Gast R2303A, R3305A-1, R3305A-13, R4P315A, R4310A-2 Operation & Maintenance Manual

...

STANDARD REGENAIR BLOWER

O

PERATION

& M

AINTENANCE

M

ANUAL

Thank you for purchasing this Gast product. It is manufactured to the highest standards

using quality materials. Please follow all recommended maintenance, operational

and safety instructions and you will receive years of trouble free service.

General information

This manual does not apply to:

• SDR Series blowers without motors

• Blowers powered with Explosion Proof Motors

PA RT NO. 70 - 6 000 F2 -2 00 (REV-J)

Model R1 Shown

Model R6P350A S h o w n

Model R7P S h o w n

Product Use Criteria:

• Pump only clean, dry air.

• Operate at -20ºF - 104ºF (-29ºC - 40ºC).

• Protect unit from dirt & moisture.

• Do not pump flammable or explosive gases or

use in an atmosphere that contains such gases.

• Protect all surrounding items from exhaust air. This

exhaust air can become very hot.

• Corrosive gases and particulate material will

damage unit. Water vapor, oil-based contaminants

or other liquids must be filtered out.

• The blower must be installed with the properly sized inlet and inline filters, gauges and

relief valves to protect the product from dirt and over-heating.

• Consult your Gast Distributor/Representative

before using at high altitudes.

Your safety and the safety of others

is extremely important.

We have provided many important safety messages

in this manual and on your product. Always read

and obey all safety messages.

This is the safety alert symbol. This symbol

alerts you to hazards that can kill or hurt you and

others. The safety alert symbol and the words

“DANGER” and “WARNING” will precede all safety

messages. These words mean:

You will be killed or seriously injured if you don’t

follow instructions.

You can be killed or seriously injured if you don’t

follow instructions.

All safety messages will identify the hazard, tell you

how to reduce the chance of injury, and tell you

what can happen if the safety instructions are not

followed.

Correct installation is your responsibility. Make sure

you have the proper installation conditions and that

installation clearances do not block air flow.

Blocking air flow over the product in any way can

cause the product to overheat.

The blower must be installed with the properly sized

inlet filter, gauge and relief valve to protect the

product from dirt and over-heating.

I N S TA L L A T I O N

Accessories

Install two vacuum gauges, one before and one after

filter, to monitor restriction through filters. As filters

become clogged, performance efficiency will be

reduced. Filters should be checked periodically and

replaced when necessary. See page 7 for installation.

Install a relief valve to avoid changes in pressure or

vacuum that can cause overloading of large blowers.

Install an intake filter with a relief valve to prevent

foreign material from entering blower if blower is used in

a vacuum application in a dirty environment. In

applications where there is high humidity or liquids

being used in the process, install a moisture separator.

See Recommended Accessories on pages 7-9 or

consult your Gast Distributor/Representative for

additional filter and accessories recommendations. Do

Not install check valves that close with a strong spring.

The recommended check valves (page 7) provide

minimal pressure drop, positive sealing and are

resistant to the high discharge temperatures of large

blowers.

WARNING

DANGER

Plumbing

Remove any foreign material (burrs, chips, welding

drops, slag, pipe cuttings, excess sealant, sand or

lime) from plumbing.

Check motor mounting and rotation before connecting

to plumbing. Inlet and outlet ports are not designed to

support plumbing.

Remove plugs from the IN and OUT ports. Use a small

amount of pipe thread lubricant when connecting

plumbing to protect the aluminum blower threads.

Connect with pipe and fittings that are the same size or

larger than the product’s threaded ports. When

installing two blowers in parallel, use plumbing that is

two whole pipe sizes larger in diameter than that of the

blower. Be sure to connect the intake and exhaust

plumbing to the correct inlet and outlet ports.

Plumbing to remove the hot discharge air of larger

blowers may be required to help maintain proper room

ambient temperature. Use a relief valve to discharge

excess air into the atmosphere. If the blower will be

operated at 125mbar (50” H2O) or higher, metal pipe is

required for hot exhaust air.

Mounting

The single impeller blower should be oriented with the

shaft in a horizontal position, unless the model’s product

features state otherwise. The dual impeller models must

be mounted with the shaft in a horizontal position.

Mounting the product to a stable, rigid operating surface

and using shock mounts will reduce noise and vibration.

Rotation

From the motor side of the blower, check that the blower is

rotating clockwise. (The motor side is marked with an

arrow on most models.) Proper rotation can also be

checked by the air flow at the IN and OUT ports. On

blowers powered by a 3-phase motor, incorrectly

connecting any two power lines can reverse direction.

