Garmin RV 890, CAMPER 890, RV1090, CAMPER1090 Owner's Manual

Getting Started with Easy Altivar ATV610

ENGLISH

Verify the Key

Points of your

installation,

identified

by this symbol.

Verify The Delivery Of The

Drive

Unpack the drive and verify that it has not been damaged.

Damaged products or accessories may cause electric shock or

unanticipated equipment operation.

Contact your local Schneider Electric sales office if you detect any damage

whatsoever.

Verify compatibility between your drive and your

application.

See the ATV610 Catalog DIA2ED2140702EN.

Environment

The drive is suitable for operation in these environments:

• Degree of protection:

IP20

• Mechanical class: 3S3 conforming to IEC/EN 60721

• Chemical class: 3C3 conforming to IEC/EN 60721

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION,

OR ARC FLASH

Do not use damaged products or accessories.

Failure to follow these instructions will result in death or serious

injury.

2

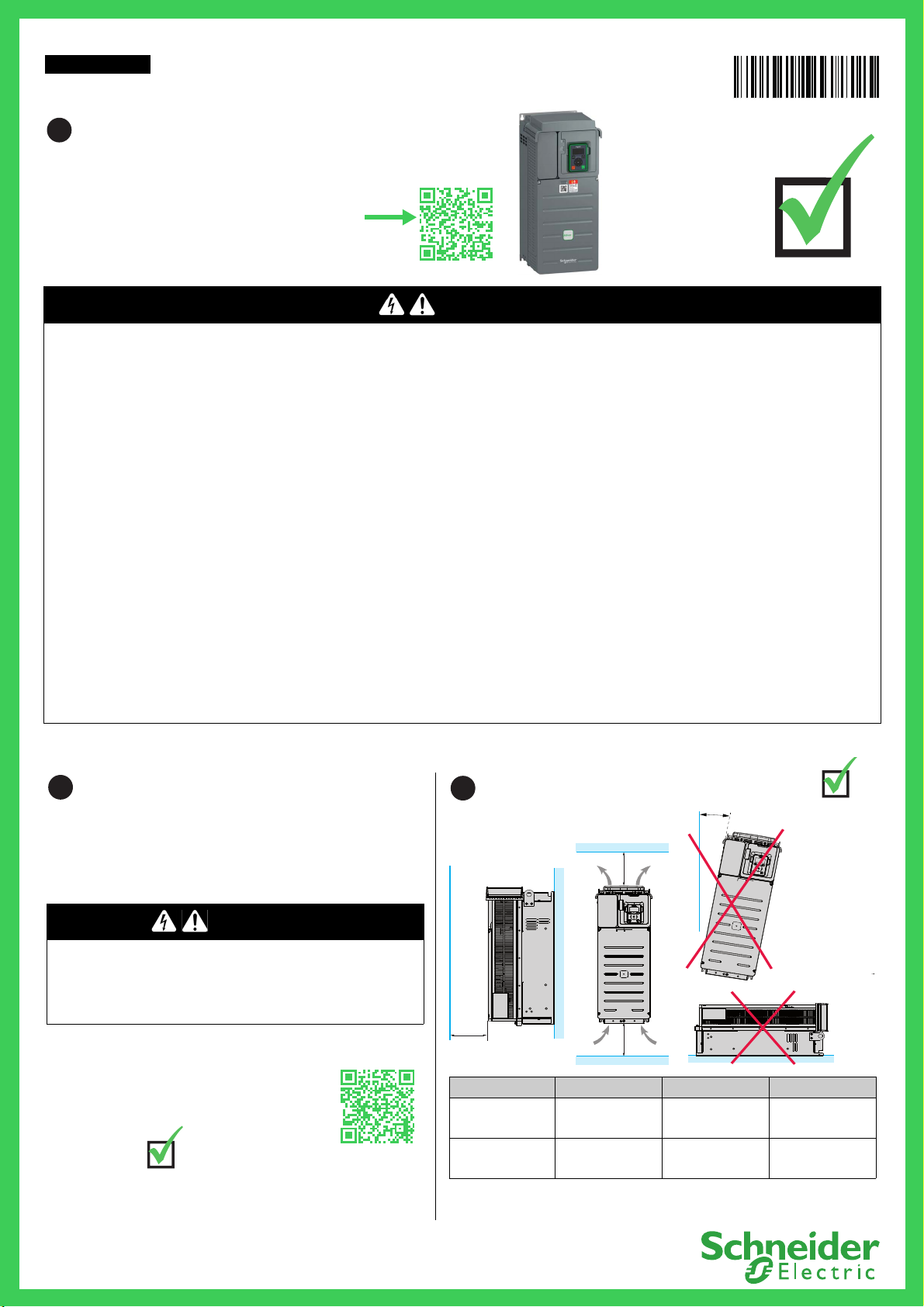

Mount The Drive Vertically

X1X2

X3

u10°

For a surrounding air temperature up to 45 °C (113 °F), and for other thermal

conditions, see installation manual (EAV64381) on se.com

Drive X1 X2 X3

ATV610U07N4...

