Garmin GHP Reactor Hydraulic Corepack, GHP Reactor Mechanical Installation Instructions

GHP™ Reactor

SmartPump

Installation Instructions

Important Safety Information

WARNING

See the Important Safety and Product Information guide in the

product box for product warnings and other important

information.

You are responsible for the safe and prudent operation of your

vessel. The autopilot is a tool that enhances your capability to

operate your boat. It does not relieve you of the responsibility of

safely operating your boat. Avoid navigational hazards and

never leave the helm unattended.

Always be prepared to promptly regain manual control of your

boat.

Learn to operate the autopilot on calm and hazard-free open

water.

Use caution when operating the autopilot near hazards in the

water, such as docks, pilings, and other boats.

CAUTION

When in use, beware of hot motor and solenoid components

and the risk of entrapment from moving parts.

Failure to install and maintain this equipment in accordance with

these instructions could result in damage or injury.

NOTICE

To avoid damage to your boat, the autopilot system should be

installed by a qualified marine installer. Specific knowledge of

hydraulic steering componentry and marine electrical systems is

required for proper installation.

Installation Preparation

The autopilot system consists of multiple components. You

should familiarize yourself with all of the component mounting

and connection considerations before beginning installation. You

must know how the components operate together in order to

correctly plan the installation on your boat.

You can consult the layout diagrams (Power and Data Layout)

to help understand the mounting and connection considerations.

You should lay out all of the components on the boat as you

plan the installation to make sure your cables will reach each

component. If needed, extension cables (sold separately) for

various components are available from your Garmin® dealer or

from www.garmin.com.

You should record the serial number of each component for

registration and warranty purposes.

Tools Needed

• Safety glasses

• Drill and drill bits

• Wrenches

• 90 mm (3.5 in.) hole saw or a rotary cutting tool

• Wire cutters/strippers

• Phillips and flat screwdrivers

• Cable ties

• Waterproof wire connectors (wire nuts) or heat-shrink tubing

and a heat gun

• Marine sealant

• Marine corrosion inhibitor spray

• Portable or handheld compass (to test for magnetic

interference)

• Hydraulic hose with machine-crimped or field-replaceable

fittings that have a minimum rating of 1000 lbf/in

• Hydraulic T-fittings

• Inline hydraulic shut-off valves

• Hydraulic fluid

• Thread sealant

• Hydraulic bleeding equipment

• Anti-seize lubricant (optional)

NOTE: Mounting screws are provided for the main components

of the autopilot system. If the provided screws are not

appropriate for the mounting surface, you must provide the

correct types of screws.

2

Mounting and Connection Considerations

The autopilot components connect to each other and to power

using the included cables. Ensure that the correct cables reach

each component and that each component is in an acceptable

location before mounting or wiring any components.

Helm Control Mounting Considerations

NOTICE

This device should be mounted in a location that is not exposed

to extreme temperatures or conditions. The temperature range

for this device is listed in the product specifications. Extended

exposure to temperatures exceeding the specified temperature

range, in storage or operating conditions, may cause device

failure. Extreme-temperature-induced damage and related

consequences are not covered by the warranty.

The mounting surface must be flat to avoid damaging the device

when it is mounted.

Using the included hardware and template, you can flush mount

the device in the dashboard. If you want to mount the device

using an alternative method where it appears flat with the front

of the dashboard, you must purchase a flat-mount kit

(professional installation recommended) from your Garmin

dealer.

When selecting a mounting location, observe these

considerations.

• The mounting location should be at or below eye level to

provide optimal viewing as you operate your vessel.

• The mounting location should allow easy access to the keys

on the device.

• The mounting surface must be strong enough to support the

weight of the device and protect it from excessive vibration or

shock.

• To avoid interference with a magnetic compass, the device

should not be installed closer to a compass than the

compass-safe distance value listed in the product

specifications.

December 2014

Printed in Taiwan 190-01767-02_0A

• The area behind the mounting surface must allow room for

the routing and connection of the cables.

Helm Control Connection Considerations

• The helm control must connect to the NMEA 2000® network.

• Optional NMEA® 0183 devices, such as wind sensors, waterspeed sensors, or GPS devices can be connected to the

helm control using a data cable (NMEA 0183 Connection

Considerations).

CCU Mounting and Connection Considerations

• The CCU is the primary sensor of the GHP Reactor

SmartPump autopilot system. For best performance, observe

these considerations when selecting a mounting location.

