Page 1

Technical

Publications

Direction 5137113-100

Rev. 3

LOGIQ P5/A5/A5Pro

GE Healthcare

0459

Quick Guide

Copyright© 2008 By General Electric Co.

Operating Documentation

Page 2

Regulatory Requirement

This product complies with regulatory requirements of the following European Directive 93/42/EEC concerning medical devices.

0459

This manual is a reference for the LOGIQ P5/A5/A5Pro. It applies to all versions of the R 3.0.x software for the LOGIQ P5/A5/A5Pro ultrasound

system.

GE Healthcare

GE Healthcare: Telex 3797371

P. O. Box 414, Milwaukee, Wisconsin 53201 U.S.A.

(Asia, Pacific, Latin America, North America)

GE Ultraschall TEL: 49 212.28.02.207

Deutschland GmbH & Co. KG FAX: 49 212.28.02.431

Beethovenstraße 239

Postfach 11 05 60

D-42655 Solingen GERMANY

Page 3

LOGIQ P5/A5/A5Pro Quick Guide Direction 5137113-100 Rev. 3 A

Revision History

REV

1

2

3

PAGE REVISION

NUMBER HISTORY

Title Rev. 3

A and B Rev. 3

1-52 Rev. 3

DATE

April 18 2007

May 22 2008

Dec 10 2008

List of Effective Page

REASON FOR CHANGE

Initial Release

BT07 SW Release

BT09 SW Release

Please verify that you are using the latest revision of this document. Information pertaining to this document is maintained on GPC (GE Medical

Systems Global Product Configuration). If you need to know the latest revision, contact your distributor, local GE Sales Representative or in the

USA call the GE Ultrasound Clinical Answer Center at 1-800-682-5327 or 262-524-5698.

Page 4

LOGIQ P5/A5/A5Pro Quick Guide Direction 5137113-100 Rev. 3 B

CAUTION

FOR USA ONLY

“United Sates law restricts this device to sale or use by or on the order of a physician” if sold in the United States.

Page 5

LOGIQ P5/A5/A5Pro Quick Guide Direction 5137113-100 Rev. 3 1

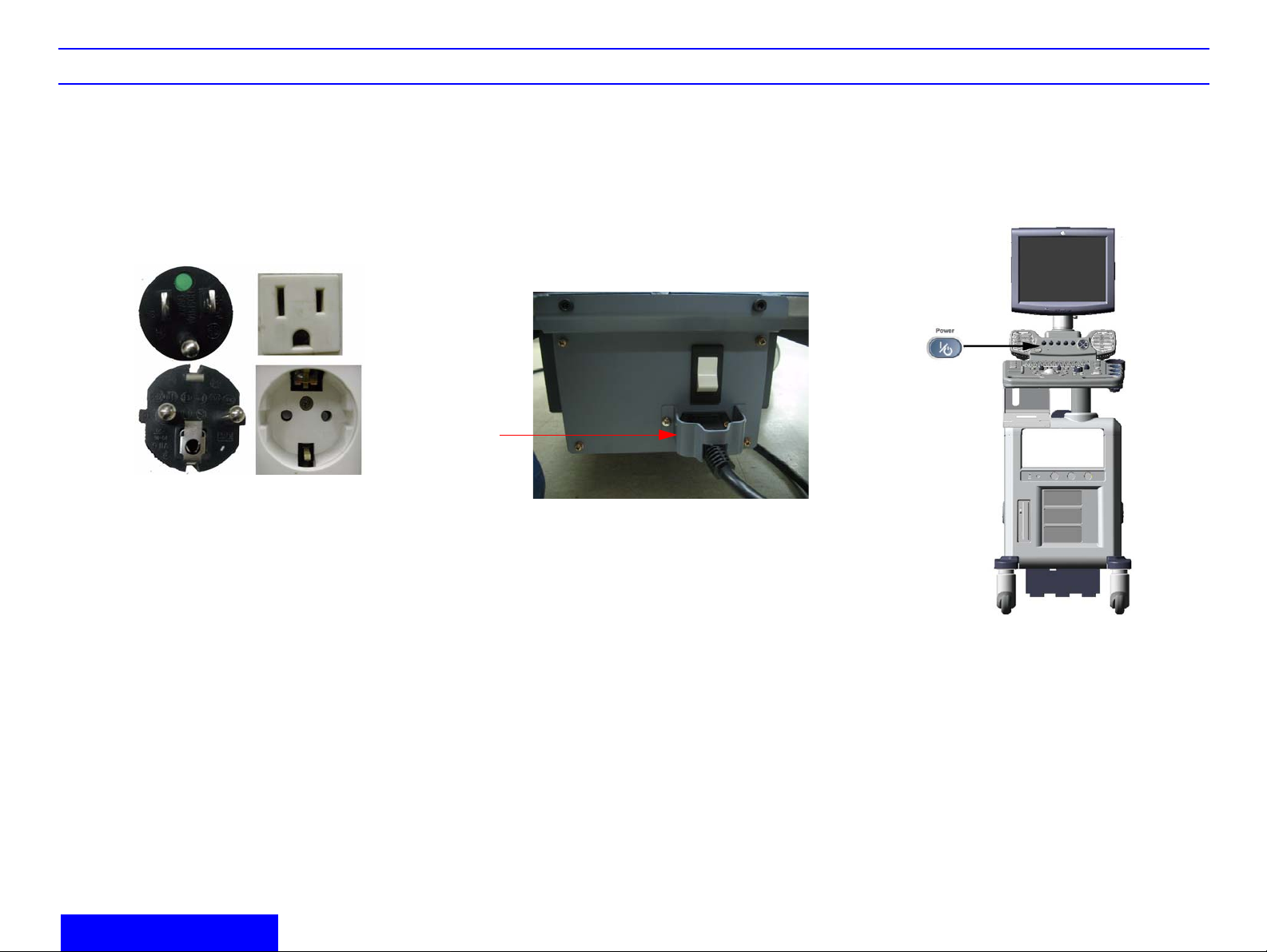

System Power

Power On

To connect the system to the electrical supply:

1. Ensure that the wall outlet is of the appropriate

type.

1)

2)

Figure 1-1. Example Plug and Outlet

Configurations

1. 100-120 VAC, 950VA

Plug and Outlet Configuration(USA)

2. 220-240 VAC, 950VA

Plug and Outlet Configuration (Europe)

2. Ensure that the power switch is turned off.

3. Unwrap the power cable. Make sure to allow

sufficient slack in the cable so that the plug is

not pulled out of the wall if the system is moved

slightly.

4. Attach the power plug to the system and secure

it in place by using the retaining clamp.

a.

a

Figure 1-2. Power Plug

a. Retaining clamp for power plug

CAUTION: Ensure that the retaining clamp for the

power plug is fixed firmly.

Use caution to ensure that the power cable does

not disconnect during system use. If the system is

accidentally unplugged, data may be lost.

Press the Power switch to turn the power on. The

circuit breaker must also be in the on position.

Figure 1-3. Power On Switch Location

Preparing for an Exam

Page 6

LOGIQ P5/A5/A5Pro Quick Guide Direction 5137113-100 Rev. 3 2

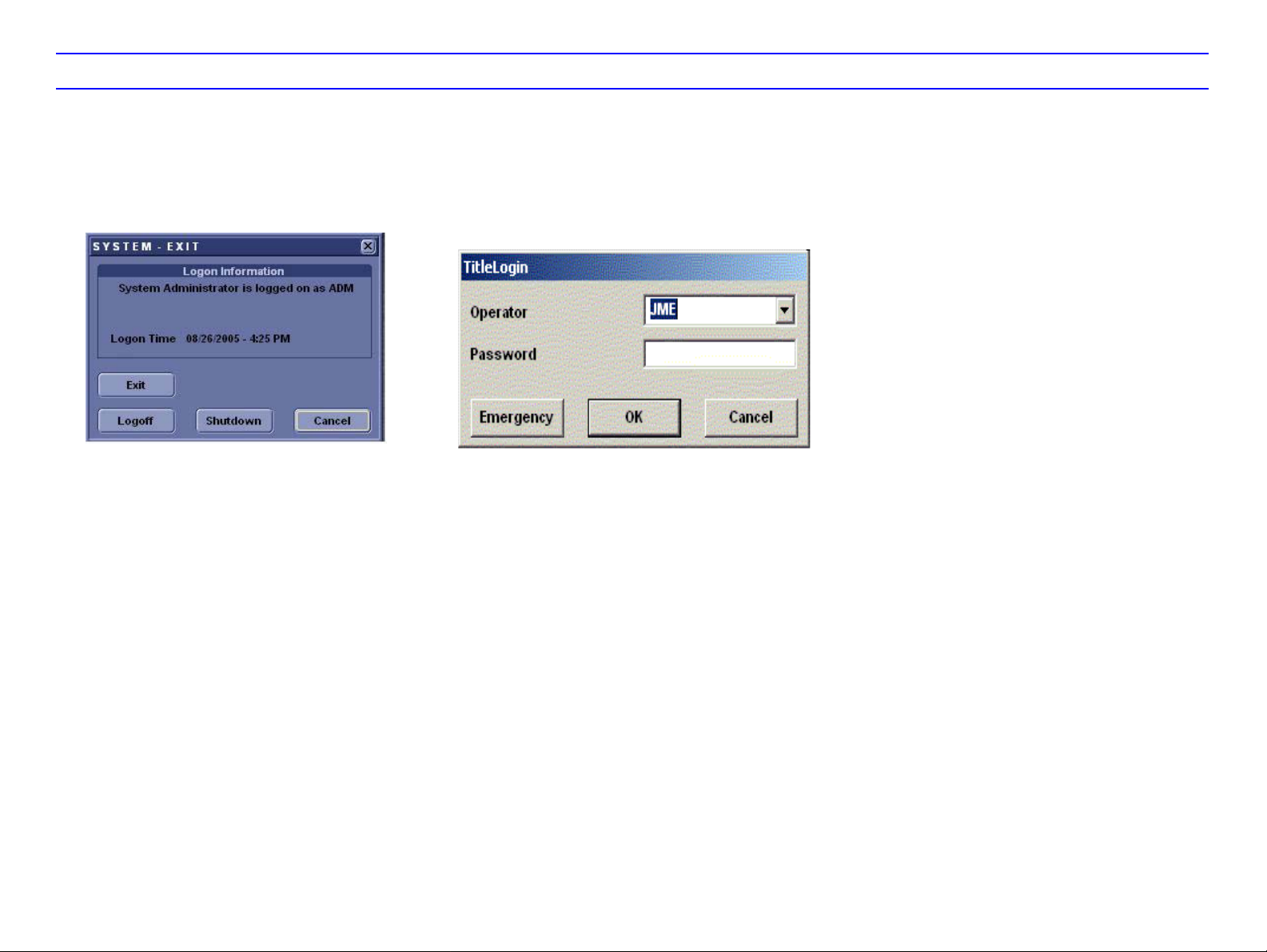

Power Off

To power down the system:

1. Press the Power On switch at the front of the

system once.

2. The System-Exit window is displayed.

3. Using the Trackball, select Shutdown.

The shutdown process takes a few seconds

and is completed when the control panel

illumination is power switch is turned off.

4. Disconnect the probes.

Clean or disinfect all probes as necessary.

Store them in their shipping cases to avoid

damage.

Starting an Exam

You need to select a pre-configured dataflow that

sets up the ultrasound system to work according to

the services associated to the dataflow.

1. Select your Operator Login and type in your

Password:

2. Press Log on.

3. Fill in the New Patient menu as described on

Page 3.

OR,

If the patient name is on the patient record list,

1. Trackball to the patient’s name to highlight the

name, (or perform a search to locate the

patient) then press Select Patient.

Page 7

LOGIQ P5/A5/A5Pro Quick Guide Direction 5137113-100 Rev. 3 3

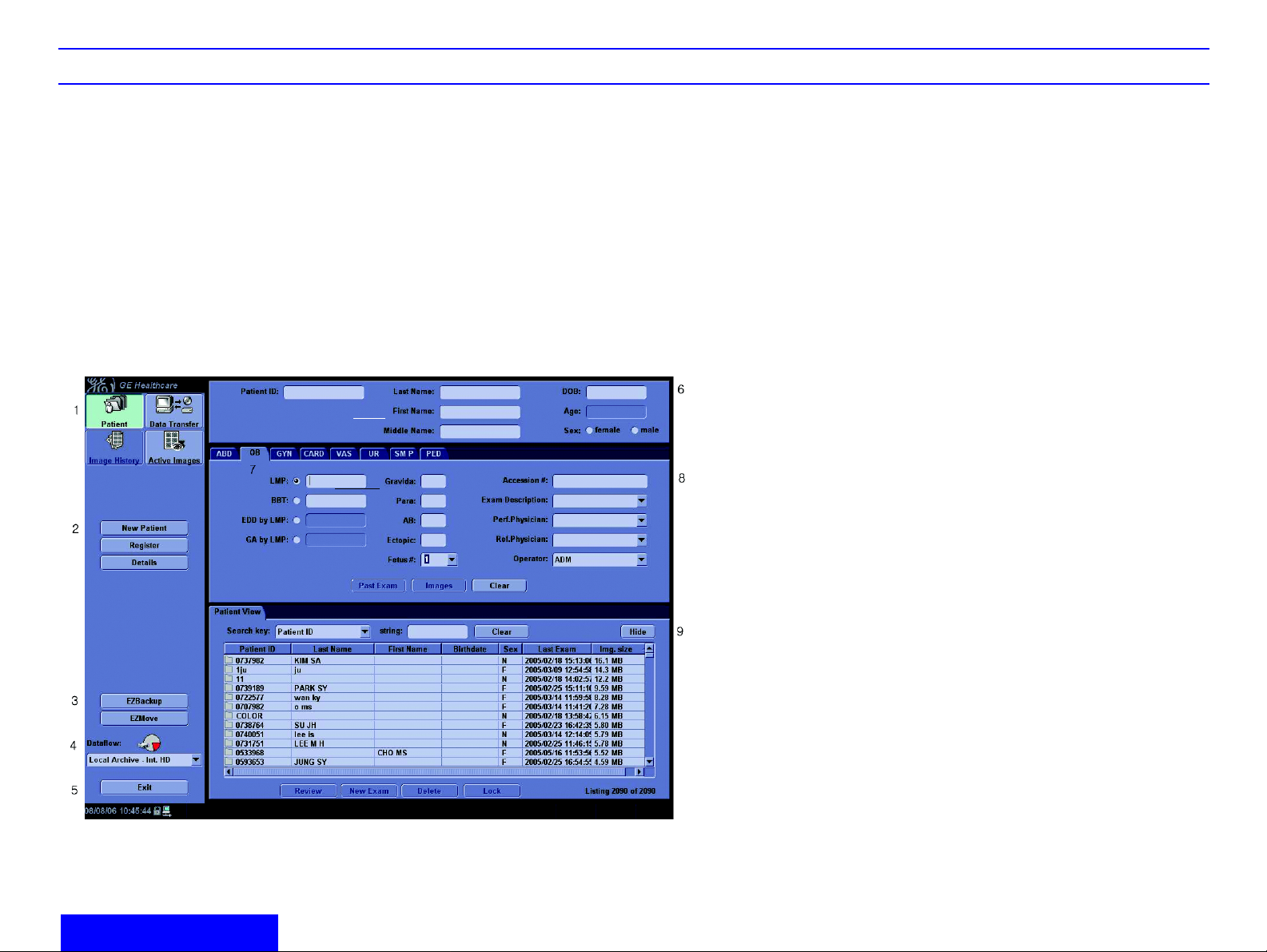

Starting an Exam

New Patient

To start a new patient’s exam,

1. Press Patient. Press the New Patient button on the

Patient menu.

