Page 1

TS-LS300 Auto-Learn

®

User’s

Pressure-Based

Electronic Line Leak Detector

System

Guide

Part Number: 000-0140 Rev. C

©

Copyright

March 2008

Page 2

NOTICE

INCON has strived to produce the finest possible manual for you, and to ensure

that the information contained in it is complete and accurate. However, INCON

makes no expressed or implied warranty with regard to its contents. INCON

assumes no liability for errors or omissions, or for any damages, direct or

consequential, that result from the use of this document or the equipment which it

describes.

This document contains proprietary information and is protected by copyright. All

rights are reserved. No part of this document may be reproduced in any form

without the prior written consent of INCON.

INCON reserves the right to change this document at any time without notice.

Need Help ? Mail Address (no packages):

INTELLIGENT CONTROLS INC

PO BOX 638

SACO ME 04072

Office Hours: 8 am to 5 pm EST, Monday through Friday

Sales – Orders 24 hour Technical Service

Delivery Schedules: RMA, Application Help:

Fax: (207) 283-0158 Fax: (207) 282-9002

Phone: (800) 872-3455 Phone: (800) 984-6266

email: sales@incon.com email: tech@incon.com

INCON is a wholly owned subsidiary of Franklin Electric and is member of the:

Franklin Fueling Systems Group. Visit our web site at:

T ank Sentinel®BriteSensors® and INCON®are registered trademarks of Intelligent Controls, Inc.

System Sentinel™ and System Sentinel ™ are trademarks of Intelligent Controls, Inc.

LS300 Auto-Learn® is a registered trademark of FE Petro®.

Copyright© 2003 – all rights reserved.

www.franklinfueling.com

INSIDE FRONT COVER

LS300 User’s Guide

Page 3

Table of Contents

Preface ............................................................................................................ P-1

Safety............................................................................................................... 1-1

Mechanical Installation..................................................................................... 2-1

Electrical Installation & Wiring ......................................................................... 3-1

Line Calibration................................................................................................ 4-1

LS300 Console Operation ............................................................................... 5-1

TS-LS300 Troubleshooting guide .................................................................... 6-1

Appendix A Specifications.................................................................................A-1

TABLE OF CONTENT Page TOC-1

LS300 User’s Guide

TOC

Page 4

P Preface

— Important – Read

NOTE

Graphic Symbol Conventions

Read and follow the entire instructions in this manual before installing or working on this equipment.

Certified Installer/Service Person: Only an INCON certified installer or service person is allowed

to access both the user interface kepad and areas internal to the TS-LS300 console.

Station Owner/Operator: The station owner or operator of the TS-LS300 console is only allowed to

access the user interface keypad. Access to areas internal to the console is strictly prohibited.

NOTE

Important information, tips, and hints are highlighted by the note graphic.

CAUTION

be followed to avoid faulty equipment operation, or environmental hazards, or personnel injury!

WARNING

must be followed to avoid faulty equipment operation or explosion. If ignored, severe injury or death

may result!

DANGER

be followed to avoid an explosion or fire hazard. If ignored, severe injury or death will result!

ELECTRICAL DANGER

contain instructions that must be followed to avoid an electrical shock. If ignored, severe injury or

death may result and even severe damage to electronic equipment.

messages are highlighted by the CAUTION graphic and contain instructions that should

messages are highlighted by the DANGER graphic and contain instructions that must

Earth Ground Terminal

messages are highlighted by the WARNING graphic and contain instructions that

messages are highlighted by the ELECTRICAL DANGER graphic and

Pressure High/Pump ON

A

T

Ground Terminal

Alarm/Failed Test

Testing/Passed Test

Pressure Low/Pump OFF

LS300 User’s Guide

H

or

Horn/Audible Alarm

Test/Reset

Single Phase Alternating

Current

PREFACE Page P-1

P

Page 5

General Overview

The TS-LS300 Auto-Learn® Line Leak Detector (LLD) is a precision electronic line-leak-detection

system that is produced for installation in a petroleum pumping system. The Auto-Learn Line Leak

Detector automatically monitors at certain times and will indicate pipeline leaks should a leak occur.

An alarm indicator lights, an audible alarm horn sounds, and positive pump shutdown happens when

a leak is detected. This complies with U.S. EPA requirements 280.41(b) & 280.44(a) for automatic

leak detection in pressurized piping. After installation, the user of the leak detector must monitor the

system to ensure that any leak alarm and pump shutdown (indicating a leak in the pipeline) is dealt

with promptly.

The Auto-Learn LLD can detect a leak from the STP check valve to the solenoid valve at the

dispenser, assuming no other Normally Closed valve is in the pipeline system. The Auto-Learn LLD

does not detect leaks from the fuel storage tank or the from the submersible pump before the output

check valve. The Auto-Learn LLD is used with motor fuels.

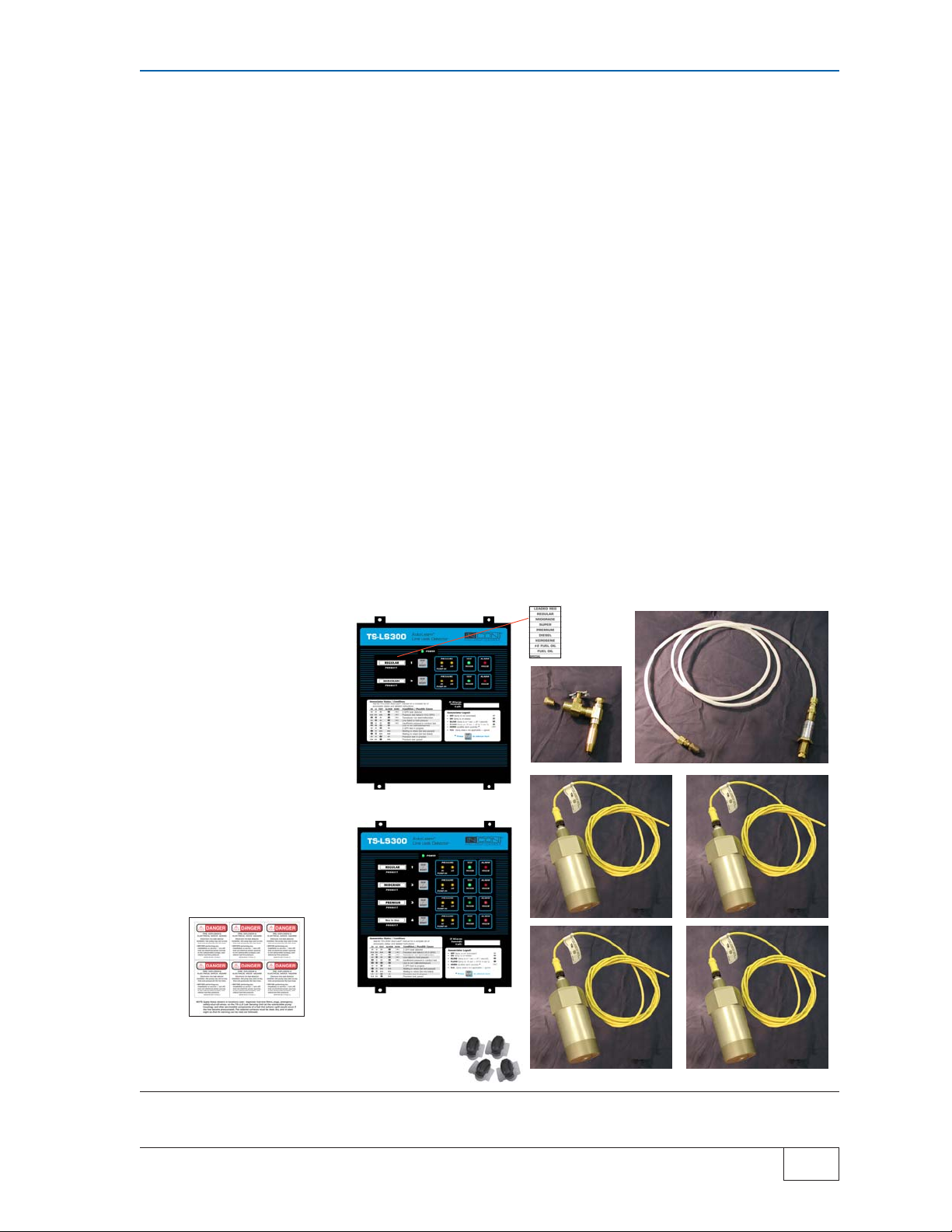

The system includes a 2 or 4 channel LSU300 console with stick-on Product ID Labels, Danger

Labels, one Auto-Learn Calibration Kit (leak-generator), 2 to 4 Needle Valve Kits, no-splice

connectors, and 2 to 4 LSU300 pressure-transducers as specified at time of order. Each channel will

monitor one piping system or product line. All line leak detectors must be tested upon start-up, and

routinely thereafter (at least annually) under NFPA standards. These NFPA and other industry

testing practices must be followed by the installer and the end user. A leak detector is not a

substitute for compliance with prudent industry practices. Fuel inventory reconciliation checks must

be performed on a daily basis by comparing dispenser meter totalizers with fuel volume changes in

the underground tank.

The Auto-Learn LLD pressure transducer is manufactured in two different versions:

1) The TS-LSU300 pressure transducers are Intrinsically Safe (I.S.) for U.S. and

international markets and are for use only with the TS-LS300 version console

2) The TS-LSU300E pressure transducers are Explosion Proof for Canadian and

U.S. markets and are for use only with the TS-LS300E version console

Wire Intrinsically Safe LSU300 transducers only with TS-LS300 consoles... physical

separation of transducer cables from non-intrinsically safe circuits is also required.

NOTE

Wire Explosion Proof LSU300E transducers only with TS-LS300E consoles in accordance

with applicable standards... use of explosion proof J-Boxes and conduit fittings in hazardous

locations. This wiring does not require separation from other non-intrinsically safe circuit wiring. This

method can be used for retrofit installations where separate conduit is not available.

