Page 1

GHP™ 10 Marine Autopilot System Installation Instructions

To obtain the best possible performance and to avoid damage to your boat, install your GHP 10 marine autopilot system according to

the following instructions. Read all installation instructions before proceeding with the installation. If you experience difculty

during the installation, contact Garmin Product Support, or seek the advice of a professional installer.

Product Registration

Help us better support you by completing our online registration today! Connect to our Web site at http://my.garmin.com. Keep the

original sales receipt, or a photocopy, in a safe place.

For future reference, write the serial number assigned to each component of your GHP 10 system in the spaces provided on page 2.

The serial numbers are located on a sticker on each component.

Contact Garmin

Contact Garmin if you have any questions while using your GHP 10. In the USA contact Garmin Product Support by phone: (913)

397-8200 or (800) 800-1020, or go to www.garmin.com/support/.

In Europe, contact Garmin (Europe) Ltd. at +44 (0) 870.8501241 (outside the UK) or 0808 2380000 (within the UK).

Warnings

You are responsible for the safe and prudent operation of your vessel. The GHP 10 is a tool that will enhance your capability

•

to operate your boat. It does not relieve you from the responsibility of safely operating your boat. Avoid navigational hazards and

never leave the helm unattended.

Always be prepared to promptly regain manual control of your boat.

•

Learn to operate the GHP 10 on calm and hazard-free open water.

•

Use caution when operating the GHP 10 at high speeds near hazards in the water, such as docks, pilings, and other boats.

•

See the Important Safety and Product Information guide in the product box for product warnings and other important

•

information.

Cautions

Always wear safety goggles, ear protection, and a dust mask when drilling, cutting, or sanding.

•

When drilling or cutting, always check the opposite side of the surface. Be aware of fuel tanks, electrical cables, and hydraulic

•

hoses.

June 2008 190-00894-02 Rev. A Printed in Taiwan

Page 2

GHP 10 Package Contents and Tools Needed

The GHP 10 autopilot system consists of multiple components. Familiarize yourself with all of the components before beginning

installation. You must know how the components operate together in order to correctly plan the installation on your boat.

As you familiarize yourself with the GHP 10 components, conrm that your package includes the following items. All the components

except for the hydraulic pump are included in the GHP 10 core box. The pump is packaged separately. If any parts are missing, contact

your Garmin dealer immediately.

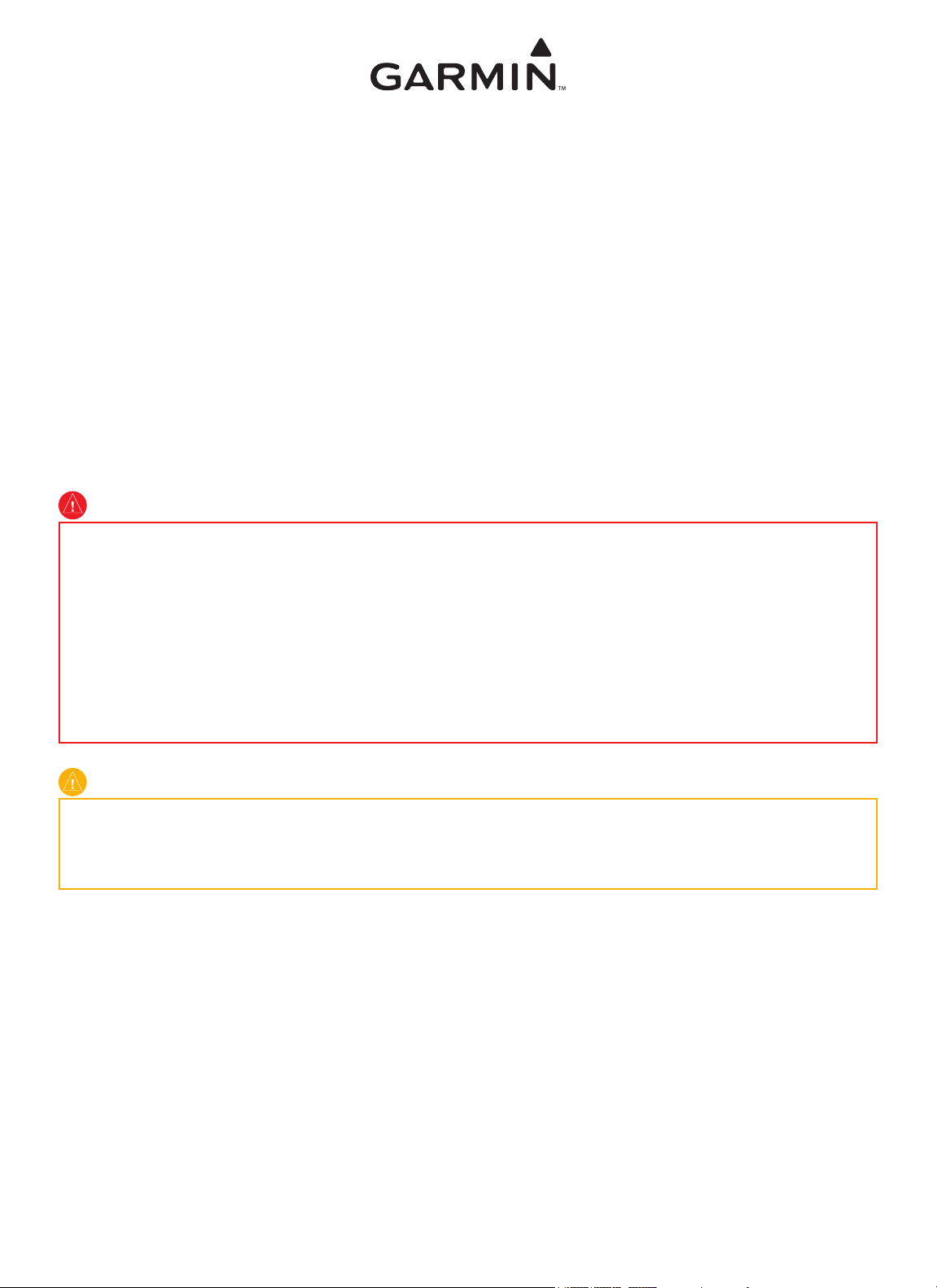

The Main Components

The GHP 10 autopilot system consists of ve main components: the Electronic Control Unit (ECU), the Course Computer Unit

(CCU), a hydraulic pump, the Shadow Drive

The Course Computer Unit (CCU)

The CCU acts as the “brain” of the GHP 10. The CCU contains the sensory equipment used to determine

heading and engine speed. The CCU connects to the Electronic Control Unit (ECU), to the GHC 10, and

to the tachometer of your boat with a single cable. The CCU also connects to a NMEA 2000® network to

communicate with the GHC 10, and to an optional NMEA 2000-compatible GPS device.

Garmin part number: 010-11052-00

Serial number

The Electronic Control Unit (ECU)

The ECU connects to the CCU and to the pump. The ECU controls the pump based on information from

the CCU. The ECU powers both the CCU and the pump.

™

, and the GHC™ 10 user control interface.

Garmin part number: 010-11053-00

Serial number

The Hydraulic Pump (and motor)

1.2 L/2.0 L Pump1.2 L/2.0 L Pump

Serial number

2.1 L Pump2.1 L Pump

The Shadow Drive

The Shadow Drive is a sensor you install in the hydraulic steering lines of your boat. While the GHP 10 is

engaged, the Shadow Drive temporarily disengages the autopilot when you manually take control of the

helm. When you manually steer the boat in a straight line again, the Shadow Drive allows the autopilot to

resume control.

Garmin part number: 010-11054-00

The hydraulic pump (and motor) steers your boat by interacting with the

hydraulic steering system, based on commands you enter using the GHC

10. The pump is not included in the GHP 10 core package box because

the type of pump you use with your GHP 10 is determined by the engine

and steering system of your boat. The pump is in a separate box.

Garmin part numbers: 010-11097-00 (2.0 L pump), 010-11098-00

(1.2 L pump), and 010-11099-00 (2.1 L pump)

Serial number

2 GHP 10 Marine Autopilot System Installation Instructions

Page 3

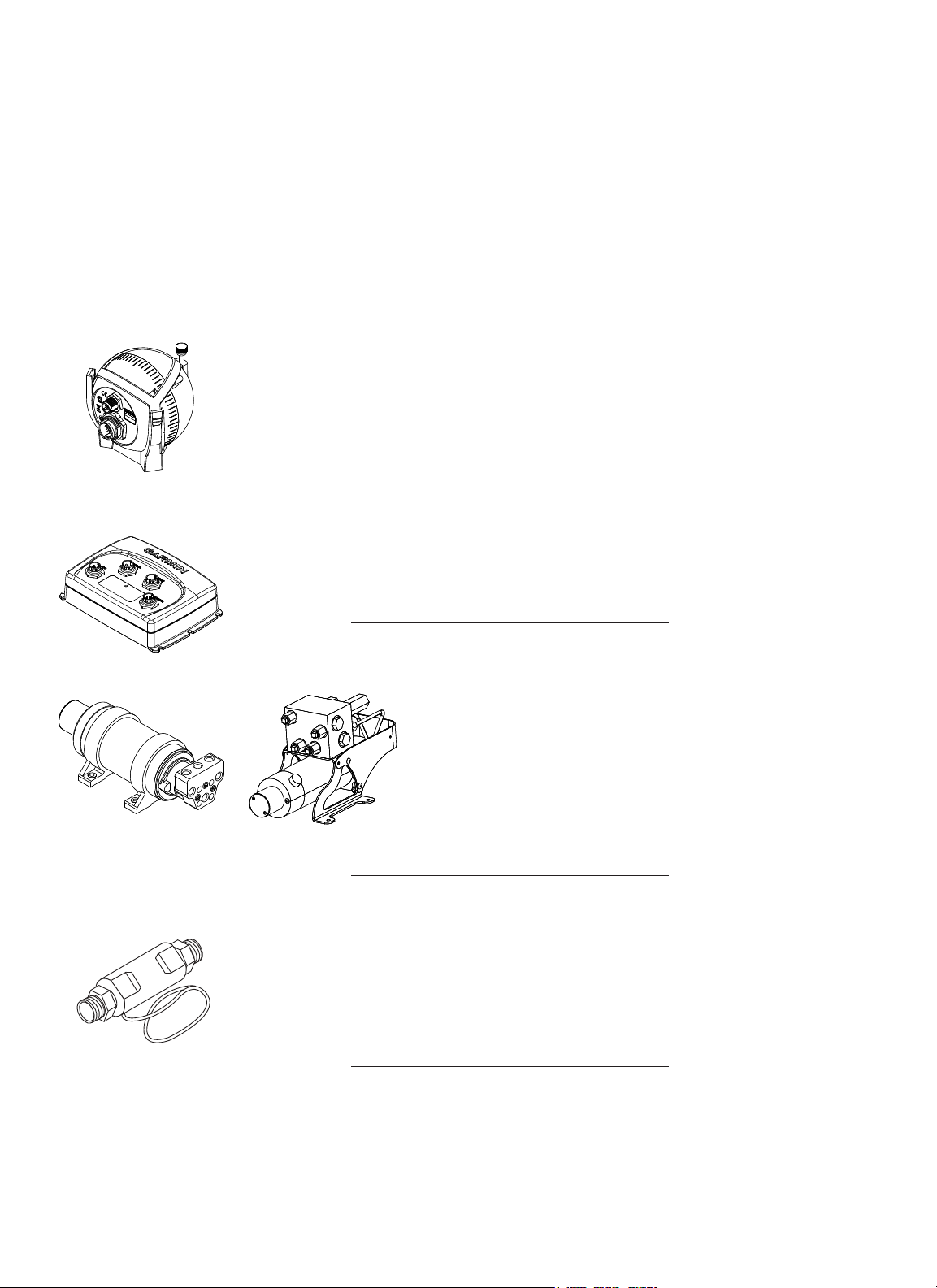

The GHC 10

Use the GHC 10 to operate the GHP 10 autopilot system. Using the GHC 10, you engage and steer

the GHP 10. You also set up and customize the GHP 10 using the GHC 10. The GHC 10 connects to

a NMEA 2000 network to communicate with the CCU and with an optional NMEA 2000-compatible

GPS device (to use waypoint and route information). If a NMEA 2000-compatible GPS device is not

available, you can wire the GHC 10 to an optional NMEA 0183-compatible GPS device instead.

Garmin part number: 010-00688-00

Serial number

Cables and Connectors

The GHP 10 autopilot system contains multiple cables. These cables connect the components to power, to each other, to an alarm, and

to optional devices such as a NMEA 0183-compatible GPS device.

CCU/ECU Interconnect Cable

This cable connects the CCU to the ECU. A portion of this cable contains color-coded wires with bare ends. These wires connect the

CCU to the tachometer of your boat, to the Shadow Drive, and to the alarm. (Garmin part number: 010-11055-00)

The Alarm

The alarm is wired to the CCU and provides audible alerts from the GHP 10. See page 18. (Garmin part number: 010-11056-00)

ECU Power Cable

This cable powers the ECU. Wire this to the battery of your boat as one of the last connections made in the GHP 10 installation.

