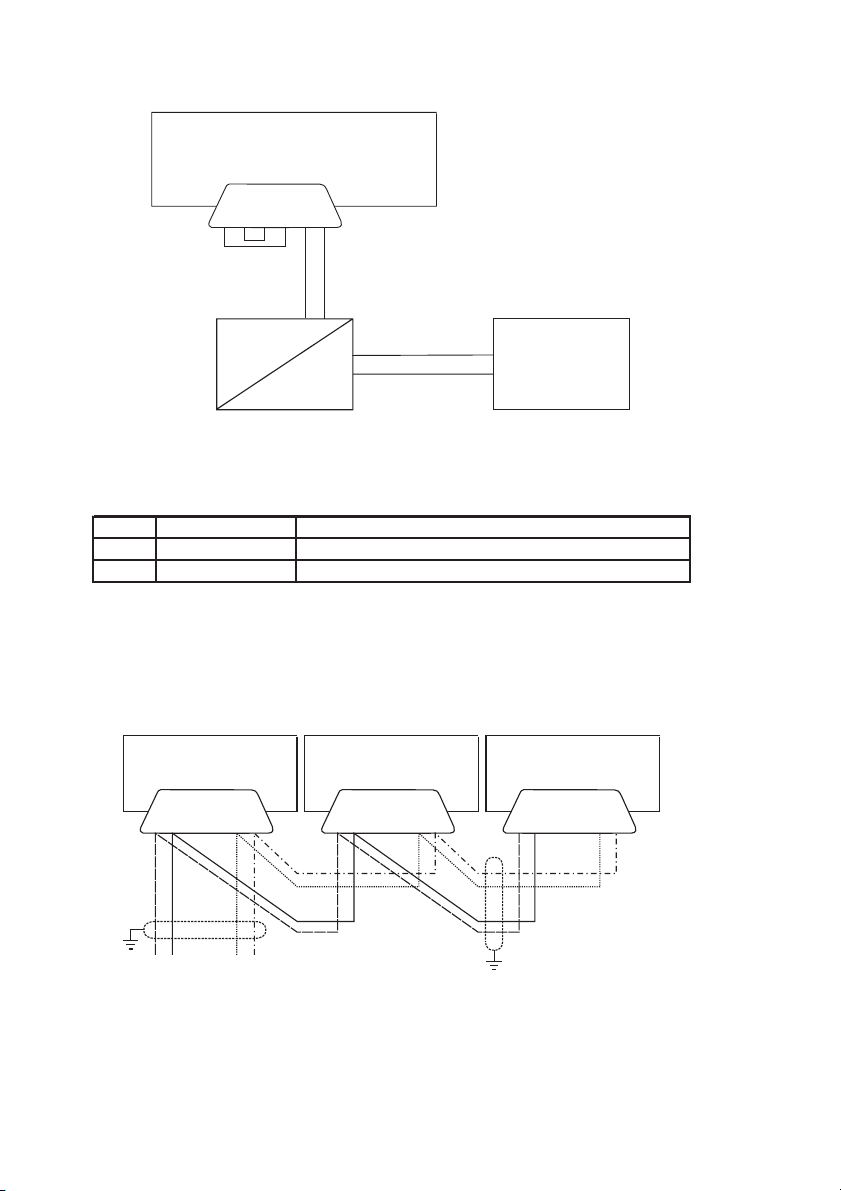

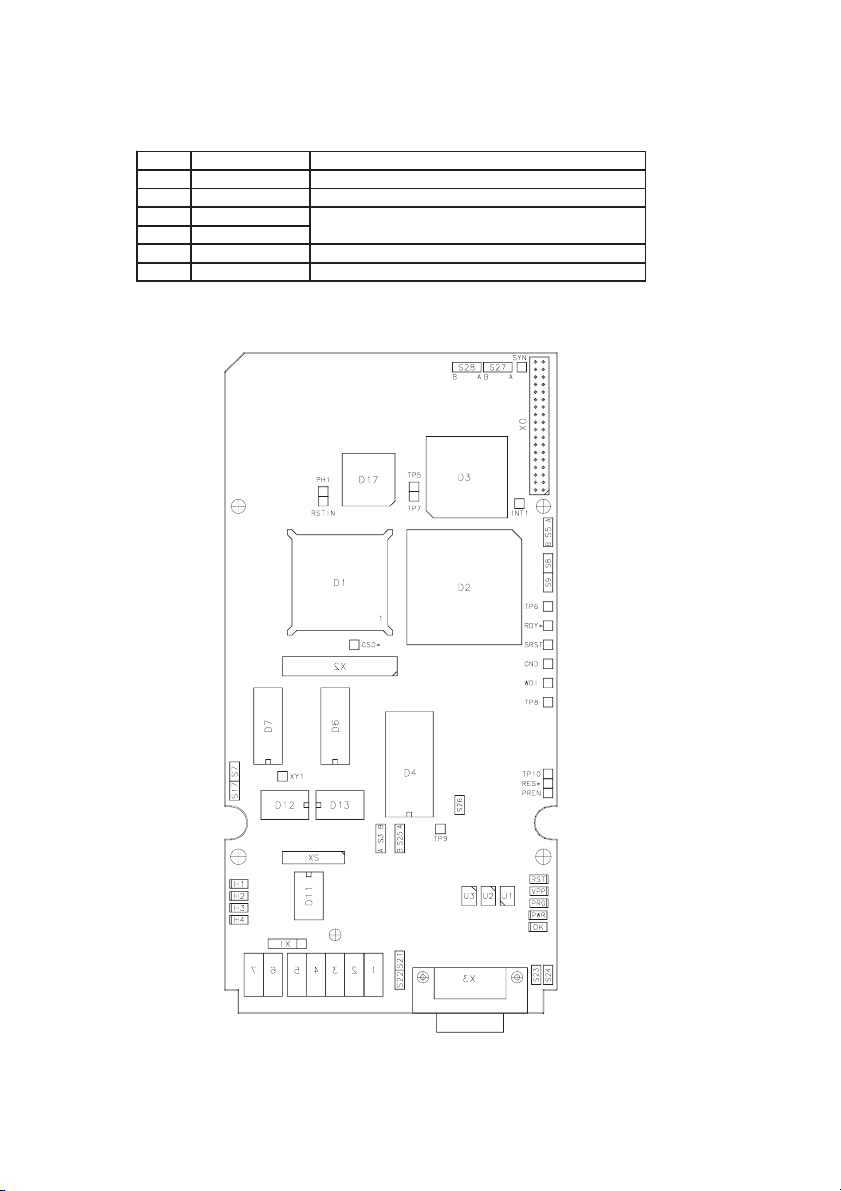

1.3 MECHANICAL LAYOUT

Figures 1.3.1 shows the location of the 6KCV301DGF card on the drive. The DNET

module are optional and therefore they may not be present. The connector connects

only the Drive Regulation Board to DGF.

For more information about the connections see Figure 1.2.1 of this manual.

Regulation board

14

DGF card

DNET module

Figure 1.3.1: DGF Location

—————— Digital General Function Card ——————

Page 15

6KCV301DGF

2. DGF OVERVIEW

2.1 INTRODUCTION

DGCF is a general purpose, where the final user can load the custom firmware which

carry out the desidered applications.

The DGF option is mounted on the drive with which it communicates through a DUAL

PORT RAM. Therefore it is possible to read drive parameters (including parameters

connected to analog and digital I/O), perform the algorithms, and write the result or

other parameters necessary to realize the desired functions.

The functional blocks also allow the reading of inputs and writing of outputs, physically

present on the optional I/O card and available to the DGF.

I/O

Firmware

D

Standard

Dbase

P

R

Communication

card

Analog I/O

Serial Link

(Profibus-DP, Interbus-S,...)

DRIVE

Digital I/O

Serial Link

(Slink3)

A

M

User

HIB

Figure 2.1.1: DGF block diagram

2.1.1 Firmware organization

The firmware of the DGF is divided in two parts: a fixed part, factory developed, and

a personalized one which can be developed even by the final user.

The final user has different possibilities to personalize the firmware of the DGF. The

main tools are the developing environment Win+Drive. Users with a programming

knowledge can develop directly with a C or Assembler language.

—————— Digital General Function Card ——————

15

Page 16

GEI-100430

2.1.2 DGF application

Application code can be obtained these ways:

1 Graphical development tool Win+Drive and design the specific application.

2 Graphical development tool Win+Drive and a factory predeveloped application.

The standard application can be modified with Win+Drive according to the specific

needs.

