Page 1

Instructions-Parts

Gateway Network

312785C

Communication Kits

Installation and program setup instructions for use with ProMix® 2KS Electronic

Proportioners. For professional use only.

Not approved for use in European explosive atmosphere locations.

See page 3 for kit information.

Important Safety Instructions

Read all warnings and instructions in this manual

and in your proportioning system manual. Save

these instructions.

EN

TI12933b

Page 2

Contents

Graco Gateway Kits . . . . . . . . . . . . . . . . . . . . . . . . . 3

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Graco Gateway Overview . . . . . . . . . . . . . . . . . . . . 5

Install the Gateway Module Hardware . . . . . . . . . . 5

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Connect the Module to the EasyKey . . . . . . . . . . 7

Cabling Connections . . . . . . . . . . . . . . . . . . . . . . 7

Mount the Control on DIN Rail . . . . . . . . . . . . . 11

Install CompactFlash

Install the GracoConfig Software . . . . . . . . . . . . . 12

System Requirements . . . . . . . . . . . . . . . . . . . . 12

Load the Software . . . . . . . . . . . . . . . . . . . . . . . 13

Software Updates . . . . . . . . . . . . . . . . . . . . . . . 13

Download the Preconfigured Database to the

Gateway Module . . . . . . . . . . . . . . . . . . . . . 14

Graco Gateway Network Communications

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . 15

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

GracoConfig Main Page . . . . . . . . . . . . . . . . . . 15

Setup the Database . . . . . . . . . . . . . . . . . . . . . 16

Map Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Modbus and I/O Data . . . . . . . . . . . . . . . . . . . . . . . 21

Start Mix Process . . . . . . . . . . . . . . . . . . . . . . . 21

Stop Mix Process . . . . . . . . . . . . . . . . . . . . . . . 21

Color Change Process . . . . . . . . . . . . . . . . . . . 21

Purge Process . . . . . . . . . . . . . . . . . . . . . . . . . 21

ProMix 2KS Active Alarms (Modbus Register

40010) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

ProMix 2KS Modbus/TCP Variable Map . . . . . . 30

ProMix 2KS Recipe Bits . . . . . . . . . . . . . . . . . . 31

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

General Troubleshooting . . . . . . . . . . . . . . . . . . 32

Graco Gateway Messages Troubleshooting . . . 35

Serial Communication Troubleshooting . . . . . . . 36

Ethernet Communication Troubleshooting . . . . 37

LED Functions . . . . . . . . . . . . . . . . . . . . . . . . . 38

System Electrical Schematic . . . . . . . . . . . . . . . . 39

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

15V331 Gateway Ethernet Kit (shown) . . . . . . . 40

15V963 Gateway DeviceNet Kit . . . . . . . . . . . . 40

15V964 Gateway Profibus Kit . . . . . . . . . . . . . . 40

®

Card . . . . . . . . . . . . . . . 11

Appendix A: DeviceNet

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

DeviceNet Port Protocols . . . . . . . . . . . . . . . . . 42

About DeviceNet . . . . . . . . . . . . . . . . . . . . . . . . 44

Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Automatic Update of the EDS File . . . . . . . . . . . 51

Configure the RSNetWorx for

DeviceNet Software . . . . . . . . . . . . . . . . . . 52

Configure the Allen Bradley ControlLogix PLC . 55

Wire the DeviceNet Network . . . . . . . . . . . . . . . 56

Appendix B: Profibus

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Profibus Port Protocols . . . . . . . . . . . . . . . . . . . 57

About Profibus DP . . . . . . . . . . . . . . . . . . . . . . . 58

Setup the PLC . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Graco Gateway Setup . . . . . . . . . . . . . . . . . . . . 66

Appendix C: Graco Gateway to ControlLogix via

Ethernet IP . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

ControlLogix Configuration . . . . . . . . . . . . . . . . 73

Graco Gateway Configuration . . . . . . . . . . . . . 77

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 82

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 82

™

Slave Communication 42

™

DP Slave Communication 57

2 312785C

Page 3

Graco Gateway Kits

Graco Gateway Kits

15V331 Gateway Ethernet Kit

Allows communication between ProMix 2KS and a PLC

over an ethernet. Enables process equipment to read

variables while operating, as well as control the ProMix

2KS and change setup. It does not provide access to job

and alarm logs.

15V963 Gateway DeviceNet Kit

Allows communication between ProMix 2KS and a PLC,

using DeviceNet process control. Enables process

equipment to read variables while operating, as well as

control the ProMix 2KS and change setup. It does not

provide access to job and alarm logs.

15V964 Gateway Profibus Kit

Allows communication between ProMix 2KS and a PLC,

using Profibus process control. Enables process equipment to read variables while operating, as well as control the ProMix 2KS and change setup. It does not

provide access to job and alarm logs.

Related Manuals

Component Manuals in English

Manual Description

312778 ProMix 2KS Automatic System

Installation

312779 ProMix 2KS Automatic System

Operation

312780 ProMix 2KS Automatic System

Repair-Parts

313386 Basic Web Interface/Advanced Web

Interface

312785C 3

Page 4

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual, refer back to these Warnings. Product-specific hazard symbols and

warnings not covered in this section may appear throughout the body of this manual where applicable.

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can cause

electric shock.

• Turn off and disconnect power at main switch before disconnecting any cables and before servicing

equipment.

• Connect only to grounded power source.

• All electrical wiring must be done by a qualified electrician and comply with all local codes and

regulations.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information

about your material, request MSDS forms from distributor or retailer.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

4 312785C

Page 5

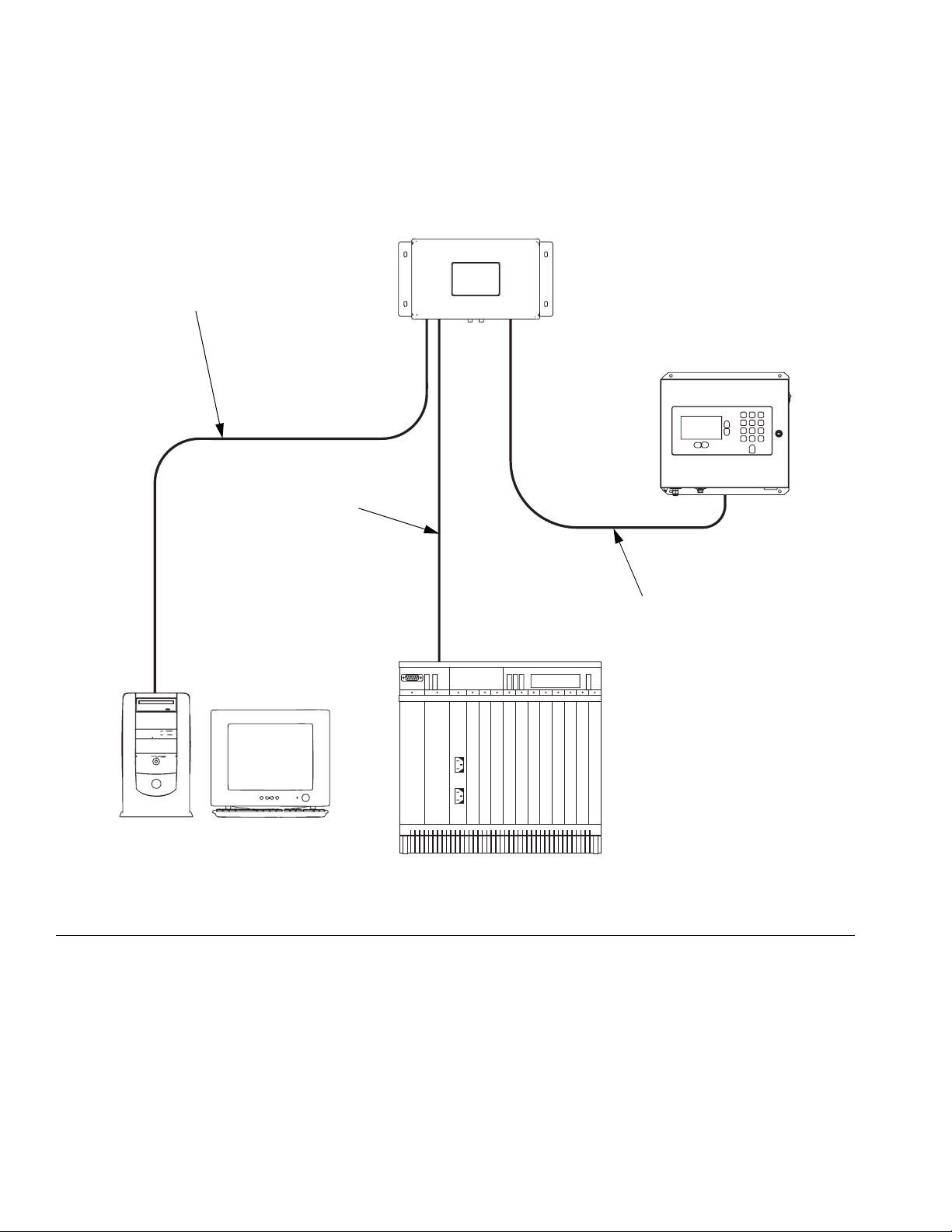

Graco Gateway Overview

Graco Gateway Overview

The Graco Gateway enables the ProMix 2KS to network

with a programmable logic controller (PLC). Kits are

available for Ethernet, DeviceNet, or Profibus protocols.

The Graco Gateway will support many other protocols;

contact Graco Technical Assistance for information to

support your desired protocol.

NOTE: Only persons very familiar with their PLC communication architecture should use this hardware and

software. This manual assumes that the person using

the Graco Gateway has full understanding of the PLC

equipment and related software.

NOTE: Network communications essentially operate

with the same rules as Discrete I/O. However, network

communications require placing correct values or

adjusting appropriate bits within various Modbus registers (for example, see Table 4). These changes should

only be made by qualified persons familiar with this type

of communication.

The module allows for most PLCs to communicate with

the ProMix 2KS via Modbus RTU protocol by bridging

the gap between the desired communication protocol

and RS485 Modbus RTU. As a result, the PLC has full

access to all the registers for monitoring and controlling

the ProMix 2KS. It is the responsibility of the integrator

or user to ensure proper configuration of the communication hardware on the PLC side.

Install the Gateway Module Hardware

Location

This equipment is not for use in explosive atmospheres. Do not install equipment approved only for

non-hazardous location in a hazardous area.

Install the Gateway module near the EasyKey™, in a

non-hazardous area.

Mounting

1. See Dimensions, page 79.

2. Ensure that the wall and mounting hardware are

strong enough to support the weight of the equipment, cables, and stress caused during operation.

3. Using the equipment as a template, mark the

mounting holes on the wall at a convenient height

for the operator and so equipment is easily accessible for maintenance.

4. Drill mounting holes in the wall. Install anchors as

needed.

5. Bolt equipment securely.

Grounding

Your system must be grounded. Read Warnings,

page 4.

The Gateway module is grounded through its connection to the EasyKey, which must be connected to a true

earth ground. See the system installation manual. A

ground wire and clamp, part no. 223547, is available

from Graco.

312785C 5

Page 6

Install the Gateway Module Hardware

USB Cable

(included), for initial

setup only

PLC Communication

Wire/Cable

(protocol dependent)

NON-HAZARDOUS AREA

Graco Gateway

Module

EasyKey

Computer (PC)

FIG. 1: Graco Gateway Typical Installation

2-wire twisted

pair cable, with

shield wire

TI13939a

Programmable Logic Controller (PLC)

6 312785C

Page 7

Connect the Module to the EasyKey

FIG. 1 is only a guide showing installation of the Graco

Gateway in a ProMix 2KS System; it is not a complete

system design, Contact your Graco distributor for assistance in designing a system to suit your particular

needs.

Install the Gateway Module Hardware

1. Shut off ProMix 2KS power (0 position). F

shut off power at main circuit breaker.

F

IG. 2: Power Off

2. Connect a 2-wire twisted pair cable with shield wire

from the EasyKey connector to the connector on the

Gateway module. Connect a communications

wire/cable (protocol dependent) from the Gateway

module to the PLC. See F

IG. 3.

IG. 2. Also

0 = OFF

TI12657a

NOTE: Graco provides expansion cards for DeviceNet

and Profibus protocols. DeviceNet setup procedures are

on page 42. Profibus setup procedures are on page 57.

See page 40 for Parts.

NOTE: If using the Graco Gateway in your system, disconnect its cable from the EasyKey before updating the

ProMix 2KS software.

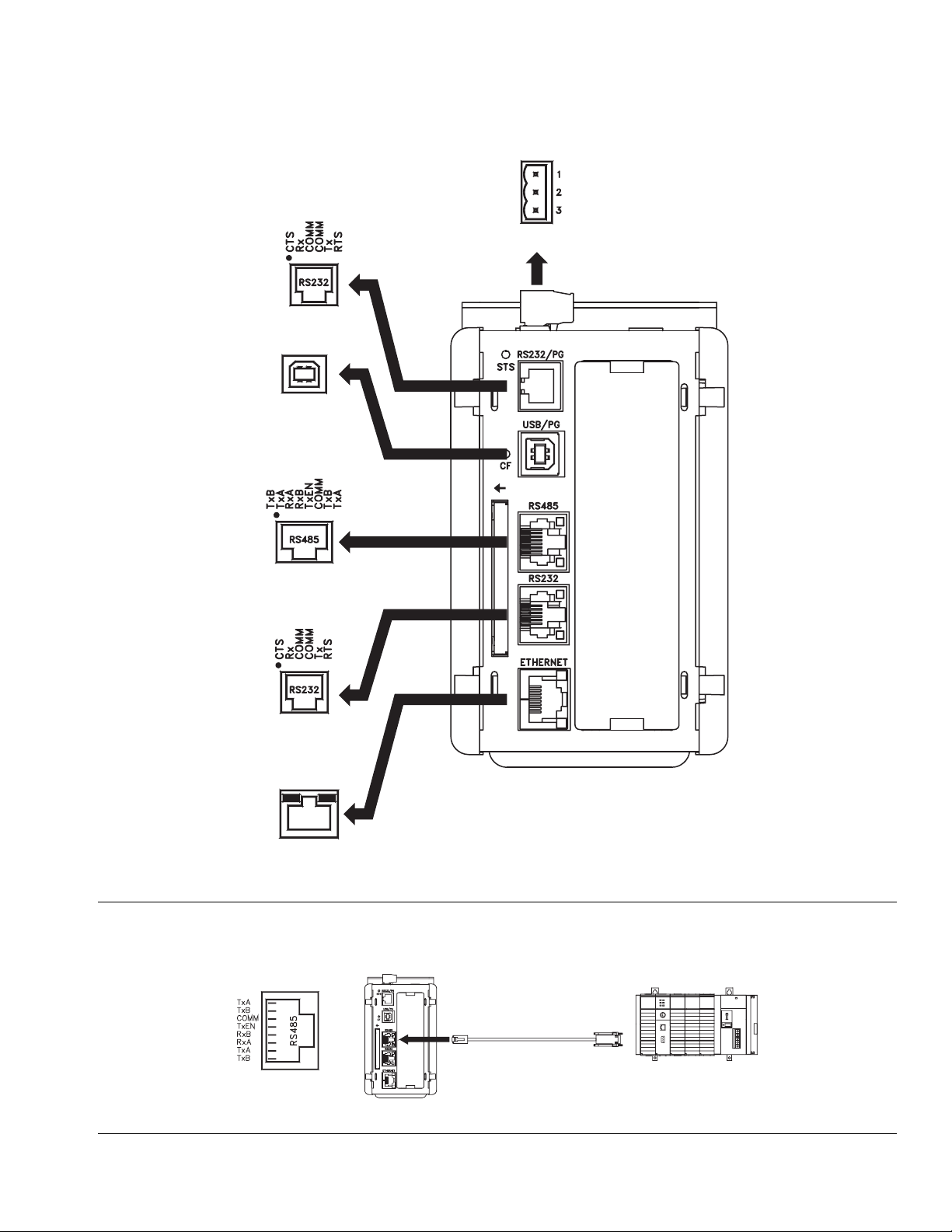

Cabling Connections

See FIG. 4 and FIG. 5 for typical cable connections in a

ProMix 2KS system.