◦ A handheld compass should be used to test for magnetic

interference in the area where the CCU is to be mounted.

If the needle on a handheld compass moves when you

hold it where you want to mount the CCU, magnetic

interference is present. Choose another location and test

again.

◦ The CCU should be mounted on a rigid surface for best

performance.

◦ Though the CCU can be installed in any orientation on

your boat, you can avoid the step of defining north in the

setup procedure by meeting all of the following

considerations when selecting a mounting location

(optional).

◦ The connectors on the CCU must point towards the

bow.

◦ The base of the CCU must be square with the roll and

pitch axis of the boat.

◦ The CCU must be located near the center of rotation of

the boat, slightly towards the front if necessary.

• The CCU cable connects the CCU to the SmartPump and is

5 m (16 ft.) long.

◦ If the CCU cannot be mounted within 5 m (16 ft.) of the

SmartPump, replacement and extension cables are

available from your local Garmin dealer or at

www.garmin.com.

◦ This cable must not be cut.

Finding the Best Mounting Location

Create a list of all suitable mounting locations for the CCU

1

where no iron, magnets, or high-current wires are located

within 60 cm (2 ft.).

A large magnet, such as a subwoofer-speaker magnet should

be no closer than 1.5 m (5 ft.) to these locations.

Locate the center of rotation of the boat, and measure the

2

distance between the center of rotation and each of the

suitable mounting locations you listed in step 1.

Select the location closest to the center of rotation.

3

If more than one location is approximately the same distance

from the center of rotation, you should select the location that

best meets these considerations.

• The best location is closest to the centerline of the boat.

• The best location is lower in the boat.

• The best location is slightly forward in the boat.

Pump Mounting Considerations

Consult the hydraulic-layout diagrams starting on Hydraulic

Layouts to help determine the pump-installation location.

• The pump must be mounted at a location to which you can

extend the hydraulic steering lines of the boat.

• The pump has five hydraulic-connector fittings, although only

three are used when installing the pump as recommended.

The illustration on Pump Valves and Fittings may be helpful

when determining the fitting layout that is best for your

installation location.

Pump Hydraulic Considerations

NOTICE

When adding hydraulic line to the system, use only hose with

machine-crimped or field-replaceable fittings that have a

minimum rating of 1000 lbf/in² (6,895 kPa).

Do not use plumber’s tape on any hydraulic fitting. Use an

appropriate thread sealant rated for marine use on all pipe

threads in the hydraulic system.

Do not attempt to use the autopilot to steer the boat until you

bleed all air from each part of the hydraulic system.

Consult the hydraulic-layout diagrams starting on Hydraulic

Layouts to help determine how to best install the pump in the

hydraulic system of the boat.

The recommended pump installation method requires the

installation of T-fittings and shutoff valves so the pump can be

removed for service without disabling the steering system. This

type of installation will use only three of the five ports on the

manifold. Although it is not recommended, all five ports can be

used instead of installing shutoff valves. See Pump Valves and

Fittings for more information on the fittings and alternate

connection methods.

Pump Valves and Fittings

The pump can be connected to the hydraulic system using one

of two methods. The recommended three-connector method

uses only the H1 À and H2 Á fittings, with a T-connector

splitting the connection between the helm and cylinder. The

return line fitting  connects to only the helm. The check valves

should not be reconfigured if the boat is equipped with a

Ã

balanced cylinder. If the boat is equipped with an unbalanced

cylinder, the check valves must be reconfigured (Configuring the

Pump for an Unbalanced Cylinder). The bypass valve Ä is

opened only for hydraulic bleeding, and must be fully tightened

during normal operation.

If necessary, the C1 Å and C2 Æ fittings can be used with the

recommended three-connector installation instead of the H1 and

H2 fittings.

Alternatively, the pump can be installed using all five

connectors. This installation option uses the C1 and C2 fittings

to connect the pump to the cylinder and the H1 and H2 fittings to

connect the pump to the helm. This type of installation is not

recommended, because the pump cannot be removed for

service without disabling the steering system of the boat.