3 Use a factory developed and tested application and load it on the DGF unmodified.

In this case the Win+Drive can be used.

4 Demo version

DRIVE PC

SLINK3

DPRAM

I/O

OPTIONAL

CARD

ARCHIVE

DBASE

EEPROM STORE AREA DBASE AREA

CAN

Controller

COPROCESSOR

387

386

Firmware

DBASE

Figure 2.1.1.1: Logical structure

NUCLEUS & FIRMWARE The firmware core of the DGF consists of the operati-

ve system multi-task real time MARTE. The core regulates the

times and the task priorities forming the firmware.

16

—————— Digital General Function Card ——————

Page 17

6KCV301DGF

CPM Mathematical co-processor 387.

DPRAM DPRAM is a bi-accessible storage device that allows the DGF

to communicate with the connected drive. Various connection

structures are available, with different exchange capacity and

priority.

I/O OPTIONAL CARD It is possible to add additional cards to expand the

hardware capability of the DGF. The detailed description of

these devices can be found in their specific documentation.

The DGF can be provided with various I/O cards.

DBASE DBASE is a block used for the communication with the external

world. It is a catalog of variables provided by the DGF and

containing different information on the system. For each

variable access modes are specified, for example:

- read-only or read and write

- limits of the variable value

- access level, etc.

All information coming from or directed to the external world

goes through DBASE.

ARCHIVE Archive is a particular storage area where DBASE data are

stored so that the DGF can restart after a supply voltage failure.

2.1.2 Working of the DGF

The software of the card is based on the multi-task real-time operating system called

MARTE.

The structure of the program comprises a nucleus of 5 tasks with the following

characteristics (see Figure 2.1.3.1):

TASK SYN DPRAM This task executes the communications with the drive, for the

parameters at high priority , using the SYN DPRAM structure

of the DPRAM. The connection is executed with the maximum

priority at constant frequency. The event which wakes up the

task is a signal coming from the drive, whose execution is

synchronous with the regulation task of the drive.

TASK PERIOD This task carries out the regulation program developed by the

user. The task is normally carried out as a sub-routine of the

task SYN DPRAM. As a consequence, it inherits the main

characteristics:

- execution at the maximum priority ,

- constant priority

- synchronous with the drive.

In particular applications the task could be carried out in an independent way from the

task SYN DPRAM. In this case the execution of the task is carried out in an

asynchronous, with respect to the drive.

—————— Digital General Function Card ——————

17

Page 18

GEI-100430

The execution cycle of the above-mentioned two tasks is fixed through a parameter

and can vary from 2 to 20 milliseconds with a tick of 2 milliseconds. The reason the

execution time of these important tasks is variable is that the TASK PERIOD carries

out the program developed by the user, and is dependant on the size of the custom

application program. A later chapter explains how to choose a correct execution time.

T ASK MEDIUM This task executes code with medium importance; in the futu-

re parts of the user-developed program will be allowed to

execute in this task. The execution time is fixed at 50

milliseconds.

T ASK ASYN DPRAM This task in the applications code executes with the drive for

the parameters at low priority, using the structure ASYN

DPRAM of the DPRAM. The connection is carried out

asynchronous from the regulation task of the drive.

T ASK POLLING This task carries out checks of very low importance. The

execution time is fixed at 500 milliseconds. The DGF interacts

with the external environment through two devices:

DRIVE DGFCy Can read and write some parameters of the drive and through

these modify the working of the drive. Moreover, the DGF

has the ability to manage directly the physical I/O of the drive.

For additional information, refer to section 2.1.7.

I/O CARDS If the physical I/O of the drive is insufficient for the application

it is possible to add additional optional cards with specific

functions. Further information is given in their respective

documentation.

The DGF operation can be configured through DGF parameters. The access from the

external world to these parameters is managed by the DBASE. The DBASE is a set of

procedures and data which coordinates and manages the access to DGF parameters.

The DBASE is the interface between the operating system of the DGF and the external

world. The devices which can access the DBASE

of the DGF are the following:

- Serial port RS-485 of the DGF in modality SLINK2, SLINK3 and SLINK4

- Serial port RS-232 of the DGF in modality SLINK2, SLINK3 and SLINK4

- Serial protocol DeviceNet

- Drive keypad from the application card or Opt 2 menu

- Optional communication cards on the drive

- Serial port RS-485 of the drive in modality SLINK3 for DGF

Further information regarding the DBASE is given in section 2.1.6.

18

—————— Digital General Function Card ——————

Page 19

6KCV301DGF

s

e

m

c

)

0

0

5

(

G

N

M

I

A

R

L

P

L

D

O

P

S

K

A

S

Q

A

L

T

C

A

T

5

0

(

N

Y

E

M

K

S

S

A

T

J

B

U

I

D

E

P

K

Q

L

C

O

-

D

P

M

(

2

D

O

I

R

D

N

Y

S

MARTE

W

m

s

e

c

)

.

/

.

2

0

m

s

P

e

R

c

A

M

DEFINED

FVAR

IVAR

NUM

D

B

A

S

E

SLINK3

SLINK2

DNET

CLQ SLINK3 DPRAM

KEY DRIVER (DPRAM)

SER1

SER2

SER1

SER2

DNET

SER

DRIVER

Figure 2.1.2.1: DGF Program Structure

2.1.3 Global organization of the DBASE

The DBASE is a set of data and procedures which regulates the parameter management of the DGF . For each parameter that has been put in the DBASE, an associated a

record of information which describes the parameter has been created:

-IP A parameter’s identifier.

-UNM 4-character label defining the measure unit of the parameter .

-DESCRIBE 10-character array which contains the parameter’s name.

-TYPE specifies the type of the parameter.

-PROCEDURE if this field is not 0, it is a procedure that will be carried out

each time the parameter is read or written.

-MINIMUM minimum value of the parameter .

-MAXIMUM maximum value of the parameter.

-LIMIT MINIMUM minimum limit of the attribute MINIMUM.

-LIMIT MAXIMUM maximum limit of the attribute MAXIMUM.

-STATUS OF ACCESS it specifies the modes of access for the reading and writing

of the parameter.

- LEVEL OF ACCESS it specifies the level of the password to enter into the parameter

modification.

-MEMO it specifies the storage modes of the parameter.

-DEFAULT parameter’s default value .

The collection of these records forms the DBASE area. For storage reasons, that will

be explained below, this area is multiplied 4 times.

- DBASE_RAM working area

- DBASE_ROM area in which the default records are stored

—————— Digital General Function Card ——————

19

Page 20

GEI-100430

- DBASE_FLASH area in which the user’s customization is stored.

- DBASE_EEPROM area in which the parameters with attribute MEMO equal to

RUN are stored

DB_RAM DB_ROM DB_FLASH DB_EEPROM

RAM: work FLASH: firmware FLASH: parameters EEPROM: data

The only area that will be used during the normal operations is the DB_RAM. The

other three areas will be used only to manage the initialization and the storage of the

data contained in the DBASE_RAM area.

To understand why there are 4 different areas and how they behave, it is necessary to

illustrate the kind of storage in which they have been allocated:

- DBASE_RAM allocated in RAM storage. This means that when the DGF is

powered off all data contained in it are lost.

- DBASE_ROM allocated in the FLASH storage. This means that this

information can neither be lost nor modified by the user.

- DBASE_FLASH allocated in a special area of the FLASH storage, which is

different from DBASE_ROM. This means that information is

not lost at power off. This area can be deleted or rewritten

through particular commands at the user’s disposal. Unfortunately the reading and writing operations are executed quite

slowly , 2 or 3 seconds, so these operations are possible only

in particular conditions.

- DBASE_EEPROM allocated in EEPROM storage. This storage can be deleted or

written quickly and all data contained in it are not lost, even

when the DGF is powered off.

As we described above, the software operates from DBASE_RAM. This area is allocated

RAM storage. This means that at power-on the data is unpredictable, so it is necessary

to carry out an initialization. The operation is done by copying the DBASE_FLASH

into the DBASE_RAM, in other words, the default values are loaded.

The DBASE_RAM is composed of a collection of records. Each record contains the

parameter and the information that describes it.

20

—————— Digital General Function Card ——————

Page 21

6KCV301DGF

The user may need to do one of the following operations:

- Read the parameter’s value.

- Change the parameter’s value.

- Read one or more information field(s) of the record associated with the parameter.

- Change one or more information field(s) of the record associated with the parameter.