F

IG. 6 through FIG. 9 show other possible cable connec-

tions.

312785C 7

Page 8

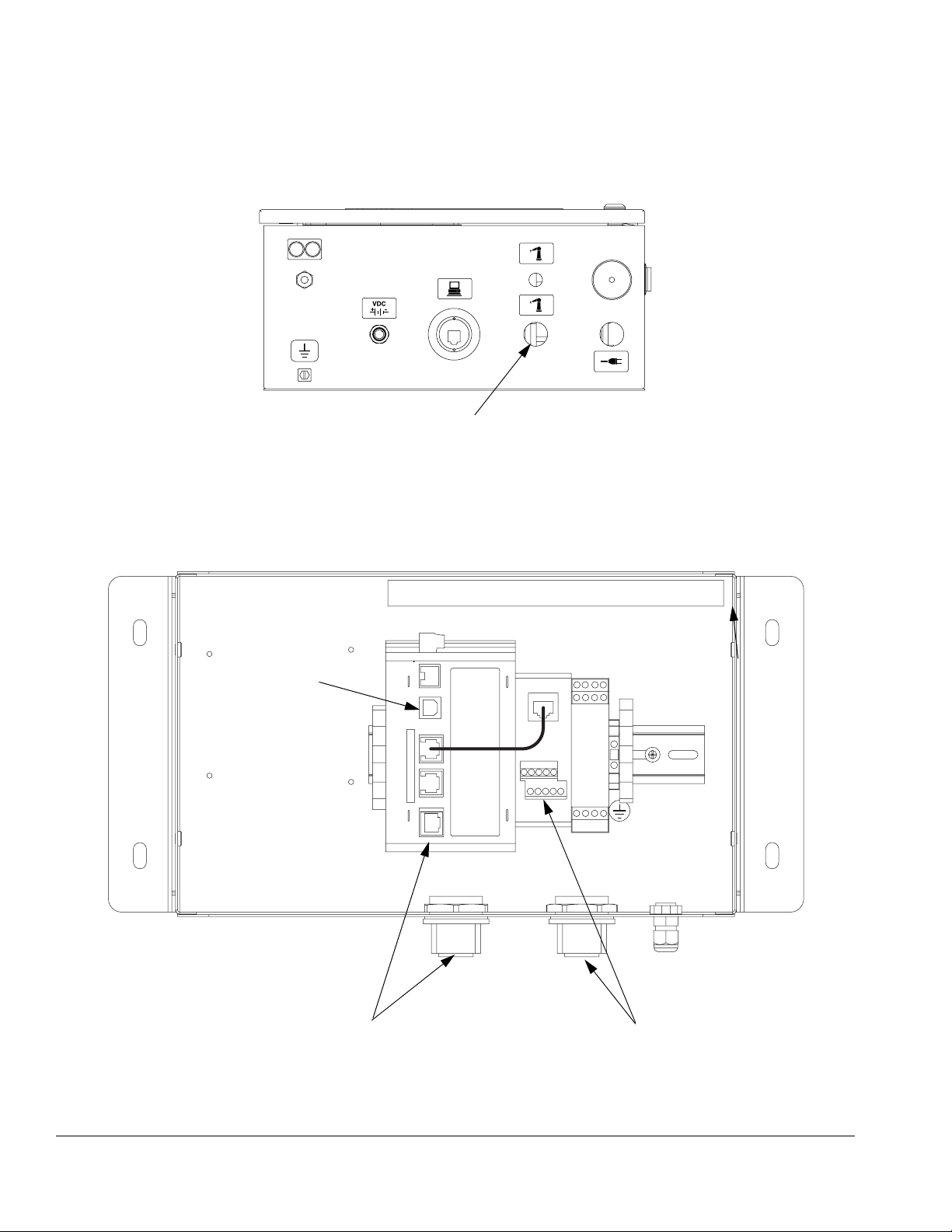

Install the Gateway Module Hardware

2-wire twisted pair cable, with

shield wire (to Gateway Module)

EasyKey (Bottom View)

TI12638a

USB Port

Gateway Module

TI12930a

Communication Wire/Cable (to PLC).

This connection is protocol dependent.

2-wire twisted pair cable, with

shield wire (to EasyKey). See

Wiring Diagrams on page 41

for pin connections.

FIG. 3: EasyKey and Module Cable Connection Points

8 312785C

Page 9

Pin 1

RS232/PG

USB/PG

Install the Gateway Module Hardware

Common

24 Vdc +/- 10%

Pin 6

N/C

Power Connector

Pin 1

Pin 8

COMMS

Pin 1

Pin 6

COMMS

Green/

Amber

LED

Ye l l o w

LED

ETHERNET (NIC)

FIG. 4: Graco Gateway Port Pin Outs

Expansion

Port

TI13974a

TI13972a

FIG. 5: RS485 Communication Port (Typical ProMix 2KS Connection)

312785C 9

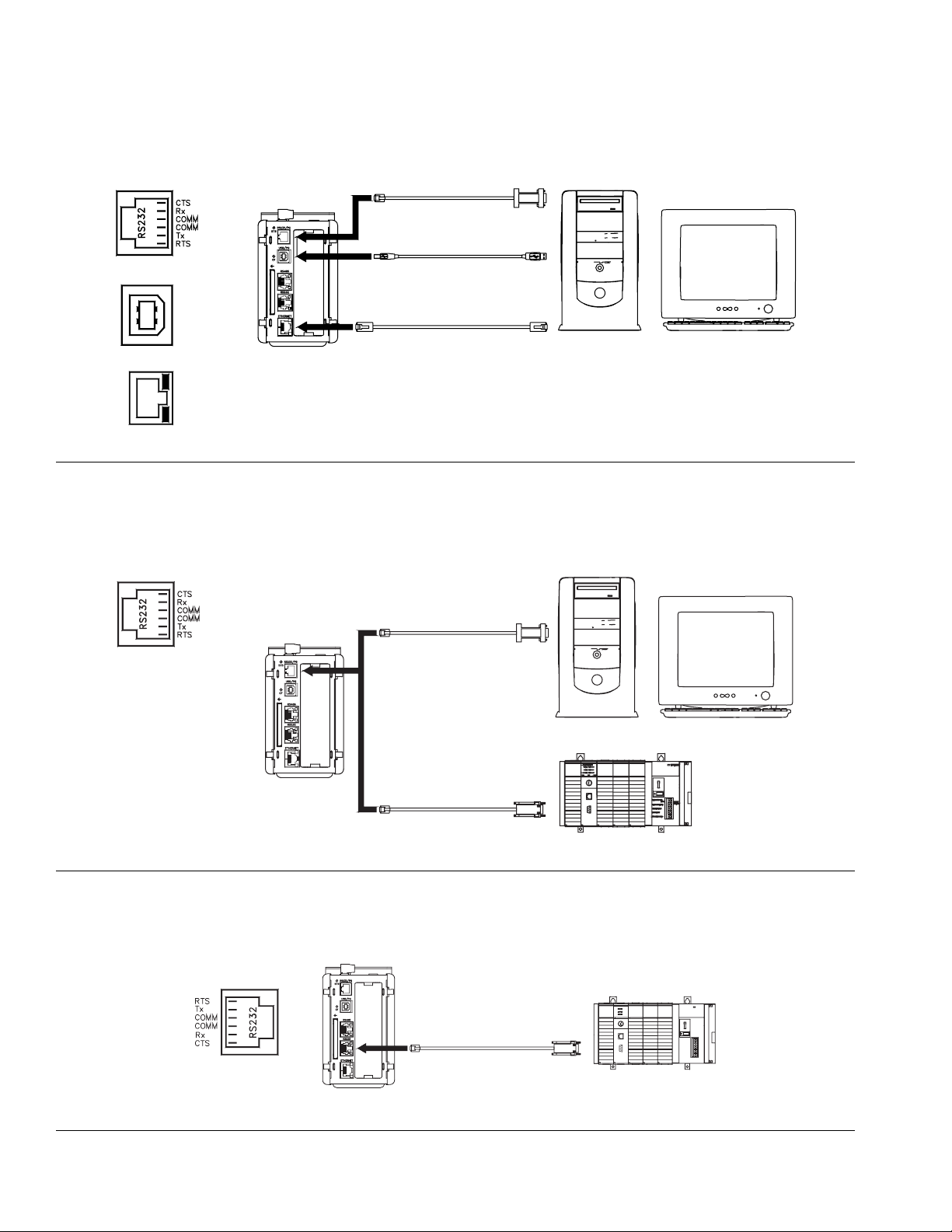

Page 10

Install the Gateway Module Hardware

RS232/PG

USB/PG

OR

OR

ETHERNET

Green/Amber LED

Yellow LED

FIG. 6: Programming Ports

RS232/PG

TI13969a

OR

TI13970a

FIG. 7: RS232/PG Communication Ports

RS232

TI13971a

F

IG. 8: RS232 Communication Ports

10 312785C

Page 11

ETHERNET

F

IG. 9: Ethernet Connection

Install the Gateway Module Hardware

Green/Amber

LED

Yel low LE D

Standard Ethernet Cable

TI13973a

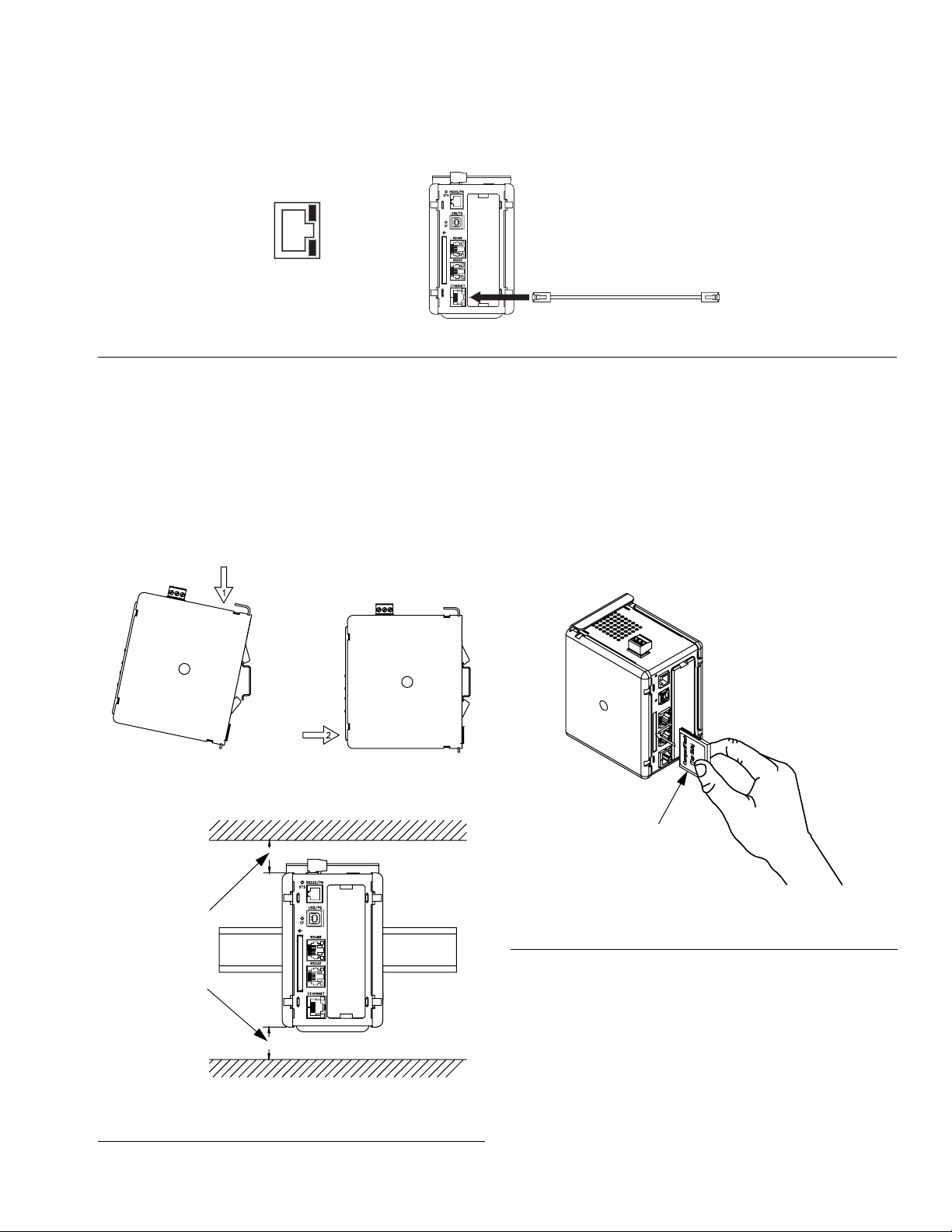

Mount the Control on DIN Rail

The Gateway control mounts on a DIN rail. Tilt the control and push down onto the DIN rail, then push in. See

F

IG. 10. A minimum clearance of 1 in. (25 mm) above

and below the control is required to ensure adequate

ventilation.

TI13965a

1 in. (25 mm)

minimum

clearance top

and bottom

Install CompactFlash® Card

The CompactFlash socket accepts either Type I or Type

II cards. These cards are available at most computer

and office supply retailers. Use cards with a minimum of

4 Mbytes and a maximum of 2 Gbytes. Use the CompactFlash card for optional database storage only. See

F

IG. 11.

Insert card with top side

on the left. Do not insert

or remove card while

power is applied.

FIG. 11: Install a CompactFlash Card

TI13967a

TI13966a

FIG. 10: Mount the Control on a DIN Rail

312785C 11

Page 12

Install the GracoConfig Software

Install the GracoConfig Software

GracoConfig software provides access to the Graco

Gateway module hardware. The CD provided contains

the GracoConfig software (GracoConfigXXX.exe, where

the XXX represents the version control number). It also

includes a preconfigured database which is essentially a

setup file for the Gateway. The database file has a .gg2

extension.

The Graco Gateway provides conversions for many protocols, including the following:

• All Allen-Bradley protocols

• DeviceNet

• Ethernet TCP/IP

• Ethernet IP

• Mitsubishi

• Modbus (ASCII, RTU)

•Profibus

•Siemens

NOTE: Graco provides expansion cards for DeviceNet

and Profibus protocols. DeviceNet setup procedures are

on page 42. Profibus setup procedures are on page 57.

See page 40 for Parts.

System Requirements

GracoConfig software will run on PCs with the following

specifications:

• A Pentium class processor as required by the chosen operating system.

NOTE: GracoConfig software will operate with all

versions of Microsoft

dows 2000 or above is recommended for more

robust operation.

• RAM and free disk space as required by the chosen

operating system.

• An additional 50MB of disk space for software

installation.

• A display of at least 800 by 600 pixels, with 256 or

more colors.

• USB port for downloading a configured database to

the Gateway module.

®

Windows 98 and above. Win-

NOTE: Contact your Graco distributor or Graco Technical Assistance for information regarding additional supported protocols.

