GE 90*-30 PLC Series, LONWORKS PE693BEM350, LONWORKS PE693BEM351, LONWORKS PE693BEM352 User Manual

Page 1

Programmable Control Products

User's Manual

I/O

PEN*

Ser ies 90*-30 PLC

LONW

GFK-1322 January 2010

ORKS*

Bus Interface Module

Page 2

GFL-002

Warnings, Cautions, and Notes

as Used in this Publication

Warning

Warning notices are used in this publication to emphasize that hazardous voltages,

currents, temperatures, or other conditions that could cause personal injury exist in this

equipment or may be associated with its use.

In situations where inattention could cause either personal injury or damage to equipment,

a Warning notice is used.

Caution

Caution notices are used where equipment might be damaged if care is not taken.

Note: Notes merely call attention to information that is especially significant to

understanding and operating the equipment.

This document is based on information available at the time of its publication. While efforts

have been made to be accurate, the information contained herein does not purport to cover all

details or variations in hardware or software, nor to provide for every possible contingency in

connection with installation, operation, or maintenance. Features may be described herein

which are not present in all hardware and software systems. GE Intelligent Platforms assumes

no obligation of notice to holders of this document with respect to changes subsequently made.

GE Intelligent Platforms makes no representation or warranty, expressed, implied, or statutory

with respect to, and assumes no responsibility for the accuracy, completeness, sufficiency, or

usefulness of the information contained herein. No warranties of merchantability or fitness for

purpose shall apply.

* indicates a trademark of GE Intelligent Platforms, Inc. and/or its affiliates. All other

trademarks are the property of their respective owners.

©Copyright 2009 GE Intelligent Platforms, Inc.

All Rights Reserved

Page 3

Support

Technical Support

If you purchased this product through an Authorized Channel Partner, please contact them directly.

General Contact Information

Online Technical Support and GlobalCare: 1Hwww.ge-ip.com/support

Additional information:

2H 3Hwww.ge-ip.com

Technical Support

If you have technical problems that cannot be resolved with the information in this guide, please

contact us by telephone or email, or on the web at

4Hwww.ge-ip.com/support

Americas

Online Technical Support: 5H6Hwww.ge-ip.com/support

Phone: 1-800-433-2682

International Americas Direct Dial: 1-434-978-5100

Technical Support Email:

Customer Care Email:

7H8Hsupport.ip@ge.com

9H10Hcustomercare.ip@ge.com

Primary language of support: English

Europe, the Middle East, and Africa

Online Technical Support: 11H12Hwww.ge-ip.com/support

Phone: +800-1-433-2682

Technical Support Email:

Customer Care Email:

13H14Hsupport.emea.ip@ge.com

15H16Hcustomercare.emea.ip@ge.com

Primary languages of support: English, French, German, Italian, Czech, Spanish

Asia Pacific

Online Technical Support: 17H18Hwww.ge-ip.com/support

Phone: +86-400-820-8208

+86-21-3217-4826 (India, Indonesia, and Pakistan)

Technical Support Email:

Customer Care Email:

19H20Hsupport.cn.ip@ge.com (China)

21H22Hsupport.jp.ip@ge.com (Japan)

23H24Hsupport.in.ip@ge.com (remaining Asia customers)

25H26Hcustomercare.apo.ip@ge.com

27Hcustomercare.cn.ip@ge.com (China)

Page 4

Page 5

This manual describes the features and operation of the Series 90™ PLC LONW

Interface Module (PE693BEM350, 351, and 352). It also provides the configuration and

programming information needed to complete the interface between a Series 90-30 programmable

logic controller (PLC) and a L

Content of this Manual

ONWORKS

network.

Preface

®

ORKS

Bus

Chapter 1. Module Overview: Provides overviews of the L

(LBIM) and the Echelon

®

LONW

ORKS

network.

ONWORKS

Bus Interface Module

Chapter 2. Operation: Describes the operation of the LBIM.

Chapter 3. Hardware Installation: Explains how to install an LBIM in a Series 90 rack.

Provides recommendations for connecting an LBIM node to a L

ONWORKS

network.

Chapter 4. Configuration: Explains how to configure the module network interface and set

configuration parameters. Describes network binding.

Chapter 5. Troubleshooting: Lists problem symptoms and corrective actions. Describes the use

of Valid bits for network variables.

Appendix A. Specifications: Lists physical specifications and electrical and environmental

requirements.

Appendix B: Standard Network Variable Types: Lists the Standard Network Variable Types

supported by the LBIM as of the time this manual was published. (Refer to the most recent version

of The SNVT Master List and Programmer’s Guide — 005-0027-01 — for a current listing.)

Appendix C. Configuration File Specifications: Contains reference information pertaining to

the files that are created by the configuration software.

Appendix D. Glossary: Provides definitions of acronyms and terminology.

Appendix Q. Quick Start Guide. Describes the steps necessary to get your LBIM up and running

quickly. To use this guide, you should have a working knowledge of L

ONWORKS

network

technology and GE Series 90-30 PLCs.

Echelon, Neuron, LONT

™ Logicmaster and Series 90 are trademarks of GE corporation.

GFK-1322A v

, and LONW

ALK

are registered trademarks of Echelon Corporation.

ORKS

Page 6

Preface

Related Publications

For more information about GE Series 90 PLCs and related products, refer to the following:

Series 90™-30 Programmable Controller Installation Manual (GFK-0356)

Logicmaster™ 90 Series 90-30/20/Micro Programming Software User’s Manual

(GFK-0466).

Series 90™-30/20/Micro Programmable Controllers Reference Manual (GFK-0467).

Series 90™

-30, 70, PLC Products, Genius® I/O Products, Field Control™ Distributed I/O

& Control Products, GE Product Approvals, Standards, General Specifications

(GFK-0867B or later)

Information about L

ONWORKS

networks can be found in the following documents, which are

available from Echelon Corporation and on the World Wide Web at www.echelon.com.

ONWORKS

L

Enhanced Media Access Control with Echelon’s L

ONTALK

L

ONTALK

L

Installation Overview (005-0006-01)

ONTALK

Response Time Measurements (005-0010-01)

Protocol (005-0017-01)

Protocol (005-0001-01)

The SNVT Master List and Programmer’s Guide and The SCPT Master List (005-0027-01)

Junction Box and Wiring Guidelines for Twisted Pair L

Optimizing L

ONMARK

L

ONMARK

L

Layers 1—6 Interoperability Guidelines (078-0014-01)

Application Layer Interoperability Guidelines (078-0120-01)

ONTALK

Response Time

(005-0011-01)

ONWORKS

Networks (005-0023-01)

vi Series 90™-30 PLC LONWORKS® Bus Interface Module User's Manual–June 1997 GFK-1322A

Page 7

Contents

Chapter 1 Overview.......................................................................................................... 1-1

LONW

Network Overview ....................................................................................1-3

ORKS

Bus Interface Module Overview ....................................................................................1-5

Controls and Indicators...........................................................................................1-6

Connectors .............................................................................................................1-7

Functional Characteristics.......................................................................................1-8

Configuration .........................................................................................................1-8

Diagnostics.............................................................................................................1-8

What You Need to Operate the Bus Interface Module....................................................1-9

Chapter 2 Operation......................................................................................................... 2-1

Overview of Operation..................................................................................................2-2

Architecture............................................................................................................2-2

Operating Modes .................................................................................................... 2-4

Powerup Sequence........................................................................................................2-4

Sweep Operation...........................................................................................................2-6

Chapter 3 Hardware Installation..................................................................................... 3-1

Rack Location for the Bus Interface Module..................................................................3-2

Module Installation and Removal ..................................................................................3-3

Module Installation.................................................................................................3-3

Module Removal.....................................................................................................3-3

Network Installation......................................................................................................3-4

Network Wiring Guidelines.....................................................................................3-4

Terminating the Network ........................................................................................3-4

Connecting a Programmer.............................................................................................3-6

Chapter 4 Configuring the LBIM.................................................................................... 4-1

Overview......................................................................................................................4-2

Using the LBIM Configuration Software.......................................................................4-4

Installation and Startup...........................................................................................4-4

Editing a Configuration...........................................................................................4-5

Binding Network Variables .........................................................................................4-23

GFK-1322A vii

Module Configuration...........................................................................................4-6

Reference Configuration.....................................................................................4-11

Field Definitions..........................................................................................4-11

Defining Variables.............................................................................................. 4-13

Menu Commands................................................................................................4-18

File Menu .................................................................................................... 4-20

Tools Menu..................................................................................................4-20

Page 8

Contents

Chapter 5 Troubleshooting............................................................................................... 5-1

Startup and Configuration.............................................................................................5-2