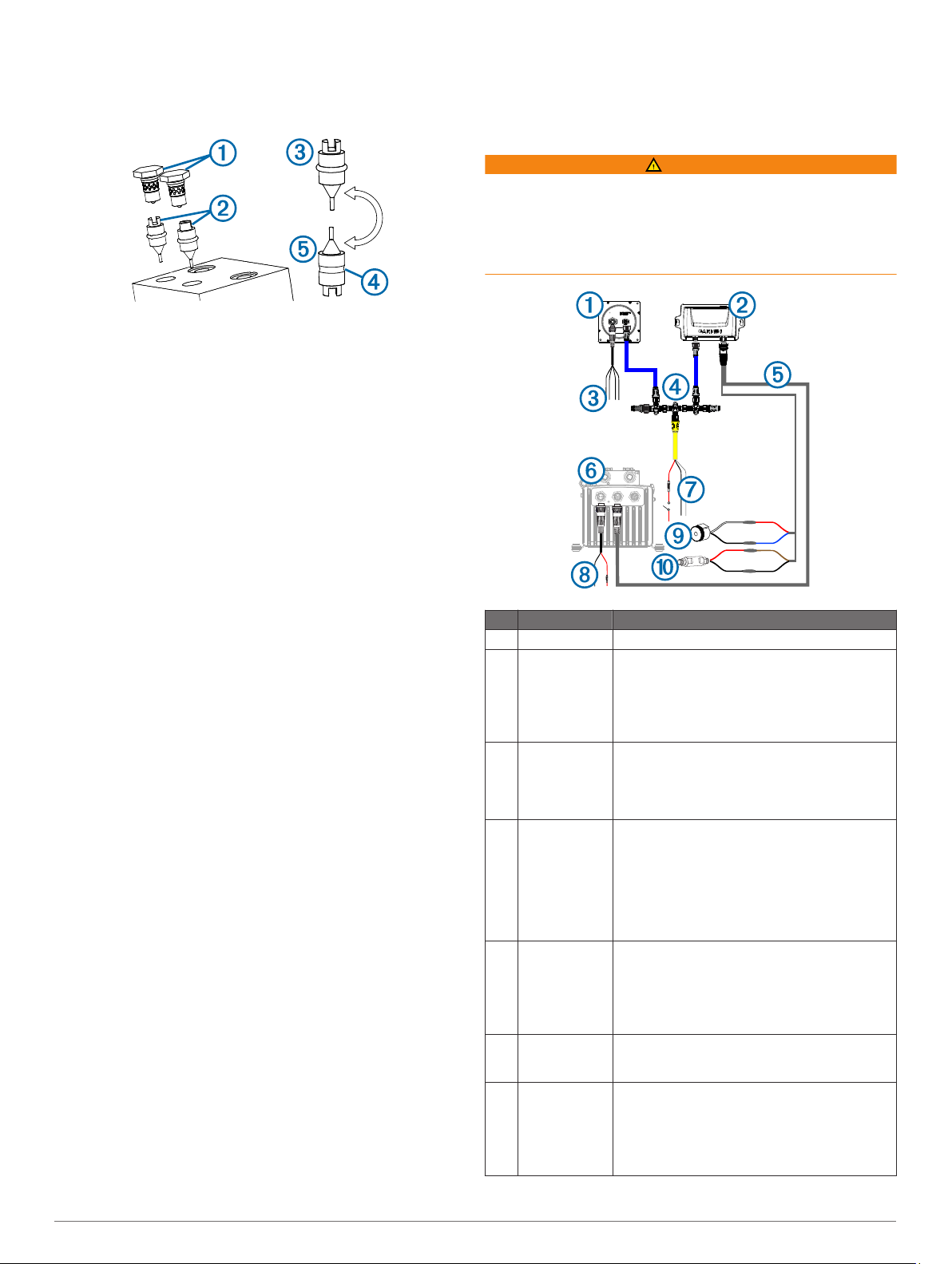

Configuring the Pump for an Unbalanced Cylinder

NOTICE

To avoid damage to the pump, keep all parts clean and free of

dust and debris while configuring the pump for an unbalancedcylinder steering system.

If you remove the check valves after bleeding the hydraulic

system, you must bleed it again. Reconfiguring the check valves

may introduce air into the hydraulic system.

2

If the boat has an unbalanced cylinder steering system, you

must configure the pump to work properly with the steering

system.

Remove the check valves À from the pump manifold.

1

Pull the pistons Á out of the pump manifold.

2

The pump is configured from the factory with the pistons in

the balanced configuration Â.

Remove the o-rings à from the pistons and discard them.

