Page 1

REACTOR™ 40 KICKER

THROTTLE ACTUATOR

INSTALLATION

INSTRUCTIONS

Important Safety Information

WARNING

See the

product box for product warnings and other important

information.

You are responsible for the safe and prudent operation of your

vessel. The autopilot is a tool that enhances your capability to

operate your boat. It does not relieve you of the responsibility of

safely operating your boat. Avoid navigational hazards and

never leave the helm unattended.

Always be prepared to promptly regain manual control of your

boat.

If your motor features a kill switch, you should know how to

operate it in case of an emergency. If your motor does not

feature a kill switch, you should install one before installing the

autopilot system.

Learn to operate the autopilot on calm and hazard-free open

water.

Use caution when operating the autopilot near hazards in the

water, such as docks, pilings, and other boats.

When in use, beware of hot surfaces on the heat-sink, motor,

and solenoid components.

When in use, beware the risk of entrapment or pinching from

moving parts.

Failure to install and maintain this equipment in accordance with

these instructions could result in damage or injury.

Tools Needed

• Wrenches

• Phillips screwdriver

• Marine sealant

• Loctite® thread lock (for Honda® motor installs)

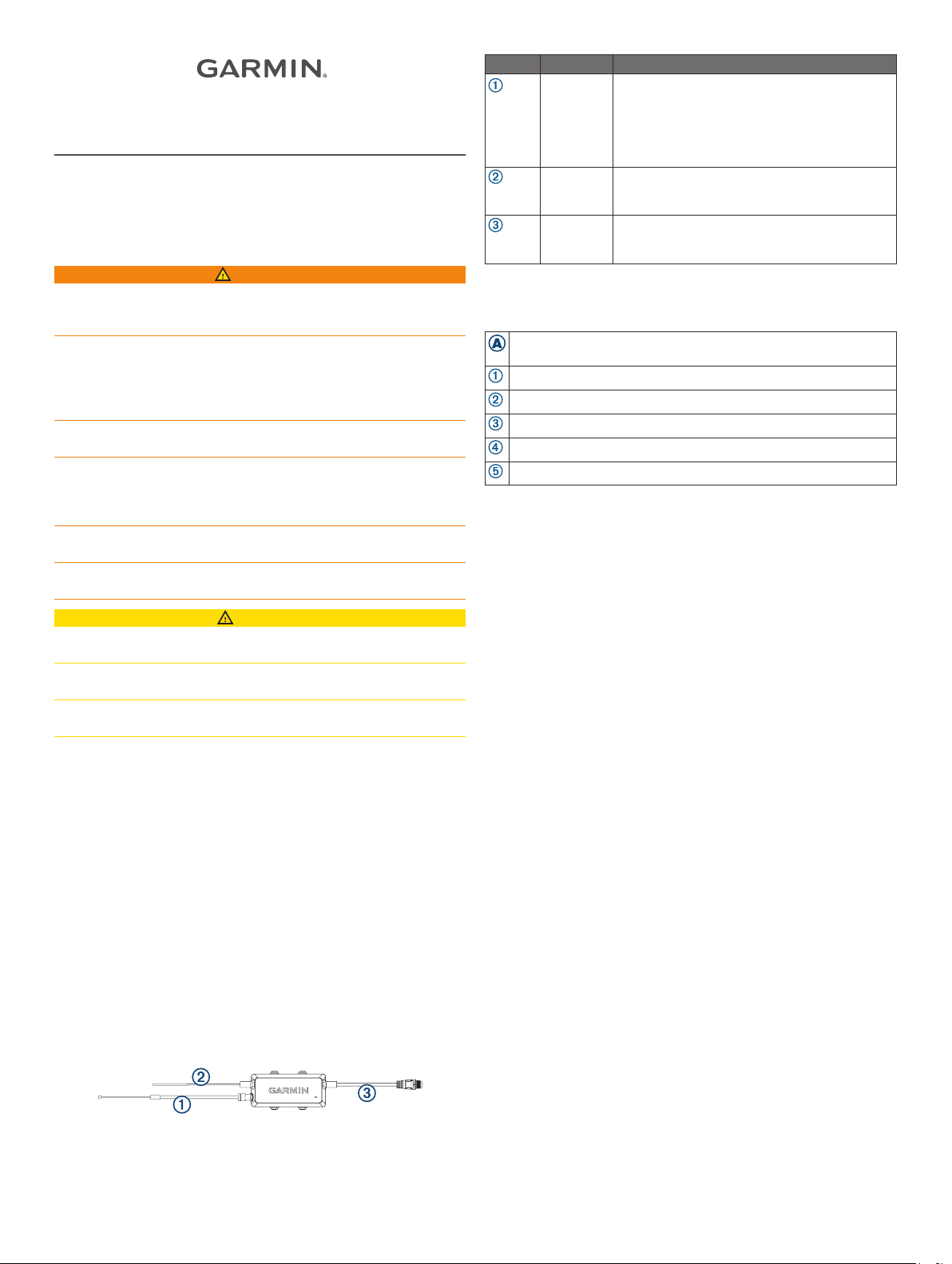

Parts Identification

The throttle actuator is the component of the Reactor 40 Kicker

autopilot system that controls the speed of the motor.

You must install the throttle actuator inside the motor housing

and connect it to the carburetor throttle lever using the linkage

parts supplied in this package. Different motor types require

different linkage parts, and the parts are separated into separate

bags. These instructions refer to the labels on the bags when

discussing the parts needed for different motor types.

Throttle Actuator

Important Safety and Product Information guide in the

CAUTION

Number Part Notes

Throttle

cable

RPM cable Connects to the spark plug to measure the

ECU cable Connects the throttle actuator to the ECU of the

Connects to the carburetor linkage to pull open

the carburetor and control the speed of the

motor.

Consult the section for your motor type for

details about how to connect this cable to the

carburetor linkage.

motor RPM (Connecting the RPM Cable,

page 5).

autopilot system (Connecting the Throttle

Actuator to the ECU

, page 5).

Parts Bags

You should refer to this table to determine which parts apply to

your motor type.

Common parts. These parts are used when installing the actuator

on all motor types.

Parts for 8 through 9.9 horsepower Yamaha® motors.

Parts for 15 through 20 horsepower Yamaha motors.

Parts for 8 through 9.9 horsepower Mercury® motors.