This Installation and Owner’s Manual gives instructions for, site assessment and preparations,

installation, wiring, calibration, and operation. Each section gives step by step process to

successfully complete the section. A troubleshooting guide is included if difficulties are encountered.

P

Page P-2 PREFACE

LS300 User’s Guide

Page 6

Each product line must be precision tested and verified free of leaks before any component of the

LS300 system is installed. After verification, the LS300 Auto-Learn

®

system is installed, wired, and

calibrated. The supplied leak-generating device/calibration kit* is attached to a needle valve, and the

appropriate line channel selector switch is placed in the learn position at the console. Each line is

calibrated separately, one at a time, to “learn” the parameters and characteristics of a line with a

known induced leak-rate.

At each STP housing, the needle valve kits* are assembled and installed in the pressure test ports,

and the LSU300 pressure-transducers are installed in 2 inch NPT line leak detector ports (LSU300

cable length must not exceed 500 feet).

After a line is calibrated the leak-generator device is moved to the next product line for Auto-Learn

calibration. The entire process is repeated until all lines are separately calibrated and the console is

left in the Run – Detect mode.

The front panel has a power on light and 4 status-lights per line. The status lights show currently

running line leak tests, faults, and alarms. Fault-alarms will cause indicator lights to blink or flash.

Certain alarms will also activate the internal alarm horn. Manual line leak tests may be started and

* The needle valve kit and the leak generating device/calibration kit have not been

evaluated by Underwriters Laboratories

.

STICK-ON

DANGER

2 CHNL LS300

2 CHNL

3 OR 4 CHNL

NO-STRIP

SPLICE

PRODUCT

ID

NEEDLE

VALVE

LEAK GENERATING

DEVICE

LSU300 TRANSDUCER

# 3 with

3/ 4 Chnl

# 4 with

4 Chnl

Figure P-1 LS300 LLD System Components

PREFACE Page P-3

LS300 User’s Guide

P

Page 7

the alarm horn can be silenced by pressing the Test/Reset push-button on the appropriate channel,

which will silence the alarm horn and can start a new manual Line Leak Test.

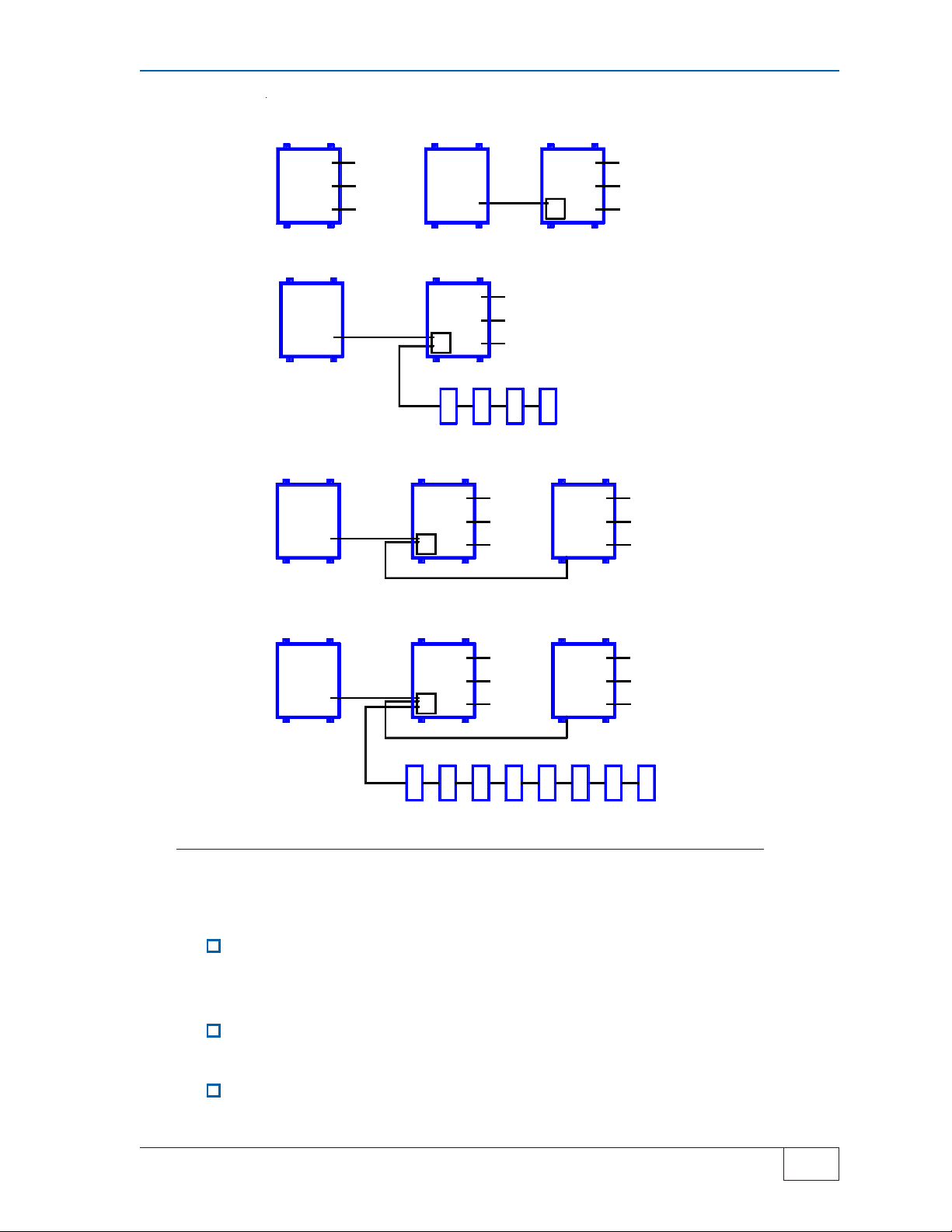

The LS300 System Applications – 5 block diagrams

The block diagrams on the next page, Figure P-1, show the 5 different applications possible with this

equipment. Only block diagram #1, Basic Auto-Learn electronic Line Leak Detector (LLD) console,

TABLE P-1 Console Channel X - Test/Reset PB

Push

#

Effect

Times

1

2

3

4

is covered in this manual, See TS-TPI, TS-1001-, TS-2001, or STP controller User guides for more

information on the other applications. The possible Applications are:

Gros s (3 gph / 11 Lph) Line Leak Tes t

Monthly (0. 2 gph / 0 . 8 L ph) Line L eak Test

Annual (0. 1 gph / 0. 4 Lph) Line Leak Tes t

Silences Alarm Horn

See the

Operation

section in this

manual or the

Quick

Reference

Guide

# 1 Basic Auto-Learn electronic Line Leak Detector (LLD) console

# 2 One LS300 Auto-Learn console with TS-TPI plus an INCON ATG (Automatic Tank

Gauge) console for LLD interface

Note: TPC is the designation for a Turbine Pump Controller throughout this

manual

# 3 One LS300 Auto-Learn console with TS-TPI for Turbine Pump Controller (TPC)

interface and an INCON ATG console for LLD and Pump Controller interface

P

# 4 Two LS300 Auto-Learn consoles for support of up to 8 lines: one console has the

TS-TPI interface circuit board enabling connection to the other LS300 console via a

special RS-232 cable and to the INCON ATG console via RS-485 communication

for LLD interface

# 5 Two LS300 Auto-Learn consoles for line leak detection of up to 8 lines: one console

has the TS-TPI interface circuit board for connection to the other LS300 console via

a special RS-232 cable and connects to the INCON ATG console via RS-485

communication for LLD interface and for Turbine Pump Controller control

Page P-4 PREFACE

LS300 User’s Guide

Page 8

TS-LS300

Auto-Learn

Console

1

Inputs (#1-4):

Lines (#)

Hooks (#)

Power

TS-ATG

Console

2

LLD

RS485

TS-LS300

Auto-Learn

Console

TS-TPI

PCB

Inputs (#1-4):

Lines (#)

Hooks (#)

Power

TS-ATG

Console

3

TS-ATG

Console

4

TS-ATG

Console

5

LLD

RS485

LLD

RS485

LLD

RS485

TS-LS300

Auto-Learn

Console

TS-TPI

PCB

TPC TPC

TS-LS300

Auto-Learn

Console #1

TS-TPI

PCB

TS-LS300

Auto-Learn

Console #1

WITH

TS-TPI

PCB

Inputs (#1-4):

Lines (#)

Hooks (#)

Power

TPC TPC

Inputs (#1-4):

Lines (#)

Hooks (#)

Power

Inputs (#1-4):

Lines (#)

Hooks (#)

Power

TS-LS300

Auto-Learn

Console #2

TS-LS300

Auto-Learn

Console #2

Inputs (#5-8):

Lines (#)

Hooks (#)

Power

Inputs (#5-8):

Lines (#)

Hooks (#)

Power

TPC TPC TPC

TPCTPC TPC TPC TPC

Figure P-1 Auto-Learn System Applications (5) – Block Diagram

Site Survey & Assessment

A precision line test must be conducted before installing the LSU300 transducer for

the first time and before replacing any line leak detector that is indicating a leak to

assure line integrity .

Before installation of Auto-Learn system verify that the equipment is proper for the

site.

Check that the pipeline volume (based on length, internal diameter, and pipe type)

is less than the 3rd party approval (see Table P-2). Third party tests have approved

PREFACE Page P-5

LS300 User’s Guide

P

Page 9

the use of Auto-Learn in rigid pipelines up to 163-gallon capacity and in flex

pipelines up to 39.5 gallons.