3

If you cannot easily pull the o-rings from the pistons, you may

need to cut them.

Re-insert the pistons into the pump manifold in the

4

unbalanced configuration Ä.

Insert the check valves into the pump manifold, and tighten

5

them.

Shadow Drive™ Mounting Considerations

• The Shadow Drive must be mounted horizontally and as level

as possible, with cable ties firmly securing it in place.

• The Shadow Drive must be mounted at least 305 mm (12 in.)

away from magnetic material, such as speakers and electric

motors.

• The Shadow Drive should be mounted closer to the helm

than to the pump.

• The Shadow Drive should be mounted lower than the helm,

but higher than the pump.

• The Shadow Drive must not be connected directly to the

fitting at the back of the helm. There must be a length of hose

between the fitting at the helm and the Shadow Drive.

• The Shadow Drive must not be connected directly to a

hydraulic T-connector in the hydraulic line. There must be a

length of hose between a T-connector and the Shadow Drive.

• In a single-helm installation, there must not be a T-connector

between the helm and the Shadow Drive.

• In a dual-helm installation, the Shadow Drive should be

installed between the pump and the hydraulic T-connector

that leads to the upper and lower helm, closer to the helm

than to the T-connector.

• The Shadow Drive must be installed in either the starboard

steering line or the port steering line.

The Shadow Drive must not be installed in either the return

line or the high-pressure line, if applicable.

Alarm Mounting and Connection Considerations

• The alarm should be mounted near the primary helm station.

• The alarm can be mounted under the dashboard.

• If needed, the alarm wires can be extended with 28 AWG

(0.08 mm2) wire.

NMEA 2000 Connection Considerations

• The CCU and the helm control must connect to a NMEA

2000 network.

• If your boat does not already have a NMEA 2000 network,

one can be built using the included NMEA 2000 cables and

connectors (Building a Basic NMEA 2000 Network for the

Autopilot System).

• To use the advanced features of the autopilot, optional

NMEA 2000 devices, such as a wind sensor, a water-speed

sensor, or a GPS device, can be connected to the NMEA

2000 network.

