Page 1

TS-RA1, TS-RA2 and TS-RK

Tank Overll Alarms

Installation Guide

Franklin Fueling Systems • 3760 Marsh Rd. • Madison, WI 53718 USA

Tel: +1 608 838 8786 • 800 225 9787 • Fax: +1 608 838 6433 • www.franklinfueling.com

1

Page 2

Important Safety Messages

INCON equipment is designed to be installed in association with volatile hydrocarbon liquids such as gasoline and diesel

fuel. Installing or working on this equipment means working in an environment in which these highly ammable liquids

may be present. Working in such a hazardous environment presents a risk of severe injury or death if these instructions

and standard industry practices are not followed. Read and follow all instructions thoroughly before installing or working

on this, or any other related, equipment.

As you read this guide, please be aware of the following symbols and their meanings:

Warning

Caution

Danger

Warning

Warning

This symbol identies a warning. A warning sign will appear in the text of this document when a potentially

hazardous situation may arise if the instructions that follow are not adhered to closely. A potentially hazardous

situation may involve the possibility of severe bodily harm or even death.

This is a caution symbol. A caution sign will appear in the text of this document when a potentially hazardous

environmental situation may arise if the instructions that follow are not adhered to closely. A potentially

hazardous environmental situation may involve the leakage of fuel from equipment that could severely harm

the environment.

This symbol identies an electrical danger. An electrical danger sign will appear in the text of this document

when a potentially hazardous situation involving large amounts of electricity may arise if the instructions that

follow are not adhered to closely. A potentially hazardous situation may involve the possibility of electrocution,

severe bodily harm, or even death.

Follow all applicable codes governing the installation and servicing of this product and the

entire system. Always lock out and tag electrical circuit breakers while installing or servicing

this equipment and any related equipment. A potentially lethal electrical shock hazard and the

possibility of an explosion or re from a spark can result if the electrical circuit breakers are

accidentally turned on during installation or servicing. Please refer to the Installation and Owner’s

Manual for this equipment, and the appropriate documentation for any other related equipment, for

complete installation and safety information.

Follow all federal, state and local laws governing the installation of this product and its associated

systems. When no other regulations apply, follow NFPA codes 30, 30A and 70 from the National Fire

Protection Association. Failure to follow these codes could result in severe injury, death, serious

property damage and/or environmental contamination.

Warning

Warning

When the Fuel Management System system is used to monitor tanks containing gasoline or other

ammable substances, you may create an explosion hazard if you do not follow the requirements in

this manual carefully.

All wiring from probes or sensors to the console must be run in conduit separate from all other

wiring. Failure to do so will create an explosion hazard.