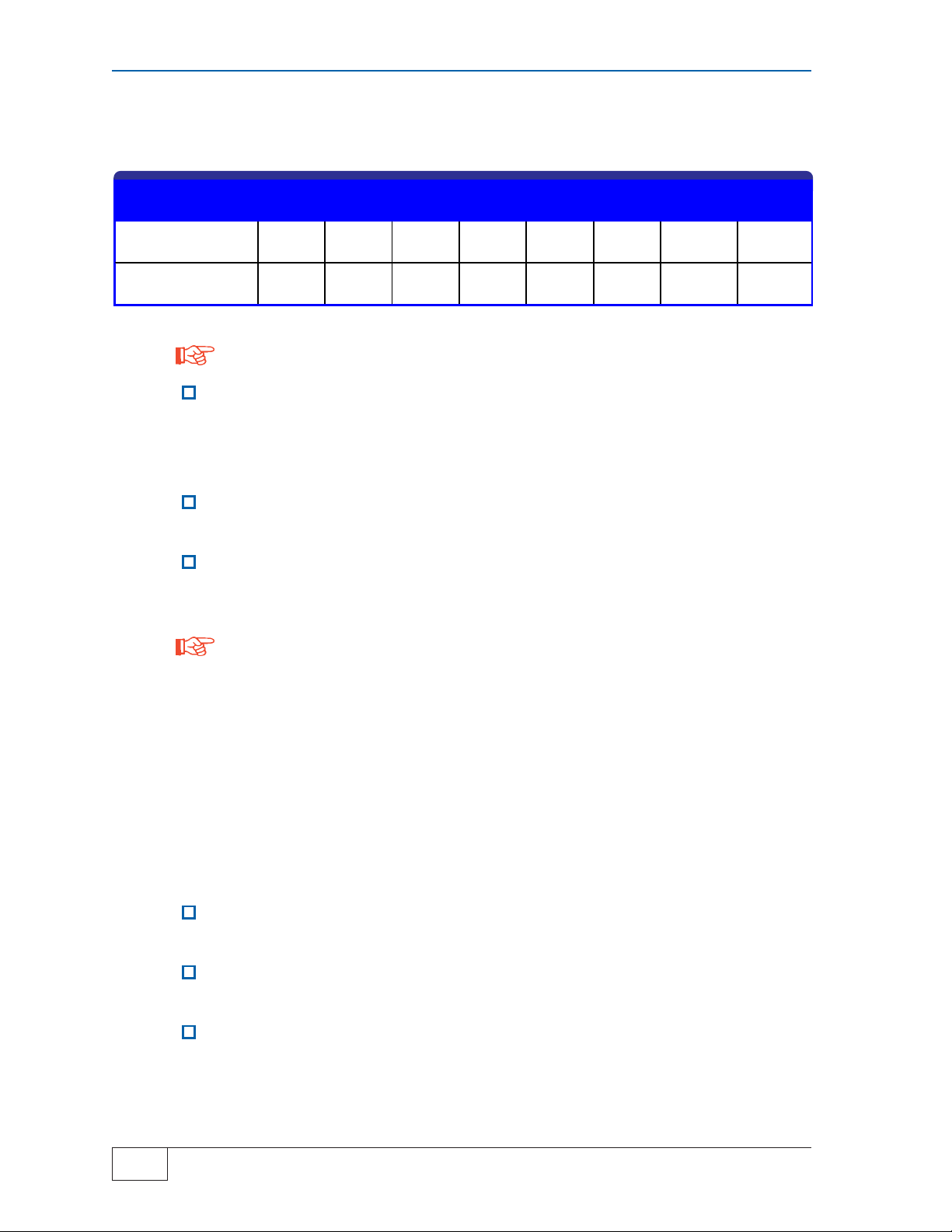

TABLE P-2 Third Party Approved — Max Pipe Lengths:

Pipe Diameter I.D.

Max. Rigid Pipe

Lengthl

Max. Flexible Pipe

Length

NOTE

Maximum pipe lengths are equivalent to: 163 gallons (617 liters) in rigid piping

systems and 39.5 gallons (149.5 liters) in flexible piping systems.

A minimum static line pressure of 17.5 psi is needed for Auto-Learn LLD to perform

a Gross (3gph) and Monthly (0.2 gph) line-leak test. If the static line pressure is

greater than 17.5 psi but less than 22.5 psi, the Annual (0.1 gph) line-leak test can

not be performed.

For each pipeline verify that the pressure is 25 psi or greater when the pump is

“ON,” and that the pressure holds at 22.5 psi or greater when the pump is “OFF.”

Use a pressure gauge to verify that each line is stable after 5 minutes of pump-off.

The pressure change in a stable pipeline must be less than 5 psi.

NOTE

To maintain proper pipeline pressure with a FE Petro STP, use FE Petro’s standard check valve.

With Red Jacket STP, use the adjustable functional element with pressure adjusted to meet the

Auto-Learn LLD pressure requirements. For proper operation of the Red Jacket functional element

the pump “ON” pressure must be at least 2 psi greater than pump “OFF” line pressure. See Red

Jacket instructions for complete details before starting.

1"

(25 mm)

3995'

(1217 m)

968'

(295)

1 1/2"

(38 mm)

1775'

(541 m)

430'

(131 m)

1 3/4"

(44 mm)2"(51 mm)

1304'

(397 m)

316'

(96 m)

998'

(304 m)

242'

(74 m)

2 1/2"

(64 mm)3"(76 mm)4"(101 mm)5"(127 mm)

639'

(195 m)

154'

(46 m)

443'

(107 m)

107'

(33 m)

249'

(76 m)

60'

(18 m)

159'

(48 m)

38'

(12 m)

Materials & Tools Required

In addition to what is supplied with the LS300 Auto-Learn electronic LLD system (the LS300

Console, LSU300 Transducers, stick-on Danger Labels, Needle Valve Kits, Leak Generator Device –

Calibration Kit, stick-on Product ID Labels, and this manual) the following materials and tools are

required:

Socket set, extension, and square socket for 1/4 inch (6.5 mm) square-head hole

plugs (Non-sparking)

Wrench, 2 3/8 inch open end hex wrench or adjustable 0-70 mm wrench (Nonsparking)

Assorted non-sparking adjustable open-end wrenches, including pipe wrenches and

slip-joint pliers (Non-sparking)

P

Page P-6 PREFACE

LS300 User’s Guide

Page 10

Petroleum absorbent and absorbent rags, and approved waste containers

Gasoline/oil resistant, non-hardening, UL Classified, Teflon Pipe Dope / Thread

Sealant (Gasoila) to seal threads of the LSU300 transducer & Needle Valve Kit

Single scale, general purpose, Pressure Gauge (1/4 inch NPT, 0 to 60 psi in 1 psi

increments) for temporary installation during site assessment and during the

LS300 Auto-Learn calibration step

Approved Gasoline/fuel oil container test tank (minimum 5-gallon capacity) to

collect product from the leak generator calibration kit during Auto-Learn calibration

Level, measuring tape, scribes/punch, and fasteners for wall mounting of console

Threaded 3/4 inch NPT (DN20NPT) rigid metal conduit, conduit bender, conduit

cutter, couplings, fittings, plus Epoxy Y Seal fittings (EYS), quick set epoxy, and

Conduit Clamps/Hangers

Explosion / Weather Proof J-Boxes

LSU300 Transducer Cable: Belden shielded cable #9363-22AWG,

#9364-20AWG, or #9365-18AWG or equivalent (#9365-18AWG is preferred)

RS-485 Cable – for ATG and Pump Controllers – use the Transducer Cable above

#9365-18AWG preferred. Shield wire is connected to RS-485 “Ground” terminal on

the TPI board (The other end of the sheild is not connected).

Wire for LS300 Auto-Learn LLD console: Power Input and Hook Inputs — per code

Electricians tools (Safety Lockouts &Tags, assorted wire strippers, cutters, various

size – flathead and phillips-head screwdrivers, multimeter with leads & clips, strainrelief fittings, spanner wrenches, slip-joint pliers [Non-sparking] conductor markers,

and indelible fine point marking pens)

PREFACE Page P-7

LS300 User’s Guide

P

Page 11

1 SAFETY

Safety First – Before Working on this Equipment

CAUTION

hydrocarbon liquids such as gasoline and diesel fuel. Installing or working on this equipment

means working in an environment in which these highly flammable liquids or vapors are

present. This presents a real risk of severe injury or death if these instructions and standard

industry practices are not followed.

Prohibit access to the work area to certified and trained installers/service personnel

Identify and mark the perimeter of the work area with signs, safety-cones and colored safety tape

Prevent unauthorized vehicle access (block access) into the work areas by using barriers,

barricades, and service trucks

Use only non-sparking tools when working in these Hazardous Areas

Occasionally check for presence of hydrocarbon vapors in containment sumps

ELECTRICAL DANGER

working on this equipment: turn off all submersible pump power / pump controller power, Tank

Sentinel console power, LS300 electronic Line Leak Detector console power, and dispenser power

at the electrical power panel(s). Lock out and tag these circuit breakers in the off position to prevent

accidental / unauthorized circuit breaker closure. Failure to turn off and lock out power would result

in severe injury or death!

This equipment is designed to be installed in association with volatile

Lethal Electrical Shock Hazard! Before installing, servicing, or

WARNING

installed or serviced. DO NOT smoke while working on or near this equipment and only use nonsparking tools. Failure to follow this instruction could result in a serious fire or explosion.

WARNING

product and the entire system. When no other regulations apply, follow NFPA 30, 30A, and 70

from the National Fire Protection Association. Failure to do so could result in serious

property damage, environmental-contamination, and severe injury or death.

ELECTRICAL DANGER

described in this manual, otherwise lethal electrical-shock-hazards could exist, which may cause

injury or death. Note: circuit breaker contact(s) can fail to open even when the circuit breaker lever

indicates off.

Highly flammable vapors may be present in the environment where this equipment is

Follow all federal, state, and local laws governing the installation of this

Verify that no voltage exists before working-on, or wiring-to circuits

SAFETY Page 1-1

LS300 User’s Guide

1

Page 12

ELECTRICAL DANGER

Electronic line leak detectors start submersible pumps

automatically to run leak-tests at full line pressure. Automatic pump starts occur between

periods of product dispensing when there is no product being dispensed. Before performing

any installation or service (such as replacing fuel-filters) – tag and lock-out all electrical power

sources to the submersible pump(s), pump controllers, and dispensers

and relieve fuel-line pressure.

Failure to turn off power and relieve fuel-line pressure before work is started can result in:

pressurized fuel spills (an environmental hazard associated with costly clean-ups), and fire or

explosion hazard that may result in injury or death.