See page 24. (Garmin part number: 010-11057-00)

GHC 10 Power/Data Cable

This cable is included in the GHC 10 box. Wire this cable to the battery of your boat as one of the last connections made in the GHP

10 installation. This cable is used to wire to an optional NMEA 0183-compatible GPS device. See page 20.

(Garmin part number: 320-00023-07)

3GHP 10 Marine Autopilot System Installation Instructions

Page 4

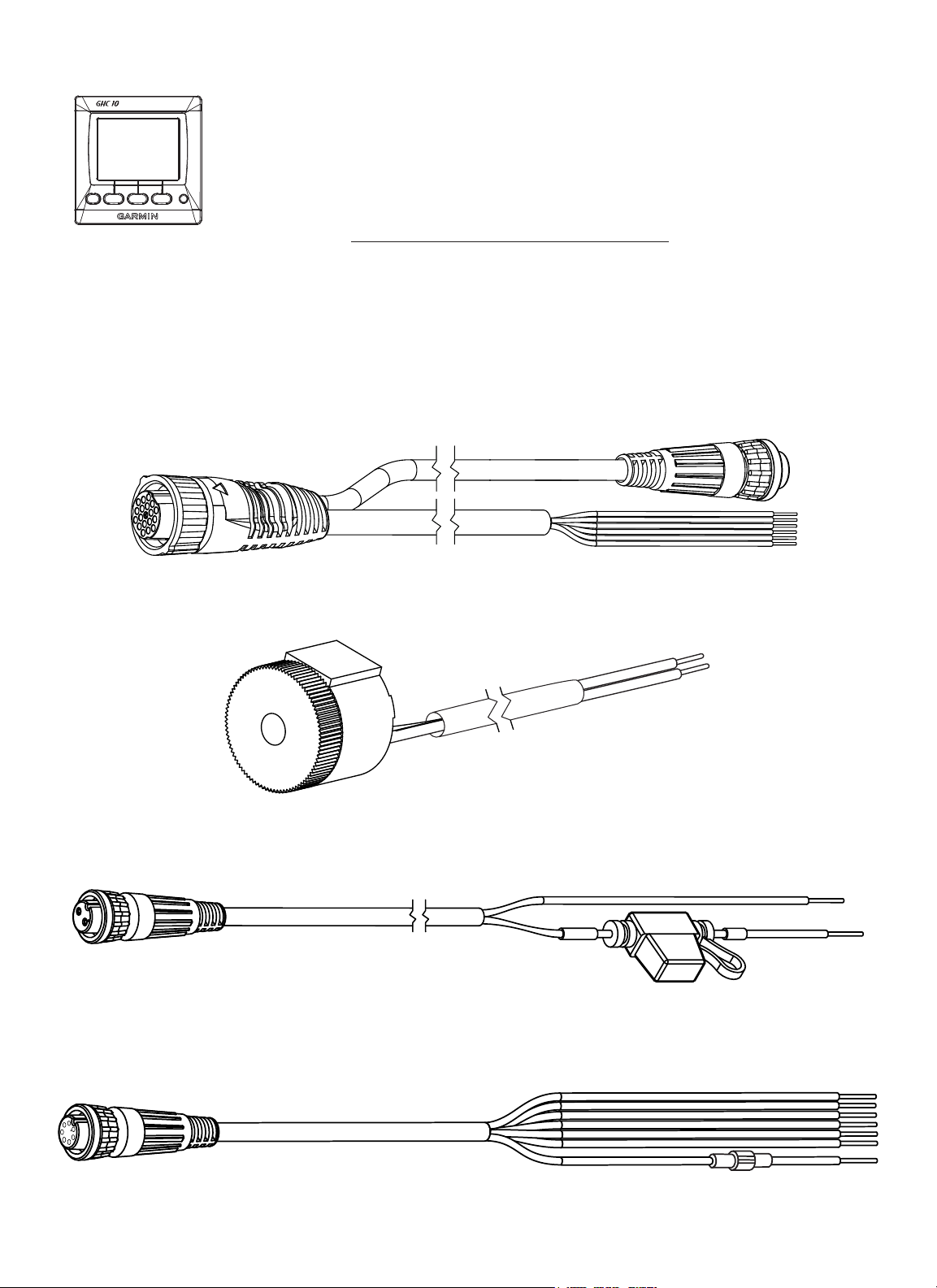

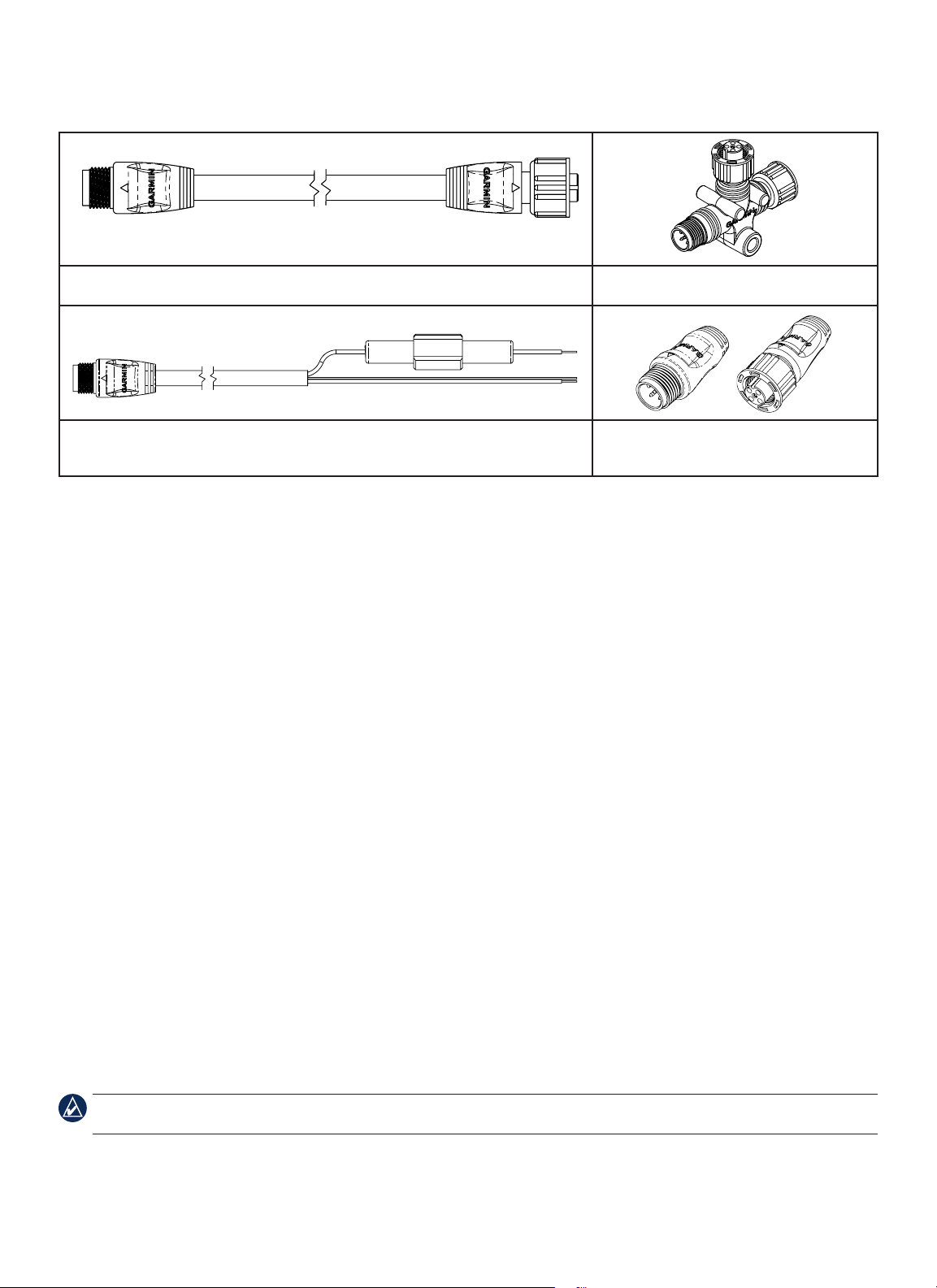

NMEA 2000 Cables and Connectors

The NMEA 2000 cables connect the CCU and the GHC 10 to the NMEA 2000 network. Use the NMEA 2000 power cable and two

terminators to create a NMEA 2000 network on your boat if one does not exist. For more information on NMEA 2000, see page 21.

NMEA 2000 drop cable, 6 ft. (2 m) (×2), Garmin part number: 320-00387-00 NMEA 2000 T-connector (×3), Garmin part

number: 330-00563-00

NMEA 2000 power cable, Garmin part number: 320-00389-00 (×1) NMEA 2000 terminators, male Garmin part

number: 330-00564-00 (×1); female Garmin part

number: 330-00565-00 (×1)

CCU/ECU Interconnect Extension Cables (Not Included)

When installing the GHP 10 system, you may need to mount the CCU farther than 91/2 ft. (3 m) from the ECU. Garmin offers two

optional extension cables for purchase if this is necessary, a 161/2 ft. (5 m) cable (Garmin part number 010-11156-00) and a 49 ft.

(15 m) cable (Garmin part number: 010-11156-01). Contact your local Garmin dealer or Garmin Product Support for ordering

information.

Tools Needed

Safety glasses

•

Drill and drill bits

•

Jigsaw or 317/32 in. (90 mm) hole saw

•

Center punch and hammer

•

Scissors

•

Wrenches

•

Pliers

•

Wire cutters/stripers

•

File and sandpaper

•

Phillips head and athead screwdrivers

•

Cable ties

•

Waterproof wire connectors (wire nuts)

•

Surface-specic mounting hardware (screws)

•

Marine sealant

•

Anti-seize lubricant (optional)

•

Compass (to test for magnetic interference)

•

NOTE: Mounting screws are provided for the GHC 10, for the CCU, for the ECU, and for the pump. If the provided screws are not

appropriate for the mounting surface, you will need to provide the correct types of screws.

Hydraulic supplies

•

Hose cutter

◦

Additional hydraulic hose with machine-crimped or

◦

eld-replaceable ttings that have a minimum rating of

1000 lb/in

Additional hydraulic uid

◦

Rags

◦

Thread sealant (Loctite® Pro Lock Tight® multipurpose

◦

2

anaerobic gel, part number 51604, or equivalent)

Helm/hydraulic bleeding equipment

◦

4 GHP 10 Marine Autopilot System Installation Instructions

Page 5

Installation Preparation

Before installing the GHP 10 autopilot system, it is important for you to completely understand where all the components will be

located on your boat. Temporarily place all the components where you plan to install them. Ensure that all cables and hydraulic hoses

can reach the necessary components before mounting any components.

Hydraulic Considerations – 2.0 L and 1.2 L Pumps

Different boats have different hydraulic considerations you must examine before mounting the pump or cutting any hoses. Before

starting the hydraulic installation, verify the type of hydraulic steering in your boat, and where to install the appropriate type of pump.

CAUTION: If the hydraulic steering of your boat does not match the hydraulic layouts in this manual, contact Garmin Product Support.

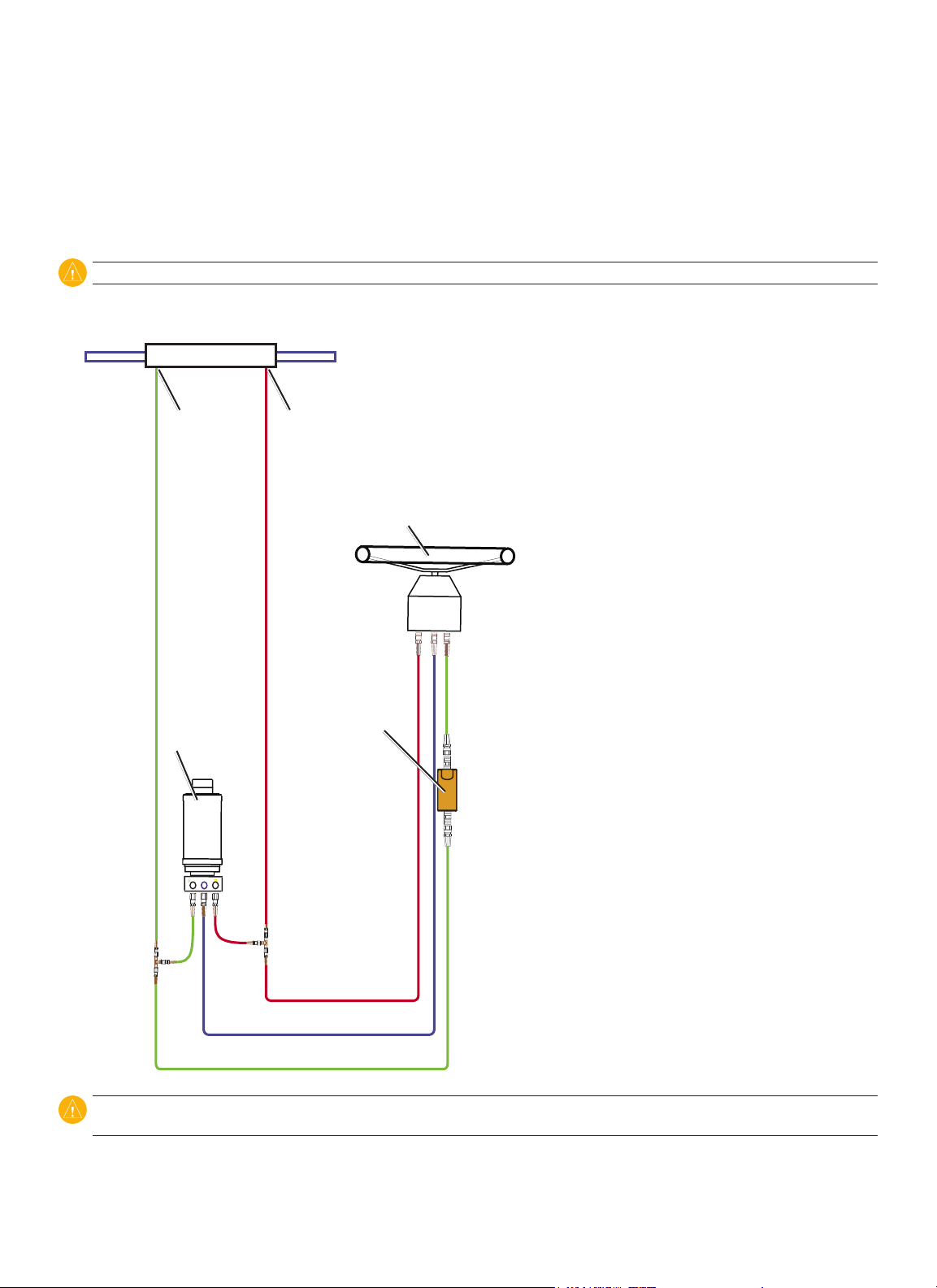

Single-Helm Boats (Without Power Assist)

Balanced cylinder

2.0 L/1.2 L pump

(and motor)

Port ttingStarboard tting

Shadow drive

Helm

P R S

Notes:

2.0 L/1.2 L pump (and motor):

•

An unbalanced cylinder requires an

◦

unbalanced valve on the pump (See page 30)

Mount the pump horizontally if possible. Do

◦

not mount the pump vertically with the pump

end (hydraulic connections) down.