2

Page 3

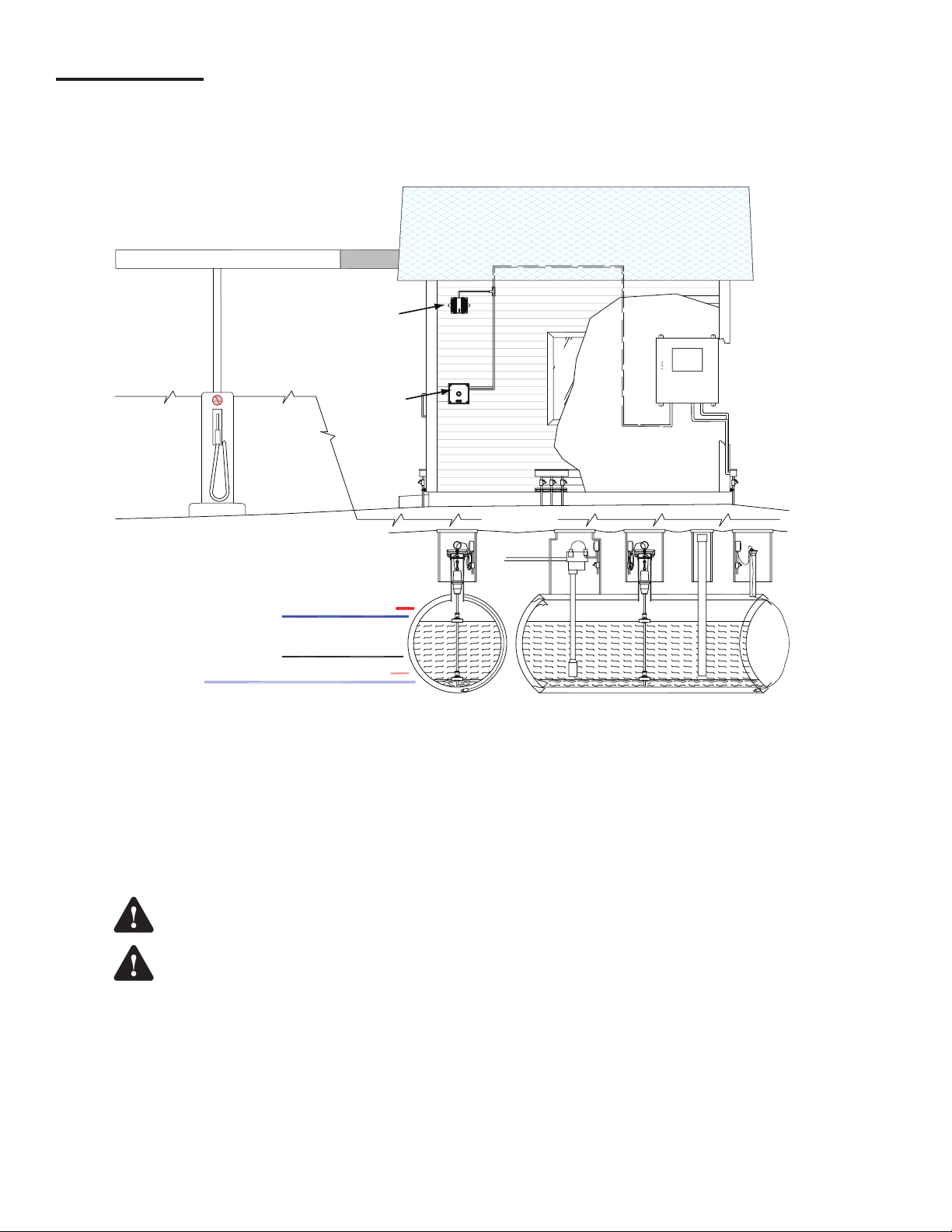

Product Overview and Theory of Operation

The TS-RA1, and TS-RA2 are remote audible and visual alarm units that are used with Fuel Management System

consoles.

The TS-RA1, TS-RA2, and the TS-RK Tank Overll Alarm and Alarm Acknowledge units are mounted near the tank

lling site. If the tank product level reaches the FMS overll alarm setpoint, then the Tank Overll Alarm will become

active. An active Tank Overll Alarm alerts the tank lling attendant to immediately stop the lling operation before a spill

occurs. The TS-RK is an optional remote alarm acknowledge unit. This unit gives the tank lling attendant the means to

silence a Tank Overll Alarm at the lling site. The TS-RK is required when a TS-RA1 or TS-RA2 is connected to a T5

series Fuel Management System console or a Colibri Automatic Tank Monitor.

When in an alarm condition, depressing the acknowledge button on the TS-RK will silence the Tank Overll Alarm at the

tank lling site.

Alarm Specications

The TS-RA1 is a standard intensity, remote alarm device that has a useful signal range up to 50 feet.

Ratings

Input Power 115 VAC (96 to 132vac), 60Hz @ 0.125 amps Maximum

Operating Temperature Range –31 to 150 °F

Humidity Range Up to 95% humidity

Signal outputs Visual (low intensity incandescent lamp) & audio tone (85 dB @ 10 feet)

The TS-RA2 is alarm device that has a strobe-light, and eight user-selectable output tones with two user-selectable sound

intensities. In the high-intensity mode, the TS -RA2 has a useful signal range up to 200 feet.