NOTE

Multiple INCON Danger stickers are supplied with electronic line

leak detectors. Apply these stickers on the pump relay box

cover, in locations near dispenser fuel-line filters, plugs,

emergency safety-shut-off valves, on or near the Leak Sensing

Unit Transducer (at the submersible pump housing), and other

serviceable components of a fuel line (where a spill would

occur if the line became pressurized). The selected surfaces

must be clean, dry, and in plain sight so that the label can be

DANGER

FIRE, EXPLOSION &

ELECTRICAL SHOCK HAZARD

Electronic line leak detector

installed—the pump may start at any

time and pressurize the fuel lines.

•

BEFORE performing any

installation or service — turn off/

lock out electrical power sources

to the submersible pump(s), and

relieve fuel-line pressure.

INCON PN 240-1175 Rev. D

read, and followed.

WARNING

The fuel line from the submersible pump to the dispenser, may be under

pressure. Turn off all pump power and relieve pipeline pressure (reference and follow the

pump manufacturer’s directions about how to do this). If the line leak detector/plug (or any

other part of the submersible pump and fuel line) is removed without first relieving pressure,

then a product leak will occur. This could cause an environmental, fire, or explosion hazard,

and may result in injury or death.

WARNING

Avoid personnel injury or property damage: keep moving vehicles and

unauthorized personnel out of the hazardous work area. Use Safety Cones, Barricades,

Warning Signs, and Safety Tape, and block access with Barricades / service trucks to the

work area to avoid injury or property damage.

WARNING

Be careful not to cause sparks when working on fuel dispensing equipment

(volatile fuel may be within the pump’s leak detector port). Allow no source of combustion

near the work area. Failure to follow these directions may cause an explosion hazard, which

could result in property damage and death.

WARNING

During the Calibration/learn process, ALWAYS secure the line leak generator in

the appropriate container. When the submersible pump is turned on, a fine stream will be

sprayed out the orifice of the line leak generator. This stream can cause movement of the line

leak generator and possibly come out of the container. This product stream can cause

physical injury and environmental hazards.

1

Page 1-2 SAFETY

LS300 User’s Guide

Page 13

WARNING

container on the ground when filling with gasoline. Use only containers approved for motor

fuel storage.

Prevent static electric sparks and possible explosions — always have fuel test

CAUTION

Electric Code (NEC), and the Automotive and Marine Service Station Code (NFPA 30A in the

USA) before installation or maintenance. This installation is designed for submersible pumps

which have a Pump Control box in the station. If a pump control box does not exist, then the

system must be retrofitted to add a pump control box in the facility to comply with Codes.

CAUTION

operating the LSU for long periods while under water. Drain the sump and manhole

immediately into a holding tank for disposal per Codes.

WARNING

equipment is being installed or serviced. Do not smoke while working on or near this

equipment. Use only non-sparking tools. Failure to follow this instruction could result in a

serious fire or explosion.

CAUTION

vapors, if vapor levels are unsafe ventilate the sump with fresh air. While working in the sump

periodically check the atmosphere in the sump, if vapors reach unsafe levels exit the sump

and ventilate it.

CAUTION

or around a containment sump. Electronic and electrical petroleum monitoring equipment is

often housed in containment sumps designed to trap hazardous liquid spills and prevent

contamination of the environment.

Refer to all applicable Federal, State, City and local codes, your National

Although the LSU300 is water resistant, INCON does not recommend

Highly flammable vapors may be present in the environment in which this

Before entering a containment sump check for the presence of hydrocarbon

ALWAYS have a second person standing by for assistance when working in

WARNING

If these vapors are inhaled they could cause dizziness or unconsciousness. If the vapors

were ignited they could explode causing serious injury or death.

ELECTRICAL DANGER

installing or servicing this equipment, pumps and related equipment. A potentially lethal

electrical shock hazard and the possibility of an explosion or fire from a spark can result if

the electrical circuit breakers are accidentally turned on during installation or servicing.

During normal operation Auto-Learn will turn on the STP as part of its leak testing process. A

shock, fire or environmental contamination hazard could result from Auto-Learn attempting to

turn on the STP while equipment is being serviced.

These containment sumps can trap dangerous amounts of hydrocarbon vapors.

ALWAYS lock out and tag electrical circuit breakers while

SAFETY Page 1-3

LS300 User’s Guide

1

Page 14

CAUTION

ALWAYS cleanup and dispose of used absorbent/rags and petroleum resistant gloves in

approved waste containers. Cleanup refuse and dispose of these immediately to avoid

personnel injury from vapors or direct skin contact to also avoid possible fire or

environmental safety hazards.

This leak detector is designed for use in specific applications and in compliance with

industry standards and practices. Using it in applications for which it was not designed or

failure to follow industry standards and practices may cause the product to malfunction or

fail.

Petroleum is carcinogenic – use adequate protection to avoid health hazards.

CAUTION

LS300 Console and the LSU300 Transducers. Lengths exceeding the 500 feet limit (152 m)

could cause unreliable system operation, which may result in creation of environmental

hazards in the event that a leak is undetected.

DO NOT exceed the 500 feet limit (152 m), maximum distance, between the

1

Page 1-4 SAFETY

LS300 User’s Guide

Page 15

2 Mechanical Installation

Mechanical Installation Sequence:

Follow the instructions here to mount the LS300 Auto-Learn console and to install the LSU300 Leak

Sensing Unit transducers, and Needle Valves at each STP containment sump (see Figure 2.2 for

typical finished installation). Be sure to ask the electrician to do any “electrical” type of work when

appropriate.

1.) Mount the LS300 Console on a vertical surface using appropriate fasteners, level, and between 2

feet (0.6 m) and 6 feet (1.9 m) high for use (see Figure 2-1 and make allowances for conduit runs

and fittings at the left, right and bottom sides)

NOTE

The LS300 AutoLearn console must be located in a pollution degree 2 environment per IEC60664 in

contries requiring CE compliance.

2.) At the electrical power panel: locked-out & Tag POWER OFF for the STP’s, Pump Controllers, and

Dispensers

DANGER

at full line pressure. Automatic pump starts occur between periods of product dispensing when there

is no product being dispensed. BEFORE performing any installation or service (such as

replacing fuel-filters) – tag and lockout all electrical power sources to the submersible

pump(s), pump controllers, and dispensers and relieve fuel-line pressure. Failure to turn off

power and relieve fuel-line pressure before work is started can result in: pressurized fuel

spills (an environmental hazard associated with costly cleanups), and fire or explosion hazard

that may result in injury or death.

WARNING

from moving vehicles. This equipment is usually mounted underground, therefore, reduced visibility

puts service personnel working on this equipment in danger from moving vehicles entering the work

area. Use Safety Cones, Barricades, Warning Signs, and Safety Tape, and block access with

Barricades / service vehicles to the work area to avoid injury or property damage.

Electronic line leak detectors start submersible pumps automatically to run leak-tests

Avoid personnel injury or property damage: ALWAYS secure the hazardous work area

3.) Relieve pipeline pressure to 0 psi per manufacturers recommendation and capture any product that

escapes or use absorbent rags to clean up any product spills and dispose of properly (FE Petro

Pumps: open Manual Pressure Relief valve / MPR valve... Red Jacket Pumps: Turn Functional

Adjustment element to 0 psi, if no adjustment exists – remove and replace with an adjustable

functional element)

WARNING

Turn off all pump power and relieve pipeline pressure (reference and follow the pump manufacturer’s

directions about how to do this). If the line leak detector/plug (or any other part of the submersible

pump and fuel line) is removed without first relieving pressure, then a product leak will occur. This

could cause an environmental, fire, or explosion hazard, and may result in injury or death.

The fuel line from the submersible pump to the dispenser, may be under pressure.

MECHANICAL INSTALLATION Page 2-1

LS300 User’s Guide

2

Page 16

4.) Remove other in-line leak detection equipment before installing the LSU300 Auto-Learn LLD

5.) Apply UL Classified Gasoline/Oil resistand teflon pipe dope thread sealant to the threads of the

LSU300 Transducer and use a 2-3/8 inch open-end wrench to install it in the Leak Detector Port of

the STP housing (see Figure 2-2)

6.) Apply UL Classified Gasoline/Oil resistand teflon pipe dope thread sealant, assemble, and install the

supplied Needle Valves in the Line Pressure Test Port of the STP and close all Needle Valves (see

Figure 2-2)

7.) Install Couplings, threaded Rigid Metal Conduit (RMC), and Explosion/Weather Proof Junction

Boxes (J-Boxes) in the STP sumps (see Figure 2-2).

8.) Install threaded RMC and EYS fittings along with Transducer Cables (Belden #9365) from LS300

console to the Explosion/Weather Proof J-Boxes (have the licensed electrician splice the cables

together. If this wiring is Intrinsically Safe it MUST NOT be run with any Explosion Proof wiring or

other non-Intrinsically Safe wiring!).

9.) After all LSU300 Leak Sensing Units (transducers) have been installed, check to see that all Needle

valves are closed, and that the system is ready to be pressurized to check for the absence of leaks.

10.) After the installation is checked and all personnel are clear, have the electrician turn on power at the

Power Panel for the STP (Submerged Turbine Pumps and Dispensers).

11.) Turn on the STP at the dispenser (do not deliver product) and check for leaks at each Sump... if

there are any leaks, immediately turn off power, lockout and tag at the Power Panel, use absorbent

rags to clean up the product spills and dispose of properly, and repair the leak(s) and repeat step 10

and step 11 until no leaks remain.

13.) Clean areas where the Danger Labels will be placed so the adhesive backing will stick to a dry

surface that is clean and free of petroleum.

14.) Cleanup and dispose of installation materials, petroleum absorbent and waste material in

appropriate containers.

15.) Stick the supplied Danger Labels (PN: 240-1175) to clean dry areas near

Dispenser Fuel Filters, Pump Controllers, and on the Cable of the

LSU300 Transducer and on the STP housing.

DANGER

FIRE, EXPLOSION &

ELECTRICAL SHOCK HAZARD

Electronic line leak detector

installed—the pump may start at any

time and pressurize the fuel lines.

