Page 1

6KCV3OOllK

InterbusS

GE

industrial

Control Systems

Page 2

GEI-100445

CONTENTS

1.0 INTRODUCTION . .................... ............... ...... ....

1.1

Information ......................................................... .................................................................................... ........................

HARDWARE DESCRIPTION . ....... ..................... .....

2.0

2.1 Drmensrons, weight, protectron level..

Mountmg..

2.2

2.3

Power

2.4 Connectors

Switches . .

2.5

LEDs ..... .....

2.6

Technical

2.7

2.8

Interface .................................................................................... ..........................................................................................

3.0 BASIC INFORMATION ABOUT INTERBUS-S

3.1

Service Models .....................................................................................................................................................................

3.1.1 Short

3.1.1.1

3.1.1.2

3.1.1.3

3.1.2 Objects description

4.0 SERVICES SUPPORTED BY THE

4.1

Context Management

4.1.1

4.1.2 Abort..

4.1 3

4.2

Variable Access Services .2

4.2 1

4.2 2

4.2.3

4.3 VFD Support Servrces

4.3.1 Status..

4.3.2 Identify..

DRIVE PARAMETERS

5.0

6.0 HOW TOCOMMUNICATE..

61

Process Data Channel Control

6.1.1

6.1.2 PDC Output data Descriptor

6.1 3 PDC Output Enable..

7.0

INTERBUS-S ALARM

Description

7.1

7.2

Communication Status.. .............................................................................................................................................

Alarm Recovery ...................

7.3

8.0 PROCEDURES FOR THE BEGINNING AND THE END OF THE PCP CONNECTION..

9.0 HANDLING OF THE DRIVE ALARMS ....

10.0 SERVICE ERROR CODES AND OPERATION RESULT

11.0 VIRTUAL DIGITAL INPUT/OUTPUT CONTROL..

11.1 Vu-tual drgital input..

11.1.1 Descriptors

11.2

12.0 PARAMETERS HANDLING THE OPTION (DGF)

12.1 Description of parameter send a command to DGF option

12.2 Description

12.3

13.0

14.0

15.0

Virtual digital output ........................................................................................................................................................

11.2.1 Descriptors vrrtual d&al

Example

12.3.1

12.3.2

12.3.3

12.3.4

GLOSSARY ..................................................................................................................................................................

ABBREVIATIONS .......

REFERENCES

............................. ........................................................................................................................................

Supply

................................................ ......................................................................................................................

................................... ...................................... ...... ....

................................................... ..................................................

..........................................

Features

service

Client

Services

Service primitives.

Initiate

Reject.......................................................................................................................................................................

Read.

Wrote .

Information

PDC Input data Descriptor..

Wrrtmg

Example writing DGF parameter .....................................................................................................................

Reading DGF parameter.............................................

Example for the reading DGF parameter ................................................................................................................

................................................................................................................................................................

description.

and

Server..

with

and without

...................................................................................................................................................................

...........................................................................................................................................................................

....................................................................................................................................................................

...............................................

Report..

...............................................................................................................................................................

....................................................................................................................................................................

............................................................................................................... .........................................................

of reading value of DGF parameter.. .......................................................

for access DGF parameters

DGF parameter ................

. .

...................

....................................................................................................................................................

....................... ............................................................................................................................

...................................................................................................................................................

.........................................................................................................................................................

Servrces..

Varrable

...................................................................................................................................................

................................

.....................................................................................................................................................

............................................................................................................................................

.....................

...........................................................

.......................................................................................

of virtual digital

....... ._.

................................................................................................................................. 4

confirmatron

6KCV300INS

..........................................................................................................................................

Access Services..................................................................................................

.................................................................................................................................

....

.... .... ........................... .... .......... .... ....

.........................................

..... ........................... ......

.................................

input

.........................................

output.............................................................................................................................

......................................

.....................................................................

....................... ..............................................

...

........

..................................................................

.........

................ .....

....

.................................................

........................

....................................................................................................................

CARD ................................... ............................................................

.............................................

...

.....

...................................................... ....................................................

.......................... ..............................................................

......................................................

............................................

..................................................

....................................................................................................

................................................................................................ ............. ....

................

.....

........

...................................................................................

.....

..................................................................................

............................................................................................

................................. ..................................................

...................

............................................. .......................

............. .....................................................................

....

............. ..............................................

.... ..........

.......................................................................

...

...................................................................

.........................................................

....

................................................................

...............................................................

.....

..................................................

..................................................................... 34

.... ..... ......

...

.... .....

...............................................

...................... .........................

....................................................

..................................................

.

..........

............................................

....

.............................................

...........................................

._ .

...........................................

...

...............

.....

.......... ......

........

.... 10

..... 20

.....

3

3

.4

5

6

6

6

.6

7

7

8

8

8

8

9

.9

9

10

10

10

10

10

10

10

11

11

11

11

12

13

14

21

22

23

23

23

.23

25

25

26

28

28

...

28

29

30

31

32

33

33

33

34

35

36

36

3 6

Page 3

Interbus -

S

This manual is updated according to the

Variations of the number replacing

The identification number of the sottware version can be read on the label of the EPROM chip mounted on

the card.

6KCV300lNS

<cX),

have no influence on the functionality of the device.

software version

V2.XOO.

1 .O INTRODUCTION

This manual describes the option card

Interbus-S network.

The DV300 and AV300 drives can be connected to the network through this card.

This manual is intended for design engineers and technicians responsible for the maintenance,

commissioning and operation of InterBus-S systems. A basic knowledge of Interbus-S is assumed. For

further information refer to ((Reference Manual for

1. I

Information

6KCV300lNS

Interbus-S-PCP),.

for the connection of

inverters

and converters to the

InterBus-S

It allows the interconnection of field devices produced by different manufacturers into a single system.

InterBus-S

(physical layer), layer 2 (data connection layer) and layer 7 (application layer). Because of costs and

efficiency the 3rd through 6th layers have not been implemented.

The 7th layer of Interbus-S is made up of two parts, PMS (Peripherals Message Specification) and LLI

(Lower Layer Interface); the

obtained with LLI.

The purpose of PMS is to supply the user with a Standard interface to several automated devices which are

able to communicate with Interbus-S thus obtaining an

PMS also supplies a subset of services defined in PROFIBUS and it is based on FMS (Fieldbus Message

Specification) of PROFIBUS; uniformity with the automated MAP system (

Protocol) is obtained even with a limited use of the PROFIBUS protocol.

is a

field

Bus designed for automated applications and industrial control.

architecture is based on the communication model

compatrbility

between the PMS layer and 2nd layer (Protocol Data Link) is

(<open

communication,> system.

ISO/OSI (IS0

7498).