If the user decides to carry out some modification on the parameter or on the record

that describes it, the new information will be stored in DBASE_RAM. With the

characteristics of the DBASE_RAM storage, all the modifications made by the user

will be lost at the first power-off of the DGF . To avoid this, the user must carry out

a storage operation of the DBASE_RAM. In other words the user must copy

DBASE_RAM into DBASE_FLASH. Below are some considerations concerning this

operation:

- Not all the parameters and their associated fields that are contained into

DBASE_RAM are copied into the DBASE_FLASH but only those parameters in

which the attribute MEMO has been set in a suitable way.

- The writing into DBASE_FLASH is a slow operation that requires 2 or 3 seconds.

For this reason this operation can be executed only when the DGF is in IDLE

status.

- At power on , after the DBASE_ROM has been copied into the DBASE_RAM,

the DBASE_FLASH is analyzed. If it is OK, it will automatically execute a copy

of the DBASE_FLASH into the DBASE_RAM, retrieving the customization made

by the user.

To save: use HIBS, or drive keypads.

The fourth area where some data of DBASE is stored is DBASE_EEPROM. For

example, it is useful in the following conditions :

- DGF configuration has been performed while drive and the DGF are working.

The Drive and DGF cannot be stopped for the couple of seconds that it requires to

make a copy of the DBASE_RAM into the DBASE_FLASH.

- DGF configuration has been performed while the drive and DGF are working. If,

for unpredictable reasons, the DGF must be powered off, we do not want to lose

the configuration parameters.

Under either of these conditions ( or any other where the value of a parameter must be

saved immediately after its modification, even if the DGF is in RUN status), the

DBASE_EEPROM is available. This storage retentive area allows the storage of the

parameter’s value, but not its attributes, when the DGF is in RUN status.

So the initialization of the DBASE of the DGF can be summarized in the following

schema:

1) Power on or reset of the DGF

2) The DBASE_ROM is copied into DBASE_RAM. All the parameters and

respective records have their default values.

3) The integrity of the DBASE_FLASH is checked. If satisfactory:

—————— Digital General Function Card ——————

21

Page 22

GEI-100430

4) The DBASE_FLASH is copied into DBASE_RAM. All the parameters and

respective records have the user’s customization.

5) The attribute MEMO of each parameter is checked and if it is equal to RUN the

parameter’s value is copied from DBASE_EEPROM to DBASE_RAM.

2.1.4 Parameters and variables

The configurations parameters of the DGF can be divided in two main categories:

- Predefined

- General

The two categories are necessary because the DGF , unlike the Drive, is a programmable

device. This means that a user, during the development of a regulation program, could

need to use parameters to configure the program developed.

The predefined parameters are used to configure the basic functions of the DGF

firmware. Their behavior is totally fixed during the development of the basic software,

as in the Drive parameters.

The general parameters are defined by the firmware but their behavior is not defined.

The behavior of these general parameters is determined by the user , who develops the

application. This means that the user can develop some regulations that can be configured

later, for instance through the keypad of the drive. General parameters have the same

rules as predefined ones.

Win+ VERSION 1:

The general parameters are effectively composed of two arrays of variables :

-FVAR is an array composed of 50 variables of floating-point type

-IVAR is an array composed of 50 variables of integer type

Win+ VERSION 2:

The general parameters are effectively composed of three arrays of variables :

-FVAR is an array composed of 200 variables of floating-point type

-IVAR is an array composed of 200 variables of integer type

-NUM is an array composed of 100 variables of configured type

All these variables can be used for any reason inside the program developed by the

user. These variables are totally at the user’ s disposal. This doesn’t mean that the DGF

firmware will not modify these variables, such as:

- Initialization

- Management of the access to the variable from the external environment

- Storage

22

—————— Digital General Function Card ——————

Page 23

6KCV301DGF

2.1.4.1 Initialization of the General variables

Each General variable (IVAR, FVAR and NUM) is combined with the attribute Init

Level stating the rule with which these variables are initialized by the firmware.

This attribute can have the following values:

Firmware

Persistent

Retentive

Volatile

The variable initialization and control is carried out by the standard

firmware and the user has no possibility to intervene

The variable initialization value can be modified by the final user and it

is stored in the DBASE. This variable is initialized with a value set at the

card start.

The initialiation value is set during the program developing phase. The

final user CAN NOT modify the initialization value but he can modify

the variable value after the initialization. The variable initialization is

carried out during every transition from the IDLE to the READY

condition.

The initialiation value is set during the program developing phase. The

final user CAN NOT modify the initialization value but he can modify

the variable value after the initialization. The variable initialization is

carried out during every transition from the READY to the RUN

condition.

d0070g

2.1.4.2 Data management inside the DBASE

Each parameter that has been put up from DBASE is identified through a unique

identifier, called IP A. Furthermore, for each parameter , predefined or general, a data

record is associated that regulates the behavior of the parameter in the different phases

of the program. The detailed description of the fields of this record will be made in

another paragraph but the functions which are conditioned by this record are the

following :

- Initialization at power-on

- Access to the parameter from the external world.

- Parameter storage

- Display of the parameter on the keyboard of the Drive.

2.1.4.3 Access to a parameter from the external world

The external world can access a parameter to perform one of the following operations:

- Parameter reading

This operation is always possible independent from the DGF status. The parameter is

normally returned in the size specified by the attribute TYPE.

—————— Digital General Function Card ——————

23

Page 24

GEI-100430

- Parameter writing

The execution of this operation is conditioned by the following attributes from the

descriptive record

STATUS OF ACCESS permissible values:

READ ONLY the parameter can only be read.

WRITE IDLE the parameter can be changed only in IDLE status.

WRITE READY the parameter can be changed in IDLE and READY status.

WRITE RUN the parameter can be changed in IDLE, READY or RUN status.

WRITE ALL the parameter can be changed independently from status.

LEVEL OF ACCESS it is possible to protect the access to a parameter through a

password.

The DBASE provides 4 level of access :

Level 0 access permitted without any protection

Level 1 access protected using a first password

Level 2 access protected through a second password

Level 3 access protected through the factory password

MINIMUM and MAXIMUM these two attributes set the limits for the new value of

the parameter .

- Reading an attribute of the associated record.

This operation is always possible independently from the status of the DGF.

- Writing an attribute of the associated record

This operation is possible only when the DGF is in IDLE status.

2.1.4.4 Storage of the parameter and of the associated record

The management of the parameter storage is regulated through the attribute MEMO

that can assume the following values:

OFF This option indicates that neither the parameter nor the

respective attributes will be saved in the DBASE_FLASH. This

means that this record assumes the default

values(DBASE_ROM) at power on.

ATTRIBUTE This option indicates that only the attributes linked with the

24

—————— Digital General Function Card ——————

Page 25

6KCV301DGF

parameter are saved in the DBASE_FLASH, while the

parameter value won’t be saved. This means that when the DGF

is reset, the DEF AUL T value of this parameter contained in the

DBASE_ROM is loaded, while the attributes record is loaded

from DBASE_FLASH. The utility of this option is when, for

instance, with a read-only parameter, the user wants to change

the attribute NAME or the attribute UNM. This operation can

be executed only when the DGF is in status of IDLE.

IDLE This option indicates that the parameter and respective attributes

are stored in the DBASE_FLASH. This operation can be carried

out only when the DGF is in IDLE status.

RUN This option indicates that the parameter is stored in

DBASE_EEPROM in each status, while the attributes will be

stored in the DBASE_FLASH only in IDLE status.

The commands that allow the execution of the above-mentioned operations are described

in Appendix A. Key-pad operation is described in section 2.4.1.

