Page 1

TS-STS

TS-STS

Quick Start Guide

Quick Start Guide

Sump Test System

Sump Test System

Pg 1

TS-STS Overview

The TS-STS system includes a TS-STS console within a convenient

portable case, leak testing probes with 50 feet of cable, and probe

hanging hardware (slip rings and chain).

After all fittings within the sump are sealed, the sump is filled with a

water-based test solution that covers all sump penetration holes. The

probe is installed so the float is floating on the surface of the test solution.

The TS-STS console is quickly programmed with the site name and

address, number of sumps, the 7-digit code-names for each sump, and

the correct Time/Day/Date before leak testing.

Pressing the Test key at the console keypad starts sump leak tests for

all sumps. The test time is 15 minutes and tests for a level change

greater than 0.002 inches. If the level of a sump drops more than the

leak

limit during the test, the Sump Leak Test Report will show a fail

result when the test is finished. Leak tests can also be programmed

(scheduled) to start at desired times.

When finished, leak test reports will automatically print out at the console

printer. Extra copies of this report can be printed using the report key. A

newly completed Sump Leak Test will overwrite the previous results

stored in memory. Save sump leak test reports and provide copies as

evidence of compliance with regulations.

TS-STS Installation

1

1.) Required Materials:

a.) Tape to secure the probe cable b.) Safety cones & signs

c.) Grounded, 3-pronged extension cord

d.) Flat pieces of metal to suspend leak testing probe over sumps

2.) Work safely — install Safety Cones and Signs at the site

3.) The probes are precision instruments — handle with care!

4.) The STS probes are shipped with cables attached, do not remove

the cable from the probe end... remove at the console case only.

5.) Inspect probes for proper float movement before use, then install

probes as shown in Section 1

6.) Connect the yellow probe cables to the receptacles at the TS-STS

Make sure to line up keyways before inserting cable and

case.

tightening the screw-on connector.

7.) Locate the TS-STS case outside of the Hazardous Area and tape

the cable down to prevent probe movement during the test and to

reduce tripping hazards

Recommendation: Use a computer and the Tech version of

System Sentinel™ to record site data, sump code-names, and test

results. Test results can also be extracted from Comm Port 1 at

NOTE

INCON P/N 000-3004 Rev.D Feb. 2009 © www

This document may change without prior notice.

the bottom of the TS-STS console (also see Section 4).

Reference Federal and State regulations for leak limit and test

time requirements. Recommendations for locating the

I

console outside of the (Class

during testing, are based on NFPA 30, NFPA 30A and NFPA 70 (NEC).

, Division 1, Group D) Hazardous Areas

®

INCON

is a Registered Trademark of Franklin Fueling Systems

TS-STS

.fraklinfueling.com

8.) Setup / Program the TS-STS console per Section 2

9.) Start sump leak test(s) on sumps that are ready

10.) Always clean, dry, and store probes in the probe carrying case after

each use

11.) Test each of the probes on a monthly basis to ensure its ability to

detect leaks. Install the probe in a test container and initiate a test.

After 5 minutes, remove about 0.12 inches of water. When the test

completes, the test report should show a Failed result if the probe

is working properly.

Page 2

Pg 2

(

)