12 312785C

Page 13

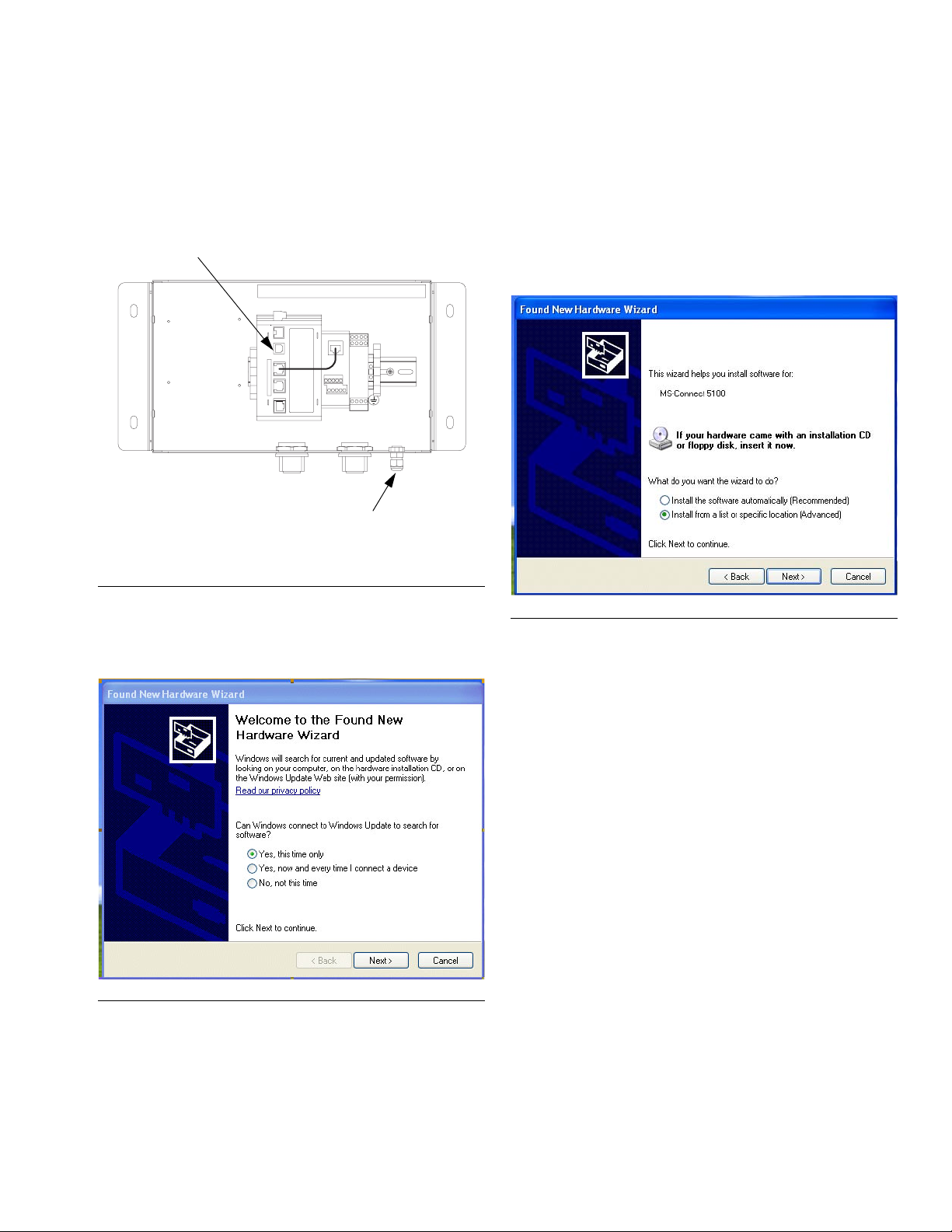

Load the Software

1. Connect the USB cable (23, supplied) between the

USB port on the Gateway module and a USB port

on your PC. See F

USB Port

IG. 12.

TI12930a

USB Cable Strain Relief

Install the GracoConfig Software

IG. 14 will appear. Insert the CD in your PC’s

3. F

CDROM drive. Select “Install the software from a list

or specific location”, then click Next. The program

location is C:\Program Files\Graco\GracoConfig\Device.

NOTE: The name of the driver may be different. Just

accept the name and proceed by following the

instructions on the screen.

F

IG. 12: Gateway Module USB Port

2. F

IG. 13 will appear. Select “Yes, this time only”, then

click Next.

F

IG. 13: Found New Hardware Screen

FIG. 14: Load Software from a Specific Location

Software Updates

Contact your distributor or Graco Technical Assistance

for software updates.

312785C 13

Page 14

Install the GracoConfig Software

Download the Preconfigured Database to the Gateway Module

Graco supplies a preconfigured database as a setup file

for the Gateway, containing parameters which communicate between the Gateway and the ProMix 2KS. The file

name has a .gg2 extension.

GracoConfig files are downloaded to the Gateway module using the Link menu. The programming link between

the PC and the Gateway module uses the USB cable.

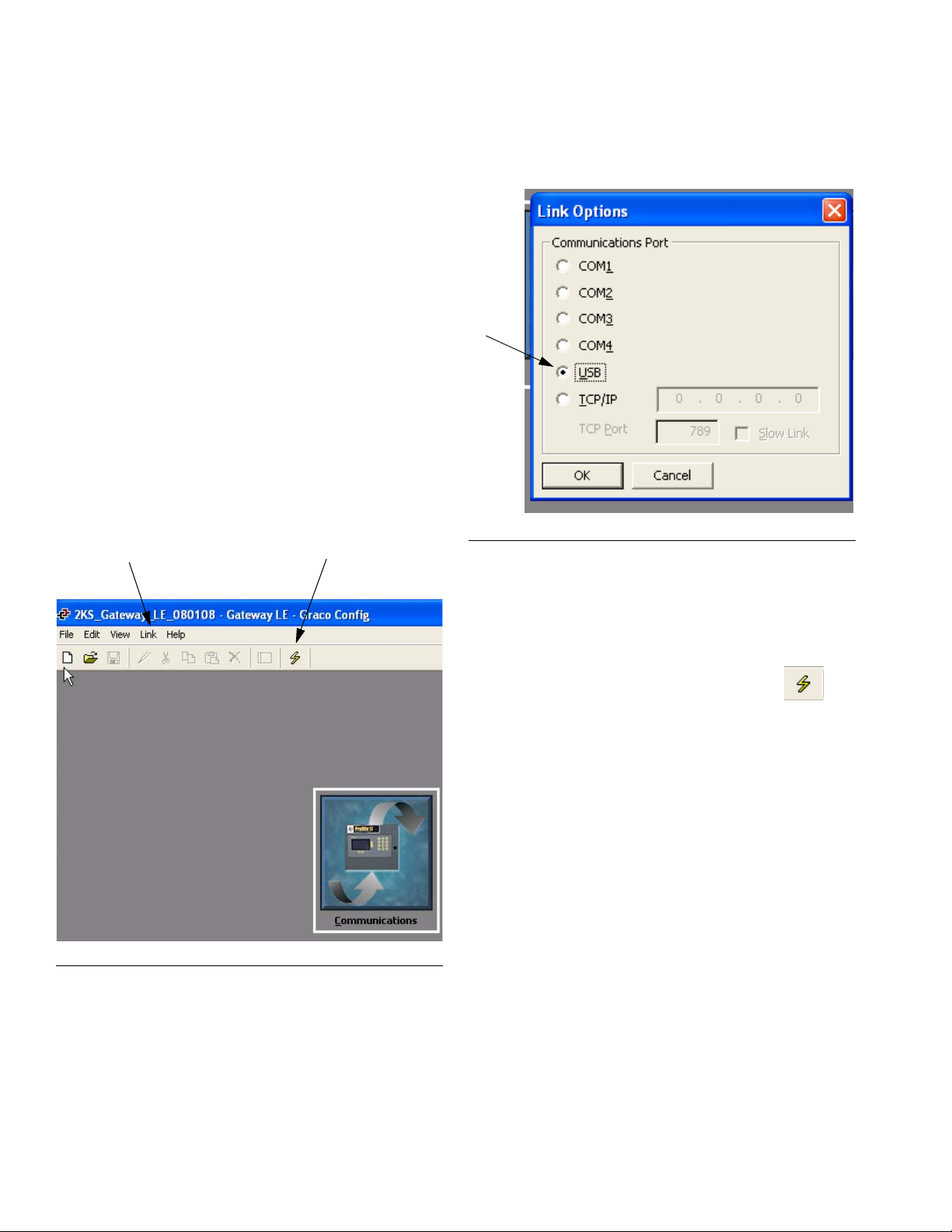

Before downloading, check that the Communications

Port is set to USB, as follows.

NOTE: During programming the Gateway module may

ask for an updated driver. Follow the instructions on the

screen to automatically find and select the drivers.

1. Go to Start>Programs>Graco>GracoConfig and run

the program. The GracoConfig main page will

appear.

Link Pulldown Menu Update Symbol

2. Using the Link pulldown menu, select Options to

open the Link Options window. Check that the Com-

munications Port is set to USB, and click OK.

IG. 16: Set Communications Port to USB

F

F

IG. 15: GracoConfig Main Page

3. Go to File>Open and select the file with the xx.gg2

extension. The file name should appear at the top of

the window (F

4. Download the database using the Link>Update

command. As a shortcut, use the Update

symbol on the toolbar. See F

NOTE: Downloading typically takes only a few seconds but may take longer if the software has to

update firmware on the Gateway module.

IG. 15) once loaded.

IG. 15.

14 312785C

Page 15

Graco Gateway Network Communications Configuration

Graco Gateway Network Communications

Configuration

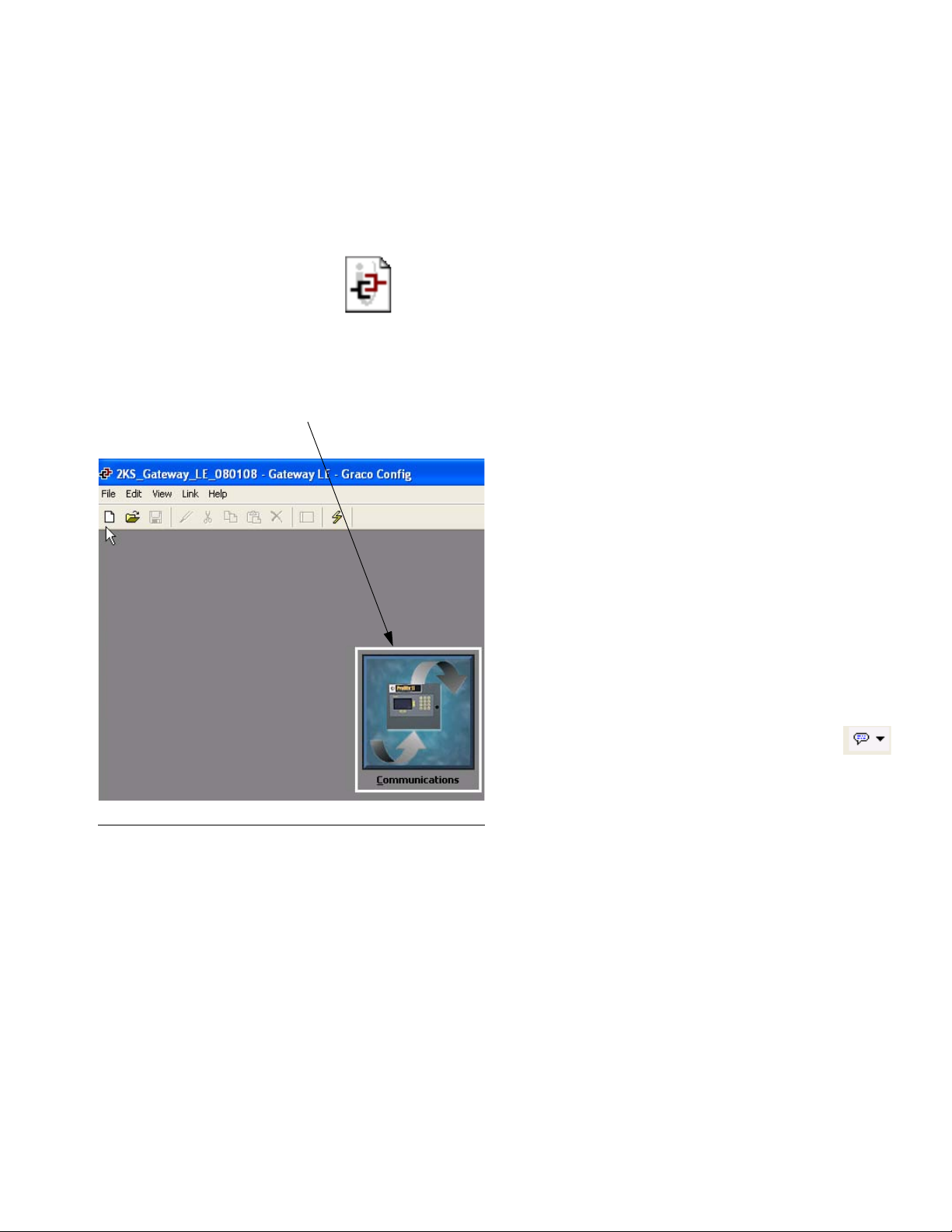

Startup

To run GracoConfig, select the icon from the

Graco folder on the Programs section of your Start

Menu. The main page will appear, showing the Commu-

nications button.

Communications Button

GracoConfig Main Page

Communications Button

The Communications button provides access to screens

used to configure your system and setup parameters,

allowing you to:

• Specify which protocols are to be used on the Gateway serial ports and on the Ethernet port.

• If using master protocols (ie., protocols by which the

Gateway initiates data transfer to and from a remote

device), you can specify one or more devices to be

accessed.

• If using slave protocols (i.e., protocols by which the

Gateway receives and responds to requests from

remote devices or computer systems), you can set

read or write access for specific data items.

• Move data between one remote device and another.

Balloon Help

F

IG. 17: Communications Button

The Balloon Help feature allows you to see help information for each icon in the main menu, or for each field

in a dialog box or window. It is controlled via the

icon at the right-hand edge of the toolbar. Balloon Help

has three user-selectable modes:

• Do Not Display disables balloon help

• When Mouse Over displays help when the mouse

pointer is held over a particular field for a certain

period of time

• When Selected displays help constantly for the currently selected field.

312785C 15

Page 16

Graco Gateway Network Communications Configuration

Setup the Database

1. Double-click on the Communications button to open

the preconfigured database (.gg2). The file is

already setup for ProMix 2KS. See F

IG. 18.

F

IG. 18: Preconfigured Database

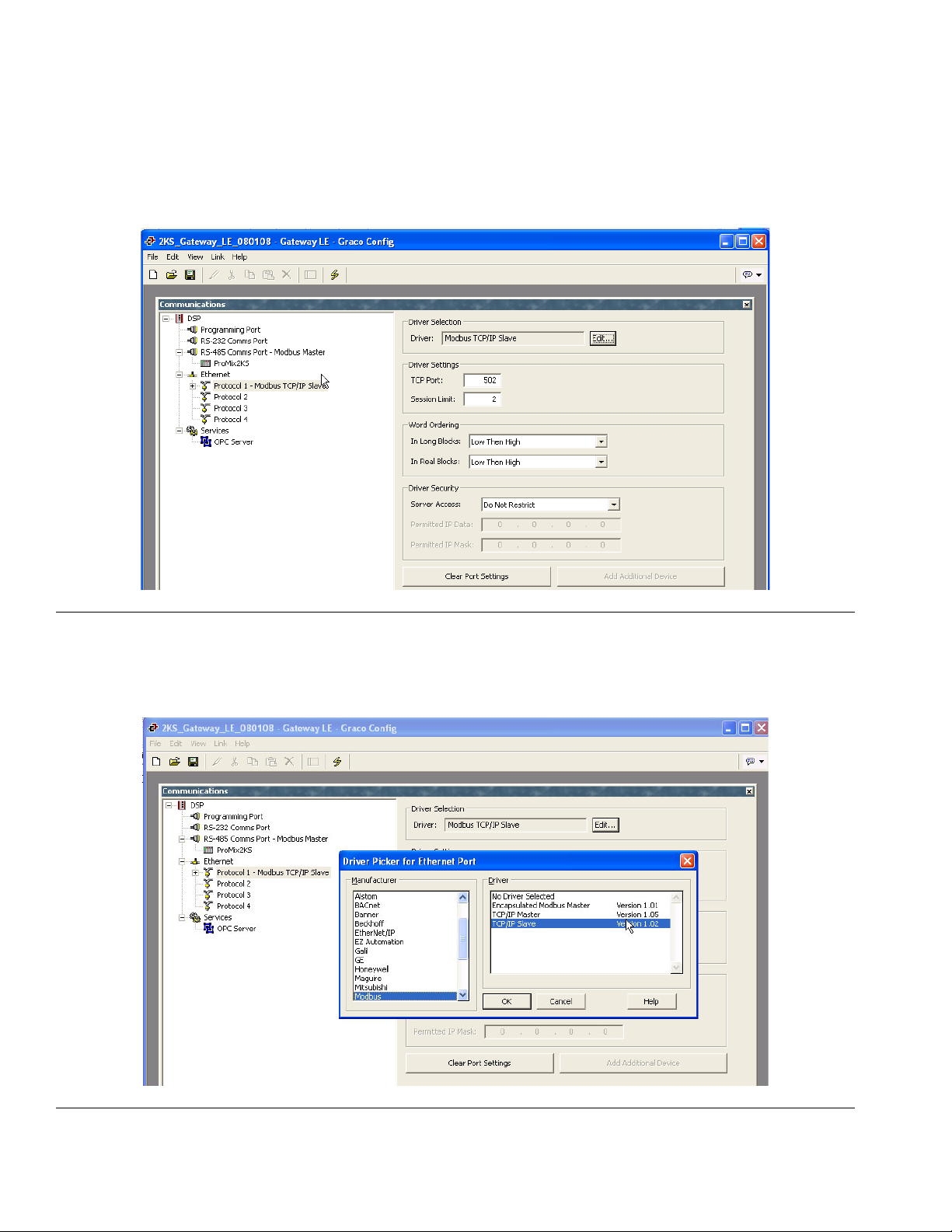

2. See F

IG. 19. Highlight Protocol 1. Click the Edit but-

ton on the right side of the window to open the

Driver Picker window. Choose a protocol from the

lists provided, in this example Modbus and TCP/IP

Slave. The system will create device PLC1.