Manufactoring

InterBus-S

uses layer 1

Automation

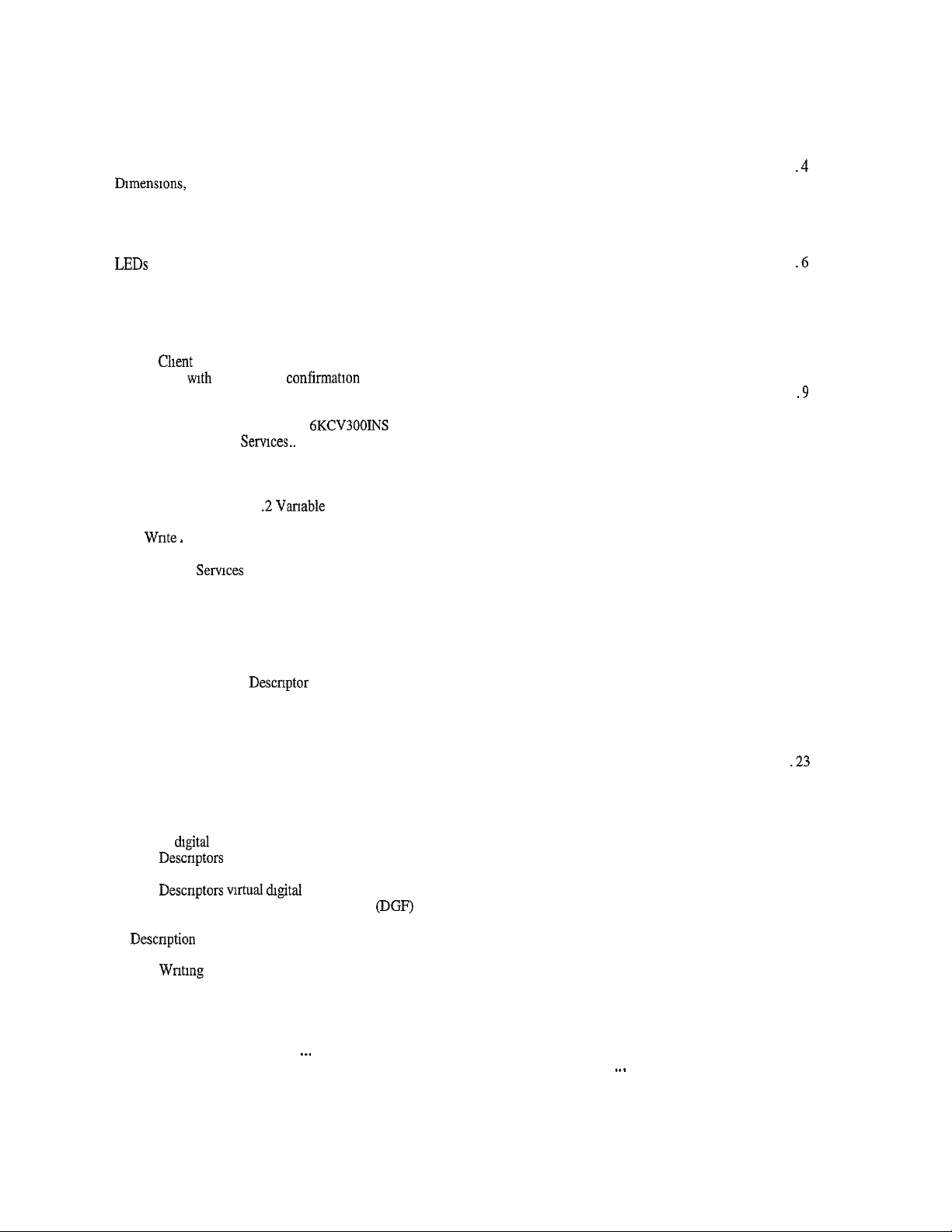

Page 4

GEL100445

2.0

2.1

HARDWARE DESCRIPTION

Dimensions, weight, protection level

4136

Dimensions (mm/inches)

Weight

Protection level

157/6.18”

200 g (7.102)

IPOO

(H) x

110/4.33”

(L)

x23/1”

(D)

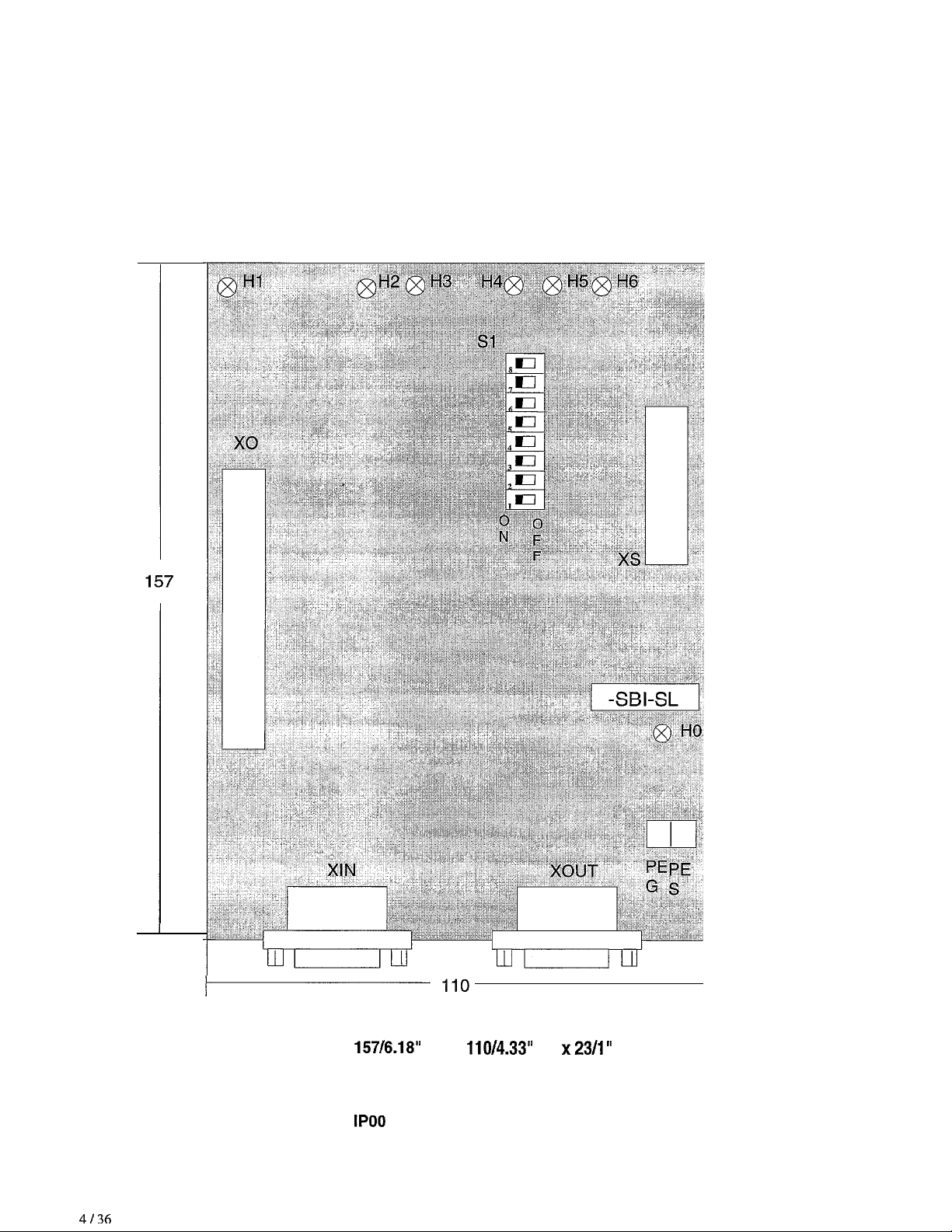

Page 5

Interbus -

S

2.2

The

6KCV300lNS

cable with connectors.

1. Switch the drive off.

2. The

Hereby we are representing as an example the card R-TPD3.

Connectors linking the Bus are placed in the same direction of the terminals belonging to the regulation card.

3. The flat cable is connected to the connector X0 already existing on the cards.

4. The dip switch Sl determines the Slave

identification code; for

this code is

and it absolutely can not be changed

otherwise the Master will not be able to

identify the card correctly .

5. Link the input local Bus cable to the

connector XIN and eventually the output

cable to the connector XOUT.

Mounting

6KCV300lNS

C3h

cards are provided with a kit made up of 4 spacers, 4 screws, washers and a 40-pole fiat

card must be fixed with the screws and the spacers to the regulation card.

6KCV300lNS

(Slave on local Bus PCP)

card

I

6. Switch on the drive and supply the local

Bus.

7. The

8. The LED H6 lights up when the Bus is

LEDs Hi

active.

The LED H3 lights up when a PCP service

is required.

and HO light up.

Page 6

GEI-100445

2.3 Power Supply

The

6KCV3001NS

and through the local Bus line InterBus-S There is no need to supply the card from the outside.

The current draw of the connector X0 is 350

is 70 mA.

card are supplied through the X0 connector which links them to the drive regulation card

mA,

while the current drawn from the local Bus line

2.4 Connectors

Interbus-S

Connector X0:

It allows to connect directly the InterBus-S interface card to the regulation card; it is

pin connector.

2.5 Switches

On the

- Sl

-

s2

- 53

-

s4

-

s5

-

S6

- 57

- 58

6KCV300lNS

Configuration Switch

It is used to connect the shield of the

has a default connection.

It is used to connect the signal INT-OPZ to the signal

(S3.B). Default S3.B.

It is used to connect the reset of the regulation card TRST to the reset circuit of the interface. It is

inserted by default.

It is used to connect the signal INT-OPZ to the signal

interface card is configured per default as OPTION 1, therefore INT-OPZ is linked to the signal

It is used to connect the signal OUT-OPZ to the signal

interface card is configured per default as OPTION 1, therefore OUT-OPZ IS linked to the signal

OUT1 .