Valid Bits .....................................................................................................................5-3

Wink Function..............................................................................................................5-3

Appendix A Specifications................................................................................................... A-1

Module Specifications.................................................................................................. A-2

Power Requirements ..............................................................................................A-2

Environmental Requirements..................................................................................A-2

Agency Approvals .................................................................................................A-2

Microprocessor Configuration................................................................................ A-3

Interface Specifications................................................................................................ A-4

Serial Communications Protocol ............................................................................A-4

Network Communications...................................................................................... A-4

Series 90-30 Backplane Interface ...........................................................................A-4

Appendix B Standard Network Variable Types.................................................................B-1

Appendix C Configuration File Specifications....................................................................C-1

Network Interface and PLC Mapping........................................................................... C-1

Network Variable Parameter Configuration.................................................................. C-2

Configuration Parameter Types.................................................................................... C-4

Appendix D Glossary...........................................................................................................D-1

Commonly Used Acronyms and Abbreviations .............................................................D-2

Glossary of Terms........................................................................................................D-3

Appendix E Quick Start Guide.......................................................................................... Q-1

Module Description...................................................................................................... Q-2

Functional Characteristics......................................................................................Q-2

Controls and Indicators..........................................................................................Q-4

Connectors ............................................................................................................Q-5

Diagnostics............................................................................................................Q-5

What You Need to Operate the Bus Interface Module...................................................Q-6

Hardware Installation and Powerup..............................................................................Q-7

Module Configuration/Network Installation.................................................................. Q-8

PLC Configuration.....................................................................................................Q-11

Summary................................................................................................................... Q-12

viii Series 90™-30 PLC LONWORKS® Bus Interface Module User's Manual–June 1997 GFK-1322A

Page 9

Contents

Figure 1-1. Sample LONW

Network Configuration..........................................................................1-2

ORKS

Figure 1-2. Topology Examples...............................................................................................................1-4

Figure 1-3. Series 90 PLC L

ONWORKS

Bus Interface Module..................................................................1-5

Figure 2-1. Overview of Bus Interface Module Operation.........................................................................2-3

Figure 2-2. Bus Interface Module Powerup Sequence...............................................................................2-5

Figure 3-1. Module Installation................................................................................................................3-3

Figure 3-2. Module Removal ...................................................................................................................3-3

Figure 3-3. Cabling for Bus and Loop Networks......................................................................................3-5

Figure 3-4. Connections for LBIM Configuration.....................................................................................3-6

Figure 3-5. Computer to L

ONWORKS

Network Connections for LBIM Configuration...............................3-7

Figure 4-1. Example: Determining What Network Variable Types are Needed..........................................4-2

Figure 4-2. Example: Assigning Network Variables Types to the LBIM and PLC Registers......................4-3

Figure 4-3. Example: Installing the LBIM in the Network and Binding the Variables..............................4-23

Figure Q-1. Sample Network Configuration............................................................................................Q-3

Figure Q-2. Example: Identifying the Network Variables Needed to Interface with the PLC ..................... Q-8

Figure Q-3. Example: Assigning Network Variables to the Module and the PLC Registers....................... Q-9

Figure Q-4. Example: Installing the Module in the Network and Binding the Variables ..........................Q-10

GFK-1322A Contents ix

Page 10

Contents

Table 1-1. Bus Interface Module Products ...............................................................................................1-1

Table 1-2. Supported Topologies ............................................................................................................. 1-3

Table 1-3. LBIM Controls and Indicators.................................................................................................1-6

Table 1-4. LBIM Connectors...................................................................................................................1-7

Table 1-5. Pin Assignments for RS-422 Port............................................................................................1-7

Table 1-6. LBIM Functional Characteristics ............................................................................................ 1-8

Table 1-7. Compatible CPU Models and Logicmaster 90 Software Versions...........................................1-10

Table 1-8. Choosing a Network Binding Tool.........................................................................................1-10

Table 1-9. Network Interface Configuration...........................................................................................1-10

Table 4-1. Configuration Editor Fields...................................................................................................4-10

Table 4-2. Network Variable Fields in the Network Variable Editor........................................................4-17

Table 4-3. Configurable Network Image Parameters ..............................................................................4-24

Table 5-1. Troubleshooting......................................................................................................................5-2

Table B-1. SNVTs Supported by the Bus Interface Module..................................................................... B-1

Table C-1. Network Variable Definition File........................................................................................... C-1

Table C-2. Configuration Parameter Value File....................................................................................... C-2

Table C-3. Configuration Parameter Template File ................................................................................. C-2

Standard Table C-4. Configuration Memory Budget................................................................................ C-2

Table C-5. PLC I/O Table Configuration................................................................................................ C-3

Table C-5. - Continued........................................................................................................................... C-4

Table Q-1. Compatible CPU Models and Logicmaster 90 Software Versions...........................................Q-6

Table Q-2. Choosing a Network Binding Tool......................................................................................... Q-6

x Series 90™-30 PLC LONWORKS® Bus Interface Module User's Manual–June 1997 GFK-1322A

Page 11

Chapter

1

Overview

The Series 90 PLC LONW

GE Series 90-30 PLC (programmable logic controller) and an Echelon L

network. The LBIM maps network variables into specific PLC register locations. It can support up

to 244 network variables (240 can be configured by the user), and map these network variables

into the %I, %Q, %AI, and %AQ PLC memory references. The Module adheres to the

Layers 1—6 Interoperability Guidelines

network

A L

ONWORKS

in a wide range of control network applications. L

architecture, in which intelligent control devices, called nodes, communicate with each other

using the L

microcontroller with the communications medium, and embedded intelligence that implements

the protocol and performs control functions. Figure 1-1 illustrates a sample network configuration

that uses an LBIM to communicate with a Series 90-30 PLC.

An individual node usually performs a simple task. Devices such as proximity sensors, switches,

relays, and motor drives can be nodes on a network. The network controls the interaction of the

nodes to perform a complex application, such as controlling a manufacturing line or automating a

building.

The LBIM can interface with networks that use twisted pair cabling . The LBIM contains a

transceiver that provides a physical communication interface between the module and a

L

ONWORKS

supported.

network can range in size from two to tens of thousands of devices and can be used