FIG. 19: Select Protocol

16 312785C

Page 17

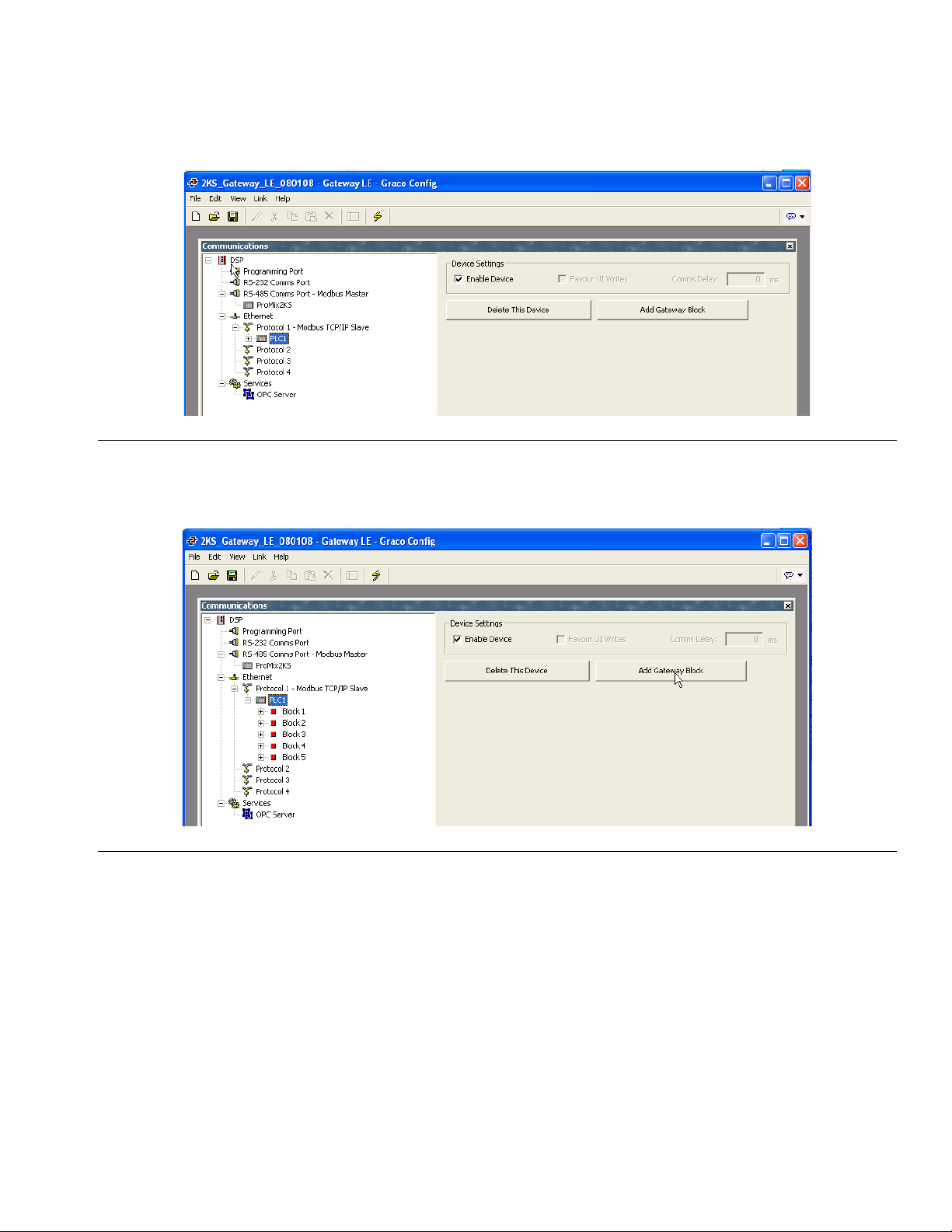

3. See FIG. 20. Right click on device PLC1 to rename it

to something meaningful for your system.

F

IG. 20: Rename PLC1

Graco Gateway Network Communications Configuration

4. See F

IG. 21. Add as many Gateway blocks as

desired under each device.

FIG. 21: Add Gateway Blocks

312785C 17

Page 18

Graco Gateway Network Communications Configuration

Map Data

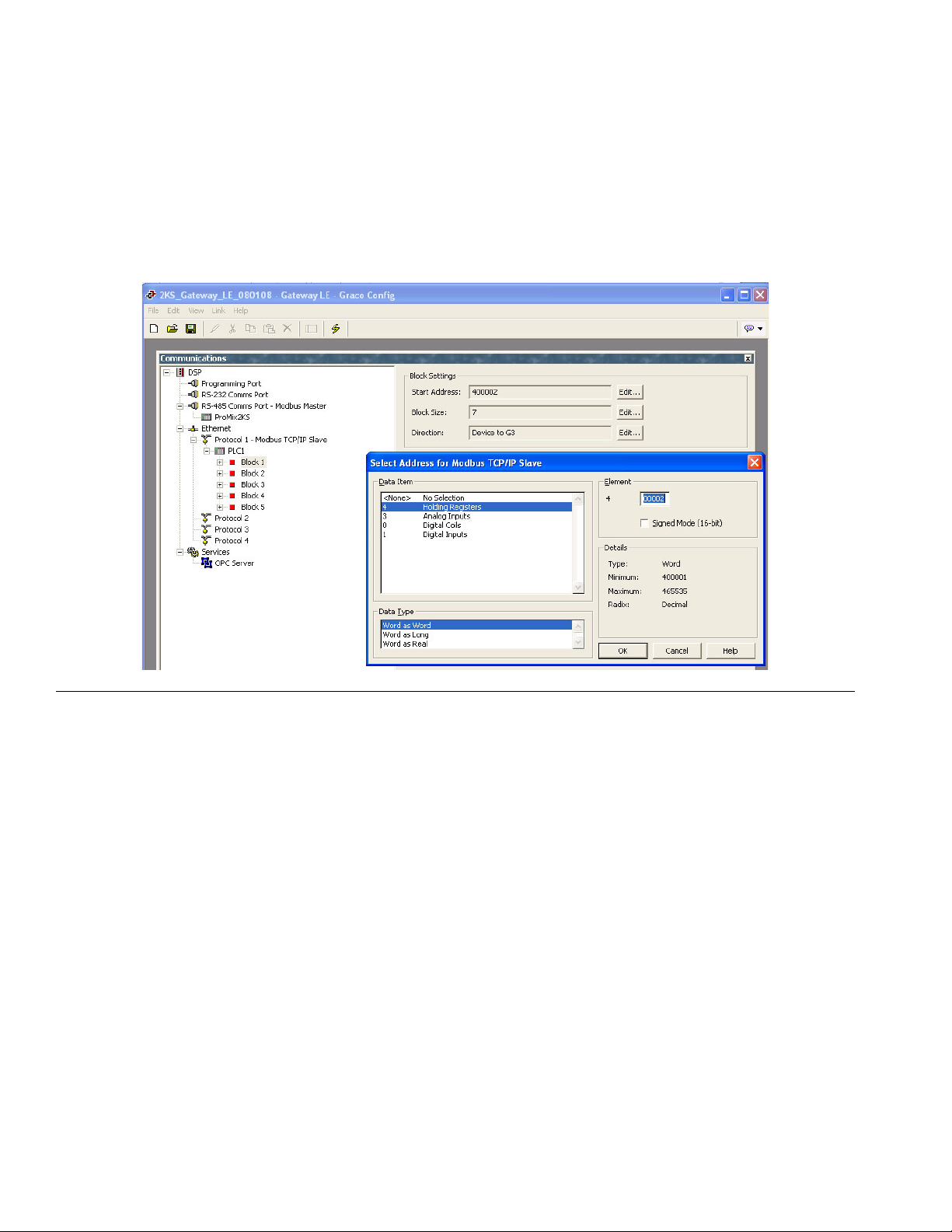

1. See FIG. 22. Select the block for data mapping. Click

the Edit button next to the Start Address field on the

right side of the window. The Select Address window will open.

2. Refer to Table 4 on page 30 for a Modbus map.

Select the desired Modbus register address as a

starting point (in this case 40002). Enter the appropriate values in the Select Address window and click

OK. The desired register address will populate the

Start Address field.

F

IG. 22: Mapping Gateway Blocks

18 312785C

Page 19

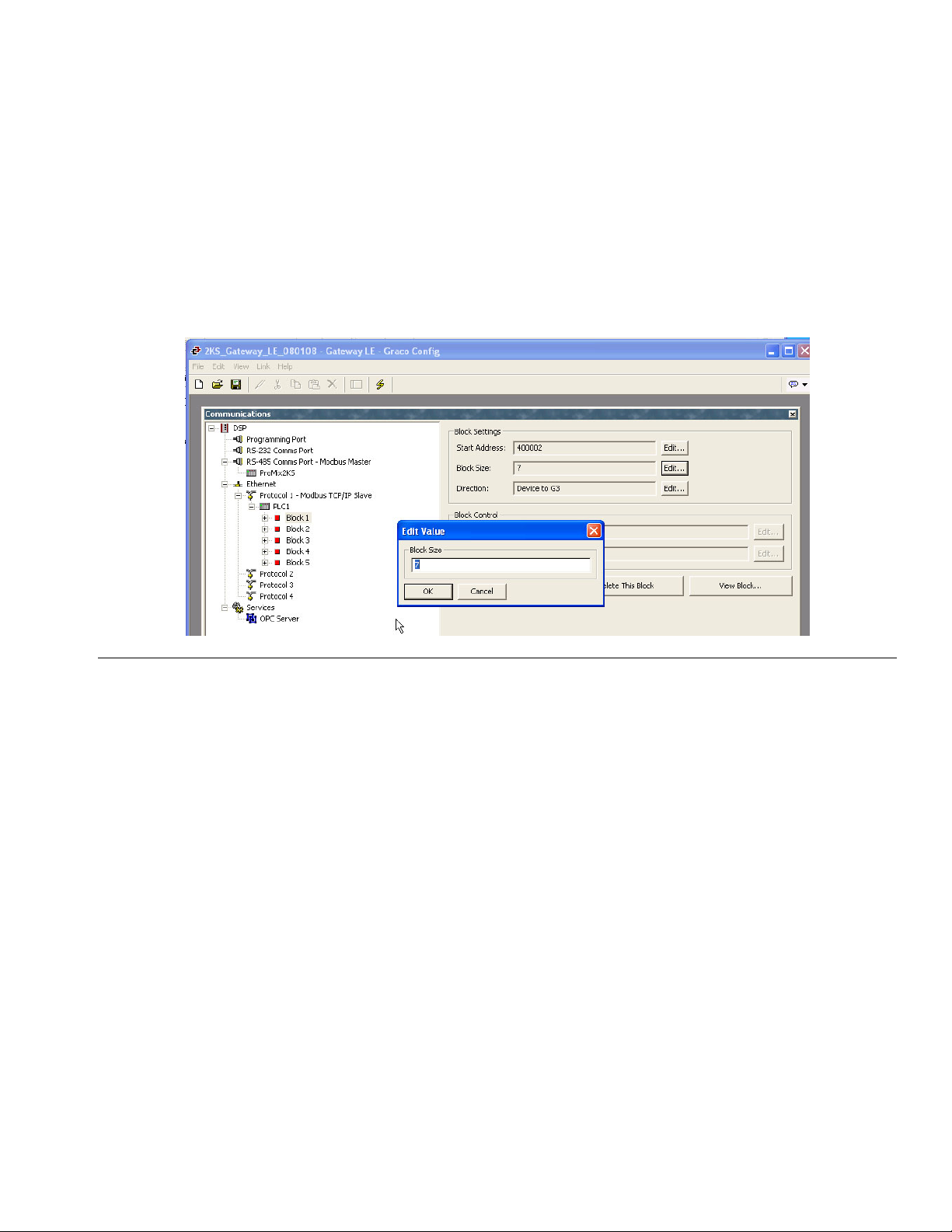

3. See FIG. 23. Click the Edit button next to the Block

Size field on the right side of the window. The Edit

Value window will open. Enter the number of Modbus register addresses in the range from the starting address entered in step 2 to the desired ending

address, inclusive. In this example, 7. The

addresses must be contiguous. This means that

each address must be available and addressable

from the ProMix 2KS. If one of the 7 addresses does

not exist within the ProMix 2KS Modbus structure,

the complete block will not communicate.

