Page 1

TS-LLD

Electronic Line Leak Detector

Installation Guide

Part Number: 000-1359, Rev. H

Copyright

TS-LLD INSTALLATION GUIDE

©

March 2012

Page 2

NOTICE

INCON has strived to produce the finest possible manual for you, and to ensure that the

information contained in it is complete and accurate. However, INCON makes no expressed or

implied warranty with regard to its contents. INCON assumes no liability for errors or omissions, or

for any damages, direct or consequential, that result from the use of this document or the

equipment which it describes.

This document contains proprietary information and is protected by copyright. All rights are

reserved. No part of this document may be reproduced in any form without the prior written

consent of INCON.

INCON reserves the right to change this document at any time without notice.

Need Help ? Contact INCON at:

INTELLIGENT CONTROLS, INC.

PO Box 638

SACO ME 04072

Office Hours: 8 a.m. to 5 p.m. EST Monday through Friday

Sales 24 hour Technical Service

Phone: (800) 872-3455 Phone: (800) 984-6266

Fax: (207) 283-0158 Fax: (207) 282-9002

E-mail: sales@intelcon.com E-mail: tech@intelcon.com

Visit our web site at: http://www.intelcon.com

INCON ® is a registered trademark of Intelligent Controls, Inc.

Tank Sentinel ® is a registered trademark of INCON

Red Jacket ® is a trademark of the Marley Pump Co.

FE Petro ® is a registered trademark of FE Petro, Inc.

The INCON TS-LLD is covered by United States Patent Number 5,918,268 (June 29, 1999)

Copyright 1995, 1996, 1997, 1998, 1999 Intelligent Controls, Inc. All rights reserved.

—

TS-LLD INSTALLATION GUIDE

❖

—

Page 3

Table of Contents

Chapter . Section Page No.

P Preface ................................................................................................. P - i

Graphic Symbol Conventions ................................................................................... P - i

Page Numbering Convention – Example: ........................................................ P - i

Page Layout Convention – Example: ................................................................ P - i

Components Included with Each TS-LLD System ................................................. P - ii

Before you Begin .................................................................................................... P - ii

NOTES ..................................................................................................... P - ii

1 TS-LLD Electronic Line Leak Detector – Overview .......................... 1 - 1

Overview and Theory of Operation.......................................................................... 1 - 1

Leak Test Requirements and Length ................................................................. 1 - 2

The LSU (Leak Sensing Unit) ............................................................................ 1 - 2

Communications ................................................................................................ 1 - 2

The Control Unit (CU) ........................................................................................ 1 - 3

Operator Interface ........................................................................................... 1 - 3

Your Notes ............................................................................................................ 1 - 4

2.0 TS-LLD Materials & Tools Required ............................................ 2.0 - 1

Do a Site Survey Before Attempting the Installation ............................................ 2.0 - 1

Submersible Turbine Pumps

Electrical Supply ........................................................................................... 2.0 - 1

Materials Required ............................................................................................... 2.0 - 1

Tools Required ..................................................................................................... 2.0 - 2

2.1 TS-LLD SAFETY............................................................................ 2.1 - 1

Important Safety Notes and Warnings................................................................. 2.1 - 1

Safety Notes and Warnings (continued... ) ...................................................... 2.1 - 2

2.2 TS-LLD LSU Installation ............................................................... 2.2 - 1

LSU Installation Steps ......................................................................................... 2.2 - 1

NOTE..................................................................................................... 2.2 - 4

NOTE..................................................................................................... 2.2 - 6

2.3 TS-LLD CU Installation & Wiring ................................................. 2.3 - 1

Control Unit ( CU ) Installation Steps ................................................................... 2.3 - 1

NOTE..................................................................................................... 2.3 - 1

TABLE 2.3 - 1 Typical Single Phase Wire Connection List ................. 2.3 - 4

NOTE..................................................................................................... 2.3 - 4

TS-LLD Line Leak Detector — Mechanical Blender Interface ............................ 2.3 - 8

Final Installation Steps .................................................................................... 2.3 - 14

TABLE OF CONTENTS Page TOC - 1 TOC

Page 4

Table of Contents

Chapter . Section Page No.