—————— Digital General Function Card ——————

25

Page 26

GEI-100430

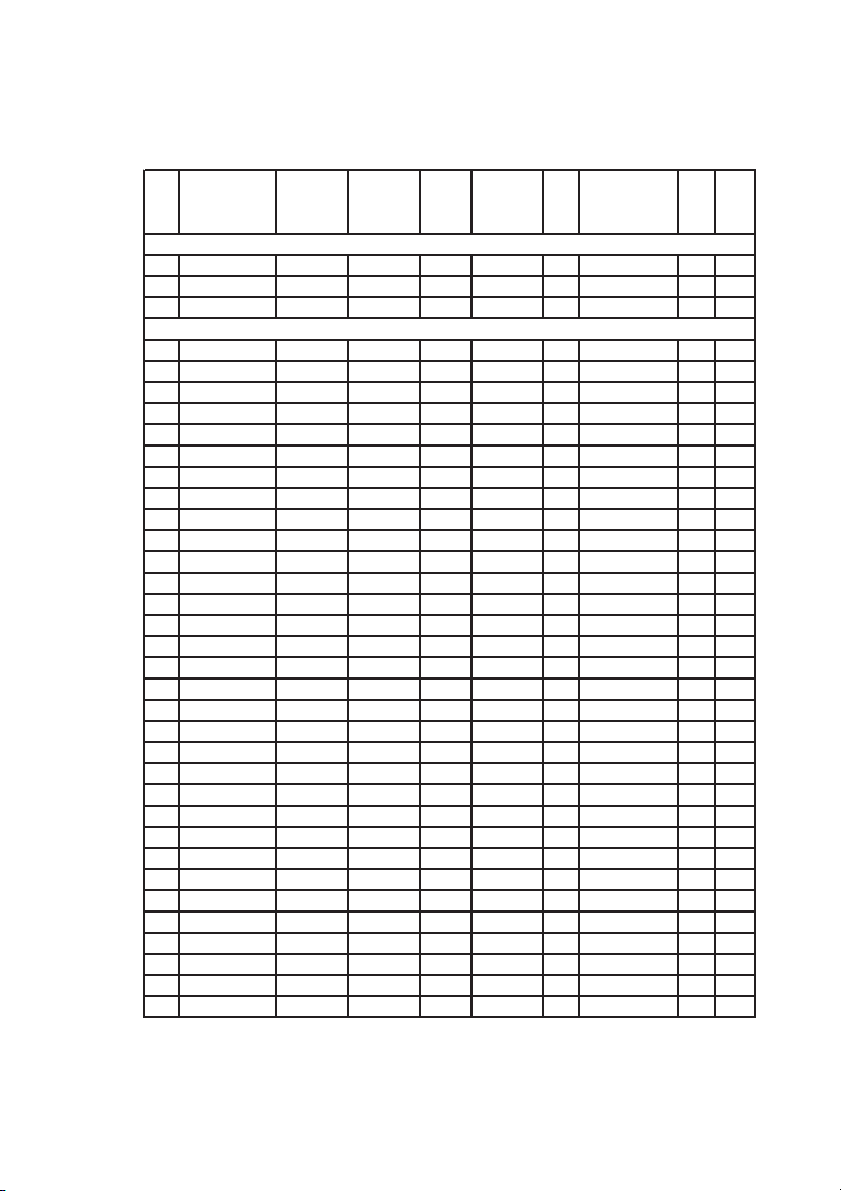

2.1.5 FVAR, IVAR and NUM

The DBASE and the FVAR and IVAR arrays have been described in the previous

paragraphs. We can imagine the DBASE as a data array that has been assembled in

connection with its function and destination.

IPA

1

2

100

299

300

349

350

399

400

499

500

599

600

699

700

799

1000

1199

1200

1399

2000

2009

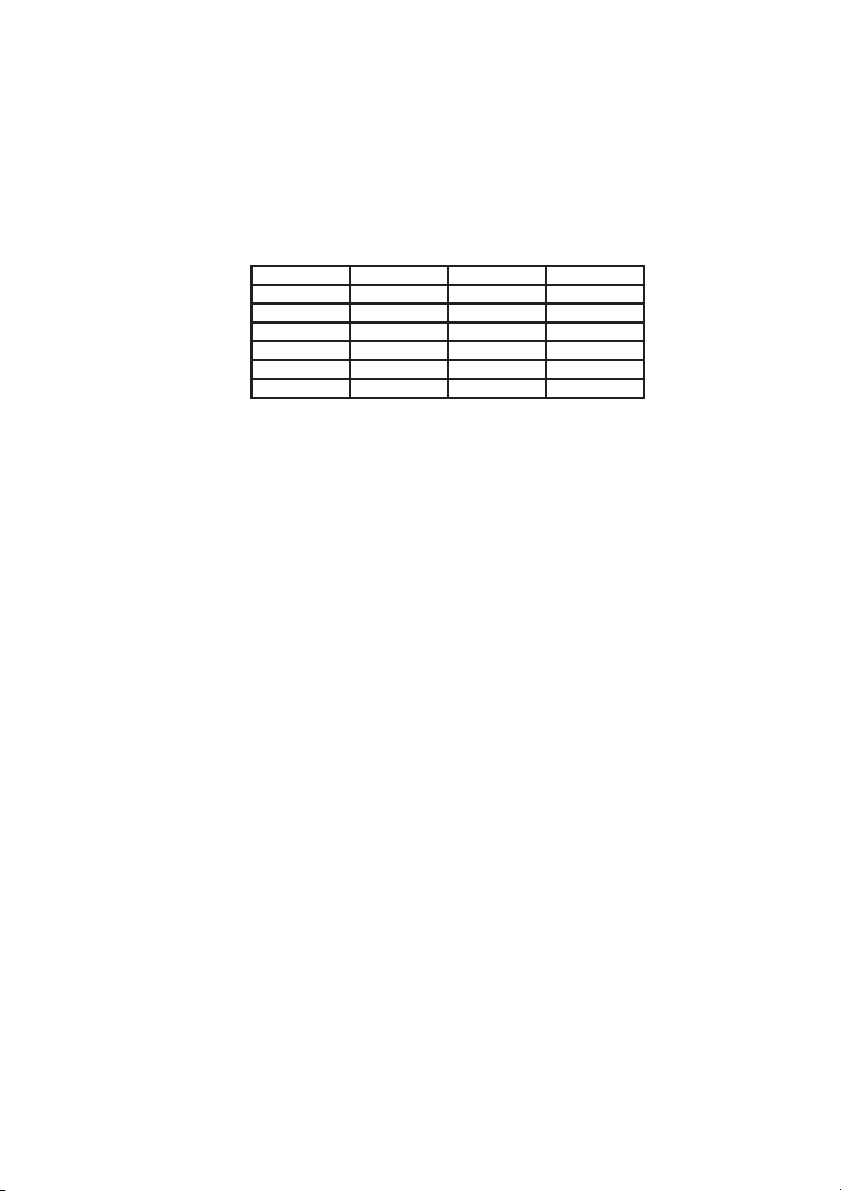

Win+ 1.X Win+ 2.X

Parameters group Parameters group

Software versions

customer codes

DPRAM configurations

hardware configurations

WIN+DRIVE configurations

DeviceNet configurations

System parameters

FVAR

n/a

IVAR

FVAR

n/a

IVAR

NUM

d0080

The observation of this table allows us to note that data written into retentive and

volatile groups will be lost at DGF power off.

2.1.6 DPRAM organization

The drive and the DGF are two devices that can be configured or conditioned through

the parameters. There are two different set of parameters: one for the Drive and one for

the DGF. The DGF can condition the Drive’s working by acting on its parameters.

Reading and writing from the DGF to the parameters of the Drive occurs through the

DPRAM.

26

—————— Digital General Function Card ——————

Page 27

6KCV301DGF

2.1.6.1 DPRAM hardware

From the hardware point of view, the DPRAM is a bi-accessible storage device.

RAM ROM

RAM ROM

D

P

R

A

M

Microp.

DGFC_386

Microp.

Figure 2.1.7.1.1: DPRAM Hardware

As shown above, the drive microprocessor accesses its own RAM and ROM and

DPRAM on the DGF . The DGF microprocessor accesses its own RAM and ROM and

DPRAM. The DPRAM chip is 2 Kbytes RAM storage. The feature of this chip is that

the storage cells can be accessed by the two buses but these buses cannot access each

other. This permits the two cards to exchange data without affecting each other.

2.1.6.2 DPRAM software organization

The DPRAM storage area has been designed with different areas to support the different

types of connection between the DGF and the Drive. These connections satisfy different

needs and are executed at different times and with different modalities. The need to

build up different kinds of connections comes from the need to satisfy and coordinate

the different elements of the system.

The drive parameters can be divided into three categories, according to the speed with

which it is possible to access them:

- “parameters of configuration”: the access time is very long so that it is not possible

to use them in the automatic connections .

- “low priority” parameters: they have a medium access time so that it is possible to

use them through the automatic asynchronous connection .

- “high priority” parameters: they have a quick access time so that it is possible to

use them with all the automatic connections.

—————— Digital General Function Card ——————

27

Page 28

GEI-100430

The defined categories in the DPRAM satisfy the following needs:

1) DGF to access the drive parameters. These channels of connection can be divided

into two main categories:

MANUAL The manual connections allow access to all the parameters of

the Drive. The goal of this connection is to allow devices

connected to the DGF , for instance through the serial port RS485, to access the Drive parameters.