2. Select the Exam Category.

3. Type the Patient ID, Patient Name, Birthdate, etc.

4. Press the Register button on the Patient menu (DO

NOT press Register if you are automatically

generating a patient ID).

5. Press Scan, B-Mode, Esc, or Exit. Select the probe .

Probe Selection

Select a probe (the system automatically selects the lastused application for this probe).

NOTE: You can preset a probe per application or an

application per probe via Utility.

Patient Entry Menu (Refer to Illustration)

Image Management Window [1]

Access to this patient’s exam history and image

management features.

Function Selection Window [2]

Worklist displays a Worklist screen. New Patient is used

to clear the patient entry screen to input a new patient’s

data into the database. Register is used to enter new

patient information into the database prior to performing

the actual exam. Details displays exam details and

additional patient information.

EZ Backup/EZMove [3]

One-step method to backup (move and delete patient

images) to an external media.

Dataflow [4]

Selects this exam’s dataflow preference.

Exit [5]

Exits the Patient Menu and returns to scanning.

Patient Information [6]

Patient ID, Name, Birthdate, Age, and Sex.

Category Selection and Exam Information [7&8]

Select the appropriate category and enter the exam

information.

Patient View and Exam View [9]

Patient View lists the patients in the database. “Search

Key” enables searching list by Patient ID, Last Name,

First Name, Birthdate, Sex and Last Exam date. “Search

key” and “string” fields help define the search parameters.

Exam View lists the exams of the selected patient. Select

the patient or the exam in Patient View and press “Exam

View” or “Review“.

Preparing for an Exam

Page 8

LOGIQ P5/A5/A5Pro Quick Guide Direction 5137113-100 Rev. 3 4

LOGIQ P5/A5/A5Pro Control Panel Tour

1. Record. Press to activate recording devices

2. Audio On/Off and Volume

3. TGC. Move slide pots left/right to adjust TGC.

4. Reverse. Press to invert the image left/right

5. Additional Feature Keys

6. Keyboard : Use the keyboard to enter patient

information and annotations.

7. Mode Keys : M Mode, Continuous W ave (CW)

and Pulsed Wave Doppler (PW) Modes, Power

Doppler Image Mode (PDI), Color Flow (CF)

Mode, B Mode, and B Flow. CW, PW, PDI, CF

keys are for LOGIQ P5 only.

8. Imaging/Measurement Keys : Clear, Comment,

Body Pattern, Ellipse, Measure, Zoom, M/D,

Cursor, Scan Area, Set. Press or rotate these

keys, as necessary.

9. Depth : Rotate to adjust the Depth.

10. Imaging Feature Keys : Auto Optimize On/Off,

THI, Multi Image Left/Right Select.

11. Print Keys : Press P Keys to archive print or

send the image.

12. Probe and Cord Holder

13. Gel Holder

14. Patient: Enter Patient screen

15. Reports: Activates default report and

Measurement Selection Menu of report

choices.

16. End Exam: Activates Image Management and

Touch Panel with end of exam options.

17. User Assigned Utility keys: Activates the

configuration system.

18. Probe/Preset keys: Select the application to

use and Probe select.

19. Mode Paramenters: To toggle between the

Primary menus of different modes

20. Top menu Controls : Activates the changes of

functions in the Top menu.

21. Sub menu controls: Activates Sub Menu for

Modes and toggles/changes functions.

22. Gain Key

23. Utility key

24. Freeze key: Press Freeze to freeze the image.

Preparing for an Exam

Page 9

LOGIQ P5/A5/A5Pro Quick Guide Direction 5137113-100 Rev. 3 5

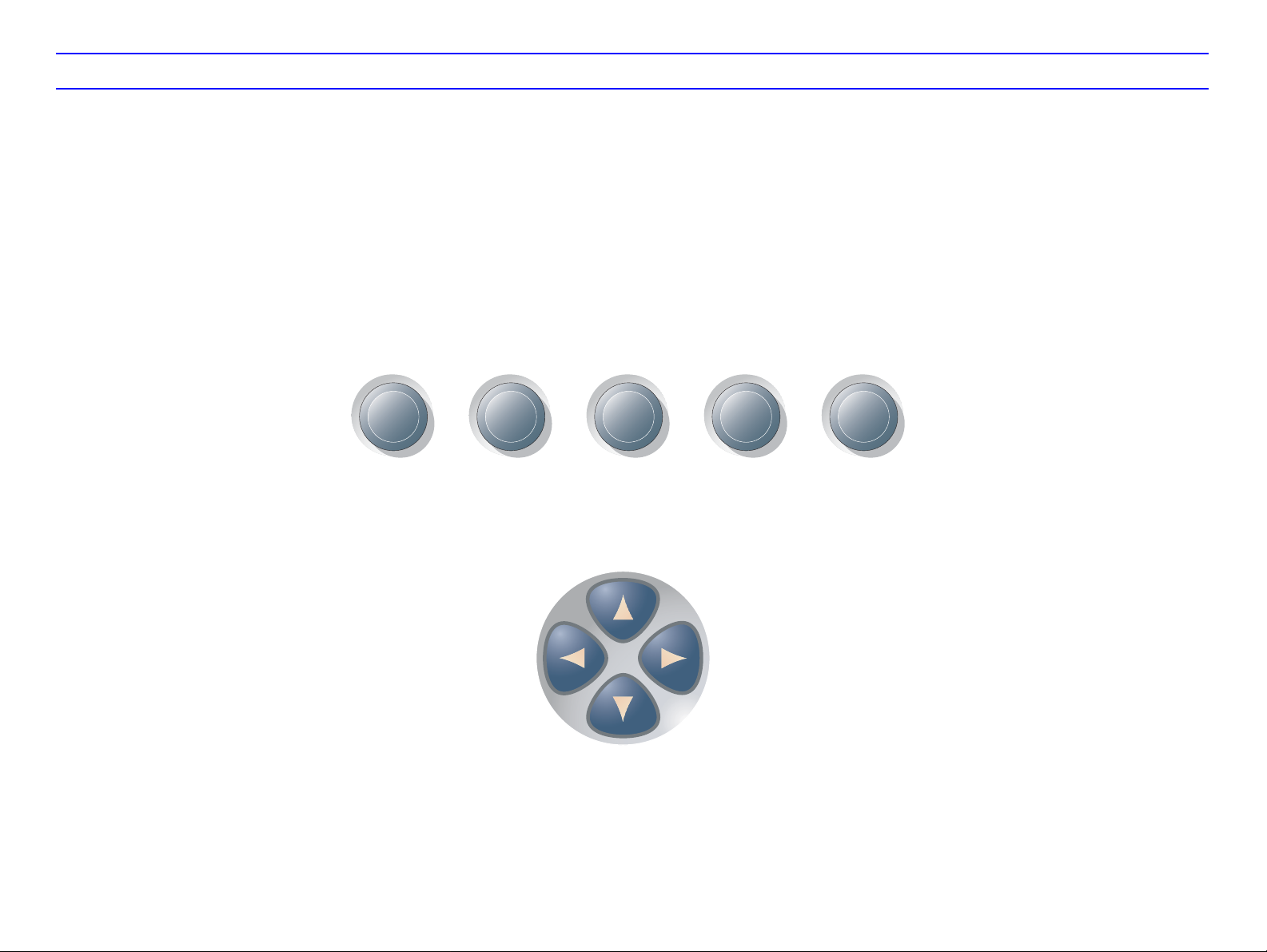

LOGIQ P5/A5/A5Pro Top and Sub Menu Controls

In general, Top Menu Controls are of two types,

they are Push & Turn Knobs, Sub Menu is of

Paddle Switch type

1. The Paddle Switch is used to select Sub Menu

Controls.

2. The Push is used to select Top Menu Controls

3. The Rotate is used to turn on/off or change the

parameter selected through Top Menu

Controls.

1

Sub Menu key functions :

1. Up.

2. Increase Value/Next Page

3. Decrease Value/Previous Page

4. Down

2

Top Menu Controls

3

1

4

5

23

4

Page 10

LOGIQ P5/A5/A5Pro Quick Guide Direction 5137113-100 Rev. 3 6

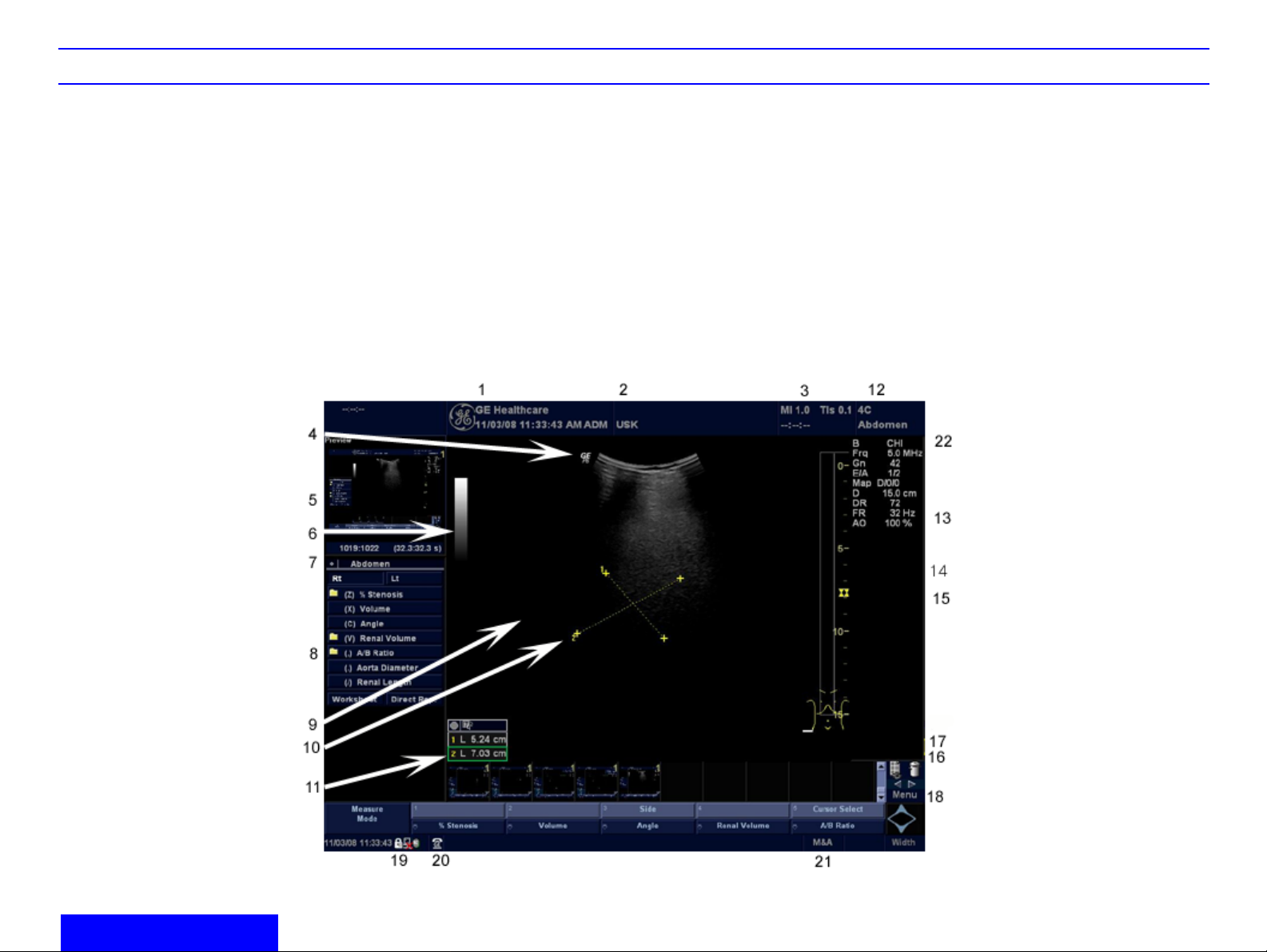

LOGIQ P5/A5/A5Pro Monitor Display Tour

1. Institution/Hospital Name, Date, Time, Operator

Identification.

2. Patient Name, Patient Identification.

3. Acoustic Output Readout, System status (realtime or frozen)

4. GE Symbol: Probe Orientation Marker.

Coincides with a probe orientation marking on

the probe.

5. Image Preview.

6. Gray/Color Bar.

7. Cine Gauge.

8. Measurement Summary Window.

9. Image.

10. Measurement.

11. Results Window.

12. Probe Identifier. Exam Study.

13. Imaging Parameters by Mode (current mode

highlighted).

14. Focus Marker.

15. TGC (not shown on the image).

16. Body Pattern.

17. Depth Scale.

18. Image Management Menu: Menu, Delete, and

Image Manager.

19. Caps Lock: On or Off.

20. iLinq icon, and system messages display.(not

shown on the image.

21. Trackball Functionality Status: Scroll,

M&A (Measurement and Analysis), Position,

Size, Scan Area Width and Tilt.