2.4OptionalTS-LLD – Tank Sentinel Console Interface............... 2.4 - 1

TS-1000 Tank Gauge Interface............................................................................ 2.4 - 1

Example TS-1000 & TS-2000 ATG Reports:.................................................... 2.4 - 2

TS-2000 Tank Gauge Interface............................................................................ 2.4 - 3

NOTE..................................................................................................... 2.4 - 3

Programming the TS-2000................................................................................ 2.4 - 4

Alarm Relays.................................................................................................. 2.4 - 4

Alarm Reports................................................................................................ 2.4 - 4

TS-1001 / TS-2001 LLDI Interface....................................................................... 2.4 - 4

Your Notes..........................................................................................................2.4 - 6

2.5TS-LLD After Installation Steps & Testing.................................. 2.5 - 1

After Installation Steps & Testing...................................................................... 2.5 - 1

Important — Warranty Registration..................................................................... 2.5 - 2

Important — Customer Documentation............................................................... 2.5 - 2

3TS-LLD System Operation & Testing................................................ 3 - 1

System Operation................................................................................................... 3 - 1

CU Component Location & Function................................................................... 3 - 2

Control Unit Display................................................................................................ 3 - 2

Normal Displays ( on steady / solid )................................................................... 3 - 2

Day Counts........................................................................................................ 3 - 2

Fault Displays ( Flashing on and off ).................................................................. 3 - 2

a. Line Leak Test Failure – Flashing Leak Alarm Codes.................................. 3 - 2

When a Leak Test Fails / Line Leak is Detected:.......................................... 3 - 3

b. Monthly-Compliance Warning – Flashing Day Codes.................................. 3 - 3

Indications:.................................................................................................... 3 - 3

Recommendation:......................................................................................... 3 - 3

c. Flashing Display Error Codes........................................................................ 3 - 3

Line Leak Test light................................................................................................. 3 - 4

Line Leak Detected light......................................................................................... 3 - 4

Display Functions, Codes & Concise Instructions.................................................. 3 - 4

Reset Test touch button — press to:....................................................................... 3 - 4

NOTE........................................................................................................ 3 - 4

Display Diagnostic Test Codes:......................................................................... 3 - 4

NOTE........................................................................................................ 3 - 4

TOC Page TOC-2 TS-LLD INSTALLATION GUIDE

Page 5

Table of Contents

Chapter . Section Page No.

3 TS-LLD System Operation & Testing (continued... )

Starting a 0.1 gph Annual Precision Leak Test ................................................ 3 - 4

Requirements: ............................................................................................... 3 - 4

Definition: quiet-time ..................................................................................... 3 - 4

How to Start a Manual Test ........................................................................... 3 - 5

Normal Operation – Sequence of Events / Steps ............................................... 3 - 5

1.) Product Dispense – Begin

( dispense: nozzle out / lever up / switch on ) ............................................. 3 - 5

2.) Product Dispense – End

( dispense: nozzle in / lever down / switch off ) ........................................... 3 - 5

3.) The 3.0 gph Gross Hourly Test .................................................................... 3 - 5

4.) The 0.2 gph Monthly-Compliance Test ........................................................ 3 - 5

NOTE........................................................................................................ 3 - 5

A 0.2 gph Test Automatically Starts When: ................................................... 3 - 6

Out of Compliance ............................................................................................ 3 - 6

Frequently Asked Questions:

Why do Days Count Up ?............................................................................... 3 - 7

Why do Error Codes 29, 30, 31, or 32 Appear ? ........................................... 3 - 7

How do I Display the Last Alarm or Error Code ? .......................................... 3 - 7

How do I Reset Flashing Error Codes ? ...How do I Allow Dispensing ?