Shadow Drive

•

Mount the Shadow Drive horizontally and as

◦

level as possible.

Install the Shadow Drive in either the port or

◦

the starboard hydraulic steering line.

Always install a length of hose between the

◦

helm and the Shadow Drive.

Do not install the Shadow Drive directly to

◦

the helm.

Install the Shadow Drive between the pump

◦

and the helm.

Do not install the Shadow Drive between

◦

the pump and the cylinder.

Port line

Return line

Starboard line

CAUTION: Do not turn the system on until you bleed all the air from the helm, the Shadow Drive, the pump, and all the hydraulic lines.

See page 24.

5GHP 10 Marine Autopilot System Installation Instructions

Page 6

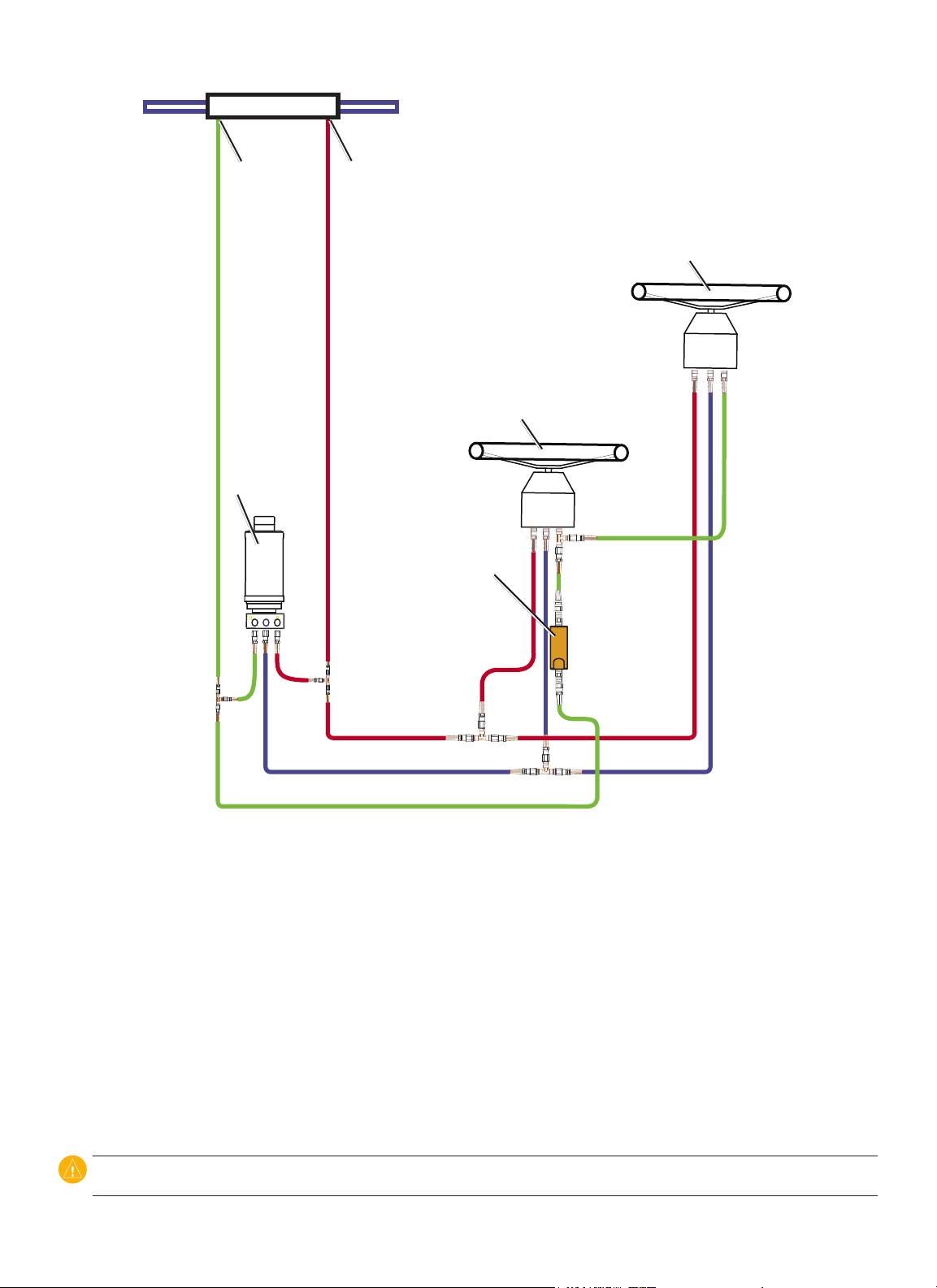

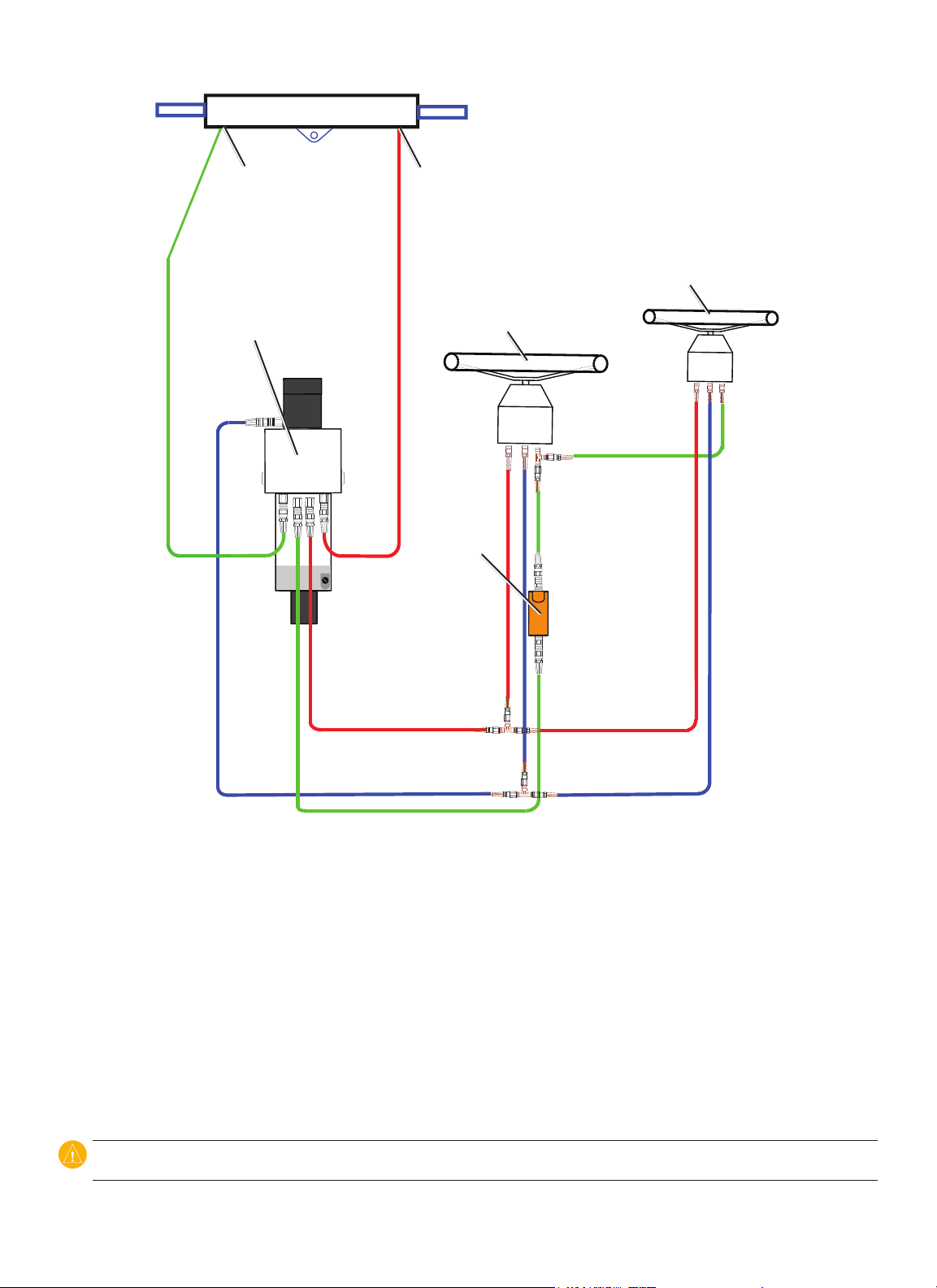

Dual-Helm Boats

Balanced cylinder

Starboard tting

2.0 L/1.2 L pump

(and motor)

Port tting

Upper helm

P R S

Lower helm

P R S

Shadow drive

Port line

Return line

Starboard line

Notes:

2.0 L/1.2 L pump (and motor):

•

An unbalanced cylinder requires an unbalanced valve on the pump (See page 30)

◦

Mount the pump horizontally if possible. Do not mount the pump vertically with the pump end (hydraulic connections) down.

◦

Shadow Drive

•

Mount the Shadow Drive horizontally and as level as possible.

◦

Install the Shadow Drive in either the port or the starboard hydraulic steering line.

◦

Always install a length of hose between the helm and the Shadow Drive.

◦

Install the Shadow Drive between the pump and both helms.

◦

Do not install the Shadow Drive directly to the helm.

◦

Do not install the Shadow Drive between the pump and the cylinder.

◦

Do not install the Shadow Drive between the two helms.

◦

CAUTION: Do not turn the system on until you bleed all the air from the helm, the Shadow Drive, the pump, and all the hydraulic lines.

See page 24.

