Furuno ETR-10N, DS-50, ETR-6 OPERATORS MANUAL

9-52 Ashihara-cho,9-52 Ashihara-cho,

A

A

*00080756800**00080756800*

*00080756800**00080756800*

*OME72410M00**OME72410M00*

Nishinomiya, JapanNishinomiya, Japan

Telephone :Telephone : 0798-65-21110798-65-2111

Telefax :Telefax : 0798-65-42000798-65-4200

ll rights reserved.

ll rights reserved.

PUB.No.PUB.No. OME-72410OME-72410

Printed in JapanPrinted in Japan

Your Local Agent/DealerYour Local Agent/Dealer

IRST EDITION :

IRST EDITION : APR.APR. 19961996

MM :: FEB.FEB. 12,200312,2003

(( DAMIDAMI ))

DS-50DS-50

* 0 0 0 8 0 7 5 6 8 0 0 ** 0 0 0 8 0 7 5 6 8 0 0 *

*OME72410M00**OME72410M00*

* O M E 7 2 4 1 0 M 0 ** O M E 7 2 4 1 0 M 0 *

SAFETY INSTRUCTIONS

WARNING

ELECTRICAL SHOCK HAZARD

Do not open the equipment.

Only qualified personnel

should work inside the

equipment.

Immediately turn off the power at the

switchboard if water leaks into the

equipment or an object is dropped into

the equipment.

Continued use of the equipment can cause

fire or electrical shock. Contact a FURUNO

agent for service.

Do not place liquid-filled containers on

the top of the equipment.

Fire or electrical shock can result if the

liquid spills into the equipment.

Do not disassemble or modify the

equipment.

CAUTION

Do not use the equipment for other than

its intended purpose.

Improper use of the equipment can result

in personal injury or equipment damage.

Turn off the equipment immediately if

you feel it is abnormal.

Turn off the power from the switchboard if

the equipment is emitting strange noises

or becomes excessively hot. Contact your

dealer for advice.

The useable ambient temperature range

is 15°C

Do not use the equipment out of the

above temperature range.

Do not place objects around the

equipment.

Overheating may result.

to

55°C.

Fire, electrical shock or serious injury can

result.

Keep the equipment away from rain

and water splash.

Fire or electrical shock can result if the

rain or water gets into the equipment.

Do not operate the equipment with wet

hands.

Electrical shock can result.

Keep heater away from equipment.

A heater can melt the equipment's power

cord, which can cause fire or electrical

shock.

Use the proper fuse.

Fuse rating is shown on the equipment.

Use of a wrong fuse can result in damage

to the equipment.

Do not power the equipment when the

transducer is in air.

The transducer may become damaged.

Handle all units carefully.

Damage can lead to corrosion.

Do not use chemical cleaners such as

alcohol, acetone and benzine to clean

the equipment.

Chemical cleaners can remove paint and

markings. Use only a soft, dry cloth. For

stubborn dirt, use a soft cloth moistened

with water-diluted mild detergent.

When dry docked remove marine life

from the transducer.

Remove marine life to maintain good

sensitivity.

Do not paint the transducer face.

Further, handle the transducer with

care.

Paint will affect equipment performance.

i

iiiiiiiiiiiii

WARNING LABEL

A warning label is attached to the

units shown right. Do not remove the

labels. If a label is missing or is illegible,

contacta FURUNO dealer or agent about

replacement.

WARNING

To avoid electrical shock, do not

remove cover. No user-serviceable

parts inside.

Name: Warning Label (1)

Type: 86-003-1011

Code No.: 100-236-230

MAIN DISPLAY UNIT

DS-500

PROCESSOR UNIT

DS-510, DS-511

Warning

label

TRANSCEIVER UNIT

DS-520

ii

iiiiiiiiiiiiiiiiiiiiiiiiii

TABLE OF CONTENTS

INTRODUCTION................................................................................................................1

SPECIFICATIONS .............................................................................................................2

SYSTEM CONFIGURATION .........................................................................................5

OPERATION ........................................................................................................................6

Controls and Indications on the Main Display Unit ........................................................... 6

Turning on the Power, Adjusting Panel Brilliance..............................................................8

Selecting Speed Tracking Mode .........................................................................................9

Selecting Unit of Speed Measurement................................................................................9

Displaying Distance Run or Keel Clearance ......................................................................9

Setting Distance Run ........................................................................................................10

System Settings.................................................................................................................11

CONTROL BOX (option) OPERATION ..................................................................13

MAINTENANCE & TROUBLESHOOTING ............................................................14

Preventive Maintenance....................................................................................................14

Troubleshooting ................................................................................................................15

Operation Checks..............................................................................................................15

Error Displays.........................................................................................................................17

Program Number ..............................................................................................................17

PRINCIPLE OF DOPPLER SPEED LOG...............................................................18

DIGITAL INTERFACE (IEC 61162-1 EDITION 2) ..................................... 19

Declaration of Conformity

iii

SPECIFICATIONS

General Specifications

1. Ultrasonic frequency 440 kHz

2. Number of beams 3 beams for dual-axis speed indication

3. Measuring range and accuracy

Ship's speed Fore/aft: -10.0 to +40.0 kt

Port-Starboard: -9.9 to +9.9 kt

Working depth Ground tracking: 1 to 200 m beneath the keel

Water tracking: 3 to 25 m below hull bottom. (It will

change by installation conditions and surrounding water

conditions of transducer. The measuring accuracy will be

reduced for the depth shallower than 30 m.)

Total distance run 0 to 99999.99 nm

Accuracy (ship's speed) 1.0% or 0.1 kt, whichever is greater. Rolling ±10°, pitching

±5°

4. Display

Main display unit LED

Digital indicator LCD or LED

5. Input/Output signals

Input External keying pulse: 2 ports

Output Ship's speed: 2 ports (digital) 1 port (analog or through

distribution box)

Distance signal: 1 port (400 p/nm, forward data only)

Distance signal: 6 ports with contact closure signal,

200 p/ nm, contact capacity 30 V,

max 0.2A, forward data only.

Alarm signal: 1 port (contact closure signal, contact

capacity 30 V, max 0.2 A)

Keying pulse: 1 port

Digital interface IEC 61162-1 2nd Edition: 2 ports

VBW, VTG, VHW, VLW (VTG is not output when the

seabed is not acquired. Heading data in VTG and VHW is

"null".)

6. Power supply 100/110/115/220 230 VAC, 50/60 Hz

7. Environmental conditions Standards: IEC 945 test methods

In-bridge units -15°C to +55°C

Relative humidity 95% at 40°C

Note: Performance may be affected by air bubbles, interference and other factors.

2

Specifications of DS-350/351 Digital Display (option)

1. Display device DS-350: LCD, DS-351: LED

2. Indication

Speed Fore/Aft: ❐❐.❐❐

Port/Starboard: ❐.❐❐

Unit Knots or meters/second

Direction cd (Fore/Aft), [ \ (Port/Starboard)

Mode Ground or Water tracking

Depth (clearance) ❐❐ .❐ m

3. Other features Dimmer controls, Mode selector, Unit of speed selector

4. Power consumption DS-350: 12 VA, DS-351: 44 VA

Specifications of DS-370 Distribution Box (option)

1. Input signal (TTL level) Digital speed signal

Log signal (400 p/nm)

Alarm signal

Power on/off signal

2. Output signal The following output boards are available optionally.

(1) OTX board Serial signal for DS-350/351 Digital Indicator and/or

cascade connection of DS-370 Distribution Box (1 port /1

board)

(2) ODD board BCD serial signal for DS-720/DS-370/DS-377 Digital

Display (Analog current signal for analog display, 1 board),

-2.5 mA to 10.0 mA/-10 kt to 40 kt or -3.33 mA to 10.0

mA/ - 10 kt to 30 kt

(3) OAD board Analog current signal for analog display, 1 board, -2.5 mA

to 10.0 mA/-10 kt to 40 kt or -3.33 mA to 10.0 mA/-10 kt

to 30 kt

(4) OLG board For Distance Indicator (1 port /1 board) and Log signal

(3 ports /1 board, 200/400 p/nm contact closure signal, 30

V/0.2A or RS-422 current loop signal). One Log signal

port can be modified for Fore/aft status signal port (contact

closure signal, 30 V/0.2A or RS-422 current loop signal).

(5) OAC board Ship's speed current voltage signal (1 port /1 board), Cur-

rent signal (4.0 mA to 20.0 mAI-10 kt to max, speed, max

impedance: 250 ohms)

3

(6) OAV board Ship's speed voltage signal (1 port / 1 board), voltage

signal (-2.50 to 10.0 V/-10 kt to 40 kt, -3.33 V to 10.0 V/

-10 kt to 30 kt, -4.00 V to 10.0 V/-10 kt to 25 kt, -5.00 V to

10.0 V/-10 kt to 20 kt, max, impedance: l kohm) + Fore aft

status signal (RS-422 current loop)

3. Power supply and power 115/230 VAC, 1ø, 50/60 Hz, 50 VA max

consumption

Specifications of DS-381 Series Analog Display (option)

1. Indication system Dual range system

2. Panel dimensions ø200 mm

3. Power consumption 5 VA approx.

Specifications of DS-382 Series Analog Display (option)

1. Indication system Dual range system

2. Panel dimensions ø200 mm

3. Power consumption 5 VA approx.

Specifications of DS-501 Control Box (option)

1. Installation method Flush mount

2. Power consumption 200 mW max

3. Illumination LED

Specifications of DS-730 Distance Indicator (option)

1. Distance run indication ❐❐❐❐❐.❐ nm

2. Indication system LCD with dimmer

3. Power consumption 2.5 VA approx.

Specifications of DS-760 Series Analog Display (option)

1. Indication range -10 to 30 kt

2. Panel dimensions DS-761/762: ø200 mm

DS-763: ø100 mm

3. Power consumption 5 VA approx.

4

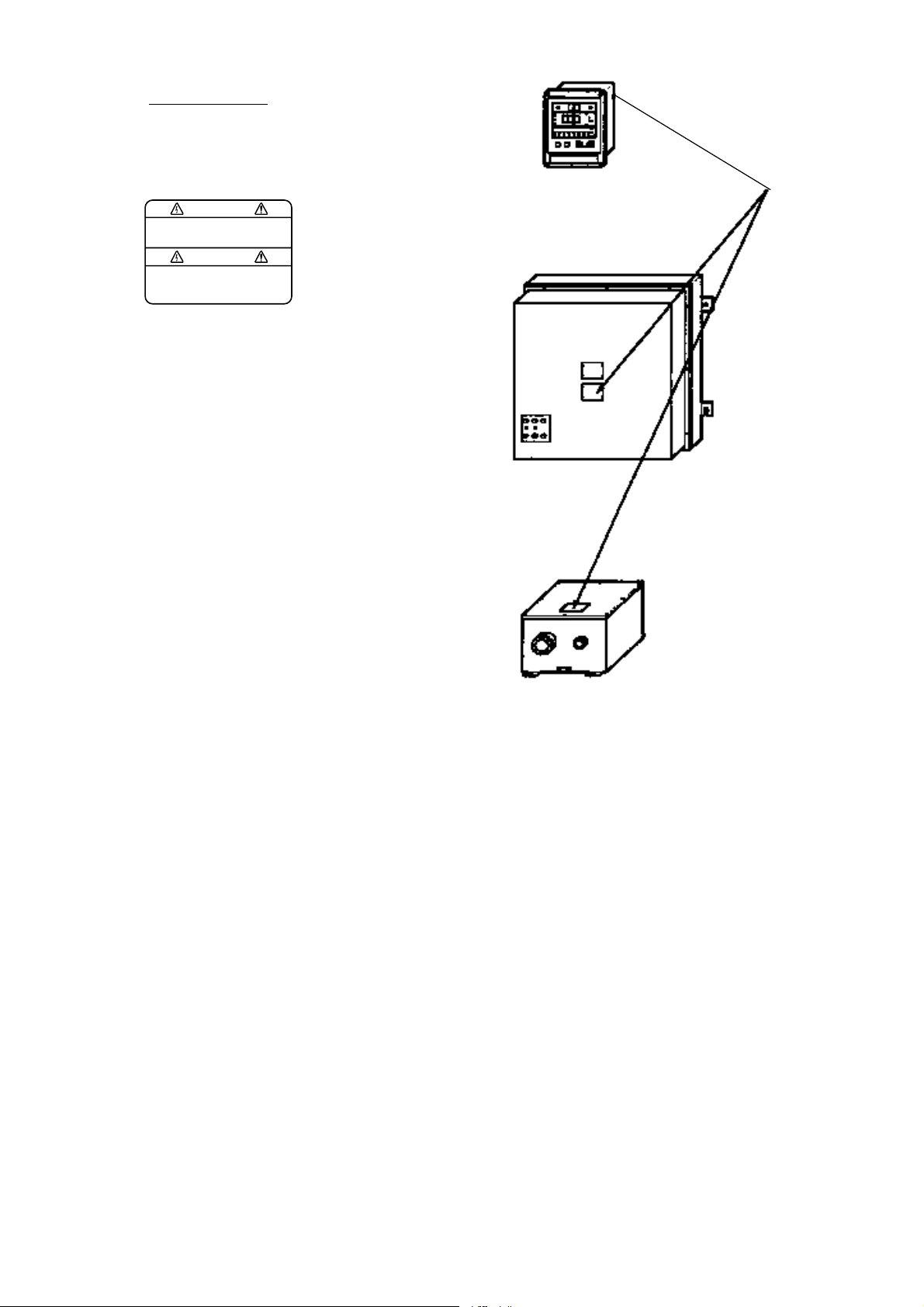

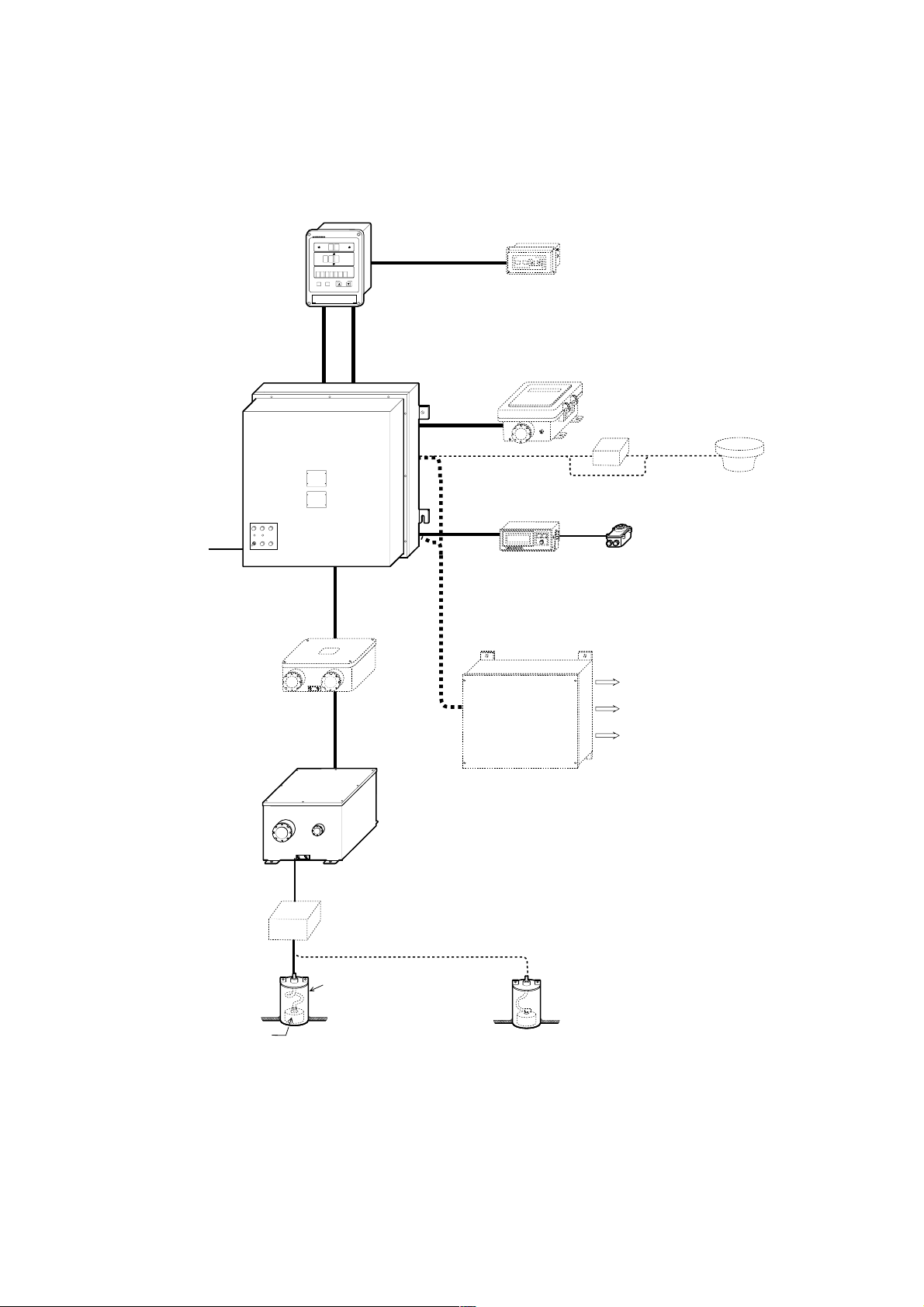

PROCESSOR

UNIT DS-511/510

SHIP'S MAINS

115/230 VAC,

50/60 Hz, 1¿

SYSTEM CONFIGURATION

MAIN DISPLAY UNIT

SIGNAL

cable

DS-50

G

G

W

W

A

A

T

T

kt

kt

m/s

m/s

AL

AL

f t

f t

f a

f a

nm

nm

POWER cable

CONTROL BOX

DS-501 (option)

DIGITAL DISPLAY

DS-350/351 (option)

DISTANCE

INDICATOR

DS-730 (option)

RANGE

SWITCH BOX

DS-389, HF-22A

DIMMER MF-22L

ANALOG INDICATOR

DS-381/382

MF-22A

JUNCTION BOX

DS-360 (option)

TRANSCEIVER UNIT

DS-520

TRANSDUCER

DS-530

DISTRIBUTION BOX

DS-370 (option)

DISTANCE RUN INDICATOR

DIGITAL DISPLAY

ANALOG DISPLAY

Note: When Processor Unit DS-510

is used Transceiver Unit is

incorporated in the DS-510.

JUNCTION BOX

CI-630

(option)

TRANSDUCER TANK

DS-531 or

GATE VALVE DS-532

TRANSDUCER TANK DS-331 /

TRANSDUCER DS-330

or

GATE VALVE for TRANSDUCER DS-335

5

Loading...

Loading...