Graco Gateway Network Communications Configuration

F

IG. 23: Setting Block Size

312785C 19

Page 20

Graco Gateway Network Communications Configuration

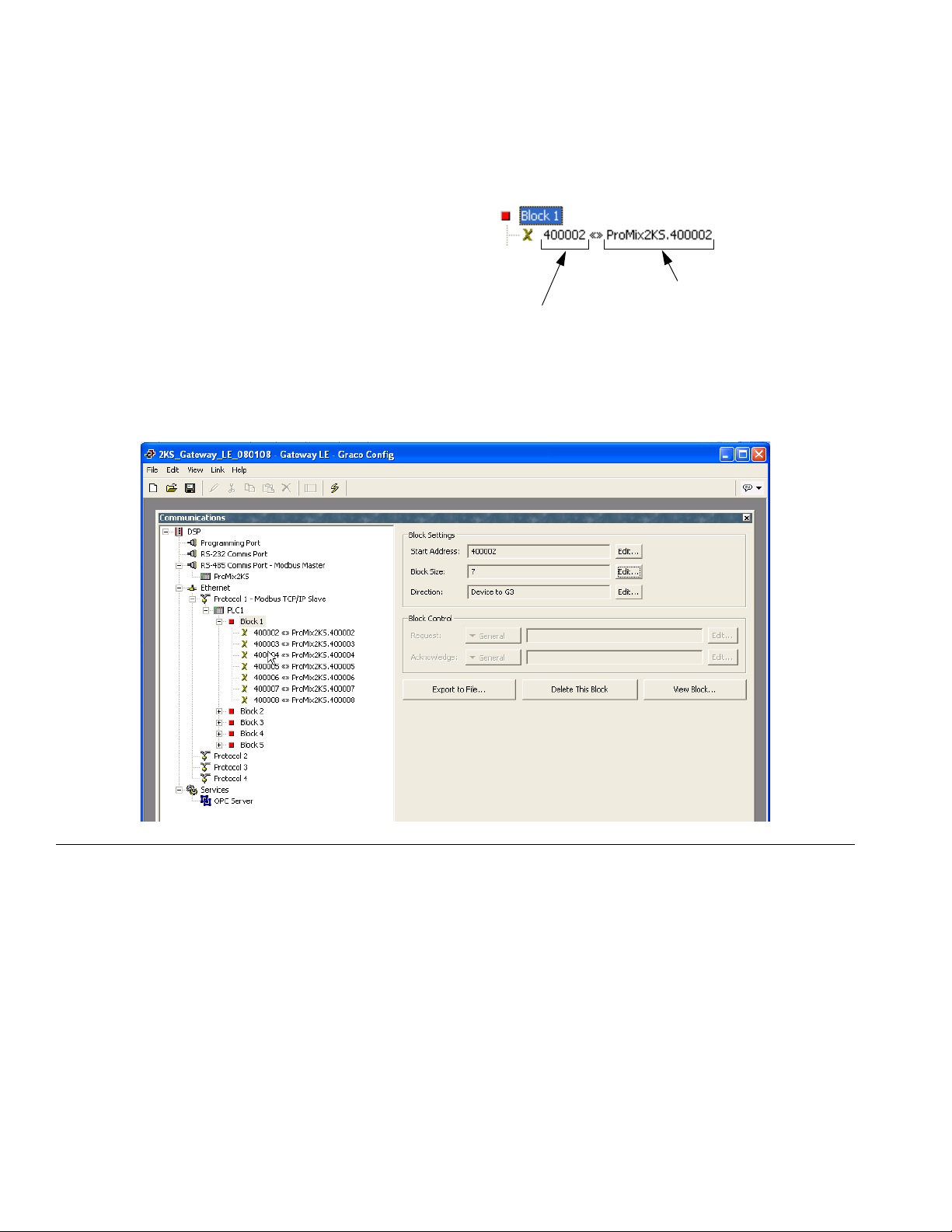

4. See FIG. 24. Click OK. The range of addresses will

appear under the appropriate Block on the left side

of the window.

NOTE: In this example, a Modbus device master

communicating via TCP/IP will have direct access to

Modbus registers 40002 through 40008 of the ProMix 2KS.

For example, see Block 1 address line 1:

Modbus address

Modbus address (command)

from TCP/IP master

connected to Gateway.

of ProMix 2KS.

5. The Direction field typically should remain set to

Device to G3.

FIG. 24: Block Mapping Data

20 312785C

Page 21

Modbus and I/O Data

Modbus and I/O Data

See Table 4 through Table 5 for Modbus register

addresses and input/output data.

Reference the Discrete I/O listing of all the inputs and

outputs (see page 30). Ensure these are fully understood. The same implementation used for Discrete I/O is

used for the Network communication protocol.

For example: The Gun Trigger Input will now be a specific bit of Modbus Register 40040. Monitoring of Modbus Register 40041 for specific output status conditions

will be required as explained in the Discrete I/O section

of the ProMix 2KS Operation manual. The PLC will have

to read the various bits, and in some cases (40040 and

40041 for example) must mask out the various bit positions to determine each of the separate input and output

statuses. This requires experience and should not be

done on the job site. A full understanding of the color

change process as well as the required timing of various

inputs and outputs is required.

NOTE: Analog input for flow control set point will now be

a dedicated Modbus register. Register 40137 will

require the specific flow rate (i.e. 125 cc/min). This is

not a voltage reading but the actual flow target.

2. The Mix Active output should clear and Mix Ready

should now be set.

NOTE: The ProMix 2KS will automatically go into Idle

mode after 2 minutes of inactivity. A general alarm will

be present and Mix Active will remain High. The Alarm

bit (40010) will indicate the system Idle alarm. When a

new Gun Trigger input is seen, the ProMix 2KS will

resume mixing material where it left off. Do not toggle

the Mix bit; doing so restarts the Mix process from the

beginning.

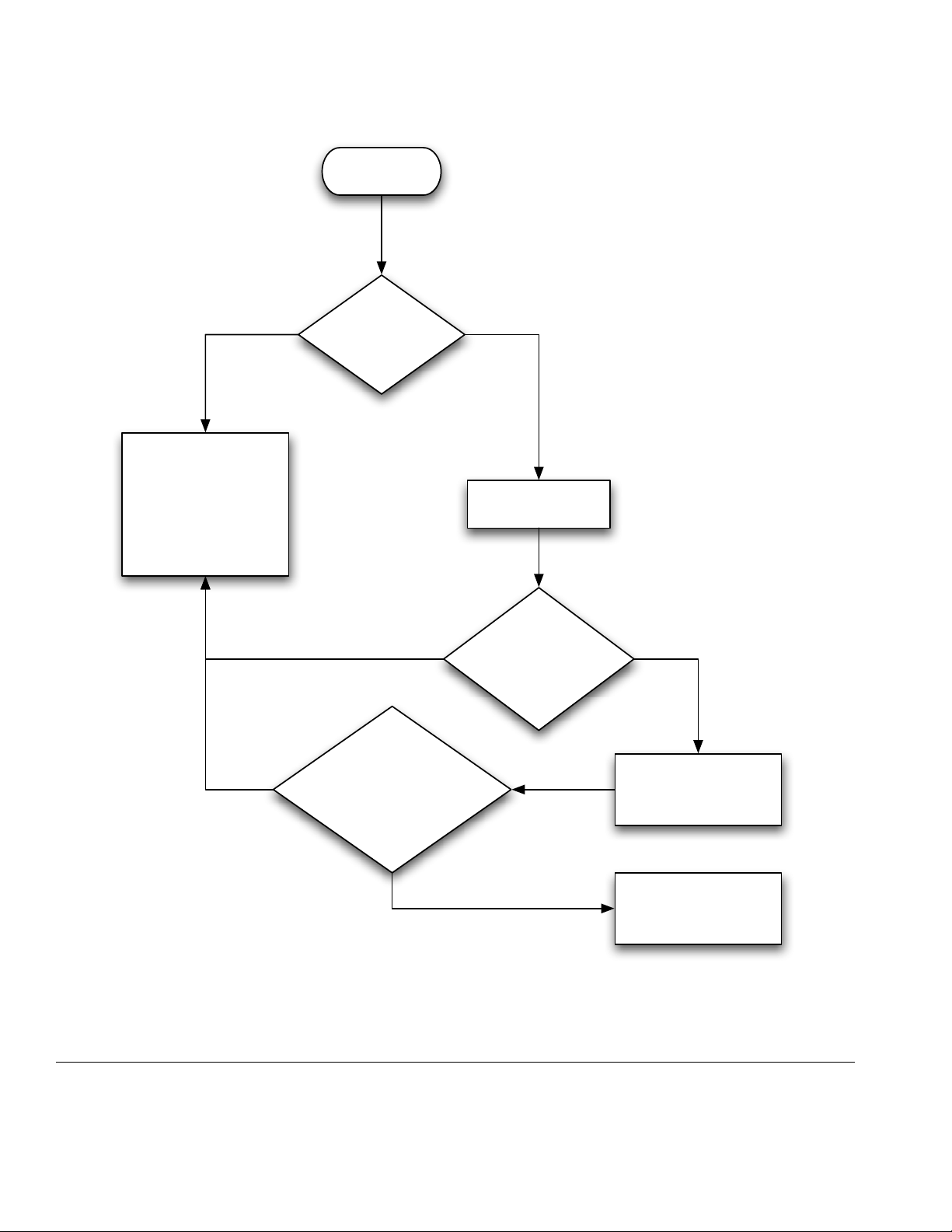

Color Change Process

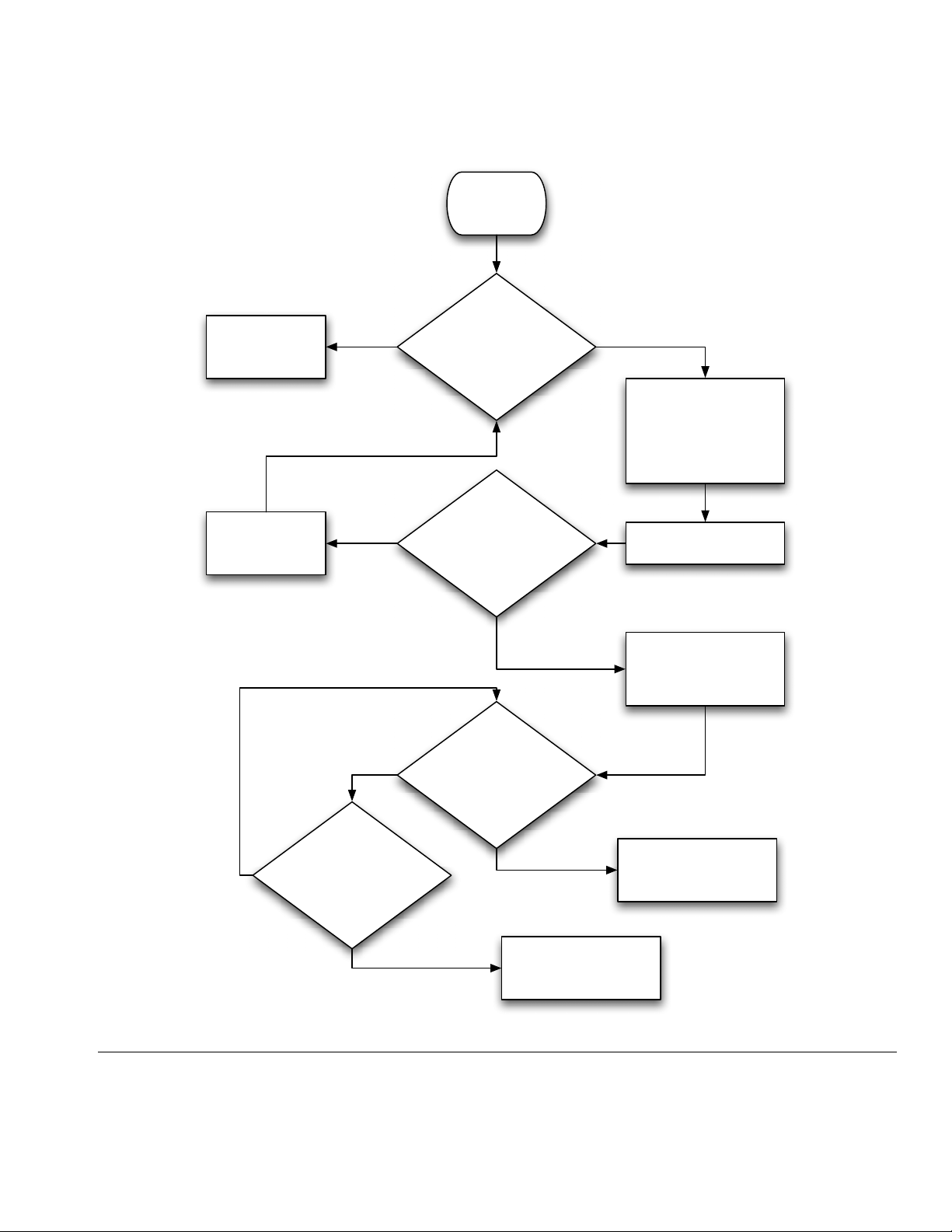

See FIG. 28, Table 1, and Table 2.

1. Verify that Mix Ready is set. This ensures that there

are no alarms and that the system is ready for the

next command.

2. Load ccNewRecipe (Modbus 40046) with a recipe

number to color change to.

3. Set color change (40040 bit 6).

4. Verify that Purge_CC_Active is seen (40041 bit 0).

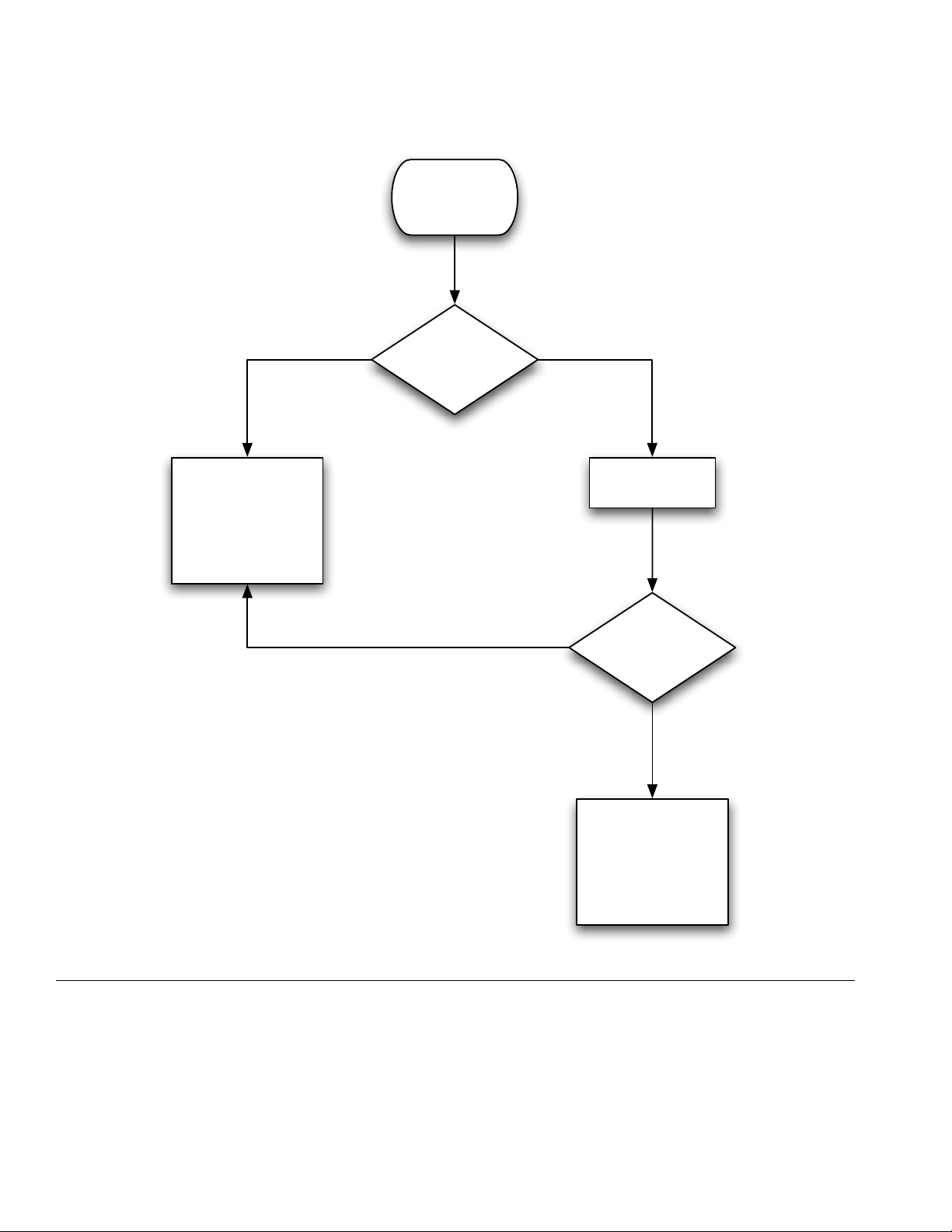

Start Mix Process

See FIG. 25, Table 1, and Table 2.

1. Verify that the Mix Ready bit (bit 2 of 40041) is on.

2. Turn on the Mix bit (bit 7 of 40040).

3. Verify that the Mix Active bit (bit 1 of 40041) is on, to

ensure that the Mix request was received.

Stop Mix Process

See FIG. 26, Table 1, and Table 2.