It is used to connect the signal

interface card is configured per default as OPTION 1, thereforei

OPZl

.

It is used to connect the signal BSY to the signal

card there are the following Switches:

SuPl

II, their value must be

InterBus-S

CEM-OPZ

C3h.

connection cables to the GND supply reference. It

OUT1 (SG.A)or

to the signal

RDY-EXT.

INTR*

(S3.A) or to the port P1.4 of CPU

INTl

(S5.A) or to the signal INT2

to the signal OUT2

OPZl (S7.A)or

It is inserted by default.

to the signal OPZ2

GEM-OPZ

is linked to the

40-

(%.B).The

INTl

(S6.B).The

(S7.B).The

signal

.

2.6

A series of diagnostic and state

-

HO

-

Hi

-

H2 Red

-

H3 Yellow Communication (LBDA).

-

H4 Red Disable the Extended RB Interface (RBDA).

-

H5 Red

-

H6 Green Active lnterbus (BA).

LEDs

Green+SV

Green+5V

LEDs

are present on the cards

(Line Power Supply).

(Regulation Power Supply).

Reset.

Errore

(Error).

6KCV300lNS:

Page 7

Interbus -

S

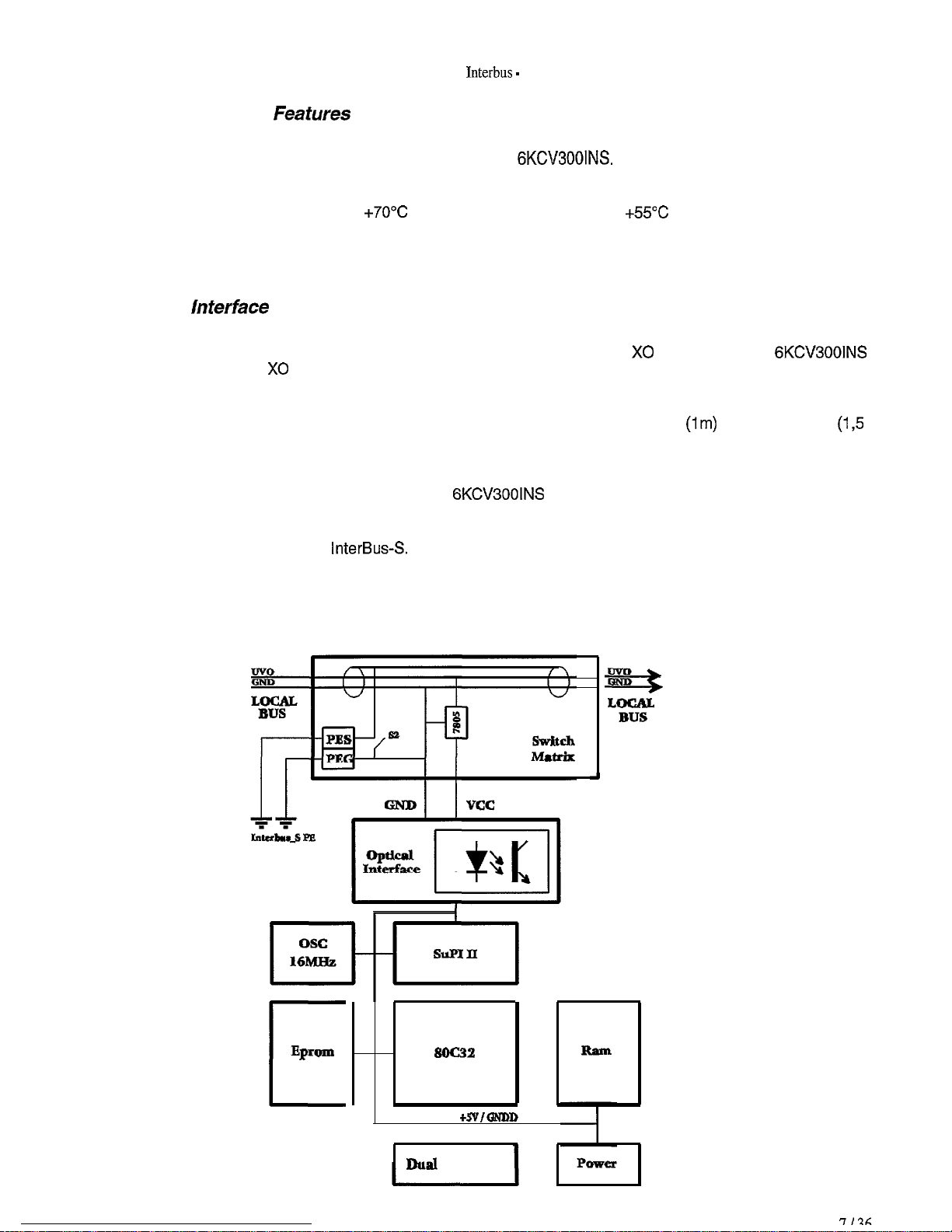

2.7 Technical

The basic model of the Interbus-S interface card is called

According to the type of the drive connected, you can find several variants.

The card used must correspond to the specific drive.

The storage temperature is -20°C

drive temperature they are connected to.

2.8

The card must be installed on the regulation card of the drive so that the X0 connector of the

cards is near the X0 connector of the regulation card, maintaining the link connectors to the line

INTERBUS-S in a downward direction. The tools provided with the card have to be used for the mechanical

connection. A 40 pin Flat Cable is necessary for the electric connection. As far as the connection to to the

Local Bus INTERBUS-S is concerned, you have to use the cables IBS PBC 100

m) which have to be linked to the connectors XIN and XOUT. If the device in use is the last of the Local Bus

line, the connector XOUT should not need to be linked to any cable.

The GND ground reference connection of the

PEG (ground), which has to be connected in one single point to the other PE terminals of the units belonging

to the same section of Local InterBus-S and to the PE terminal of the BK (Bus Terminal) modulus which

generates the local section of

lnferface

Feafures

InterBusS.

6KCV300lNS.

+7O”C

and the operating one is 0°C

6KCV300INS

+55”C

These are adequate to the

6KCV300lNS

(lm)

or IBS PBC 150

card can be carried out through the terminal

(1,5

The shield ground connection of the cables of the Local Bus Interbus-S can be carried out through the PES

terminal , which has to be connected in one single point to the other PE terminals of the units belonging to

the same section of Local InterBus-S and to the PE terminal of the BK (Bus Terminal) modulus which

generates the local section InterBus-S.

EpWIO

soc32

c

+SVIQ54DD

I

Dual Port Ram

Page 8

GEI-100445

3.0

PMS provides the user with some services allowing the

required by all the applications; for specific applications regarding a profile some limitations exist.

The services offered take into consideration the following criteria:

BASIC INFORMATION ABOUT INTERBUS-S

<(open

communication,. The whole service set is not

The service set becomes suitable for the application field of

The uniformity with PROFIBUS is only partially guaranteed.

The services available must be compatible with PROFIBUS.

The times required for the application must be taken into consideration.

The services correspond to an object orientated planning.

InterbusS.

3.7 Service Models

The service models allow to process an object; a part of the object is implicitly specified (for example it is

determined by the interface PMS). The other part is explicitly specified in the object dictionary (called OV).

The access to an object is possible through some services and the addressing can be logical (through an

index) symbolical or implicit.

3.1.1 Short service description

The following services can be used with PMS:

-

Initiate.

-

Abort.

-

Reject.

-

Status.

-

Identify.

-

Get OV.

-

Read.

-

Write.

-

Information Report.

3.1 .l

.I

From a communication point of

VFD functionalities (Virtual Field Device) of the remote user process. The Server, on the contrary, carries out

these duties and provides the Client with its VFD functionalities.

A user process can be both Server and Client (the

Client and Server

view

a Client is an application which assigns some duties in order to use the

6KCV300lNS

cards can only act as Servers).

The Client services are only used to assign a duty; such duty is transmitted to the Server through a PDU

message (Protocol Data Unit).

Page 9

Interbus -

S

3.1 .I .2Services with and without confirmation

There are services with and without confirmation.