...How do I Clear Flashing Codes ? ............................................................... 3 - 7

Why can’t I Reset and Dispense ?................................................................. 3 - 7

How Do I Verify a Leak ? ................................................................................ 3 - 7

How do I Start a Manual Test ? ...................................................................... 3 - 8

How Often Should the Manual Test be Run ? ............................................... 3 - 8

What Should I Do:

When a 3 gph Leak Test Fails / Gross Leak is Detected ? ............................ 3 - 8

When a 0.2 gph Leak Test Fails / Leak is Detected ? ................................... 3 - 8

When a 0.1 gph Annual Precision Leak Test Fails / Leak is Detected ? ....... 3 - 8

4 TS-LLD Line Leak Detection .............................................................. 4 - 1

When a Line Leak is Detected................................................................................ 4 - 1

NOTE........................................................................................................ 4 - 1

Steps to take When a Line Leak is Detected: ..................................................... 4 - 1

NOTE........................................................................................................ 4 - 2

How Often Should a Manual ).1 gph Test be Run ? ................................................ 4 - 2

Need help ? ....................................................................................................... 4 - 2

TABLE OF CONTENTS Page TOC - 3 TOC

Page 6

Table of Contents

Chapter . Section Page No.

5 TS-LLD Maintenance & Service ......................................................... 5 - 1

NOTE........................................................................................................ 5 - 1

Cleaning the Control Unit ........................................................................................ 5 - 1

Control Unit Replacement Parts ............................................................................. 5 - 1

Pump Relay Control Box Replacement Parts ......................................................... 5 - 1

Leak Sensing Unit (LSU) Adapters & Replacement Parts ..................................... 5 - 2

LSU Removal for Service / Inspection and Cleaning ........................................ 5 - 2

After Maintenance or Service DO – .................................................................. 5 - 2

6.0 Service & Factory Support .......................................................... 6.0 - 1

Where to Find Help .............................................................................................. 6.0 - 1

Service ................................................................................................................. 6.0 - 1

Need help ? Factory Support ............................................................................. 6.0 - 2

Phone and Pax members: ................................................................................ 6.0 - 2

Sales & Tech. Service numbers,

Technical Service & After Hours – Pager – ................................................ 6.0 - 2

INCON Office Hours ....................................................................................... 6.0 - 2

Before calling INCON ..................................................................................... 6.0 - 2

Return Shipments ................................................................................................ 6.0 - 2

Warranty Registration Form

Your Notes ......................................................................................................... 6.0 - 4

(copy, & Fax Reg. Form back to INCON) ....... 6.0 - 3

6.1 Test Fail Alarms, Warnings & Error Codes ................................ 6.1 - 1

Display Codes ..................................................................................................... 6.1 - 1

Normal Display Codes (on steady – not flashing)......................................... 6.1 - 1

Flashing Alarms, Warnings, and Errors Display Codes ............................... 6.1 - 1

Diagnostic Display Codes (on steady – not flashing) ................................... 6.1 - 1

Your Notes ......................................................................................................... 6.1 - 2

6.2 TS-LLD Troubleshooting Guide .................................................. 6.2 - 1

Display Codes ...................................................................................................... 6.2 - 1

Problem Description/Symptom

NOTE..................................................................................................... 6.2 - 2

Your Notes ......................................................................................................... 6.2 - 4

Probable Cause

(Action to take) ....... 6.2 - 1

6.3 TS-LLD Warranty & Terms ........................................................... 6.3 - 1

Warranty .............................................................................................................. 6.3 - 1

Warranty Disclaimer and Limitation of Liability ................................................... 6.3 - 1

For Further Information, Contact INCON ........................................................... 6.3 - 2

Your Notes ......................................................................................................... 6.3 - 2

TOC Page TOC - 4 TS-LLD INSTALLATION GUIDE

Page 7

Table of Contents

Chapter . Section Page No.

Appendix A TS-LLD Technical Specifications ......................................... A - 1

Operating Specifications ......................................................................................... A - 1

Electrical Specifications .......................................................................................... A - 1

Allowable Pipe Type and Length ............................................................................. A - 1

Environmental Specifications .................................................................................. A - 2

Mechanical Specifications ...................................................................................... A - 2

Safety Approvals and Listings ................................................................................ A - 2

User Feedback Form .......................................................................................... U - 1

Table of Figures & Diagrams

Chapter . Section Page No.