Parts for 15 through 20 horsepower Mercury EFI motors.

Parts for 8 through 20 horsepower Honda motors.

Installation Preparation

Mounting and Connection Considerations

When preparing to install the throttle actuator, observe the

following considerations:

• You must install the throttle actuator inside the motor

housing.

• Most motors use a throttle linkage to control the carburetor

throttle lever. You should replace the factory-installed throttle

linkage with the provided throttle linkage to prevent the

throttle actuator from back-driving the throttle on the tiller

(Tiller Back Drive Considerations, page 1).

• You must secure the throttle cable to the motor manifold and

connect it to the carburetor throttle lever on the motor using

the included bracket and linkage specific to your motor type.

• You can place the throttle actuator box in any available space

inside the motor housing after you secure the throttle cable to

the manifold and route the other cables. You can use the

included large zip ties to secure the throttle actuator box

inside the motor housing to keep it from moving during use.

• You must secure the RPM cable to the outside of a spark

plug cable (Connecting the RPM Cable, page 5).

• You must connect the throttle actuator to the ECU of the

autopilot system using the provided cable run from inside the

motor housing (Connecting the Throttle Actuator to the ECU,

page 5).

Tiller Back Drive Considerations

Most motors use a throttle linkage to control the carburetor

throttle lever. This linkage opens and closes the carburetor

when you adjust the throttle on the tiller arm. Because the

autopilot throttle actuator controls the speed of the motor from

inside the motor housing, you should replace the factoryinstalled throttle linkage with the provided throttle linkage. This

prevents the throttle actuator from back-driving the throttle on

the tiller arm, but still allows you to use the throttle on the tiller

arm when you are not using the autopilot system to control the

motor.

See the connections diagram for your motor type to locate the

existing throttle linkage and replace it with the included linkage.

NOTE: Because of the motor design, you cannot replace the

throttle linkage on Honda motors. Under typical operation, the

February 2019

190-02451-94_0A

Page 2

throttle actuator back-drives the throttle on the tiller arm on

Honda motors, and you must adjust the friction collar on the

throttle to allow the actuator to control the speed of the motor

(Adjusting the Throttle Friction, page 5).

Assembling the Carburetor Linkage

The carburetor linkage allows the throttle cable from the actuator

to pull open the carburetor throttle lever on the motor.

Remove the carburetor linkage arm from the bag

1

containing the parts for your motor.