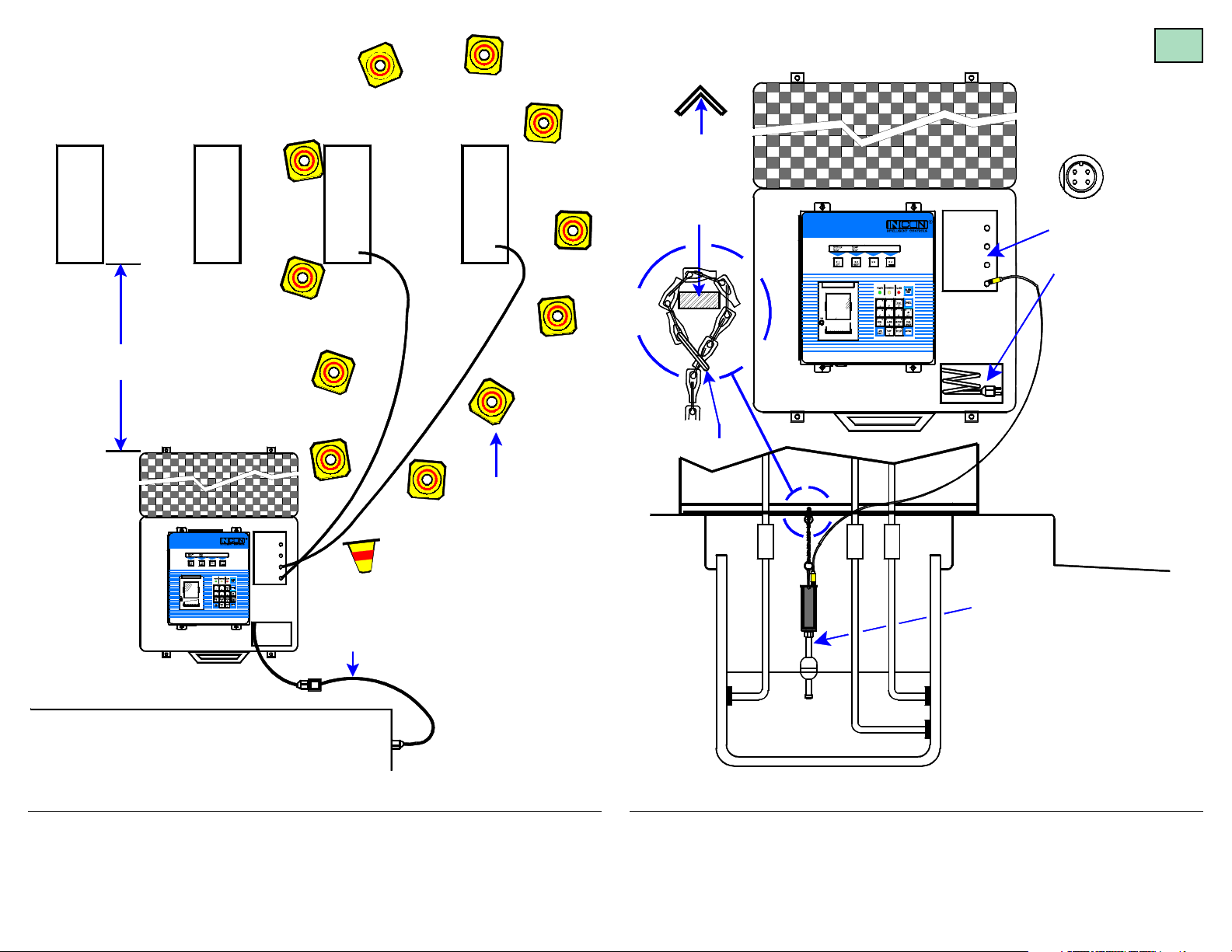

DISPENSER

DISPENSER

1 / 2

20 Feet - Min. Distance

Per NFPA 30A

TS-STS

SUMP TEST SYSTEM

TS-STS

SUMP TEST SYSTEM

3 / 4

SUMP

DISPENSER

4

3

2

1

GROUNDED

3 PRONG

EXTENSION

CORD REQ'D

5 / 6

DISPENSER

7 / 8

SAFETY

CONES

INCON RECOMMENDS

TESTING DISPENSOR

SUMPS IN GROUPS

SO OTHER DISPENSORS

ARE LEFT IN SERVICE

DURING TESTING

FLAT METAL

/ ANGLE IRON

REQUIRED

TO SUSPEND

PROBE

SIDE VIEW

SPLIT RING

TS-STS

SUMP TEST SYSTEM

TS-STS

SUMP TEST SYSTEM

SUMP

4

3

2

1

STS-PRB-12

LEAK TESTING

PROBE WITH:

TSP-SSP

STAINLESS

STEEL FLOAT

RECEPTACLES

FOR FOUR

SCREW-IN, PROBE

CABLE PLUGS

POWER CORD

WITH A GROUNDED

3-PRONGED

PLUG

BUILDING

Figure 1.1 Typical Leak Detection Probe – Dispenser Sump Installation

Overview

DISPENSER SUMP

WITH TEST SOLUTION

(Side View)