1. Clear the Mix bit.

5. Clear color change bit (momentary only).

6. Do not change the ccNewRecipe value until a new

recipe change is requested.

7. The color change process will stop automatically as

programmed. Monitor Purge_CC_Active bit for completion.

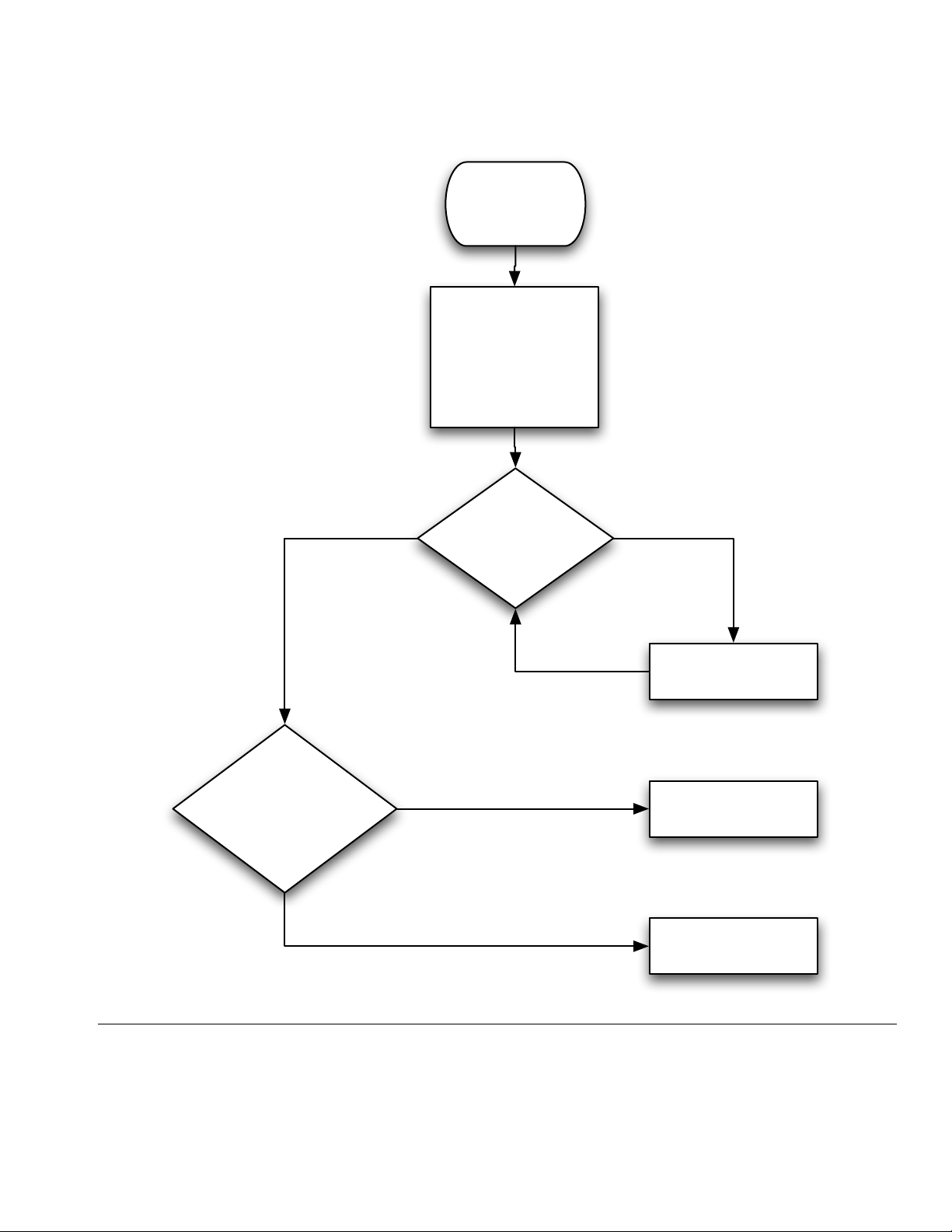

Purge Process

See FIG. 27, Table 1, and Table 2.

1. Verify that Mix Ready is set. This ensures that there

are no alarms and that the system is ready for the

next command.

2. Set purge (40040 bit 8).

3. Verify that Purge_CC_Active is seen (40041 bit 0).

4. When Purge_CC_Active bit clears, clear

Purge_Start bit. Clearing this bit in the middle of a

purge sequence will abort the purge sequence.

312785C 21

Page 22

Modbus and I/O Data

Start Mix

Mode Process

Must be Alarm Condi-

tion or Active Recipe

61. See Alarm Pro-

cessing on page 26,

or Startup from Recipe

61 (see NOTE below)

NOTE: At power up the system

defaults to Recipe 61, which is

not a valid recipe number. Initiate

a color change to Recipe 0 or a

valid recipe number (1-60).

Is Mix Ready

bit = 1?

NO

YESNO

Set Mix bit = 1

Is Mix Active

bit = 1?

YES

ProMix 2KS in Mix

Mode (Complete)

Mix Active = 1 while

the ProMix 2KS is in

Mix mode

FIG. 25. Start Mix Mode Process Flow Chart

22 312785C

Page 23

Mixing Mode

Process

Mixing Mode is desired.

PLC is polling to ensure

Mixing Mode is main-

tained.

Modbus and I/O Data

Check Alarm

Condition: is Alarm_

General bit = 1?

YES

NO

Is Mix Active

bit = 1?

YESNO

Mixing Process active

2KS is in Standby. Go to

Start Mix Process, page

21.

Go to Alarm Process-

ing, page 26

FIG. 26. Mixing Mode Process Flow Chart

312785C 23

Page 24

Modbus and I/O Data

Start

Must be Alarm

Condition or Active

Recipe 61. See

Alarm Processing

on page 26, or

Startup from Recipe

61 (see NOTE below).

Is Mix Ready

bit = 1?

NO

YESNO

Set Purge bit = 1?

Is Purge_CC_Active

bit = 1?

YES

ProMix 2KS in

Purge_CC Mode

(Process Started)

Set Purge Bit = 0.

ProMix 2KS Purge

Process (Complete)

NO

NOTE: At power up the system

defaults to Recipe 61, which is

not a valid recipe number. Initiate

a color change to Recipe 0 or a

valid recipe number (1-60).

(Wait for Mix Ready)

Is Mix Ready

bit = 1?

YES

FIG. 27. Purge Mode Process Flow Chart

24 312785C

Page 25

Color Change

Process

(basic)

Modbus and I/O Data

Do nothing.

Spraying at

desired recipe.

Ensure Color-

Change bit is seen

by ProMix 2KS

YES NO

NO

NO

Is Active Recipe =

to desired recipe?

(Register 40005).

Is

Purge_CC_Active

bit = 1?

YES

(Wait for Mix Ready)

Load ccNewRecipe

(Register 40046) with

recipe number to Color

Change to (0 through

60 is valid).

Set ColorChange (CC)

bit = 1.

Clear ColorChange (CC)

bit (momentary input).

CC process started.

Is Mix Ready

bit = 1?

NO

Check Alarm

Condition: is Alarm_

General bit = 1?

YES

YES

Process Alarm. See

Alarm Processing,

page 26.

ProMix 2KS Color

Change Process

(Complete)

FIG. 28. Color Change Mode Process Flow Chart

312785C 25

Page 26

Modbus and I/O Data

Alarm Processing

See FIG. 29, Table 1, Table 2, and Table 3.

Alarm Processing

An Alarm Condition

has been found

previously.

Alarm_General = 1.

Determine the exact alarm

from Table 3 on page 29

and solve what caused the

alarm, as required.

Reset the alarm.

Reset_Alarm = 1.

NO YES

Is Mix Ready

bit = 1?

Check if Potlife

Alarm: is Alarm_

Potlife bit = 1?

YESNO

Two options:

• Purge or Color Change to remove

mixed material in the line.

• Place in Mix mode and spray the

Potlife Volume set in the ProMix

2KS.

NOTE: The Reset key only silences

the alarm. To clear the alarm you must

use one of these two options.

Go to next process,

as desired.

IG. 29. Alarm Processing Flow Chart

F

26 312785C

Page 27

Modbus and I/O Data

Table 1: ProMix 2KS Digital Inputs (Modbus Register 40040)

Bit Digital Input Binary Name Details

0:5 0000000000XXXXXXRecipe Binary bits for viewing discrete inputs only.

6 000000000

1000000Color Change

Set bit to “1” to initiate Color Change (momentary)

(CC)

7 00000000

8 0000000

10000000Mix Set bit initiate Mix mode (maintain)

100000000Purge Set bit to “1” to initiate Purge sequence (maintained)

9 0000001000000000Job_Complete Set bit to “1” to initiate Job Complete input (momen-

tary)

10 0000010000000000External CC

Ready

Set bit to “1” to initiate External Color Change

(momentary)

11 0000100000000000Not Used

12 0001000000000000FC _Calibrate Set bit to “1” to initiate a Flow Control Calibrate input

(momentary)

13 0010000000000000Gun_Trigger Set bit to “1” to indicate the gun is actually triggered

(maintain while gun is triggered, remove when gun is

closed)

14 0

100000000000000Reset_Alarm Set bit to “1” to clear an active Alarm (momentary)

15 1000000000000000Remote Stop Set bit to remotely stop unit (momentary)

NOTE: Shaded cells relate to the flow charts on pages 23-26.

312785C 27

Page 28

Modbus and I/O Data

Table 2: ProMix 2KS Digital Outputs (Modbus Register 40041)

Bit Digital Input Binary Name Details

0 000000000000000

1 Purge_CC_Active “1” indicates Purge or Color Change is in prog-

ress

1 00000000000000

2 0000000000000

10Mix_Active “1” indicates Mix is in progress

100Mix_Ready “1” indicates No Alarms and OK to Mix

3 0000000000001000CC_Fill_Active “1” indicates the Fill portion of a Color Change is

in progress

4 0000000000010000FCalActive “1” indicates the Flow Control Calibrate routine is

in progress

5 0000000000100000Flow_Rate_Alarm “1” indicates the Flow Rate Alarm/Warning is

active

6 0000000001000000Special_1 “1” indicates the Special_1 output is on (monitor

only)

7 0000000010000000Special_2 “1” indicates the Special_2 output is on (monitor

only)

8 0000000100000000Special_3 “1” indicates the Special_3 output is on (monitor

only)

9 0000001000000000Special_4 “1” indicates the Special_4 output is on (monitor

only)

10 0000010000000000Not Used

11 0000100000000000Not Used

12 0 0 0

1000000000000Alarm_General “1” indicates a General Alarm is in process. (If

Mix_Active is still High, then a Warning only.) See

ProMix 2KS Active Alarms (Modbus Register

40010) on page 29 for details on type.

13 0010000000000000Alarm_Potlife “1” indicates a Potlife Alarm is in process.

NOTE: Shaded cells relate to the flow charts on pages 23-26.

28 312785C

Page 29

ProMix 2KS Active Alarms (Modbus Register 40010)

Table 3: ProMix 2KS Active Alarms (Modbus Register 40010)

Bit Digital Input Binary Name Details

Low Byte: 0 0000 0000 0000 0000 No Bits Set No Active Alarms

Low Byte: 0 0000 0000 0000 0001 Comm_Error

Low Byte: 0 0000 0000 0000 0010 Potlife_Alarm

Low Byte: 0 0000 0000 0000 0100 Ratio_High_Alarm

Low Byte: 0 0000 0000 0000 1000 Ratio_Low_Alarm

Low Byte: 0 0000 0000 0001 0000 Overdose_A_Alarm

Low Byte: 0 0000 0000 0010 0000 Overdose_B_Alarm

Low Byte: 0 0000 0000 0100 0000 Dose_Time_A_Alarm

Low Byte: 0 0000 0000 1000 0000 Dose_Time_B_Alarm

Low Byte: 0 0000 0001 0000 0000 Mix_In_Setup_Alarm

Low Byte: 0 0000 0010 0000 0000 Remote_Stop_Alarm

Low Byte: 0 0000 0100 0000 0000 Purge_Volume_Alarm

Low Byte: 0 0000 1000 0000 0000 CC_Comm_Error_Alarm

Low Byte: 0 0001 0000 0000 0000 High_Flow_Alarm

Low Byte: 0 0010 0000 0000 0000 Low_Flow_Alarm

Low Byte: 0 0100 0000 0000 0000 System_Idle_Alarm

Low Byte: 0 1000 0000 0000 0000 Setup_Change_Alarm

High Byte: 0 0000 0000 0000 0001 Power_On_Alarm

High Byte: 0 0000 0000 0000 0010 Defaults_Loaded_Alarm

High Byte: 0 0000 0000 0000 0100 IO_Alarm

High Byte: 0 0000 0000 0000 1000 Purge_Initiate_Error

High Byte: 0 0000 0000 0001 0000 Material_Fill_Alarm

High Byte: 0 0000 0000 0010 0000 Tank_A_Low_Alarm

High Byte: 0 0000 0000 0100 0000 Tank_B_Low_Alarm

High Byte: 0 0000 0000 1000 0000 Tank_S_Low_Alarm

High Byte: 0 0000 0001 0000 0000 Auto_Dump_Complete

High Byte: 0 0000 0010 0000 0000 Color/Catalyst_Purge_Alarm

High Byte: 0 0000 0100 0000 0000 Color/Catalyst_Fill_Alarm

High Byte: 0 0000 1000 0000 0000 Num_Alarm_Desc

High Byte: 0 0001 0000 0000 0000 Spare3_Alarm

High Byte: 0 0010 0000 0000 0000 Spare2_Alarm

High Byte: 0 0100 0000 0000 0000 Spare1_Alarm

High Byte: 0 1000 0000 0000 0000 Potlife_Buzzer

Modbus and I/O Data

312785C 29

Page 30

Modbus and I/O Data

ProMix 2KS Modbus/TCP Variable Map

Table 4: ProMix 2KS Modbus/TCP Variable Map

EasyKey

* Read/Write

Status

Read Only 40003 Current flow rate 16 Bit cc/min 0 5000

Read Only 40004 Actual ratio 16 Bit none 0 9999

Read Only 40005 Active recipe 16 Bit none 0 60

Read Only 40006 Potlife 1 remaining 16 Bit sec 0 9999

Read/Write 40007 Job complete 16 Bit none 0 0xFFFF

Read/Write 40008 Reset job total 16 Bit none 0 9

Read Only 40009 Potlife 2 remaining 16 Bit sec 0 9999

Read Only 40010 Active fault 32 Bit none 0 0xffffffff

Read Only 40032 Control version 32 Bit none 0 0xffffffff

Read/Write 40040 Robot digital input 16 Bit none 0x0000 0xFFFF

Read Only 40041 Robot digital output 16 Bit none 0x0000 0xFFFF

Read/Write 40046 New recipe 16 Bit none 0 60

Read Only 40048 Current fluid pressure 16 Bit psi 0 5000

Read Only 40049 V/P percent output 16 Bit % 0 100

Read Only **40056 Actual ratio reducer 16 Bit none 0 9999

Read Only 40114 Flow control option 16 Bit 0=proportioning only

Read/Write 40115 Flow setpoint data source 16 Bit 0=discrete

Read/Write 40120 Manual override percent

Read/Write 40125 Flow control range 16 Bit 0=0-300 cc/min

Read/Write 40126 Flow control tolerance 16 Bit % 0 99

Read/Write 40127 Flow control proportional

Read/Write 40128 Flow control integral gain Ki16 Bit default=40 0 9999

Modbus

Register Description Size Units Low Limit High Limit

04

1=1K flow control

(future)

2=2K flow control

3=pressure override

4=manual percent

override

01

1=network

16 Bit % 0 100

opening

02

1=0-600 cc/min

2=0-1200 cc/min

16 Bit default=400 0 9999

gain Kp

Read/Write 40129 Flow control alarm time 16 Bit sec 0 99

Read/Write 40137 Flow control setpoint 16 Bit cc/min 0 1200

Read/Write 43123 Flow control override

mode

Read/Write 43141 Flow control enable 16 Bit 0=off

* This column represents the rule that must be implemented by automation. Writing to Read Only registers must be

avoided.