AUTOMATIC The automatic connections allow access to only some of the

Drive’s parameters. The goal of these connections is to allow

the DGF regulation program to manage the Drive. There are

two automatic connections:

SYNCHRONOUS The automatic synchronous connection

, called SYN DPRAM, allows access

to only the “HIGH PRIORITY”

parameters of the Drive. This

connection is managed by the DGF

from the task SYN DPRAM with all

the characteristics of this task.

ASYNCHRONOUS The automatic asynchronous

connection, called ASYN DPRAM,

allows access to only the HIGH and

LOW PRIORITY parameters of the

Drive. This connection is managed on

the DGF from the task ASYN DPRAM

with all the charac-teristics of this task.

2) DGF to manage the keypad of the Drive. This operation is executed by the structure

of connection GSTKEY.

3) Devices connected to the Drive through the optional card SBI to access the

parameters of the DGF.

4) Issue messages SLINK3 received from the Drive by the serial port RS-485 to the

DGF .

5) Management of a special status structure which allows two devices, the DGF and

Drive, to know the respective status.

6) Management of a check structure like Watch-dog which ensures a check on the

correct working of the operations.

28

—————— Digital General Function Card ——————

Page 29

6KCV301DGF

2.2 DGF STATUS

The software of the DGF has a status logic. In each status different functions are executed.

The following figure shows all the possible states and transitions of DGF modes.

RESET

0

SINCRO

1

IDLE

3

2

11

READY

5

RUN

4

8

7

9

ALERT

6

Figure 2.2.1: Logic of DGF status

The transition from one status to another occurs via commands sent to the card by the

DGF serial line, keypad, serial line of the drive, field bus, or digital input.

SINCRO: The DGF moves into this state only after a reset of the system.

In this phase the following operations are executed:

- initialization of hardware devices

- synchronization with the drive

- initialization of DBASE data from ARCHIVE DBASE

At the end of these operations the DGF goes automatically

into IDLE.

IDLE: The DGF can move into this state from any other one. IDLE is

the programming status. In this state, the following commands

can be executed:

- configuration of DPRAM automatic structures

- configuration of system parameters

- loading and updating of ARCHIVE DBASE areas

—————— Digital General Function Card ——————

29

Page 30

GEI-100430

- reading / writing of all the parameters

- loading and saving database commands

- moving to the READY status

The DGF can also arrive in this state from RUN or READY

status When the DGF is in this status the drive is placed into a

“Block” condition. From the IDLE status only the transition to

the READY status is possible. This transition is automatic only

at the start-up, in any other case it must be requested by the user.

Before leaving the IDLE status, the DGF always checks that

all functions are correctly configured. If not, the DGF remains

in IDLE.

READY: Normal status of the card at the start-up, if there are no problems

at configuration.

The control can move into this condition from any other one.

In READY, the card is ready to execute the user program that

has been loaded; the parameters of the card can be read or

written but the loading and saving commands of database cannot

be performed. Automatic structures with the drive are alive

but the read value are ignored and the values written are

fixed(usually set to 0). From this status the card can move to

IDLE, RUN and, in case of malfunction to ALERT. This is the

only status that allows the transition into RUN.

RUN: DGF can arrive in this condition only from READY. The

software executes periodically the following operations:

1 - execution of applications program

2 - synchronous and asynchronous communication with the

drive

3 - interface to any optional I/O cards

From RUN the card can move to the READY, IDLE or ALERT

conditions.

ALERT : The DGF can arrive in this condition from any other status, if

a system malfunction is detected. The transition to ALERT

status causes an alarm on the drive (“Opt2”).

The card can exit this status via an alarm reset command.

From ALERT, the card can move to READY or to IDLE.

The main events that can move this card into this status are:

- malfunctioning of the hardware

- errors of co-processor 80C387

- DPRAM communication errors

- watch dog hardware

- regulation alert

30

—————— Digital General Function Card ——————

Page 31

6KCV301DGF

2.2.1 Status commands

The status can be changed by writing the status parameter, by a digital input, by the

status transition of the drive or by the keypad of the drive.

It is also possible to know the status by reading the status parameter or by looking at

the LEDs H1, H2, H3 and H4 of the DGF.

The following table shows how the LEDs change their state depending on DGF status.

LED H1 is always blinking when the DGF communicates with the drive.

at RESET ON ON ON

SINCRO ON OFF OFF

IDLE OFF ON OFF

READY ON ON OFF

RUN OFF OFF ON

ALERT Blink Blink Blink

LED H4 LED H3 LED H2

d0110g

Table 2.2.1: Leds status

If the execution of an illegal transition is attempted, the command is ignored.

Possible status transitions

1 - RESET->IDLE:

At the start up or at the reset of the card, the system moves into the IDLE condition,

and if an application program is loaded, the DGF moves automatically to READY.

Otherwise it remains in IDLE.

2 - IDLE->READY:

This transition occurs if a the program is formally correct. The following cases are

possible:

- automatic at the start up if an application program is loaded

- by writing the status parameter

3 - READY->IDLE:

This transition is possible only by writing the status parameter.

4 - 5 READY->RUN and RUN->READY:

These two transitions depend on a parameter.

By writing this parameter, it is possible to select the event that determines the transition.

Possible events are:

- only by writing the status parameter

- only by enable/disable transition of the drive

- only by digital input

—————— Digital General Function Card ——————

31

Page 32

GEI-100430

6 - 7 - 8 STATUS->ALERT:

From any status, the DGF moves automatically into the ALERT status in case of detected

malfunction. An alarm “Opt2” is forced to the drive.

It is also possible to put the DGF in an alarm condition via the serial line of the option.

NOTE: This transition disables the drive.

9 - ALERT->READY:

The transition occurs if the DGF moves to ALERT from the READY or RUN status.

This transition depends on a parameter.

By writing this parameter it is possible to program the event that allows exiting the

alert status. Possible events are :

- only by writing the status parameter

- only by the failure reset of the drive

- only by digital input

10 - ALERT->IDLE:

This transition occurs if the DGF moves to ALERT from IDLE condition. The

description at point 9 is valid also here.

11 - RUN->IDLE:

This transition is possible only by writing the status parameter.

NOTE: This transition disables the drive.

2.2.2 Alarms

When an alarm is generated, the DGF always moves to ALERT status. This forces an

alarm “Opt2” on the drive. Note that all the alarms disable the drive. There are two

types of alarms:

Alarm type 1: “simple” alarms (e.g. alarms generated from an application) . It is possible

to exit from alarm status by executing a transition 9 of the status logic.

Alarm type 2: Severe alarms or malfunctions of the DGF (e.g. hardware). It is possible

to exit this status only by resetting the DGF or switching the drive off.

The alarm code can be read through an “ERROR CODE” via serial line, by using a

HIBS program, or via the keypad.

Any DGF alarm has an alarm code and may also have an alarm cause (description).

Both kinds of information are available on local drive keypad and through the HIBS

program. When an alarm occurs while using the keypad, the following message blinks

on the keypad:

Failure

Opt2: XXXX-YYYY

XXXX = ALARM CODE is the main code

YYYY = ALARM CAUSE contains more detailed information about the alarm

32

—————— Digital General Function Card ——————

Page 33

6KCV301DGF

The following table shows the list of alarm codes.

CODE NAME TYPE DESCRIPTION

0 AL_NONE - no alarms

1 AL_WD_DPRAM 2 DPRAM watchdog

2 AL_DPRAM 2 DPRAM communication

3 AL_DRIVE 2 Drive alarm

4 AL_AZT_CHK 2 DPRAM checksum error

5 AL_AZT_UCMD 2 Unknown command from drive

6 AL_NPX 2 Numeric processor exception

7 AL_PERIOD 2 Period not executed

8 AL_SER 1 Serial line

11 AL_BRICK_UNK 2 Unknown brick

12 AL_BRICK_USR 1 Brick ALL alarm (applications alarm)

13 AL_BRICK_FUN 2 Unknown I/O Brick functions

14 AL_BRICK_DP 2 DPRAM brick alarm

15 AL_REGISTER 2 Reserved (GS or FS register corrupted)

16 AL_CCZ 2 CCZ hardware alarm

17 AL_STACK TASK 2 Reserved (Task stack overflow)

18 AL_TIME_BASE 1

20 AL_WPD_CFG 1 WPD configuration alarm

21 AL_WPD_EXE 1 WPD execution alarm

22 AL_DNET 1 DeviceNet

30 AL_EH_TYPE_0 2 Reserved

Time base DGF card different from Time base

AZT

Table 2.2.2.1: DGF alarm codes

d0120g

CAUSE NAME DESCRIPTION

1 rd_sincro new_cfg != CFG_OK

2 rd_sincro SEM busy

3 rd_sincro checksum

4 rd_sincro LAST WRITE not updated

11 wr_sincro new_cfg != CFG_OK

12 wr_sincro SEM busy

14 wr_sincro LAST WRITE not updated

21 first initialization or synchronization failed

22 medio dpram task not activated

30 rd_stato 30+control status

41 wd_asincro

42 wd_asincro configuration

51 rd_asincro

52 rd_asincro configuration

Table 2.2.2.2: Alarm code 2 (AL_DPRAM)cause

—————— Digital General Function Card ——————

d0140g

33

Page 34

GEI-100430

Alarm CODE 1, 2, 4, 5: generated if there are hardware problems in the communication

with the drive. Replace DGF or Regulation card, check XO

connections. See table 2.2.2.2.