6 GHP 10 Marine Autopilot System Installation Instructions

Page 7

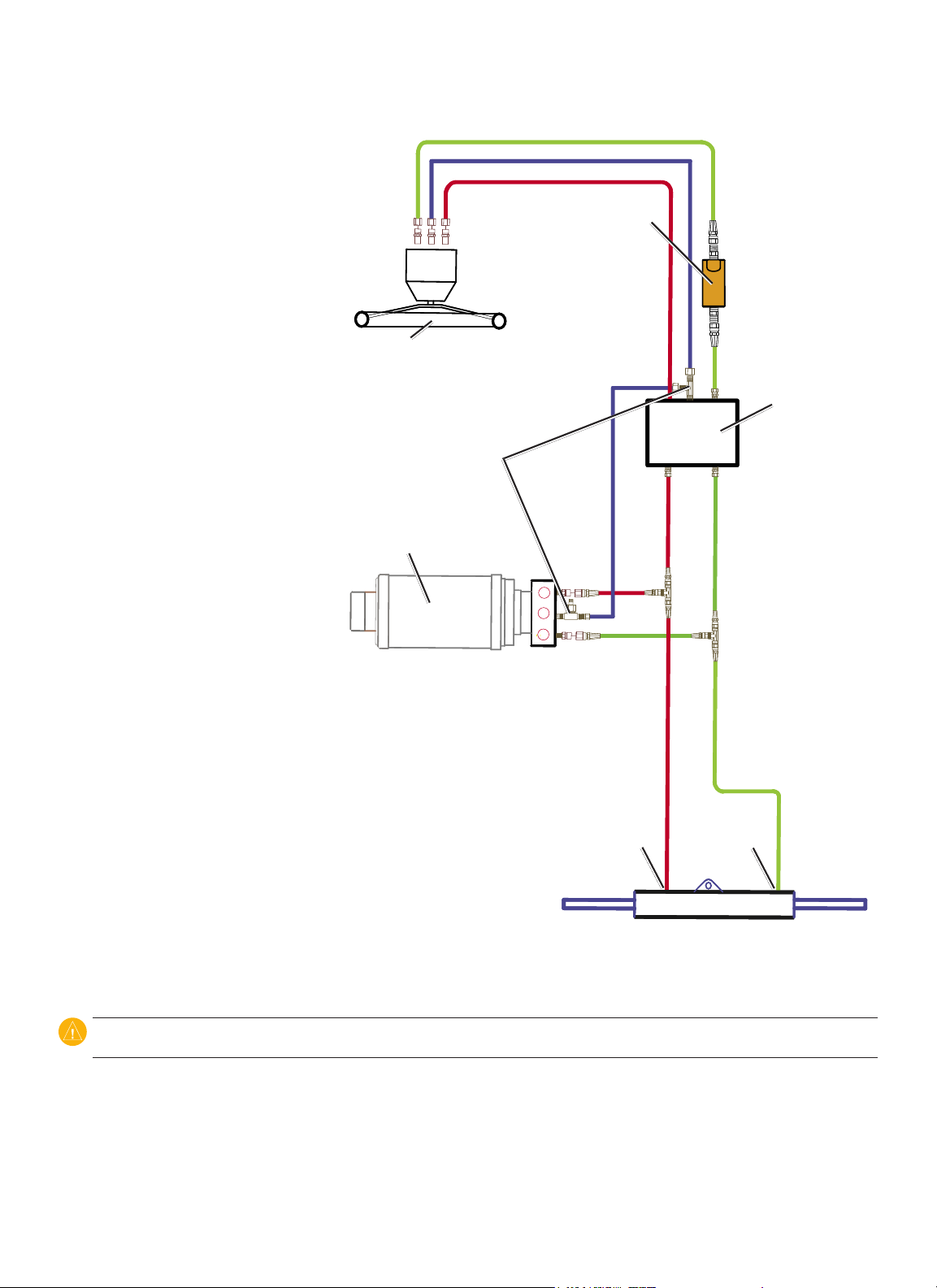

SeaStar Power Assist-Enabled Boats

Notes:

Starboard line

Power Assist module:

•

It may be necessary to remove the

◦

Power Assist module to gain access

to the ttings, the hoses, and the

bleed-tee tting.

S R P

Remove the bleed-tee tting from

◦

S R P

the Power Assist module and

relocate it to the return port on the

pump.

2.0 L/1.2 L pump (and motor):

•

Install the pump to the steering lines

◦

Helm

Helm

between the cylinder and the Power

Assist module.

Do not install the pump to the

◦

Bleed-tee tting

Bleed-tee tting

(relocate to the pump)

(relocate to the pump)

steering lines between the helm

and the Power Assist module.

An unbalanced cylinder requires

◦

an unbalanced valve on the pump

2.0 L/1.2 L pump

2.0 L/1.2 L pump

(and motor)

(and motor)

(See page 30)

Mount the pump horizontally if

◦

possible. Do not mount the pump

vertically with the pump end

(hydraulic connections) down.

Shadow Drive

•

Mount the Shadow Drive

◦

horizontally and as level as possible.

Install the Shadow Drive in either

◦

the port or the starboard hydraulic

steering line.

Always install a length of hose

◦

between the helm and the Shadow

Drive.

Do not install the Shadow Drive

◦

directly to the helm.

Install the Shadow Drive between the helm and the Power Assist module.

◦

◦

Do not install the Shadow Drive between the Power Assist module and the pump.

◦

Do not install the Shadow Drive between the Power Assist module and the cylinder.

Starboard line

Return line

Return line

Port line

Port line

Shadow drive

Shadow drive

Return line

Return line

Port tting

Port tting

H1 H2

H1 H2

C2C1

C2C1

Starboard tting

Starboard tting

Balanced cylinder

Balanced cylinder

Sea Star

Sea Star

Power Assist

Power Assist

module

module

CAUTION: Do not turn the system on until you bleed all the air from the Power Assist module, the helm, the Shadow Drive, the pump, and

all the hydraulic lines. See page 24.

7GHP 10 Marine Autopilot System Installation Instructions

Page 8

Hydraulic Considerations – 2.1 L Pump

Different boats have different hydraulic considerations you must examine before mounting the pump or cutting any hoses. Before

starting the hydraulic installation, verify the type of hydraulic steering in your boat, and where to install the appropriate type of pump.

CAUTION: If the hydraulic steering of your boat does not match the hydraulic layouts in this manual, contact Garmin Product Support.

Single-Helm Boats

Balanced cylinder

Port ttingStarboard tting

Notes:

2.1 L pump (and motor):

•

Do not use the 2.1 L pump on a system with an

◦

unbalanced cylinder.

Mount the pump horizontally if possible. Do not

◦

mount the pump vertically with the pump end

(hydraulic connections) down.

2.1 L pump

(and motor)

Shadow drive

Helm

P R S

Shadow Drive

•

Mount the Shadow Drive horizontally and as

◦

level as possible.

Install the Shadow Drive in either the port or the

◦

starboard hydraulic line.

Always install a length of hose between the helm

◦

and the Shadow Drive.

Install the Shadow Drive between the pump and

◦

the helm.

Do not install the Shadow Drive directly to the

◦

helm.

Do not install the Shadow Drive between the

◦

pump and the cylinder.

Port line

Return line

Starboard line

CAUTION: Do not turn on the system until you bleed all the air from the Power Assist module, the helm, the Shadow Drive, the pump, and

all the hydraulic lines. See page 24.

8 GHP 10 Marine Autopilot System Installation Instructions

Page 9

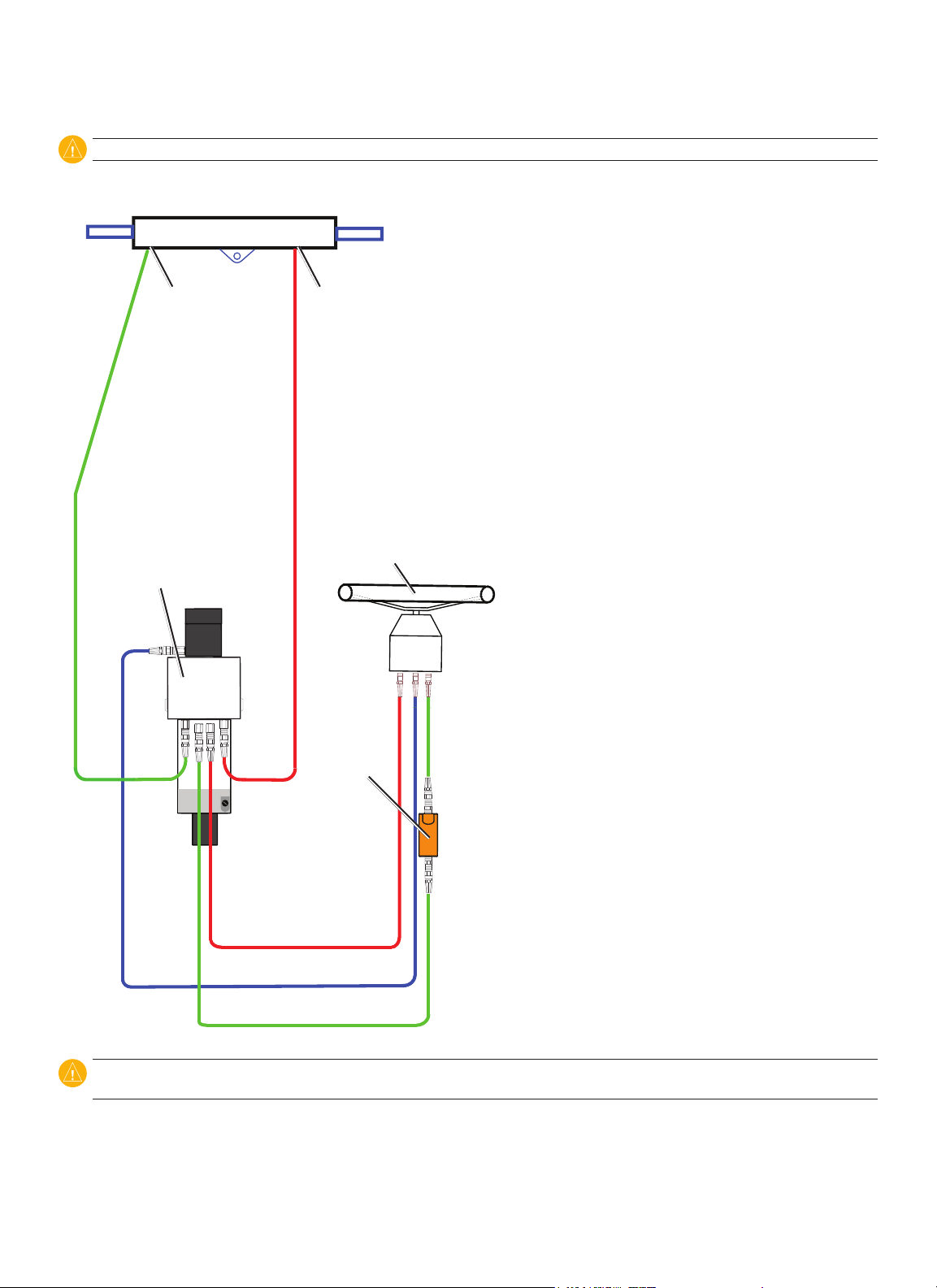

Dual-Helm Boats

Balanced cylinder

Starboard tting

2.1 L pump

(and motor)

Port tting

Upper helm

Lower helm

P R S

P R S

Shadow drive

Port line

Return line

Starboard line

Notes:

2.1 L pump (and motor):

•

Do not use the 2.1 L pump on a system with an unbalanced cylinder.

◦

Mount the pump horizontally if possible. Do not mount the pump vertically with the pump end (hydraulic connections) down.

◦

Shadow Drive

•

Mount the Shadow Drive horizontally and as level as possible.

◦

Install the Shadow Drive in either the port or the starboard hydraulic line.

◦

Always install a length of hose between the helm and the Shadow Drive.

◦

Install the Shadow Drive between the pump and the helm.

◦

Do not install the Shadow Drive directly to the helm.

◦

Do not install the Shadow Drive between the pump and the cylinder.

◦

CAUTION: Do not turn on the system until you bleed all the air from the Power Assist module, the helm, the Shadow Drive, the pump, and

all the hydraulic lines. See page 24.

9GHP 10 Marine Autopilot System Installation Instructions

Page 10

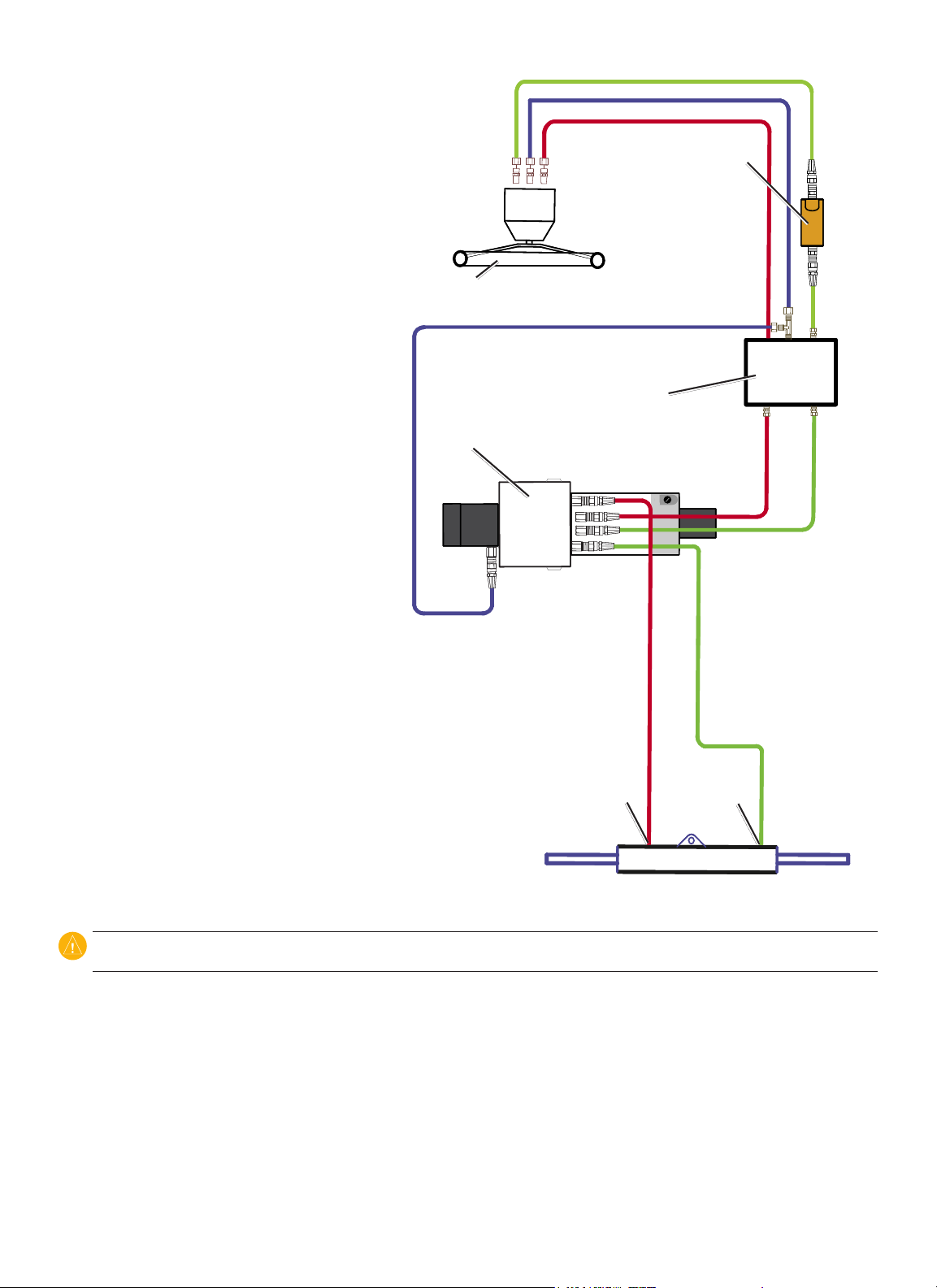

SeaStar Power Assist-Enabled Boats

Notes:

Power Assist module:

•

It may be necessary to remove the Power Assist

◦

module to gain access to the ttings, the hoses,

and the bleed-tee tting

You may need to add a tee tting in the return

◦

line at the Power Assist module to connect the

pump.