22. Sub menu

Preparing for an Exam

Page 11

LOGIQ P5/A5/A5Pro Quick Guide Direction 5137113-100 Rev. 3 7

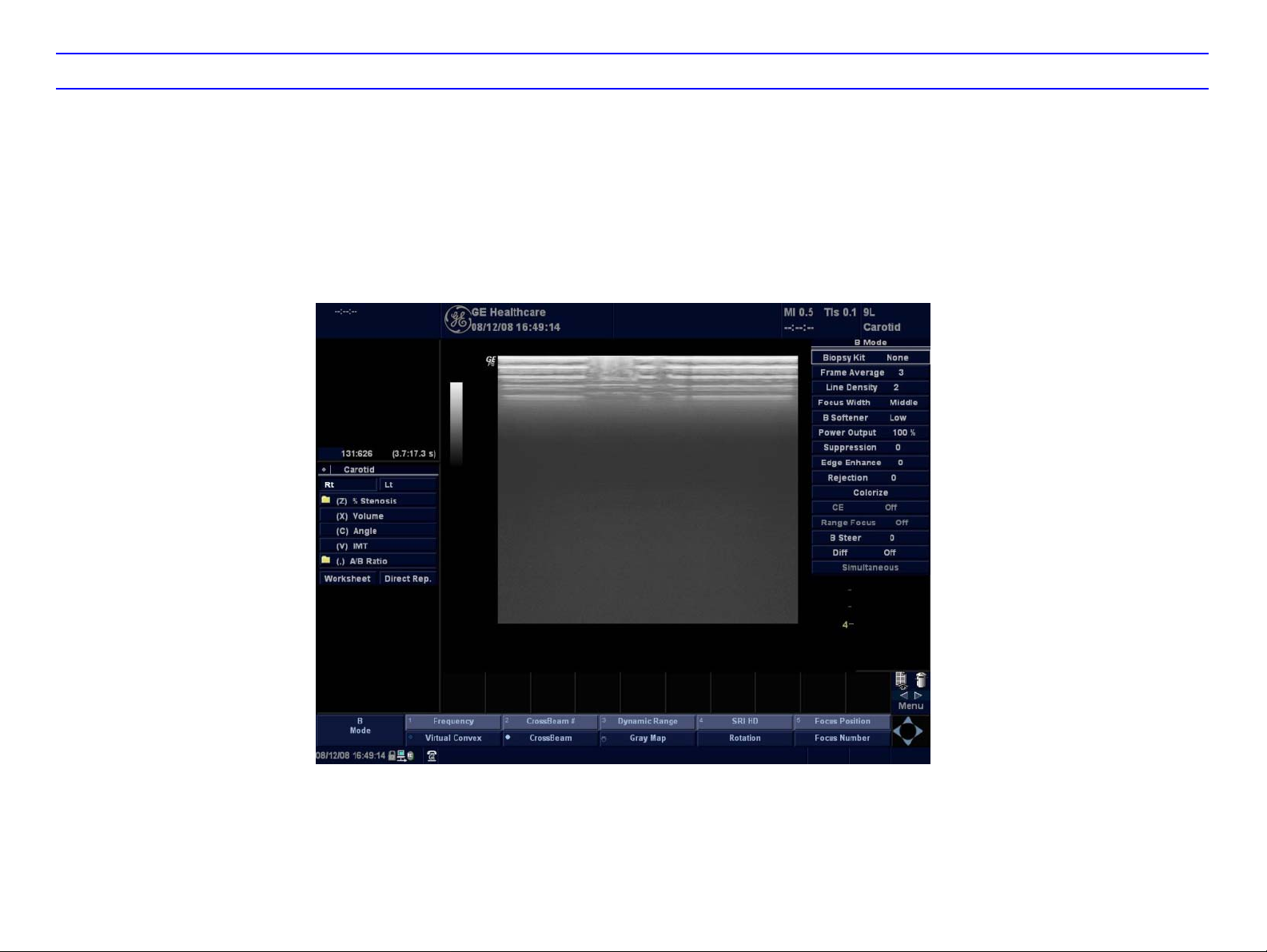

B/M Mode Image Optimize

Power Output

Optimizes image quality and allows user to reduce

beam intensity. 10% increments between 0-100%.

Values greater than 0.1 are displayed.

Dynamic Range

Dynamic Range controls how echo intensities are

converted to shades of gray, thereby increasing the

adjustable range of contrast.

Focus Number and Position

Increases the number of transmit focal zones or

moves the focal zone(s) so that you can tighten up

the beam for a specific area. A graphic caret

corresponding to the focal zone position(s) appears

on the right edge of the image.

NOTE: Push key to toggle between Focus Number

and Focus Position.

Rejection

Frame Average

Temporal filter that averages frames together. This

has the effect of presenting a smoother, softer

image.

Colorize

Enables gray scale image colorization. To

deactivate, reselect a Gray Map.

Gray Map

Determines how the echo intensity levels received

are presented as shades of gray.

Rotation (Up/Down)

Rotates the image by selecting the value from the

pop up menu.

Frequency

Multi Frequency mode lets you downshift to the

probe's next lower frequency or shift up to a higher

frequency.

B Mode Control Panel Controls

Auto Optimize

Automatic Tis sue Optimi zatio n optimizes the image

based upon a specified Region of Interest (ROI) or

anatomy within the display.

Zoom

Magnifies a zoom region of interest, which is

magnified to approximately the size of a full-sized

image. An un-zoomed reference image is displayed

adjacent to the zoom window . The system adjusts

all imaging parameters accordingly. Press Zoom

key to activate. Press right zoom key again to

deactivate. Use the Trackball to position the Zoom

ROI.

Reverse

Flips the image left/right.

Selects a level below which echoes will not be

amplified (an echo must have a certain minimum

amplitude before it will be processed).

Edge Enhance

Edge Enhance brings out subtle tissue differences

and boundaries by enhancing the gray scale

differences corresponding to the edges of

structures. Adjustments to M Mode's edge

enhancement affects the M Mode only.

Preparing for an Exam

Frame Rate/Resolution

Optimizes B Mode frame rate or spatial resolution

for the best possible image.

Anatomical M Mode

Allows you to move the M Mode trace in order to

Image difficult -to - reach anatomy.

Sweep Speed

Changes the speed at which the time line is swept.

Page 12

LOGIQ P5/A5/A5Pro Quick Guide Direction 5137113-100 Rev. 3 8

B/M Mode Image Optimize (continued)

B/M Mode Scanning Hints

Auto Optimize. Improves imaging performance

while reducing optimization time.

Frequency. Changes system parameters to best

optimize for a particular patient type.

Maps. There is an inter-dependency between gray

maps, gain, and dynamic range. If you change a

map, revisit gain and dynamic range settings.

Dynamic Range. Affects the amount of gray scale

information displayed. If you increase the gain, you

may want to decrease the dynamic range.

Edge Enhance. Better delineates the amount of

border crispness.

Frame Average. Smooths the image by averaging

frames. Affects the amount of speckle reduction.

B Mode Top Menu and Sub Menu 1

Page 13

LOGIQ P5/A5/A5Pro Quick Guide Direction 5137113-100 Rev. 3 9

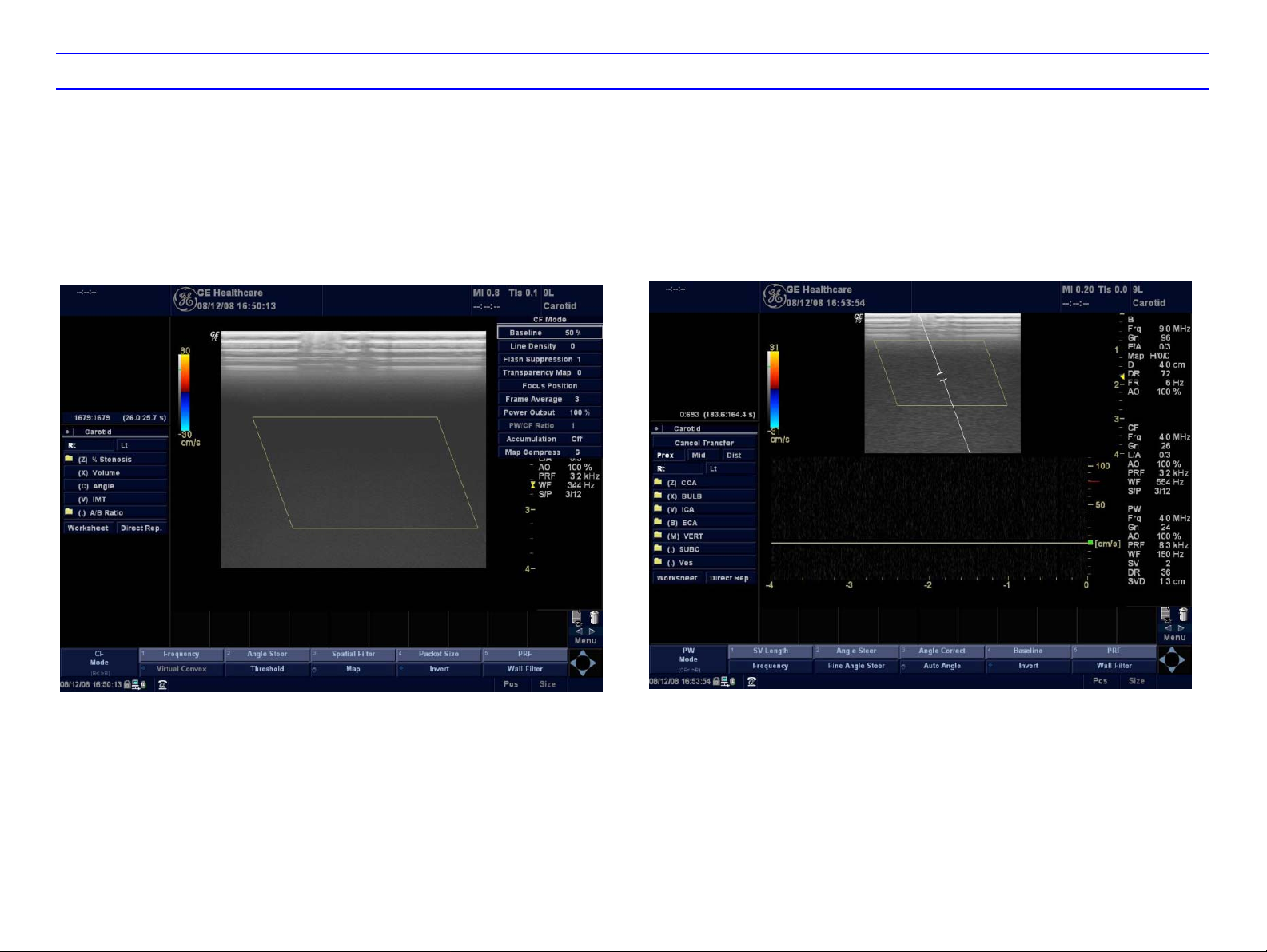

Color Flow/Doppler Image Optimize

Baseline

Adjusts the baseline to accommodate faster or

slower blood flows to eliminate aliasing.

PRF/Wall Filter

Velocity scale determines pulse repetition

frequency. If the sample volume gate range

exceeds single gate PRF capability, the system

automatically switches to high PRF mode. Multiple

gates appear , and HPRF is ind icated on the d isplay.

Wall Filter insulates the Doppler signal from

excessive noise caused from vessel movement.

NOTE: Push key to toggle between PRF and Wall

Filter.

Angle Correct

Estimates the flow velocity in a direction at an angle

to the Doppler vector by computing the angle

between the Doppler vector and the flow to be

measured.

Auto Angle

Adjuste the angle to the direction of the Flow.

Angle Steer

Slants the Color Flow region of interest or the

Dopple M Line to obtain a better doppler angle.

Doppler Display Formats

Display layout can be preset to have B-Mode and

Time-motion side-by-side or over-under.

Sample Volume Gate Length

Sizes the sample volume gate.

Map

Allows a specific color map to be selected. After a

selection has been made, the color bar displays the

resultant map.

Packet Size

Controls the number of samples gathered for a

single color flow vector.

Invert

Allows blood flow to be viewed from a different

perspective, i.e. red away (negative velocities) and

blue toward (positive velocities). The real-time or

frozen image can be inverted.

Color Flow Control Panel Control

Scan Area

Toggles between the CFM window size and

position.

Controls in Common with B Mode

For more information on Focal Zone, Power Output,

FR/RES, Frame Averaging, Dynamic Range, Map,

and Colorize, refer to the B/M Mode Image

Optimize section in this Quick Guide on Page 6.

Scanning Hints

Line Density. Trades frame rate for sensitivity and

spatial resolution. If the frame rate is too slow,

reduce the size of the region of interest, select a

different line density setting, or reduce the packet

size.

Wall Filter. Affects low flow sensitivity versus

motion artifact.

To improve sensitivity.

1. Increase the Gain.

2. Decrease the PRF.

3. Increase the Power Output.

4. Adjust the Line Density.

5. Decrease the Wall Filter.

6. Increase Frame Averaging.

7. Increase the Packet Size.

8. Reduce the ROI to the smallest reasonable

size.

9. Position the Focal Zones properly.

To decrease motion artifact,

1. Increase the PRF.

2. Increase the Wall Filter.

Threshold

Threshold assigns the gray scale level at which

color information stops.

Preparing for an Exam

To eliminate aliasing,

1. Increase the PRF.

2. Lower the Baseline.

Page 14

LOGIQ P5/A5/A5Pro Quick Guide Direction 5137113-100 Rev. 3 10

Color Flow/Doppler Image Optimize (continued)

For venous imaging,

1. Ensure that you have selected the small parts

exam category.

2. Select a venous application.

3. Select the appropriate probe for very superficial

structure.

4. Select two focal zones.

5. Adjust the depth to the anatomy to be imaged.

6. Maintain a low gain setting for gray scale.

7. Activate Color Flow.

8. Maintain the PRF at a lower setting.

9. Increase Frame Averaging for more

persistence.

CFM Mode Top and Sub Menu

PWD Mode Top and Sub Menu

Page 15

LOGIQ P5/A5/A5Pro Quick Guide Direction 5137113-100 Rev. 3 11

Basic Measurements

NOTE: The following instructions assume that you

first scan the patient and then press Freeze.

Distance and Tissue Depth Measurements

1. Press Measure once; an active caliper

displays.

2. To position the active caliper at the start point

(distance) or the most anterior point (tissue

depth), move the Trackball.

3. To fix the start point, press Set. The system

fixes the first caliper and displays a second

active caliper.

4. To position the second active caliper at the end

point (distance) or the most posterior point

(tissue depth), move the Trackball.

5. To complete the measurement, press Set. The

system displays the distance or tissue depth

value in the measurement results window.

NOTE: Before you complete a measurement:

To toggle between active calipers, press

Measure.

T o erase the second caliper and the current

data measured and start the measurement

again, press Clear once.

NOTE: After you complete the measurement, to

erase all data that has been measured to this point,

but not data entered onto worksheets, press Clear.

Circumference/Area (Ellipse) Measurement

1. Press Measure once; an active caliper

displays.

2. To position the active caliper, move the

Trackball.

3. To fix the start point, press Set. The system

fixes the first caliper and displays a second

active caliper.

4. To position the second caliper, move the

Trackball.

5. Turn the Ellipse control; an ellipse with an

initial circle shape appears.

NOTE: Be careful not to press the Ellipse control

as this activates the Body Pattern.

6. To position the ellipse and to size the measured

axes (move the calipers), move the Trackball.

7. To increase the size, Turn the Ellipse control in

a clockwise direction. T o decrease the size, turn

the Ellipse control in a counterclockwise

direction.