®

ONTALK

network. The type of embedded transceiver determines the network topology

protocol. Each node consists of a physical interface that couples the node

Bus Interface Module (LBIM) provides an interface between the

ORKS

ONWORKS

(078-0120-01)for the interface to the L

ONWORKS

technology uses peer-to-peer

ONWORKS

ONMARK

L

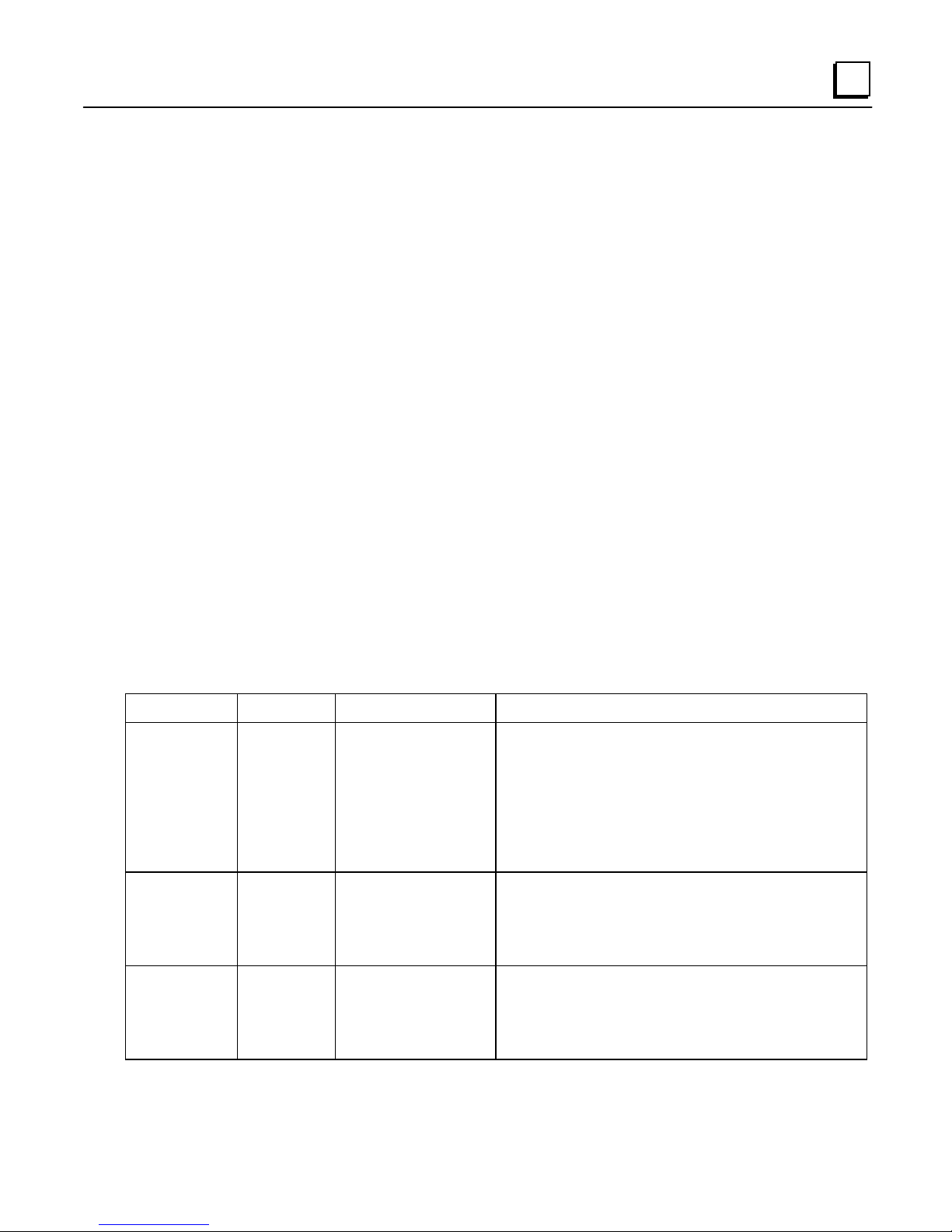

Table 1-1. Bus Interface Module Products

Catalog No. Embedded Transceiver Topologies Supported

PE693BEM350

PE693BEM351

PE693BEM352

The following topics are presented in this chapter:

L

ONWORKS

Bus Interface Module Overview..................................................................................1-5

GFK-1322A 1-1

TP/FT-10 Free

(Bus, Star, Loop, Others,

Combinations)

TP/XF-78 Bus/Loop

TP/XF-1250 Bus/Loop

Network Overview...................................................................................1-2

Page 12

1

What You Need to Operate the Bus Interface Module ................................................. 1-9

CONFIGURATION

PORT

I/O DEVICES

LONTALK

ADAPTOR

Series 90-30

CPU

NODE NODE NODE

LON

I/O I/O

BIU

BIM

FREE TOPOLOGY NETWORK

SUBNET A

POWER LINE NETWORK

I/O DEVICES

ROUTER

NODENODE NODE

Figure 1-1. Sample LONW

1-2 Series 90™-30 PLC LONWORKS® Bus Interface Module User's Manual – June 1997 GFK-1322A

ORKS

Network Configuration

SUBNET B

Page 13

1

LONW

ORKS

Network Overview

A control network consists of intelligent control devices, called nodes, that communicate using a

common protocol. Each node in the network contains embedded intelligence that implements the

protocol and performs control functions. In addition, each node includes a physical interface that

couples the node’s microcontroller with the communications medium.

In a L

ONWORKS

pair, power line, fiber optic cable, coaxial cable, RF, or infrared. At the heart of each node is the

Neuron

protocol that ensures that nodes can interoperate using an efficient and reliable communications

standard. Because Neuron chips can be connected directly to the sensors and outputs that they

supervise, a single Neuron chip will process sensor/output status, execute control algorithms, and

communicate with other Neuron chips.

The L

different manufacturers to communicate with each other. Echelon’s

Types

pressure, temperature, and volume. The LBIM supports SNVTs that are less than 32 bytes in

length, and are defined in

The LBIM contains a transceiver that provides a physical communication interface between the

module’s Neuron chip and a L

based on the TP/XF-T78 and TP/XF-1250 transceivers, and free topology, based on the TP/FT-10

transceiver. The free topology allows more options for network design. Table 1-2 lists the

topologies supported by each type of LBIM. Figure 1-2 illustrates the supported topologies.

®

chip which contains the LONT

ONTALK

(SNVTs) provide standard units of measurement for common control quantities, such as

network, the nodes communicate over one or more media such as twisted wire

protocol, a complete seven-layer communications

ALK

protocol uses I/O points, known as

The SNVT Master List and Programmers Guide

ONWORKS

network. The LBIM supports bus and loop topologies,

network variables

, to allow devices from

Standard Network Variable

(005-0027-01).

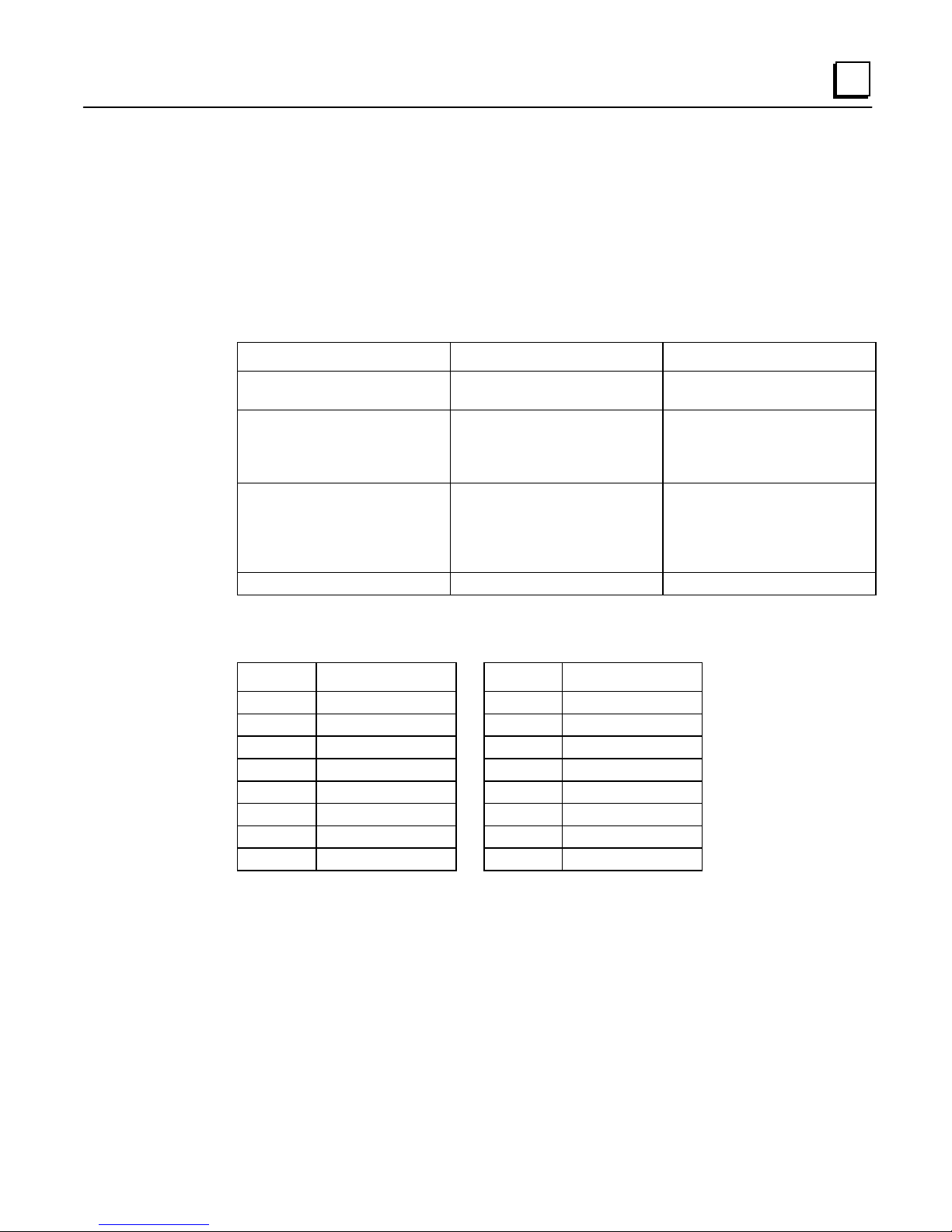

Table 1-2.

Catalog No. Transceiver Topology Network Characteristics

PE693BEM350

PE693BEM351

PE693BEM352

TP/FT-10 Free

TP/XF-78 Bus/Loop Bit Rate: 1.25Mbps

TP/XF-1250 Bus/Loop Bit Rate: 78Kbps

Supported Topologies

(Bus, Star, Loop,

Others, Combinations)

Bit Rate: 78Kbps

Distance: 500m free topology, 2,700m with doubly

terminated bus. Distance can be multiplied with

repeaters.