ATV610D90N4

u 100 mm (3.9 in.) u 100 mm (3.9 in.) u 10 mm (0.39 in.)

ATV610C11N4...

ATV610C16N4

u 250 mm (10 in.) u 250 mm (10 in.) u 10 mm (0.39 in.)

EAV6437406

1

Download The Manuals

You must have detailed information to be able to carry out the installation and

commissioning. This information can be found in the following manuals that

can be downloaded on www.se.com

or scan the QR code in front of the Drive.

- The ATV610 Installation manual (EAV64381)

- The ATV610 Programming manual (EAV64387)

The Getting Started manual does not replace the Installation

and the Programming manuals.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Only appropriately trained persons who are familiar with and understand the contents of this manual and all other pertinent product documentation and who

have received safety training to recognize and avoid hazards involved are authorized to work on and with this drive system. Installation, adjustment, repair and

maintenance must be performed by qualified personnel.

• The system integrator is responsible for compliance with all local and national electrical code requirements as well as all other applicable regulations with

respect to grounding of all equipment.

• Many components of the product, including the printed circuit boards, operate with mains voltage.

• Only use properly rated, electrically insulated tools and measuring equipment.

• Do not touch unshielded components or terminals with voltage present.

• Motors can generate voltage when the shaft is rotated. Prior to performing any type of work on the drive system, block the motor shaft to prevent rotation.

• AC voltage can couple voltage to unused conductors in the motor cable. Insulate both ends of unused conductors of the motor cable.

• Do not short across the DC bus terminals or the DC bus capacitors or the braking resistor terminals.

• Before performing work on the drive system:

• Disconnect all power, including external control power that may be present. Take into account that the circuit breaker or main switch does not de-energize

all circuits.

• Place a Do Not Turn On label on all power switches related to the drive system.

• Lock all power switches in the open position.

• Wait 15 minutes to allow the DC bus capacitors to discharge.

• Follow the instructions given in the chapter "Verifying the Absence of Voltage" in the installation manual of the product.

• Before applying voltage to the drive system:

• Verify that the work has been completed and that the entire installation cannot cause hazards.

• If the mains input terminals and the motor output terminals have been grounded and short-circuited, remove the ground and the shor t ci rcu its on the ma ins

input terminals and the motor output terminals.

• Verify proper grounding of all equipment.

• Verify that all protective equipment such as covers, doors, grids is installed and/or closed.

Failure to follow these instructions will result in death or serious injury.

Electrical equipment should be installed, operated, serviced, and maintained only by qualified personnel. No responsibility is assumed by Schneider Electric for any

consequences arising out of the use of this product.

3

www.se.com 1/4 EAV64374 - 04/2020

4

L1

R

L2SL3

T

UT1VT2W

T3

PE

PA/+PC/

-

PA/+PA/+

PC/-PC/-

PA/ +PA/+ PC/-PC/-

L1L1 L2L2 L3L 3L1 L2 L3 PA/+ PC/- U V W

> 500 mm

(20 in.)

> 200 mm (8 in.)

> 300 mm (12 in.)

3 a 380/415 V

R/L1

S/L2

T/L3

Control

Power

OR

Download the white paper An Improved Approach for Connecting VSD

and Electric Motors (998-2095-10-17-13AR0_EN).