8. To toggle between active calipers, press

Measure.

9. To complete the measurement, press Set. The

system displays the circumference and area in

the measurement results window.

NOTE: Before you complete a measurement:

To erase the ellipse and the current data

measured, press Clear once. The original

caliper is displayed to restart the

measurement.

To exit the measurement function without

completing the measurement, press Clear

a second time.

Circumference/Area (Trace) Measurement

1. Press Measure twice; a trace caliper displays.

2. To position the trace caliper at the start point,

move the Trackball.

3. To fix the trace start point, press Set. The trace

caliper changes to an active caliper.

4. To trace the measurement area, move the

Trackball around the anatomy. A dotted line

shows the traced area.

NOTE: To erase the dotted line but not the trace

caliper, press Clear once. To clear the trace caliper

and the current data measured, press Clear twice.

NOTE: To erase the line (bit by bit) back from its

current point, move the Trackball or turn the

Ellipse control counterclockwise.

5. To complete the measurement, press Set. The

system displays the circumference and the area

in the measurement results window.

NOTE: Before you complete a measurement:

To erase the line (bit by bit) back from its

current point, move the T rackball or turn the

Ellipse control counterclockwise.

To erase the dotted line but not the trace

caliper, press Clear once.

To clear the trace caliper and the current

data measured, press Clear twice.

Preparing for an Exam

Page 16

LOGIQ P5/A5/A5Pro Quick Guide Direction 5137113-100 Rev. 3 12

Volume

1. To make a volume calculation, do one of the

following:

• Make one distance measurement.

• Make two distance measurements.

• Make three distance measurements.

NOTE: Three distances should be done in the

dual format mode (side by side images). One

measurement is usually made in the sagittal

plane and two measurements in the axial pla ne.

• Make one distance and one ellipse

measurement.

• Make one ellipse measurement.

2. Select Volume.

Time Interval Measurement

1. Press Measure twice; and active caliper with a

vertical dotted line displays.

2. To position the active caliper at the start point,

move the Trackball.

3. To fix the start point, press Set. The system

fixes the first caliper and displays a second

active caliper.

4. To position the second caliper at the end point,

move the Trackball.

5. To complete the measurement, press Set. The

system displays the time interval betwee n th e

two calipers in the measurement results

window.

Velocity Measurement

1. Press Measure; an active calip er with a vertical

dotted line displays.

2. To position the caliper at the desired

measurement point, move the Trackball.

3. To complete the measurement, press Set. The

system displays the velocity measurement in

the measurement results window.

PI, RI, S/D Ratio, D/S Ratio or A/B Ratio

Select PI, RI, S/D Ratio, A/B Ratio or D/S Ratio

from the Doppler Primary & Secondary Controls.

Perform velocity measurements.

1. The first caliper is the start point on the Doppler

waveform. This would be V

velocity for RI, systole for S/D ratio, “A” velocity

for A/B ratio or diastole for D/S ratio.

2. The second caliper is the end-point caliper to

the end point of the Doppler waveform. This

would be V

diastole for S/D ratio, “B” velocity for A/B ratio

or systole for D/S ratio.

NOTE: For the PI calculation, if Trace Auto is not

selected, manually trace the waveform between

V

and Vd.

MAX

NOTE: For the PI calculation, if Trace Auto is on,

the system automatically traces the waveform when

Set is pressed to fix V

for PI, minimum velocity for RI,

d

.

d

for PI, peak

MAX

Worksheets

Measurement/Calculation worksheets are available

to display and edit measurements and calculation s.

There are generic worksheets as well as

Application specific worksheets. The worksheets

are selected from the worksheet button on the

screen.

Page 17

LOGIQ P5/A5/A5Pro Quick Guide Direction 5137113-100 Rev. 3 13

Using Probes

Connecting a probe

1. Place the probe's carrying case on a stable

surface and open the case.

2. Carefully remove the probe and unwrap the

probe cable.

3. DO NOT allow the probe head to hang free.

Impact to the probe head could result in

irreparable damage.

4. Turn the connector locking handle counter

clockwise.

5. Align the connector with the probe port and

carefully push into place.

6. Turn the connector locking handle clockwise to

secure the probe connector.

7. Carefully position the probe cable in the probe

cord holder spot so it is free to move, but not

resting on the floor .

Activating the probe

Press the Probe/Preset button on the front panel.

Move the cursor to the probe icon displayed on the

monitor screen and press SET.

The probe activates in the currently-selected

operating mode. The probe's default settings for the

mode and selected exam are used automatically.

Deactivating the probe

When deactivating the probe, the probe is

automatically placed in standby mode.

1. Press the Freeze key.

2. Gently wipe the excess gel from the face of the

probe.

3. Carefully slide the probe around the right side

of the keyboard, toward the probe holder.

Ensure that the probe is placed gently in the

probe holder.

Disconnecting the probe

Probes can be disconnected at any time. However,

the probe should not be selected as the active

probe.

1. Move the probe locking handle

counterclockwise. Pull the probe and connector

straight out of the probe port.

2. Carefully slide the probe and connector away

from the probe port and around the right side of

the keyboard. Ensure the cable is free.

3.

Be sure that the probe head is clean before

placing the probe in its storage box.

Using Probes

Page 18

LOGIQ P5/A5/A5Pro Quick Guide Direction 5137113-100 Rev. 3 14

LOGIQ P5/A5/A5Pro Probe Applications

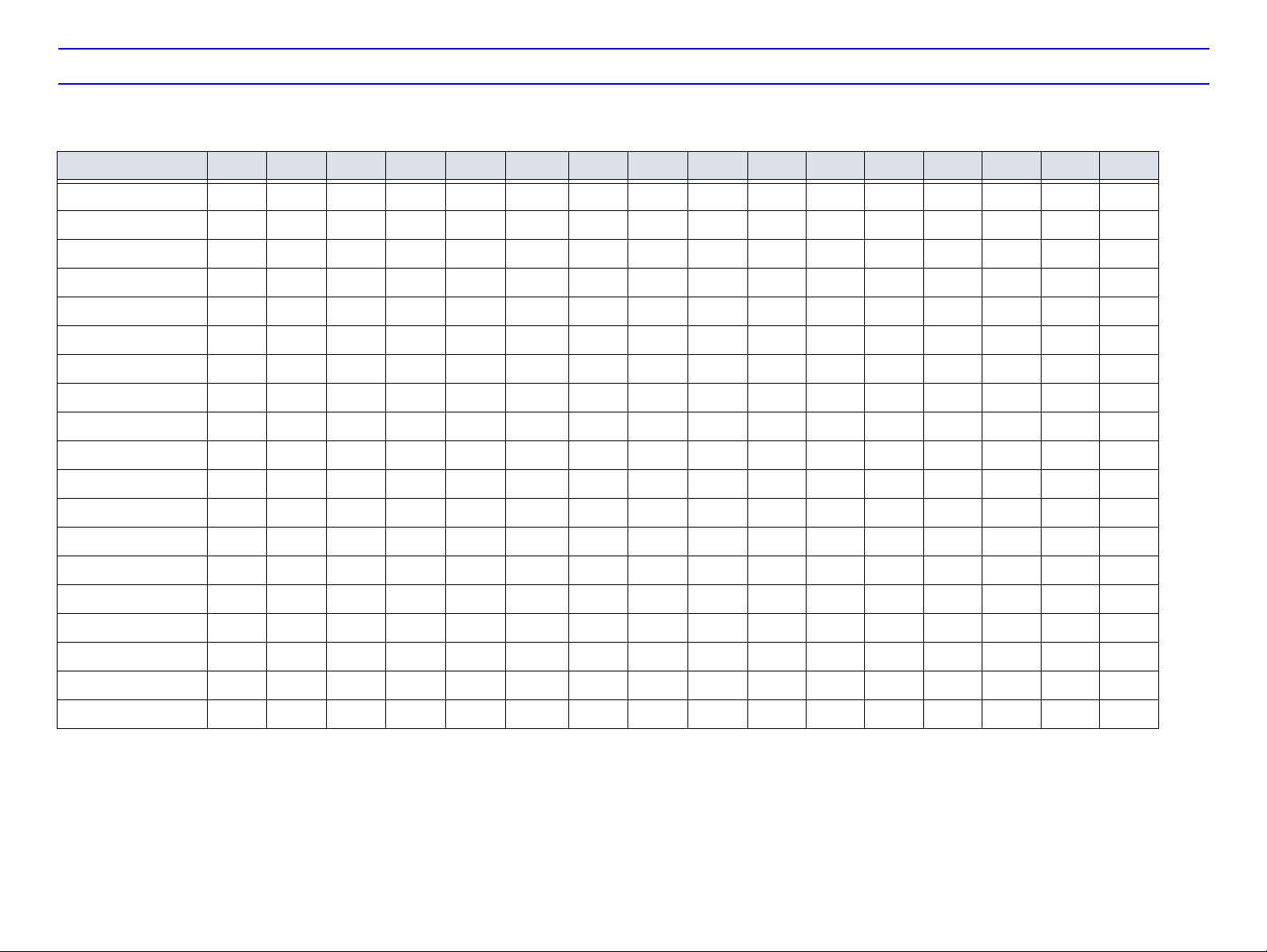

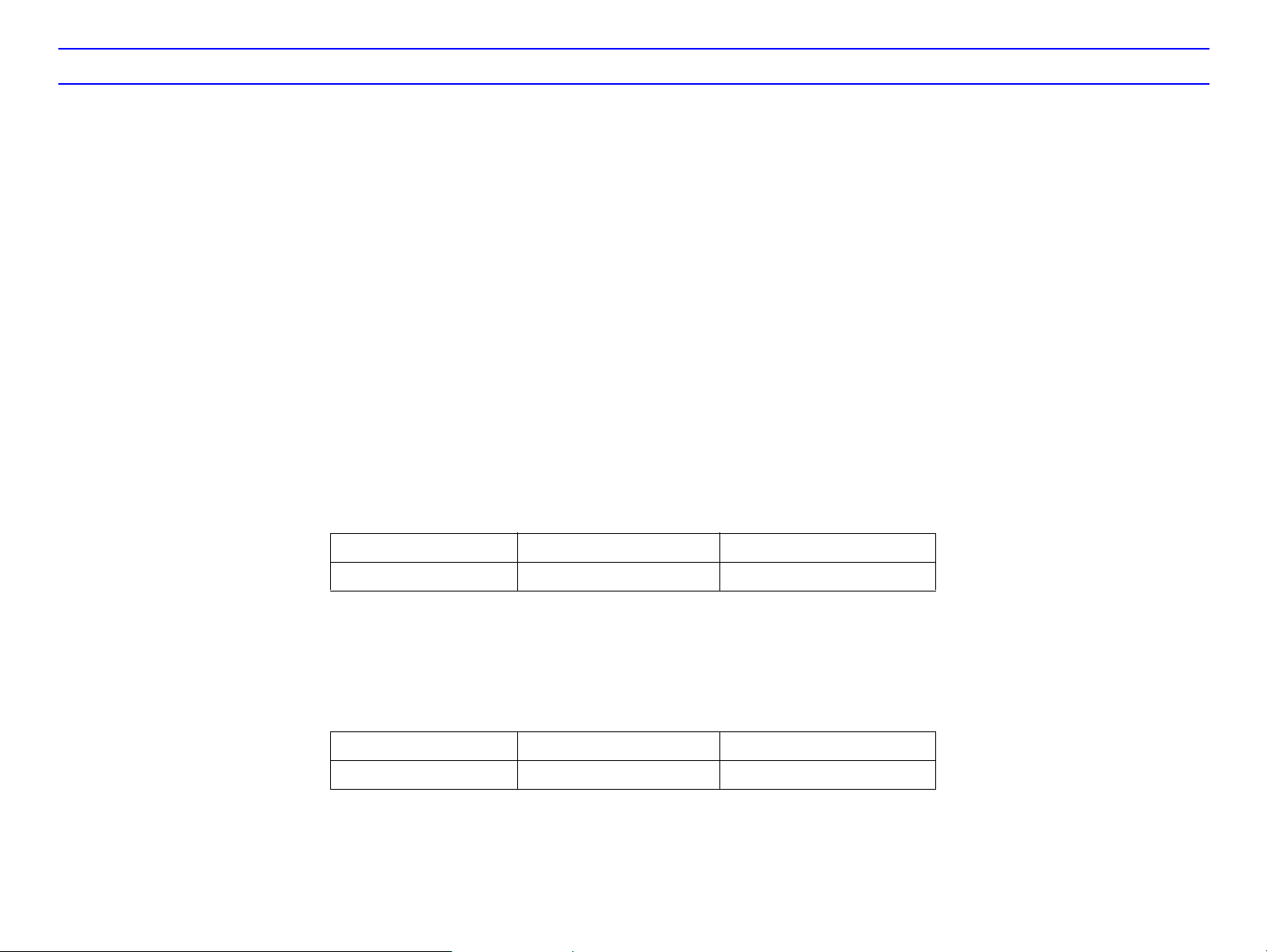

Table 1-1: Probe Indications for Use

Probe Application 3.5C 3.5CS 4C 5CS 8C E8C E8CS 8L 9L 10L 11L 12L i739 t739 3S 5S