No. of Nodes: up to 64

Other: Transformer-isolated; high impedance when

unpowered

Distance: 500m (0.3m stubs)

No. of Nodes: up to 64

Other: Transformer-isolated

Distance: 2000m (3m stubs)

No. of Nodes: up to 64

Other: Transformer-isolated

GFK-1322A Chapter 1 Overview 1-3

Page 14

1

Bus

Loop

NNN

TT

N

N N

N

S

NN

Free

T Termination Network

N Node

Switch and Termination Node

S

(closes loop when activated)

Figure 1-2. Topology Examples

N N

NN

T

N

NN

S

1-4 Series 90™-30 PLC LONWORKS® Bus Interface Module User's Manual – June 1997 GFK-1322A

Page 15

Bus Interface Module Overview

The LBIM is a standard, rack-mounted Series 90-30 PLC module. (The table on page 1-10 lists

compatible CPUs.) The module plugs easily into the PLC’s backplane or into a remote PLC

baseplate. The latch on the bottom of the module secures it in position.

There are no DIP switches or jumpers to set on the LBIM. It is configured using the IOPEN.EXE

configuration software, provided with the module on floppy disk. Procedures for configuration are

provided in Chapter 4.

1

a45599

LONWORKS

Bus

Interface

Module

N

E

T

W

O

R

K

COM

PORT

RS-422

PWR

OUT

MSG

IN

MSG

SVC

SERVICE

Figure 1-3. Series 90 PLC LONW

GFK-1322A Chapter 1 Overview 1-5

ORKS

Bus Interface Module

Page 16

1

Controls and Indicators

The only external control is the SERVICE pushbutton. The LEDs on the front of the LBIM

indicate its operating status.

Table 1-3. LBIM Controls and Indicators

SERVICE Momentary contact

PWR Lighted (Power) +5 VDC primary power is present at the LBIM’s logic

OUT MSG Flashes briefly (Outbound Message) An update message for a bound network

Switch Type Function

When pressed, the LBIM’s Neuron chip broadcasts its unique 48-

pushbutton

bit Neuron identification code and program identifier to the

ONWORKS

L

installation of the LBIM in the L

network. This function is used to facilitate

ONWORKS

Indicator State Meaning

circuitry.

variable is sent by the LBIM to the L

network.

ONWORKS

network.

Lighted briefly Powerup sequence in process.

The configuration parameter value file or the network variable

bindings are being saved into the flash memory.

Flashes alternately

with IN MSG LED

Flashes together with

IN MSG LED

A powerup error has occurred. For troubleshooting information,

refer to Chapter 5.

ORKS

LONW

wink function implemented. See “Wink Function” in

Chapter 5.

IN MSG Flashes briefly (Inbound Message) Flashes briefly (10ms) when an update

message for a bound network variable is received by the LBIM

from the L

ONWORKS

network.

Also lighted briefly during powerup sequence.

Lighted briefly Powerup sequence in process.

The network variable configuration is being saved into the flash

memory.

Flashes alternately

with OUT MSG LED

Flashes together with

OUT MSG LED

A powerup error has occurred. For troubleshooting information,

refer to Chapter 5.

ORKS

LONW

wink function implemented. See “Wink Function” in

Chapter 5.

SVC Not lighted Normal operation.

Flashing (Service) The LBIM is in a LONW

ORKS

unconfigured state. (The

LBIM network variables and PLC mapping are configured and it

is waiting for configuration from a network management tool.)

Lighted When SERVICE button is pressed.

1-6 Series 90™-30 PLC LONWORKS® Bus Interface Module User's Manual – June 1997 GFK-1322A

Page 17

Connectors

During normal operation, the only external connection to the LBIM is the network connection to

the two-pin removable header on the front panel. The RJ-45 connector is reserved for easy

connection of network management tools during configuration of the interface and binding of

network variables. The RS-422 serial port is used to update LBIM firmware and is not normally

needed by the user.

Table 1-4. LBIM Connectors

Connector Function Type

NETWORK Connection of network

management tools

NETWORK Provides LONW

field connection (NETA, NETB)

using 18-24 AWG (0.86mm

0.22mm

COM PORT RS-422 RS-422 serial port that supports

SNP communications (SNP and

SNPX). Used to update LBIM

firmware. (Does not support

Hand-Held Programmer.)

Series 90-30 backplane Connection to PLC backplane 24-pin connector

ORKS

network

2

) twisted pair wires.

2

to

RJ-45

NetA, NetB

2-pin removable screw terminal

DB-15, female

1

Table 1-5. Pin Assignments for RS-422 Port

Pin Signal Name Pin Signal Name

1 Shield 8 CTS (B)

2 No connection 9 RT

3 No connection 10 RD (A)

4 No connection 11 RD (B)

5 No connection 12 SD (A)

6 RTS (A) 13 SD (B)

7 OV 14 RTS (B)

15 CTS (A)

GFK-1322A Chapter 1 Overview 1-7

Page 18

1

Functional Characteristics

Configuration

Most parameters are supported to the limits of the LONT

Protocol and the LONW

ALK

ORKS

node

limits.

Table 1-6. LBIM Functional Characteristics

Microprocessor

Maximum number of network

variables supported by LBIM

Standard Network Variable Types

(SNVTs)

PLC memory types supported

Neuron chip running the Microprocessor Interface Program

(MIP) with 80C186 host processor.

244 (240 of these can be configured by user)

The maximum number of network variables depends on the

size and type of the variables, limited by the LBIM’s PLC

register space (2 Kbytes each direction) and the configuration

memory budget.

Supports L

List

network variable must be no more than 31 bytes in length.

%I, %Q, %AI, %AQ

ONWORKS

published by Echelon corporation as of June 1996. Each

SNVTs as listed in

The SNVT Master

Configuration of the LBIM consists of defining network variable types and mapping them into the

PLC reference space using the IOPEN configuration software. Network Variable types mapped to

memory types %I or %Q must be of type SNVT_switch, SNVT_lev_disc, or other bit-represented

types. Once the LBIM’s network interface has been configured, network configuration and

binding can be performed as for any other

LONW

node. Also, after the LBIM’s network

ORKS

interface has been configured, the Series 90-30 backplane CPU must be set up to recognize the

LBIM as a foreign smart module with a reference map required to implement the network

interface. For details on configuration, refer to Chapter 4.

Diagnostics

The LBIM does not report faults to the PLC. Module errors cause the LBIM to reset. If an

acknowledge NV update command fails, it is up to the destination device to assume that a fault

has occurred. Configuration errors will cause the LBIM to not be mapped.

For troubleshooting and diagnostics information, refer to Chapter 5.

1-8 Series 90™-30 PLC LONWORKS® Bus Interface Module User's Manual – June 1997 GFK-1322A

Page 19

What You Need to Operate the Bus Interface Module

To configure and operate the LBIM, you need:

• A personal computer or laptop computer that runs Microsoft

• Series 90-30 backplane with CPU module

See Table 1-7 for models that can be used with the LBIM.

• Logicmaster 90 software

Required to configure and program the Series 90-30 PLC. See Table 1-7 for versions that can

be used with the LBIM.

®

Windows® software.

1

• L

ONWORKS

network binding tool

Many third-party network management software packages that include network binding tools

are available. (See Table 1-8 for suggestions.)

• IOPEN network interface configuration software: (for Microsoft Windows) This software is

provided on the utility disk supplied with the LBIM.

• A L

ONTALK

adapter and a device driver (See Table 1-9 for the adapter types that can be used

by each model of LBIM.)

This is required to run the network interface configuration software.

®

Windows is a registered trademark of Microsoft Corporation.

GFK-1322A Chapter 1 Overview 1-9

Page 20

1

Table 1-7. Compatible CPU Models and Logicmaster 90 Software Versions

CPU Models

CPU Firmware Logicmaster 90 Software

IC693CPU___

release 5.0 or later (release 5.0 or later)

In each case,

311S

331T

313H

323H

340B

341K

351AA release 6.0 or later (release 6.0 or later)

351AB release 6.02 or later (release 6.0 or later)

models or versions can be used.

later

Table 1-8. Choosing a Network Binding Tool

Third-party network

management tools

Considerations

LONM

•

• ICELAN-G from Intelligent Energy Corporation

• MetraVision from Metra Corporation

• others

• How well it handles nodes that have a large number of network

variables

• Ability to handle Standard Configuration Parameter Types

(SCPT) and load these values using L

from Echelon

AKER

IC641SWP___

301R

306K

311A

311A

ONTALK

File Transfer

301S

306L

Table 1-9. Network Interface Configuration

LBIM Model L

ONTALK

and Configuration Utility

PE693BEM350

(free topology type)

PE693BEM351

PE693BEM352

(bus/loop topology types) PCLTA card

SLTA

NodeUtil utility

PCLTA card

NodeUtil utility

PCMIA card (PCC-10) none

SLTA

NodeUtil utility

NodeUtil utility

Adapter

Cables

RS-232

none

RS-232

none

1-10 Series 90™-30 PLC LONWORKS® Bus Interface Module User's Manual – June 1997 GFK-1322A

Page 21

Chapter

2

Operation

The following topics are presented in this chapter:

Overview of Operation................................................................................................2-2

Powerup Sequence......................................................................................................2-4

Sweep Operation ........................................................................................................2-6

GFK-1322A 2-1

Page 22

2

Overview of Operation

Architecture

The LBIM communicates with other LONW

LBIM communicates with the PLC CPU over the PLC backplane.