Figure 1.2 Leak Detection Probe Installation

Dispenser Sump

Page 3

Pg 3

(

)

(

)

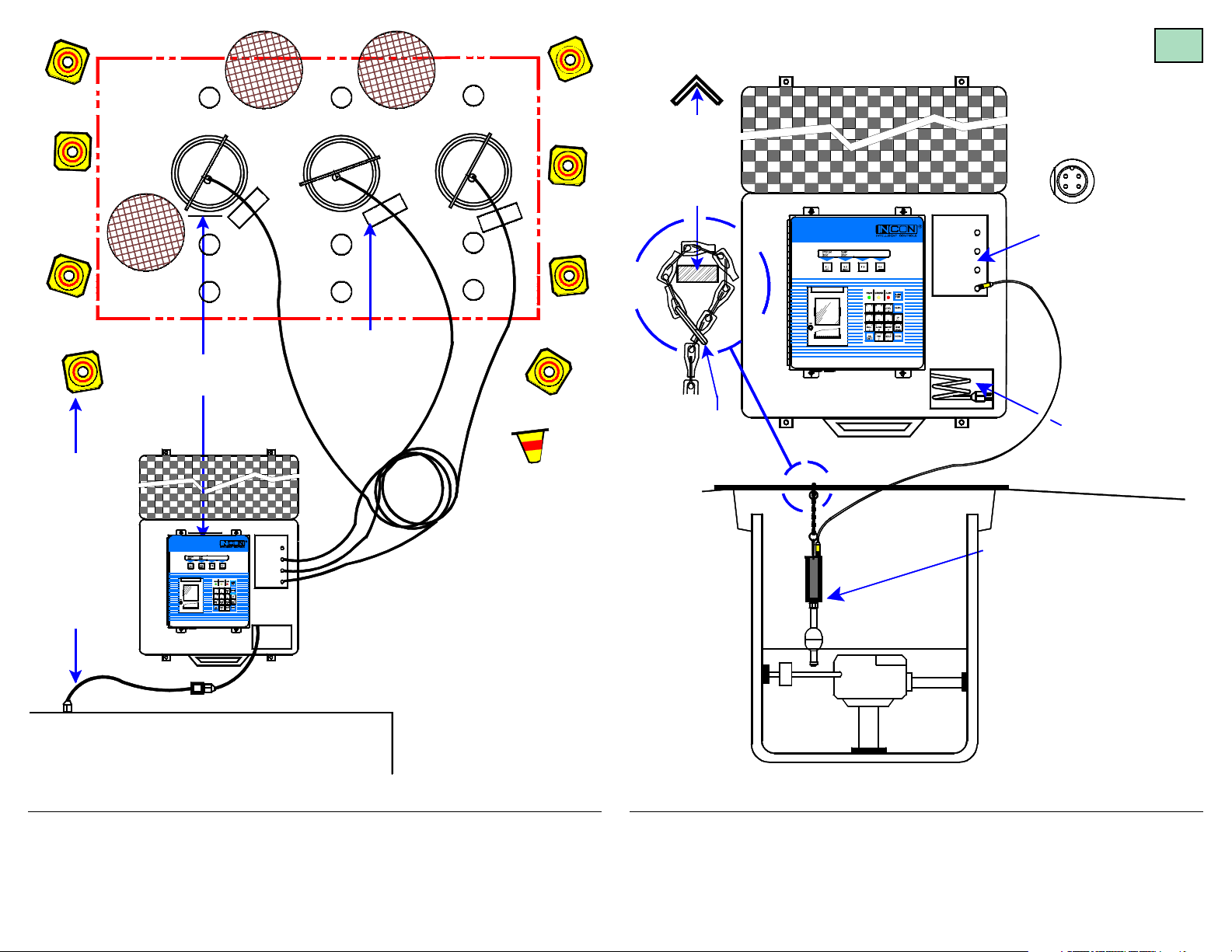

Tank Pad

10 Feet - Min. Distance

SAFETY

CONES

GROUNDED

3 PRONG

EXTENSION

CORD REQ'D

Turbine

Sump

1

Per NFPA 30A

TS-STS

SUMP TEST SYSTEM

TS-STS

SUMP TEST SYSTEM

Turbine

Sump

2

TAPE / WEIGHT DOWN

CABLE TO PREVENT

ACCIDENTAL

MOVEMENT DURING

LEAK TESTING

(PROBE CABLE

PN: 600-0200

= 50 FEET)