•

BEFORE performing any

installation or service — turn off/

lock out electrical power sources

to the submersible pump(s), and

relieve fuel-line pressure.

INCON PN 240-1175 Rev. D

2

Page 2-2 MECHANICAL INSTALLATION

LS300 User’s Guide

Page 17

7.00 (178 mm)

1.50

(38mm)

TYP.

13.38

(340

mm)

REF

11.75

(298

mm)

REF

HINGE SIDE of

CONSOLE DOOR

11.00 x 12.00

(280 x 305 mm)

CONSOLE DEPTH

4.00 (102 MM)

REF

1.00

(25 mm)

TYP.

THRU MOUNTING HOLES

0.31 (8 mm)

TYP. FOUR PLACES

12.75

(324

mm)

0.31

(8 mm)

TYP.

10.75 (273 mm) REF

Optional

TS-TPI to

TS Console

Figure 2-1 LS300 Console Mounting Dimensions & Knockout Locations

RS232 Comm Port

MECHANICAL INSTALLATION Page 2-3

LSU300

Transducers

Dispenser

Hooks

Input

Power

L

LS300 User’s Guide

D

TS-LS300 Console

Dimensions

in inches and (mm) –

Enclosure Only:

H

11.75H x 10.75L x 3.75D

(298H x 273L x 95D)

With Door Closed:

12H x 11L x 4D

(305H x 279L x 102D)

Dual-Sized Conduit Knockouts:

1/2 or 3/4 inch NPT

(DN13NPT or DN20NPT)

2

Page 18

3/4 INCH

NPT

(DN20NPT)

2-3/8

INCHES

(69.85 mm)

ACROSS

FLATS

(NEEDL E

VALVE KIT) @

LINE PRESSURE

TEST PORT

NEEDLE VALVE

ACCESSORY

KIT

(UNASSEMBLED)

REF: 020-1029

1 REQ'D AT

EACH

STP HOUSING

LSU300

TRANSDUCER

6.25

INCHES

(158.75

mm)

LSU300

Leak

Sensing

Unit

Transducer

2 INCH NPT

(DN50 NPT)

5.13

INCHES

(130.18

mm)

See Figures

3-2 and 3-3

for Electrical

installation details

and CE approval notes

STP

HOUSING

NORMAL

OPERATIONAL

VIEW

Figure 2-2 Needle Valve Kit & LSU300 Mounting

2

Page 2-4 MECHANICAL INSTALLATION

LS300 User’s Guide

Page 19

3 Electrical Installation & Wiring

Electrical Installation & Wiring Sequence:

Basic Installation & Wiring

Follow the instructions here to wire the LS300 Auto-Learn console, the

LSU300 Transducers from each STP containment sump, the Dispenser

Hook Inputs, and Console Power Input. (see Figure P-1 & Figure 3-1).

NOTE

Ask the service tech to do “mechanical - pump/dispenser” work if

appropriate.

1.) All cables from the LSU300 transducer to the LS300 console must be installed in metal conduit in

countries requiring CE compliance. Power and communication wires do not need metal conduit

unless it is required by local code.

WARNING

from moving vehicles. This equipment is usually mounted underground, therefore, reduced visibility

puts service personnel working on this equipment in danger from moving vehicles entering the work

area. Use Safety Cones, Barricades, Warning Signs, and Safety Tape, and block access with

Barricades / service vehicles to the work area to avoid injury or property damage.

2.) At the electrical power panel: locked-out & Tag POWER OFF for the STP’s, Pump Controllers, and

Dispensers.

ELECTRICAL DANGER Hook inputs are 120/240 Vac. Disconnect all high voltage sources before

accessing internal electronics

Avoid personnel injury or property damage: ALWAYS secure the hazardous work area

TS-LS300

Auto-Learn

Console

1

Inputs (#1-4):

Lines (#)

Hooks (#)

Power

DANGER Electronic line leak detectors start submersible pumps automatically to run leak-tests at

full line pressure. Automatic pump starts occur between periods of product dispensing when there is

no product being dispensed. BEFORE performing any installation or service (such as replacing

fuel-filters) – tag and lock-out all electrical power sources to the submersible pump(s), pump

controllers, and dispensers and relieve fuel-line pressure. Failure to turn off power and

relieve fuel-line pressure before work is started can result in: pressurized fuel spills (an

environmental hazard associated with costly cleanups), and fire or explosion hazard that may

result in injury or death.

3.) If not done during Mechanical Installation, chapter 2, Run 3 conductor shielded cable from each

Explosion proof/Weatherproof Junction Box in the STP sump where the LSU300 Transducer is

installed, to the LS300 console for Transducer wiring leaving about an 8 inch (203 mm) service loop

(Figure 3-2 & 3-3). Label/Mark each cable jacket with the Tank # / LSU300 Transducer number.

ELECTRICAL INSTALLATION & WIRING Page 3-1

LS300 User’s Guide

3

Page 20

Optional

TS-TPI to

TS

Console

RS232 Comm

Port

LSU300

Transducers

Dispenser

Hooks

Input

Power

L

D

H

Auto-Learn

TS-LS300

TS ATG

Console

NON-HAZARDOUS AREA

Line Leak Detector

Annunciator States/Conditions

FE Petro Models: SCI & VFC4

Turbine Pump Controllers (TPC)

Annunciator Legend

LS300

AutoLearn

Console

LS300

Auto-Learn LLD

Console

LSU300

LLD

Transducer

HAZARDOUS AREA CLASS 1, DIVISION 1,

GROUP C & D

MANHOLE & COVER

STP Power

STP

UST

o

r

t

e

P

E

F

Figure 3-1 Typical – Partial Installation & LS300 Console Conduit Designations

3

Page 3-2 ELECTRICAL INSTALLATION & WIRING

LS300 User’s Guide

Page 21

NOTE

TS-LS300

Annunciator States/Conditions

R

Auto-Learn

Line Leak Detector

POWER

PRESSURE

TEST

/

1

RESET

HI

PUMP ON

PRESSURE

TEST

/

2

RESET

HI

PUMP ON

PRESSURE

TEST

/

3

RESET

HI

PUMP ON

PRESSURE

TEST

/

4

RESET

HI

PUMP ON

Wire Intrinsically Safe LSU300 transducers only to

TS-LS300 version consoles in conduit apart from non-intrinsically safe

wiring. DO NOT run intrinsically safe wiring in the same conduit with non-

intrinsically safe wiring.

INTELLIGENT CONTROLS

ALARM

TEST

PASSED

LO

TEST

PASSED

LO

TEST

LO

PASSED

TEST

PASSED

LO

Annunciator Legend

FAILED

ALARM

FAILED

ALARM

FAILED

ALARM

FAILED

LS300 Auto-Learn

Line Leak Detector

Console (CU)

3/4 inch NPT Conduit

and Fittings

(DN20 NP T )

for I.S. Wiring O nly

- Typical -

Beldon #9363-22 AWG,

#9364-20 AWG, #9365-18AWG

or equivalent recommended.

Max Cable length is 500 feet.

EYS (Epoxy Y Seal)

Fitting TYP

RED

RED

WHT

BLK

SHIELD

SHIELD

TO SPLICE:

INSERT

UNSTRIPPED

WIRES & USE

SLIP-JOINT

PLIERS TO SEAT BLACK PIECE

Follow all federal, state, and local

laws & codes governing the

install ation of this product & the

entire system.

Maximum safe area voltage must

not be greater than 250 Vrms.

WHT

BLK

3 CONDUCTOR

CABLE 6FT

(1.83 meters)

Supplied

Syphon

Plug

Tank

Plug

No-Strip Elect rical

Connectors inside

Weather

Proof J-Box

(Junction Box)

5 FT (1 .5 3 m e te r s)

MAX from LSU300

Transducer

STP

HOUSING

LSU300

Pressure

Transducer

NOTE

Coupling

For CE

compliance the

cables from the

console to the

LSU300

Transducer must

be installed in

metal conduit,

rigid or flexible

Figure 3-2 LSU300 Intrinsically Safe Wiring w/ No-Strip Wire Splice at

Weatherproof Junction Box

ELECTRICAL INSTALLATION & WIRING Page 3-3

LS300 User’s Guide

3

Page 22

NOTE

Wire Explosion Proof LSU300E transducers only to TS-LS300E consoles in accordance with

applicable standards. Explosion proof J-Boxes and conduit fittings must be used in this

application in hazardous locations. This wiring does not require separation from other non-

intrinsically safe wiring.

This method can be used for retrofit installations where separate conduit is not available.

R

Annunciator Stat es/Conditions

Auto-Learn

Line Leak Detector

POWER

PRESSURE

TEST

/

1

RESET

HI

PUMP ON

PRESSURE

TEST

/

2

RESET

HI

PUMP ON

PRESSURE

TEST

/

3

RESET

HI

PUMP ON

PRESSURE

TEST

/

4

RESET

HI

PUMP ON

INTELLIGENT CONTROLS

TEST

PASSED

LO

TEST

PASSED

LO

TEST

PASSED

LO

TEST

PASSED

LO

Annunciator Legen d

ALARM

FAILED

ALARM

FAILED

ALARM

FAILED

ALARM

FAILED

LS300E Auto-Learn

Line Leak Detector

Console (CU)

Beldon #9363-22 AWG,

#9364-20 AWG, #9365-18AWG

or equivalent recommended.

Max Cable length is 500 feet.

RED

3/4 inch NPT Conduit

(DN20NPT)

w/ Explosion Proof

Fittings

- Typical -

EYS (Epoxy Y Seal)

Fitting TYP

TS-LS300

RED

WHT

BLK

SHIELD

SHIELD

TO SPLICE:

INSERT

UNSTRIPPED

WIRES & USE

SLIP-JOINT

PLIERS TO SEAT BLACK PIECE

Follow all federa l, st a te , an d lo c al

laws & codes governing the

installation of this product & the

entire system.

Maximum safe area voltage must

not be greater than 250 Vrms.