Figure 2-1 provides an overview of the LBIM’s architecture. The LBIM has two processors: an

Intel 80186EC processor provides host functions and a 3150 Neuron processor that runs Echelon’s

Microprocessor Interface Program (MIP) handles the L

interface is provided by GE Series 90-30 API (application programming interface)

software.

When an input network variable is updated, the data associated with it is copied into the

corresponding PLC input buffer location. The Store Inputs routine is then called to update the

PLC memory during the next PLC scan.

The API (Application Programming Interface) buffers the information for transfer to the PLC

during a subsequent scan. When a scan is received from the PLC, the API initiates a callback, in

which the LBIM’s entire PLC output buffer is copied. Each network variable in the output buffer

is then checked to determine whether it differs from the current value of the output buffer. If the

values are different, the network variable is updated over the L

Send Time has been configured, the network variable will not be updated until the Min Send

Time has expired.

The Max Send Time configuration parameter can also drive updating of output network variables

if the value does not change. This assures that, even though data in the source is not changing,

any newly added users will receive a copy and that users also know that the source is still online.

This is how heartbeats are sent across the L

modules through bound network variables. The

ORKS

network. The Series 90-30

ONWORKS

network. If the Min

ONWORKS

ONWORKS

network.

A separate function determines which network variables need updating and forwards the data to

the microprocessor interface program (MIP) through the host interface.

2-2 Series 90™-30 PLC LONWORKS® Bus Interface Module User's Manual – June 1997 GFK-1322A

Page 23

LonW orks N et w ork (T P- 78, T P -1 25 0, or FT 10 )

Microprocessor Interface Program

with U plink Int erru pt

2

3150 Neuron

Host Interface Library

Output

Network

Variable

Updates

API Callbacks

Check Outputs

Input

Network

Variable

Updates

Network

Binding/S CPT

Storage

Network

Interfac e

Configuration

Engine

Series 90-30 PLC API

PLC Backplane

Figure 2-1. Overview of Bus Interface Module Operation

80186E C

SNP

Boot

Loader

Serial

Port

GFK-1322A Chapter 2 Operation 2-3

Page 24

2

Operating Modes

The LBIM has four modes of operation:

Unconfigured This is how the LBIM is shipped from the factory. Four default network

variables are set up to allow the network interface to be configured over

the L

ONWORKS

L

ONMARK

SNVT_obj_request, SNVT_obj_status, SNVT_file_req, SNVT_file_status.

This mode is also entered if the network interface configuration

information is corrupted or if an invalid configuration is loaded to the

LBIM.

Unbound This mode exists after the LBIM’s network interface has been configured,

but before network variables are bound. The LBIM presents self

documentation information to the network (in response to queries) and can

be configured in the PLC backplane. Network variables are not updated

across the network.

Network. These network variables are part of the

node object that has the four network variables (index 0—3):

Normal Operation If one or more network variables are bound to other L

Software Download If the boot loader is used to update the software, the LBIM does not

Powerup Sequence

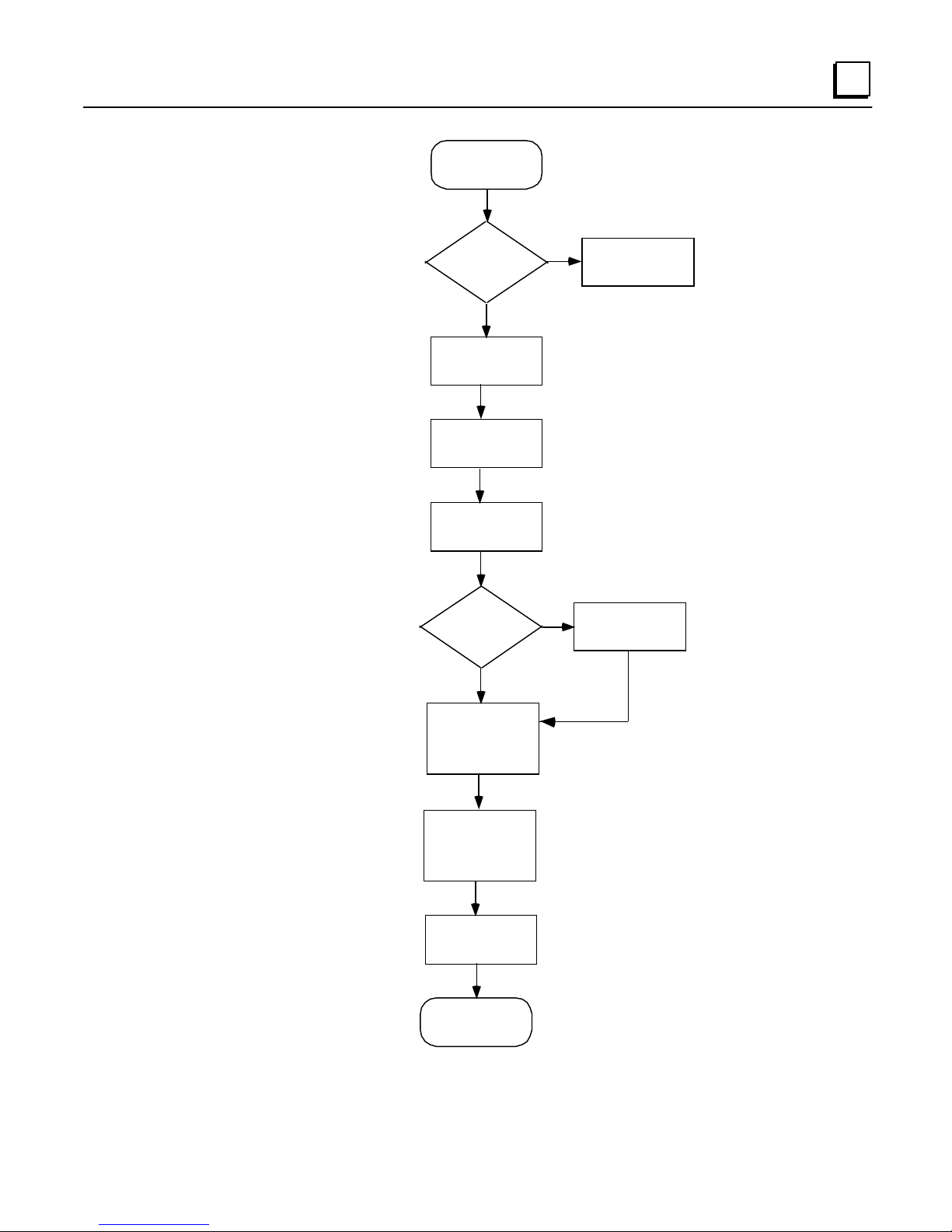

The self-test sequence performed by the LBIM during powerup is illustrated in Figure 2-2.

The default network interface configuration consists of the LonMark node object with four

network variables (index 0—3).

• SNVT_obj_request Object request

• SNVT_obj_status Object status

• SNVT_file_req File request

• SNVT_file_status File status

ONWORKS

data updated by the PLC will be sent across the network to the other node.

Input network variables for the module can also be updated (and the data

sent to the PLC) if the network variables are bound.

respond to the network or the PLC interface. The LBIM should be put offline before downloading new code.

nodes,

2-4 Series 90™-30 PLC LONWORKS® Bus Interface Module User's Manual – June 1997 GFK-1322A

Page 25

Clear RAM

2

Checksum

on code space

correct?

Yes

Turn on

IN M SG and

OUT MSG LEDs

Initialize PL C

backplane

driver

Read s tored

network interface

configuration

Configuration

valid?

Yes

No

No

Boot loader

Set configuration

to default values

Initialize

LONW

ne tw ork in terfa ce

Initi aliz e d e fa ult d ata

values and timeouts

Configu re PLC

reference spac e

wh en re quested

by PLC

Turn off the IN MSG

and O UT MSG

LE D s

Main loop

proce s sing

ORKS

Figure 2-2. Bus Interface Module Powerup Sequence

GFK-1322A Chapter 2 Operation 2-5

Page 26

2

Sweep Operation

The data flow for information that is sent from the LONW

separately from the flow of data from the PLC to the L

Input data: When an input network variable is updated, the data associated with the network

variable is copied into the proper location in a PLC input buffer. The Store Inputs routine is then

called to update the data in the PLC at the next scan time.