SUMP

4

3

2

1

Turbine

Sump

3

FLAT METAL

/ ANGLE IRON

REQUIRED

TO SUSPEND

PROBE

SIDE VIEW

SPLIT RING

TS-STS

SUMP TEST SYSTEM

TS-STS

SUMP TEST SYSTEM

STP

SUMP

4

3

2

1

STS-PRB-12

LEAK TESTING

PROBE WITH:

TSP-SSP

STAINLESS

STEEL FLOAT

RECEPTACLES

FOR FOUR

SCREW-IN, PROBE

CABLE PLUGS

POWER CORD

WITH A GROUNDED

3-PRONGED

PLUG

TURBINE SUMP

WITH TEST SOLUTION

Side View

BUILDING

Figure 1.3 Typical Leak Detection Probe – Turbine Sump Installation

Overview

Figure 1.4 Leak Detection Probe Installation

Turbine Sump

—

❖

—

Page 4

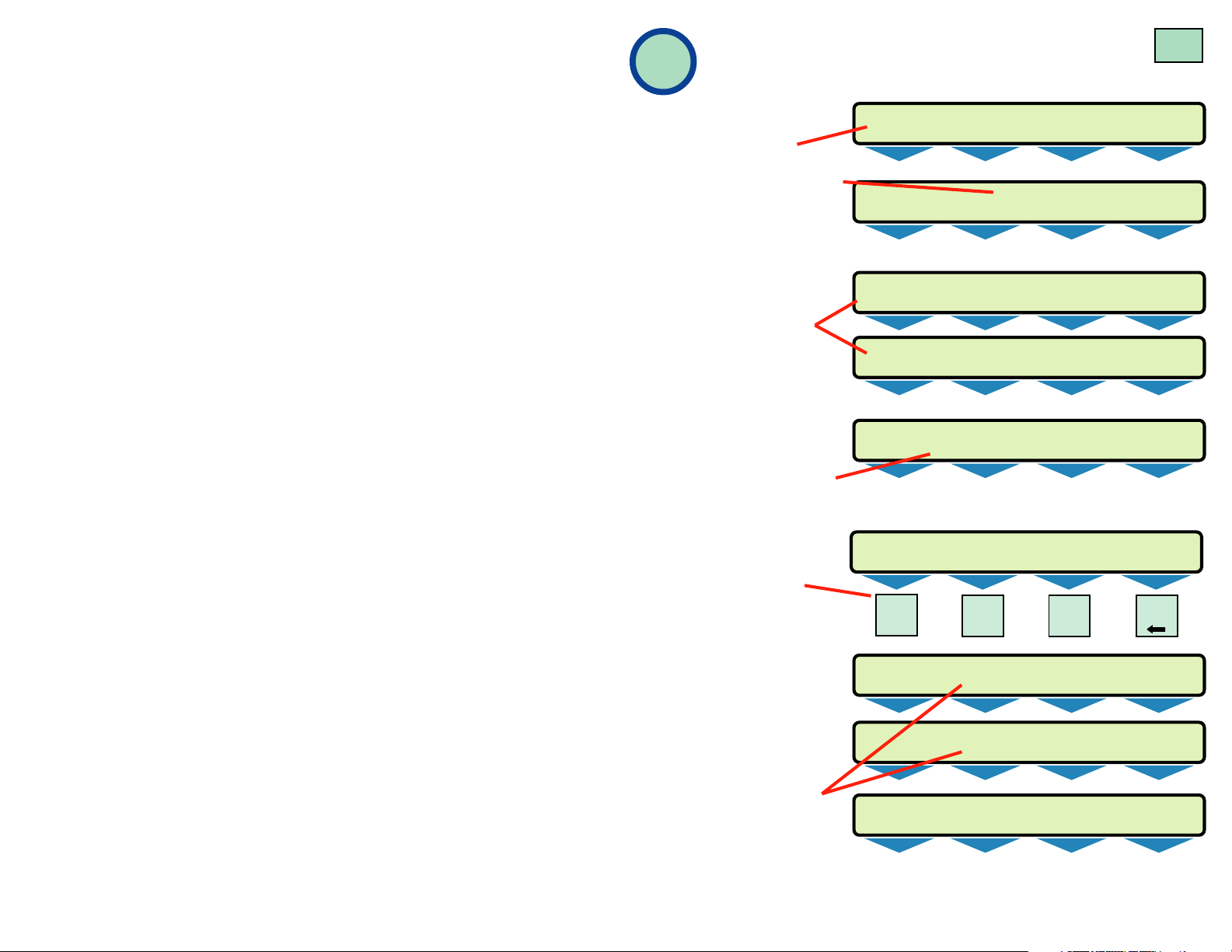

Setup - Program the Console

SELECT MENU OPTION

SETUP

SETUP MENU (MORE)

EXIT SYSTEM SUMPS CLK/CAL

SETUP MENU (MORE)

EXIT SYSTEM SUMPS CLK/CAL

SETUP MENU (MORE)

EXIT SYSTEM SUMPS CLK/CAL

SETUP MENU (MORE)

COM PORTS

Pg 4

2

NaNa

vigatingvigating

Na

vigating

NaNa

vigatingvigating

Menus:Menus:

Menus:

Menus:Menus:

• Push the

UP/DOWN

H U

MENU

7

keys ▲ ▼ to show

other menus or other

choices

• Use menu keys

M4)

to access menus

(M1

to

M1

LEFT

or to help edit text

• Press the

to make a setup choice

ENTER

key

M1

LEFT

or to move down in the

menu

• Press the

key to cancel before

entry or to move up

tree

CANCEL

M1

LEFT

and out of the menu

tree

M1

Input

Alphanumeric

LEFT

Press the Down key ▼ to see next display

Text

(in setup mode):

Press the

ACK

SHIFT

key at the keypad

1, or 2, or 3 times to