2.1 L pump (and motor):

•

Install the pump to the steering lines between

◦

the cylinder and the Power Assist module.

Do not install the pump to the steering lines

◦

between the helm and the Power Assist

module.

Do not use the 2.1 L pump on a system with

◦

an unbalanced cylinder.

Mount the pump horizontally if possible. Do

◦

not mount the pump vertically with the pump

end (hydraulic connections) down.

Shadow Drive

•

Mount the Shadow Drive horizontally and as

◦

level as possible.

Install the Shadow Drive in either the port or

◦

the starboard hydraulic steering line.

Always install a length of hose between the

◦

helm and the Shadow Drive.

Install the Shadow Drive between the helm and

◦

the Power Assist module.

Do not install the Shadow Drive directly to

◦

the helm.

Do not install the Shadow Drive between the

◦

Power Assist module and the pump.

Do not install the Shadow Drive between the

◦

Power Assist module and the cylinder.

S R P

S R P

Helm

Helm

Return line

Return line

2.1 L pump (and motor)

2.1 L pump (and motor)

Starboard line

Starboard line

Return line

Return line

Port line

Port line

Sea Star

Sea Star

Power Assist

Power Assist

module

module

Port tting

Port tting

Shadow drive

Shadow drive

Starboard tting

Starboard tting

Balanced cylinder

Balanced cylinder

H1 H2

H1 H2

C2

C2

C1

C1

CAUTION: Do not turn the system on until you bleed all the air from the Power Assist module, the helm, the Shadow Drive, the pump, and

all the hydraulic lines. See page 24.

10 GHP 10 Marine Autopilot System Installation Instructions

Page 11

Electrical/Data Connection and Mounting Considerations

The GHP 10 components connect to each other and to power using the included cables. Ensure that the correct cables reach

each component, and that each component is in an acceptable location, before mounting any components. Read the following

considerations and consult the diagram on the next page before you begin installation.

The Pump and the ECU

The pump must be located within 19 in. (0.5 m) of the ECU, mounted horizontally if possible. If you cannot mount the pump

•

horizontally, do not mount the pump vertically with the pump head (connectors) down.

•

The cables from the pump to the ECU cannot be extended.

The ECU power cable connects to the boat battery.

•

The CCU and the ECU

Do not mount the CCU or the ECU in a location where they will be submerged or exposed to wash-down.

•

•

Mount the CCU in the forward half of the boat, no higher than 10 ft. (3.05 m) above the waterline.

You can mount the CCU below the waterline, as long as it is not in a location where it will be submerged or exposed to wash-

•

down.

Mount the CCU bracket on a vertical surface or under a horizontal surface, so that the connected wires hang straight down.

•

•

Do not mount the CCU near magnetic material, magnets (speakers and electric motors), or high-current wires.

CCU at least 24 in. (0.61 m) away from movable or changing magnetic disturbances such as anchors, anchor chain, wiper motors,

tool boxes, and the autopilot pump. Use a handheld compass to test for magnetic interference in the area.

The CCU/ECU interconnect cable connects the CCU to the ECU, and is 91/2 ft. (3 m) long. If you cannot mount the CCU within

•

91/2 ft. (3 m) of the ECU, extension cables are available in lengths of 16

The CCU/ECU interconnect cable connects the CCU to the Shadow Drive, the alarm buzzer, the tachometer of the boat, and the

•

yellow CCU signal wire of the GHC 10 using wires with bare ends. See page 17 for wiring instructions and diagrams.

1

/2 ft. (5 m) and 49 ft. (15 m). (See page 4).

Mount the

The CCU and the GHC 10

The CCU and the GHC 10 connect to a NMEA 2000 network. If you do not have a NMEA 2000 network on your boat, the

•

equipment necessary to build one is provided. For instructions on setting up the NMEA 2000 network, see page 21.

You can connect an optional NMEA 2000-compatible GPS device to the NMEA 2000 network to use waypoint and route data with

•

the GHP 10.

The GHC 10

Wire the GHC 10 to the battery of the boat and to the yellow CCU signal wire of the CCU/ECU interconnect cable.

•

If you do not have an optional NMEA 2000-compatible GPS device, you can wire an optional NMEA 0183-compatible GPS

•

device to the power/data cable of the GHC 10 instead (see page 23).

The Shadow Drive

Install the Shadow Drive closer to the helm than to the pump.

•

Mount the Shadow Drive horizontally, as level as possible.

•

Mount the Shadow Drive at least 12 in. (0.3 m) away from magnetic material such as speakers and electric motors,

•

including the autopilot pump.

11GHP 10 Marine Autopilot System Installation Instructions

Page 12

ENCODER

CCU

POWER

}

PUMP

Ignition or

in-line switch

Yellow CCU signal wire

(see page 20)

8-32 Vdc

1 A fuse

Black (-)

GHC 10

Red (+)

9-16 Vdc

3 A fuse

Pump

(2.1 L pictured)

Red (+)

Black (-)

Drain (-)

NMEA 2000 power cable

Red (+)

12 Vdc

40 A fuse

NMEA 2000 network (see page 21)

ECU

Black (-)

CCU/ECU Interconnect cable

GHP 10 General Wiring Outline

CCU

For tachometer wiring,

see page 18

Boat tachometer

Orange - unconnected

White (+)

Red (+)

Blue (-)

For CCU bare-wire connections, see page 17.

Brown (+)

Yellow CCU signal wire (see page 20)

Black (-)

Alarm buzzer

Red (+)

Black (-)Black (-)

Shadow Drive

Notes:

This diagram is for planning purposes. Specic wiring diagrams are included in the detailed installation instructions for each

•

component. Hydraulic connections are not shown in this diagram.

Connect an optional NMEA 0183-compatible GPS device to the power/data cable on the GHC 10. See page 23 for more

•

information.

Connect an optional NMEA 2000-compatible GPS device to the NMEA 2000 network. See page 23 for more information.

•

12 GHP 10 Marine Autopilot System Installation Instructions

Page 13

Installation Procedures

After you have completely planned the GHP 10 installation on your boat, and have satised all the hydraulic, mounting, and wiring

considerations for your particular installation, you can begin mounting and connecting the components.

Installing the Pump (and Motor)

Install the pump by mounting it on your boat, connecting it to the hydraulic steering lines of your boat, and connecting it to the ECU.

If your boat uses an unbalanced-cylinder steering system, be sure you have a 2.0 L or 1.2 L pump with the unbalanced kit installed. If

your 2.0 L or 1.2 L pump does not have an unbalanced kit installed, follow the directions on page 30 to install an unbalanced kit for

use with an unbalanced-cylinder steering system. Do not use a 2.1 L pump with an unbalanced-cylinder steering system.

Mounting the Pump

Mount the pump horizontally on a solid surface. Mounting the pump horizontally on the oor is preferable, but you can also mount the

pump horizontally on a wall. If horizontal mounting is not possible, do not install the pump vertically with the pump head (containing

the hose ttings) down. Mount the pump within 19 in. (.5 m) of the ECU. Mount the pump in a location to which you can extend

the hydraulic steering lines of the boat.

To mount the pump:

1. Determine the best location for the pump on your boat, satisfying the hydraulic and wiring considerations.

2. Determine the correct type of screws for the mounting surface. Mounting screws are included with the pump, but you may need to

provide different screws if the supplied screws are not suitable for the mounting surface.

3. Use the correct mounting template for your pump. The templates are provided on page 33. Tape the template to the mounting

location and use a center punch and hammer to mark the pilot-hole locations.

4. Drill pilot holes at the four mounting locations.

5. Use screws to mount the pump.

NOTE: To reduce noise while the autopilot is running, install a vibration-isolation mounting pad between the pump and the mounting

surface.

6. Use a spray-on corrosion blocker on the pump after it is mounted and all hydraulic and electrical connections are made.

Connecting the 2.0 L or the 1.2 L Pump to the Hydraulic Lines

Before disconnecting any hydraulic lines on your boat, consult the manufacturer of your boat or steering system. You must know how

to properly prepare the hoses for removal, and you must know how to properly bleed the hydraulic system of air when you complete

the connections. When adding hydraulic hose to the steering system, only use hose with machine-crimped or eld-replaceable

ttings that have a minimum rating of 1000 lb/in

The 2.0 L and the 1.2 L pump manifolds have two sets of hose-connector ttings, both upper and lower, to allow for different

hose congurations. You can use the upper ttings, the lower ttings, or a combination of the two. Do not use Teon tape on any

hydraulic tting. Use an appropriate thread sealant such as Loctite Pro Lock Tight multipurpose anaerobic gel, part number 51604, or

equivalent, on all pipe threads in the hydraulic system.

Pump/motor body

2

.

Upper ttings

Lower ttings

Pump manifold

13GHP 10 Marine Autopilot System Installation Instructions

Page 14

To connect the pump to the hydraulic lines:

1. Consult the hydraulic layout diagrams starting on page 5 to nd the correct place to connect the pump to your hydraulic system.

2. Prepare to disconnect the hydraulic lines in your boat as specied by the manufacturer of your boat or steering system.

3. Disconnect the hydraulic lines from the steering system where appropriate.

4. Add additional hose where necessary, and add the included t-connectors in the hydraulic lines.

5. Add hydraulic hose from the t-connectors to the pump, using the included ttings to attach the hose to the pump.

6. Add hydraulic hose from the return connector at the back of the helm to the pump, using the included ttings.

7. Connect the hoses to the upper ttings, the lower ttings, or a combination of both ttings on the pump. Do not connect more than

three hoses to the pump (port, starboard, and return).

8. Insert, tighten, and seal the included plugs in the three unused pump ttings.

9. You will eventually need to bleed the hydraulic system, but not until the Shadow Drive is installed. See page 24 for more

information.

NOTE: The pump may vibrate the hydraulic lines and cause noise when the autopilot is running. To eliminate the noise, tie the hydraulic

lines to a solid surface.

Operating the Shutoff Valve

The 2.0 L and the 1.2 L pumps feature a shutoff valve for troubleshooting and repairing the system. To engage the shutoff valve and

isolate the pump from the hydraulic system, fully tighten the three brass screws near the lower hydraulic connectors. To disengage the

shutoff valve, loosen the three brass screws until they stop.

Socket-headed cap screws

Brass shutoff

screws

Socket-headed cap screws

CAUTION: Do not force the three brass screws past the stopping point when disengaging the shutoff valve. Forcing the screws past the

stopping point may permanently damage the manifold.

When the shutoff valve is engaged, the boat will steer normally, and the pump will not control the steering system. When the shutoff

valve is engaged, you can remove the pump from the system for repair without disconnecting any hydraulic lines.

To remove the pump from the shutoff-valve manifold:

1. Tighten the three brass screws near the lower hydraulic connectors.

2. Remove the four socket-head cap screws that connect the manifold to the pump.

3. The manifold is no longer connected to the pump, and the pump can be disconnected from the ECU and removed from its

mounting location. The hydraulic steering system will operate normally.

To reconnect the pump to the shutoff-valve manifold:

1. Remount the pump and reconnect the pump to the ECU.

2. Connect the manifold to the pump using the four socket-head cap screws.

3. Loosen the three brass screws near the lower hydraulic connectors until they stop. Do not loosen the screws past the stopping

point.

Connecting the Pump to the ECU

Do not connect the pump to the ECU until you have mounted the ECU to the boat following the procedures on page 16.

14 GHP 10 Marine Autopilot System Installation Instructions

Page 15

Connecting the 2.1 L Pump to the Hydraulic Lines

The 2.1 L pump must be isolated from the electrical ground of the boat. Use insulating washers under the pump if it is installed on an

electrically-grounded (metal) surface. Install the washers between the pump bracket and the grounded surface

Before disconnecting any hydraulic lines on your boat, consult the manufacturer of your boat or steering system. You must know how

to properly prepare the hoses for removal, and you must know how to properly bleed the hydraulic system of air when you complete

the connections. When adding hydraulic hose to the steering system, only use hose with machine-crimped or eld-replaceable

ttings that have a minimum rating of 1000 lb/in

Install the 2.1 L pump inline with the hydraulic steering lines of the boat. The 2.1 L pump does not branch off of the hydraulic steering

lines like the 2.0 L or the 1.2 L pumps. The 2.1 L pump manifold has ve hose-connector ttings, three to the helm (port, starboard,

and return), and two to the cylinder (port and starboard). Do not use Teon tape on any hydraulic tting. Use an appropriate thread

sealant such as Loctite Pro Lock Tight multipurpose anaerobic gel, part number 51604, or equivalent, on all pipe threads in the

hydraulic system.

2

.

Cylinder starboard

connector

Helm starboard

connector

Pump/motor

body

To connect the pump to the hydraulic lines:

1. Consult the hydraulic layout diagrams starting on page 8 to determine the correct place to connect the pump to your hydraulic

system.

2. Prepare to disconnect the hydraulic lines in your boat as specied by the manufacturer of your boat or steering system.

3. Disconnect the hydraulic lines from the steering system where appropriate.

4. Remove the plugs from the ve connectors on the pump.

5. Add hydraulic hose as necessary, and route the hose to the pump.

6. Use the included ttings to attach the hoses to the pump. Use the above diagram to identify the connectors on the pump.

7. Add hydraulic hose from the return connector at the back of the helm to the pump.

8. Connect the hose to the helm and to the return-line connector on the pump using the included ttings.

9. You will eventually need to bleed the hydraulic system, but not until the Shadow Drive is installed. See page 24 for more

information.

Cylinder port

connector

Helm port

connector

Helm return-line

connector

NOTE: The pump may vibrate the hydraulic lines and cause noise when the autopilot is running. To eliminate the noise, tie the hydraulic

lines to a solid surface.

Connecting the Pump to the ECU

Do not connect the pump to the ECU until you have mounted the ECU to the boat following the procedures on page 16.

15GHP 10 Marine Autopilot System Installation Instructions

Page 16

Installing the Electronic Control Unit (ECU)

To install the ECU, mount it to your boat, connect it to the pump and to the CCU, and wire it to the boat battery.

Mounting the ECU

Mount the ECU horizontally on a at surface within 19 in. (.5 m) of the pump. The cables from the pump cannot be extended.

Mount the ECU in a location where you can run wire to the boat battery, but do not connect it to the battery at this time. The power

wire can be extended, if necessary. Use the table on page 24 to determine the correct type of wire for extending the battery cable.

To mount the ECU:

1. Determine the best location for the ECU on your boat, satisfying the wiring considerations.

2. Determine the correct type of screws for the mounting surface. Mounting screws are included with the ECU, but you may need to

provide different screws if the supplied screws are not suitable for the mounting surface.

3. Use the mounting template provided on page 31. Tape the template to the mounting location and use a center punch and hammer

to mark the pilot-hole locations.

4. Drill pilot holes at the four mounting locations.

5. Use screws to mount the ECU.

Wiring the ECU

Connect the two wires from the pump to the connectors marked PUMP and ENCODER on the ECU. The connectors are keyed to the

appropriate ttings on the wires. Do not connect the ECU to power until all the connections of the entire GHP 10 system have

been completed (page 24). Wait to connect the CCU/ECU interconnect cable until you have mounted the CCU by following the

procedures in the next section.

Installing the Course Computer Unit (CCU)

Install the CCU by mounting it to your boat, connecting it to the ECU and to a NMEA 2000 network, and wiring it to the Shadow

Drive, to the tachometer of your boat, to the alarm buzzer, and to the yellow CCU signal wire on the GHC 10.

Mounting the CCU

Mount the CCU on the boat by using the included bracket. The CCU bracket has two portions, the mounting portion and the securing

portion. Install the mounting portion on the mounting surface, and secure the CCU in the bracket with the securing portion.

When mounting the CCU:

Mount the CCU in the forward half of the boat, no higher than 10 ft. (3.05 m) above the waterline.

•

You can mount the CCU below the waterline, as long as it is not in a location where it will be submerged or exposed to wash-down.

•

Mount the CCU bracket on a vertical surface or under a horizontal surface, so that the connected wires hang straight down.

•

Do not mount the CCU near magnetic material, magnets (speakers and electric motors), or high-current wires.

•

Mount the CCU at least 24 in. (0.6 m) away from movable or changing magnetic disturbances such as anchors, anchor chain,

•

wiper motors, tool boxes, and the autopilot pump.

Use a handheld compass to verify the absence of magnetic interference. If the handheld compass does not point north when you

•

hold it in the location you want to mount the CCU, then there is magnetic interference. Choose another location and test again.

If possible, mount the CCU within 9

•

extensions are available in lengths of 16

To mount the CCU bracket

1. Determine the best location for the CCU on your boat. Use a handheld compass to be

sure that the location is free of magnetic interference.

2. Determine the correct type of screws for the mounting surface. Mounting screws are

included with the CCU, but you may need to provide different screws if the supplied

screws are not suitable for the mounting surface.

3. Use the mounting template provided on page 31. Be sure to install the mounting

portion of the bracket with an opening at the bottom. Tape the template to the mounting

location and use a center punch and hammer to mark the pilot-hole locations.

4. Drill pilot holes at the three mounting locations.

5. Use screws to secure the mounting portion of the CCU bracket.

1

/2 ft. (3 m) of the ECU. If you cannot mount the CCU within 9

1

/2 ft. (5 m) and 49 ft. (15 m). (See page 4.)

Thumbscrew

Thumbscrew

Mounting

Mounting

screws (×3)

screws (×3)

1

/2 ft. (3 m) of the ECU,

Opening for cables

Opening for cables

16 GHP 10 Marine Autopilot System Installation Instructions

Page 17

To secure the CCU in the CCU bracket:

1. Connect the CCU/ECU interconnect cable and the NMEA 2000 drop cable to the CCU.

2. Place the CCU in the mounting portion of the CCU bracket with the wires hanging straight down,

toward the water.

3. Place the securing portion of the bracket over the ball and snap it into the mounting portion of the

bracket, starting with the two arms that do not have the thumbscrew.

4. Make sure the cables hang straight down, toward the water, and connect the arm with the

thumbscrew. The cables must hang straight down for the CCU to accurately read your

heading.

5. Hand-tighten the thumbscrew until the CCU is held rmly in the bracket. Do not overtighten the

thumbscrew.

Thumbscrew

Thumbscrew

Wiring the CCU

Route the connector-terminated end of the CCU/ECU interconnect cable to the ECU and make the

Cables

connection. Do not connect the bare-wire portion of the cable CCU/ECU interconnect cable at this

Cables

time. Before you connect the bare-wire portion, install the Shadow Drive and the alarm buzzer (page

18), and mount the GHC 10 (page 19).

Installing the Shadow Drive

Install the Shadow Drive by connecting it to the hydraulic steering line of your boat and wiring it to the CCU/ECU interconnect cable.

Connecting the Shadow Drive to the Hydraulics

Choose a location at which to connect the Shadow Drive to the hydraulic steering of your boat by consulting the hydraulic-layout

diagrams starting on page 5. Use the included connectors to install the Shadow Drive in the hydraulic line.

When connecting the Shadow Drive to the hydraulic system:

Install the Shadow Drive lower than the helm, but higher than the pump. Mount the Shadow drive horizontally, and as level as

•

possible, using cable ties to rmly secure it in place.

Avoid making loops in the hydraulic lines. Install the Shadow Drive closer to the helm than to the pump.

•

Do not mount the Shadow Drive within 12 in. (0.3 m) of any magnetic interference such as speakers and electric motors.

•

Do not install the Shadow Drive directly to the ttings at the back of the helm. Install a length of hose between the tting at the

•

helm and the Shadow Drive.

Do not install the Shadow Drive directly to a hydraulic t-connector in the hydraulic line. Install a length of hose between a

•

t-connector and the Shadow Drive.

In a single-helm installation, do not install a t-connector between the helm and the Shadow Drive.

•

In a dual-helm installation, install the Shadow Drive between the pump and the lower helm, closer to the helm than to

•

the pump.

Install the Shadow Drive in either the starboard steering line or the port steering line. Do not install the Shadow Drive in the

•

return line.

Do not use Teon tape on any hydraulic tting. Use an appropriate thread sealant such as Loctite Pro Lock Tight multipurpose

•

anaerobic gel, part number 51604, or equivalent, on all pipe threads in the hydraulic system.

Wiring the Shadow Drive

Wire the Shadow Drive to the CCU/ECU interconnect cable.

To wire the Shadow Drive:

1. Route the bare-wire end of the CCU/ECU interconnect cable to the Shadow Drive. If the cable is not long enough, extend the

appropriate wires with 28 AWG wire.

2. Use the Shadow Drive Wiring Table to make the appropriate connections.

Shadow Drive Wire Color CCU/ECU Interconnect Cable Wire Color

Red (+) Brown (+)

Black (-) Black (-)

Shadow Drive Wiring Table

3. Solder and cover all bare-wire connections.

17GHP 10 Marine Autopilot System Installation Instructions

Page 18

Wiring the GHP 10 to the Tachometer

The tachometer connection is an important part of the GHP 10 system, and must be wired correctly for the autopilot to function. If

your engine supports NMEA 2000 engine data, and is connected to the same NMEA 2000 network as the GHC 10 and the CCU, then

no other tachometry wiring is necessary. For more information on the NMEA 2000 network, see page 21. If your engine does not

support NMEA 2000 engine data, then wire the GHP 10 autopilot system to the tachometer of your boat using the bare-wire portion of

the CCU/ECU interconnect cable. In most cases, this connection can be made behind the dashboard at the tachometer display. Refer

to the owner’s manual or shop manual for your engine to identify the color codes and location of the tachometer wiring on

your boat.

To wire the GHP 10 to the tachometer of your boat:

1. Identify the location and wire assignments of the tachometer (or tachometers) on your boat.

2. Route the bare-wire end of the CCU/ECU interconnect cable to the tachometer (or tachometers). If the cable is not long enough,

extend the wires with twisted pair, 22 AWG wire.

3. Use the Tachometer Wiring Table to determine the appropriate wires on the CCU/ECU interconnect cable. Connect the tachometer

wire or wires from the CCU/ECU interconnect cable to the tachometer sensor wire or wires from the engine ((or engines)). Connect

the ground wires to a clean ground.

Engine Conguration Tachometer Ground

Single engine Green and violet (twist together) White and grey (twist together)

Dual engines Port engine = violet Grey

Starboard engine = green White

Tachometer Wiring Table

NOTE: For three or more outboard engines, connect to the outermost port and starboard engines, according to the table.

4. Solder and cover all bare-wire connections.

Installing the Alarm Buzzer

The alarm buzzer audibly alerts you to important GHP 10 events. It must be installed near the helm station.

Mounting the Alarm Buzzer

Mount the alarm buzzer near the helm station. You can mount the alarm buzzer under the dashboard if you prefer. Secure the alarm

buzzer with cable ties or other appropriate mounting hardware (not included).

Wiring the Alarm Buzzer

Wire the alarm buzzer to the CCU/ECU interconnect cable.

To wire the alarm buzzer:

1. Route the alarm-buzzer cable to the bare-wire end of the CCU/ECU interconnect cable. If the cable is not long enough, extend the

appropriate wires with 28 AWG wire.

2. Use the Alarm Buzzer Wiring Table to make the appropriate connections.

Alarm Buzzer Wire Color CCU/ECU Interconnect Cable Wire Color

White (+) Red (+)

Black (-) Blue (-)

Alarm Buzzer Wiring Table

3. Solder and cover all bare-wire connections.

18 GHP 10 Marine Autopilot System Installation Instructions

Page 19

Installing the GHC 10

Install the GHC 10 by ush-mounting it in the dashboard near the helm, connecting it to power and to the yellow CCU signal wire

from the CCU/ECU interconnect cable, and connecting it to a NMEA 2000 network. Optionally, you can connect the GHC 10 to a

NEMA 2000 or NMEA 0183-compatible GPS device to use waypoint and route data.

Mounting the GHC 10

Flush mount the GHC 10 in the dashboard near the helm.

When you select an installation location for the GHC 10, choose a location with the following characteristics:

Provides optimal viewing as you operate your vessel.

•

Allows easy access to the keypad on the GHC 10.

•

Is strong enough to support the weight of the GHC 10 and protect it from excessive vibration or shock.

•

Allows room for the routing and connection of the cables for power and data. There should be at least a 3-inch (8 cm) clearance

•

behind the case.

Is at least 91/2 in. (0.24 m) from a magnetic compass, to avoid interference.

•

Is in an area that is not exposed to extreme temperature conditions.

•

NOTE: The temperature range for the GHC 10 is from 5°F to 158°F (from -15°C to 70°C). Extended exposure to temperatures outside of

this range (in storage or operating conditions) may cause failure of the LCD screen or other components. This type of failure and related

consequences are not covered by the manufacturer’s limited warranty.

To ush mount the GHC 10:

1. The ush-mount template is included in the product box. Trim the template and ensure it will t in the location at which you want to

ush mount the GHC 10.

2. The ush-mount template has adhesive on the back. Remove the protective liner and

apply the template to the location where you want to ush mount the GHC 10.

3. If you will be cutting the hole with a jigsaw, and not a 317/

3

/8 in. (10 mm) drill bit to drill a pilot hole as indicated on the template to begin cutting the

mounting surface.

4. Using the jigsaw or the 317/

32

in. (90 mm) hole saw, cut the mounting surface along

the inside of the dashed line indicated on the ush-mount template. Use a le and

sandpaper to rene the size of the hole.

5. Place the GHC 10 into the cutout to conrm that the four mounting holes are correct

after rening the hole. If not, mark the correct locations of the four mounting holes.

Remove the GHC 10 from the cutout.

6. Using the center punch, indent the center of each of the four pilot-hole locations.

7. Drill the four

1

/8 in. (3.2 mm) pilot holes.

32

in. (90 mm) hole saw, use a

NOTE: If you are mounting the GHC 10 in berglass, it is recommended to use a countersink bit to drill a clearance counterbore through

only the top gel-coat layer. This will help to avoid any cracking in the gel-coat layer when the screws are tightened.

8. Remove the remainder of the template.

9. Place the GHC 10 into the cutout.

10. Securely tighten the four mounting screws through the GHC 10 into the drilled mounting holes.

NOTE: Stainless-steel screws may bind when screwed into berglass and overtightened. Garmin recommends applying an anti-galling,

stainless anti-seize lubricant to the screws before installing them.

11. Snap the mounting covers into place to install them.

19GHP 10 Marine Autopilot System Installation Instructions

Page 20

Wiring the GHC 10 to Power and to the CCU/ECU Interconnect Cable

With the GHC 10 power/data cable, wire the GHC 10 to power and to the yellow CCU signal wire on the CCU/ECU interconnect

cable. Optionally, you can wire the GHC 10 power/data cable to a NMEA 0183-compatible GPS device to use waypoint and route

information with the GHP 10, although a NMEA 2000 GPS device is preferred.

To wire the GHC 10 to power:

1. Route the GHC 10 power/data cable to the boat battery.

2. Use a voltmeter to determine the polarity of the voltage source.

3. Connect the red (+ or positive) wire to the positive voltage terminal. (If you use the fuse

block on the boat, route the positive connection through the fuse.)

4. Connect the black (- or ground) wire to the negative voltage terminal.

5. Install or check the AGC/3AG – 1 A fuse (on the fuse block or in the in-line holder).

6. Do not connect the power/data cable to the GHC 10 until all the connections of the

entire GHP 10 system have been completed (page 24).

Notes:

The replacement fuse is an AGC/3AG – 1 A fuse.

•

If it is necessary to extend the power wires, use 18 AWG wire.

•

If your boat has an electrical system, you might be able to wire the GHC 10 directly to an unused holder on your current fuse

•

block. If you are using the fuse block, remove the in-line fuse holder supplied with the GHC 10.

CAUTION: The GHC 10 maximum input voltage is 32 Vdc. Do not exceed this voltage, because this can damage the GHC 10 and void the

warranty.

Power/data NMEA 2000Power/data NMEA 2000

NOTE: During a typical installation, use only the red, black, and yellow wires. The other wires are used for NMEA 0183 connections, and do

not have to be connected for normal operation of the GHC 10. For information on connecting to a NMEA 0183-compatible GPS device, see

page 23.

To wire the yellow CCU signal wire from the GHC 10 power/data cable to the CCU/ECU interconnect cable:

1. Route the GHC 10 power/data cable to the bare end of the color-coded wires from the CCU/ECU interconnect cable. If the cable is

not long enough, extend the yellow CCU signal wire with 22 AWG wire.

2. Connect the yellow CCU signal wire from the GHC 10 power/data cable to the yellow wire on the CCU/ECU interconnect cable.

If you install multiple GHC 10 units and want to turn the GHP 10 autopilot system on with any of the installed GHC 10 units,

connect all of the yellow CCU signal wires from the GHC 10 units to the yellow wire on the CCU/ECU interconnect cable.

3. Solder and cover all bare-wire connections.

NOTE: The yellow CCU signal wire must be connected from the GHC 10 power/data cable to the CCU/ECU interconnect cable, or the GHP

10 autopilot system will not power on with the GHC 10.

20 GHP 10 Marine Autopilot System Installation Instructions

Page 21

Connecting the GHC 10 to a NMEA 2000 Network

Connect the GHC 10 to the CCU through your existing NMEA 2000 network. If you do not have an existing NMEA 2000 network

on your boat, all the parts needed to build one are supplied in the GHP 10 package. Optionally, you can connect a NMEA 2000compatible GPS device to your NMEA 2000 network to use waypoint and route information with the GHP 10. For more information

on NMEA 2000, visit www.garmin.com.

To connect the GHC 10 to your existing NMEA 2000 network:

1. Determine where you would like to connect the GHC 10 to your existing NMEA 2000 network.

2. Disconnect one side of a NMEA 2000 T-connector from the network at an appropriate location.

If you need to extend the NMEA 2000 network backbone, connect an appropriate NMEA 2000 backbone extension cable (not

included) to the side of the T-connector you disconnected.

3. Add the included T-connector for the GHC 10 in the NMEA 2000 network by connecting it to the side of the T-connector you

disconnected.

4. Route the included drop cable to the bottom of the T-connector you just added to your NMEA 2000 network.

If the included drop cable is not long enough, you can use a drop cable up to 20 ft. (6 m) long (not included).

5. Connect the drop cable to the T-connector and the GHC 10.

6. Do not power the NMEA 2000 network on until all of the GHP 10 components are installed correctly. (See page 24.)

CAUTION: If you have an existing NMEA 2000 network on your boat, it should already be connected to power. Do not connect the

included NMEA 2000 power cable to an existing NMEA 2000 network, because only one power source should be connected to a NMEA

2000 network.

CCU

GHC 10

Optional

NMEA 2000

GPS device

(not included)

Additional

Drop cable

(included)

T-connector

(included)

Connecting the GHC 10 (and CCU) to an Existing

drop cable

and

T-connector

(not included)

Existing NMEA 2000 network

NMEA 2000 Network

Drop cable

(included)

T-connector

(included)

To connect the CCU to your existing NMEA 2000 network:

1. Determine where you would like to connect the CCU to your existing NMEA 2000 network.

2. Disconnect one side of a NMEA 2000 T-connector from the network at an appropriate location.

If you need to extend the NMEA 2000 network backbone, connect an appropriate NMEA 2000 backbone extension cable (not

included) to the side of the T-connector you disconnected.

21GHP 10 Marine Autopilot System Installation Instructions

Page 22

3. Add the included T-connector for the CCU in the NMEA 2000 network by connecting it to the side of the T-connector you

+

-

disconnected.

4. Route the included drop cable to the bottom of the T-connector you just added to your NMEA 2000 network.

If the included drop cable is not long enough, you can use a drop cable up to 20 ft. (6 m) long (not included).

5. Connect the drop cable to the T-connector and the CCU.

6. Do not power the NMEA 2000 network on until all of the GHP 10 components are installed correctly. (See page 24.)

CAUTION: If you have an existing NMEA 2000 network on your boat, it should already be connected to power. Do not connect the

included NMEA 2000 power cable to an existing NMEA 2000 network, because only one power source should be connected to a NMEA

2000 network.

Notes:

The GHC 10 is not powered by the NMEA 2000 network. It must be separately connected to the power source.

•

The GHC 10 must also connect to the CCU with the yellow CCU signal wire in the GHC 10 power/data cable.

•

To add additional sensors to your NMEA 2000 network, follow the instructions included with the sensor.

•

To create a basic NMEA 2000 Network for the GHC 10 and the CCU:

1. Connect the three T-connectors together by their sides.

2. The included NMEA 2000 power cable must be connected to a 12 Vdc power source through a switch. Connect to the ignition

switch of the boat if possible, or through an appropriate additional switch (not included).

3. Connect the NMEA 2000 power cable to one of the T-connectors.

4. Connect one of the included NMEA 2000 drop cables to one of the T-connectors and to the GHC 10.

5. Connect the other included NMEA 2000 drop cable to the remaining T-connector and to the CCU.

6. Connect the appropriate terminators to each end of the combined T-connectors.

7. Do not power the NMEA 2000 network on until all of the GHP 10 components are installed correctly. (See page 24.)

CAUTION: You must connect the included NMEA 2000 power cable to the boat ignition switch, or through another in-line switch. The

GHC 10 will drain your battery if it is connected directly.

GHC 10

Ignition or

in-line switch

Fuse

12 Vdc battery

Drop cables

Power cable

T-connectors

Female

terminator

CCU

Male

terminator

Creating a Basic NMEA 2000 Network for the GHC 10 and the CCU

Notes:

To add additional sensors to your NMEA 2000 network, follow the instructions included with the sensor.

•

The GHC 10 is not powered by the NMEA 2000 network. It must be separately connected to the power source.

•

The GHC 10 must also connect to the CCU with the yellow CCU signal wire in the GHC 10 power/data cable.

•

22 GHP 10 Marine Autopilot System Installation Instructions

Page 23

Connecting an Optional GPS Device to the GHP 10 Autopilot System

>

>

>

>

+

-

>

>

>

>

Connect an optional GPS device to the NMEA 2000 network to use waypoint and route information with the GHP 10. Alternatively,

you can connect a NMEA 0183-compatible GPS device to the GHC 10 to use waypoint and route information with the GHP 10.

To connect an optional NMEA 2000-compatible GPS device to your GHP 10:

1. Add an additional T-connector (not included) for the optional GPS device you want to add to the NMEA 2000 network.

2. Connect the GPS device to the T-connector by following the instructions provided with the GPS device.

To connect an optional NMEA 0183-compatible GPS device to your GHP 10:

1. Determine the NMEA 0183 wiring assignments of your NMEA 0183-compatible GPS device.

2. Use the GHC 10 power/data cable wiring diagrams to correctly wire your NMEA 0183-compatible GPS device.

3. Use 22 AWG twisted-pair wire for extended runs of wire.

4. Solder and cover all bare-wire connections.

Color Function

GHC 10

Device

Fuse

1 A

Red

Black

Yellow

Power

Ground

CCU Signal

Blue

White

Brown

Green

GHC 10 Power/Data Cable

Spare

Spare

Rx/A(+)

Rx/B(-)

Example:

Battery

12 Vdc

WIRE

FUNCTION

RED

POWER GND

NMEA GND

Tx/A (+)

Tx/B (-)

NMEA 0183 Compatible

Device

GHC 10

Device

WIRE

COLOR

Fuse

RED

BLACK

1 A

BROWN

GREEN

Wiring the GHC 10 to a NMEA 0183 Device

Notes:

Consult the installation instructions for your NMEA 0183-compatible device to identify the Transfer (Tx) A(+) and B(-) wires.

•

If your NMEA 0183-compatible device has only one transmitting wire (Tx), connect it to the brown wire (Rx/A) from the GHC 10,

•

and connect the green wire (Rx/B) to ground.

The blue (Tx/A) and white (Tx/B) wires are not used when wiring the GHC 10 to a GPS device.

•

The yellow (CCU signal) wire must be wired to the yellow wire of the CCU/ECU interconnect cable.

•

23GHP 10 Marine Autopilot System Installation Instructions

Page 24

Making the Final Power Connections

After all the components are mounted, connected to the hydraulics of your boat, and wired correctly, connect the ECU to the boat

battery and connect the power/data cable to the GHC 10. Use the checklist provided in the back of this manual to ensure that the

preceding installation procedures are complete. Connect the ECU power cable directly to the boat battery if possible. Though it is not

recommended, if you connect the power cable to a terminal block or other source, connect it through a 40 A supply.

CAUTION: Do not remove the in-line fuse holder from the battery cable when connecting to the battery. If you remove the in-line fuse

holder, you will void the GHP 10 warranty, and may damage the GHP 10 autopilot system.

To connect the ECU to the battery:

1. Route the connector-terminated end of the ECU power cable to the ECU, and route the bare-wire end of the ECU power cable to

the boat battery. If the wire is not long enough, use the Wire Gauge Table to determine the correct wire gauge for an extended run.

Extended Length 10 ft. (3 m) 15 ft. (4.5 m) 20 ft. (6 m) 25 ft. (7.5 m)

Recommended Wire Gauge 12 10 10 8

Wire Gauge Table

2. Connect the black wire (-) to the negative (-) side of the battery rst.

3. Connect the red wire (+) to the positive (+) side of the battery next.

4. Connect the ECU power cable to the ECU last.

To connect the power/data cable to the GHC 10:

Align the notches on the cable plug and on the back of the GHC 10. Insert the cable into the connector, and turn the locking ring

clockwise until it stops.

NOTE: After the ECU and the GHC 10 are connected to power, the GHP 10 autopilot system and the NMEA 2000 network can be powered

on.

Bleeding the Hydraulic Steering System

Air must be purged completely from all the hydraulic lines, the helms, the cylinders, the pump, and the Shadow Drive for the system

to function. If the hydraulic system is not bled, then the GHP 10 autopilot system will not work correctly. Follow the instructions

provided by the manufacturer of your steering system to properly bleed the hydraulic system on your boat. Treat the pump as

the lowest helm when bleeding the system.