WHT

BLK

3 CONDUCTOR

CABLE 6FT

(1.83 mete rs)

Supplied

Syphon

Plug

Tank

Plug

No-Strip Electrica l

Connectors inside

Explosion Proof

J-Box

(Junction Box)

5 FT (1.53 meters)

MAX from LSU300E

Transducer

Cou p ling

STP

HOUSING

LSU300E

Pressure

Transducer

Figure 3-3 LSU300E Explosion Proof Transducer Wiring at

Explosion Proof Junction Box

3

Page 3-4 ELECTRICAL INSTALLATION & WIRING

LS300 User’s Guide

Page 23

Basic Installation & Wiring – all Applications (Continued... )

4.) Remove a portion of the cable jacket (service-loop) inside the J-Box, and install the no-strip electrical

connectors inside the J-Box (see Figures 3-2 & 3-3).

5.) Verify that all connections are correct and that the like colored and unstripped wires are fully inserted

into the no-splice connectors (RED to RED, WHITE to WHITE, BLACK TO BLACK, and SHIELD

DRAIN to SHIELD DRAIN) and are spliced together... make sure that the black, oval-shaped

compression part is firmly seated down into the connector with slipjoint pliers (see Figures 3-2 & 3-

3). Install J-Box cover after wire-splicing is completed and checked.

6.) Remove the metal Terminal Safety Guard and Wire LSU300 Transducers to the Transducer Input

channel terminals inside the LS300 console. See Figure 3-4 for Tank, Line, and Product

associations, and TABLE 3-1 for wiring. Maintain these associations accurately when wiring

Transducer and Hook Input terminals.

NOTE

Channel N must operate the STPs at Tank/Line N

A.) Strip off 3/16 of a inch (5 mm) of insulation from the ends of each conductor

B.) Wire Transducers # 1 – 4 (see Figure 3-4). Make sure all wires

are fully inserted and clamped at the terminal block. Make sure

no stray strands of wire are shorting to adjacent terminal block

connections.

C.) Install the metal Terminal Safety Guard after verifying all

Transducer Input Channel wiring is correct

D.) Verify that all splices in the manhole Junction Boxes are

accurate

E.) Lastly, install the Explosion proof/Weatherproof Junction Box

Covers

WARNING

safety guard is removed

Never power up the LS300 console when the terminal

Photo 3-3

Transducer Inputs

ELECTRICAL INSTALLATION & WIRING Page 3-5

LS300 User’s Guide

3

Page 24

Basic Installation & Wiring (Continued... )

7.) Wire Dispenser Hooks (switches) to the Hooks terminals inside the LS300 console, see Figure 3-4.

A.) Follow these associations accurately when wiring.

Hook 1 must operate the STP at Tank/Line 1, Hook 2 for Tank/Line 2,

Hook 3 for Tank/Line 3, Hook 4 for Tank/Line 4.

B.) Wire the Hook Inputs to the proper Channels, to Turbine Pump Controllers, and to

Dispenser Hook Isolators as shown in Figure 3-4.

TS-LS300 Auto-Learn Console

+V = 15 VDC OUTPUT

TRANSDUCER'S

Ch1, Ch2

Ch3, Ch4

OPTIONAL

TS-TPI

Ch1, Ch2

Ch3, Ch4

PCB

POWER

BLK

BLK

SIGNAL

GROUND

GROUND

HOOKS

L2 (240 v) or

N (120 v)

GROUND

IN

GROUND

Submersible

Pump

Controller

HOOK INPUT:

SUPPLY

RETURN

Dispenser

Hook

Isolatio n

OUTPUT:

SUPPLY

RETURN

OUT

RED

+V

WHT

BLK

SHIELD

RED

IN

RED

120 v

240 v

BLK

WHT

GRN

GRN

BRN

BLU

GRN/YEL

GRN/YEL

L1

SHIELD

Electrical

Power

Panel

RED

RED

RED

WHT

BLK

BLK

SHIELD

LSU300

TRANSDUCER

LINE / TANK

HOOK =

CHANNEL # N

DISPENSER

HANDLE

SWITCH

R

S

E

U

T

P

U

P

R

L

Y

N

RED

WHT

Photo 3-4

Hook Inputs

Note, the color of

some components

may be different

depending

on Supply

Manufacturer

DISPENSER HANDLE

INPUTS:

RETURN

SUPPLY

BLK

RED

Figure 3-4 Dispenser Hook and Console Interface

3

Page 3-6 ELECTRICAL INSTALLATION & WIRING

LS300 User’s Guide

Page 25

Basic Installation & Wiring (Continued... )

8.) Wire Console Power to the Power Input terminals

inside the LS300 console (see Figure 3-4):

A.) Install / use a 10 ampere Circuit Breaker at

the Electrical Power Panel that is

dedicated/and used only for the LS300

Console(s).

ELECTRICAL DANGER Match the voltage

shown on the Lower Left side label only when

selecting the console input power source,

otherwise damage to the LS300 console will

result. Any equipment damage caused by using

the incorrect input power source is not be

covered under warranty.

F2

F1

Photo 3-5

Input Power

SW1

CAUTION

may affect the operation and reliability of the LS300 LLD system!

B.) Remove the clear plastic, Terminal Safety Guard at the console and run wire within 1/2 inch

or 3/4 inch ( mm) RMC — size wire to the circuit breaker used and length of run (14 gauge is

recommended).

C.) Wire according to TABLE 3-1 for 120 v power or TABLE 3-2 for 240 v power:

DO NOT use this circuit breaker for any other equipment, otherwise electrical noise

TABLE 3-1 LS300 Console Input Power From/To Wire List 120

Vac

TABLE 3-2 LS300 Console Input Power From/To Wire List 240

Vac

ELECTRICAL INSTALLATION & WIRING Page 3-7

LS300 User’s Guide

3

Page 26

S

t

9.) Ground Stud: The installer is to connect the Earth Ground Conductor to the most convenient

ground terminal as long as it meets local and national codes. If the ground stud is to be used

the installer shall follow the proper stacking configuration shown in figure 3-5. The earth

ground conductor must be 12 AWG or larger.

tud: #8 threaded pos

Nut

Lock Washer

Earth Ground Conductor

Cup W asher

Enclosure

Figure 3-5

Ground Stud

3

Page 3-8 ELECTRICAL INSTALLATION & WIRING

LS300 User’s Guide

Page 27

4 Line Calibration

NOTE ! Before Calibrating a Line:

1.) A PRECISION LINE TEST MUST BE CONDUCTED on each line before installing the LS300 AutoLearn® LLD system for the first time, or before replacing, or before adding a new LSU300 LLD

Transducer.

2.) USE A PRESSURE GAUGE TO VERIFY THAT EACH LINE IS STABLE. THE PRESSURE

CHANGE WITHIN THE PIPELINE AFTER 5 MINUTES OF PUMP-OFF MUST BE LESS THAN 5

PSI. The LS300 Auto-Learn LLD system will not calibrate properly unless the product is stable in

pipeline.

3.) A LEAK GENERATOR DEVICE/CALIBRATION KIT (SUPPLIED) MUST BE INSTALLED AT THE

STP TO PERFORM CALIBRATION OR MANUAL TESTING. Follow steps 1 to 12 and see Photo 4-1

for this installation.

4.) Turn on and CALIBRATE ONLY ONE CHANNEL AT A TIME! When that channel is complete, turn

off that channel and turn on the next channel to calibrate.

5.) ALWAYS PLACE THE RUN STOP (SW3) IN THE STOP POSITION, AND WAIT 10 SECONDS

BEFORE MOVING ANY OTHER SWITCH.

Configuration Slide-Switches

RUN STOP SW3 always position to STOP {down}

and wait 10 seconds before moving any other slideswitch

LEARN CH-N DETECT

SW4 = Channel-1 / Line #1

SW5 = Channel-2 / Line #2

SW6 = Channel-3 / Line #3

SW7 = Channel-4 / Line #4

CHANNEL ENABLE SW2

miniature slide-switches for

channels/lines # 1 to 4

(ON / ENABLE = up & OFF

= down)

ON

NOTE

The Run Stop and Learn

Detect-switches are in the

console at the upper-left.

LINE CALIBRATION (LEARN MODE) Page 4-1

LS300 User’s Guide

OFF

Photo 4-1 Channel / Learn

4

Page 28

Line Calibration Steps

Steps to Install the Leak Generator Device {Calibration Kit}

NOTE

The Leak Generator Device can be installed during the Mechanical Installation of the needle

valve, See chaper 2.

1.) Disconnect power, Lock out and Tag the electrical circuit breakers to the submersible pump,

dispensers and related devices at the electrical supply box associated with the product line to be

worked on.

ELECTRICAL DANGER

ALWAYS lock out and tag electrical circuit breakers

while installing or servicing this equipment, pumps and related equipment. A

potentially lethal electrical shock hazard and the possibility of an explosion or fire

from a spark can result if the electrical circuit breakers are accidentally turned on

during installation or servicing.

WARNING

Before commencing with the installation of a leak generator device,

secure the work area by using safety cones, barricades, trucks, etc.

2.) Make sure the Needle Valve is closed, turned completely clockwise, or relieve the line pressure to

zero and then remove the Brass Plug (Figure 4-1).

3.) Apply UL-classified non-hardening, non-toxic pipe thread sealant to the 1/4-inch threads of the Leak

Generator Device (Figure 4-1).

4.) Install the Leak Generator Device in the place of the Brass Plug (Figure 4-1). Install a 0-60 psi

pressure gauge, obtained locally, into the product line (Figure 4-1).

5.) Place and secure the orifice of the Leak Generator into a suitable container, minimum 5-gallon

capacity.

* The needle valve kit and the calibration kit have not been evaluated by

Underwriters Laboratories.

CAUTION

Take steps to prevent foreign materials from getting into the orifice

of the leak generator device. Foreign matter may block flow through the orifice and

prevent proper calibration or give inaccurate results during a test. Never attempt to

clean the orifice, as damage and improper calibration may result.

NOTE

Do not allow the orifice to be submerged or blocked during the calibration or testing

process.