** For ProMix 3KS Systems only.

30 312785C

16 Bit 0=off (normal)

1=% open

2=pressure mode

1=on

02

01

Page 31

ProMix 2KS Recipe Bits

Table 5: ProMix 2KS Recipe Bits

Recipe Bits Number

543210 543210

000000 0 100001 33

000001 1 100010 34

000010 2 100011 35

000011 3 100100 36

000100 4 100101 37

000101 5 100110 38

000110 6 100111 39

000111 7 101000 40

001000 8 101001 41

001001 9 101010 42

001010 10 101011 43

001011 11 101100 44

001100 12 101101 45

001101 13 101110 46

001110 14 101111 47

001111 15 110000 48

010000 16 110001 49

010001 17 110010 50

010010 18 110011 51

010011 19 110100 52

010100 20 110101 53

010101 21 110110 54

010110 22 110111 55

010111 23 111000 56

011000 24 111001 57

011001 25 111010 58

011010 26 111011 59

011011 27 111100 60

011100 28

011101 29

011110 30

011111 31

100000 32

Recipe Bits Number

Modbus and I/O Data

312785C 31

Page 32

Troubleshooting

Troubleshooting

NOTE: This section covers the most common problems

encountered while setting up, programming or using the

product. Do not forget to always download in the device

after changing settings in Graco Gateway.

General Troubleshooting

PROBLEM CAUSE SOLUTION

Unit screen is blank and PWR LED is

off.

Unit screen is blank and PWR LED is

on.

Unit continually cycles on and off. Cross-references between tags, e.g.,

Unit cycles power after an operation. Most likely a program going in an

CF LED flashing slowly. CF card corrupted or invalid. Format the card from Graco Gateway

No power applied to the unit. Check power supply. Units require 24

VDC, ± 10%.

Contrast too low (Graco Gateway

only).

No primitives on the display. Add objects to the User Interface in

Backlight is off. Push one of the soft keys to turn it

Backlight tube is broken. Replace the backlight tube.

Var1 uses Var2 as maximum which in

turn uses Var1 as minimum.

Database is corrupted. Create a new database or send to

endless loop.

Program one of the soft keys with the

action as User Defined and the following code in the field On Pressed:

dispcontrast++

Graco Gateway.

back on.

Remove one of the references or use

formula tags for indirect reference,

e.g., Form1 is equal to Var1 and used

in Var2 minimum instead of Var1.

technical support for debugging.

Check if the operation launches pro-

gram containing loops with no exit

point.

using the Link > Format Flash menu.

32 312785C

Page 33

Troubleshooting

PROBLEM CAUSE SOLUTION

Unit shows “Version Mismatch”. The database currently in the device

does not match Graco Gateway’s

Download the database from Graco

Gateway again.

firmware version. (Message occurs

after a download with a new version

of C2 interrupted before the database

was downloaded.)

Unit shows “Invalid Database”. The database in the device is cor-

rupted or there are no databases in

Download a database from Graco

Gateway.

the device.

Values show “----” No communication with target device. See Serial Communication Trou-

bleshooting (page 36) or Ethernet

Communication Troubleshooting

(page 37).

Value does not update. The tag on the screen is not linked

correctly.

Check the tag mapping making sure

the target device (PLC, etc.) register

is correct.

Check the primitive Data Source in

the user interface in case the word

WAS is displayed. Re-link the tag in

this case.

Value shows +BIG or –BIG. Not enough digits before the decimal

point to show the number. For exam-

Increase the number of digits before

the decimal point in the tag format.

ple, data is 1000.5 and format is

three digits before the decimal point

and one after.

Value deviates by a factor of ten. The tag format is not correct. Change the decimal point position in

the tag format.

Value is invalid. Incorrect tag type. Check if the tag type corresponds to

the data type. Is the data a floating

point number and thus the tag a real

(Pi symbol), and not an integer (X

symbol)?

Incorrect data mapping. Check if the tag is accessing the cor-

rect target device register.

Incorrect primitive on the display. Check if the primitive corresponds to

the tag type. For example, primitive is

a Text Integer so the tag has to be an

integer.

Data received is not what’s expected.

For example, bytes reversed in the

word.

Use the transform property on the tag

to modify the data source. You might

have to try multiple solutions to solve

the issue.

312785C 33

Page 34

Troubleshooting

PROBLEM CAUSE SOLUTION

Symbol or image leaves a trace when

animated.

The background of the image is not

refreshed.

Change the primitive Fill Format to

Solid color.

Add the system variable dispcount

in the background of the image to

force the refresh.

Rich Bar Graph or Dial Gauge does

not move

Tag minimum and maximum are not

setup.

Check the tag’s minimum and maximum values. These are used by both

primitives for minimum and maximum.

Trend Viewer curve stuck at the bottom.

No minimum and maximum setup on

the data tags displayed in the viewer.

Check that all displayed tags in the

trend viewer have a Minimum and a

Maximum setup.

USB Drivers location for Windows. Location of the drivers unknown. The drivers are located under Graco

Gateway 2.0\Device installation

folder. For example C:\Program

Files\Graco Gateway\Device.

USB Driver installation. The operating system is unable to

find the driver or the installation

failed.

In your operating system device manager, check if the Graco Gateway is

present. If so, uninstall that device.

Follow the USB installation guide.

Upgrading Graco Gateway did not

upgrade the software version.

The option selected during the

upgrade was Modify instead of

Launch the upgrade again and

choose Repair when prompted.

Repair.

34 312785C

Page 35

Troubleshooting

Graco Gateway Messages Troubleshooting

PROBLEM CAUSE SOLUTION

Device incompatible with file. The device you are trying to down-

load into doesn’t match the database

device.

Unable to open communication port. The communication port you try to

download with is unavailable:

• Cable not connected. Check if the cable is connected cor-

• Incorrect download communica-

tion port.

• Port already used. Check that the communication port is

• Target device IP address incor-

rect.

• No USB Drivers. Check that the USB drivers were

No reply from terminal. Cable is not connected. Make sure the cable is connected or

If the message appears while downloading to the device.

CompactFlash required for upgrade. The version of Graco Gateway on the

PC is different from the target device

firmware version when attempting a

download via Ethernet.

The window is too small to allow editing.

The device returned an unexpected

reply code.

The current User interface view is too

small to allow editing.

The device you are trying to download to is not supported by this version of Graco Gateway.

Create a new database file corre-

sponding to your device (File > New).

rectly to the PC and the device pro-

gramming ports (USB or PG Port).

Check that Graco Gateway is

directed to the correct communica-

tion port (Link > Options).

not used by another service or soft-

ware especially for serial ports.

If you download via Ethernet, check

the IP address of the target device in

Link > Options.

installed successfully. Reinstall

Graco Gateway USB driver under the

PC device manager if necessary.

check above solutions.

Download again with Link > Update

or F9.

Insert a CompactFlash Card in the

target device.

Use another communication port for

download: USB or Serial.

Change the panel view using View >

Panel > Display only.

Update Graco Gateway to the latest

version available (contact your Graco

distributor or Graco Technical Assis-

tance). Choose Repair when upgrad-

ing.

312785C 35

Page 36

Troubleshooting

Serial Communication Troubleshooting

This section is used to troubleshoot the communication between two devices linked via serial ports, i.e. RS232 or

RS485.

TIP: For communication troubleshooting, it is strongly advised to create a new Graco Gateway database including

only one data tag mapped to a known register in the target device.

PROBLEM CAUSE SOLUTION

Values show “----” Port settings do not match. Check that the port settings of the

Graco Gateway device match the target device (i.e. Baud, Parity, etc.).

Incorrect target device address. Check that the target device address

in Graco Gateway (in communications on the PLC symbol) matches

the target device address setup.

Incorrect cable. Check the cable part number or

cabling to match your protocol.

Incorrect communication port. Check if the cable is connected to the

correct communication port.

Values blink between the data and

“----”

If the above is correct, check that the

protocol settings are on the correct

communication port in Graco Gateway.

Communication port connector pins

bent inward.

Incorrect tag mapping. Check that the tag is mapped to an

Incorrect tag mapping on one of the

tags on the display.

Communications times-out. Increase the Slave Response or

Although unlikely, check the communication port connector pins on the

Graco Gateway in case some are

bent inward resulting in a bad contact

with the cable.

existing register in the target device.

Delete tags one after another and

download in-between. When the values on the screen stop blinking, the

last deleted tag was mapped incorrectly or accessed an unknown register in the target device.

Device Timeout on the communication port or target device in Graco

Gateway.

36 312785C

Page 37

Troubleshooting

Ethernet Communication Troubleshooting

This section is used to troubleshoot the communication between two devices linked via Ethernet.

TIP: For communication troubleshooting, it is strongly advised to create a new Graco Gateway database including

only one data tag mapped to a known register in the target device.

PROBLEM CAUSE SOLUTION

Values show “----” Incorrect target device IP address. Check the target device IP address in

Graco Gateway (in communications

on the PLC symbol) to match the tar-

get device IP address setup.

Incorrect cable or wrong connection. Check the LED on the Graco Gate-

way device Ethernet port. If none are

lit, there are no connections. Check

the cable or that the Ethernet port is

enabled in Graco Gateway, see

below.

Ethernet port disabled. Check that the Ethernet port in Graco

Gateway is enabled.

Graco Gateway and target devices

are in a different address domain:

Values blink between the data and

“----”

• If no routers are present on the

network.

• If a router is present on the net-

work.

Incorrect tag mapping. Check that the tag is mapped to an

Incorrect tag mapping on one of the

tags on the display.

Communications times-out. Increase the Slave Response or

Check that the target device IP

address and Graco Gateway device

IP address are different but in the

same domain. (For example, both

start with the same three first num-

bers; ex: 192.168.2.xxx if the mask is

255.255.255.0).

Check the Graco Gateway device

Ethernet port Gateway address to

match the router IP address.

existing register in the target device.

Delete tags one after another and

download in-between. When the val-

ues on the screen stop blinking, the

last deleted tag was mapped incor-

rectly or accessed an unknown regis-

ter in the target device.

Device Timeout on the communica-

tion port or target device in Graco

Gateway.

312785C 37

Page 38

Troubleshooting

LED Functions

Status (STS) LED

The green Status LED provides information on the status of the Graco Gateway, including various stages of

the startup routine and any errors that occur.

Status Indication

Rapidly

Flashing

Steady Graco Gateway is operating normally.

Graco Gateway is currently running the

boot loader and/or being upgraded.

User Communication Ports - TX/RX LEDs

Status Indication

Green Transmitting

Red Receiving

Ethernet LEDs

Status Indication

Yellow

(Steady)

Yellow

(Flashing)

Green 10 BASE-T Communications

Amber 10 BASE-TX Communications

Link Established

Network Activity

CompactFlash (CF) LED

Status Indication

Off No CompactFlash card is present.

Steady Valid CompactFlash card is present.

Rapidly

Flashing

Flickering Unit is writing to the CompactFlash

Slowly

Flashing

* Do not turn off power to the unit while this light is

flickering. The unit writes data in two minute intervals. Later Microsoft operating systems will not lock

the drive unless they need to writer data; Windows

98 may lock the drive any time it is mounted, thereby

interfering with logging. Contact Graco Technical

Assistance for further information.

CompactFlash card is being checked.

card, either to store data or because the

PC connected via the USB port has

locked the drive.*

Incorrectly formatted CompactFlash

card is present.

38 312785C

Page 39

System Electrical Schematic

Non-Hazardous Area

OPERATOR INTERFACE

+

POWER

+

SUPPLY

-

-

BARRIER

BOARD

POWER DIST.

TERMINAL

BLOCKS

-

-

-

-

I/O HARNESSES

12L1

N

1

UNUSED

2

UNUSED

3

UNUSED

J1

4

UNUSED

5

UNUSED

1

J5

2

3

1

J4

+

+

+

+

+24VDC

2

OPEN

3

COMMON

MEMBRANE

SWITCH

WITH

RIBBON

CABLE

DISPLAY

J4

1

2

3

4

5

6

7

8

9

10

11

J2

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

POWER HARNESS

DISPLAY

BOARD

RJ45

J6

J10

DC OK

+24 VDC

COMMON

COMMON

1

+

2

-

J9

3

4

RJ45

FLOW CONTROL CAL. (BLK)

1

GUN TRIGGER (WHT )

2

DIGITAL IN COMMON (RED)

3

REMOTE STOP (GRN)

4

ALARM RESET (BRN)

5

J5

ALARM OUTPUT (BLU)

6

DIGITAL OUTPUT COMMON (ORG)

7

POT LIFE (YEL)

8

FLOW RATE ANALOG IN (PUR)

9

FLOW RATE ANALOG COMMON (GRAY)

10

RS485 INTEGRATION A (WHT/BLU)

1

RS485 INTEGRATION B (BLU/WHT)

2

RS485 INTEGRATION GROUND (SHIELD)

3

RS485 NETWORK A (WHT/ORG)

4

RS485 NETWORK B (ORG/WHT)

5

RS485 NETWORK GROUND (SHIELD)

6

85-250 VAC

+12VDC I/S (RED)

COM (BLACK)

SHIELD

+

-

SHIELD

HARNESS

3'

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

ALARM

RJ45

RJ45

REMOTE

I/O

INTEGRATION

BOARD

TERMINAL

BLOCKS

System Electrical Schematic

NON-HAZARDOUS AREA

LINE

FILTER

OPEN

OPEN

J2

J3

J4

J5

L1

N

GND

1

GND LUG

2

3

1

POWER

2

ROCKER

1A

SWITCH

1B

2A

2B

CABLE

(50' STD.)/

(100' OPTION)

1

MIX INPUT

2

PURGE INPUT

3

JOB COMPLETE INPUT

4

EXTERNAL CLR CHG READY

5

RESET ALARM INPUT

6

DIGITAL INPUT COMMON

1

DIGITAL INPUT COMMON

2

RECIPE BIT 0 INPUT

3

RECIPE BIT 1 INPUT

4

RECIPE BIT 2 INPUT

5

RECIPE BIT 3 INPUT

6

RECIPE BIT 4 INPUT

7

RECIPE BIT 5 INPUT

8

RECIPE CHANGE INPUT

1

DIGITAL OUTPUT COMMON/POWER

2

PURGE/RECIPE CHG ACTIVE OUTPUT

3

MIX ACTIVE OUTPUT

4

MIX READY OUTPUT

5

FILL ACTIVE

6

FLOW CAL. ACTIVE

7

FLOW RATE ALARM OUTPUT

8

DIGITAL OUTPUT COMMON/POWER

1

DIGITAL OUTPUT COMMON/POWER

2

SPECIAL OUTPUT #1

3

SPECIAL OUTPUT #2

4

SPECIAL OUTPUT #3

5

SPECIAL OUTPUT #4

6

DIGITAL OUTPUT COMMON/POWER

L1

N

GND

(+24) YEL

(COM) GRAY

ORG

BRN

RED

TERMINAL

BLOCK

L1

N

GND

BEACON

GND N L1

85-250

VAC

L1

N

CABLE

J7

FO IN (BLK)

J8

FO OUT (BLU)

RJ45

RJ45

P1

3'

RJ45

BULKHEAD

3'

(25'-200' OPTIONS)

RJ45

WEB SERVER

RJ45

MODULE

312785C 39

Page 40

Parts

Parts

15V331 Gateway Ethernet Kit (shown)

15V963 Gateway DeviceNet Kit

15V964 Gateway Profibus Kit

Ref.