Motor Installation

It is your responsibility to contact a qualified

electrician and assure that the electrical installation

is adequate and in conformance with all national

and local codes and ordinances.

Select fuses, motor protective switches or thermal

protective switches to provide protection. Fuses act as

short circuit protection for the motor, not as protection

against overload. Incoming line fuses must be able to

withstand the motor’s starting current. Motor starters

with thermal magnetic overload or circuit breakers

protect motor from overload or reduced voltage

conditions. Motors without automatic restart require

thermal protection or magnetic over-current cutout to

prevent motor overloading from one phase in a 3-phase

circuit, high starting frequency or jammed blower.

The power required will rise as differential pressure

increases. The wiring diagram attached to the product

or on page 6 of this manual provides required electrical

information. Large motors have two diagrams, one for

50Hz wiring specifications and the other for 60Hz wiring

specifications. Check that the power source is correct

to properly operate the dual-voltage motor. If additional

information is required, please consult your Gast

Distributor/Representative.

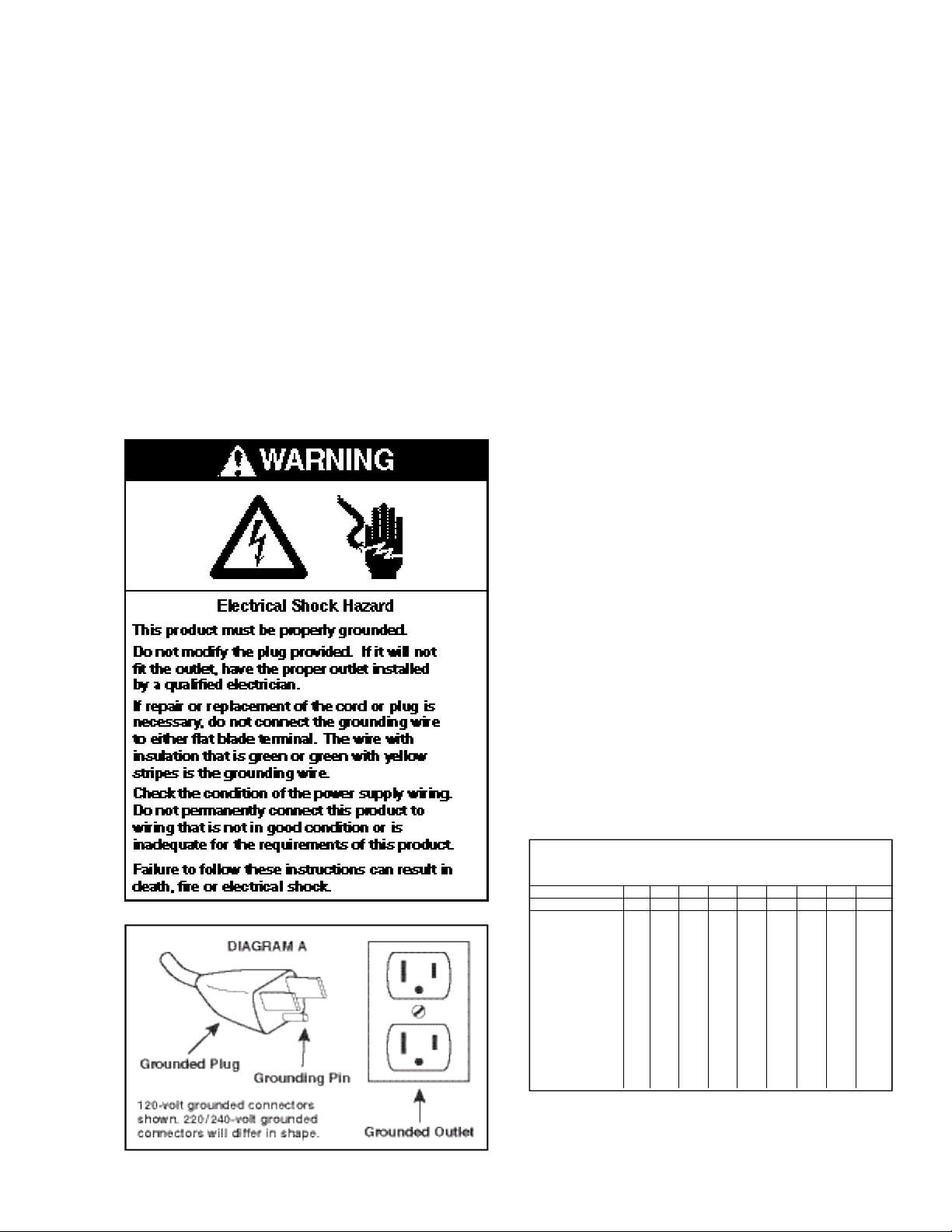

Model with a power supply cord:

This product must be grounded. For either 120-volt or

220/240-volt circuits connect power supply cord

grounding plug to a matching grounded outlet. Do not

use an adapter. (See DIAGRAM A)

Model that is permanently wired:

This product must be connected to a grounded,

metallic, permanent wiring system, or an equipment

grounding terminal or lead on the product.

Power supply wiring must conform to all required safety

codes and be installed by a qualified person. Check

that supply voltage agrees with that listed on product

nameplate.

Extension cords:

Use only a 3-wire extension cord that has a 3-blade

grounding plug. Connect extension cord plug to a

matching 3-slot receptacle. Do not use an adapter.

Make sure your extension cord is in good condition.

Check that the gage wire of the extension cord is the

correct size wire to carry the current this product will

draw.

An undersized cord is a potential fire hazard, and will

cause a drop in line voltage resulting in loss of power

causing the product to overheat. The following table

indicates the correct size cord for length required and

the ampere rating listed on the product nameplate. If in

doubt, use the next heavier gage cord. The smaller

the gage number, the heavier the wire gage.

Check with a qualified electrician or serviceman if

the grounding instructions are not completely

understood, or if you are not sure whether the

product is properly grounded. Do not modify the

plug provided. If it will not fit the outlet, have the

proper outlet installed by a qualified electrician.

In the event of an electrical short circuit, grounding

reduces the risk of electric shock by providing an

escape wire for the electric current. This product may

be equipped with a power supply cord having a

grounding wire with an appropriate grounding plug.

The plug must be plugged into an outlet that is properly

installed and grounded in accordance with all local

codes and ordinances.