Remove the carburetor linkage bracket from the bag

2

containing common parts .

Using the bolt and nut in the bag containing common parts,

3

connect the carburetor linkage bracket to the carburetor

linkage arm on the tapered end of the arm.

Tighten the nut so the bracket is securely connected to the

4

arm, but loose enough so the bracket moves freely.

Connecting the Throttle Actuator Cable to the Carburetor Linkage

The carburetor linkage is designed to hold the cable from the

throttle actuator securely. Because of the design, you must

connect the throttle actuator cable to the carburetor linkage

before you secure the parts to the motor.

If necessary, assemble the carburetor linkage (Assembling

1

the Carburetor Linkage, page 2).

Place the round end of the throttle actuator cable into the

2

hole on the end of the carburetor linkage.

Number Part Notes

Throttle

actuator cable

(from the

throttle

actuator box)

Throttle cable

bracket

Manifold

mounting

location

Carburetor

linkage

Motor

carburetor

throttle lever

Tiller throttle

linkage rod

Tiller throttle

linkage

You should connect the throttle actuator

cable to the carburetor linkage before

securing it to the throttle cable bracket

(Connecting the Throttle Actuator Cable to

the Carburetor Linkage, page 2).

You must secure the throttle actuator cable

to the throttle cable bracket using the

included zip ties (Securing the Throttle

Actuator Cable to the Bracket for Most Motor

Types, page 5).

You must remove the existing bolt on the

manifold and use it to secure the throttle

cable bracket .

You may need to move the hose connected

to the bolt to properly secure the bracket.

You must assemble the carburetor linkage

before installing it (Assembling the

Carburetor Linkage, page 2).

You must remove the set screw on the

throttle lever to disconnect the tiller throttle

linkage rod and install the carburetor

linkage and plastic washers.

You do not replace this rod when installing

the other linkage parts, but you must remove

it temporarily to secure the carburetor linkage

to the throttle lever .

TIP: You can mark the location on the rod

where it connects to the throttle lever so it is

easier to note the proper motor idle when you

reconnect it.

You must replace this linkage component

with the new part provided in the parts bag.

You should save the linkage component in

case you need to restore the motor to its

factory configuration in the future.

Rotate the cable so it feeds through the slot on the end of the

3

linkage.

Yamaha 8 through 9.9 Horsepower

Connections

Setting the Linkage Components for Proper Idle

After you install the throttle actuator components on the motor,

you must adjust them so the motor idles correctly.

Loosen the throttle actuator bracket on the engine manifold

1

until the throttle actuator does not pull open the carburetor

throttle lever.

There should be obvious slack in the throttle actuator cable.

Adjust the tiller throttle to idle, start the motor, and complete

2

an action:

• If the motor is not idling correctly, loosen the set screw on

the carburetor throttle lever, adjust the tiller throttle linkage

rod until the motor idles correctly, and tighten the set

screw.

• If the motor idles correctly, proceed to the next step.

Using the tiller throttle, increase the speed of the motor, and

3

complete an action:

• If the motor does not increase its speed and return to idle

correctly, repeat the previous step to adjust the tiller

throttle linkage rod.

• If the motor increases its speed and returns to idle

correctly, proceed to the next step.

Adjust the position of the throttle actuator bracket until no

4

slack remains in the throttle actuator cable and the motor

idles correctly.

Tighten the throttle actuator bracket on the engine manifold

5

to set the cable tension.

If necessary, turn off the motor.

6

2

Page 3

Yamaha 15 through 20 Horsepower Connections

Number Part Notes

Throttle actuator

cable (from the

throttle actuator

box)

Throttle cable

bracket

Manifold

mounting

location

Carburetor

linkage

Motor

carburetor

throttle lever

Tiller throttle

linkage barrelslider

mechanism

You should connect the throttle actuator

cable to the carburetor linkage before

securing it to the throttle cable bracket

(Connecting the Throttle Actuator Cable to

the Carburetor Linkage, page 2).

You must secure the throttle actuator cable

to the throttle cable bracket using the

included zip ties (Securing the Throttle

Actuator Cable to the Bracket for Most

Motor Types, page 5).

You must remove the existing bolt on the

manifold and use it to secure the throttle

cable bracket.

You must assemble the carburetor linkage

before installing it (Assembling the

Carburetor Linkage, page 2).

