Furuno FCV30BB Installation Instructions

Installation Manual

Back

COLOR SOUNDER FCV-30

SAFETY INSTRUCTIONS ......................................................................................................................i

SYSTEM CONFIGURATION.................................................................................................................iii

EQUIPMENT LISTS..............................................................................................................................iv

1. MOUNTING........................................................................................................................................1

1.1 Control Unit.................................................................................................................................1

1.2 Processor Unit............................................................................................................................3

1.3 Transceiver Unit..........................................................................................................................4

1.4 Transducer..................................................................................................................................5

1.5 Junction Box .............................................................................................................................6

2. WIRING ..............................................................................................................................................7

2.1 Interconnection...........................................................................................................................7

2.2 Cable Fabrication .......................................................................................................................9

2.3 Synchronizing Transmission with Echo Sounder or Other Sonar............................................11

2.4 Input/Output Sentences........................................................................................................... 12

3. SYSTEM SETTINGS AFTER INSTALLATION ............................................................................... 13

OUTLINE DRAWINGS.......................................................................................................................D-1

INTERCONNECTION DIAGRAM ......................................................................................................S-1

www.furuno.co.jp

All brand and product names are trademarks, registered trademarks or service marks of their respective holders.

Thepaperusedinthismanual

9‑52Ashihara‑cho,

Fax:

A:FEB

2005

.

E:OCT.20,2009

Pub.No.

(

)

*

00015183714

**00015183714

*

Nishinomiya,662‑8580,JAPAN

Telephone: +81‑(0)798‑65‑2111

+81‑(0)798‑65‑4200

iselementalchlorinefree.

・FURUNOAuthorizedDistributor/Dealer

Allrightsreserved.

DAMI

FCV‑30

PrintedinJapan

IME‑23730‑E

*00015183714**00015183714*

*00015183714*

SAFETY INSTRUCTIONS

WARNING

ELECTRICAL SHOCK HAZARD

Do not open the equipment

unless totally familiar with

electrical circuits and

service manual.

Only qualified personnel

should work inside the

equipment.

Turn off the power at the switchboard

before beginning the installation.

Fire or electrical shock can result if the

power is left on.

Do not install the equipment where it

may get wet from rain or water splash.

Water in the equipment can result in fire,

electrical shock or equipment damage.

WARNING

Install the transducer according

to the installation instructions.

Failure to install the transducer correctly

may result in water leakage and damage to

the ship's hull.

For wooden or FRP vessel using a steel

tank, attach a zinc plate to the hull to

prevent electrolytic corrosion.

Electrolytic corrosion can, in the worst

case, result in loss of the transducer.

Be sure no water leaks in at the transducer mounting location.

Water leakage can sink the vessel. Also,

confirm that the transducer will not loosen

by ship's vibration. The installer of the

equipment is solely responsible for the

proper installation of the equipment.

FURUNO will assume no responsibility for

any damage associated with improper

installation.

Be sure that the power supply is

compatible with the voltage rating of

the equipment.

Connection of an incorrect power supply

can cause fire or equipment damage. The

voltage rating of the equipment appears

on the label above the power connector.

i

SAFETY INSTRUCTIONS

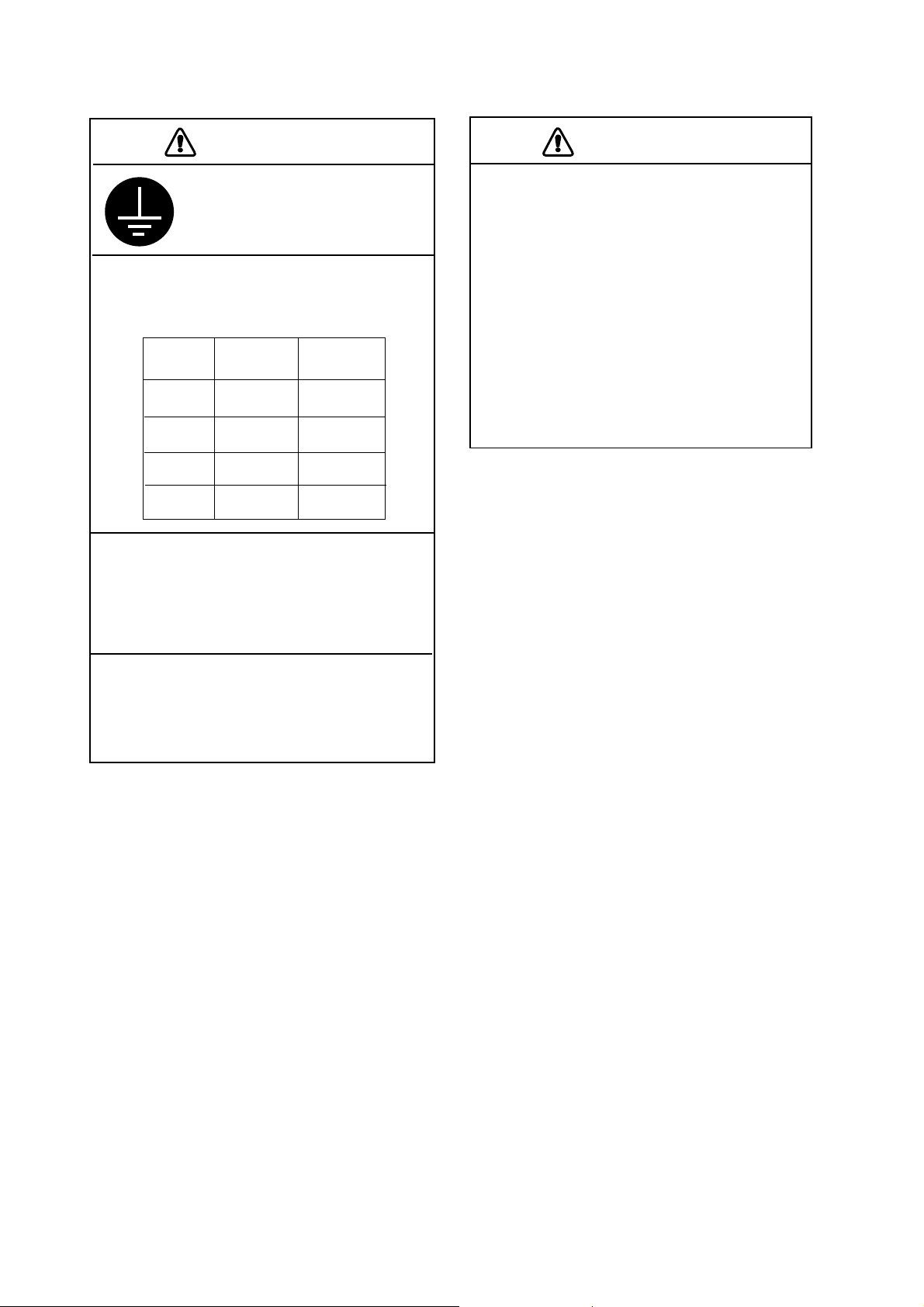

CAUTION

Ground the equipment to

prevent mutual interference.

Observe the following compass safe

distances to prevent interference to a

magnetic compass:

Standard

compass

CV-301

CV-302

CV-300

CV-304

0.85 m 0.55 m

1.55 m 0.95 m

1.25 m 0.70 m

1.10 m 0.70 m

Do not allow warm water or any other

liquid other than seawater or freshwater

to contact the transducer.

Steering

compass

CAUTION

The transducer cable must he handled

carefully, following the guidelines

below.

• Keep fuels and oils away from the

cable.

• Locate the cable where it will not be

damaged.

• The cable sheath is made of chloro-

phrene or polychloride vinyl, which

are easily by damaged plastic solvents

such as toulene. Locate the cable

well away from plastic solvents.

Damage to the transducer may result.

Do not install the transducer where

noise or air bubbles is present.

Performance will be affected.

ii

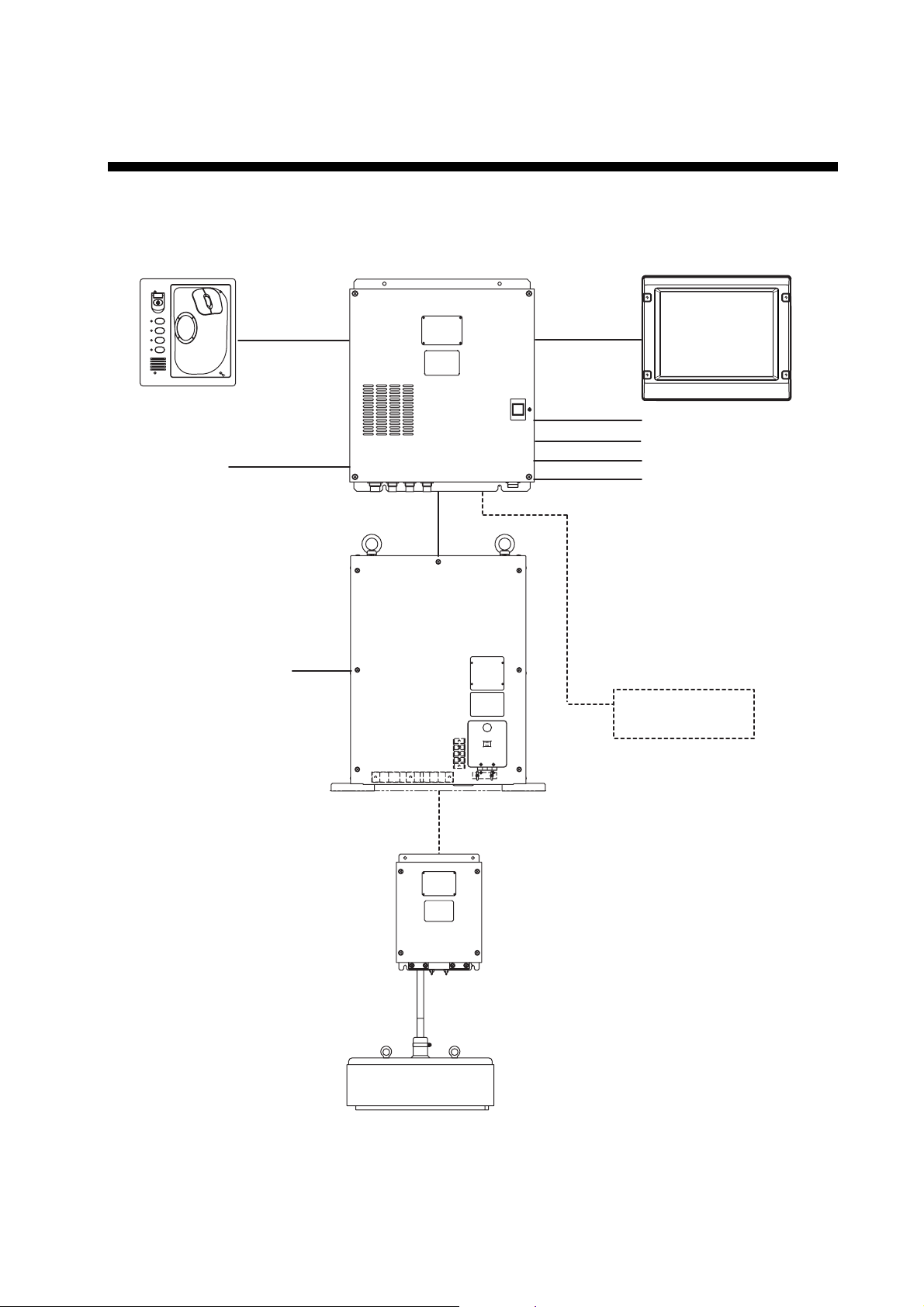

SYSTEM CONFIGURATION

Display Unit (option)

Control Unit

CV-301

F1

F2

F3

F4

100-240 V AC

1

φ

, 50/60 Hz

Processor Unit

CV-300

POWER

Transceiver Unit

CV-302

MU-151C/MU-201C

or commercially available monitor

Navigator

Satellite Compass

Net Sonde

Hard Disk

USB Memory

100-120/200-240 V AC

1

φ

, 50/60 Hz

Network Sounder

ETR-30N

Junction Box

(option)

CV-304

Transducer

CV-303

iii

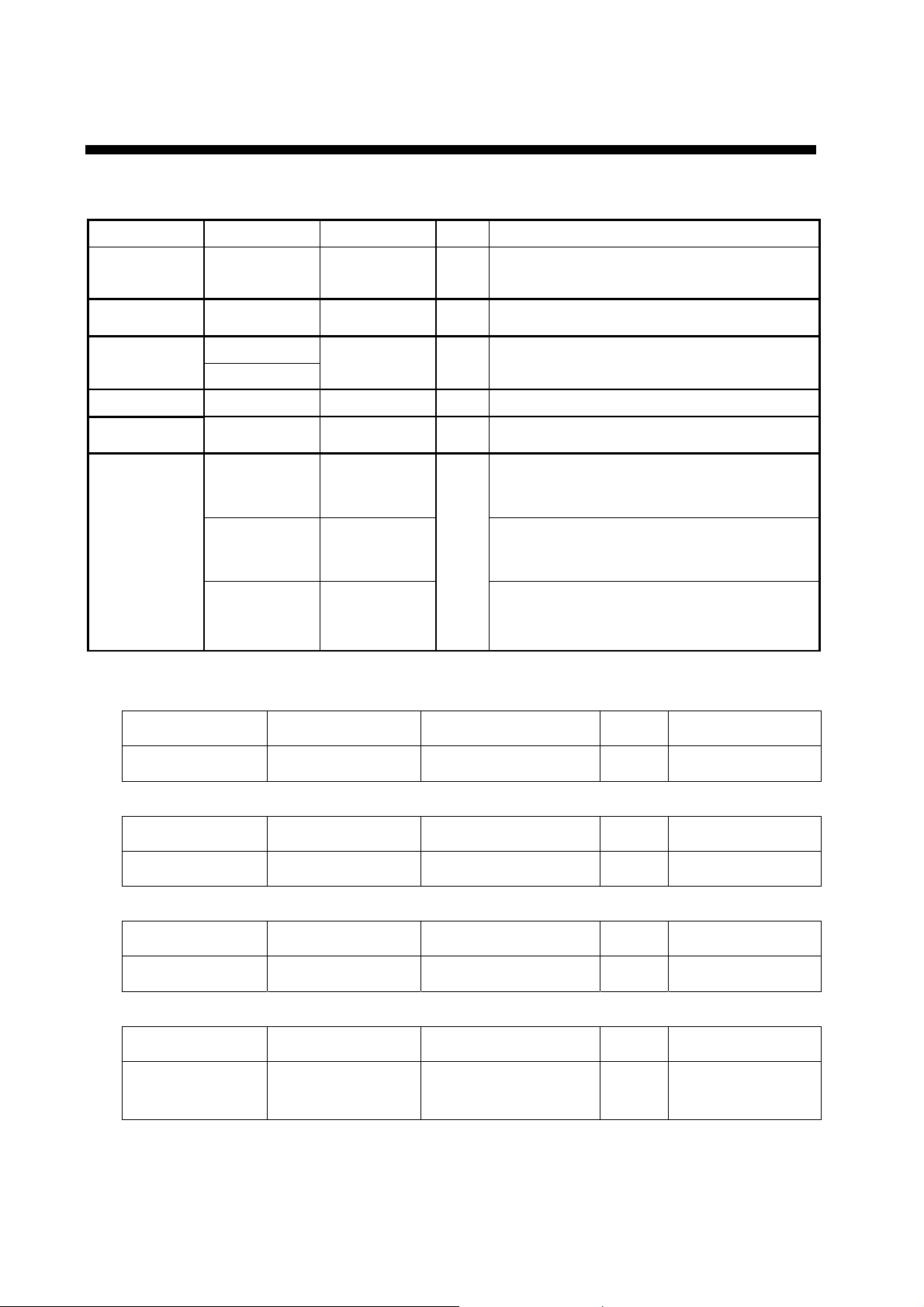

EQUIPMENT LISTS

Standard supply

Name Type Code No. Qty Remarks

Processor

Unit

CV-300

−

With spare parts S P02-0 4801, SP02-05101

1

and installation materials CP06-01401

Control Unit

Unit

Transducer CV-303

Thru-hull pipe TFB-1600 000-012-539 1

Installation

Materials

CV-301

CV-302 Transceiver

CV-302-MS

CP03-28900 000-082-658

CP03-28910

CP03-28920

−

−

−

000-082-659

000-082-660

1 set

Installation Materials CP06-01401: 001-403-810

Name Type Code no. Qty Remarks

With FP03-09860 & CP03-2560 4

1

With SP02-04901 & CP02-0780 1

1

1

Connector CP03-28901 (MPS588- C:

000-166-044-10, 2 pcs) & cable

FR-FTPC-CY *10m*

Connector CP03-28901 (MPS588- C:

000-148-322, 2 pcs) & cable FR-FTPC-CY

*20m*

Connector CP03-28901 (MPS588- C:

000-148-322, 2 pcs) & cable FR-FTPC-CY

*30m*

Connector SRCN6A13-3S 000-160-725-10 1 For power lin e

Installation Mater ials C P03-25604: 008-539-850

Name Type Code no. Qty Remarks

Screw M4x12 000-163-192-10 4

Installation Mater ials C P02-07801: 001-416-080

Name Type Code no. Qty Remarks

Crimp-on lug FV5.5-S4 000-166-750-10 3

Sp are parts SP02-05101: 001-4 16-060

Name Type Code no. Qty Remarks

Fuse FGMB 250V 5A

PBF

000-157-570-10 2

iv

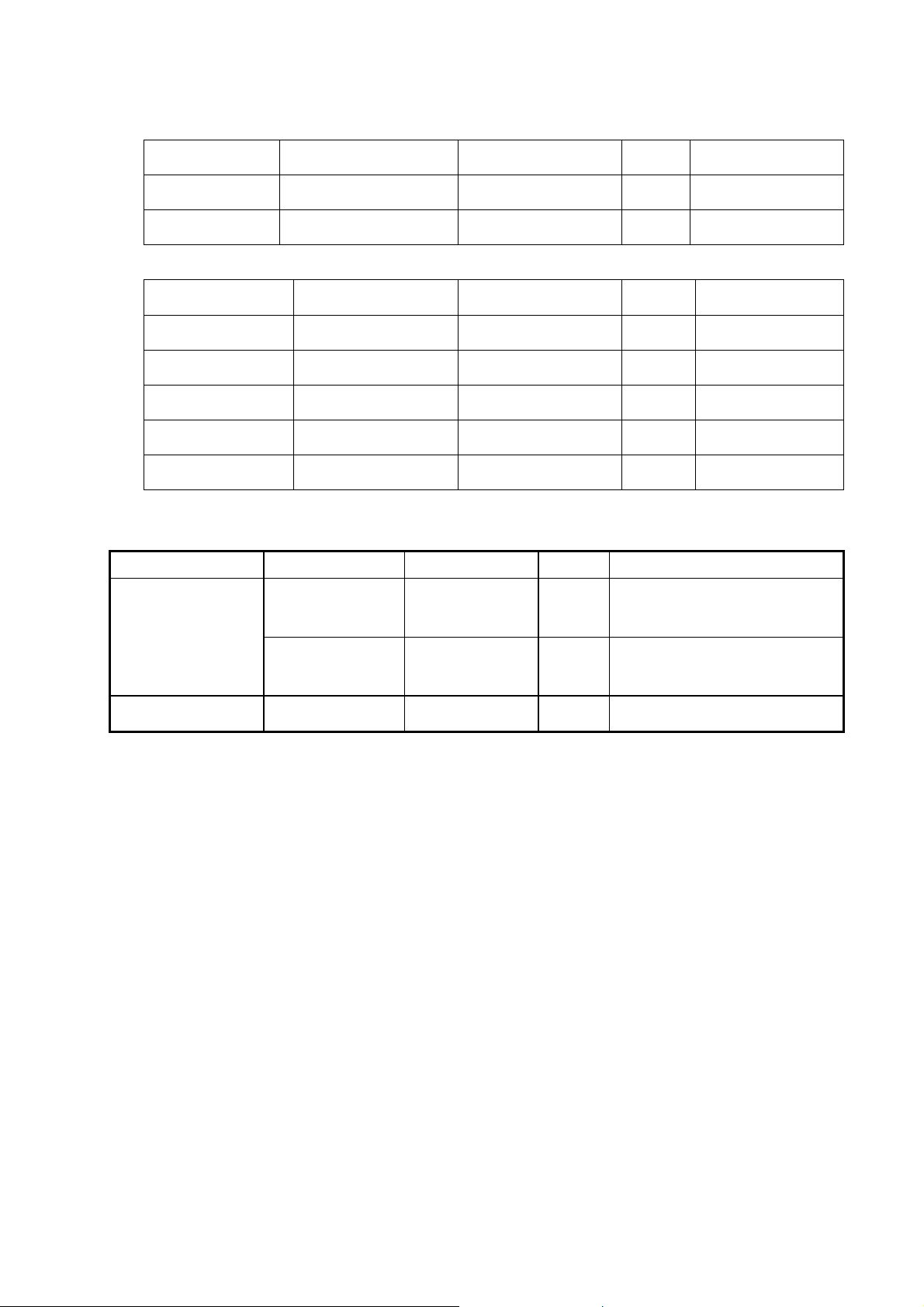

EQUIPMENT LISTS

Sp are parts SP02-04901: 001-4 16-070

Name Type Code no. Qty Remarks

Fuse FGMB 125V 10A PBF 000-157-470-10 2

Fuse FGMB 250V 5A PBF 000-157-570-10 2

Accessories SP03-09860: 008-535-69 0

Name Type Code no. Qty Remarks

Cushion TM-180-302 000-166-468-10 2

Grommet G-49 000-166-406-10 1

Blind seal 22-020-1005-1 100-173-591-10 3

KB fixing metal 03-163-7821-1 100-306-291-10 1

Pan head screw M4x12 000-163-192-10 2

Optional equipment

Name Type Code No. Qty Remarks

CV-304-10 000-012-540 1

Junction box

CV-304-20 000-012-541

Transducer tank T-625 000-012-545 1

With cable Z-FNH-SB

68XP26AWG , 10 m

With cable Z-FNH-SB

68XP26AWG , 20 m

v

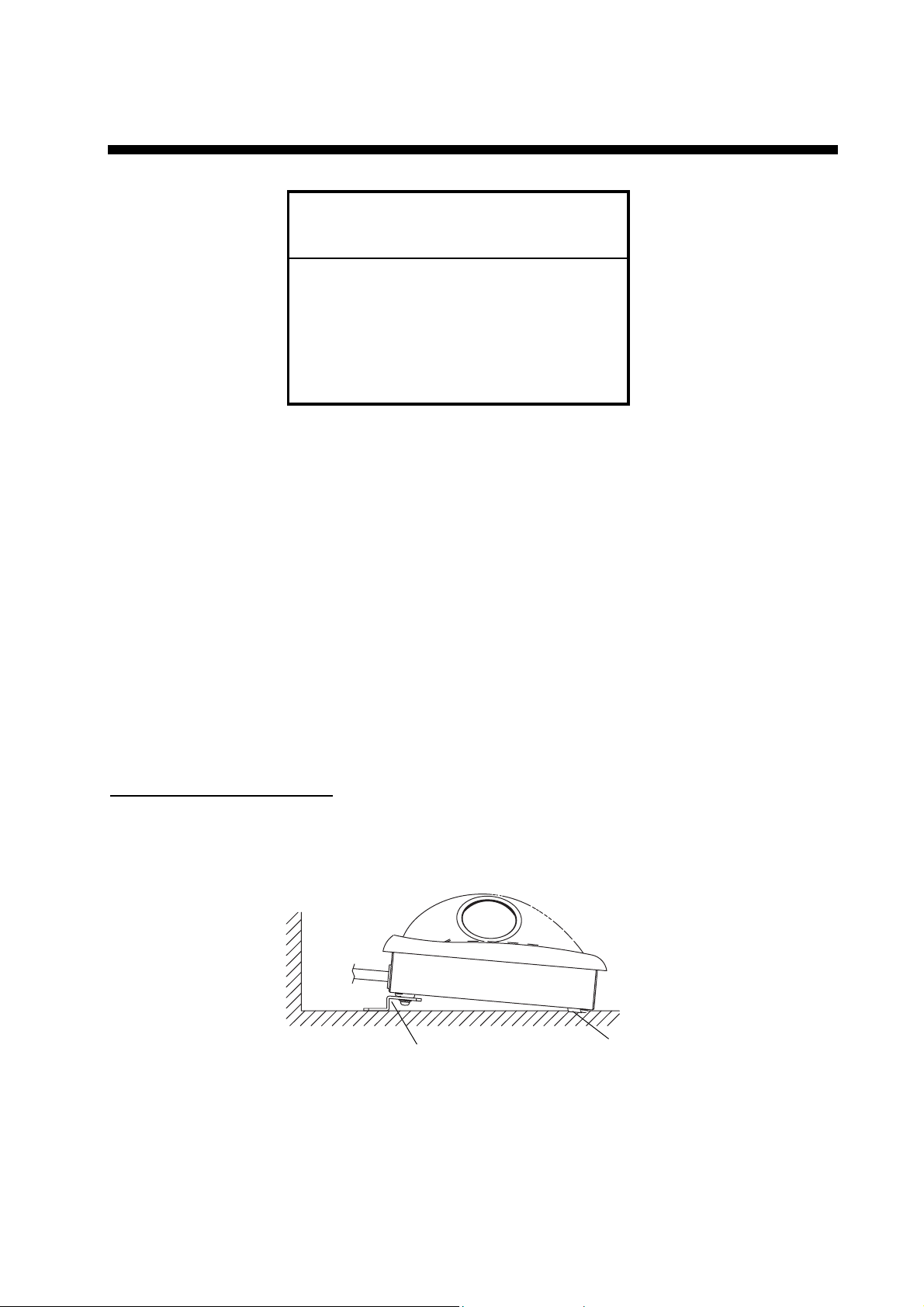

1. MOUNTING

NOTICE

Do not apply paint, anti-corrosive sealant

or contact spray to coating or plastic

parts of the equipment.

Those items contain organic solvents that

can damage coating and plastic parts,

especially plastic connectors.

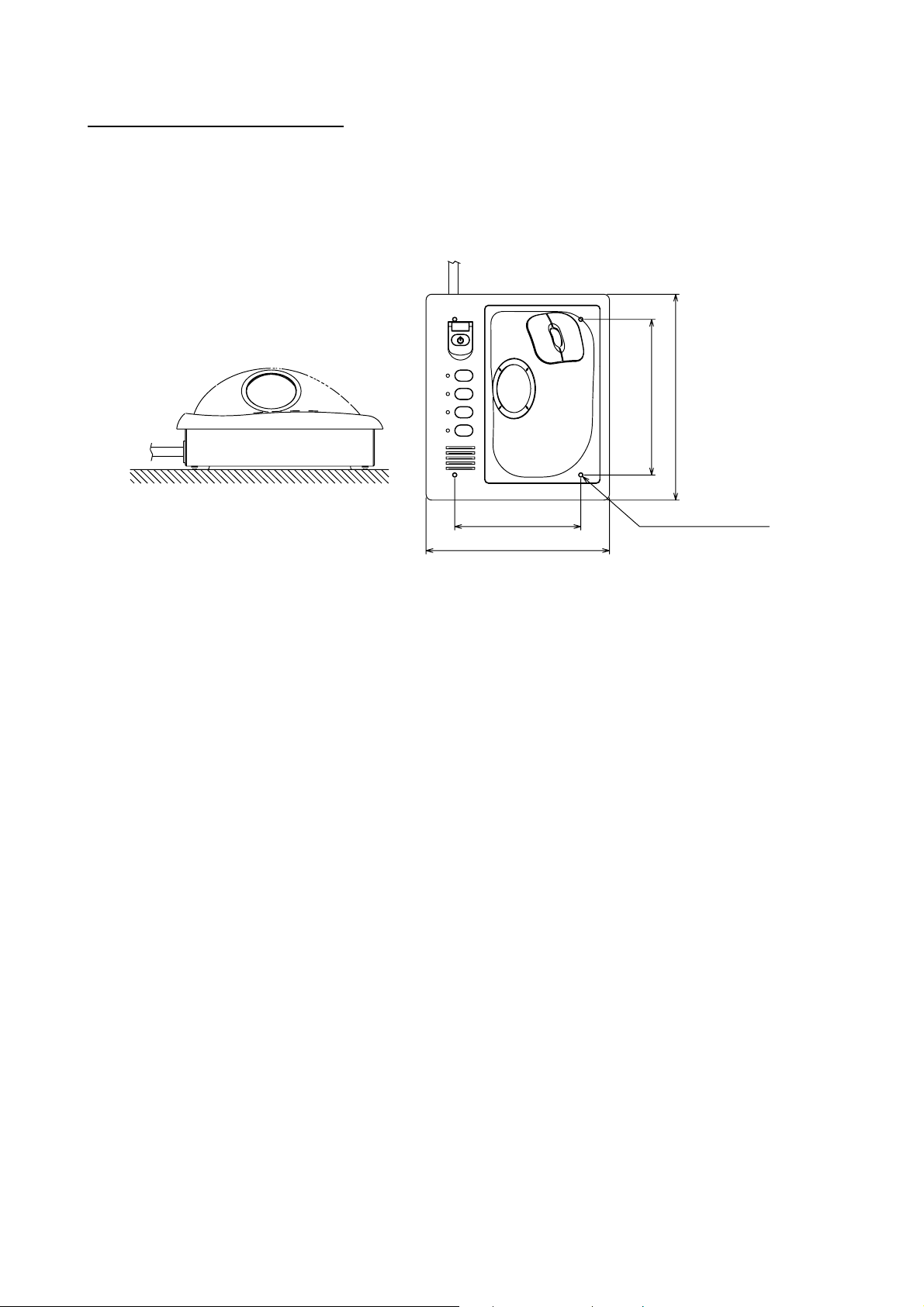

1.1 Control Unit

Mounting considerations

When selecting a mounting location, keep in mind the following points:

• Select a location where the control unit can be operated conveniently.

• Locate the unit away from heat sources because of h eat that can build up inside the unit.

• Locate the equipment away from places subject to water splash and rain.

• Determine the mounting location cons idering the length of the signal cable between the

control unit and the processor unit. (The length of the signal cable is 5 m.)

• Observe the compass safe distances on page ii to prevent dev iation of a magnetic

compass.

Fixing with KB fixing plate

1. Fix the KB fixing plate to the bottom of the control unit.

2. Attach cushions to the bottom of the control unit as shown below.

3. Fix it to a desired location with self-tapping screws (local supply).

KB fixing plate

1

Cushion

1. MOUNTING

Fixing without KB fixing metal

1. Drill four mounting holes of 5 mm diameter referring to the drawing below.

2. Fix the control unit with four screws (M4) from under side of the desktop. Us e M4x12

(supplied) for mounting panel thickness “t” between 2 and 5 mm. For greater thickness,

screw length shall be M4x(t+7.8±2).

F1

F2

F3

F4

180

136±1

110±1

160

4-M4 (Fixing holes)

(bottom)

2

1. MOUNTING

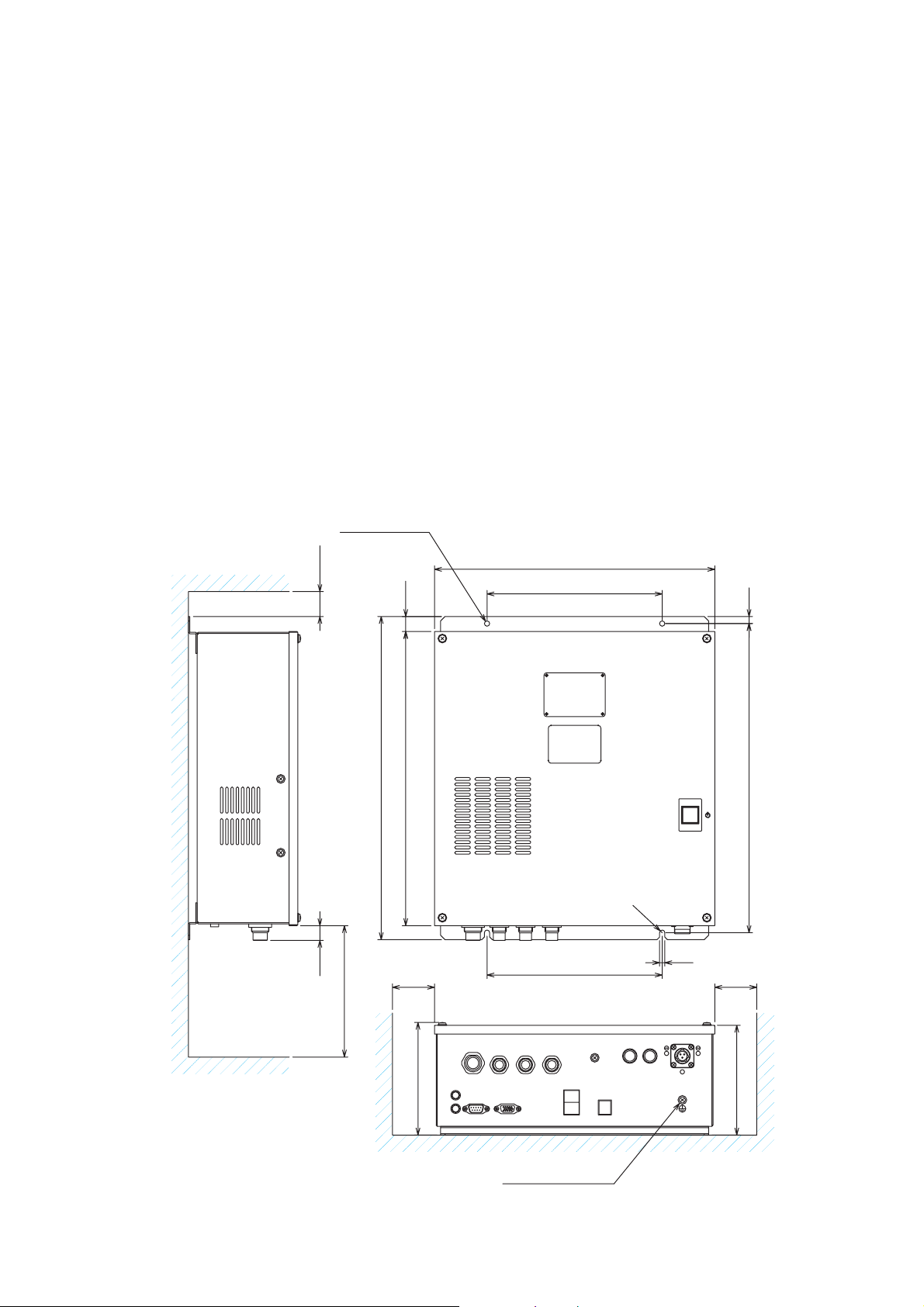

1.2 Processor Unit

The processor unit can be mounted on the deck, a desktop or on a bulkhead. Select a

mounting location considering the points below.

• Locate the unit out of direct sunlight.

• Select a location where temperature and humidity are moderate and stable.

• Locate the unit where its cover can be e asily removed and cabling easily accessed.

• For mounting on a bulkhead be sure the mount ing location is strong enough to support

the unit under the pitching and rolling normally encountered on the vessel.

• Leave sufficient space around the unit for maintenance and servic ing. Recommended

maintenance space “#” appears in the fig ure below .

Tabletop or deck mounting: Fasten with four tapping screws.

Bulkhead mounting: Screw in two tapping screws in mounting location for lower mounting

holes of the unit, leaving 5 mm protruding. Set the processor unit to the screws, tighten

screws and screw in two tapping screws for upper mounting holes of the un it.

Fixing holes

2-φ6

#50

17

#150

368

17

335

#50

320

200±0.5

200±0.5

R3

6

POWER

8

352±2

#50

2

1

5A5A

3

128

KEY-

BOARD

COM1

RGB OUT

LAN2

LAN1

USB

NMEA1CONT NMEA2 CIF

MOUSE

Ground terminal

3

GND

INPUT 100-240 VAC

3A 50/60 Hz

125

1. MOUNTING

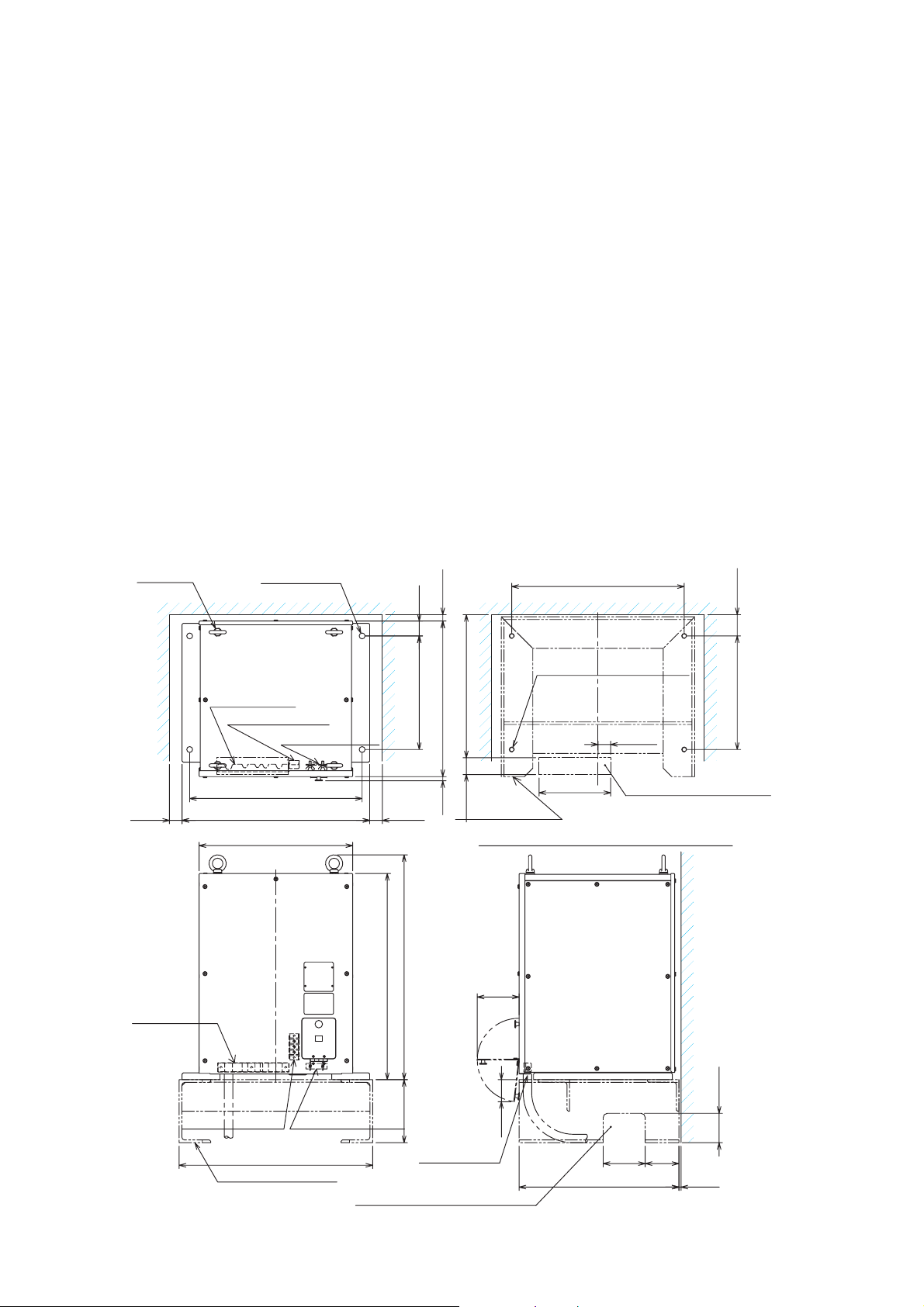

1.3 Transceiver Unit

The transceiver unit is designed to be mounted on the deck. Select a mou ntin g location

considering the points below.

• The transceiver unit generates heat so the mounting location should be well ventilated

and dry.

• The unit is only designed for deck mounting.

• Secure the maintenance space “#” shown in the figure below for ease of maintenance

and service.

• For the CV -302-MS (transceiver unit with motion sensor), install it horizontally in the

location where the ambient temperature is lower than 45°C. If the front panel of the unit is

oriented to port, its motion sensor faces the bow, i.e., the arrow mark on the NOTE label on

the transceiver unit orients to bow. After installation, compensate for installation angle error,

referring to chapter 3.

If necessary, install a channel base on the mounting location, consulting with the shipyard.

Fasten the transceiver unit to the channel base with M12 bolts. If nec essary, reinforce the

transceiver unit against vibration by stays extending from the eyebolts.

Eye bolt

(4 pcs.)

Cable clamp

#300

Cable clamp

Fixing holes

4-φ14

Terminal board

Ground terminal

410±1

446

365

(410±1)

(15)

35

(4-M12-6H)

370

270±0.5

(40) (340)

10

#300

534

490

POWER

FUSE

Channel base

Channel base & Deck side cable entry

99

(Fixing holes of

Transceiver unit)

(30)

(170)

Deck side cable entry

(50)

(270±0.5)

(70)

Terminal board

Channel base

(Shipyard supply)

Ground terminal

(460)

(150)

Cable entry

Cable entry (Channel base)

52

4

(380)

(100)

(80)

(5)

Loading...

Loading...