Ratings

Input Power 115 VAC (96 to 132vac), 60Hz @ 0.125 amps Maximum

Operating Temperature Range –31 to 150 °F

Humidity Range Up to 95% humidity

Signal outputs Visual strobe (15 Candela), and audio tone (99 dB to 75 dB @ 10 feet).

When properly installed, wired, and programmed, this alarm system will help prevent dangerous fuel spills, environmental

contamination, and cleanup costs.

3

Page 4

Installation

Overview

The mounting location of TS-RA1, TS-RA2, TS-RK units should be based on: cable run length, ease of conduit routing,

alarm light visibility, alarm horn audible range limitations, and the distance away from hazardous areas. In addition, the

following limitations and requirements must be met.

(high)WATER

Limit setpoint

HIGH Limit

(Tank full) setpoint

LOW Limit

(Reorder) setpoint

TS-RA1, or TS-RA2

Tank Overfill Alarm

(TS-RA2 shown)

Alarm Acknowledge

HAZARDOUS

(Tank Overfill) setpoint

LO LO Limit setpoint

TS-RK

NON-HAZARDOUS

AREA

AREA

HI HI Limit

Unit

TANK OVERFILL ALARM

MODEL TS-RA2

SACO, MAINE 04072

74 INDUSTRIAL PARK RD.

INTELLIGENT CONTROLS

TANK OVERFILL ALARM

ACKNOWLEDGE

MODEL TS-RK

INTELLIGENT CONTROLS INC.

74 INDUSTRIAL PARK ROAD

SACO, MAINE 04072

Tank Filling Site

HAZARDOUS

AREA

FMS

Console

NON-HAZARDOUS

AREA

Figure 1: TS-RA and TS-RK Installation Overview

• The location of the Tank Overll Alarm and Alarm Acknowledge unit enclosures must be less than 1000 feet away from

the 120 VAC electrical power (source) panel.

• The TS-RA1, or TS-RA2 Tank Overll Alarm unit should be mounted near the fuel tank lling area.

• The alarm light must be visible and the alarm horn must be audible at the fuel tank lling area.

•

These units should be mounted in a protected location that minimizes exposure to direct sunlight, snow and rain.

• The TS-RK Tank Overll Alarm Acknowledge unit should be accessible to the tank lling attendant. Access to the TS-RK

from the lling area must be clear with no obstructions.

DO NOT install the Tank Overll Alarm, or Alarm Acknowledge units in a volatile, combustible, or

Warning

explosive atmosphere. Failure to do so may create an explosion hazard.

Warning

4

Run wiring from the Tank Sentinel console to the TS-RA1 / TS-RA2 Tank Overll Alarm, and TS-RK

Alarm Acknowledge units in separate conduit apart from any other wiring. All conduits must enter

through supplied non-intrinsically safe enclosure knockouts only. Failure to do so may create an

explosion hazard.

Page 5

Mounting the Units

• Mount the TS-RA1, and/or TS-RK units through the four (4)

mounting holes provided in the case under the front cover.

(4) Holes for

#8-32 Mounting Screws

(Flasher)

• Mount the TS-RA2 unit through the two (2) mounting

holes provided.

110 VAC

(LINE)

110 VAC

(NEUT)

GND

EXT

ALARM

CON.

G1

4.22"

107 mm

4.22"

107 mm

Internal View (Cover Removed)

Figure 2: TS-RA1 Mounting Details

(4) Holes For

#8-32 Mounting Screws

F1

2-1

ACKN

SWITCH

2-2

2-3

LATCH

MODE

2-4

4.22"

107 mm

Internal View (Cover Removed)

1-3

1-4

1-5

1-6

1-7

1-8

1-9

LINE1-1

NEUTRAL1-2

GROUND

REMOTE

ALARM

SIGNAL

FLASH

DRIVE

FLASH

SHUNT

OUTPUT

OUTPUT

RETURN

4.22"

107 mm

Figure 3: TS-RK Mounting Details

5.0"

127 mm

0.25 DIA (6.4 MM)

(2) HOLES

Figure 4: TS-RA2 Mounting Details

Wiring the Units

Materials Required

• Wire: 18 to 14 AWG, 300 Volt, type TFFN, THWN,

or THHN (Note: THHN is not available in 18 AWG).