You must remove the set screw on the

throttle lever to disconnect the tiller throttle

linkage rod and install the carburetor

linkage .

You must replace the existing tiller throttle

linkage rod with the barrel-slider

mechanism provided in the parts bag

(Assembling the Barrel Slider Throttle

Linkage, page 3). You should save the

existing tiller throttle linkage rod in case you

need to restore the motor to its factory

configuration in the future.

Setting the Linkage Components for Proper Idle

After you install the throttle actuator components on the motor,

you must adjust them so the motor idles correctly.

Loosen the throttle actuator bracket on the engine manifold

1

until the throttle actuator does not pull open the carburetor

throttle lever.

There should be obvious slack in the throttle actuator cable.

Loosen the set screw on the carburetor throttle lever, and

2

slide the rod into the barrel slider until it stops.

Tighten the set screw.

3

Adjust the tiller throttle to idle, start the motor, and complete

4

an action:

• If the motor is not idling correctly, loosen the set screw on

the carburetor throttle lever, adjust the tiller throttle linkage

rod in the barrel slider until the motor idles correctly, and

tighten the set screw.

• If the motor idles correctly, proceed to the next step.

Using the tiller throttle, increase the speed of the motor, and

5

complete an action:

• If the motor does not increase its speed and return to idle

correctly, repeat the previous step to adjust the tiller

throttle linkage rod in the barrel slider.

• If the motor increases its speed and returns to idle

correctly, proceed to the next step.

Adjust the position of the throttle actuator bracket until no

6

slack remains in the throttle actuator cable and the motor

idles correctly.

Tighten the throttle actuator bracket on the engine manifold

7

to set the cable tension.

If necessary, turn off the motor.