V1.0 IE 00 18.5kW

ATV610D18N4

10mm² 70Cu

IP20

1.8 N.m

50/60

380-415Φ3

0...380-415Φ3Output

Output

Output

0...500

37.2MAX

39.2

Made in China

Schneider Electric Industries SAS

35 Rue Joseph Monier

FR-92500 Rueil Malmaison

www.se.com/contact

Input

Input

Input

KCC-REI-SEk

-ATV610D18N4

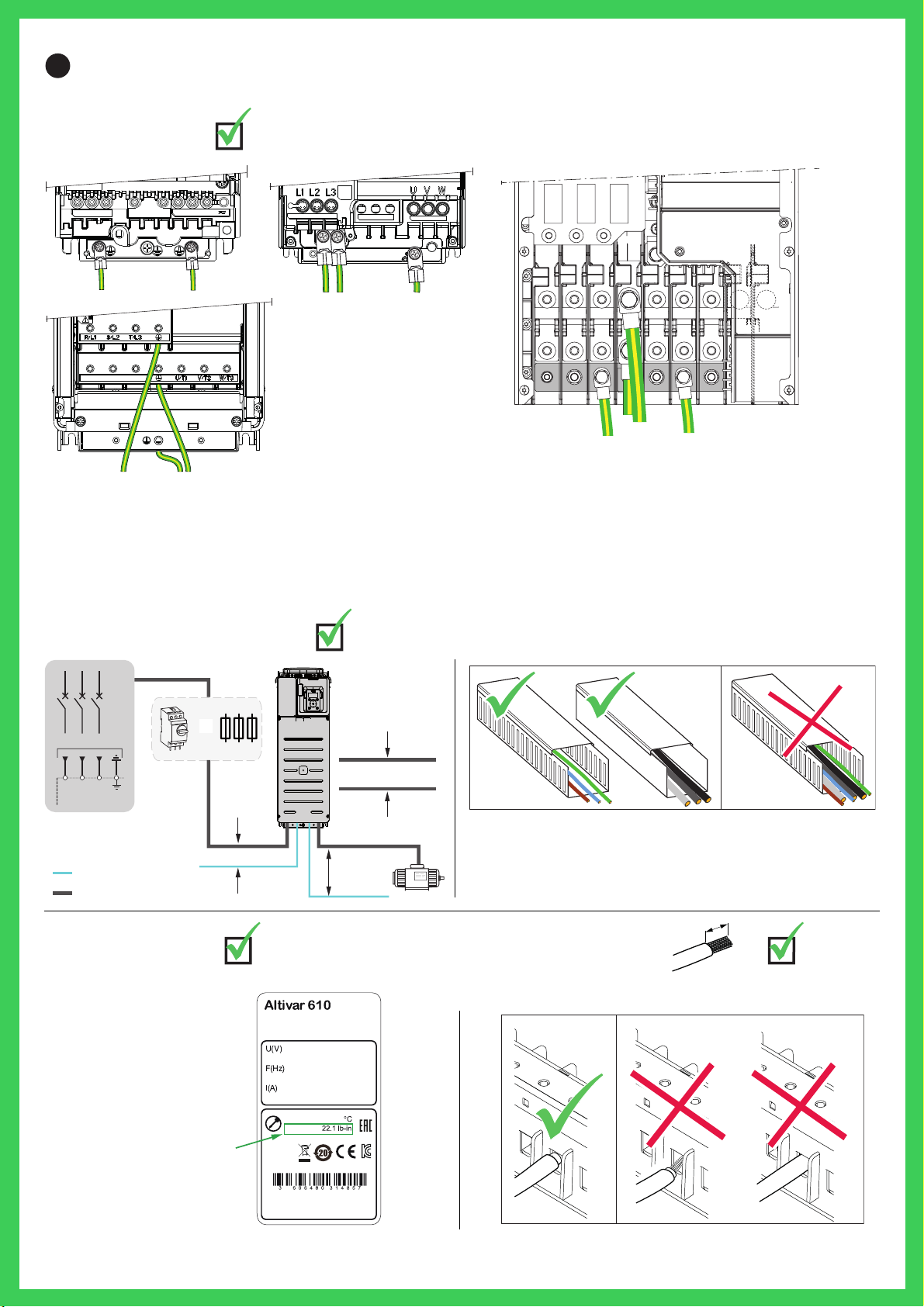

xx N.m xx lb-in

Refer to the tightening torque

instructions on the name plate.

Stripping lengths

Refer to the instructions given in the installation manual

(EAV64381)

Tightening torque

Connect The Drive: Power Part

Ground the drive

Verify the ratings

• Verify circuit breaker rating or fuse rating (see the ATV610 Catalog DIA2ED2140702EN).

• Verify that the nominal motor voltage is compatible with the drive voltage. Nominal motor voltage ______volts.

Cable the power part

Minimum distance between the cables

24 V 380 V

www.se.com 2/4 EAV64374 - 04/2020

Loading...

Loading...