Output data: When the API callback notifies the LBIM that an output scan has arrived, the data

is copied into a holding buffer. This buffer is then scheduled to be checked against the current

value of each output network variable. If the data is different, the network variable is updated over

the L

ONWORKS

Send Time was configured). This prevents overloading the network with frequently changing

data.

If a network variable is configured to be a SNVT_lev_disc or a SNVT_switch and is mapped into

the %I or %Q reference area, the data is converted to a bit. This conversion occurs when the data

is moved to or from the PLC buffer.

The total sweep time depends on the amount of reference memory used by the LBIM. This is a

maximum of 1K words input and 1K words output, and is set when the LBIM’s Network Interface

is configured.

The I/O response times depend on the following factors:

• number and size of network variables for which the LBIM is configured

• rate at which network variables are updated

network if the Min Send Time for the network variable has expired (only if Min

ONWORKS

network to the PLC is handled

ORKS

network.

• number of network variables that are bound

• service type (ACKD, UNACKD) of each network variable

• network bandwidth

• network traffic

• whether network variables are input or output network variables

2-6 Series 90™-30 PLC LONWORKS® Bus Interface Module User's Manual – June 1997 GFK-1322A

Page 27

Chapter

3

Hardware Installation

This chapter describes:

Rack Location for the Bus Interface Module ...............................................................3-2

Module Installation and Removal ...............................................................................3-3

Network Installation...................................................................................................3-4

Connecting a Programmer.......................................................................................... 3-5

GFK-1322A 3-1

Page 28

3

Rack Location for the Bus Interface Module

The LBIM can be located in any rack in any slot (except for the slots in the main rack that are

reserved for the power supply and CPU) in a Series 90-30 PLC. For the most efficient system

operation, the main baseplate is preferred.

The following slots are reserved in the PLC main rack:

Models 331, 340, 341, 351, 352 and later: Slot 0 reserved for power supply

Models 311 and 313: Slot 0 reserved for power supply (The CPU is built into the

baseplate.)

To estimate whether the system you want to design is possible, complete steps 1–3, below.

1. The I/O configuration block uses a base of 90 bytes of user memory. Each smart module uses

257 bytes of user memory for parameter data. Finally, every I/O segment uses an additional

40 bytes of user memory.

Slot 1 reserved for CPU

Example of segments:

A discrete input module has one segment (%I).

2. The total user memory required by a configuration is the sum of all these parts:

base configuration size (90)

+ number of smart modules *257

+ number of segments *40

= total user memory required for the configuration

3. The total user memory available for configuration varies with CPU model. If the number

derived from the formula above is greater than the number next to the CPU that you are

using, the system will not work due to memory limitations.

CPU Available Memory

(bytes)

311 4,720

313 4,720

323 4,720

331 4,656

340/341 8,176

351/352 16,368

3-2 Series 90™-30 PLC LONWORKS® Bus Interface Module User's Manual – June 1997 GFK-1322A

Page 29

Module Installation and Removal

Module Installation

3

Module Removal

The LBIM is installed and removed in the

same manner as all other Series 90-30

modules. Power must be OFF when

installing or removing the module.

To install the LBIM in the Series 90-30

PLC baseplate

.

1

Grasp the module with the rear hook

facing away from you.

.

2

Align the module with the desired

base slot and connector. Tilt the

module upward so that the top rear

hook on the module engages the slot

on the baseplate.

.

3

Swing the module downward until the connectors mate and the locking lever on the bottom of

the module snaps into place, engaging the baseplate notch.

Power must be removed from the PLC rack

before removing the LBIM from the

baseplate. However, it is not necessary to power

down the L

before removing the module. Do not disconnect

the bus cable or any terminating resistor.

ONWORKS

communications bus

Figure 3-1. Module Installation

a43055

a43056

If the rest of the bus is powered down, the bus

wiring can be removed from the module.

To remove the module:

.

1

Locate the release lever on the bottom of the

module. Firmly press it up toward the

module.

.

2

While holding the module firmly at the top, continue fully depressing the release lever and

swing the module upward.

.

3

Disengage the hook at the top of the module by raising the module up and moving it away

from the baseplate.

GFK-1322A Chapter 3 Hardware Installation 3-3

PRESS

RELEAS E L EVER

Figure 3-2. Module Removal

Page 30

3

(

)

(

)

g

Network Installation

During normal operation, the network is the only external connection to the LBIM. The network

is connected to the Module by means of the two-pin removable header on the front panel.

The LBIM adheres to the

the interface to the L

Network Wiring Guidelines

Junction Boxes:

A junction box is required to provide an interface between each L

the twisted pair cable. Depending on the topology, pass-through, stub, and local loop junction

boxes can be used. Echelon recommends Weidmüller BLZ (or equivalent) connectors and

receptacles for connections to junction boxes.

Cabling:

The network bus wiring should be 22 AWG (0.36 mm

18-24 AWG wiring with connection through a 5.08mm two-position screw terminal block. Either

22 (0.36mm

and the L

ONWORKS

Detailed recommendations for network cabling, junction boxes, and connectors can be found in

Junction Box and Wiring Guidelines for Twisted Pair L

Terminating the Network

ONMARK

L

ONWORKS

2)

or 24 AWG (0.22mm2) cabling can be used on the stub between the junction box

Layers 1—6 Interoperability Guidelines

network.

ONWORKS

2

) twisted pair wiring. The LBIM supports

(078-0014-01) for

application node and

application node. (For an example wiring scheme, refer to Figure 3-3)

ONWORKS

®

Networks

(005-0023-01).

Network termination is not provided by the LBIM. Termination must be provided by the network

as described in the LonWorks Transceiver User’s Guide for the transceiver type used or in the

LONMARK Layers 1-6 Interoperability Guidelines

Junction Box

22 or 24 AWG

Stub

LonWorks

Application Node

0.22mm

2

(078-0014-01).

22 AWG

Network Cablin

0.36mm

2

Figure 3-3. Cabling for Bus and Loop Networks

3-4 Series 90™-30 PLC LONWORKS® Bus Interface Module User's Manual – June 1997 GFK-1322A

Page 31

Connecting a Programmer

)

)

To configure the LBIM, the computer serial communications port must be connected to the

L

ONWORKS

on the network. As shown in Figure 3-5, three types of L

External SLTA Can be used with all LBIM models.

PCLTA card Can be used with all LBIM models.

PCMCIA Interface card (PCC-10), available

from Echelon Corporation

network through a LONT

adapter (Figure 3-4). In effect, the computer is a node

ALK

ONTALK

Can be used only with PE693BEM350 (free topology)

LBIM.

In all cases, the LONTALK adaptor transceiever

type must match that of the LBIM used.

ORKS

LONW

adapters are available:

Network

PLCSeries 90-30

L

B

I

M

3

to P C wit h

LonTalk adapter

22 ( 0.36m m

24 (0.22m m

2

or

2

Twisted Pair Cable

Node

to two-pin rem ovable screw terminal

NETW OR K port

on LBIM

Node

Node

Figure 3-4. Connections for LBIM Configuration

GFK-1322A Chapter 3 Hardware Installation 3-5

Page 32

3

(

)

(

)

IB M P C

IBM PCwith PCLT A card

RS-232

IC690CBL702

PCLTA C ard

RS-232

IC690CBL702

PCMIA Card

0.36mm

22

24

0.22mm

SLTA

Tw iste d Pair C a ble

TP/XT 1250,

TP/XT 78, or

FTT-10

To LonW orks network

2

or

2

To LonW orks network

IBM PCwith PCLT A card

PCC-10

RS-232

IC690CBL702

Use w ith P E69 3B EM 3 50 (free topo logy) LBIM only.

Figure 3-5. Computer to LONW

ORKS

Network Connections for LBIM Configuration

To LonW orks network

3-6 Series 90™-30 PLC LONWORKS® Bus Interface Module User's Manual – June 1997 GFK-1322A

Page 33

Chapter

4

Configuring the LBIM

The following topics are presented in this chapter:

Overview.................................................................................................................... 4-2

Using the LBIM Configuration Software ....................................................................4-4

Binding Network Variables ......................................................................................4-24

GFK-1322A 4-1

Page 34

4

Overview

The LBIM is configured using the I/Open LBIM Configuration program for Microsoft Windows.