8

Mercury 8 through 9.9 Horsepower

Connections

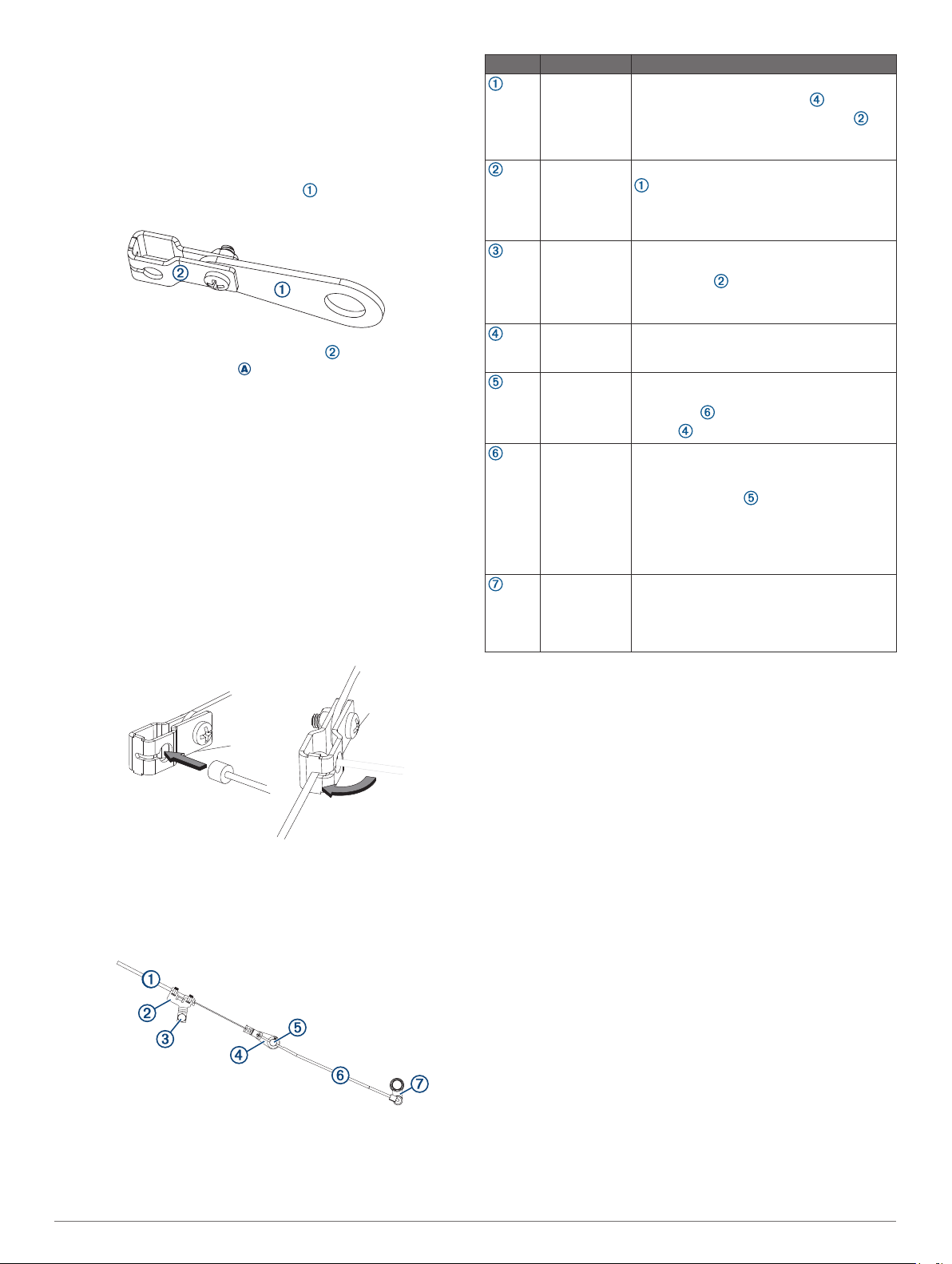

Assembling the Barrel Slider Throttle Linkage

For some motors, you must replace the existing throttle linkage

with a barrel-slider mechanism to prevent back-driving the tiller

throttle.

If necessary, open the parts bag for your motor model, and

1

remove the barrel-slider mechanism parts.

Insert the small bent rod into the short end of the barrel .

2

The flat portion of the small rod fits into the barrel one way

only.

Secure the small rod using the set screw .

3

Insert the round end of the long rod into the other side of

4

the barrel.

Number Part Notes

Throttle

actuator cable

(from the

throttle actuator

box)

Throttle cable

bracket

Manifold

mounting

location

Carburetor

linkage

You should connect the throttle actuator

cable to the carburetor linkage before

securing it to the throttle cable bracket

(Connecting the Throttle Actuator Cable to

the Carburetor Linkage, page 2).

You must secure the throttle actuator cable

to the throttle cable bracket using the

included zip ties (Securing the Throttle

Actuator Cable to the Bracket for Most Motor

Types, page 5).

You must remove the existing bolt on the

manifold and use it to secure the throttle

cable bracket .

You must assemble the carburetor linkage

before installing it (Assembling the

Carburetor Linkage, page 2).

3

Page 4

Number Part Notes

Motor

carburetor

throttle lever

Tiller throttle

linkage rod

You must remove the set screw on the

throttle lever to disconnect the tiller throttle

linkage rod and install the carburetor

linkage and plastic washers.

You must replace the existing tiller throttle

linkage rod with the new rod provided in the

parts bag. You should save the existing tiller

throttle linkage rod in case you need to

restore the motor to its factory configuration

in the future.

Number Part Notes

Carburetor

linkage

Motor

carburetor

throttle lever

Tiller throttle

linkage

You must assemble the carburetor linkage

before installing it (Assembling the

Carburetor Linkage, page 2).

You must disconnect the tiller throttle

linkage from the throttle lever to install

the carburetor linkage .

You must modify the factory tiller throttle

linkage using the new part provided in the

parts bag (Modifying the Tiller Throttle

Linkage, page 4).

Setting the Linkage Components for Proper Idle

After you install the throttle actuator components on the motor,

you must adjust them so the motor idles correctly.

Loosen the throttle actuator bracket on the engine manifold

1

until the throttle actuator does not pull open the carburetor

throttle lever.

There should be obvious slack in the throttle actuator cable.

Adjust the tiller throttle to idle, start the motor, and complete

2

an action:

• If the motor is not idling correctly, loosen the set screw on

the carburetor throttle lever, adjust the tiller throttle linkage

rod until the motor idles correctly, and tighten the set

screw.

• If the motor idles correctly, proceed to the next step.

Using the tiller throttle, increase the speed of the motor, and

3

complete an action:

• If the motor does not increase its speed and return to idle

correctly, repeat the previous step to adjust the tiller

throttle linkage rod.

• If the motor increases its speed and returns to idle

correctly, proceed to the next step.

Adjust the position of the throttle actuator bracket until no

4

slack remains in the throttle actuator cable and the motor

idles correctly.