Electrical Connection

Minimum gage for extension cords

Amps Volts Length of cord in feet

120v 25 50 100 150 200 250 300 400 500

240v 50 100 200 300 400 500 600 800 1000

0-2 18 18 18 16 16 14 14 12 12

2-3 18 18 16 14 14 12 12 10 10

3-4 18 18 16 14 12 12 10 10 8

4-5 18 18 14 12 12 10 10 8 8

5-6 18 16 14 12 10 10 8 8 8

6-8 18 16 12 10 10 8 6 6 6

8-10 18 14 12 10 8 8 6 6 4

10-12 16 14 10 8 8 6 6 4 4

12-14 16 12 10 8 6 6 6 4 2

14-16 16 12 10 8 6 6 4 4 2

16-18 14 12 8 8 6 4 4 2 2

18-20 14 12 8 6 6 4 4 2 2

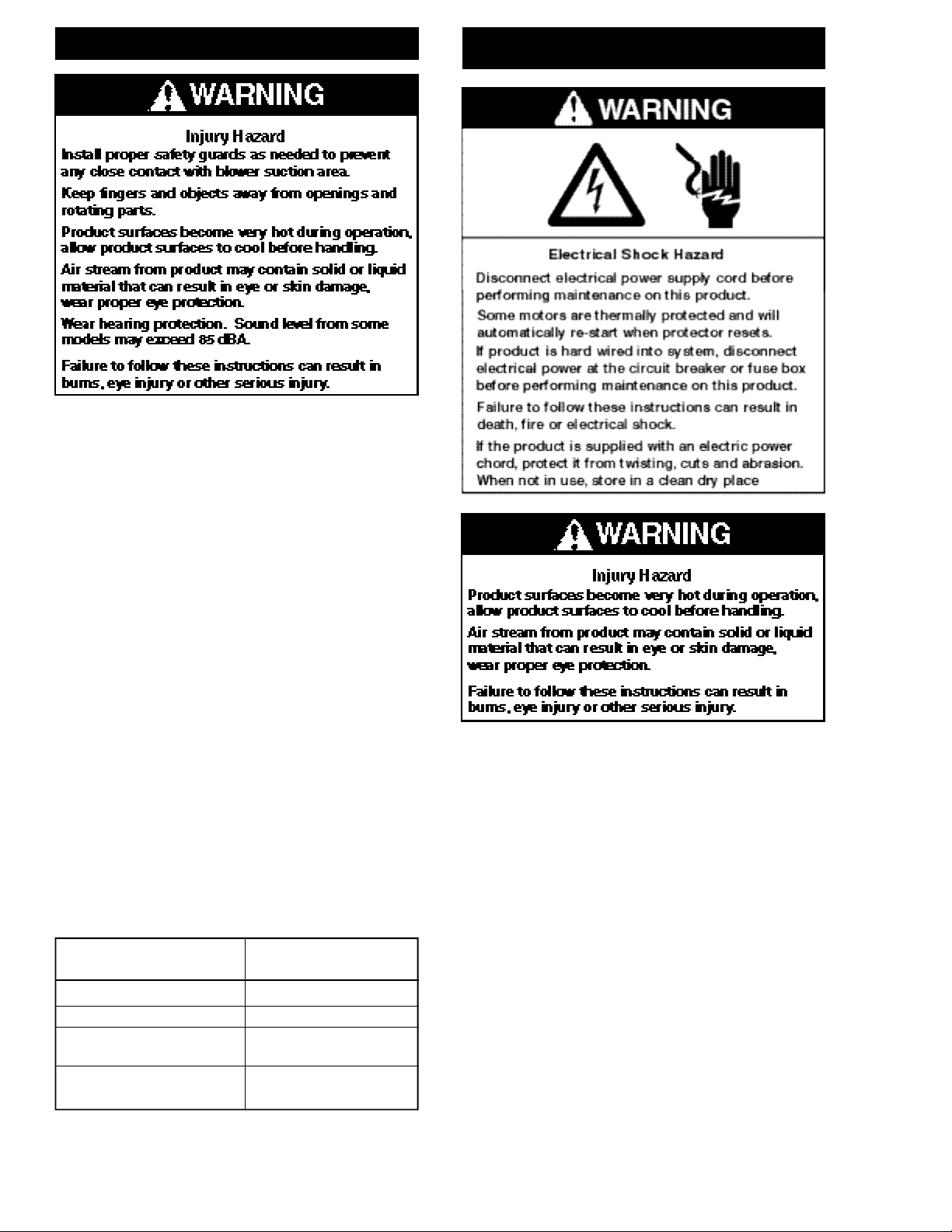

Start Up

Operate blower for an hour and then check:

1. Ambient temperature – Check room and discharge

air temperatures. Increased room temperatures

may require stronger ventilation especially for larger

blowers. Exhaust air should not exceed 215ºF

(102ºC) for all blowers less than 3.5 Hp. Exhaust air

should not exceed 275ºF (135ºC) for all blowers

above 3.5 Hp.

2. Working pressure and vacuum values – Adjust

relief valve pressure or vacuum setting, if needed.

3. Motor current – Check that supply current matches

recommended current rating on product nameplate.

4. Electrical overload cutout – Check that current

matches rating on product nameplate.

It is your responsibility to operate this product at

recommended pressures or vacuum duties and

room ambient temperatures. Do not operate R4P or

larger size blowers without air flowing through the

blower. Do not throttle discharge or suction pipe to

reducer capacity. Throttle will increase differential

pressure causing increasing power absorption and

working temperatures.

O P E R AT I O N

If motor fails to start or slows down significantly under

load, shut off and disconnect from power supply. Check

that the voltage is correct for motor and that motor is

turning in the proper direction.

M A I N T E N A N C E

It is your responsibility to regularly inspect and

make necessary repairs to this product in order to

maintain proper operation. Make sure that pressure

and vacuum is released from product before

starting maintenance.

Check filter elements and noise absorbing foam used in

mufflers and clean motor and blower after first 500

hours of operation. Replace filter elements and

determine how frequently mufflers should be checked

during future operation. This one procedure will help

assure the product’s performance and service life.

When there is an increase in the differential pressure

across the inlet filter it is beginning to clog with dirt.

Replace the cartridge when the filter will not come

clean.

Small motor bearings (less than 5.5 Hp) never need to

be greased. Larger motor bearings (greater than 5.5

Hp) have alemite grease fittings. Use a grease gun and

apply one or two strokes of Exxon POLYREX® grease

to the fittings to lubricate larger motor bearings.

Check that all external accessories such as relief

valves and gauges are not damaged before reoperating product.

Hours of Service Relubrication

Per Year Intervals

5,000 3 years

Continual Normal Service 1 year

Seasonal Service (motor 1 year at beginning of

idle for 6 months or more) season

Continuous-high ambients, 6 months

dirty or moist applications

FOR BLOWERS WITH GREASE FITTINGS

Loading...

Loading...