cycle between the

unique key characters

(at positions 1, 2, and 3).

Select and press a key

to input the desired

alphanumeric character.

M1

LEFT

ACK

SHIFT

Press the

the highlighted sequence below

to view the Setup Menus

M2

RIGHT

M2

RIGHT

M2

RIGHT

M2

RIGHT

M2

RIGHT

1 2

MENU

a b

key and follow

M3 M4

M3 M4

M3 M4

M3 M4

M3 M4

KEY

#

3

Display

Menu Select Keys

(M1 – M4)

Keypad:

(Multi-Function,

Alphanumeric)

ACK SHIFT key

Report Printer

(thermal printer)

Editing Text:

• Press the

• Use

• Use

M2

M4

NOTES

M1

key to move the cursor to the left

to move the cursor to the right

to backspace & delete text to the left of the cursor

Follow the highlighted sequence at left to program the

console.

Menus are in indented format (lower levels to the right).

The setup program factory default settings are shown

in ITALIC TEXT. The console will auto-exit the setup

mode if no key is pressed after 3 minutes.

Minimum Setup Requirements

1) From SETUP>SYSTEM (SYSTEM INFO), program the

System ID data and the No. (number of) Sumps

2) SETUP>SUMPS>DATA>SUMP N>NAME>Sump Name (code-

name for each containment sump that will be leak tested)

3) SETUP>CLK/CAL>Set Time (input the correct time), Set Date

(input the correct date), Set Day (choose the day of the week)

Page 5

Setup Menu

EXIT SYSTEM SUMPS CLK/CAL COM PORTS

Pg 5

Setup>System menu

SYSTEM INFO

SYSTEM ID (customize the Site ID information)