Alarm CODE 6: generated if an error code in the mathematics co-processor is

detected (e.g. zero indexing). The possible errors of the

mathematics co-processor are shown in the table 2.2.2.3. Check

the scheme for Mathematical error (E.g. division by 0).

DEFAULT

MSG Exception Cause

Illegal Operation on a signal,

unsupported format, indeterminate

-

∞

form (0

or stack overflow / underflow (SF is

also set)

, 0/0), (+∞)+(-∞), etc.)

IE

Invalid

Operation

ACTION (If

exception is

Masked

Result is a quiet

NaN, integer

indefinite or BCD

indefinite

The operand is

normalized, and

normal processing

continues

Result is

Result is largest

finite value

Result is

denormalized or

zero

Normal processing

continues

∞

∞

d0130

Denormalized

DE

operand

ZE Zero Divisor

OE Overflow

UE Underflow

Inexact Result

PE

(Precision)

At least one of the operands is

denormalized, i.e. it has the

smallest exponent but a nonzero

significand

The divisor is zero while the

dividend is a noninfinite, nonzero

number

The result is too large in magnitude

to fit in the specified format

The true result is nonzero but too

small to be represented in the

specified format, and, if underflow

exception is masked,

denormalization causes loss of

accuracy

The true result is not exactly

representable in the specified

format (e.g.1/3); the result is

rounded according to the rounding

mode

Table 2.2.2.3: Alarm code 6 cause

Alarm CODE 7: generated if the execution cycle of the application code remains

active for a longer time than the max. time expected (50 ms).

This is possible if, for instance, there is an infinite loop in the

program. Increase execution time or reduce your application.

34

—————— Digital General Function Card ——————

Page 35

6KCV301DGF

Alarm CODE 8: generated via the DGF serial line.

Alarm CODE 11: unknown block. The program contains an unknown block.

Check the scheme.

Alarm CODE 12: alarm generated by the application program or Win+Drive via

an ALL block.

E.g.: space error in a system like “ELECTRICAL AXIS” or

block for this alarm is used in the application.

Alarm CODE 13: generated if the program contains a call to an invalid I/O block

(I/O optional cards).

Verify the connections in your scheme I/O blocks.

Alarm CODE 14: software alarm in the DPRAM interface due to a wrong

conversion of the read or written value.

V erify the DPRAM block setting on the scheme (e.g. FLOA T to

integer).

CAUSE NAME DESCRIPTION

0..99 AL_BRICK_DP_S_IE INT—>EXT syn

100..199 AL_BRICK_DP_S_EI EXT—>INT syn

200..299 AL_BRICK_DP_A_IE INT—>EXT asyn

300..399 AL_BRICK_DP_A_EI EXT—>INT asyn

Table 2.2.2.4: Alarm code 14 (AL_BRICKS_DP) cause

d0150g

Alarm CODE 15, 17,30: DGFCy internal software alarms.

CAUSE NAME DESCRIPTION

1 AL_FS FS register alarm

2 AL_GS GS register alarm

d0160g

Table 2.2.2.5: Alarm code 15 (AL_REGISTER) cause

Alarm CODE 16: CCZ hardware alarm, signaling a hardware malfunction of

the card. Replace the card or check X0 connector.

CAUSE NAME DESCRIPTION

1 ALC_CCZ_1 CCZ not false at start

2 ALC_CCZ_2 CCZ not true at start

3 ALC_CCZ_3 CCZ is at first FALSE and then TRUE

d0170g

Table 2.2.2.6: Alarm code 16 (AL_CCZ) cause

Alarm CODE 18: generated if the DGF time base is different from drive time

base. See the system parameter value (IPA 500 up to IPA600)

Alarm CODE 20: Win+Drive configuration alarm. Verify the DPRAM block

setting on the scheme (e.g. DPRAM configuration error).

Alarm CODE 21: Win+Drive execution alarm.

Alarm CODE 22: DeviceNet. See Dnet Manual.

—————— Digital General Function Card ——————

35

Page 36

GEI-100430

CAUSE NAME DESCRIPTION

0..1000 ALC_WFIX WFIX brick alarm

1000..1999 ALC_RFIX RFIX brick alarm

2000..3999 ALC_CFIX CFIX brick alarm

10000 ALC_M10_TIMEOUT Time-out mode 10

d0180g

Table 2.2.2.7: Alarm code 22 (AL_DNET) cause

2.2.2.1 Alarm code from the drive

The following ALARM CODES are generated by the drive if it detects a malfunction

with the DGF.

Replace DGF or Regulation card, check XO connections

CODE NAME TYPE DESCRIPTION

100 AL_DPRAM_DRV 1 DPRAM communications on Drive

101 AL_CCZ_DRV 2 CCZ hardware on drive

d0190g

Alarm 100 (AL_DPRAM_DRV): ALARM CAUSES

CAUSE NAME DESCRIPTION

1 AL_WD_SW Software watchdog on drive

2 AL_CHK_KEY Checksum err. on keypad communication

3 AL_CFG_OPAZ_LP Configuration err. IE-ASYN

4 AL_CHK_OPAZ_LP Checksum err. IE-ASYN

5 AL_CFG_OPAZ_HP Configuration err. IE-SYN

6 AL_SEM_OPAZ_HP Semaphore IE-SYN

7 AL_LWR_OPAZ_HP Last write IE-SYN

8 AL_CHK_OPAZ_HP Checksum IE-SYN

9 AL_CFG_AZOP_LP Configuration EI-ASYN

10 AL_CFG_AZOP_HP Configuration EI-SYN

11 AL_SEM_AZOP_HP Semaphore EI-SYN

12 AL_LWR_AZOP_HP Last write EI-SYN

13 AL_SYNC_WD Watch dog synchronization alarm

99 AL_GEN_DPRAM

111 OPT2_TMO_SINCRO Synchronization timeout

Drive DPRAM structure has been

disabled

d0200g

2.2.2.2 Severe alarm

It is not always possible for the DGFCy to recover from an unexpected condition. In

this case all functionality of the card is disabled. The DGFCy starts blinking LEDs

H1,H2,H3 and H4. The following table describes the type of these errors. The exception

ID is the number that is blinked on the LEDs.

36

—————— Digital General Function Card ——————

Page 37

6KCV301DGF

LEDs H4-H3-

EXCEPTION

ID

1 80387 0-0-0-1 severe hardware error (*)

2 divide error 0-0-1-0

4

5 array bound 0-1-0-1

6 invalid opcode 0-1-1-0

7

8 double fault 1-0-0-0

9

10 invalid Tss 1-0-1-0

11

12 stack exception 1-1-0-0

13 general protection 1-1-0-1

14 page fault 1-1-1-0

15 bus failure 1-1-1-1 severe hardware error (*)

NAME

INT0 detected

overflow

coprocessor not

available

coprocessor

segment overrun

segment not

present

H2-H1

(1=ON,0=

OFF)

0-1-0-0

0-1-1-1 severe hardware error (*)

1-0-0-1

1-0-1-1

BRIEF DESCRIPTION

division by 0/division overflow

(**)

severe software error (*)

severe software error (*)

d0210g

(*) : Replace DGF or Regulation card. If the problem persist please contact your

sales office.

(**): Verify application,check the scheme or parameter for Mathematical error (E.g.

division by 0).