Recommended insulation colors are black, white, green,

and blue.

• Conduit: 1/2 inch, or 3/4 inch (the TS-RA2 has a 1/2 inch

NPT for threaded conduit / tting).

•

Fittings: for conduit used, and conduit hold-down clamps.

• Sealant: waterproof conduit, ttings, tting threads, and

conduit accesses to the building.

• Fasteners: appropriate for the wall construction involved.

Refer to the schematics on the following page for

connection information.

5

Page 6

Schematics

TS-RA1

110 VAC

(LINE)

110 VAC

(NEUT)

GND

EXT

ALARM

CON.

Console Relay Outputs

NC1

C1

NO1

NC2

C2

NO2

2AG 3A Fuse

ACKN

SWITCH

LATCH

MODE

2-1

2-2

2-3

2-4

1-1 LINE

1-2 NEUTRAL

1-3 GROUND

1-4

REMOTE ALARM SIGNAL

1-5

1-6 FLASH DRIVE

1-7 FLASH SHUNT

1-8 OUTPUT

1-9 OUTPUT RETURN

TS-RK

TS-RK and TS-RA1 Wiring Schematic

To 110 VAC

Power Supply

6

Page 7

SW1

1 2 3 4

O

N

See Table below

Console Relay Outputs

NC1

C1

NO1

NC2

C2

NO2

ACKN

SWITCH

LATCH

MODE

TS-RK

N STB

N AUD L

L

TS-RA2

2AG 3A Fuse

2-1

2-2

2-3

2-4

TS-RK and TS-RA2 Wiring Schematic

1-1 LINE

1-2 NEUTRAL

1-3 GROUND

1-4

REMOTE ALARM SIGNAL

1-5

1-6 FLASH DRIVE

1-7 FLASH SHUNT

1-8 OUTPUT

1-9 OUTPUT RETURN

To 110 VAC

Power Supply

TS-RA2 SW1 Switch Position Settings

(factory settings are shown in bold italic)

Sound Ouput

Position 1 Tone Pos. 2 Pos. 3 Pos. 4

Level

High dB ON Horn

ON ON ON

(continuous)

Standard db OFF Bell ON OFF ON

March Time Horn OFF OFF ON

Code-3 Horn ON ON OFF

Code-3 Tone OFF ON ON

Slow Whoop OFF ON OFF

Siren ON OFF OFF

HI/LO OFF OFF OFF

7

Page 8

Setup and Operation

The console will need to be setup for proper alarm

operation.

The steps below show setup via the console touch-screen.

The steps would be the same if logged onto the console

via computer.

Access Setup / Power Supply Module

The screens below show Channel 1 set up to alarm on a

tank overll alarm.

Select Relays

Select the channel that the TS-RK is

wired to. Refer to the wiring schematics.

Setting up Alarm Rules

Navigate back to the setup screen and select rules.

8

Page 9

If a Rule is not already in the system for the alarm you

need, Click on the to Select or create a rule for the Tank

Overfill Alarm.

Navigate back to the Rules setup page and select Actions,

and set the relay to activate.

Select Events

After selecting Events / Event, the following screen shows

the setup for the alarm.

The code could be either High product level or High

product Volume depending on the choice under the Fuel

Management System High Product Limit. Choosing the

incorrect code will lead to the rule not functioning as

designed.

Navigate back to the Rules / Actions page and add another

action.

Set this up the same as the previous screen, but have the

action set to deactivate. This will allow the relay to reset

(the alarm will continue until it is acknowledged).

9

Page 10

Testing the Alarm Wiring

The procedure below is used to verify that the tank

Overll Alarm is wired correctly.

1. Select the Main Menu button.

2. Select Diagnostics.

4. Select the Tank Overll Alarm Relay

5. Select Activate Relay.

3. Select relay

The alarm should now be activated. After the test,

repeat these steps again, but choose DEACTIVATE the

relay.

10

Page 11

Page intentionally blank

11

Page 12

© FFS 2010 000-1027 Rev F

Loading...

Loading...