Abdomen XXXX XXXX XX

Small Parats XXXXXXX

Periph. Vasc. XXXX XXXXXXX

Obstetrics XXXX X X X X

Gynecology XXXX X X X X

Pediatrics X X X X X X X

Neonatal X X X X X

Urology XXXX X X

Surgery XX

Cardiac XX

Endocavitary

Transcranial X

Intraoperative XX

Neonatal Cephalic

Adult Cephalic

Musculoskeletal

Transesophageal

Transvaginal X X

Transrectal

Page 19

LOGIQ P5/A5/A5Pro Quick Guide Direction 5137113-100 Rev. 3 15

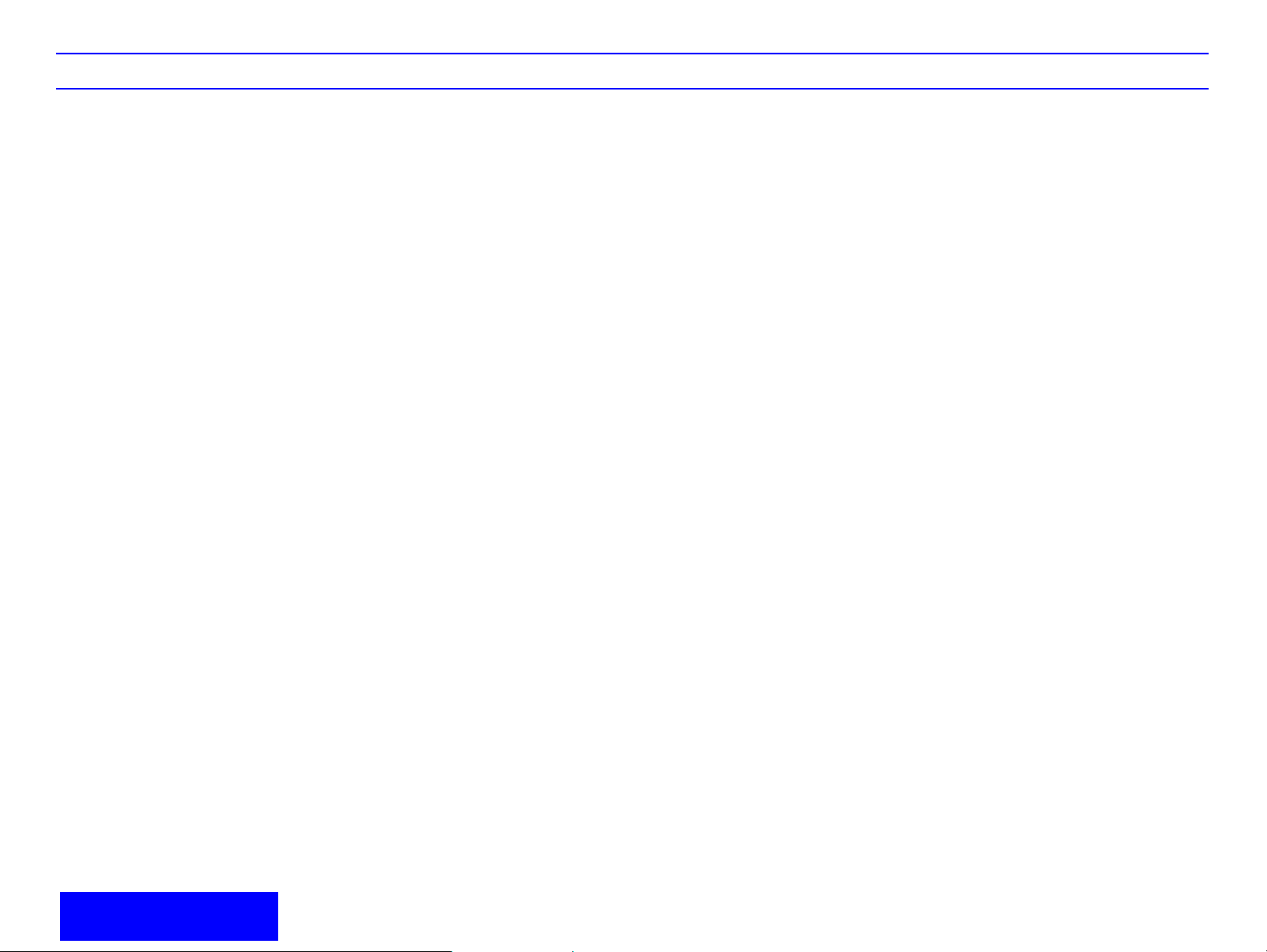

LOGIQ P5/A5/A5Pro Probe Applications (continued)

Table 1-2: Probe Indications for Use (continued)

Probe Application 7S i12L BE9CS 4D8C 3CRF 3Sp 5Sp ERB BE9C P2D P6D 4D3C-L 4DE7C UG7C

Abdomen X X X X

Small Parts X

Periph. Vasc. X X

Obstetrics X XX

Gynecology X XX

Pediatrics X X X X X X X

Neonatal X X

Urology X X X X X X

Surgery

Cardiac X X X X X

Endocavitary X

Transcranial XX

Intraoperative X

Neonatal Cephalic

Adult Cephalic

Musculoskeletal

Transesophageal X

Transvaginal X X

Transrectal X X X

Using Probes

Page 20

LOGIQ P5/A5/A5Pro Quick Guide Direction 5137113-100 Rev. 3 16

LOGIQ P5/A5/A5Pro Features

Table 1-3: Probe Features

Probe Application 3.5C 3.5CS 4C 5CS 8C E8C E8CS 8L 9L 10L 11L 12L i739 t739 3S 5S

Coded Excitation X X X X

Coded Harmonics X X XXXXXXXXXXXXXX

B-Flow XXX XXXX XX

SRI XX XXXXX XXX XXXX

Coded Contrast X X X X XX

LOGIQ View XXXXXXXXXXXXXX

Virtual Convex XXXX XXXXXXXXX

Easy 3D XX XXXXXXXXXXXXXX

Advanced 3D XX XXXXXXXXXXXXXX

Anatomical M XX XXXXXXXXXXXXXX

M Color Flow XX XXXXXXXXXXXXXX

Tru Access XX XXXXXXXXXXXXXX

Non-Imaging CW

CrossBeam XX XXXXXXXXXXXX

Biopsy XX XX XXXXXXX XXX

CW XX

4D

Page 21

LOGIQ P5/A5/A5Pro Quick Guide Direction 5137113-100 Rev. 3 17

LOGIQ P5/A5/A5Pro Features (continued)

Table 1-4: Probe Features (continued)

Probe Application 7S ERB BE9C P2D P6D 4D3C-L 4DE7C UG7C i12L BE9CS 4D8C 3CRF 3Sp 5Sp

Coded Excitation X X X

Coded Harmonics X X X X X X X X XXXX

B-Flow XX

SRI XXX X X XXX XXXX

Coded Contrast

LOGIQ View XXX X X XXX XXXX

Virtual Convex XX X X X XXXX

Easy 3D XXX XXX XXX

Advanced 3D X X X X X X X X X

Anatomical M XXX X X XXX XXXX

M Color Flow XXX X X XXX XXXX

Tru Access XXX X X XXX XXXX

Non-Imaging CW X X

CrossBeam X X X X X X X X

Biopsy XX X X X X XXXX

CW X XX

4D XX X

Using Probes

Page 22

LOGIQ P5/A5/A5Pro Quick Guide Direction 5137113-100 Rev. 3 18

Probe Cleaning and Disinfection Instructions

Probe Safety

WARNING

CAUTION

Electrical

Hazard

Ultrasound probes are highly sensitive medical instruments that can easily be damaged by improper handling. Use care when handling and protect from damage when not in

use. DO NOT use a damaged or defective probe. Failure to follow these precautions can result in serious injury and equipment damage.

Ultrasound transducers can easily be damaged by improper handling and by contact with certain chemicals. Failure to follow these precautions can result in serious injury

and equipment damage.

• Do not immerse the probe into any liquid beyond the level specified for that probe. Never immerse the transducer connector or probe adapters into any liquid.

• Avoid mechanical shock or impact to the transducer and do not apply excessive bending or pulling force to the cable.

• Transducer damage can result from contact with inappropriate coupling or cleaning agents:

• Do not soak or saturate transducers with solutions containing alcohol, bleach, ammonium chloride compounds or hydrogen peroxide

• Avoid contact with solutions or coupling gels containing mineral oil or lanolin

• Avoid temperatures above 60°C.

• Inspect the probe prior to use for damage or degeneration to the housing, strain relief, lens and seal. Do not use a damaged or defective probe.

Adequate cleaning and disinfection are necessary to prevent disease transmission. It is the responsibility of the equipment user to verify and maintain the effectiveness of the

infection control procedures in use. Always use sterile, legally marketed probe sheaths for intra-cavitary and intra-operative procedures.

For neurological intra-operative procedures, use of a legally marketed, sterile, pyrogen free probe sheath is REQUIRED. Probes for neuro surgical use must not be sterilized

with liquid chemical sterilants because of the possibility of neuro toxic residues remaining on the probe.

A defective probe or excessive force can cause patient injury or probe damage:

• Observe depth markings and do not apply excessive force when inserting or manipulating intercavity probes.

• Inspect probes for sharp edges or rough surfaces that could injure sensitive tissue.

In order for liquid chemical germicides to be effective, all visible residue must be removed during the cleaning process. Thoroughly clean the probe, as described on the

following page before attempting disinfection.

CREUTZFIELD-JACOB DISEASE

Neurological use on patients with this disease must be avoided. If a probe becomes contaminated, there is no adequate disinfecting means.

The probe is driven with electrical energy that can injure the patient or user if live internal parts are contacted by conductive solution:

• DO NOT immerse the probe into any liquid beyond the level indicated by the immersion level diagram. Never immerse the probe connector or probe adaptors into any liquid.

• DO NOT drop the probes or subject them to other types of mechanical shock or impact. Degraded performance or damage such as cracks or chips in the housing may

result.

• Inspect the probe before and after each use for damage or degradation to the housing, strain relief, lens, and seal. A thorough inspection should be conducted during the

cleaning process.

• DO NOT kink, tightly coil, or apply excessive force on the probe cable. Insulation failure may result.

• Electrical leakage checks should be performed on a routine basis by GE Service or qualified hospital personnel. Refer to the service manual for leakage check procedures.

Page 23

LOGIQ P5/A5/A5Pro Quick Guide Direction 5137113-100 Rev. 3 19

Probe Cleaning, After Each Use

1. Disconnect probe from ultrasound console and

remove all coupling gel from probe by wiping

with a soft cloth and rinsing with flowing water.

2. Wash the probe with mild soap in lukewarm

water. Scrub the probe as needed using a soft

sponge, gauze, or cloth to remove all visible

residue from the probe surface. Prolonged

soaking or scrubbing with a soft bristle brush

(such as a toothbrush) may be necessary if

material has dried onto the probe surface.

3. Rinse the probe with enough clean potable

water to remove all visible soap residue.

4. Air dry or dry with a soft cloth.

Probe Disinfection, After Each Use

1. Prepare the germicide solution according to the

manufacturer's instructions. Be sure to follow all

precautions for storage, use and disposal.

2. Place the cleaned and dried probe in contact

with the germicide for the time specified by the

germicide manufacturer. High-level disinfection

is recommended for surface probes and is

required for endocavitary and intraoperative

probes (follow the germicide manufacturer's

recommended time).

Probes for neuro surgical intra-operative use

must NOT be sterilized with liquid chemical

sterilants because of the possibility of neuro

toxic residues remaining on the probe.

Neurological procedures must be done with the

use of legally marketed, sterile, pyrogen free

probe sheaths.

3. After removing from the germicide, rinse the

probe following the germicide manufacturer's

rinsing instructions. Flush all visible germicide

residue from the probe and allow to air dry.

Probe Immersion Levels

1. Fluid Level

2. Aperture

3. Contact face within patient environment

Probe Disinfection Agents

Ultrasound probes can be disinfected using liquid

chemical germicides. The level of disinfection is

directly related to the duration of contact with the

germicide. Increased contact time produces a

higher level of disinfection.

Refer to the Probe Care Card.

http://www.gemedicalsystems.com/rad/us/

probe_care.html

Using Probes

Page 24

LOGIQ P5/A5/A5Pro Quick Guide Direction 5137113-100 Rev. 3 20

Image Management

Clipboard

As images are saved by pressing any of the print keys

(P1, P2 or Print Screen), the images appear at the bottom

of the display on the clipboard as thumbnails of the

images saved during the exam. These images remain on

the clipboard until the end of the exam.

Printing Images

Press the appropriate print key (P1, P2 or Print Screen).

For more information on programming the Print buttons,

See “Buttons” on page 22.

Browsing an Exam’s Stored Images

‘Mouse over’ the image in the clipboard, then double click

Set to view an enlarged thumbnail image.

Managing an Exam’s Stored Images

From the Display, press Active Images; from the New

Patient menu, open Active Images.

Deleting an Image

Select the image on the clipboard, then press the

onscreen Delete shortcut.

Or, go to Active Images (lower, right-hand portion of the

display). Highlight all the images that need to be deleted

and press Delete All Temp Images.

Formatting a CD/DVD

1. Insert the backup media. Format the backup media.

Go to the Utility page by pressing “Ins” Key. Select

Connectivity, then Removable Media. Label the

media appropriately. Press Format.

CAUTION

Storiage media includes: CD-R, DVD-R, NDL

256MByte 066E0690 USB Flash Drive.

2. The Ultrasound system displays a pop-up menu

when the formatting has been completed. Press Ok

to continue. Verify that the format was successful.

DO NOT use DVD-RW or

CD-RW media.

Backing Up Patient Information

Format the media prior to performing these steps.

1. Go to the Utility tab. Select System, then Backup/

Restore.

2. Select the media.

3. Select the parameter under Backup by placing

a check mark. Then press Backup.

4. Answer ‘OK’ to the Back-Up pop-up message.

NOTE: The detailed section of this menu decouples the

user defined configuration above. This allows you to

selectively restore what you want to restore across

multiple machines.

NOTE: DO NOT restore service back-ups across

systems (from one LOGIQ P5/A5/A5Pro system to

another LOGIQ P5/A5/A5Pro system).

Image/ Patient Management

and Connectivity

Page 25

LOGIQ P5/A5/A5Pro Quick Guide Direction 5137113-100 Rev. 3 21

Moving Data Between Ultrasound Systems

There are 5 options (Import, Export, Q/R, Worklist and

MPEGvue) under Data Transfer.

Import

1. At the other Ultrasound system, insert the

removable media.

2. Press Patient and select Data Transfer.

3. Select Import.

4. Select Local Archive-Int. HD from the T ransfer

To pull-down menu.

5. Select the patient(s) or exam(s) from the

Transfer From Search field for import.

6. Press Transfer.

7. Wait until the patient information is copied and

press F3 when finished to eject the media.

Export

1. Insert, format and label the removable media.

2. Press Patient and select Data Transfer.

3. Select Export.

4. Select the patient(s) or exam(s) to expo rt in the

Transfer From Search field (the top portion).

5. Select the destination at the Transfer To pulldown menu.

6. Press Transfer. The progress bar displays

during the transfer.

7. Press F3 to eject the media. Specify that you

want to finalize the media.

Query/Retrieve (Q/R)

1. Press Patient and select Data Transfer.

2. Select Q/R. The local archive is enabled for the

transfer process.

3. Select the Query/Retrieve server from the

Transfer From pull-down men u.

4. Press Query in the Transfer From section. The

server’s patient list displays.

5. Select the patient(s) or exam(s) to retrieve from

the patient list.

6. Press Transfer. The data is retrieved from the

server as the progress bar displays.

Worklist

1. Press Patient and select Worklist. The last

Worklist used displays on the monitor.

2. Press Refresh to refresh the list or select

another Worklist server from the transfer From

pull-down menu.

3. Select the patient(s) or exam(s) from the list.

4. Press Transfer. The progress bar displays

during the transfer.

MPEGvue

Save the data to CD-R to view on PC

1. Format and label the media; insert the USB

Flash / Hard Drive into the front USB Port.

2. Press Patient and select Data Transfer.

3. Select MPEGvue. The patient list in the Local

Archive-Int. HD displays in the Transfer From

section.