LINE 1

LOCATION LINE 1 (input 24 characters Max)

INCON Enter the Business Name

LINE 2

LOCATION LINE 2 (input 24 characters Max)

INTELLIGENT CONTROLS INC Enter other Business data

LINE 3

LOCATION LINE 3 (input 24 characters Max)

P.O. BOX 638 Enter the Street Address

LINE 4

LOCATION LINE 4 (input 24 characters Max)

SACO ME 04072 Enter the City and Zip code

LINE 5

LOCATION LINE 5 (input 24 characters Max)

1-800-984-6266 Enter the Business Number

NO. SUMPS (enter total number of sumps [4 max.])

NUMBER OF SUMPS

1

Setup>System menu Continued...

COLD BOOT (Replaces all custom-setup data with default values)

IF YOU CONTINUE, ALL SYSTEM PROGRAMMING

AND DATA WILL BE LOST...

:

PRESS ENTER IF YOU ARE SURE THAT

YOU WANT TO CONTINUE WITH COLD BOOT

Setup>Sumps menu

SUMPS

DATA

SUMP DATA

SUMP 1

SUMP

SUMP

2

:

4

SUMP DATA N

NAME (Rename the sump using a

SUMP NAME N Code-Name for each Sump)

SUMP N code-names can be up to 7

N = Sump number

Select sump and program new name

alphanumeric characters long

(e.g. ULD SMP, SUP SMP, DSP 1-2)

SUMP TST (sump leak test, start time + leak limit)

START TIME (Do not set when tests are started from the front panel)

SUMP TEST START TIME Tests are 15 minutes in length

00.28.00

LEAK LIM

LEAK LIMIT

0.002

Add 12 to pm times from 1 to 11:59 pm

(alarm threshold... 0.002 to 9999 in level units)

(12:28 am in 24 hour format)

Input time in 24 hour format...

Page 6

Setup>Clk/Cal menu

SYSTEM SUMP

OKAY OKAY

SYSTEM SUMP

WARNING OKAY

SYSTEM SUMP

NO PAPER OKAY

SYSTEM SUMP

OKAY OKAY

SYSTEM SUMP

OKAY TEST

LEVEL SUMP 1 SUMP 2 SUMP 3 SUMP 4

INCHES 2.01 3.09 1.76 3.12

SELECTFUNCTION 10:39:08 AM 10-29-2001

DISPLAY PRINTER

SYSTEM SUMP

OKAY LEAK

SELECT LEAK TEST OPTION

STATUS START ABORT

Leak Testing /

Pg 6

CLOCK/CALENDAR

DAY SAV

DAYLITE SAVINGS

ENABLED Enable

DISABLED Disable = does not

TM STYLE Select the time style for displays & reports

TIME STYLE

12 HOUR

24 HOUR

DT STYLE Select the time style for displays & reports

DATE STYLE

MM/DD/YY

DD/MM/YY

YY/MM/DD (YY = Year, MM = Month, DD = Day)

SET TIME Input current time in 24 hour format

SET SYSTEM TIME Two digits are required, use leading

HH:MM:SS

SET DATE Input current DATE

SET SYSTEM DATE

YYYY:MM:DD

SET DAY

SET SYSTEM DAY OF WEEK Select the current day

SUNDAY

MONDAY

TUESDAY

WEDNESDAY

THURSDAY

FRIDAY

SATURDAY

= allows daylight savings time changes

zeros before single digits

(e.g. input 05 not 5)

(YYYY = year, MM = Month, DD = Day)...

2 digits are required for month and day –

use leading zeros before single digits

(e.g.. input 04 not 4)

Add 12 to p.m. times

from 1 to 11:59 p.m.

3

Console Operation

Displays:

1.) Normal Display

2.) Press the Check key

to check the time and

date.

3.) The System –

Warning message

alternates with the

No Paper (if out).

Replace printer

paper before starting

sump leak tests.

4.) Press the Level key

to check the test fluid

level in sumps (sumps

can’t be leak tested if

empty).