As for the services

services without confirmation there is no acknowledgement on the side of the Server.

wrth

confirmation, the Server can acknowledge the duty carried out; in the case of

3.1.1.3

As for the Client, the assignment of the service is specified by the primitive

the acknowledgement on the side of the Server by the primitive

For the Server, the primitive to which the service is assigned to is called

is sent by the primitive

Service primitives

<<Request,,,

&onfirmatiom~.

-Indication>>,

((Response>>.

3.1.2 Objects description

Espkit

PMS identifies explicitly the following objects specified in the object dictionary:

objects

Object dictionary.

Access to single variables.

Access to vectors.

Access to structures.

while the reception of

while the identification

Page 10

GEI-100445

4.0 SERVICES SUPPORTED BY THE

Hereby you have a description of the services which a Master can require to the

6KCV300lNS

CARD

6KCV300lNS

cards .

4.1 Context Management Services

The services regarding the system control are the following:

Initiate

Abort

Reject.

4.1.1 Initiate

This service can establish the connection between two communication Partners. To achieve this, there is an

information exchange about the possible services accepted and the length of PDU.

4.1.2 Abort

This service terminates the previously established connection between two communication Partners.

4.1.3 Reject

With this service PMS rejects a non-allowed PDU.

4.2 Variable Access Services

The services regarding the access to the variables are:

Read

Write

Information Report.

.2

Variable Access Services

4.2.1 Read

This service gives the possibility to read the values of a parameter, an array or a structure. As far as arrays

and structures are concerned, their values can be entirely read (by setting the subindex to zero) or read the

elements one by one (by setting in the subindex the number of the element involved in the operation).

4.2.2 Write

Page 11

Interbus -

This service gives the possibility to write the values of a parameter, an array or a structure. As far as arrays

and structures are concerned, their values can be entirely written (by setting the subindex zero) or written the

elements one by one (by setting in the subindex the number of the element involved in the operation).

S

4.2.3 Information Report

This service is an information message carried out by the Slave in the Master direction: this service has not

been previously required by the Master.

The Slave generates this service when for example it has to indicate an alarm condition.

4.3 VFD Support Services

The following VFD services are supported:

Status

Identify.

4.3.1 Status

The status of the user device (Slave) can be read through this service.

4.3.2 Identify

Information suitable for the identification of VFD (and therefore of the user device) can be read with this

service.

Page 12

GEI- 100445

5.0 DRIVE PARAMETERS

The user parameters have an Offset referred to the type of drive linked to Interbus-S; in order to obtain the

parameter index, the specific Offset for that drive has to be added to the index of the drive parameter.

At present the Offsets are the following:

DRIVE OFFSET (in

hexadecimal)

AV300 2000hex

DV300 2000hex

Example:

The DV300 drive parameter having the index

the index 200Fhex.

The Drivecom parameters start with the index 6000h (hexadecimal); for their indexes see paragraph

5.2.1.1.4.2 of the manual

The Drivecom parameters for the configuration of the process data channels

implemented on all the cards in order to allow the configuration of the above-mentioned channels, which are

later described.

All the drive parameters can be transmitted through the PCP; as for the meaning of the parameters see the

drive manual.

DRIVECOM

,

PROFILE 21.

OFh

(which corresponds to 15 decimal) with InterBus-S has

6000h,

6001 h and 6002h are

Page 13

Interbus - S

6.0 HOW TO COMMUNICATE

Communicating is possible through a series of services demanded by the Master to the Slave; such services

are:

-

Context Management:

-

Initiate.

-

Abort.

-

Reject.

-

VFD Support Services:

-

Status.

-

Identify.

-

Variable Access:

-

Read.

-

Write.

-

information Report

In order to communicate through the Communication Channel it is necessary that the Master sends to the

Slave a request to initiate the communication (Initiate Service) and that the Slave acknowledges a positive

response.

After the

reading and writing.

The Slave can only carry out the services requested by the Master; it can not ask for any service: only with

the Information Report can the Slave carry out a service for the Master without it being asked previously.

When the Master asks the Slave to read a parameter, it must send the parameter index and eventually the

subindex; if the data is correct, the Slave responds positively with the parameter value, otherwise it responds

negatively indicating the error cause.

As for writing a parameter, the Master sends to the Slave the parameter index, eventually the subindex and

the writing value; in this case the Slave responds positively if the writing has been carried out successfully

otherwise it responds negatively indicating the error cause.

The Slave always verifies the validity of the index, of the subindex, of the access rights and in the case of

writing the length of the value sent and if the value is in range of the stated limits; it verifies also if in that

moment the parameter can be written.

As for error codes, the composition and the meanrng of the different services, see the Reference Manual for

InterBus-S ( see reference chapter).

communication

is initialized, the Master can request to the Slave all the other services, such as

Page 14

GEI- 100445

6.7

Process

Dafa

Channel Control

This function allows to assign drive parameters to the Process Data Channel Bytes.

In InterBus-S ring the

6KCV300lNS

cards occupy a total of four words (WORD); the first Word (that is 16 Bit)

is represented by the PCP, while the following three are avaliable for the Process Data Channel

(abbreviation PDC).

Representation of the words occupied in InterBus-S ring by the

. . . . . . . . . . . . . . . ..*......

.

WORD 1 l l WORD 2 n . WORD 3 l l WORD 4 l

.

.

PCP

. . . . . . . . ...* . .

The

6KCV300lNS

The data read by the

the

6KCV300lNS

. . . . . . . . . . . . . . . . . . . . .

. .

.

.

.

.

. .

l

. . . . . . ..*............

e......

. . . . . . . . . . . . .

l lPDC 1 l . PDC 2 l l PDC 3 l

..t.......

card can both read and write the Process Data Channel.

6KCV3001NS

card from InterBus-S are referred to as output data; the data written by

card in Interbus-S are referred to as input data.

l Process Data

l Drive parameters

.

.

.

l *m Input data descriptor

Process

Channel

Control

.

l Process data

l Drive parameters

.

.

.

l ** Output data descriptor

.

l -- Output data enable

.

. . . . . . . . . . . . . . . . . . . . . . .

. . . ...*.....

6KCV300lNS

..*........

cards :

*

Assigning the drive parameters to the communication object

c<PDC

are read with cyclicity by the Master.

Assigning the drive parameters to the communication object

transmits to the Server with cyclicity such parameters.

Input data Descriptor,,, such parameters

(<PDC

Output data Descriptor),, the Master

Page 15

Interbus

\

-S

The assignment of the processed data to specific drive parameters can be set. To this purpose the

Input data

data can be enabled or disabled by the

Descriptor>>

and

<<PDC

Output data

Descriptor>>

<(PDC

output Enable= communication object .

communication objects are involved . The output

How it works:

Process Data from Interbus-S

.

<cPDC

.................................

I

l 1=2*3*4*5*6*7*8* PDC Output Channel

.................................

........

.................................

l 1*2*3*4*5*6*7*8* PDC Output Memory

.......................................................

.........

........................

..............................................

..............................

.........

........

.......................................................

l

P.l*P.l*P.l*P.l=P.2*P.2*P.2*P.2*

.................................

.

PARAMETER 1 l PARAMETER 2 l

.................................

.

DRIVE

PARAMETERS

.................................

.

PARAMETER 1 l

.................................

l

P.l*P.l*P.l*P.l*P.2*P.2*P.2*P.2*

PARAMETER

2 l

.................................

..............................

.........

........

..............................

.................................

l 1*2*3*4*5*6*7*&* PDC Input Memory

.................................

........

.................................

~1*2*3*4*5*6*7*8*

.................................

.

PDC Output

***Enable

**PDC Output data

-descriptor

.

PDC Input data

***descriptor

PDC Input Channel

.

.

.

.

.

.

I

Process Data for Interbus-S

Page 16

GEI- 100445

The

<<PDC

Input data Descriptor>> communication object (input data for the Master) determines the drive

parameter assigned to the Bytes of the Process Data Channel . The

<<PDC

Output data Descriptor),

communication object (output data for the Master) determines the Bytes of the Process Data Channel

assigned to the drive parameter.

The assignment of the drive parameters to the Bytes of the Process Data Channel is performed through the

index and the subindex of the parameter itself. The dimension of the structures

and

c<PDC

the

6KCV300lNS

Output data

Descriptor>>

depends on the length of the Process Data Channel, which in the case of

card is three Words. In the first element of these two objects you can find the length (in

(<PDC

Input data Descriptor,,

Bytes) of the Process Data Channel.