Tighten the throttle actuator bracket on the engine manifold

5

to set the cable tension.

If necessary, turn off the motor.

6

Mercury 15 through 20 Horsepower Connections

Securing the Throttle Actuator Cable to the Bracket for Mercury 15 through 20 Horsepower Motors

Before securing the cable to the bracket, you should connect the

end of the throttle actuator cable to the carburetor linkage

(Connecting the Throttle Actuator Cable to the Carburetor

Linkage, page 2).

NOTE: This type of bracket is used to secure the throttle

actuator cable for the Mercury 15 through 20 horsepower motor

only. If you are installing the throttle actuator on all other motor

types, you must follow the instructions for that bracket instead

(Securing the Throttle Actuator Cable to the Bracket for Most

Motor Types, page 5).

Place the top of the bracket over the raised portion of the

1

throttle actuator cable .

Secure the cable to the bracket using the included screws .

2

Modifying the Tiller Throttle Linkage

On Mercury 15 through 20 horsepower motors, you must modify

the tiller throttle linkage to prevent the throttle actuator from

back-driving the tiller throttle.

Disconnect the existing tiller throttle linkage from the motor.

1

Remove one end of the linkage and the nut by

2

unscrewing the rod .

Number Part Notes

Throttle

actuator cable

(from the

throttle actuator

box)

Throttle cable

bracket

Manifold

mounting

location

4

You should connect the throttle actuator

cable to the carburetor linkage before

securing it to the throttle cable bracket

(Connecting the Throttle Actuator Cable to

the Carburetor Linkage, page 2).

You must secure the throttle actuator cable

to the throttle cable bracket using the

screws on the bracket (Securing the Throttle

Actuator Cable to the Bracket for Mercury

15 through 20 Horsepower Motors,

page 4).

You must remove the existing bolt on the

manifold and use it to secure the throttle

cable bracket .

Store the rod and other end of the linkage in case you need

3

to restore the motor to factory condition in the future.

Screw the existing nut onto the replacement rod from the

4

parts bag.

Screw the existing end of the linkage onto the replacement

5

rod.

Setting the Linkage Components for Proper Idle

Loosen the two screws that hold the throttle actuator cable to

1

the bracket until the throttle actuator does not pull open the

carburetor throttle lever.

There should be obvious slack in the throttle actuator cable.

Page 5

Adjust the tiller throttle to idle, start the motor, and complete

2

an action:

• If the motor is not idling correctly, remove the tiller throttle

linkage and adjust the length of the rod until the motor

idles correctly.

• If the motor idles correctly, proceed to the next step.

Using the tiller throttle, increase the speed of the motor, and

3

complete an action:

• If the motor does not increase its speed and return to idle

correctly, repeat the previous step to adjust the tiller

throttle linkage.

• If the motor increases its speed and returns to idle

correctly, proceed to the next step.

Adjust the position of the throttle actuator cable in the bracket

4

until no slack remains in the cable and the motor idles

correctly.

Tighten the two screws to secure the throttle actuator cable

5

to the bracket and set the cable tension.

If necessary, turn off the motor.

6

Honda 8 through 20 Horsepower Connections

The friction collar adjusts the tension on the tiller throttle, and

when fully tightened, keeps the throttle at a set position.

Adjust the friction collar so that it is fully loosened.

2

The throttle actuator is able to control the speed of the motor

only when the friction collar is fully loosened.

Common Installation Procedures

These procedures are the same for all motor models.

Securing the Throttle Actuator Cable to the Bracket for Most Motor Types

Before you secure the cable to the bracket, you should connect

the end of the throttle actuator cable to the carburetor linkage

(Connecting the Throttle Actuator Cable to the Carburetor

Linkage, page 2).

NOTE: This type of bracket is used to secure the throttle

actuator cable for most motor types. If you are installing the

throttle actuator on a Mercury 15 through 20 horsepower motor,

you must follow the instructions for that bracket instead

(Securing the Throttle Actuator Cable to the Bracket for Mercury

15 through 20 Horsepower Motors, page 4).

Place the raised portion of the throttle actuator cable into

1

the bracket between the raised tabs .

Number Part Notes

Throttle

actuator cable

(from the

throttle

actuator box)

Throttle cable

bracket

Manifold

mounting

location

Carburetor

linkage

You should connect the throttle actuator cable

to the carburetor linkage before securing it

to the throttle cable bracket (Connecting

the Throttle Actuator Cable to the Carburetor

Linkage, page 2).