4. Select the media from the Transfer To pulldown menu.

5. Select the patient(s) or exam(s) from the list.

6. Press Transfer. The progress bar displays

during the transfer. Files are saved in mpeg

format.

Send To the DICOM device

1. Press Patient.

2. Search and select the patient and press Exam.

The Patient Exam screen displays.

3. Select the exam which has the images and

press Send To.

NOTE: You can only select the Local ArchiveInt. HD for Workflow.

4. The Send To dialogue box displays. Choose the

destination device and select OK.

NOTE: The destination device is configured in

the Utility screen. Multiple devices are able to

be configured.

5. The successful/unsuccessful message is displayed

at the bottom of the screen.

NOTE: If you press the Clear button in the T ransfer

From and T ransfer To section, all the search criteria

is cleared and the list is refreshed accordingly.

NOTE: ALWAYS exit to scanning after any Data

Transfer function to ensure that the ope ration

has completed.

Page 26

LOGIQ P5/A5/A5Pro Quick Guide Direction 5137113-100 Rev. 3 22

EZBackup/Move

NOTE: EZBackup/EZMove allows you to manage

hard disk space (move images off the hard drive)

while maintaining the patient database on the

scanner, as well as to back up the patie nt data base

and images.

NOTE: EZBackup/EZMove can take up to 20

minutes. Make sure to schedule this at the same

time daily, when no patients are scheduled.

1. To start the EZBackup/EZMove procedure, go

to the Patient menu and select the EZBackup/

EZMove button at the bottom of the Patient list.

The EZBackup/EZMove Wizard starts.

2. Verify the information on the first page of the

EZBackup/EZMove Wizard, then press Next.

NOTE: If the EZBackup/EZMove presets need to

be modified, those requirements are specified on

the Utility --> System --> Backup/Restore page.

3. Verify the information on the EZBackup/

EZMove Wizard, Page 2. This page tells you

how many medias you need to do this backup.

After you have gathered the media, you are

ready to begin the backup. Press Next.

4. A pop-up message appears that provides you

with the media label. Label the media, then

insert the media. Press OK.

5. The status menu appears.

NOTE: When/if you need to insert the next media,

a message appears providing you with the media

label a well. Label the media, then insert the media

and press OK.

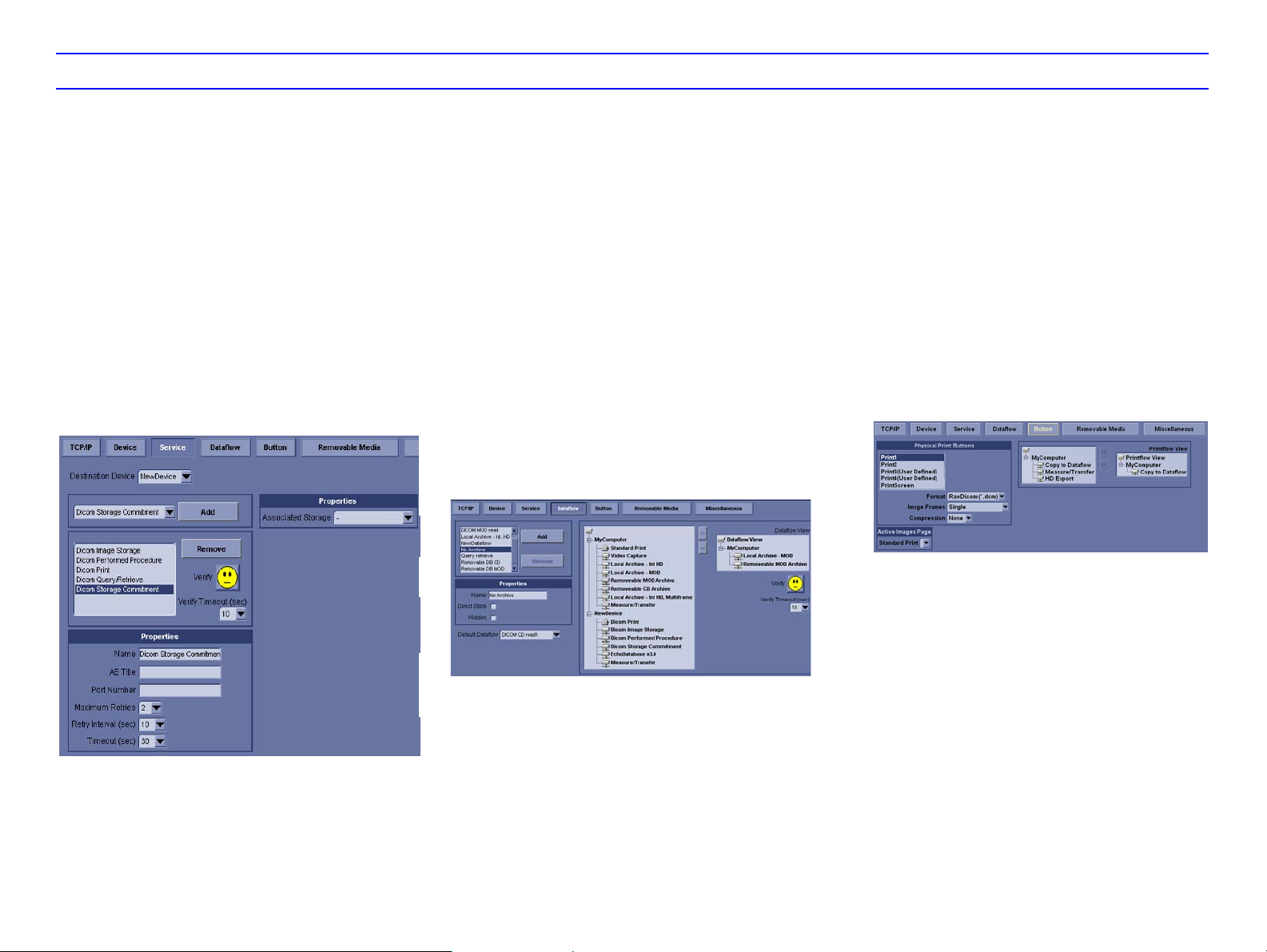

Connectivity

Connectivity on the LOGIQ P5/A5/A5Pro is based

on the Dataflow concept.

Login as Administrator. Select Utility. Select Connectivity. Configure the menus from left to right, starting with TCP/IP first. When finished making connectivity changes to the utility menus, restart the system.

TCP/IP

Type in the Computer’s Name (better known as the AE

Title). Identify the Ultrasound system to the rest of the

network by filling in its IP Address, Subnet Mask, and

Gateway (if applicable). Press Save.

Device

Use the Device tab to add DICOM destinations.

1. Press Add.

2. Type the name of the device and it s IP address.

3. Press Ping, then Save.

.

Figure 1-1.

6. When the backup is complete, the Backup

completed page appears.

To view the media, do so via the Patient menu by

selecting the patient and loading the appropriate

media, or via Import, or via DICOM CD View.

Image/ Patient Management

and Connectivity

Page 27

LOGIQ P5/A5/A5Pro Quick Guide Direction 5137113-100 Rev. 3 23

Services

To add a service,

1. Select the destination device.

2. Select the service to add and press Add.

3. Type the name in the Name Field.

4. Specify criteria in the Properties b oxes (located

in the upper right-hand side and lower lef t-hand

side).

5. Press Verify, then Save.

There are two service types that pertain to printers:

• Standard Printer is used for digital peripherals.

• Video Capture Device is used for devices that

are triggered by a contact closure, typically

analog devices.

Dataflow

The Dataflow page allows you to add services to

the selected dataflow. For example, DICOM

services may be for storage, worklist, verify, etc. In

addition, there are other service types like video

print or standard color print

Set up dataflows for the services.

1. Press Add and type the dataflow name in the

name field.

2. Select the service you want to use under My

Computer and press >> to add to Dataflow

view.

3. Press Verify, then Save.

NOTE: Query/Retrieve MUST be the only

service in a dataflow.

NOTE: Set Query/Retrieve to Hidden so that it

cannot be selected from the Patient Menu.

Buttons

You can assign print buttons to a device or to a

dataflow.

1. Select the print button to configure and the

properties on the left of the screen.

2. Select the service you want to use under My

Computer and press >> to add to Printflow

view.

NOTE: Select the Standard Print und er Active

Images Page as necessary.

3. Press Save.

NOTE: You can configure each print key to

multiple output devices/workflow.

Page 28

LOGIQ P5/A5/A5Pro Quick Guide Direction 5137113-100 Rev. 3 24

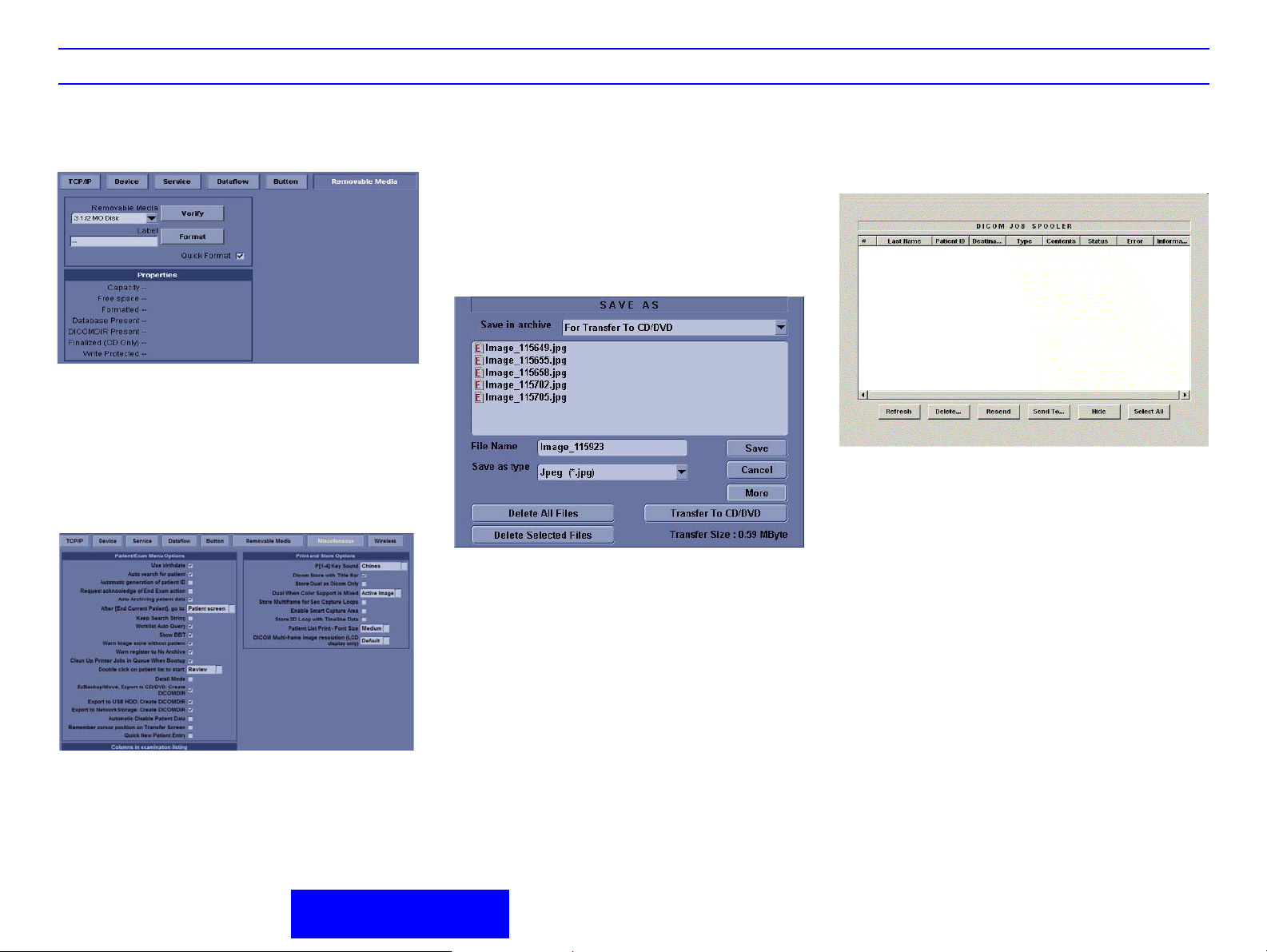

Removable Media

Format and verify media.

Miscellaneous

Set up Patient/Exam menu options and Printer and

Store Op tions

Saving Images as JPEG files and CINE Loops as AVI files

Format the media prior to following these steps.

1. Insert a media into the drive or an USB Drive

into the USB Port.

2. Press Menu (on the lower, right-hand portion of

the display) and select Save As. The SAVE AS

menu appears.

3. Specify Compression and Save As Type and

press Save. The image is saved to the media.

4. Finalize the media by selecting Yes. The media

is ejected from the system.

NOTE: If you want to add more images to the

media, select “No” and do not finalize the media.

DICOM Status

To check the status of all DICOM jobs or redirect

DICOM jobs, press F4.

Image/ Patient Management

and Connectivity

Page 29

LOGIQ P5/A5/A5Pro Quick Guide Direction 5137113-100 Rev. 3 25

Using CINE

Activating CINE

Press Freeze, then roll the Trackball to activate CINE. To

start CINE Loop playback, press Run/Stop. To stop CINE

Loop playback. press Run/Stop.

To activate Timeline CINE, press Freeze, press Scan

Area, then roll the Trackball to activate CINE.

Quickly Move to Start/End Frame

Press First to move to the first CINE frame; press Last to

move to the last CINE frame.

Start Frame/End Frame

Turn the Start Frame dial to the left to move to the

beginning of the CINE Loop. Turn the dial to the right to

move forward through the CINE Loop.

Turn the End Frame dial to the right to move to the end of

the CINE Loop. Turn the dial to the left to move backward

through the CINE Loop.

Adjusting the CINE Loop Playback Speed

Turn the Loop Speed dial clockwise/counter-clockwise to

increase/decrease the CINE Loop playback speed.

Disconnecting B-Mode CINE from Timeline CINE

To review the B-Mode CINE Loop only, press Cine Mode

Selection and select B Only.

T o review the T imeline CINE Loop only , press Cine Mode

Selection and select TL Only.

To return to linked B-Mode and Timeline CINE Loop review, press Cine Mode Selection and select B/TL.

Moving through a CINE Loop Frame By Frame

Turn Frame by Frame to move through CINE memory

one frame at a time.