—————— Digital General Function Card ——————

37

Page 38

GEI-100430

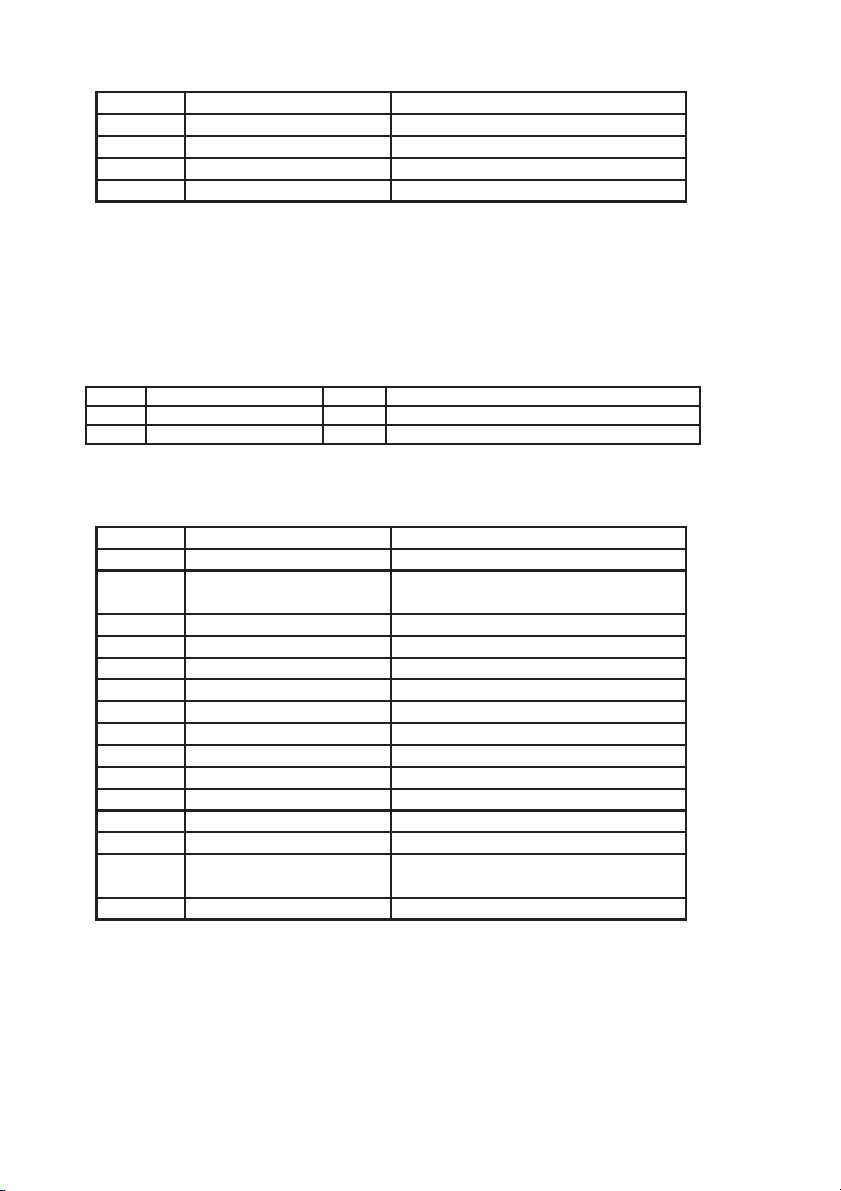

2.3 DATA FORMATS

The table shows the characteristics of each type of data used in the DGF.

Name in

TYPE

language

VOID void 0 N/A N/A N/A

CHAR char 1 1 0 255

UCHAR

INT int 3 2 -32768 32767 Signed integer

UINT

LINT long int 5 4 -2147483648 2147483647 Signed integer

ULINT

FLOAT float 7 4 -3.40E+38 3.40E+38

DOUBLE double 8 8 -1.79E+308 +1.79E+308

LDOUBLE N/A 9 10 -1.1E+4932 1.1E+4932

SHREAL N/A 10 4 -1.677E+70 1.677E+70 (2)

SLREAL N/A 11 4 -32768E+63 32768E+63 (3)

S3HREAL N/A 12 3 -5.2E+12 5.2E+12 (2)

S3LREAL N/A 13 3 -32768E+63 32768E+63 (3)

HUCHAR N/A 21 1 0 255

HUINT N/A 22 2 0 65535

HULINT N/A 23 4 0 4294967295

unsigned

unsigned

unsigned

long int

(2) Floating point, base 10 representation, high precision

(3) Floating point, base 10 representation, low precision

C

char

int

TYPEIDLength

in bytes

2 1 -128 127

4 2 0 65535

6 4 0 4294967295

MIN(1) MAX(1)

Signed

character

Unsigned

character

Unsigned

integer

Unsigned

integer

Floating

point(7 digits

BCD)

Floating point

(not used)

Integer 32 bit

in hexadecimal

format

d0220g

N/A: not applicable

(1) for floating point, MIN and MAX values are approximate

2.3.1 Description of base-10 floating point

2.3.1.1 SHREAL format

Characteristics: mantissa = 24 bits + sign (25 bit as complement of 2)

38

—————— Digital General Function Card ——————

Page 39

6KCV301DGF

exponent (base 10) = 6 bits + sign (7 bit as complement of 2)

Sm Se 6 bit exp. Hi-byte Med-byte Low-byte

Mantissa (3 bytes as complement of 2)Exponent

d0230g

Low-Med-Hi bytes + Sm = mantissa as complement of 2 (25 bit)

Exp + Se = exponent as complement of 2 (7 bit)

2.3.1.2 SLREAL format

Characteristics: mantissa = 15 bits + sign (16 bit as complement of 2)

exponent (base 10) = 15 bits + sign (16 bit as complement of 2)

HIGH WORD Exponent

Se Hi-byte

15 bit exp. (*) Low-byte

Mantissa (2 bytes as complement of 2)

LOW WORD

d0250g

Low-Hi bytes = mantissa as complement of 2

Exp + Se = exponent as complement of 2

(*) representation of the exponent limited to 63 by the software.

2.3.1.3 S3HREAL format

Characteristics: mantissa = 19 bits + sign (20 bits as complement of 2)

exponent (base 10) = 3 bits + sign ( 4 bits as complement of 2)

HIGH BYTE HIGH BYTE LOW BYTE

HIGH WORD LOW WORD LOW WORD

Always 0 Se Exp SM Mantissa

15 .......................... 8 7 6 . 4 3 2 ......... 0 15 ................... 8 7 ....................... 0

LOW BYTE

HIGH WORD

Bit Number

Exp + Se = exponent as complement of 2 (4 bit)

Mantissa + Sm = mantissa as complement of 2 (20 bit)

2.3.1.4 S3LREAL format

Characteristics: mantissa = 1 word + sign (as complement of 2)

exponent (base 10) = 1 byte + sign (as complement of 2)

HIGH BYTE HIGH BYTE LOW BYTE

HIGH WORD LOW WORD LOW WORD

Always 0

15 .......................... 8 15 ................... 8 7 ....................... 0

LOW BYTE

HIGH WORD

Exponent (*) Mantissa

7 ............................. 0

Bit Number

Exponent = exponent as complement of 2

Mantissa = mantissa as complement of 2

(*) representation limited to 63 by the software.