There is the possibility to assign to the Process Data Channel different drive parameters with different

dimensions, except Byte parameters.

Output data descriptor in a Process Data Channel:

PDC OUTPUT DATA DESCRIPTOR

. . . . . . . . . .

l

PDC WID.*

. . . . . . . . . .

. . . .

. . . . . . . . . . .

. .

. . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . .

.

.

.

.

.

.

.

.

. ..*.... . ..*......

.

.

. .

. . . .

. . . .

. l . . . . . . . . .

. .

. .

. . . . . . . . . . .

. . . . . .

. . . . . . .

.

C....................

f 10

. 20 l 30 . 40 . . m . . .

. . . . . . . . . . . . . . .

. l

.

. . . . . . . . . . . . . . . . . . . . .

Ref. 1

Speed

Ramp

1

202A l l *

00 l **

. . . . . . . . . .

0000 l l *

00 l **

. . . . . . . . . .

202c

00 l *-

0000 l l -

00 l *’

- -

.

m

. . . . . . . . . .

. . .

l * 1st Byte PDC

l * 2nd Byte PDC

l

-0

l * 3rd Byte PDC

l * 4th Byte PDC

l * nth Byte PDC

. . . . . . . . . .

NOTE:

The meaning of the parameters with index 0000 is that the Byte is not assigned as it is already

occupied by the previous parameter.

Page 17

Interbus - S

To reconfigure the PDC data outcoming from the Master it is necessary to interrupt the data transfer to the

drive parameters.

This is the task of the communication object

<<PDC

Output

Enable,>.

Enabling of the PDC output:

PDC OUTPUT DATA DESCRIPTOR

. . . . . . . . . .

l

PDC

WID.*

. . . . . . . . . .

. . . .

.

. .

. . . . . . . . ...*.....

.

.

.

.

.

.

.

.

. .

. .

. .

. . . . . . . . . . . . . . . . . . . . . .

l

. ..*.................

.

. . . . . . . .

.

.

. . . . . . . . . . . . . . .

. . . .

. . . .

.

. .

. .

. . . . . . . . . . . . . . .

. . . .

. .

. 10 . 20 . 30 . 40 . .

. . . . . . . . . . . . ..*......

REF.

Ramp

202A . .

. ...**...*

00 l l

. . . . . . . . . .

.

0000 l l

00 l l

. . ...*....

202c

. ...*.....

00 l l

. ...*....*

0000 l l

00 l l

- -

xxxx

. . . . . . . . . . . . . .

. . . .

l l

. . . .

-Y

xx

. .

. . . . . . . . . .

Speed

PDC OUTPUT

ENABLE

. . . . . . . . . . . .

.

Bit 0

. . . . . . . . . . . .

9

.

.

Bit1 l

.

t...........

.

Bit 2 l

.

. . . . . . . . . . . .

.

Bit 3 l

.

. . . . . . . . . .

:

.

Bit n l

.

. . . . . . . ...*.

Every Bit of the

<cPDC

output

enablej>communication

object is assigned to a Byte of the Process Data

Channel.

The meaning is the following:

Bit = 0

Bit = 1

-

The assignment of the Byte to a drive parameter is disabled.

-

The assignment of the Byte to a drive parameter is enabled.

If an drive parameter occupies more than one Byte, the Bit assigned to the first Byte becomes significant.

This corresponds to the position of the drive parameter

Descriptor)>

and in the object

c<PDC

input data Descriptor

Index

both in the object

1’.

The remaining Bits have no importance.

<<PDC

output data

With the writing of the object cc PDC output data Descriptor>> the data transfer of the PDC data outcoming

from the Master is automatically interrupted; this is possible by clearing the corresponding control Bit in

<cPDC

Output Enable)).

Example 1:

If the assignment of the first parameter in the

c<PDC

output data Descriptor)> is modified, the Bit 0 is

cleared. The remaining Bits do not change.

Example 2:

If the assignment of all parameters

c<PDC

output data

Descriptor)>is modified, all the Bits are cleared.

Page 18

GEI-100445

This is an example of the assignment of the drive parameters to the object

and to the object

I-

Drive Parameter A Type of datum: Unsigned1 6

2-

Not used

3-

Drive Parameter B Type of datum: Unsigned16

4-

Not used

(<PDC

input data Descriptor c( in the case of

6KCV3001NS

card with 16 Bit parameters.

Object subindex Meaning of the object element Byte number of the

sPDC

input data Descriptor>>

({PDC

output data Descriptor

Process Data Channel

)X

1

2

Length of the Process Data Channel

Index of the Drive parameter A

(16 Bit)

3

Subindex of the Drive

parameter A

4

Not used.

Index = 0000

5 Not used.

Subindex = 00

6

Index of the Drive Parameter B

(16 Bit)

7

Subindex of the Drive

Parameter B

8 Not used.

Index = 0000

9 Not used.

Subindex = 00

“-

1

1

2

2

3

3

4

4

Page 19

Interbus -

This is an example of the assignment of the drive parameters to the object

and to the object

l-

Parameter A

2-

Not used.

3-

Not used.

4-

Not used.

c<PDC

input data

Data Type: Unsigned32

Descriptor,>

with a32 Bit parameter.

S

<<PDC

output data

Descriptonr

wPDC

Object

input data

subindex

1

2

3

4

5 Not used.

6 Not used.

7 Not used.

8 Not used.

Descriptoru

Meaning of the object element

Length of the Process Data Channel

Index of the drive parameter A

I 32 Bit

Subindex of the drive parameter A

Not used.

Index = 0000

Subindex = 00

Index = 0000

Subindex = 00

Index = 0000

Byte number of the

Process

Data

1

1

2

2

3

3

4

Channel

9 Not used.

Subindex = 00

If the assignment of a drive parameter to the Process Channel is replaced with the assignment of a larger

parameter, the following Bytes of the object

must be cleared. If the assignment can not be correctly carried out , the response is negative.

-

IMPORTANT

In the current versions ot the

drive parameters to the Process Data Channel; the user, therefore, must control with care such assignment,

avording,

the case these assignments are not carried out in a proper way, the system could behave in an unexpected

and potentially dangerous way.

for example, the overlap of parameters or the overflow of the Process Data Channel capacities. In

6KCV300lNS

<<Process

cards there is no control on the validity of the assignment of the

Data Channel Descriptors, involved in the operation

4

Page 20

GEI- 100445

6.1 .IPDC Input data Descriptor

This communication object has the information which determines the assignment of the Process Data

Channel data incoming to the Master to the drive parameters. In the case of a conflict between the index and

the subindex the assignment is not carried out and an error message is generated.

Description of the communication object ’ PDC Input data Descriptor),:

OBJECT ATTRIBUTE VALUE

Index 6000h

Object Code 09

Index of the data Type 20

Password

Access Group

Access Rights

Local Address

Range of the descriptor values:

Subindex 1

Subindex 2 : Unsigned1 6

: Unsigned8

00

00

03

xxxx

MEANING

PDC Input data descriptor

Record

Structure PDB

Non-existing

”

Non-existing

Read-All,

Write-All

Manufacterer

Specific

Subindex 3

Subindex 4 : Unsigned1 6

Subindex 5

Subindex n : Unsigned1 6

Sublndex

For further information refer to the Manual Profile 21 Drivecom.

n + 1

: Unsigned8

:

Unsigned8

: Unsigned8

Page 21

Interbus -

S

6.1.2

This communication object has the information which determines the assignment of the drive parameters to

the data of the Process Data Channel outcoming from the Master. With the writing of this object the data

transfer of the data outcoming from the Master is automatically interrupted. In the case there is a conflict

between the index and the subindex, the assignment is not carried out and an error message is generated.

Moreover, the writing of this object causes the clearing of the corresponding Bit in the object

enable,,.

Description of the object

PDC Output data Descriptor

c<PDC

Output data descriptor>>:

OBJECT ATTRIBUTE VALUE MEANING

II

Index of the data Type

II

Index

Object code

Password

Gruppo d’accesso

c<PDC

output

I

I

I

6001 h

09

20

‘00

00

PDC Output data descriptor

I

Record

Structure PDB

I

I

Non-existing

Non-exisrting

Access rights 03

Local Address xxxx

Range of the descriptor values:

Subidex 1

Subindex 2

Subindex 3

Subindex 4 : Unsigned1 6

Subindex 5

Subindex n

Subindex n +

For further information refer to the Manual Profile 21 Drivecorn.