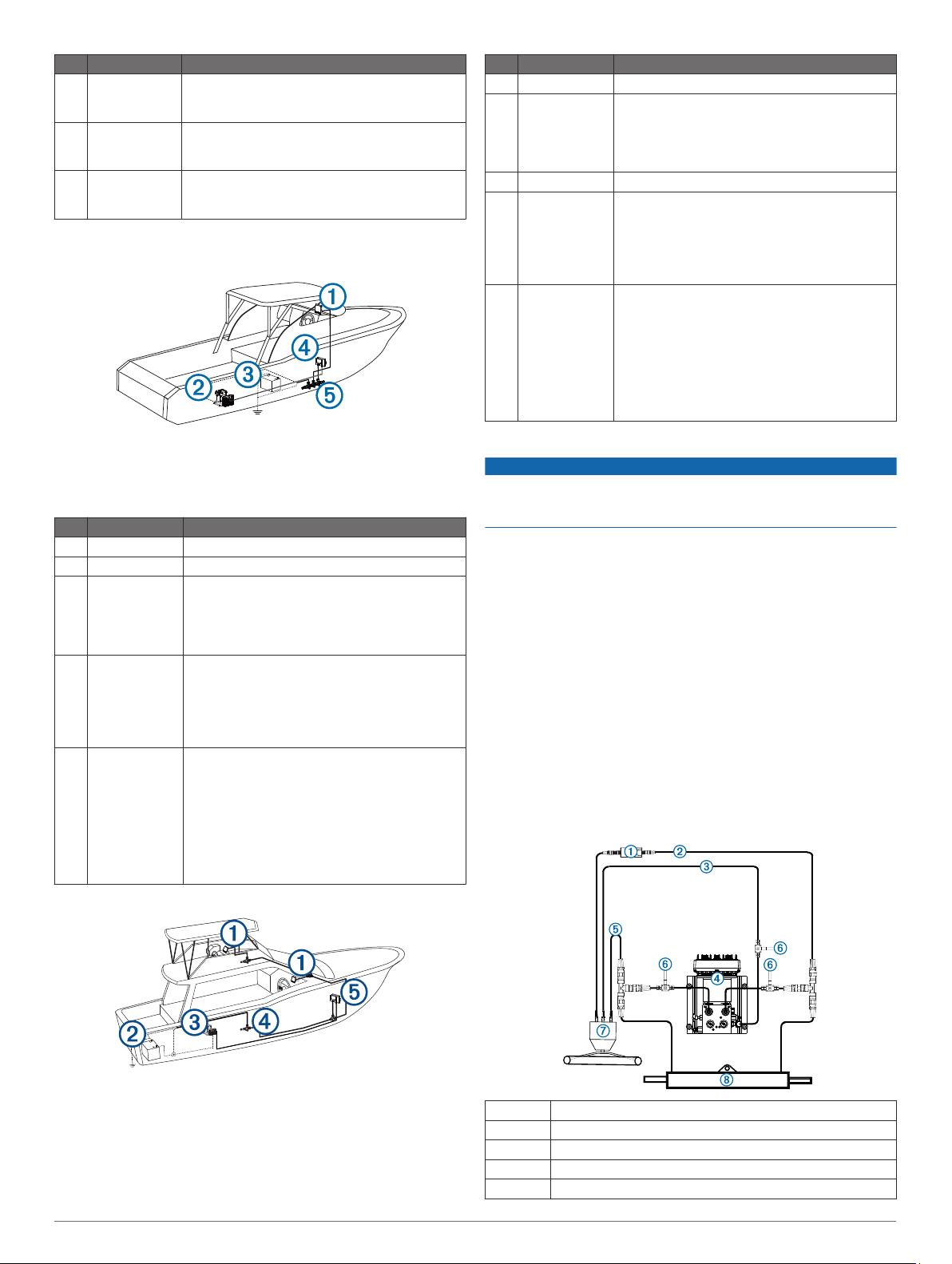

Power and Data Layout

WARNING

When connecting the power cable, do not remove the in-line

fuse holder. To prevent the possibility of injury or product

damage caused by fire or overheating, the appropriate fuse

must be in place as indicated in the product specifications. In

addition, connecting the power cable without the appropriate

fuse in place will void the product warranty.

Item Description Important Considerations

Helm control

À

CCU The CCU can be mounted in a non-submerged

Á

Helm control

Â

data cable

NMEA 2000

Ã

network

CCU cable To extend this cable to reach the ECU,

Ä

SmartPump This diagram does not show any hydraulic

Å

NMEA 2000

Æ

power cable

location near the center of the boat, in any

orientation (CCU Mounting and Connection

Considerations).

The CCU must be located away from sources of

magnetic interference.

This cable should be installed only if you are

connecting the autopilot to optional NMEA 0183

devices, such as a wind sensor, a water-speed

sensor, or a GPS device (NMEA 0183

Connection Considerations).

The helm control and the CCU must be

connected to a NMEA 2000 network using the

included T-connectors (NMEA 2000 Connection

Considerations).

If there is not an existing NMEA 2000 network on

your boat, you can build one using the supplied

cables and connectors (Building a Basic NMEA

2000 Network for the Autopilot System).

extensions (sold separately) may be necessary

(CCU Mounting and Connection

Considerations).

This cable connects to the alarm and the

Shadow Drive.

connections. Consult the hydraulic-layout

diagrams for details Hydraulic Layouts.

This cable should be installed only if you are

building a NMEA 2000 network. Do not install

this cable if there is an existing NMEA 2000

network on your boat.

The NMEA 2000 power cable must be

connected to a 9 to 16 Vdc power source.

3

Item Description Important Considerations

Pump power

Ç

cable

Alarm The alarm provides audible alerts from the

È

Shadow Drive The Shadow Drive must be installed properly in

É

The pump must be connected to a 12 to 24 Vdc

power source. To extend this cable, use the

correct wire gauge (Power Cable Extensions).

autopilot system, and should be installed near

the helm control (Installing the Alarm).

the hydraulic steering line, and connected to the

CCU cable (Installing the Shadow Drive).