—————— Digital General Function Card ——————

d00260g

d0270g

39

Page 40

GEI-100430

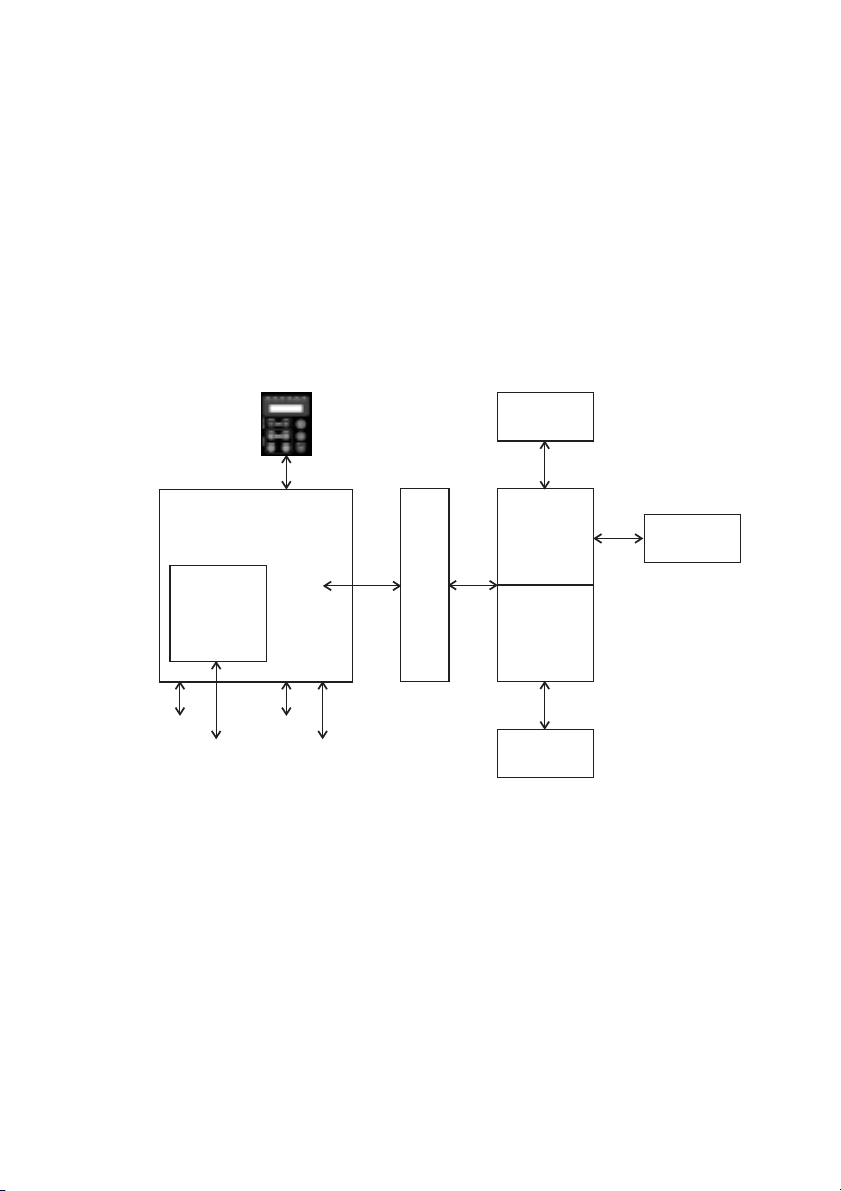

2.4 INTERFACE

The most common access to the parameters of the card is done using the drive keypad.

From the OPTIONS\Option2\Menu menu, the parameters of the option can be read/

written, status and database commands can be executed.

DRIVE

PLC

FIELD BUS card

DNET card

DGFC

FIELDBUS

card

BUSDNET

SLINK3 SLINK3

RS485RS485

Figure 2.4.1: DGF Communication

A second possibility is the use of the DGF serial line, connecting it to a personal

computer and using a HIBS program. It is possible to execute read/write parameter

commands, supervision pages, to visualize the card parameters, execute status commands

or database load and save commands from/to disk. The serial line of the option uses SLINK3 protocol.

DGF parameters can be read or written also via the serial line of the drive on which it

is installed. Figure 2.4.1 shows the various connection and communication possibilities.

2.4.1 Drive keypad

The drive keypad can be used to control the functions of the DGF, and to modify the

DGF parameters.

T o enter the DGF Menu from the drive main menu, it is necessary to call the submenu

OPTION, then OPTION 2.

The “OPTIONS/OPTION2/OPT2” submenu contains the Enable/Disable option

command that enables or disables the DGF. This parameter is read only once at

power on. If modified, the new value is operative after the next power on.

In the “OPTION/OPTION2/MENU”, the DGF controls the keypad. DGF items are

displayed through the menus and submenus; you can move in the menu by pressing

UP (from the current item to the previous one) and DOWN (from the current item to

the next one). If you are not able to access OPTION2\MENU, this means that the DGF

is not recognized by the drive.

The current menu or submenu can be entered by pressing ENT (access to submenus)

and ESCAPE (return to the previous menu or submenu).

The structure of the various menus of the DGF is shown in the following diagram:

40

—————— Digital General Function Card ——————

Page 41

6KCV301DGF

MENU

OPT2

VIEW PARAMETER

VIEW DATA BASE

STATUS DGFC

RESET ALARM

IDLE TO READY

READY TO RUN

STATUS TO IDLE

ARCHIVES

CHECK ALL DB

SAVE ALL DB

LOAD ALL DB

INIT ALL DB

CHECK PARAMETERS

SAVE PARAMETERS

LOAD PARAMETERS

DEFAULT PARAMETERS

CHECK BRICKS

SAVE BRICKS

LOAD BRICKS

INIT BRICKS

SPECIAL FUNCTIONS

PASSWORD

d0028

MENU VIEW PARAMETER:

In this submenu all parameters of the card are displayed. If the parameters can be

changed and the status logic permits it, they can be written.

To access this menu (from OPTION/OPTION2/MENU) move among menus by pressing

UP and DOWN until you find:

opt: DGFC

view parameters

k001

then press enter(ENT).

You are now in the view parameters DGF menu.

Once enter is pressed the following information will be displayed:

1DgfcBrk386

1.000 ver

k002

The first line shows a number (this is the IPA of parameter) and a string (this is the

DESCRIPTOR).

The second line shows the actual value of the parameter and the measure unit, if any. If

the parameter type is defined as hexadecimal, the parameter is displayed in hexadecimal

notation. You can move from a parameter to another by pressing UP and DOWN .

For example, by pressing DOWN , a new parameter will be displayed:

—————— Digital General Function Card ——————

41

Page 42

GEI-100430

749 ivar 49

0

_______

k003

If you want know some of the parameter attributes press enter(ENT).

749 ivar 49

par 0

k004

By pressing UP and DOWN you can display some attributes of the parameter.

Available attributes are:

par

min

max

att

proc

def

type

ipa

k005

Refer to the DBASE description for the meaning of these attributes.

T wo of these fields are also writable. These fields are:

par

ipa

k006

If you change the par attribute you change the value of the parameter.

If you change the ipa attribute you can move directly to a new parameter, without the

use of UP and DOWN (this can be faster).

To enter a new value, you must select the desired attribute, then press enter(ENT). If

the attribute is writable the rightmost digit starts blinking. You can:

1) change the value of the blinking digit by pressing plus(+) and minus(-) keys. The

available characters you can enter are:

IF THE VALUE YOU WANT TO

ENTER IS IN DECIMAL NOTATION

‘0’ to ‘9’ ‘0’ to ‘9’

e ‘A’ to ‘F’

.

-

space

IF THE VALUE YOU WANT TO

ENTER IS IN HEXADECIMAL

NOTATION

d0290g

As you can see, if the number is in decimal notation you can enter even the exponential

notation.

42

—————— Digital General Function Card ——————

Page 43

6KCV301DGF

For example, you can enter :

7 e-1 for 0.700.

2) change the digit you want to modify, by pressing UP and DOWN . The blinking

digit changes its position

3) enter the value you have written, by pressing enter(ENT)

4) abort the edit, by pressing cancel(CANC)

IMPORTANT: after the value is entered, the value is displayed “as best is possible”.

So, it may happen, that the value entered in exponential notation seems not to be

“accepted” by the DGF, for example when it has too many decimals to fit the normal

notation of the keypad. For example, if you enter:

1.0001 e-10

this will be displayed as:

1.000 e-10

while the real value is the value entered. Note also that the value displayed may be

rounded. For example, if you enter:

1.0005 e-10

this will be displayed as:

1.001 e-10

while the real value is the value entered. To exit this menu press cancel(CANC) until

you find:

opt: DGFC

view parameters

k001

MENU STATUS DGF:

In this menu the current status of the card is displayed. It can also be modified. To

access this menu(from

OPTION/OPTION2/MENU) move among menus by pressing UP and DOWN until

you find:

opt: DGFC

status DGFC

k007

then press enter(ENT).

Y ou are now in the status DGF menu. Once enter is pressed the following information

will be displayed:

status IDLE

reset alarm

k008

The first line shows the actual status of the DGF.

The second line shows the actual transition you can perform by pressing enter(ENT).

By pressing UP and DOWN you can change the possible transitions:

The available transitions are:

—————— Digital General Function Card ——————

43

Page 44

GEI-100430

reset alarm

status to IDLE

READY to RUN

IDLE to READY

k010

If you want to perform one of the above transitions, display it and then press enter(ENT).

If it is possible to perform the selected transition, the new status will be displayed in

the first line of the menu.

To return to the main menu of the DGF press cancel (CANC) until you find:

opt: DGFC

status DGFC

k007

MENU ARCHIVES: