FujiFilm T-75G, T-70, M series, G-XPC series Instructions Manual

CONTENTS

Contents . . . . . . . . . . . . . . . . . . . .1

Safety Precautions . . . . . . . . . . . . . . .2 - 4

Getting Started. . . . . . . . . . . . . . . . . . . .5

Spray Pattern . . . . . . . . . . . . . . . . . . . .6

Spraying Technique . . . . . . . . . . . . . 7

Aircap Selection . . . . . . . . . . . . . . . . . .8

Viscosity Guide . . . . . . . . . . . . . . . . . . .9

Latex Paint . . . . . . . . . . . . . . . . . . . . . .10

General Cleaning . . . . . . . . . . . . . . . . . . . . 11

Cleaning Fluid Passages . . . . . . . . . . . . .12

Finish Problems . . . . . . . . . . . . . . . . . .13

Spray Gun Problems . . . . . . . . . . . . .14 - 16

Needle Packing Nut . . . . . . . . . . . . . . . 16

Pressure Pot use . . . . . . . . . . . . . 17

Turbine Care and Maintenance . . . . . . . . . . 18

Spray Gun Holder . . . . . . . . . . . . . . . . . . 19

Parts Diagram . . . . . . . . . . . . . . . . 20 - 22

Service Information . . . . . . . . . . . . . . . 23

Warranty Information . . . . . . . . . . . . . . . . . . 24

CE Declaration . . . . . . . . . . . . Back Cover

Please read these instructions carefully before using the equipment

GROUNDING

This appliance must be grounded. If it should malfunction or break down,

grounding provides a path of least resistance for electric current to reduce

the risk of electric shock. This appliance is equipped with a cord having

an equipment-grounding conductor and grounding plug. The plug must

be inserted into an appropriate outlet that is properly installed and grounded

in accordance with all local codes and ordinances.

This appliance is for use on a nominal 120-volt circuit and has a grounding

attachment plug that looks like the plug illustrated. Make sure that the

appliance is connected to an outlet having the same configuration as the

plug.

Please Note* For UK, Australia, Asia etc. your voltage will be

220-240v. Check the label on the base of the turbine to ensure

your unit is at the correct voltage for your location.

ELECTRIC SHOCK HAZARD

Improper connection of the equipment grounding conductor can

result in the risk of electric shock.

· Check with a qualified electrician or service person if you are in doubt

as to whether the outlet is properly grounded.

· Use only a 3-wire extension cord that has a 3-blade grounding plug

and a 3-slot receptacle that accepts the plug on the product.

· An undersized cord results in a drop in line voltage and loss of power

and overheating.

· Do not modify the plug provided with the appliance. If it will not fit the

outlet, have a proper outlet installed by a qualified electrician.

· To reduce the risk of electric shock or injury, do not expose to rain.

· Never allow unit to freeze.

2 23

· Always store the unit inside in a dry location. Store on the floor if in a

basement setting.

· The operator must wear shoes and the floor must not be wet.

FIRE AND EXPLOSION HAZARD

Turbine must not be used in an area contaminated by volatile or

flammable materials since sparking can be expected in the

normal operation of the motor. This could ignite the contaminants causing a dangerous explosion.

· Do not spray flammable or combustible materials near an open flame

or sources of ignition such as cigarettes, motors, and electrical

equipment.

· Keep spray area well-ventilated. Keep a good supply of fresh air

moving through the area. Keep turbine in a well ventilated area.

· Do not spray turbine.

· Turn off and disconnect power cord before servicing equipment.

· Do not smoke in the spray area.

· Do not operate light switches, engines, or similar spark producing

products in the spray area.

· Keep area clean and free of paint or solvent containers, rags, and

other flammable materials.

· Fire extinguisher equipment shall be present and working.

· Sprayer generates sparks. When flammable liquid is used in or near

the sprayer or for flushing or cleaning, keep sprayer at least 20 feet

(6 m) away from explosive vapors or spraying area.

· Ensure ground prongs are intact on sprayer and extension cords.

· Always disconnect unit from main supply when filling the paint

container.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if

splashed in the eyes or on skin, inhaled, or swallowed.

· Read MSDS (Material Safety Data Sheet) to know the specific

hazards of the fluids you are using.

· Always wear appropriate gloves and eye protection

· Always wear a respirator or mask. Read all instructions of the

respirator or mask to ensure that it will provide the necessary

protection against the inhalation of harmful vapors. Please also check

with the local jurisdiction.

3

· Paint, solvents, insecticides and other materials may be harmful if

inhaled.

· Store hazardous fl uid in approved containers, and dispose of it

according to applicable guideline.

· Do not stop or defl ect fl uid leaks with your hand or body.

EQUIPMENT MISUSE HAZARD

Misuse of equipment can cause serious injury or death.

· Never aim the spray gun at another person or animal. In the event of

injury, seek expert medical advice immediately.

· Do not operate or spray near children. Keep children away from

equipment at all times.

· Do not overreach or stand on an unstable support. Keep eff ective

footing and balance at all times.

· Stay alert and watch what you are doing.

· Do not operate the unit when fatigued or under the infl uence of drugs

or alcohol.

· Do not kink or over-bend the hose.

· Do not use the hose as a strength member to pull or lift the

equipment.

· Do not cover turbine case as this will restrict air to the intake and

result to overheating and premature failure of the motor.

· Do not carry turbine while spraying.

· Check the hose, hose connectors and power cord daily. Any worn or

damaged parts should be replaced immediately.

· Use only genuine Fuji Spray replacement parts.

· It is normal for the turbine air outlet (manifold) to become hot during

use, please allow your Fuji Spray turbine to cool for a few minutes

before removing the hose from the turbine manifold.

Prop 65 Warning for California Residents

WARNING: This product may contain chemicals known

to the State of California to cause cancer, birth defects, or

other reproductive harm.

4 21

GETTING STARTED

Please register your Fuji Spray Product at www.fujispray.com/product-registration

NOTE: Throughout this Manual we have used the generic word ‘Paint’ to

describe all and any coatings. Please substitute the word ‘Paint’ for

whatever finish or coating you are spraying.

Your Fuji Spray Gun has been adjusted at the factory and is ready for

spraying. To clean out any impurities that may have accumulated during

assembly or shipping, we recommend spraying a small quantity of clean

paint thinner through the gun. Before tackling any serious spraying,

experiment with the Gun on a scrap piece of wood until you become

familiar with all the controls.

HOSE CONNECTION

Connect the Hex Nut at the end of the Hose (Female Connector) to the

Turbine Air Outlet. Tighten this Nut lightly. Overturning could cause

the internal Manifold to rotate and break the internal Seal to the

Motor. A Male Quick Connect Coupler 2046M is available as an acces-

sory for the connection to the turbine.

AIR CONTROL VALVE

The Air Control Valve 2032 is located on the Hose next to the brass

Quick-Connect. It provides you with a means of controlling the air flow

through the Gun. It offers you fingertip control when you need it to

reduce bounceback and overspray. It is important to remember that the

Air Control Valve - is the ‘last in the chain’ of operations after...

1) Thinning the paint

2) Adjusting the shape and size of the spray pattern

3) Adjusting the flow of paint through the Gun.

After performing these operations, you should spray a few passes onto a

scrap piece of plywood or cardboard. This will allow you to determine if

the paint levels nicely. Once the Gun is producing a perfect finish with

full air, you may then experiment with turning the air down until

bounceback is reduced to a mininum. However, if orange-peel results,

you have no option but to turn the air up again a slight amount.

PLASTIC DIAPHRAGM

The 1 Quart pressurized Cup has a plastic Diaphragm 2038 (not found in

the Gravity Spray Gun). This Diaphragm prevents paint from entering the

Pressure Tube 2024. The small air hole in the Diaphragm should not be

placed directly below the air hole in the Nipple. Position the Diaphragm

hole to the rear of the Cup. The Spray Gun can be turned to different

angles when spraying but never turned more than horizontal.

5

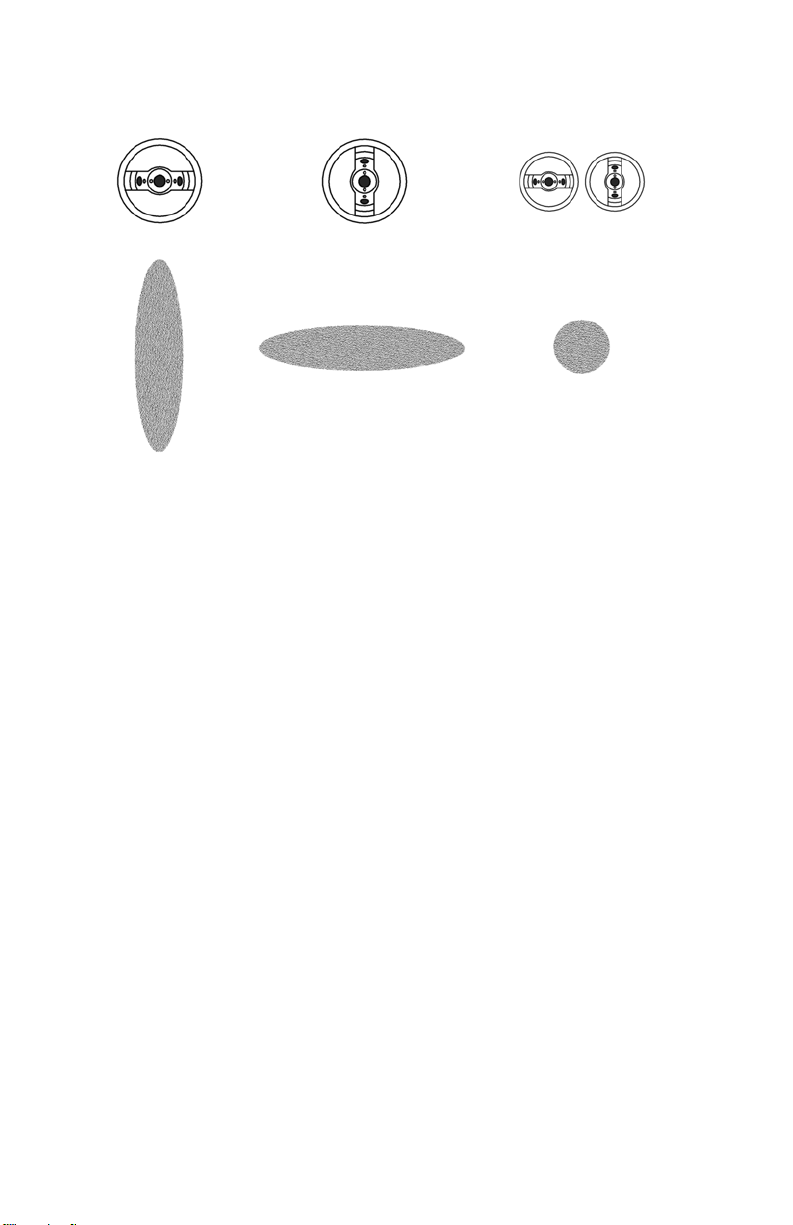

CHANGING THE SHAPE OF THE FAN

A) Loosen the Collar 5201. Turn the Air Cap 5202 to the horizontal

position then re-tighten the Collar to lock it into place. This setting

produces a vertical spray pattern. This pattern is used more than any

other by experienced spray painters.

B) Setting the Air Cap in a vertical position produces a horizontal

spray pattern. To lock it in position, tighten the Collar. The horizontal

fan pattern is the most useful for painting vertically such as a

doorframe.

CHANGING THE SIZE OF THE FAN

To produce a smaller fan pattern, turn the Pattern Control Knob

5225 counter-clockwise. Because the spray pattern size is now much

smaller, you must turn down the amount of paint spraying through

the Nozzle at the Fluid Adjusting Knob 5221 (rear of gun). If you do

not do this, you will get runs.

To set the fluid output, simply turn the Fluid Adjusting Knob counterclockwise for more ‘paint’ and clockwise for less. Once you set the

fluid to your liking, you can leave it in this position - unless of course,

you change the size of the fan pattern.

For the very smallest pattern (less than 1”), you must move the Gun

closer to the workpiece - but don’t forget to reduce the amount of

paint at the Fluid Adjusting Knob.

6

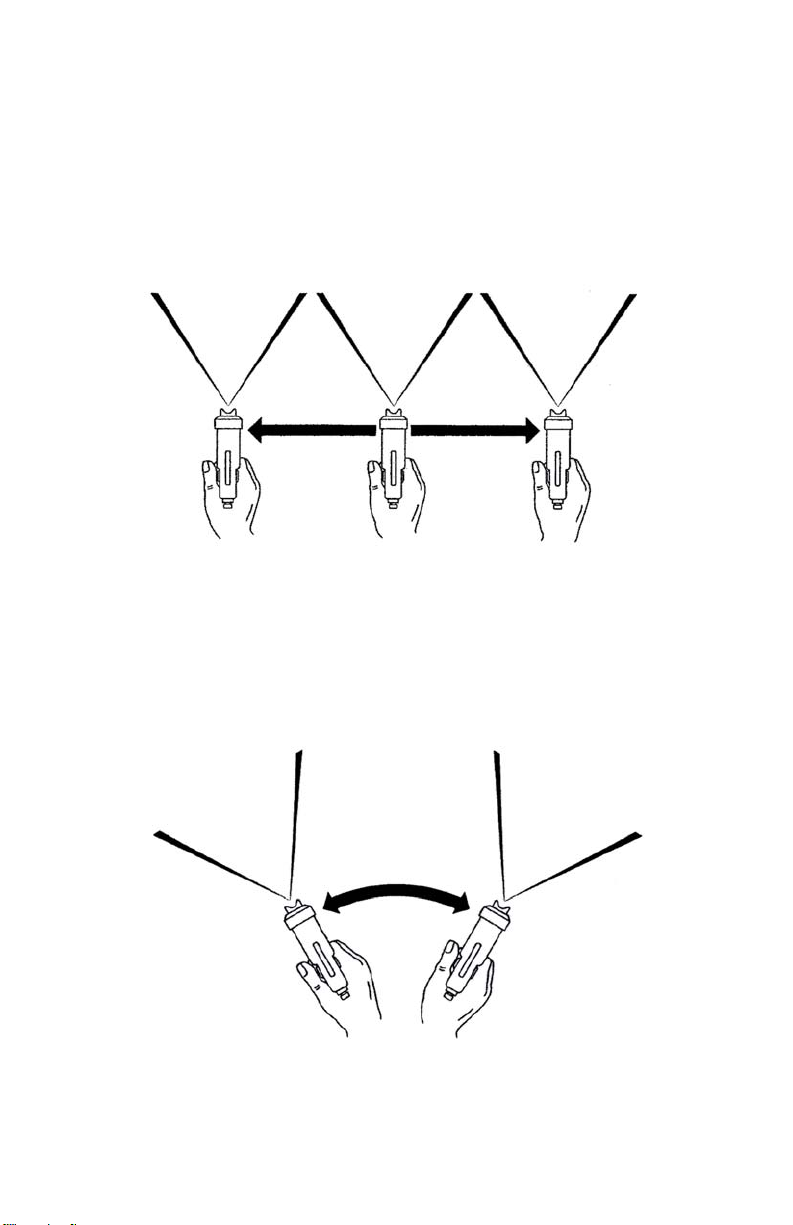

ACTUAL SPRAYING TECHNIQUES.

The Spray Gun should be held perpendicular to the surface at all

times. HOLD THE GUN NO MORE THAN 8” (20cm) AWAY FROM

THE SURFACE TO BE PAINTED.

CORRECT METHOD

Start off the piece. Pull the Trigger and move the Spray Gun in the

direction you want to spray. Continue off the edge of the piece on the

other end before releasing the Trigger. Between each successive pass,

overlap by about a half.

INCORRECT METHOD

CAUTION: Never, for any reason, point the Spray Gun directly at

the face, or head of a person.

7

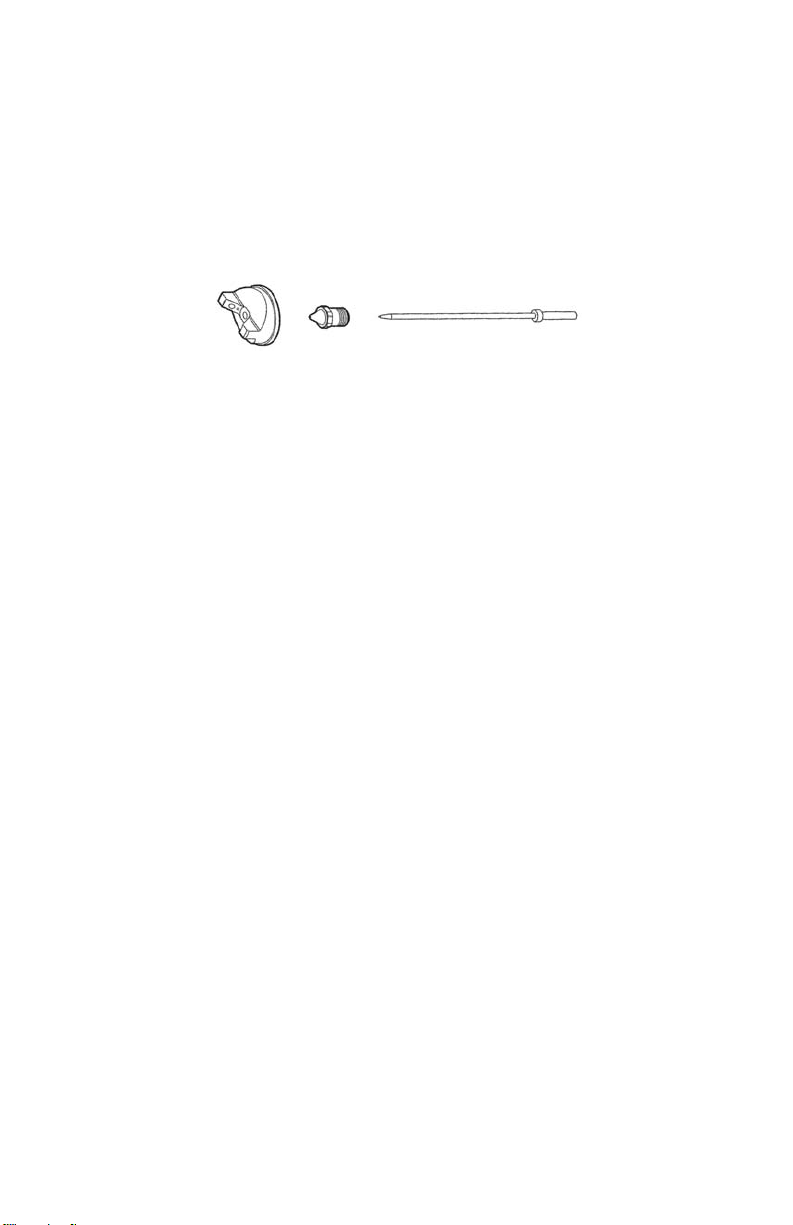

AIR CAP SET SELECTION

Six additional size Setups are available as accessories. Size No.3

(1.3mm) is standard with all Fuji T-Spray Guns. 1.0mm, 1.3mm or

1.5mm can be used for any type of fine-finishing application. The

larger sizes such as 1.5mm allow for more fluid output - desirable with

fast drying lacquers.

AIR CAP SET - Part 5100 Series

If you do not intend on spraying walls & ceilings the only additional Setups you need would be the 1.0mm, 1.5mm, and

1.8mm.

No. 1 (Part 5100-1) .8mm (.031") SUPER-FINE OUTPUT

SHADING, STAINS.

No. 2 (Part 5100-2) 1.0mm (.039") FINE OUTPUT

SHADING, STAINS, WATERBORNE COATINGS.

No. 3 (Part 5100-3) 1.3mm (.051") FINE - MEDIUM OUTPUT -

STANDARD

WATER-BASED LACQUERS, ACRYLICS, POLYURETHANE,

STAINS.

No. 4 (Part 5100-4) 1.5mm (.059") MEDIUM OUTPUT

Similar to No. 3 but more coverage. Best for AUTOMOTIVE

ENAMELS, LACQUER and LATEX for cabinetry and furniture. Also

VARNISHES, PRIMERS, OIL-BASED PAINTS.

No. 5 (Part 5100-5) 1.8mm (.070") HIGH OUTPUT

Larger surfaces, thick layers, spotted effects. SEALERS, VARNISH,

POLYURETHANE, OIL BASED PAINTS, ENAMELS, EPOXIES,

LATEX on walls, ceilings ETC.

No. 6 (Part 5100-6) 2.0mm (.078") EXTRA HIGH OUTPUT

Very heavy flows, fast coverage. STONE FINISH PAINTS, TEXTURE

COATING, INDUSTRIAL PRIMERS, MULTI-FLECK PAINTS, LATEX on

walls, ceilings ETC.

No. 7 (Part 5100-7) 2.5mm (.098") MAXIMUM HIGH OUTPUT

Heavy flows, faster coverage. LATEX HOUSE PAINT on walls etc.

8 17

Loading...

Loading...