Preparing for an Exam

Page 30

LOGIQ P5/A5/A5Pro Quick Guide Direction 5137113-100 Rev. 3 26

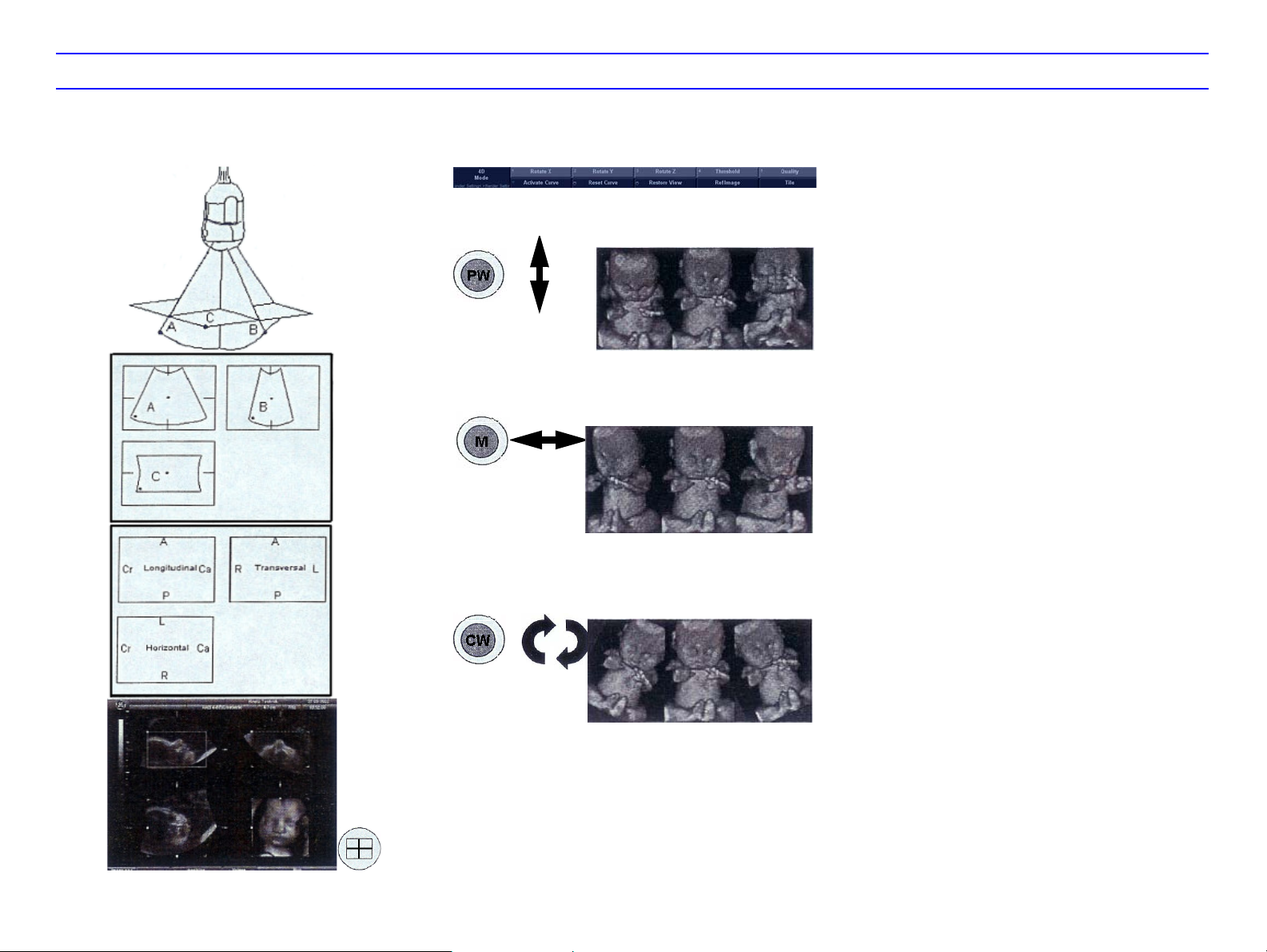

Easy 3D (option)

Acquiring a 3D Scan

1. Optimize the B-Mode image. Ensure even gel

coverage.

2. Press the 3D control panel key. Two screens

appear.

3. To start acquiring the image, press ‘L’ (the left

split screen key).

4. To perform a parallel scan, scan evenly. To

perform a sweep (fan) scan, rock the probe

once. Note the distance of the scan.

5. The 3D volume of interest is dynamically

assembled on the right side of the screen.

NOTE: If the image stops before you’re done

scanning, start acquiring the 3D volume of interest

again.

6. To complete the 3D scan, press ‘R’ (the right

split screen key).

NOTE: You can also press Freeze, but then you

need to also press the 3D key to obtain the final

render.

Manipulating the 3D Scan

Imagine you are able to manipulate the 3D volume

of interest (VOI) in your hand.

You can rotate it left to right or right to left. You can

rotate it forward/backward (white hand).

Then, imagine that you can view the volume of

interest one slice at a time through the anatomy

(red hand).

Also imagine that you are able to pull back tissue to

view specific portions of anatomy (yellow and green

hands).

The 3D volume of interest is a tangible anatomical

object that you can see and manipulate easily using

the Trackball and Set control panel keys.

Practice positioning the pointer at different places

within the 3D volume of interest. Highlight different

colors, press Set to select this volume for

manipulation. Use the hand to move the 3D vo lume.

Adjusting the 3D Volume of Interest

You can colorize the 3D volume of interest.

You can resize the VOI by adjusting the scan

distance.

Performing a Surface Render

From the 3D Top Menu press Texture to add a

photorealistic/clay-like quality to the render.

Adjust the opacity and density via Threshold/

Opacity (press the key to adjust opacity). This

adjusts what ‘grays’ the system recognizes,

allowing you to emphasize/de-emphasize grays as

necessary.

Scalpel

To scalpel away portions of the anatomy,

1. Press Scalpel. A caliper appears on the 3D

VOI.

2. Press Set to set the caliper. Trackball around

the portion to be cut away.

3. Double click and apply the scalpel.

4. Change the projection and scalpel again.

NOTE: You can undo one scalpel.

3DView Scanning Hints

Set the appropriate values for the 3D Acq Mode

and Scan Plane.

It is advisable to set the scan distance before the

scan begins.

Page 31

LOGIQ P5/A5/A5Pro Quick Guide Direction 5137113-100 Rev. 3 27

Basic 4D

1. Scan in 2D and obtain the best possible view of your

Region of Interest (ROI).

TIP: Any fluid interface provides the best results. For

example, for a 3D/4D view of the fetal face, first

obtain the best profile view.

2. Press 3D.

3. Press Real Time 4D.

4. Adjust the size and position of the ROI box using the

Scan Area button and Trackball.

Press the Scan Area button ONCE to resize the

ROI; move the Trackball left/right or up/down.

Press Scan Area AGAIN to re-position the ROI,

using the Trackball to move the ROI.

5. Select Preset.

6. To start 4D acquisition, press “SET” button.

7. Use the Tile button change the display between the

following screens:

Quad Split Full

TIP: Orientation adjustment may be needed,

depending on the anatomy being scanned. For

example, if the fetus is in the breech position, the top

of the baby’s head is facing up. However, if the fetus

is vertex, the top of the head faces down and the

orientation needs to be flipped 180 degrees.

Use the 3D Orient button to change the orientation.

Preparing for an Exam

Page 32

LOGIQ P5/A5/A5Pro Quick Guide Direction 5137113-100 Rev. 3 28

Optimizing the 4D Rendered Image

Orientation Rotations (when on full screen mode)

Rotates Image Up and Down

Rotate X

Rotates Image Left and Right

Rotate Y

Rotates Image Clockwise and

Counterclockwise

Rotate Z

Tools to Improve 4D Image Quality

TIP: When scanning in 4D, use slow movements to

keep the ROI in the field of view.

Select the Render Setting tab.

Quality

High Quality–best resolution but slower acquisition

rates.

Lower Quality–fastest acquisition speeds but less

resolution of 3D/4D image.

Lower Threshold

The higher numbers effectively make the image

brighter by taking away the low level echoes.

Typical range for OB: 10-45.

Render Modes

Rend Mode 1 & 2

• Surface Texture–better for older fetuses, more

detail.

• Surface Smooth–better for younger fetuses,

smoother rendered image.

• Transp MAX–highlights High Intensity echoes,

for fetal skeleton or echogenic structures.

• Transp MIN–highlights Low Intensity echoes, for

vascular structures or cystic areas.

• Transp X-RAY–used with colo r/power Doppler

to show vessels within the volume.

• Gradient Light–more shad ows, bette r de pth

perception.

• Light--brighter near field structures, darker far

field structures.

Mix

Combination of two Render Modes (=100%).

Page 33

LOGIQ P5/A5/A5Pro Quick Guide Direction 5137113-100 Rev. 3 29

Contact Information

INTERNET

http://www.gemedicalsystems.com

USA

GE Healthcare

Ultrasound Service Engineering

9900 Innovation Drive

Wauwatosa, WI 53226

TEL: (1) 800-437-1171 or FAX: (1) 414-721-3865

Clinical Questions

For information in the United States, Canada,

Mexico and parts of the Caribbean, call the

Customer Answer Center:

TEL: (1) 800-682-5327 or (1) 262-524-5698

In other locations, contact your local Applications,

Sales or Service Representative.

Service Questions

For service in the United States, call GE CARES

TEL: (1) 800-437-1171

Accessories Catalog Requests

To request the latest GE Accessories catalog or

equipment brochures in the United States, call the

Response Center: TEL: (1) 800-643-6439

In other locations, contact your local Applications,

Sales or Service Representative.

Placing an Order

To place an order , order supplies or ask an

accesory-related question in the United States, call

the GE Access Center: TEL: (1) 800-472-3666

In other locations, contact your local Applications,

Sales or Service Representative.

OTHER COUNTRIES

NO TOLL FREE

TEL: international code + 33 1 39 20 0007

CANADA

GE Healthcare

Ultrasound Svc Engineering TEL: (1) 800-664-0732

9900 Innovation Drive

Wauwatosa, WI 53226

Customer Answer Center TEL: (1) 262-524-5698

LATIN & SOUTH AMERICA

GE Healthcare

Ultrasound Svc Engineering TEL: (1) 262-524-5300

9900 Innovation Drive

Wauwatosa, WI 53226

Customer Answer Center TEL: (1) 262-524-5698

EUROPE

GE Ultraschall

Deutschland GmbH & Co. KG

Beethovenstraße 239

Postfach 11 05 60

D-42655 Solingen -- TEL: 0130 81 6370 toll free

TEL: (49) 212.28.02.207 -- FAX: (49) 212.28.02.431

ASIA

GE Medical Systems Asia

Asia Support Center

67-4 Takakura cho, Hachiouji-shi

Tokyo, 192-0033

TEL: (81) 426-48-2940 -- FAX: (81) 426-48-2905

ARGENTINA

GEME S.A.

Miranda 5237

Buenos Aires - 1407

TEL: (1) 639-1619 -- FAX: (1) 567-2678

AUSTRIA

GE GesmbH Medical Systems Austria

Prinz Eugen Strasse 8/8

A-1040 WIEN

TLX: 136314

TEL: 0660 8459 toll free -- FAX: +43 1 505 38 74

BELGIUM

GE Medical Systems Benelux

Gulkenrodestraat 3

B-2160 WOMMELGEM

TEL: 0 800 11733 toll free

FAX: +32 0 3 320 12 59

TLX: 72722

BRAZIL

GE Sistemas Médicos

Av Nove de Julho 5229

01407-907 São Paulo SP

TEL: 0800-122345 -- FAX: (011) 3067-8298

Preparing for an Exam

Page 34

LOGIQ P5/A5/A5Pro Quick Guide Direction 5137113-100 Rev. 3 30

DENMARK

GE Medical Systems

Fabriksparken 20

DK-2600 GLOSTRUP

TEL: +45 4348 5400 -- FAX: +45 4348 5399

FRANCE

GE Medical Systems

738 rue Yves Carmen

F-92658 BOULOGNE CEDEX

TEL: 05 49 33 71 toll free -- F AX: +33 1 46 10 01 20

GERMANY

GE Ultraschall

Deutschland GmbH & Co. KG

Beethovenstraße 239

Postfach 11 05 60

D-42655 Solingen

TEL: 0130 81 6370 toll free

TEL: (49) 212.28.02.207 -- F AX: (4 9) 212.28.02.431

GREECE

GE Medical Systems Hellas

41, Nikolaou Plastira Street

G-171 21 NEA SMYRNI

TEL: +30 1 93 24 582 -- FAX: +30 1 93 58 414

ITALY

GE Medical Systems Italia

Via Monte Albenza 9

I-20052 MONZA

TEL: 1678 744 73 toll free -- FAX: +39 39 73 37 86

TLX: 3333 28

LUXEMBOURG

TEL: 0800 2603 toll free

MEXICO

GE Sistemas Médicos de Mexico S.A. de C.V.

Rio Lerma #302, 1º y 2º Pisos

Colonia Cuauhtémoc

06500-México, D.F.

TEL: (5) 228-9600 -- FAX: (5) 211-4631

NETHERLANDS

GE Medical Systems Nederland B.V.

Atoomweg 512

NL-3542 AB UTRECHT

TEL: 06 022 3797 toll free -- FAX: +31 304 11702

POLAND

GE Medical Systems Polska

Krzywickiego 34

P-02-078 WARSZAWA

TEL: +48 2 625 59 62 -- FAX: +48 2 615 59 66

PORTUGAL

GE Medical Systems Portuguesa S.A.

Rua Sa da Bandeira, 585

Apartado 4094 TLX: 22804

P-4002 PORTO CODEX

TEL: 05 05 33 7313 toll free - F AX: +351 2 2084494

RUSSIA

GE VNIIEM

Mantulinskaya UI. 5A

123100 MOSCOW

TEL: +7 095 956 7037 -- FAX: +7 502 220 32 59

TLX: 613020 GEMED SU

SPAIN

GE Healthcare TEL. : +34 (91) 663 25 00

Avda. Europa, 22 FAX : +34 (91) 663 25 01

E-28108 Alcobendas, Madrid

SWEDEN

GE Medical Systems

PO-BOX 1243

S-16428 KISTA

TEL: 020 795 433 toll free -- FAX: +46 87 51 30 90

TLX: 12228 CGRSWES

SWITZERLAND

GE Medical Systems (Schweiz) AG

Sternmattweg 1

CH-6010 KRIENS

TEL: 155 5306 -- FAX: +41 41 421859

TURKEY

GE Med. Sys. Turkiye A.S.

Mevluk Pehliran Sodak

Yilmaz Han, No 24 Kat 1

Gayretteppe

ISTANBUL

TEL: +90 212 75 5552 -- FAX: +90 212 211 2571

UNITED KINGDOM

GE Medical Systems

Coolidge House

352 Buckingham Avenue

SLOUGH

Berkshire SL1 4ER

TEL: 0800 89 7905 toll free -- F AX: +44 753 696067

Page 35

LOGIQ P5/A5/A5Pro Quick Guide Direction 5137113-100 Rev. 3 31

DANGER

G

Precaution Levels

Icon description

V ario us levels of safety pre cautions may be fo und on the equ ipment and different levels of concern are identified by one of the following flag words and icons which

precede the precautionary statement.