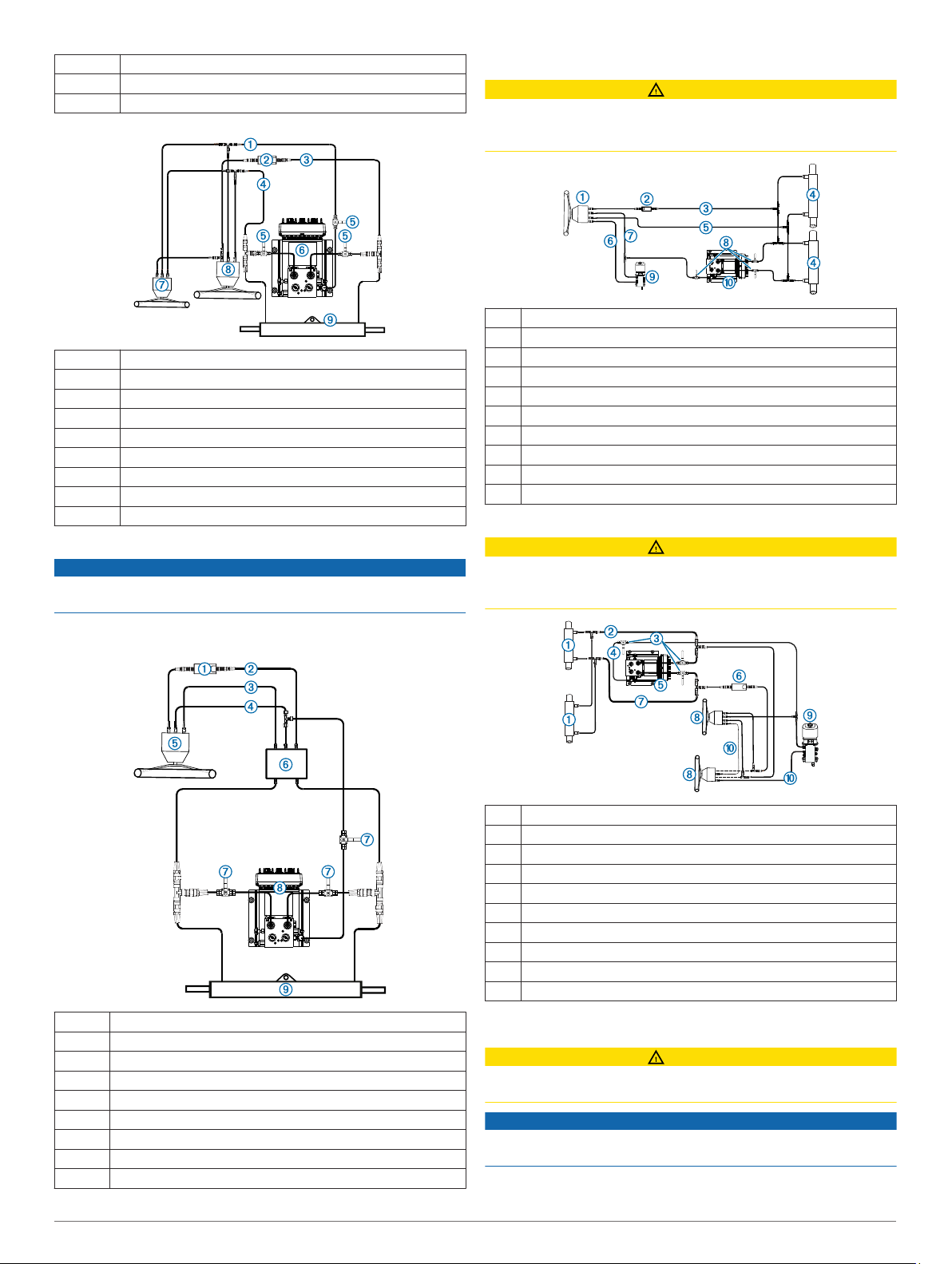

Component Layout

Single-Helm Layout

Item Description Important Considerations

Helm control

À

12 to 24 Vdc

Á

battery

SmartPump

Â

CCU The CCU can be mounted in a non-submerged

Ã

NMEA 2000

Ä

network

The pump must be connected to a 12 to 24 Vdc

power source. To extend this cable, use the

correct wire gauge (Power Cable Extensions).

The NMEA 2000 power cable must be

connected to a 9 to 16 Vdc power source.

location near the center of the boat, in any

orientation (CCU Mounting and Connection

Considerations).

The CCU must be located away from sources of

magnetic interference.

The helm control and the CCU must be

connected to a NMEA 2000 network using the

included T-connectors (NMEA 2000 Connection

Considerations).

If there is not an existing NMEA 2000 network

on your boat, you can build one using the

supplied cables and connectors (Building a

Basic NMEA 2000 Network for the Autopilot

System).

NOTE: This diagram is for planning purposes only. If needed,

specific connection diagrams are included in the detailed

installation instructions for each component.