WARNING

ALWAYS secure the Leak Generator Device in the container. When

the submersible pump is turned on a fine stream will be sprayed out the orifice of

the Leak Generator Device. This stream can cause the orifice to move and

possibly come out of the container. The stream can cause physical injury and

environmental issues.

4

Page 4-2 LINE CALIBRATION (LEARN MODE)

LS300 User’s Guide

Page 29

LS300

CALIBRATION KIT

ABOUT 72 INCHES

(182.88 cm) LONG

REF: 020-0315

1 REQUIRED

PER SYSTEM

LEAK

GENERATOR

CALIBRATION

KIT AT STP

(NEEDLE VALVE)

...ONLY ONE LINE

IS CALIBRATED AT

A TIME DURING

LS300 AUTO-LEARN

MODE

PRESSURE

GAUGE

Figure 4-1 Leak Generator Device {Calibration Kit} & Pressure Gauge at STP

6.) If not done in chapter 3, Wire the dispenser hook signal to the proper channel associated with the

product line being worked on (Figure 4-2).

7.) Turn power on at the load center to LS300 Auto-Learn

related equipment for product with Leak Generator Device installed.

Turn RUN/Stop switch to STOP. For the channel to be learned install

the Leak Generator Device in the line, if not already done, set the

CHANNEL ENABLE Switch to ON, the LEARN/DETECT Switch to

LEARN (See Figure 4-2) and set all other channel enable switches to

OFF. Wait 10 seconds, and then set the STOP/RUN switch to RUN

(See Figure 4-3). Verify the Calibration Kit is secure to a suitable

container and energize the submersible for this product. Check

Transducer and Leak Generator Device installation for leaks. If there

®

, pumps and

Figure 4-3 Run/Stop

Switch

LINE CALIBRATION (LEARN MODE) Page 4-3

LS300 User’s Guide

4

Page 30

Run/Stop

Switch

Learn/Detect

Switches

Transducer

Terminal

Blocks

Red

White

Black

Shield

Channel

Up-Enable

Down-

Enable

Switch

Disable

Hook

Terminal

Blocks

Hook In:

From

dispenser

Hook Out:

To Pump

Controller

Input

Power

L1

L2 (or N)

Ground

Ground

Fuse F1 (Hook Input Circuits)

Fuse F2 (Over-current protection)

115V

Input Voltage

Selector

230V

Figure 4-2 LS300 Console Circuit board Layout

4

Page 4-4 LINE CALIBRATION (LEARN MODE)

LS300 User’s Guide

Page 31

are any leaks, immediately turn off the power at the load center, lock out and tag out breakers, and

repair the leaks before proceeding.

NOTE

When making changes to the switch settings, LEARN/DETECT or CHANNEL

ENABLE switches, the STOP/RUN switch must be moved to the STOP position for

ten seconds, after the switch changes are completed, before the changes will take

effect and returning the console to RUN.

8.) Purge remaining air from the system as follows: Dispense enough gasoline from the dispenser

farthest from the pump to remove all the air from that line. Repeat this procedure with each

dispenser, working your way back to the pump (other methods may be used as long as the air is

removed). Also open the Needle Valve to the Calibration Kit and remove air from this area. The

LS300 Auto-Learn® will not calibrate properly if all of the air is not removed from the system. Once

complete, close the Needle Valve and turn off the submerged pump.

NOTE

During the calibration process, no other activity should take place on this product

line. Product line stability is key to proper calibration of the LS300 console.

Calibrate only one channel at a time, completing the calibration process in a timely

fashion.

NOTE

If the Leak Generator Device is not installed in the line to be calibrated follow steps

11 to 18 of Leak Generator Device Installation Section (see Figure 4-1). Leak

Generator Device must be installed in line to perform calibration.

9.) Energize the submerged pump and pressurize this product line. With the pump OFF, a pressure

gauge in the pipeline, and a minimum line pressure of 17.5 psi, ensure that the pressure change in

each pipeline is less than 5 psi within 5 minutes before beginning calibration process.

CAUTION

Static line pressure must conform to Step 9 before proceeding with

the calibration process. Improper static line pressure values can prevent proper

calibration, which could result in not properly detecting line leaks in this system.

Repeat Step 9 until proper values are obtained or call Technical Support at (800)

984-6266 for assistance.

10.) Open the Needle Valve to the Leak Generator and completely bleed the line pressure to zero psi.

Allow needle valve to remain open during the calibration process, as this is necessary for proper

calibration.

NOTE

After opening the needle valve to the Leak Generating Device, ensure that the fuel

flow through the orifice is a steady stream from pump OFF pressure to zero line

pressure. If there is not a steady stream, or line pressure does not drop completely

to zero, replace the Leak Generating Device or call Technical Support at (800) 9846266 for assistance. Never attempt to clean the orifice, as damage, or improper

calibration, may result.

LINE CALIBRATION (LEARN MODE) Page 4-5

LS300 User’s Guide

4

Page 32

WARNING

Prevent Static electric sparks and possible explosion by placing

container on ground. Always have container on the ground when filling with

gasoline. Use only containers approved for motor fuel storage.

11.) Switch the STOP/RUN switch to STOP (Figure 4-3). See Figure 4-2 for switch location.

12.) Verify Mode Select Switch for this channel is in the LEARN

position (Figure 4-4).

13.) Verify the CHANNEL ENABLE Switch for this channel is in

the Enabled (ON) position (Figure 4-2).

NOTE

When making changes to the switch settings,

LEARN/DETECT or CHANNEL ENABLE switches,

the STOP/RUN switch must be moved to the

STOP position for ten seconds, after the switch

changes are completed, before the changes will

Figure 4-4 Learn/

Detect Switch

take effect and returning the console to RUN.

14.) Wait 10 seconds, and then switch the STOP/RUN switch to RUN.

15.) Press the TEST/RESET button on console cover to enter the learn mode.

16.) The HI, LOW and TEST indicator lamps will blink, indicating the unit is ready to learn.

NOTE

During the calibration process, the LS300 Auto-Learn

®

console learns the

zero pressure point, turns ON the pump for at least 10 seconds, and learns

the specific characteristics of a leak for the system (this may take several

minutes depending on piping system installed).

17.) Press and hold the TEST/RESET button until the LO light comes on, approximately one to two

seconds.

NOTE

When the Console HI lamp starts blinking during the calibration process, the pump

will be on.

18.) The calibration process for this channel is successfully completed when the TEST lamp stops

blinking, and the HI, LOW and TEST indicator lamps are ON steady or all OFF. See

Troubleshooting Guide for further details on lamp indications.

NOTE

The ALARM indicator lamp indicates abnormal conditions during the

calibration. Go to Learn Mode (Calibration) Troubleshooting Guide to assist

in correcting conditions. When alarm condition is corrected, redo calibration

process from Step 9.

19.) Switch the STOP/RUN switch to STOP

20.) Set the Mode Select Switch to DETECT.

21.) Wait ten seconds, and then switch the STOP/RUN switch to RUN.

4

Page 4-6 LINE CALIBRATION (LEARN MODE)

LS300 User’s Guide

Page 33

22.) Press the TEST/RESET button to put channel into detection mode.

23.) Verify the channel learned the pipeline correcly by manually starting a Gross (3 GPH) leak test with

the Leak Generator Kit still installed and the Needle Valve still open, see Chapter 5 LS300 console

Operation for manual start of leak tests. If the leak is not detected, repeat the Calibration process or

call Technical Support at (800) 984-6266 for assistance.

24.) Disconnect power, Lock out and Tag the electrical circuit breakers to the submersible pump

associated with this product line.

25.) Close the needle valve, remove the Leak Generator device and replace the Brass Plug. Remove the

pressure gauge from the line and replace the pipe plug, applying UL-classified non-hardening, nontoxic pipe thread sealant to the 1/4-inch threads.

26.) Energize the submersible for this product. Check Needle Valve area for leaks. If there are any

leaks, immediately turn off the power at the load center, lock out and tag out breakers, and repair the

leaks

NOTE

Follow the Leak Generator Device Installation and Calibration process for

each channel that is to be used. Repeat Steps 11-27 for each product line that

the LS300 Auto-Learn® Console is to monitor.

For Normal Operation

27.) After calibration and testing is complete on all Channels to monitor, verify that all active channels

have the Mode Select Switch set to the DETECT position and the CHANNEL ENABLE switch set to

the ON position. If switch changes are made, switch the STOP/RUN switch to STOP for 10

seconds, and then to RUN for normal operation.

NOTE

See LS300 Console Operation or Troubleshooting Guide at end of this

manual for information on verifying LS300 Auto-Learn

®

. Call Technical

Support at (800) 984-6266 for any other concerns or questions regarding

installation or service of the LS300 Auto-Learn

®

system.

For installation instructions for connecting the TS-LS300 console to an Incon tank

gauge, please refer to the TS-TPI Programming User’s Guide.

LINE CALIBRATION (LEARN MODE) Page 4-7

LS300 User’s Guide

4

Page 34

5 LS300 Console Operation

Line Leak Tests

For normal operation verify the following:

At the LS300 Auto-Learn® Console: For each channel in use the corresponding

channel enable switch is in the ON position. The Mode Select switch, for each

channel in use, is set in the DETECT position. The “STOP/RUN” switch is in the

RUN position.

At the STP: The needle valve is closed, the Leak Generator is removed, and the

brass plug is in place. Turn power on to the LS300 Auto-Learn®, the STP,

dispensers and other equipment for the dispensing system.

To Clear Lamp Indicators and Alarms: Push the Test/Reset button on the console.

When the Test/Reset button is released the lamp indicators will cycle on in the

following sequence: HI, LO, Test and Alarm.

Three automatic line leak tests are conducted and monitored from the LS300 AutoLearn console.

GROSS (3.0 GPH) Leak Test

The Gross (3 GPH) leak test is initiated after each dispense cycle or after 45

minutes of quiet time. The test consists of 3 consecutive tests, timed at 5-minute

intervals. If one of the three tests pass, the line is determined to have no Gross

leak. If there is a failure, the test will continue until three consecutive tests fail.