No. Part No. Description Qty

1 15V339 PANEL, back 1

2 15T752 COVER 1

3 n/a DIN RAIL 1

4 120369 POWER SUPPLY, 24 Vdc 1

5 15V345 GROMMET, cable entry 2

6 111987 CONNECTOR, strain relief 1

7n/aWIREWAY 1

8▲ 186620 LABEL, ground 1

9 n/a COVER, wireway 1

10 CONTROL BOX, Gateway

10a 15V966 BOX, DeviceNet; includes

items 20a, 23, and 27; used

on 15V963 Kit only

10b 15V965 BOX, Profibus; includes items

20b, 23, and 27; used on

15V964 Kit only

10c 15X492 BOX, ethernet; includes items

23 and 27; used on 15V331

Kit only

1

1

1

Ref.

No. Part No. Description Qty

11 120838 BLOCK, clamp end 2

12 103833 SCREW, machine 4

13 112443 BLOCK, terminal, ground 1

14 15V344 CONNECTOR 1

15 121994 CABLE, CAT 5 1

16 121700 CABLE, 2 connector 1

17 n/a WIRE, copper, 16 ga.; 9 in.

(230 mm)

18 n/a WIRE, copper, 16 ga; 9 in.

(230 mm)

20a 15V347 CARD, DeviceNet; 15V963 Kit

only

20b 15V346 CARD, Profibus; 15V964 Kit

only

23 15T999 CABLE, USB; not shown 1

25 n/a SCREW, machine, serrated

hex-head

27 258527 CD ROM, software, Gateway;

not shown

1

1

1

1

4

1

▲ Replacement Danger and Warning labels, tags, and

cards are available at no cost.

Parts labeled n/a are not available separately.

NOTE: All brand names or marks are used for identifica-

tion purposes and are trademarks of their respective

owners.

40 312785C

Page 41

Parts

Screw Location

(item 25)

USB Port

(ref item 23)

10a, b, or c 20a or b

4

7, 9, 121, 2

1314

11

12

3

8

TI12930a

DRRJ45 Network Terminals

12345678shsh

16

123

ASHB

ProMix 2KS EasyKey

RS485 Network Terminals

TI12931a

14

4

To 4

Wiring Diagrams

17

18

56

10

15

14

17

TI12929a

To 1 0

18

TI12932a

312785C 41

Page 42

Appendix A: DeviceNet™ Slave Communication

Appendix A: DeviceNet™ Slave Communication

Overview

This appendix describes the Gateway’s support for DeviceNet and details the configuration steps necessary to

use this feature. It does not provide a detailed description of DeviceNet, but only a brief introduction, necessary to define the terms that are used throughout the

remainder of this document.

Introduction

DeviceNet is a low-level network using the Controller

Area Network (CAN) technology, to provide communication between a range of industrial devices, from simple

devices such as sensors and actuators, to high-level

devices such as controllers and HMIs.

DeviceNet Port Protocols

The DeviceNet option card has one DeviceNet port. See

F

IG. 30. The port may be configured for various Devi-

ceNet protocols. Contact Graco Technical Assistance for

currently supported protocols.

• CAN_H

Position 4 of the pluggable connector provides the

CAN_H bus line (active high). This terminal is isolated from the Graco Gateway.

• V+ (optional 24 Vdc)

Position 5 of the pluggable connector is provided for

optional 24 Vdc connections. This position is available only to tie 24 Vdc wires together. The DeviceNet option card neither provides or uses 24 Vdc

power through this connection. The V+ position is

not connected to any circuitry internal to the DeviceNet option card or Graco Gateway.

Also see Appendix A: DeviceNet

cation on page 42.

™

Slave Communi-

DeviceNet Option Card Pin Outs

• V-

Position 1 of the pluggable connector provides a

CAN ground connection. This terminal is isolated

from the Graco Gateway.

• CAN_L

Position 2 of the pluggable connector provides the

CAN_L bus line (active low). This terminal is isolated from the Graco Gateway.

• DRAIN (optional)

Position 3 of the pluggable connector is provided for

optional drain connections. This position is available

only to tie drain wires together or to earth ground.

There is no internal connection to earth ground. The

DRAIN position is not connected to any circuitry

internal to the DeviceNet option card.

42 312785C

Page 43

LED

Appendix A: DeviceNet™ Slave Communication

V-

CAN_L

DRAIN

CAN_H

V+

TI13963a

PLC Connection

DeviceNet

Option Card

FIG. 30: DeviceNet Port Pin Outs and PLC Connection

XCDN

NET STS

V-

CAN_L

DRAIN

CAN_H

V+

TI13962a

312785C 43

Page 44

Appendix A: DeviceNet™ Slave Communication

About DeviceNet

DeviceNet is a connection-based network. In this context the term connection refers to a communication path

between two or more devices, and not the physical

(cable) connection to the DeviceNet network. A connection must be established between two devices in order

to transfer data.

There are two types of connection defined by the DeviceNet specification. Each has different characteristics

and is suited to a specific type of communication.

• I/O Connection – Dedicated data transfer between

a producer and one or more consumers. The format

of the data is known or implied by the connection.

• Explicit Messaging – Generic multi-purpose mes-

saging connection, typically command and

response message commands.

Each connection type has an extensive number of

parameters, which can affect the characteristics of the

communication path. For many Master/Slave communications scenarios, a defined set of connections, together

with their respective parameter settings exist under the

collective name Predefined Master/Slave Connection

Set. Many of the steps involved in creating and configuring a connection have been removed with this connection set, thus simplifying the network configuration.

• I/O Poll Connection: The Poll connection is an I/O

connection over which Poll command and response

messages are transferred. The Poll command is

transmitted by the master, and is directed to a single

slave device. The slave device in turn responds with

a Poll response message. Both the Poll command

and Poll response messages can contain any number of bytes.

• I/O Data Connection: The I/O Data connection is

part of the Predefined Master/Slave Connection Set,

but instead is included for devices, which support

creating I/O data connections via the UCMM

(Unconnected Message Manager).

Level of Support

The Gateway provides Group 2 Server level support: A

UCMM capable device that is configured to act as a

Slave for the Predefined Master/Slave connection set.

Predefined Master/Slave Connection Set

The DeviceNet specification details a number of connections that facilitate data transfer between a Master

and Slave devices. The following sections detail the connection types supported by the Gateway.

• I/O Bit-Strobe Connection: The Bit-Strobe connec-

tion is an I/O connection over which Bit-Strobe I/O

command and response messages are transferred.

The Bit-Strobe command is broadcast by the Master

device and is received by all slave devices simultaneously. The command message contains a single

bit of information for each slave on the network.

Each slave device is required to respond with a BitStrobe response message. The response message

can contain up to 8 bytes of information.

44 312785C

Page 45

Appendix A: DeviceNet™ Slave Communication

Hardware

To use DeviceNet on the Gateway, an option card must

first be installed. The option card provides the hardware

necessary to support the CAN physical layer specification as required by the DeviceNet standard.

Configuring the option card is a two-stage process; first

the option card must be selected in Gateway (DeviceNet

Option Card), and then the ‘DeviceNet Predefined

Group 2 Server Driver’ configured to run on the newly

created DeviceNet Interface port.

Gateway Configuration

The following example requires use of an Allen Bradley

1756-ControlLogix PLC, along with RSLogix 5000 and

RSNetWorx for DeviceNet software and a Gateway.

Configure the Gateway DeviceNet Option

Card

Install the Gateway DN0000 option card in the Gateway

as per the provided instructions.

Click on File>New to create a new Gateway database

and select Gateway Series HMI – Gateway 10.

Enter the Communications section. In the tree on the

left, select Gateway from the top of the tree. Select the

Edit button at the right, and select the DeviceNet Option

Card from the dialog box as shown in F

IG. 31. Click OK.

IG. 31: Select DeviceNet Option Card

F

312785C 45

Page 46

Appendix A: DeviceNet™ Slave Communication

The DeviceNet Option card appears at the end of the

tree. Select the DeviceNet Interface from under the

DeviceNet Option Card item.

IG. 32: Select DeviceNet Server

F

On the right hand pane, click on the Edit button to open

the driver picker dialog box. Select the DeviceNet Pre-

defined Group 2 Server driver. F

IG. 32.

Set the appropriate Station Address, Baud Rate, and I/O

Poll Size. Make sure the Data Format Settings are set to

Transform: Swap Bytes In Word. F

IG. 33.

46 312785C

Page 47

IMPORTANT NOTE: The I/O Polled Size is determined

by the settings in both the DeviceNet Master and the

registered .EDS file for the Gateway. To change these

settings, see Automatic Update of the EDS File on

page 51 before setting up the PLC.

Appendix A: DeviceNet™ Slave Communication

F

IG. 33: Device Settings

312785C 47

Page 48

Appendix A: DeviceNet™ Slave Communication

Create Gateway Blocks

Select the DeviceNet device from the tree at the left, and

add two Gateway Blocks; one for Read Data and one for

Write Data, using the Add Gateway Block button on the

right hand pane.

IG. 34: Add a Gateway Block

F

Select the first Gateway Block and select the Edit button

at the right.

Set the block for I/O Polled Command Data, starting at

element PollC 00000. F

IG. 35.

48 312785C

Page 49

NOTE: For 16-bit support, select Word as Word. For

32-bit support, select Word as Long. The latter is recommended as DeviceNet uses 32 bits integer addressing.

Set the block size for 4, and the Direction for: Device To

Gateway. This will be the Read Data block.

Appendix A: DeviceNet™ Slave Communication

F

IG. 35: Select Data Type (Word as Long)

312785C 49

Page 50

Appendix A: DeviceNet™ Slave Communication

Select the second Gateway Block and set it up for I/O

Polled Response Data 00000, with a length of 4, and the

Direction Gateway To Device. This will be the Write Data

Block. F

IG. 36 shows both Gateway blocks once com-

pleted.

F

IG. 36: DeviceNet Block Mapping

NOTE: Read and Write are from the Gateway point of

view. This means the master can send data in Block A,

so the Gateway can read data. On the other hand, the

master can only pull data from Block B, so the Gateway

can only write data.

The addressing scheme available is outlined below:

BitC – Identifies the I/O Bit-Strobe command data (Master to Slave).

BitR – Identifies the I/O Bit-Strobe response data (Slave

to Master).

PollC – Identifies the I/O Poll command data (Master to

Slave).

PollR – Identifies the I/O Poll response data (Slave to

Master).

DataC – Identifies the I/O Consumed Data (Master to

Slave).

DataP – Identifies the I/O Produced Data (Slave to Master).

50 312785C

Page 51

Automatic Update of the EDS File

Appendix A: DeviceNet™ Slave Communication

DeviceNet nodes use an EDS (Electronic Data Sheet) to

describe the communications parameters available at

each device on the DeviceNet network.

By design, each DeviceNet master can handle a maximum of 124 Input words and 123 Output words. In the

default EDS file for the Gateway, the Input and Output

data sizes are set at 16 bytes each. This equates to four

words of data input and four words of data output. These

values can be set higher, but it is important to note that if

the default values are set higher, they might conflict with

other DeviceNet implementations.

Gateway provides an EDS file generator tool to create a

file that matches your Gateway settings. This file can

therefore be used to configure the Master.

To generate this file, enter the Communications module

and select the DeviceNet interface on the left. Under the

Electronic Data Sheet, select Yes in Synchronize and

choose the path and name where the file should be

saved using the Browse button. F

IG. 37.

F

IG. 37: Automatic EDS Update

Saving the database using the File>Save command will

synchronize and therefore update the EDS file.

Each time EDS parameters are modified, the EDS file

will need to be re-registered within RSNetWorx for DeviceNet. These changes will also need to be reflected in

the following locations:

• RSNetWorx master node Scanlist, Input Table, and

Output Table

• ControlLogix PLC DeviceNet Scanner configuration

312785C 51

NOTE: Inputs and Outputs are with respect to the master, therefore inputs refer to data sent from the slave and

read by the master.

Page 52

Appendix A: DeviceNet™ Slave Communication

Configure the RSNetWorx for DeviceNet Software

RSNetWorx for DeviceNet is used to set up and manage

a DeviceNet network. To begin the configuration, launch

RSNetWorx for DeviceNet from your development PC.

Start a new network by selecting: File>New>DeviceNet

Configuration.

Register the EDS file generated by Gateway as shown

in the previous section of this document by selecting:

Tools>EDS Wizard>Register an EDS file(s).

Make sure that the .EDS file validation is successful.

FIG. 40: EDS Validation

If desired, select a new image file to represent the Gateway.

F

IG. 38: Register the EDS File

Select Register a single file, and browse to the location

where you saved the Gateway.EDS file.

F

IG. 39: Browse to Graco Gateway EDS File

IG. 41: EDS Image File

F

52 312785C

Page 53

Appendix A: DeviceNet™ Slave Communication

Review the EDS registration, and finish the process.

F

IG. 42: Review EDS Registration

Select the DeviceNet Master by navigating in the tree on

the left hand side. Navigate to: DeviceNet>Category>Communication Adapter>1756-DNB/A. Select the

appropriate Major Rev and drag it into the network workspace at the right.

Select the Gateway Slave by navigating in the tree on

the left. Navigate to: DeviceNet>Vendor>Graco Controls>Generic Device. Select the Gateway-SERVER and

drag it into the network workspace at the right.

Configure the master to add the slave device to the

scanlist. Right click the DNB module and select properties.

From the Scanlist tab, select the Gateway-SERVER

from the Available Devices pane, and add it to the Scan-

list pane. Select the Edit I/O Parameters button.

FIG. 43: Configure the DeviceNet Master

312785C 53

Page 54

Appendix A: DeviceNet™ Slave Communication

Make sure that the Strobed or Change of State boxes

are not selected. In the Polled section, verify that the

Input and Output sizes are 16 bytes. These must match

the I/O Poll Size selections made above in the Gateway.

In DeviceNet networks, 4 bytes constitute a full word.

Therefore the 16 bytes selection represents 4 full words

of addressable 32-bit data.

Select the Input tab. Verify that the four words of Gateway-SERVER data are mapped to YourDNBSlot:I.Data[0…3]. From the Output tab, verify that the

four words are mapped to YourDNBSlot:O.Data[0…3].

Apply the changes, and save your RSNetWorx for DeviceNet configuration.

F

IG. 44: Apply and Save

54 312785C

Page 55

Appendix A: DeviceNet™ Slave Communication

Configure the Allen Bradley ControlLogix PLC

Allen Bradley ControlLogix PLCs are programmed with

RSLogix 5000 programming software. To begin the

DeviceNet configuration, launch RSLogix 5000 from

your development PC.

Create a ControlLogix program containing a valid DeviceNet Scanner. In this application a 1756-DNB was

used.

F

IG. 45: Create Valid DeviceNet Scanner

312785C 55

Page 56

Appendix A: DeviceNet™ Slave Communication

Configure the DeviceNet Scanner to be address 0.

Make sure to set up the 32-bit Input and Output memory

spaces for a size of 32 (to match the configuration made

above in both Gateway and RSNetWorx for DeviceNet).

Select the RSNetWorx tab, and navigate to the RSNetWorx for DeviceNet configuration that you have previously created. Open the configuration from here and

download it to the network.

F

IG. 46: Main Task Tree

In the Main Task tree, open the Main Routine Ladder

Logic file. Create a rung of ladder to enable the DeviceNet network. The required output is always:

Local:YourDNBSlot:0.CommandRegister.Run

Create a few rungs by taking the DeviceNet Input data,

Local:2:I.Data[0…3], and adding 1 to them. Store the

results in Local:2:O.Data[0…3]. Based on the configuration in the Gateway, if values are changed on the Gateway Write tags, the Read tags will display the respective

values, plus one.

Save and download this configuration to the ControlLogix PLC.

56 312785C

Wire the DeviceNet Network

All DeviceNet networks require a termination resistor at

the two end nodes on the network. Place a ¼ watt 120

ohm resistor between CAN H (White) and CAN L (Blue)

of the DeviceNet connection.

Page 57

Appendix B: Profibus™ DP Slave Communication

Appendix B: Profibus™ DP Slave Communication

Overview

This appendix describes the Gateway’s support for Profibus DP and details the configuration steps necessary