Using this utility, a configuration file is created. This file is in the external interface file format

(.XIF) for L

ONWORKS

devices. The file contains node and network variable information along

with the register mapping information needed by the LBIM to configure the interface. The .XIF

file is downloaded to the LBIM by the configuration software over the L

L

ONMARK

File Transfer Protocol. The following general procedure is used to configure the

ONWORKS

network using

LBIM.

Step A. Determine what network variable types will be needed to interface with the PLC.

Example:

Inputs Outputs

SNVT_temp 3 SNVT_temp 1

SNVT_count 2 display 1

SNVT_freq_f 1

SNVT_temp_f 1

p

p

p

p

p

p

Figure 4-1. Example: Determining What Network Variable Types are Needed

4-2 Series 90™-30 PLC LONWORKS® Bus Interface Module User's Manual – June 1997 GFK-1322A

Page 35

Note

y

Care should be taken to assure proper orientation or direction of variables

defined. An input device such as a temperature sensor will send the value to the

network as an output network variable. That network variable would then be

declared as an input to the LBIM and be mapped into an input register within

the PLC.

Step B. Using the configuration utility software, assign network variable types to the LBIM and

the registers in the PLC memory space to which the variable types will map

a45644

PLC LonWorks BIM

CPU

Reg 1

Reg 2

Reg 3

Reg 4

Reg 5

Reg 6

Reg 7

Reg 8

Reg 9

Reg 10

Reg 11

Reg 12

Reg 13

SNVT_temp

SNVT_temp

SNVT_temp

SNVT_count

SNVT_count

SNVT_freq_f

SNVT_temp_f

SNVT_temp

displa

4

Figure 4-2. Example: Assigning Network Variables Types to the LBIM and PLC Registers

In the example illustrated in Figure 4-2, SNVT_temp and SNVT_count network variable types are

one-word values that map directly into a single register address. SNVT_freq_f and SNVT_temp_f

are double word values that map into two register locations. The type

is a three-word user-

display

defined network variable that maps into three register locations.

At this point, the module mapping is defined, but the actual network variables are not yet bound

to the module and the module is also not configured with the L

ONWORKS

network image. (See

“Binding Network Variables.”)

GFK-1322A Chapter 4 Configuring the LBIM 4-3

Page 36

4

Using the LBIM Configuration Software

The Gateway configuration software can be used with Windows 95, or 3.x versions of Windows.

Installation and Startup

Install the Windows LBIM configuration software by inserting the installation disk into the

appropriate computer drive. From Windows 95, select RUN from the START menu. From

Windows, select RUN from the FILE menu. Modify the command line to run A:\SETUP.EXE.

Choose RUN and answer any setup questions while the setup application runs.

The setup program may request that you add “SHARE.EXE” to your CONFIG.SYS PATH

statements if it is not already present. Consult a Windows user manual or reference guide for

more information.

The setup program will create a desktop group window called “I/Open”. Within this group is the

LBIM Config icon. To run the program, double click on the icon or select the icon and choose

RUN from the FILE menu (START menu in Windows 95).

4-4 Series 90™-30 PLC LONWORKS® Bus Interface Module User's Manual – June 1997 GFK-1322A

Page 37

Editing a Configuration

4

Note

We recommend a limit for configuration names of a maximum of 7 characters to

ensure compatibility with Logicmaster 90 software. (The LBIM configuration

software allows names with up to 10 characters.)

When you run the LBIM Config program you will see a blank main screen.

To Edit an existing configuration, choose OPEN from the FILE menu and choose the file

name of the configuration desired. To open a new configuration, choose NEW from the

FILE menu. Choosing NEW will open a module configuration screen used to set the

configuration name and overall module parameters.

GFK-1322A Chapter 4 Configuring the LBIM 4-5

Page 38

4

Module Configuration

When choosing to open a new configuration, the program will call the module

configuration screen. It will be necessary to define the general parameters of the module

before defining network variables. The module configuration information can be edited

after network variable assignments have been made by choosing Configuration under the

View menu in the Reference Configuration screen.

Program ID

The program ID assignment serves two functions. The first is the filename by which this

configuration is saved. For this reason, the program ID name must conform to DOS file

naming conventions and contain no more than 8 characters. The other function served

by the program ID is to provide the LONTALK external interface file identification for

the L

to identify a particular configuration in a LBIM during network commissioning.

4-6 Series 90™-30 PLC LONWORKS® Bus Interface Module User's Manual – June 1997 GFK-1322A

ONWORKS

:

network. The program ID can be accessed by network management tools

Page 39

4

CPU type

This field allows the user to choose the type of CPU to be used in the system. The choice

of CPU may affect the maximum number of network variables that can be assigned to

each of the registers. While the number of variables that can be assigned will depend on

a number of issues, in some cases the size of the particular register is less than the

number of allowed variables. In this case, the program will default to a maximum size

that corresponds with the register size for the CPU model chosen. If there is doubt as to

which CPU model will be used, choose the smaller (lower model number) of the available

CPUs to assure compatibility. If the number of variables needed exceeds the capacity of a

particular CPU, a larger CPU should be chosen. Keep in mind that there are limits to the

number of I/O references that can be used by any one module on the backplane. The

limit for analog references is 64 inputs and 64 outputs (%AI and %AQ) for all CPUs.

The limit for each discrete register is 1024 for the 351 CPU and 512 for all other CPUs.

Some versions of LogicMaster will not allow assignment of more than 16 analog inputs

or outputs to a single module.

Transceiver

Using a pull-down menu, the program allows the user to choose a particular transceiver

type for the configuration. This is necessary to assure that the proper communications

parameters are specified in the external interface file created by the program. If the

wrong transceiver type is configured, the module will not communicate properly. The

LBIM comes factory equipped with one of three transceiver types as listed below. Be

sure to choose the transceiver type of the module to be used.

Module Number Transceiver Description

PE693BEM350 TP/FT-10 Free topology twisted pair @ 78K bps

PE693BEM351 TP/XF-78 Isolated twisted pair @ 78K bps

PE693BEM352 TP/XF-1250 Isolated twisted pair @ 1.25M bps

LONM

For information on LONM

see the L

ARK

Objects

ONMARK

Interoperability guidelines and LONM

ARK

objects, please

ARK

Application Layer Interoperability Guidelines (Version 1.3 or greater)

published by Echelon Corporation.

SCPT_max_send_t

This field allows the user to set a maximum send time configuration parameter. This

parameter determines the maximum elapsed time between network transactions. If a

network variable update has not been sent when this time has expired, an update will be

transmitted. Sending an update will reset the timer. This feature is usually used for two

purposes. The first is to establish a “heartbeat” so that remote network members will

know if the LBIM node is offline if an update has not been received within a specified

time period. The other is to update variables on the network so that new network

members will receive current data within a specified period after being put on the

network. Setting this value to 0 (default) disables this feature.

GFK-1322A Chapter 4 Configuring the LBIM 4-7

Page 40

4

Register Configuration

The area in the center of the Module Configuration screen is used to configure and

monitor the register definitions for the module. During the initial module definition

phase the only parameters that need attention are the maximum sizes and the start

addresses. The other fields will be automatically updated as network variables are

defined.

The maximum sizes begin as default values based on the choice of CPU type (see above).

The default register size defaults to the maximum register size for the chosen CPU or the

maximum size based on the network variable capacity of the LBIM. The LBIM can use

up to 240 network variables, so the maximum for the discrete registers would be 240

discrete locations for network variables. Additionally, the %I register is where the valid

bits for all network variables are stored. For a configuration using 240 %I references,

there are 240 bits plus 240 valid bits plus 8 reserved bits for a total of 488 possible %I

references.

The maximum size definition is only for configuration error checking purposes and can

be changed later if necessary. Defaults for the various CPU types can be changed by the

user (see Default Button command below).

The Start Addr fields allow the user to define any valid beginning reference value for the

individual registers. This start definition is relative to the configured start address as

defined for the module in the PLC backplane. This allows two or modules to use

identical module configurations and be configured into the same PLC backplane with

differing address ranges. For example, if two modules had identical configurations with

%I starting at address 1 with length 100, they could be configured into the same

backplane using Logicmaster software as foreign modules with start addresses in %I of 1

and 101 respectively. The PLC program then addresses the variables in the two modules

using references that are offset by 100 from each other.

The Entries field is for monitoring only and shows the number of variables currently

defined for that particular register. The Length field is for monitoring only and shows

the total length of the defined register space. This value includes gaps left between

variables as the register configuration must be contiguous. The graphical usage display

shows a bar graph representation of the defined variable space versus the maximum

defined space.

4-8 Series 90™-30 PLC LONWORKS® Bus Interface Module User's Manual – June 1997 GFK-1322A

Page 41

4

Note

The configured length of each register must match EXACTLY the length

defined in the 90-30 backplane configuration for the module.