: Unsigned8

: Unsigned1 6

: Unsigned8

: Unsigned8

: Unsigned16

1

: Unsigned8

Read-All,

Write-All

Manufacterer

Specific

Page 22

6.1.3 PDC Output Enable

GEI- 100445

Each Bit of the communication object

Channel.

Therefore, the following assignment must be taken into consideration :

-

Bit = 0 The corresponding value of the process data is disabled.

-

Bit =

1

If a drive parameter occupies more than one Byte, the Bit considered is the one assigned to the parameter.

Description of the object

OBJECT ATTRIBUTE

II

Object code 07

Index of the data Type 20

The corresponding value of the process data is enabled.

c<PDC

Output

Index 6002h

Length

<cPDC

Output

Enables):

VALUE

I

On

Enable))

I

is assigned to a Byte of the Process Data

MEANING

PDC Output Enable

Single variable

Octet string: manufacterer specific, it

depends on the width of the PDC

n Byte: manufacterer specific; it

depends on the width of the PDC

II

II

Password

Access Group

Access Rights 03

Local Address xxxx

I

I

00

00

I

I

Non-existing

Non-existing

Read-Ail,

Write-All

Manufacterer Specific

Page 23

7.0 INTERBUS-S ALARM

Interbus -

S

7.1

The alarms regarding Interbus-S are:

I-

2-

3-

Description

Bus

Loss; if an accidental interruption of the connection occurs, this alarm is generated; the

visualization of the corresponding alarm message depends on the drive configuration.

SBI Hardware Fault; if the Interbus-S interface card is faulted, this alarm is generated; the visualization

of the alarm message depends on the drive configuration.

SBI Ram Fault; this alarm is generated if there is a fault in the Dual-Port-Ram of interface between the

drive and the InterBus-S card;the visualization of the alarm message depends on the drive

configuration.

7.2 Communication Status

In case of alarm the behaviour of the interface

following cases must be distinguished:

l-

The communication between the Master and the drive has already been established; more precisely it

means that the Peripherals Communication Protocol (PCP) IS active and therefore the Initiate Service

has already successfully been carried out.

2-

The communication between the Master and the drive has not been established yet; it means that the

Peripherals

3-

The Abort Service has successfully been carried out; this case is the same as case number two and

therefore it is treated in the same way; the Peripherals Communication Protocol is not active.

Communrcation

Protocol PCP is not active.

InterBusS

card depends on the communication status. The

N.B. The concept of established communication makes reference to the activation of the Peripherals

Communication Protocol (PCP); it means that the Process Data Channel is active in any way and the

data exchange through this channel takes place regularly.

7.3 Alarm Recovery

The description of the behaviour takes into consideration the above-mentioned communication status; it is

necessary to remember, anyway, that what will be described depends on how the drive has been set to

handle the alarm; in the following description it is assumed that the drive totally handles the alarm of Field

Bus

Loss.

1 - First case of communication status

a - Reaction to the alarm.

If the above-mentioned conditions are respected, in case of InterBus-S alarm the drive stops

immediately the motor, displays the alarm message and waits for its recovery; the InterBus-S

interface card interrupts the data transfer of the Process Data Channel outcoming from the Master by

clearing the parameter

c<PDC

Output

Enable>,

(Index 6002h).

Page 24

GEI-100445

b - Procedures for the recovery and the restarting.

In the case of alarm caused by a

the cause in the Hardware of the card and eventually replace it.

If the connection has accidentally been stopped (for example a cable breaking), after reestablishing

the

phisical

Now the data cycle is active again.

line, proceed as follows:

The Master data cycle must be established.

If the Bus control has not been stored in the drive, control must be recovered by acting as

required by the drive (see relative manual).

Clear the alarm acting as required by the drive (see relative manual).

Enable the Process Data Channel outcoming from the Master by correctly setting the parameter

aPDC

Output

Enables,,

InterBusS

(Index 6002h).

Card Hardware fault or Dpram fault you must look for

2 - Second case of communication status.

In this case the

If the Peripherals Communication Protocol is not active, the Master can not control the drive; be aware that

the Process Data Channel has been enabled and therefore the exchange of data can be carried out through

it; more precisely the data outcoming from the Master and incoming in the drive (PDC Output) are transferred

but they are not active because the parameter

active after the setting of this parameter, while the data incoming in the Master and outcoming from the drive

(PDC Input) are always active.

This is valid only if the Process Data Channel has already been configured by setting the parameters 6000h

for the data incoming in the Master and 6001 h for the data outcoming from the Master.

InterBusS

interface card does not indicate any alarm to the drive.

<(PDC

Output

Enable,>

has been cleared; they will become

3 - Third case of communication status.

This case is similar to case number two because the Peripherals Communication Protocol is not active; the

above-mentioned considerations are valid too.

We should emphize the behaviour in case the Abort service is successfully carried out while the drive is

active, i.e. it is controlling a motor (the Abort service should be never carried out under this condition).

The card acts in the following way:

The command ‘Drive Stop’ is sent to the drive.

The data of the parameters PDC Output are cleared (data outcoming from the Master; incoming

in the drive).

The Process Data Channel outcoming from the Master and incoming in the drive (PDC Output)

is disabled by clearing the parameter ” PDC Output Enable”.

Note that the drive does not display an alarm message because this case is not considered a real alarm.

Procedures for the recovery and the starting.

Reactivate the Communication Channel by successfully carrying out the Initiate service.

Enable the PDC data outcoming from the Master (PDC Output) by setting the parameter

Output Enable)).

((PDC

Page 25

Interbus -

S

8.0

PROCEDURES FOR THE BEGINNING AND THE END OF THE PCP

CONNECTION

At the beginning it is suggested to supply power first to the drive and then the Master;

when the Master has terminated successfully the identification cycle, proceed as follows:

l-

Establish the connection by activating the Peripherals Communication Protocol by successfully

carrying out Initiate service.

2-

If the Bus control has not been stored in the drive, activate such control by acting as required by

the drive (see relative manual).

Configure the Process Data Channel by setting the relative parameters (see chapter 6).

3-

4-

Enable the Process Data Channel outcoming from the Master (PDC Output) by setting the

parameter

To switch off the system or stop the connection proceed as follows:

l-

Stop the motor and disable the control by acting as required by the drive (see the relative

manual).

2-

Disable the PDC data outcoming from the drive by clearing the parameter

Enable,).

3-

Stop the Peripherals Communication Protocol by successfully carrying out the Abort service; if

the previous two points have not been carried out, the case

occurs.

<<PDC

Output

Enable,,.

&ommunication

<<PDC

Output

Status number 3”

From now on potential alarms of Interbus-S are no longer indicated by the interface card to the drive:

To avoid generating the

If the Master is switched off without carrying out the ABORT Service, to activate the bus again proceed as

follows:

Carry out the Warm-Start command of the Master

al

Carry out the Initiate-Request Service (code 0088 hex)

b)

The Slave responds with an Abort-Indication (code 81AD hex)

with Abort-ID = 02 and Reason-Code = 02.

Carry out again a Warm-Start command of the Master

cl

Carry out again the Initiate-Request Service (code 008B hex).

d)

In this case the Slave responds an Initiate-Response (code

This procedure is necessary to allow the correct synchronization of the Layer 2 of the Master and of the

Slave.

9.0

Every time the drive status changes, the

the Information-Report service. This service sends the

alarm, the index of the drrve parameter which contains the

parameter, whose length is 2 byte, containing the alarm code. In order to identify the alarm code see the

drive manual.

HANDLING OF THE DRIVE ALARMS

<(Field Loss>

alarm at power off, proceed as described above.

818B

hex).

6KCV300lNS

card

indrcates

Communication-Reference

codlflcation

it immediately to the Master through

of the alarm and the value of such

of the Slave

indicating

the

Page 26

GEI- 100445

10.0 SERVICE ERROR CODES AND OPERATION RESULT

The following table shows the different error codes that may occur during the execution of a service. These

codes are contained in the “Additional error codes” field.