You must secure the throttle actuator cable to

the throttle cable bracket using the included

zip ties (Securing the Throttle Actuator Cable

to the Bracket for Most Motor Types,

page 5).

You must loosen the existing bolt on the

manifold and slide the throttle cable bracket

into place .

You should not remove the bolt from the

manifold, because it is difficult to put the bolt

back in place after it has been removed.

You must assemble the carburetor linkage

before installing it (Assembling the Carburetor

Linkage, page 2).

The carburetor linkage arm is keyed to fit one

way on the carburetor only.

You must remove the existing lock washer to

install the carburetor linkage bracket, and you

should apply Loctite thread lock to the bolt

when securing the bracket.

Adjusting the Throttle Friction

Because the throttle actuator back-drives the tiller throttle on

Honda motors, you must adjust the throttle friction on the tiller

arm for the actuator to work properly.

Locate the friction collar on the tiller arm.

1

Secure the cable to the bracket using the included zip ties .

2

Connecting the RPM Cable

NOTICE

You must not cut or strip the RPM cable or the spark plug cable.

Cutting or stripping either cable will result in damage to the

throttle actuator, the motor, or both.

The RPM cable monitors engine RPM, and is needed for proper

autopilot operation.

Route the RPM cable from the throttle actuator box to a spark

1

plug cable on the motor.

Secure the RPM cable to the outside of the spark plug cable

2

using the included zip ties.

Connecting the Throttle Actuator to the ECU

After you connect the throttle actuator and linkages inside the

motor, you must connect the throttle actuator to the autopilot

ECU.

Locate the cable pass-through location on the motor.

1

This area is where the motor cables are routed from the

inside of the motor to the outside of the motor, and is usually

near the tiller arm.

If necessary, create a cable pass-through opening in the

2

motor housing for the ECU cable.

5

Page 6

Route the ECU cable on the throttle actuator from the inside

3

of the motor to the outside of the motor.

Route the ECU cable to the location where you installed the

4

autopilot ECU, and connect it to the THROTTLE port.

If necessary, apply marine sealant to the cable pass-through

5

opening to protect the inside of the motor from water ingress.

Testing the Throttle Actuator Installation

Before you can test the installation, you must install all of the

autopilot components and all of the throttle actuator linkage

components, and connect the throttle actuator to the ECU.

Turn on the motor.

1

Turn on the autopilot system.

2

Engage the autopilot.

3

On the remote control, press to increase the throttle using

4

the throttle actuator.

The throttle actuator should move the throttle to full speed.

On the remote control, press to decrease the throttle using

5

the throttle actuator.

The throttle actuator should return the motor to idle.

Complete an action:

6

• If the throttle actuator does not move the throttle from full

speed to idle, adjust the throttle cable bracket and repeat

this test.

• If the throttle actuator controls the throttle correctly, turn

off the motor and the autopilot system.

Specifications

Dimensions (L × W × H) 151 × 60 × 23 mm (6 × 2.35 × 0.9 in.)

Weight 181 g (6.4 oz.)

Temperature range From 0° to 70°C (from 32° to 158°F)

Material Glass-reinforced nylon and aluminum

Water rating* Throttle actuator housing: IEC 60529 IPX7*

ECU cable length 3 m (9 ft.)

Input voltage From 12 to 24 Vdc

*The device withstands incidental exposure to water of up to 1 m

for up to 30 min. For more information, go to www.garmin.com

/waterrating.

© 2019 Garmin Ltd. or its subsidiaries

Garmin® and the Garmin logo are trademarks of Garmin Ltd. or its subsidiaries,

registered in the USA and other countries. Reactor™ is a trademark of Garmin Ltd. or its

subsidiaries. This trademark may not be used without the express permission of Garmin.

Honda® is a registered trademark of Honda Motor Co., Ltd. and its subsidiaries and

Loctite® is a trademark of Henkel Corporation in the U.S. and elsewhere.

affiliates.

Mercury® is a trademark of Brunswick Corporation. NMEA®, NMEA 2000®, and the NMEA

2000 logo are trademarks of the National Marine Electronics Association.

trademark of the Yamaha Motor Corporation.

Yamaha® is a

support.garmin.com

Loading...

Loading...