Valid Bit End Address

Valid bits are automatically assigned by the program and begin at the highest defined %I

location and grow down in the %I space. Setting the valid bit end address determines

where the program begins assigning the valid bits. For example, if a configuration will

be using 50 %I references and 64 total valid bits, the valid bit end address should be

defined at or above 50 + 64 + 8 (reserved) = %I0122. The first defined variable will have

a valid bit assigned to %I0122, the next will be assigned to %I00121, and so on. Valid

bit referencing can be altered after variables are defined.

Button Commands

1.

Defaults

Click on this button to set the default maximum sizes and start addresses for CPU types.

Clicking the button activates an edit screen. After changing the desired values, click the

default button again to save the changes and return to the module configuration screen.

2.

Modules Report

Click this button to print a report that contains the current configuration values.

3.

Save Cfg

Click on this button to save the current configuration to disk. This action does not save

the configuration to the LBIM module.

4.

Cancel

Click on the cancel command button to leave this screen without saving the configuration

to disk. All changes since the last save will be lost.

GFK-1322A Chapter 4 Configuring the LBIM 4-9

Page 42

4

Table 4-1. Configuration Editor Fields

Field Description

Program ID LONW

CPU PLC CPU Model Number. To change, click on arrows to scroll through choices.

Transceiver Transceiver Type. Use pull down menu to view choices.

Max Size (4 fields) Maximum number of register references allowed in this configuration.

Entries Number of Variable entries defined for the reference space. This is a display-

Start Addr Beginning reference for the register. To change, highlight the current value and

Reserved Number of reserved reference locations. The reserved locations will occupy the

Length Length or number of references currently configured.

Usage Graphical representation of the configured portion of the reference space as a

Valid Bit End Addr Reference address of the beginning of the valid bit space. Valid bits are stored in

Defaults Default size parameters. Activating this command allows the user to set default

Module Rep Print Module Report. Activating this command prints a report to the system

Save Cfg Save configuration. Activating this command saves the current configuration to

Cancel Cancel. Activating this command returns control to the register configuration

Node Object Network Variable Names

The LBIM implements a standard Node Object as specified in the L

You can configure the names of the standard network variables for this object.

nviObjRequest The name of the Object Request (SNVT_obj_request, index 0) network variable.

nvoObjStatus The name of the Object Status (SNVT_obj_status, index 1) network variable.

nviFileRequest The name of the File Request (SNVT_file_req, index 2) network variable.

nvoFileStatus The name of the File Status (SNVT_file_status, index 3) network variable.

SCPT_max_snd_t Configuration parameter for Maximum Send Time. Set value by Selecting

ORKS

Program ID. Same as the Configuration Name. To change, type up to

8 characters in the field (7 characters maximum recommended) and press

E

.

NTER

only field.

type in a new reference address.

lowest address locations.

portion of the maximum allowed space.

the %I space and are assigned automatically beginning at this address and grow

down as more are defined. Change this field by highlighting the current value

and entering a new value. Note that the current valid bit configuration may need

to updated manually to affect this change.

values for the maximum sizes allowed for the various CPU choices.

printer showing the configuration details.

the file.

screen without saving any changes since the last save.

ONMARK

current value and type in new value.

Interoperability Guidelines.

4-10 Series 90™-30 PLC LONWORKS® Bus Interface Module User's Manual – June 1997 GFK-1322A

Page 43

Reference Configuration

After setting the module parameters for a new configuration, the Reference Configuration

screen will appear as below. This screen is used to view the configuration of the

individual registers. Only one register is displayed at a time. From this screen the user

can go to variable editing, valid bit editing, module configuration, exporting and

downloading interface files, and environment setup.

4

Field Definitions

PLC Register Box

In the upper left corner of the screen is the PLC Register list. To choose a particular

register to become active in the display, simply click in the proper radio button next to

the desired register label. This will cause the chosen register to be displayed in the main

register listing and the Register parameters to be displayed.

GFK-1322A Chapter 4 Configuring the LBIM 4-11

Page 44

4

Register Parameters

The Start, End, and Length parameters for the active register are displayed in the

Register box at the top of the screen just left of center. This display contains information

about the current defined state of that register. The length parameter includes any

reserved addresses and includes the valid bit area in the %I register display.

.

Register Configuration Box

The main list on this screen contains information on the current definition of the active

reference space.

Addr Network Var SNVT Type Size Array Length %I %V Initial Tin 1 Tout1 Tout2 Bytemap

Addr

Network Var

SNVT

This value is the reference address of the variable within the active

register space.

The name of the network variable.

Network variable type description.

Type

Size

Array

Length

%V

%I

Initial

Tin 1

Tout 1

Tout 2

Network variable type number.

Number of register locations required for this variable

Number of elements in an array

Total length of the variable or array.

The number designation of the valid bit associated with this variable.

The location within the %I space where the valid bit is stored.

Initial state of the variable on power-up (Hold or zero).

The value of the configuration parameter max_rec_time in seconds.

This parameter has meaning for input variables only and will appear as

zero for outputs or if not defined for the input variable.

The value of the configuration parameter max_send_time in seconds.

This parameter has meaning for output variables only and will appear

as zero for inputs or if not defined for output variables.

The value of the configuration parameter min_send_time in seconds.

This parameter has meaning for output variables only and will appear

as zero for inputs or if not defined for output variables.

4-12 Series 90™-30 PLC LONWORKS® Bus Interface Module User's Manual – June 1997 GFK-1322A

Page 45

Defining Variables

To add a new variable From the Reference Configuration screen, select a location by

clicking on either an existing variable or the “begin” address line and then click in the

“NEW” command button. This will add a variable that will be placed in the next

available location after the highlighted address. The Edit Variable screen will then

appear.

4

Field Definitions

Var Name

naming conventions

Var Addr

Reference address with the active register space.

SNVT

Description of the network variable’s type. Chosen with pull-down list or entered as a

user-defined type.

Type

The network variable type number.

GFK-1322A Chapter 4 Configuring the LBIM 4-13

Network variable name. The name must follow LONTALK variable

Page 46

4

SNVT Size

Size of the network variable in 8-bit bytes. This is the variable size as viewed from the

LONWORKS network.

PLC Size

Number of PLC register addresses needed to hold this variable or a single element if the

variable is an array. In the case of discrete registers (%I and %Q) this number represents

the number of bits required. For analog registers (%AI and %AQ) this is the number of

16-bit register locations needed for this variable.

Array Size

Array size is the number of array elements defined for the variable. To change, highlight

the value and type new value over the old. The program will recalculate the variable

length. An array of size zero represents a single normal variable with no array indexing.

An array of size one is treated as a single variable, but includes array indexing.

Variable Array Size Resulting Names

NVI_MyVar 0 NVI_MyVar

NVI_MyVar 1 NVI_MyVar[0]

NVI_MyVar 2 NVI_MyVar[0]

NVI_MyVar[1]

NVI_MyVar i NVI_MyVar[0]

NVI_MyVar[1]

.........

NVI_MyVar[i-1]

Length

Length is the total number of register locations used by the currently defined variable. It

includes all elements of an array.

SCPTs

Depending on the direction of the current variable, one of the following configuration

parameters can be edited from this screen. If the variable is an input, the maximum

receive time parameter is displayed. The maximum send time and minimum send time

parameters apply to output variables. SCPTs are NOT defined in the .XIF file created for

the module configuration. SCPTs are contained in the Value File which must be

downloaded to the module in a separate download operation.

4-14 Series 90™-30 PLC LONWORKS® Bus Interface Module User's Manual – June 1997 GFK-1322A

Page 47

4

SCPT_max_rec_t

The configuration parameter SCPT_max_recv_time can be set by entering a value into

this field. The maximum receive time can be set in whole increments of one second.

This value is the maximum time period between updates of an input variable before a

fault is recognized. If the variable is set to 10 seconds and 11 second elapse since the last

update of the variable, then a fault is generated meaning that the sending node is

presumed to be off-line. The fault is signified by the setting of the valid bit associated

with the particular variable. To download this to the module, be sure to download the

“Value File” with the Download tool.

SCPT max_send_t

The configuration parameter SCPT_max_send_time can be set by entering a value into

this field. The maximum send time can be set in whole increments of one second. This

value is the maximum time period between updates of an output variable. If the variable

has not been sent to the network due to a change in value over the max_send_time

period, the variable is sent to the network even if the it has not changed since the last

update. This will allow other devices on the network to assure that the value they have is

current and that the LBIM is still online. Setting this parameter to zero (default) disables

the operation of this feature. To download this to the module, be sure to download the

“Value File” with the Download tool.

SCPT min_send_t