I

OK no error

Parameter not exist

Reserved

Control Access denied

Reserved

Attribute Access denied

Type value error

Reserved

Destination option not exist

Parameter Access Conflict

Value out of the maximun ranae

Value out of the minimun range

Value not supported

Parameter Confiauration Conflict

Command Submitted

Reserved

Unknown Command

Read only Parameter

Write not allowed

Value out of constant limits

State not correct

Password

Type Unknown

Hardware Fail

Checksum Fail

Reserved

Reserved

NOK generic

User defined

RESULT

1 CODES

OOOOH

0001 H

OOOZH

0003H

0004H

0005H

0006H

0007H-OOOFH

OOlOH

OOllH

0012H

0013H

0014H

0015H

0016H

0017H

0018H

0019H

OOIAH

001 BH

001 CH

001 DH

001 EH

0030H

0031 H

001 FH-007CH

0082H-OOFCH

OOFFH

01 OOH-FFFFH

moo

t

Page 27

Explana

Con:

Interbus -

S

Parameter not exist

Control Access denied

Attribute Access denied

Type value error

Destination option not exist

Parameter Access Conflict

The specified parameter does not exist

The access is denied because of the control status

The parameter attributes do not allow the access

The specified type value is incorrect

The destination option does not exist at node

The addressed parameter can not be accessed (for example if the command

is write and parameter is connected to an external input)

Value out of the max range

Value out of the min range

Value not supported

Value is out of the maximum range

Value is out of the minimum range

Value is in range but not allowed

Parameter Configuration Conflict The addressed parameter can not be accessed for sistem configuration

conflict (for example try to connect an input source to a

paramete;

that is

already connected to an input source)

Command Submitted

Command has been submitted but is not possible to know if it has been

executed

Unknown Command

Read only Parameter

Write not allowed

Value out of constant limits

State not correct

Password

Type Unknown

Hardware Fail

Checksum Fail

NOK generic

The command is not known

The parameter has read only attribute

Write operation is not allowed for the slave conditions

Value is out of constant fixed

limits

The control state doesn’t allow the command execution

The command is not executed because the password is active

The parameter type is not known

The access is denied because of an hardware failure

The access is aborted because of an error in

cheksum

control

The access is aborted because of an indeterminated error

Page 28

GEI-100445

11 .O VIRTUAL DIGITAL INPUT/OUTPUT CONTROL

The control of the virtual digital

for the control forwarding.

It is

imporfant

input/output of the drive, thus meaning that the Master

output.

I 1. I

The parameters taken into consideration for the virtual digital input are:

-

Parameter index 5EFCh: configuration virtual digital input.

-

Parameter index 5EFEh: writing of the values to virtual digital input.

Parameter 5EFCh: 16 element array Unsigned Int.

This array is used to configure the virtual digital input; therefore, it must be written before using the input

themselves. It has the drive codes assigned to the input; these inputs are then written through the parameter

5EFEh,

the virtual digital

Example:

Element I of the parameter array

AV300 drive, which means Ramp-Out = 0.

The functioning is the following: after configuring the element I of the parameter

index

the parameter

Virtual digital input

type Unsigned Int, where the status of the single Bit indicates the command which must be sent to

2158hex,

to notice that in this chapter virtual digital input/output make reference to the digital

Input

assigned through the configuration array.

the function Ramp-Out = 0 of the the

5EFEh.

I/O

of the drive is possible through configuration parameters and parameters

5EFCh

contains

ccwritesp

tee

parameter index

DV300 -

the digital inputs and

2158hex,

5EFCh

AV300 drive is controlled through the Bit of

((reads>>

referring to the

with the parameter

the digital

DV300 -

11 .I .1 Descriptors of virtual digital input

The parameter 5EFCh is used to configure the virtual digital input, it can be written/read through each single

element or as a whole object (by setting the subindex to 0).

OBJECT ATTRIBUTE VALUE MEANING

Index

Object code

Number of the elements

~ I- ~~~

Tvw

Password

Access group

Access rights

Local address xxxx

SEFCh

08

16

I

06

00

00

03

virtual digital input configuration

-1 ~

16 virtual digital input channel

I

I

Manufacterer

Array

Unsigned1 6

Non-existing

Non-existing

Read-All,

Write-All

Specific

Page 29

Interbus -

The parameter 5EFEh is used to control the virtual digital input previously configured; the status of the single

Bits controls the virtual

digrtal

input assigned to the Bit during the configuration:

S

OBJECT ATTRIBUTE

Index

Object code

Index of the type of datum

Length

Password

Access group

Access rights

Local address

11.2

As for the virtual digital output the parameters used to control are:

Virtual digital output

VALUE

I

5EFEh

I

I

I

1 MEANING

07

05

02 2 Byte

00 Non-existing

00

02

xxxx

I

The status of the single Bit controls the

I

I

Value (drive)

virtual digital input

Single variable

virtual digital input assigned

Non-existing

Write-Ail

Manufacterer

Specific

-

Parameter index 5EFDh:

-

Parameter index 5EFFh: reading of the values virtual digital output.

Parameter

This array is used to configure the virtual digital output; it has to be written before using the virtual digital

output. It has the drive codes assigned to the the output; these outputs are then controlled through the

parameter

virtual digital output assigned during the configuration.

Example:

The elemenf I of fhe parameter array

AV300 drive, which means Drive-Ready.

The functioning is the following: after configuring the element I of the parameter

index

paramefer

5EFDh:16

5EFFh,

217Chex,

5EFFh.

type Unsigned Int where the status of the single Bits corresponds to the status of the

the status Drive-Ready of the the

configuaration

element array Unsigned Int.

virtual digital output.

5EFD

contains

the

parameter index

DV300-AV300

217Chex,

drive is read fhrough fhe

referring to fhe

5EFDh

with the parameter

DV300-

Bit

0 of the

Page 30

11.2.1 Descriptors virtual digital output

GE&100445

The parameter 5EFDh is used to configure the virtual

single element or as a whole object (by setting the subindex to 0).

OBJECT ATTRIBUTE

Index 5EFDh

Object code

Number of the elements

VALUE

I

I

Type

Password

Access group

Access rights

Local address

I

xxxx

08

16

06

00

00

digrtal

output; it can be written/read through each

I

I

I

MEANING

virtual digital output configuration

Array

16 Channels virtual digital output

Unsigned 16

Non-existing

Non-existing

Read-All,

Write-All

Manufacterer Specific

The parameter 5EFFh is used to read the virtual digital output previously configured; the

status of the single Bits corresponds to the status of the virtual digital output assigned to the

Bit during the configuration:

OBJECTATTRIBUTE

Index

Object code

Index of the type of datum 05 The status of the single Bit

Length

Password

Access group

Access rights

Local address

I

I

I

VALUE

5EFFh

07

02 2 Byte

00 Non-existing

00

01

xxxx

I

corresponds to the

virtual digital output assigned

1

~~~

I

MEANING

Value (current status)

virtual digital output

Single variable

Non-existing

Read-All

Manufacterer Specific

status

of the

Page 31

Interbus -

S

12.0 PARAMETERS HANDLING THE OPTION (DGF)

In order to handle the option DGF parameters two

Parameter 5EFAh: command sent to DGF.

Parameter 5EFBh: reading of the parameter and DGF operation result.

For better undrestanding of this chapter see the DGF manual , in particularly the organization of the

parameters.

The handling of the

mentioned in this chapter make reference to the DGF communication.

The InterBus-S parameter 5EFAh is a Record made up of:

Ne

EL

1

2

3

InterBusS

errors is not mentioned in the following chapter, therefore the error causes

ELEMENT

Command

Type

IPA

InterBusS

LEN.

BYTE

1

1

2

parameters are involved:

MEANING

Operation which has to be carried out

by the DGF (reading/writing etc.)

DGF Parameter type

DGF parameter index involved in the

operation

4

This is a write only parameter: the access to this parameter is possible in the following ways:

l-

In the case of writing DGF parameter all the elements have to be filled, that is 8 Bytes have to be sent:

for the elements with more than one Byte the filling order starts from the less significant Byte to the

most

significant

2-

In the case of reading DGF parameter the Parameter Value element has not to be filled; that is 4

Bytes have to be sent: even in this case for the elements

starts from the less

To correctly carry out the operation required, the exact number of necessary Bytes must be sent: every

attempt to access a single element (by using

of Bytes (for example by carrying out a reading service sending also the DGF parameter value) is rejected

and the operation

5EFAh must always be 0.

V-PAR (Write Only)

one.

signrficant

termrnates

with a negative result; for this reason the subindex of the InterBus-S parameter

4

Byte to the most significant one.

InterbusS

subindex different from 0), or with a wrong number

Value to be written to the DGF

parameter (Only by wiriting)

with

more than one Byte, the filling order

Page 32

GEI-100445

The InterBus-S parameter 5EFBh is a Record made up as follows:

NeEL

1 ELEMENT LENG.BYTE 1 MEANING

2

1

3

4

This is a read only parameter; the access to this parameter is possible in the following ways:

I-

In case of writing DGF parameter: if this writing has a negative result the Result element (operation

result) contains the specific error cause (for the meaning of the error code see the DGF manuals).

2-

In case of reading: if the reading has a positive result the V-PAR element contains the value of the

DGF parameter involved in the operation; if the reading has a negative result the Result element

(operation result) contains the specific cause of the error (for the meaning of the error code see the

DGF manuals).

A>

for the elements with more than one Byte the order of the Bytes received starts always from the less

significant Byte to the most significant one.

The elements of this Record can be read one by one, by entering the subindex or all together (by setting the

subindex to 0) .

IPA

Parameter

V-PAR (Read

Only)

2

4

Result of the operation carried out

by the DGF (reading/writing etc.)

DGF Paramete type

DGF parameter index involved in

the operation

DGF parameter value read

(only by reading)

12.

I Description of parameter send a command to DGF option

OBJECT ATTRIBUTE VALUE

Index 5EFAh

Object code

Index of the

Range of the descriptor values:

tvpe

of datum 1

Password

Access group 00 Non-existing

Access rights

Local address xxxx

Bubindex 1

Subindex 2 : Unsigned8

Subindex 3

Subindex 4 : Unsigned32

I

09

21

00 Non-existing

02

: Unsigned8

: Unsigned1 6

Parameter send command to

1

1 Structure of DGF command

Manufacterer

MEANING

DGF

Record

Write-All

Specific

Page 33

Interbus - S

12.2

Range of the descriptor values:

Description of reading value of DGF parameter

OBJECT ATTRIBUTE VALUE

Index

Object code

Index of the type of datum

Password 00

Access group

II ~~

Access rights

Local address xxxx

Subindex

Subindex

Subindex

Subindex 4

MEANING

5EFBh

09

22

00

I

1

2

3

:

Unsigned1 6

:

Unsigned8

:

Unsigned1 6

:

Unsigned32

01

Parameter reading value DGF

parameter

Record

Structure reading DGF

parameter

Non-existing

Non-existing

I

Read-All

Manufacterer

Specific

II

12.3

Example for access DGF parameters

12.3.1 Writing DGF parameter

l-

Fill the elements of the InterBus-S parameter 5EFAh in the following way:

Element Command

;;

Element Type with DGF parameter type.

Element

c)

Element V-PAR with DGF parameter value (4 Bytes have always to be written; in the case of

d)

DGF parameters with a length less then 4 Bytes fill the remaining Bytes with 0).

The elements with more than one Byte must always be filled starting from the less significant Byte to

the most significant one.

2-

Carry out the InterBus-S ‘Write’ service by always setting the Interbus-S subindex to 0 and wait for

the response.

3-

If the response is positive, the value of the DGF parameter has been correctly written.

4-

If the response is negative, the error cause can be found by reading, with the Interbus-S “Read”

service , the Result element (operation result) of the Interbus-S parameter 5EFBh. The single element

can be read by setting the subindex to 1, or the whole parameter can be read by setting the subindex

to 0 (in this case the V-PAR element has no meaning).

IPA

with DGF parameter index.

with

a command writing DGF parameter.

Page 34

GEI-100445

123.2 Example writing DGF parameter

-

Index:

-

Type: Integer.

-

Value:

Fill the elements of the InterBus-S parameter 5EFAh as follows:

102h.

2134h

ELEMENT

Command

Type

IPA

V-PAR

If the response is positive, the DGF parameter has been correctly written.

If the response is negative, the error cause can be found by reading the

our example it has the following values:

ELEMENT

Result

Type

IPA

V-PAR

VALUE

xx

YY

02101

34121100100

VALUE

LL-HH

YY

02101

xxlxxlxxlxx

MEANING

Command writing DGF parameter

DGF Parameter type: Integer

DGF parameter index

DGF parameter value to be written

MEANING

Result of the operation as

low Byte - high Byte

DGF parameter type: Integer

DGF parameter index

No meaning

InterBusS

parameter

5EFBh;

in

12.3.3 Reading DGF parameter

-I-

Fill the elements of the InterBus-S parameter 5EFAh as follows:

Element Command with command reading DGF parameter.

a)

Element Type with DGF parameter type.

b)

Element

c)

The elements with more than one Byte have always to be filled from the less significant Byte to the

most

sianificant

2-

Carry out the Interbus-S

response.

3-

Either with a negative or a positive response, read the Inter&us-S parameter 5EFBh by carrying out

the

InterbusS <<Read,)

4-

If the response is positve the value of the DGF parameter is in the V-PAR element

5-

If the response is negative, the error cause can be found by reading the Result element (operation

result) of the Interbus-S parameter 5EFBh. The elements can be read one by one, by setting the

subindex to 1, or the entire structure can be read by setting the subindex to 0 (in this case the

V-PAR element has no meaning).

IPA

with DGF parameter index.

one.

<<Write>>

service .

service by setting the InterBus-S subindex to 0 and wait for the

Page 35

Interbus -

S

123.4 Example for the reading DGF parameter

-

Index:’

-

Type: Integer.

-

Value: 4567h

Fill the elements of the InterBus-S parameter 5EFAh as follows:

201h.

ELEMENT

Command xx

Type

IPA

If the response is positive, the DGF parameter has been correctly read and the value can be obtained by

reading the InterBus-S parameter 5EFBh; in the specific case of this example it has the following values:

ELEMENT

Result

Type

II

IPA

V-PAR

I

VALUE

YY

01102

VALUE

00100

YY

01102

67145100100

MEANING

Command writing DGF parameter

DGF Parameter type: Integer

DGF Parameter index

MEANING

Operation result = 0 OK

DGF parameter type: Integer

I

DGF parameter index

Value of the parameter read

If the response is negative, the error cause can be obtained by reading the InterBus-S parameter

for our example it has the following values:

ELEMENT

Result

Type

IPA

V-PAR

VALUE

LL-HH

YY

01102

xxlxxlxxlxx

MEANING

Result of the operation as

low Byte- high Byte

DGF parameter type: Integer

DGF parameter index

No meaning

5EFBh;

as

Page 36

GEI-100445

13.0 GLOSSARY

-

Master:

-

Slave: Device for the drive or for the modules Input/Output which can not have access to the Bus.

-

Client:

-

Server: The Server carries out a service required by a Client.

PLC

o PC device which drives and controls InterBus-S; it can therefore have access to the Bus.

The Client asks for a service to the Server.

-VFD:

Virtual Field Device: refer to the Reference Manual for Inter&us-S (see the chapter References)

14.0 ABBREVIATIONS

- ALI

-

PMS

-

LLI

-

MAP

-

MMS

-

FMS

-0v

- PCP

-

PDC

Application Layer Interface.

Peripherals Message Specification.

Lower Layer Interface.

Manufacturing Automation Protocol.

Manufacturing Message specification.

Fieldbus

Object Dictionary ( Dizionario Oggetti

Peripherals Communication Protocol).

Process Data Channel).

Message Specification

).

-

PDL

-

PDU

Protocol Data Link.

Protocol Data Unit.

15.0 REFERENCES

1.

Reference Manual for InterBus-S. Peripherals Communication Protocol. Version 1.5 ( PCP 1.2 ). Code:

IBS PCP RE HB E

2.

Manual Profile 21 Drivecorn. Number of the order: DRI 21 - E

3. Option DGF manuals

4.

Drive manuals DV300, AV300,

5. User Manual Peripherals Communication Protocol Revision: A Type: IBM PCP UM E Order No.

275393 1.

Number of the order: 27 80 99 1

etc.

Loading...

Loading...