Hydraulic connections are not shown in this diagram.

Item Description Important Considerations

Helm control

À

SmartPump

Á

12 to 24 Vdc

Â

battery

CCU The CCU can be mounted in a non-submerged

Ã

NMEA 2000

Ä

network

The pump must be connected to a 12 to 24 Vdc

power source. To extend this cable, use the

correct wire gauge (Power Cable Extensions).

The NMEA 2000 power cable must be

connected to a 9 to 16 Vdc power source.

location near the center of the boat, in any

orientation (CCU Mounting and Connection

Considerations).

The CCU must be located away from sources of

magnetic interference.

The helm control and the CCU must be

connected to a NMEA 2000 network using the

included T-connectors (NMEA 2000 Connection

Considerations).

If there is not an existing NMEA 2000 network

on your boat, you can build one using the

supplied cables and connectors (Building a

Basic NMEA 2000 Network for the Autopilot

System).

Dual-Helm Layout Guidelines

Hydraulic Layouts

NOTICE

If the steering system in your boat does not match any of the

hydraulic layouts in this manual and you are unsure how to

install the pump, contact Garmin Product Support.

Before you start the pump installation, identify the type of

hydraulic steering system in your boat. Each boat is different,

and you must consider certain aspects of the existing hydraulic

layout before deciding where to mount the pump.

Important Considerations

• The pump must be reconfigured if the boat is equipped with

an unbalanced steering cylinder (Configuring the Pump for an

Unbalanced Cylinder).

• Garmin recommends using T-connectors to connect the

hydraulic lines to the pump.

• To allow for easy pump disabling and removal, Garmin

recommends installing shut-off valves in the hydraulic lines

between the pump manifold and T-connectors.

• Teflon® tape must not be used on any hydraulic fitting.

• An appropriate thread sealant should be used on all pipe

threads in the hydraulic system.

Single-Helm without Power Assist Layout

NOTE: This diagram is for planning purposes only. If needed,

specific connection diagrams are included in the detailed

installation instructions for each component.

Hydraulic connections are not shown in this diagram.

4

À

Á

Â

Ã

Ä

Shadow Drive

Starboard line

Return line

Pump

Port line

Å

L

T

R

P

L

T

R

P

L

T

R

P

Æ

Ç

Shut-off valves

Helm

Steering cylinder

Dual-Helm without Power Assist Layout

À

Á

Â

Ã

Ä

Å

Æ

Ç

È

Return line

Shadow Drive

Starboard line

Port line

Shut-off valves

Pump

Upper helm

Lower helm

Steering cylinder

Single-Helm with Power Assist Layout

NOTICE

The pump must be installed between the cylinder and the

power-assist module to function correctly.

Single-Helm with Uflex® MasterDrive™ Layout

CAUTION

When installing the pump in a system with a Uflex MasterDrive,

do not cut the high-pressure line connecting the power unit to

the helm to avoid injury or property damage.

Helm

À

Shadow Drive

Á

Starboard line

Â

Steering cylinders

Ã

Port line

Ä

High pressure line - DO NOT CUT

Å

Return line

Æ

Shutoff valves

Ç

Uflex MasterDrive power unit

È

Pump

É

Dual-Helm with Uflex MasterDrive Layout

CAUTION

When installing the pump in a system with a Uflex MasterDrive,

do not cut the high-pressure line connecting the power unit to

the helm to avoid injury or property damage.

NOTE: Removal of the power assist-module may be necessary

to gain access to the fittings, hoses, and bleed-tee fitting.

À

Á

Â

Ã

Ä

Å

Æ

Ç

È

Shadow Drive

Starboard line

Port line

Return line

Helm

Power-assist module

Shut-off valves

Pump

Steering cylinder

Steering cylinders

À

Port line

Á

Shutoff valves

Â

Return line

Ã

Pump

Ä

Shadow Drive

Å

Starboard line

Æ

Helms

Ç

Uflex MasterDrive power unit

È

High pressure line - DO NOT CUT

É

Installation Procedures

CAUTION

Always wear safety goggles, ear protection, and a dust mask

when drilling, cutting, or sanding.

NOTICE

When drilling or cutting, always check what is on the opposite

side of the surface.

After you have planned the autopilot installation on your boat

and satisfied all of the mounting and wiring considerations for

5

Loading...

Loading...