5.) Press the Test key at

the keypad & and the

menu select key

(M1 M2

follow instructions to:

• Show the Status of

tests including Start

time / date

• Start tests, and to

• Abort leak test(s)...

Okay & Testing are

alternately displayed

when a sump leak

test is running.

or

M3)

and

M1

LEFT

M2

RIGHT

M3 M4

— ❖ —

Page 7

Leak Testing /

SELECT SUMP REPORT

TEST LEVEL

SELECT SUMP

SUMP 1 SUMP 2 SUMP 3 ALL

SELECT ALARM TYPE

SYSTEM SUMP ALL

SELECT (SYSTEM / SUMP) ALARM STATUS

ACTIVE CLEARED HISTORY

SELECT REPORT

SUMP ALARM

Console Operation Continued...

Pg 7

6.) To view an alarm/warning, press the M1 or M2 Key under the

word Alarm / Warning. While viewing the alarm, press the

SHIFT key at the keypad to acknowledge.

Cleared and

ACK

transient alarms should be acknowledged prior to starting

another test.

7.) Press the Report key at the keypad to show various report

choices.

—

❖

—

Reports

4

Reports can printout automatically or on

demand from the keypad. The

Sump Leak Test and Alarm

Reports print automatically.

The other reports, such as

the Sump Level Reports,

Alarm Reports, and Sump

Test Reports can be printed

on demand.

M1

LEFT

M2

RIGHT

M1

LEFT

M3 M4

ACK

SHIFT

J W

REPORT

M2

RIGHT

9

INCON

P .O. BOX 638

SACO ME 04072

1-800-984-6266

SUMP 1

M3

M1

LEFT

M4

M2

RIGHT

M3 M4

INTELLIGENT CONTROLS INC.

2.

10/31/2001 12:15 PM

SUMP LEAK TEST REPORT

TEST STARTED 12:00 PM

TEST STARTED 10/31/01

BEGIN LEVEL 2.0120 IN

END TIME 12:15 PM

END DATE 10/31/01

END LEVEL 2.0120 IN

LEAK THRESHOLD 0.002 IN

TEST RESULT : P ASSED

Press the menu select keys

and choose the type of report

that you wish to printout.

Alarm reports will print as

soon as an alarm is detected.

M1

LEFT

Leak test reports print

automatically after the leak test is finished.

Note that

when a new leak test is complete the data will

overwrite a previous result.

Of the three reports shown here, one is a Level

Summary report and two are Sump Leak Test

Reports.

Up to 4 sumps can be leak-tested at the same

time.

REPORTS continued...

M2

RIGHT

M3 M4

M1

LEFT

M2

RIGHT

M3 M4

INTELLIGENT CONTROLS INC.

10/31/2001 11:58AM

1.

SUMP 1

SUMP 2 7.201 IN

SUMP 3 3.218 IN

INCON

P.O.. BOX 638

SACO ME 04072

1-800-984-6266

SUMP LEVEL REPORT

2.012 IN

INTELLIGENT CONTROLS INC.

3.

10/31/2001 12:15 PM

SUMP LEAK TEST REPORT

TEST ST ARTED 12:00 PM

TEST ST ARTED 10/31/01

BEGIN LEVEL 7.0230 IN

END TIME 12:15 PM

END DATE 10/31/01

END LEVEL 7.0209 IN

LEAK THRESHOLD 0.002 IN

TEST RESULT : FAILED

INCON

P .O . BO X 638

SACO ME 04072

1-800-984-6266

SUMP 2

Page 8

Reports

Continued...

4

A digital copy of the Sump Test Report can be retrieved from the TS-STS

console through the communications port (Comm Port 1). This port is

located at the bottom side.

As with the printed reports, this data is overwritten when a new test is

run, so it must be collected after each test. The data can be stored in a

database as opposed to saving the printouts.

For more information on this feature contact INCON Technical Service at

1-800-984-6266.

Pg 8

—

INCON P/N 000-3004 Rev.D Feb. 2009 © Franklin Fueling Systems

This document may change without prior notice.

—

®

INCON

is a Registered Trademark of Franklin Fueling Systems

www

.franklinfueling.com

Loading...

Loading...