Indicates that a specific hazard is known to exist which through inappropriate conditions or actions will cause:

• Severe or fatal personal injury

• Substantial property damage.

WARNIN

CAUTION

NOTE: Indicates precautions or recommendations that should be used in the operation of the ultrasound system, specifically:

• Maintaining an optimum system environment

• Using this Manual

• Notes to emphasize or clarify a point.

Indicates that a specific hazard is known to exist which through inappropriate conditions or actions may cause:

• Severe personal injury

• Substantial property damage.

Indicates that a potential hazard may exist which through inappropriate conditions or actions will or can cause:

• Minor injury

• Property damage.

Safety

Page 36

LOGIQ P5/A5/A5Pro Quick Guide Direction 5137113-100 Rev. 3 32

Biological

A

Explosi

Hazard Symbols - Icon Description

Potential hazards are indicated by the following icons:

Table 1-1: Potential Hazards

Icon Potential Hazard Usage Source

Hazard

Electrical

Hazard

Moving

Hazard

coustic

Output

Hazard

on

Hazard

Smoke &

Fire Hazard

• Patient/user infection due to contaminated equipment. • Cleaning and care instructions

• Sheath and glove guidelines

• Electrical micro-shock to patient, e.g., ventricular • Probes

• ECG

• Connections to back panel

• Console, accessories or optional storage devices that can fall on patient, user, or others.

• Collision with persons or objects result in injury while maneuvering or during system

transport.

• Injury to user from moving the console.

• Patient injury or tissue damage from ultrasound radiation. • ALARA, the use of power output following

• Risk of explosion if used in the presence of flammable anesthetics. • Flammable anesthetic

• Patient/user injury or adverse reaction from fire or smoke.

• Patient/use injury from explosion and fire.

• Moving

• Using brakes

• Transporting

the as low as reasonably achievable

principle

• Replacing fuses

• Outlet guidelines

ISO 7000

No. 0659

Page 37

LOGIQ P5/A5/A5Pro Quick Guide Direction 5137113-100 Rev. 3 33

G

Important Safety Considerations

The following topic headings (Patient Safety, and Equipment and Personnel Safety) are intended to make the equipment user aware of particular hazards

associated with the use of this equipment and the extent to which injury can occur if precautions are not observed. Additional precautions may be provided

throughout the manual.

CAUTION

Improper use can result in serious injury. The user must be thoroughly familiar with the instructions and potential hazards involving

ultrasound examination before attempting to use the device. Training assistance is available from GE Medical Systems if needed.

The equipment user is obligated to be familiar with these concerns and avoid conditions that could result in injury.

Patient Safety

Related Hazards

WARNIN

Patient identification

Always include proper identification with all patient data and veri fy the accuracy of the patient's name or ID numbers when entering such data. Make sure correct

patient ID is provided on all recorded data and hard copy prints. Identification errors could result in an incorrect diagnosis.

Diagnostic information

Equipment malfunction or incorrect settings can result in measurement errors or failure to detect details within the image. The equipment user must become

thoroughly familiar with the equipment operation in order to optimize its performance and recognize possible malfunctions. Applications training is available through

the local GE representative. Added confidence in the equipment operation can be gained by establishing a quality assurance program.

The concerns listed can seriously affect the safety of patients undergoing a diagnostic ultrasound examination.

CAUTION

Safety

The system’s acoustic output remains transmitting when the user controls are being used. Allowing the system to transmit acousti c output

with the probe not in use (or in its holder) can cause the probe to build up he at. Always turn off acoustic output or freeze the image when

not in use.

Page 38

LOGIQ P5/A5/A5Pro Quick Guide Direction 5137113-100 Rev. 3 34

Related Hazards (continued)

Mechanical hazards

The use of damaged probes or improper use and manipulation of intr acavity probes can result in injury or increased risk of infection. Inspect probes often for sharp,

pointed, or rough surface damage that could cause injury or tear protective barriers. Never use excessive force when manipulating intracavity probes. Become

familiar with all instructions and precautions provided with special purpose probes.

Electrical

Hazard

CAUTION

CAUTION

CAUTION

Training

It is recommended that all users receive proper training in applications before performing them in a clinical setting. Please contact the local GE representative for

training assistance.

ALARA training is provided by GE Application Specialists. The ALARA education program for the clinical end-user covers basic ultrasound pr inc iple s , possib l e

biological effects, the derivation and meaning of the indices, ALARA principles, and examples of specific applications of the ALARA principle.

A damaged probe can also increase the risk of e lectric shock if conductive solutions come in contact with internal live part s. Inspect probes

often for cracks or openings in the housing and holes in and around the acoustic le ns or other damage that could allow liquid entry.

Become familiar with the probe's use and care precautions outlined in Probes and Biopsy.

Ultrasound transducers are sensitive instruments which can easily be damaged by rough handling. Take extra care not to drop

transducers and avoid contact with sharp or abrasive surfaces. A damaged hou sing, lens or cable can result in patient injury or serious

impairment or operation.

Ultrasound can produce harmful effects in tissue and potentially result in patient injury. Always minimize exposure time and keep

ultrasound levels low when there is no medical benefit. Use the principle of ALARA (A

only when needed to obtain diagnostic image quality. Observe the acoustic output display and be familiar with all controls affecting the

output level. See the Bioeffects section of the Acoustic Output chapter in the Advanced Reference Manual for more information.

Do not use with Defibrillator.

This equipment does not have a defibrillator approved applied part.

s Low As Reasonably Achievable), increasing output

Page 39

LOGIQ P5/A5/A5Pro Quick Guide Direction 5137113-100 Rev. 3 35

G

G

DANGER

Explosi

Equipment and Personnel Safety

Related Hazards

WARNIN

WARNIN

on

Hazard

Electrical

Hazard

This equipment contains dangerous voltages that are capable of serious injury or death.

If any defects are observed or malfunctions occur, stop operating the equipment and perform the proper action for the patient. Inform a

qualified service person and contact a Service Representative for information.

There are no user serviceable comp on en ts inside the cons ole . Refer all servicing to qualified service personnel only.

Only approved and recommended peripherals and accessories should be used. All peripherals and accessories must be securely

mounted to the LOGIQ P5/A5/A5Pro.

The concerns listed below can seriously affect the safety of equipment and personnel during a diagnostic ultrasound examination.

Risk of explosion if used in the presence of flammable anesthetics.

To avoid injury:

• Do not remove protective covers. No user serviceable parts are inside. Refer servicing to qualified service personnel.

• To assure adequate grounding, connect the attachment plug to a reliable (hospital grade) grounding outlet.

• Never use any adaptor or converter of a three-prong-to-two-prong type to connect with a mains power plug. The protective earth

connection will loosen.

• Do not place liquids on or above the console. Spilled liquid may contact live parts and increase the risk of shock.

Safety

• Plug any peripherals into the LOGIQ P5/A5/A5 Pro AC powe r outle t.

Page 40

LOGIQ P5/A5/A5Pro Quick Guide Direction 5137113-100 Rev. 3 36

Biological

Related Hazards (continued)

CAUTION

Smoke &

Fire Hazard

Hazard

CAUTION

CAUTION

Do not use this equipment if a safety problem is known to exist. Have the unit repaired and performance verified by qualified service

personnel before returning to use.

The system must be supplied from an adequately rated electrical circuit. The capacity of the supply circuit must be as specified in

Chapter 3 of the Basic User Manual.

For patient and personnel safety, be aware of biological hazards while performing invasive procedures. To avoid the risk of disease

transmission:

• Use protective barriers (gloves and probe sheaths) whenever possible. Follow sterile procedures when appropriate.

• Thoroughly clean probes and reusable accessories after each patient examination and disinfect or sterilize as needed. Refer to

Probes and Biopsy in the Basic User Manual for probe use and care instructions.

• Follow all infection control policies established by your office, department or institution as they apply to personnel and equipment.

Contact with natural rubber latex may cause a severe anaphylactic reaction in persons sensitive to the natural latex protein. Sensitive

users and patients must avoid contact with these items. Refer to package labeling to determine latex content and FDA’s March 29, 1991

Medical Alert on latex products.

The system is equipped with an Auto Freeze feature which disables acou stic output and fr eeze s the image when th e system is not in use.

Take care when deactivating this feature.

CAUTION

Never put any device onto the monitor.

Page 41

LOGIQ P5/A5/A5Pro Quick Guide Direction 5137113-100 Rev. 3 37

Related Hazards (continued)

CAUTION

CAUTION

CAUTION

Archived data is managed at the individual sites. Performing data backup (to any device) is recommended on a daily basis.

Do not unpack the LOGIQ P5/A5/A5Pro. This must be performed by qualified service personnel only.

Do not use the LOGIQ P5/A5/A5Pro Ultrasound system ECG wave for diagnosis and monitorin g.

Safety

Page 42

LOGIQ P5/A5/A5Pro Quick Guide Direction 5137113-100 Rev. 3 38

Device Labels

Label Icon Description

The following table describes the purpose and location of safety labels and other important information provided on the equipment.

Table 1-2: Label Icons

Label/Icon Purpose/Meaning Location

Identification and Rating Plate Manufacture’s name and address

Date of manufacture

Model and serial numbers

Electrical ratings (Volts, Amps, phase, and frequency)

Type/Class Label Used to indicate the degree of safety or protection.

IP Code (IPX8) Indicates the degree of protection provided by the enclosure per IEC60 529. Can be used in operating room

environment.

Type CF Applied Part (heart in the box) symbol is in accordance with IEC 878-02-03. ECG marked Type CF

“ATTENTION” - Consult accompanying documents” is intended to alert the user to refer to the operator manual

or other instructions when complete information cannot be provided on the label.

!

“CAUTION” - Dangerous voltage” (the lightning flash with arrowhead) is used to indicate electric shock

hazards.

“Mains OFF” indicates the power off position of the mains power breaker. Refer to Chapter 3 in the Basic User Manual for

“Mains ON” indicates the power on position of the mains power breaker. Refer to Chapter 3 in the Basic User Manual for

See “Warning Label Locations” on page 51.

Foot Switch

Various

Inside of console

location information.

location information.

“ON” indicates the power on position of the power switch.

CAUTION: This Power Switch DOES NOT ISOLATE Mains Supply.

Refer to Chapter 3 in the Basic User Manual for

location information.

Page 43

LOGIQ P5/A5/A5Pro Quick Guide Direction 5137113-100 Rev. 3 39

Table 1-2: Label Icons

Label/Icon Purpose/Meaning Location

“Protective Earth” indicates the protective earth (grounding) terminal. Internal

“Equipotentiality” indicates the terminal to be used for connecting equipotential conductors when

interconnecting (grounding) with other equipment.

This symbol indicates that the waste of electrical and electronic equipment must not be disposed as unsorted municip al waste

and must be collected separately. Please contact an authorized representative of the manufacturer for information concerning

the decommissioning of your equipment

.

Rear of console

Rear of console.

Safety

Page 44

LOGIQ P5/A5/A5Pro Quick Guide Direction 5137113-100 Rev. 3 40

Classifications

Type of protection against electric shock

Class I Equipment (*1)

Degree of protection against electric shock

Type CF Applied part (*3)

(for ECG, Probes marked with CF symbol)

Continuous Operation

System is Ordinary Equipment (IPX0)

Footswitch is IPX8

*1. Class I EQUIPMENT

EQUIPMENT in which protection against electric shock does not rely on BASIC INSULATION only, but includes an earth ground. This additional safety precaution

prevents exposed metal parts from becoming LIVE in the event of an insulation failure.

*2. Type BF APPLIED PART

TYPE BF APPLIED PART providing a specified degree of protection against electric shock, with particular regard to allowable LEAKAGE CURRENT.

Table 1-3: Type BF Equipment

Normal Mode Single fault condition

Patient leakage current Less than 100 microA Less than 500 microA

*3. Type CF APPLIED PART

Type CF Applied Part providing a degree of protection higher than that for TYPE BF Applied Part against electric shock particularly regarding allowable LEAKAGE

CURRENTS.

Table 1-4: Type CF Equipment

Normal Mode Single fault condition

Patient leakage current Less than 10 microA Less than 50 microA

Page 45

LOGIQ P5/A5/A5Pro Quick Guide Direction 5137113-100 Rev. 3 41

EMC (Electromagnetic Compatibility)

NOTE: This equipment generates, uses and can radiate radio frequency energy. The equipment may cause radio frequency interference to other medical and nonmedical devices and radio communications. To provide reasonable protection against such interference, this product complies with emissions limits for a Group 1,

Class A Medical Devices Directive as stated in EN 60601-1-2. However, there is no guarantee that interference will not occur in a particular installation.

NOTE: If this equipment is found to cause interference (which may be determined by turning the equipment on and off), the user (or qualified service personnel)

should attempt to correct the problem by one or more of the following measure(s):

• reorient or relocate the affected device(s)

• increase the separation between the equipment and the affected device

• power the equipment from a source different from that of the affected device

• consult the point of purchase or service representative for further suggestions.

NOTE: The manufacturer is not responsible for any interference caused by using other than recommended interconnect cables or by unauthorized chang es or

modifications to this equipment. Unauthorized changes or modifications could void the users’ authority to operate the equipment.

NOTE: To comply with the regulations on electromagnetic interference for a Class A FCC Device, all interconnect cables to peripheral devices must be shielded

and properly grounded. Use of cables not properly shielded and grounded may result in the equipment causing radio frequency interference in violation of the FCC

regulations.

NOTE: Do not use devices which intentionally transmit RF Signals (cellular phones, transceivers, or radio-controlled products) in the vicinity of the equipment as it

may cause performance outside the published specifications. Keep the power to these types of devices turned off when near this equipment.

The medical staff in charge of this equipment is required to instruct technicians, patients, and other peopl e who maybe around this equipment to fully comply with the

above requirement.

EMC Performance

All types of electronic equipment may characteristically cause electromagnetic interference with other equipment, either transmitted through air or connecting

cables. The term EMC (Electromagnetic Compatibility) indicates the capability of equipment to curb electromagnetic influence from other equipment and at the same

time not affect other equipment with similar electromagnetic radiation from itself.

Proper installation following the service manual is required in order to achieve the full EMC performance of the product.

The product must be installed as stipulated in 4.2, Notice upon Installation of Product.

In case of issues related to EMC, please call your service personnel.

Safety

Page 46

LOGIQ P5/A5/A5Pro Quick Guide Direction 5137113-100 Rev. 3 42

The manufacturer is not responsible for any interference caused by using other th an recommended interconnect cables or by unauthorized changes or mod ifications

to this equipment. Unauthorized changes or modifications could void the users’ authority to operate the equipment.

CAUTION