Three failures will cause the ALARM light to blink, the alarm HORN to sound,

and the pump to shut down. If there is dispensing from the line during the testing

process, the testing will restart as soon as dispensing is complete. During

dispensing inactivity the Gross (3 GPH) test will repeat every 45 minutes after

passing tests, or until there has been no dispensing (line inactive) for 3 hours.

Monthly (0.2 GPH) Leak Test

When the line has been inactive for 3 hours, a monthly (0.2 GPH) test is initiated.

This test will be performed every 5 minutes until a test has passed. If there are

three consecutive failures, with no passes, the ALARM light will flash, and the

HORN will sound, indicating that there is a precision leak in the system. This

ALARM indication will not shut down the pump.

LS300 CONSOLE OPERATION Page 5-1

LS300 User’s Guide

5

Page 35

Annual (0.1 GPH) Leak Test

When the line has been inactive for 6 hours, an annual (0.1 GPH) test is initiated.

This test will be performed every 5 minutes until a test has passed. If there are

three consecutive failures, with no passes, the ALARM light will flash, and the

HORN will sound, indicating that there is a precision leak in the system. This

ALARM indication will not shut down the pump.

Silence Alarms

NOTES

Before pushing the Test/reset button take note of the displayed Alarm conditon, see

chapter 6 troubleshooting section. Some alarm conditions will not clear until the

detected conditon is corrected (i.e. transducer not seen).

Push the Test/Reset button on console for the Line with an active, blinking or

flashing Alarm light. When the Test/Reset button is released the alarm is cleared.

The audible alarm will silence and the Alarm light will stop blinking or flashing, and

the line test will continue its normal testing procedures. The Monthly (0.2 gph/

0.75 Lph) tests will automatically restart after 3 hours of inactive time, and the

annual (0.1 gph/0.38 Lph) test will automatically restart after 6 hours of

inactive time. DO NOT restart precision line leak tests before the 3 or 6 hour

no-dispense stabilization-time has passed.

MANUAL Line Leak Tests

Leak tests may be manually started at any time. The Monthly (0.2 gph) leak test

requires 3 hours of inactive time to insure a valid test. The Annual (0.1 gph) leak

tests requires 6 hours of inactive time to insure a valid test. Not waiting the

required inactive time means a passed or failed test is inconclusive.

Gross (3 gph /11 Lph) test: Press and release the Test/Reset button as if clearing

alarms (see above) wait for the TEST lamp to turn on then press and release the

Test/Reset button again (2 Test/Reset pushbutton presses). The Pump will turn on

for 5 to 10 seconds to pressurize the line, and testing will begin. A single PASS or

three consecutive FAILURES are required to complete the Gross (3 GPH) test. In

between these tests, lamps will indicate whether the last test passed or failed. A

PASS will put Auto-Learn back into normal DETECT mode, with indicator lamps in

the OFF condition. Three consecutive FAILURES will put Auto-Learn in alarm

condition, and provide positive shut-down of the pump.

Monthly (0.2 gph/ 0.75 Lph) test: To initiate a monthly (0.2 gph) test press and

release the Test/Reset button as if clearing alarms and wait for the TEST lamp to

turn on then press and release the Test/Reset button again. Press and release the

Test/Reset button a third time when the TEST lamp turns on (3 Test/Reset

pushbutton presses). The Pump will turn on for 5 to 10 seconds to pressurize the

line, and testing will begin. A single PASS or three consecutive FAILURES are

5

Page 5-2 LS300 CONSOLE OPERATION

LS300 User’s Guide

Page 36

required to complete the monthly (0.2 GPH) test. In between these tests, lamps will

indicate whether the last test passed or failed. A PASS will be indicated by a single

flash on the Test indicator lamp. Three consecutive FAILURES will put Auto-Learn

in alarm condition.

Annual (0.1 gph/ 0.38 lph) precision test: To initiate a manual Annual precision

test press and release the Test/Reset button wait for the TEST lamp to turn and

repeat that sequence a total of 4 times (4 Test/Reset pushbutton presses). The

Pump will turn on for 5 to 10 seconds to pressurize the line, and testing will begin.

A single PASS or three consecutive FAILURES are required to complete the annual

(0.1 GPH) precision test. In between these tests, lamps will indicate whether the

last test passed or failed. A PASS will be indicated by a double flash on the Test

indicator lamp. Three consecutive FAILURES will put Auto-Learn in alarm

condition.

Line Leak Detection

Detected line leaks may be an actual or false line leak alarms. Treat all detected

line leak alarms as actual line leaks until verified true or false.

False line leaks can occur because of the follow reasons:

product line instability (was a manual precision test started without waiting the

required 3 or 6 hour stabilization delay?), air trapped in a line or a loose fuel filter

(this is likely to occur after a new installation/maintence/service ...when was the last

service done?), thermal contractions in the line, STP/check-valve malfunction, or a

vapor recovery system malfunction.

DANGER

action to locate and repair the source of the leak to avoid environmental

contamination, and to avoid fire or explosion hazards. A detected GROSS leak will

cause a positive pump shut-down, which will stop product dispensing.

WARNING

leaks, these also require action to locate and repair the leak, to avoid environmental

contamination and to avoid fire or explosion hazards.

CAUTION

single line leak detected alarm – confirm the presence of a leak before attempting /

scheduling any repairs.

A Gross (3 gph/ 11 Lph) leak is a large leak requiring immediate

Although monthly (0.2 gph) and annual (0.1 gph) leaks are smaller

DO NOT excavate / repair a fuel-line solely on the basis of a

LS300 CONSOLE OPERATION Page 5-3

LS300 User’s Guide

5

Page 37

Detected Leaks

When a line leak is detected, you the owner/authorized representative must follow

the steps outlined below:

1) Record (log) and identify: the type of leak test that failed (Gross test, Monthly

test, or an annual line leak test), the time it failed, the date, the product line

number, and the product-name. Record this in a special station log at your site.

2) Inspect the piping system, dispensers, fittings, and hoses for obvious leaks.

Open the dispenser enclosure and inspect the fittings and fuel filter for leaks

(especially if maintenance or service was done recently).

3) Stop/ Prevent dispensing from that product line (“bag” tape a poly-bag, over the

appropiate dispenser nozzels and lever). If a leak was found in Step 2 skip Steps 4

& 5, and do Step # 6.

4) Reset the line at the LS300 console (initiate a manual test for the failed test) to

allow a verification (re-test) for Gross, Monthly, Annual test.

5) For precision leak test failures, wait 3 hours for Monthly (0.2 gph/0.75 Lph) test

failures, or 6 hours for annual (0.1 gph/ 0.38 Lph) test failures — failed precision

tests will restart automatically when the 3 or 6 hour line-stabilization time has

elapsed. The test can also be manually restart after 3 or 6 hours (reference Monthly

and Annual line leak tests in this Chapter).

6) If a leak is discovered by visual inspection, or the second (verification) line

leak test fails and detects a line leak on the same line:

a.) Immediately shut-off power to the affected pump, line, & dispenser, and call

our Technical Service telephone number

b.) Take correct action in accordance with local, State, and Federal rules and

regulations

c.) Contact the local inspection agency about the leak, and follow all procedures/

instructions as required by law

7) A line is considered verified tight and not leaking if a second (verification)

line leak test of the same or greater precision passes.

Reporting Line LeaksReporting Line Leaks

Reporting Line Leaks

Reporting Line LeaksReporting Line Leaks

When a line leak is detected, it is the site owner’s obligation to contact the local

inspection agency about line leaks, and to comply with the requirements concerning

reporting and cleanup as determined by local/State/Federal Laws and Regulations.

These and other regulations as required, must be followed quickly and to the letter.

5

Page 5-4 LS300 CONSOLE OPERATION

LS300 User’s Guide

Page 38

WARNING Serious legal, health, and safety hazards could result from not taking

the proper action within a specied time.

Where codes and regulations conict with this manual, follow the regulations.

Compliance Reporting

The monthly or annual line leak testing requirements often vary from area to area.

It is the site owner’s obligation to know the frequency of line leak testing, the

compliance reporting requirements, and to comply with these requirements with

appropriate documentation. Compliance is determined by local/State / Federal Laws

and Regulations. Non-compliance may cause site shut-down, nes, or legal action.

The TS-TPI Turbine Pump Interface can also be wired to INCON TS-1001/TS2001automatic tank gauges (and other future models as developed), which could

provide all Tank and Line leak test Compliance Data automatically on a programmed

schedule to modems/fax machines at remote sites.

NOTE: The LS300 does not have a printer. You need to interface with the TS-1001 /

TS-2001 to print reports. Many localities require records showing the line tests are

passing. Hand-written records of the LED status can be recorded on a monthly

basis. Check with your local inspector to use this as a reporting method. See page

A6 for a form that can be used for recording TS-LS300 status.

LS300 CONSOLE OPERATION

LS300 User’s Guide

Page 5-5

5

Page 39

Line Pressure Transducer

Signal Voltage

0 PSI 1.00 VDC

5 PSI 1.20 VDC

10 PSI 1.40 VDC

15 PSI 1.60 VDC

20 PSI 1.80 VDC

25 PSI 2.00 VDC

30 PSI 2.20 VDC

35 PSI 2.40 VDC

40 PSI 2.60 VDC

45 PSI 2.80 VDC

6 TS-LS300 Troubleshooting Guide

Transducer Troubleshooting

The transducer is one of the main components of the LS300 Auto-Learn system.

This section is to aid in the proper troubleshooting of the transducer and its wiring.

A loose or broken wire connection, or damaged insulation on a wire, can cause the

transducer to give erratic voltage readings.

Figure 6-1 shows the approximate Transducer Signal

Voltage (DC) seen at the respective line pressure.

Figure 6-1

Transducer Signal Voltage

ELECTRICAL DANGER

is done with power applied to the LS300 Auto-Learn Console. Take care to

probe only the Transducer test points as instructed, as equipment damage or

personal injury could result.

NOTE

different. Transducer VDC listings are

only approximates. Verify Line

Pressure by installing a pressure

gauge in the line.