Notes:

Disable the Shadow Drive from the GHC 10 to make the bleeding process easier. On the GHC 10, select Menu > Setup >

•

Autopilot Conguration > Hydraulic Setup > Shadow Drive Enable. Change the Shadow Drive Enable setting to Disable.

Remember to enable the Shadow Drive after the bleeding process is complete.

•

To completely bleed the hydraulic system, it may be necessary to drive the autopilot pump in both directions to remove any air

•

trapped within the pump. You can do this during the Verify Steering Direction portion of the Dockside Wizard (see page 25).

Drive the rudder to each stop in each direction, and then perform any additional bleeding that may be necessary.

IMPORTANT: Check for leaks at every hydraulic tting, both after the bleeding process is complete and after the sea trial is complete.

24 GHP 10 Marine Autopilot System Installation Instructions

Page 25

Conguring the GHP 10

The GHP 10 must be congured and tuned to your boat dynamics and motor conguration. Use the Dockside Wizard and the Sea Trial

Wizard on the GHC 10 to congure the GHP 10. These wizards will walk you through the necessary conguration steps.

Advanced Conguration Power-on Procedure

Neither the wizards nor the advanced conguration options are available on the GHC 10 under normal conditions. To access the

wizards and the advanced conguration settings of the GHP 10, use the advanced conguration power-on procedure.

Hold these

To access the wizards and advanced conguration options:

1. With the power off, press both the center and the right soft keys on the GHC 10.

2. While pressing the center and the right soft keys, power the GHC 10 on.

3. Press all 3 buttons until the heading screen appears. Release the buttons.

To make sure the wizards and advanced conguration options are available:

1. From the heading screen, select Menu > Setup.

2. If the option for Dealer Autopilot Conguration is available, you correctly performed the

advanced conguration power-on procedure.

Hold these

soft keys

soft keys

Advanced Conguration

Advanced Conguration

Power-on Procedure

Power-on Procedure

The Dockside Wizard

The Dockside Wizard can be performed at the dock, before heading for open water. Power the GHC 10 on using the advanced

conguration power-on procedure. The rst time you power the GHP 10 on, you are prompted to complete a short setup sequence

on the GHC 10. Use the soft keys to select the language, the units of measure, the heading type, and the auto power-on setting if

necessary. When you complete the initial setup, you are ready to start the Dockside Wizard.

and power the

and power the

GHC 10 on

GHC 10 on

To complete the Dockside Wizard conguration:

1. After completing the initial setup, from the Heading screen, select Menu > Setup > Dealer Autopilot Conguration > Wizards >

Dockside Wizard. The Dockside Wizard welcome screen appears on the GHC 10. Select Begin to start the wizard.

2. Lock to Lock: Count the number of turns it takes your helm to go from lock to lock (fully turned port to fully turned starboard). Use

the arrows on the GHC 10 to enter the value you counted (the default is 4.5) and select Done.

3. Helm Displacement: The helm displacement is usually written on the body of the helm pump. If you are unsure, consult the

manufacturer of your boat for the helm displacement value. Use the arrows on the GHC 10 to enter the helm displacement value

(the default is 1.7 in3) and select Done.

4. Steering Direction: Use the arrows on the GHC 10 to test the steering direction. When you push the right arrow, the motor should

turn the boat to the right, and vice versa. Select Menu. If the steering test turned the boat in the correct direction, select Finished.

If the steering test turned the boat in the opposite direction, select Switch Directions.

5. RPM Source: Select the engine (or engines) to which you wired the tachometer sensor from the CCU. If you connected a NMEA

2000-compatible engine (or engines) to the NMEA 2000 network, select NMEA 2000. For a single-engine boat, select port.

6. Verify Tachometer: With the engine (or engines) running, compare the RPM readings on the GHC 10 with the tachometer (or

tachometers) on the dashboard of your boat. Adjust the Pulses Per Rev with the arrows if the values do not match, and then

select Done. When you adjust the Pulses Per Rev with the arrows, there is a delay before the new RPM readings appear on the

GHC 10. For each adjustment, be sure to wait until the GHC 10 adjusts to the new reading.

7. Dockside Wizard Review: The GHC 10 displays the values you chose when you ran the Dockside Wizard. If any of the values are

incorrect, use the arrow to select the value and select Select to re-enter the value. When you are nished reviewing the values,

select Done.

The Sea Trial Wizard

The Sea Trial Wizard must be performed in open water, free of obstacles. It is highly recommended to perform the Sea Trial Wizard in

calm water. Power the GHC 10 on using the advanced conguration power-on procedure. Drive the boat to calm, open water to start

the Sea Trial Wizard.

To complete the Sea Trial Wizard conguration:

1. Drive to calm, open water and select Menu > Setup > Dealer Autopilot Conguration > Wizards > Sea Trial Wizard. The Sea

Trial Wizard welcome screen appears on the GHC 10. Select Begin to start the wizard.

25GHP 10 Marine Autopilot System Installation Instructions

Page 26

2. Planing RPM: Take note of the RPM reading from the tachometer on the dashboard of your boat at the point your boat transitions

from displacement to planing speed. If the tachometer value does not match the value on the GHC 10, use the arrows to adjust the

value. When you are nished, select Done.

3. Calibrate Compass: Follow the directions on the GHC 10. Drive your boat in a straight line, and select Begin when you are

ready. When instructed, turn the boat slowly, taking care to make as steady and at a turn as possible. On a dual engine boat,

run the port engine forward and the starboard engine in reverse to pivot on a stationary position. After you successfully complete

the calibration, the GHC 10 displays a completion message; select Done. If the calibration fails, select Retry to begin the process

again.

4. Autotune: The Autotune conguration adjusts feedback gains. Follow the directions on the GHC 10. Drive your boat in a straight

line, at a constant RPM below planing speed, and select Begin when you are ready. The boat will perform a number of zigzag

motions while the Autotuning is in progress. When the GHC 10 displays a completion message, select Done. Be sure to take

manual control of the boat when Autotuning is complete. If the Autotuning fails, select Retry to begin the process again.

5. Set North: To perform this step, you must have a large stretch of open water available. Be sure to have at least 45 seconds of

hazard-free, open water available while at planing speed. Drive the boat in a straight line, at planing speed, and select Begin when

you are ready. When the GHC 10 displays a completion message, select Done. If the calibration fails, select Retry to begin the

process again.

Manually Running the Dockside and Sea Trial Wizards

The Dockside Wizard and the Sea Trial Wizard allow you to quickly dene all of the important conguration settings on the GHP 10.

If, after running the wizards, you do not feel as though the GHP 10 is working correctly, you can run the wizards again at any time. To

access the wizards, power the GHC 10 on using the advanced conguration power-on procedure.

To manually run the Dockside Wizard:

1. From the Heading screen, select Menu > Setup > Dealer Autopilot Conguration > Wizards > Dockside Wizard.

2. Perform the steps as prompted. For more information, see page 25.

To manually run the Sea Trial Wizard:

1. From the Heading screen, select Menu > Setup > Dealer Autopilot Conguration > Wizards > Sea Trial Wizard.

2. Perform the steps as prompted. For more information, see page 25.

Changing Advanced Conguration Settings

You can run the Autotune automated conguration process, calibrate the compass, and dene north on the GHP 10 through the

GHC 10 without running the wizards. Additionally, without running the wizards, you can individually dene each conguration

setting. To access the automated conguration settings and the advanced conguration settings, power the GHC 10 on using the

advanced conguration power-on procedure

To manually run the automated conguration settings:

1. From the Heading screen, select Menu > Setup > Dealer Autopilot Conguration > Automated Setup.

2. Select Autotune, Calibrate Compass, or Set North.

3. Perform the steps as prompted. For more information on each automated conguration setting, see page 25.

To manually dene individual conguration settings:

1. From the Heading screen, select Menu > Setup > Dealer Autopilot Conguration.

2. Select the appropriate category of setting you want to congure.

3. Select the setting you want to congure.

Category Setting Description

Tachometer Setup Verify Tachometer With the engine (or engines) running, compare the RPM readings on the

GHC 10 with the tachometer on the dashboard of your boat. Adjust the

Pulses Per Rev with the arrows if the values do not match, and then

select Done. When you adjust the Pulses Per Rev with the arrows, there

is a delay before the new RPM readings appear on the GHC 10. For each

adjustment, be sure to wait until the GHC 10 adjusts to the new reading.

Tachometer Setup RPM Source Select the engine (or engines) to which you wired the tachometer sensor

from the CCU. If you connected a NMEA 2000-compatible engine to the

NMEA 2000 network, select NMEA 2000. For a single-engine boat, select

port.

26 GHP 10 Marine Autopilot System Installation Instructions

Page 27

Category Setting Description

Tachometer Setup Planing RPM Take note of the RPM reading from the tachometer on the dashboard of

your boat at the point your boat transitions from displacement to planing

speed. If the value does not match the value on the GHC 10, use the

arrows to adjust the value.

Tachometer Setup Low RPM Limit Take note of the RPM reading from the tachometer on the dashboard of

your boat at the lowest RPM point. If the value does not match the value

on the GHC 10, use the arrows to adjust the value.

Tachometer Setup High RPM Limit Take note of the RPM reading from the tachometer on the dashboard of

your boat at the highest RPM point. If the value does not match the value

on the GHC 10, use the arrows to adjust the value.

Hydraulic Setup Helm Displacement The helm displacement is usually written on the body of the helm pump.

If you are unsure, consult the manufacturer of your boat for the helm

displacement value. Use the arrows on the GHC 10 to enter the helm

displacement value.

Hydraulic Setup Lock to Lock Turns Count the number of turns it takes your helm to go from lock to lock (fully

turned port to fully turned starboard). Use the arrows on the GHC 10 to

enter the value you counted.

Hydraulic Setup Verify Steering Direction Use the arrows on the GHC 10 to test the steering direction. When you

push the right arrow, the motor should turn the boat to the right, and vice

versa. Determine if the engines are steering in the correct direction and

press Continue. Use the GHC 10 to answer the questions.

Hydraulic Setup Linkage Compensation Adjust the linkage compensation if the steering is loose or sloppy. The

higher you set this value, the more the autopilot compensates for loose or

sloppy steering. Use this setting with caution.

Turn Fine Tuning Setup > Rudder Gains Low Speed Set the rudder gain for low speeds.

Turn Fine Tuning Setup > Rudder Gains Low Speed Counter Set the rudder gain counter-correction for low speeds.

Turn Fine Tuning Setup > Rudder Gains High Speed Set the rudder gain for high speeds.

Turn Fine Tuning Setup > Rudder Gains High Speed Counter Set the rudder gain counter-correction for high speeds.

Turn Fine Tuning Setup Acceleration Limiter Limit the aggressiveness of autopilot-controlled turns. Increase the

percentage to limit the turn rate, and decrease the percentage to allow

higher turn rates.

Navigation Setup Fine Heading Adjustment Increase or decrease to ne-tune the autopilot heading.

Navigation Setup > NMEA Setup NMEA Checksum If the connected GPS unit incorrectly calculates checksums, you may

still be able to use it if you turn this setting off. When off, data integrity is

compromised.

Navigation Setup > NMEA Setup Reversed XTE If the connected GPS unit sends the incorrect steering direction with the

cross track error signal, use this setting to correct the steering direction.

Navigation Setup Navigation Gain Because the cross track error data transmitted by a NMEA 0183 GPS

device is only accurate within .01 mile (60 ft.), the gain may need

adjustment. Increase this setting until the boat oscillates back and forth

near the course line, then lower it a few levels.

Navigation Setup Navigation Trim Gain After adjusting the Navigation gain, increase this setting until you can see

the standoff from the course line decreasing over time.

NOTE: Certain conguration settings are available when using the GHC 10 normally, such as enabling and disabling the Shadow Drive,

adjusting the sensitivity of the Shadow Drive, and adjusting the Sea State Filtering setting. See the conguration section of the GHP 10/GHC

10 Quick Start Manual for more information.

27GHP 10 Marine Autopilot System Installation Instructions

Page 28

Appendix

Specications

ECU

Physical

Dimensions (W×H×D): 619/32 in. × 419/32 in. × 2 in. (167.6 mm × 116.8 mm × 50.8 mm)

Weight: 1.5 lb. (0.68 kg)

Temperature Range: from 5°F to 131°F (from -15°C to 55°C)

Case Material: Fully gasketed, high-impact aluminum alloy, waterproof to IEC 529 IPX7 standards

Power Cable Length: 9 ft. (2.7 m)

Power

Input Power: 11.5–14 Vdc

Fuse: 40 A

Main Power Usage: 1 A (not including the pump)

CCU

Physical

Dimensions: 319/32 in. diameter (91.4 mm)

Weight: 5.6 oz. (159 g)

Temperature Range: from 5°F to 131°F (from -15°C to 55°C)

Case Material: Fully gasketed, high-impact plastic alloy, waterproof to IEC 529 IPX7 standards

CCU/ECU Interconnect Cable Length: 91/2 ft. (3 m)

Power

NMEA 2000 Power Input: 9–16 Vdc

NMEA 2000 LEN: 2 (100 mA)

1.2L/2.0L Pump

Physical

Dimensions (W×H×D): 11 in. × 411/16 in. × 311/16 in. (279.4 mm × 119.4 mm × 94 mm)

Weight: 8.05 lb. (3.65 kg)

Temperature Range: from 5°F to 131°F (from -15°C to 55°C)