Chapter 1

Figure 1.1 LSU Outline ...................................................................... 1 - 1

Figure 1.2 CU Outline Dimensions ...................................................... 1 - 1

Chapter 2 . Section 2

Figure 2.2-1 MI Cable Adapter Installation (before and after) ............ 2.2 - 1

Figure 2.2-2 Plug Location – RedJacket STP Housing ...................... 2.2 - 2

Figure 2.2-3 Plug Location – FE Petro STP Housing ......................... 2.2 - 3

Figure 2.2-4 TS-LLD Leak Sensing Unit – Thread Doping ................ 2.2 - 3

Figure 2.2-5 Line Leak Detector Installation – RedJacket Pump ....... 2.2 - 4

Figure 2.2-6 Line Leak Detector Installation – FE Petro Pump.......... 2.2 - 5

Figure 2.2-7 Line Leak Detector Wiring – RedJacket Pump .............. 2.2 - 6

Figure 2.2-8 Line Leak Detector Wiring – FE Petro Pump Housing... 2.2 - 7

Figure 2.2-9 MI Cable Adapter Installation – RedJacket Pump ......... 2.2 - 8

Figure 2.2-10 MI Cable Adapter Installation – FE Petro Pump ............ 2.2 - 9

Figure 2.2-11 Tightening MI Cable Adapter Fitting – RedJacket ....... 2.2 - 10

Figure 2.2-12 Tightening MI Cable Adapter Fitting – FE Petro .......... 2.2 - 11

Figure 2.2-13 Typical Installation TS-LLD Line Leak Detector ........... 2.2 - 12

Figure 2.2-14 INCON TS-LLD Installation @ Ext. Leak Det. Port ...... 2.2 - 13

Figure 2.2-15 INCON TS-LLD Installation at BigFlo

Diaphragm Valve ..................................... 2.2 -14 & 2.2 - 15

Figure 2.2-16 INCON TS-LLD Installation at FE Petro

STP or IST pumps (Single or Three Phase)............. 2.2 - 16

TABLE OF CONTENTS Page TOC - 5 TOC

Page 8

Table of Figures & Diagrams

Chapter . Section Page No.

Chapter 2 . Section 3

Figure 2.3-1 CU Internal & Bottom Views, and Relay Box Top View .. 2.3 - 1

Figure 2.3-2 CU Component Location - Internal View........................ 2.3 - 2

Figure 2.3-3 TS-LLD CU Typical Mounting and Conduit Routing....... 2.3 - 3

TABLE 2.3 -1 Typical Single Phase Wire Connection List .............. 2.3 - 4

Figure 2.3-4 Typical Single Phase 240 VAC

Pump Relay Box & Control Unit Wiring Diagram ........ 2.3 - 5

Figure 2.3-5 Typical Single Phase 240 VAC

Pump & Control Unit Interface Schematic .................. 2.3 - 6

Figure 2.3-6 Single Phase 240 VAC Multiple Pump & Manifolded

Line w/ Single LSU & CU Interface Schematic .......... 2.3 - 7

Figure 2.3-7 Mechanical Blender Dispensers to

TS-LLD Control Unit Interface Schematic .................. 2.3 - 8

Figure 2.3-8 Three Phase 240 VAC Pump & Control Unit

Interface Schematic .................................................... 2.3 - 9

Figure 2.3-9 Three Phase 240 VAC Supply – Starter – Motor

Control Box – and BigFlo Pump (3 wire)

Interface Schematic to TS-LLD ................................ 2.3 - 10

Figure 2.3-10 Three Phase 240 VAC Supply – Starter – Motor

Control Box – and BigFlo Pump (5 wire)

Interface Schematic to TS-LLD ................................ 2.3 - 11

Figure 2.3-11 Three Phase 240 VAC Supply – Starter & Motor

Control Box – Standard (FE Petro STP)

Interface Schematic to TS-LLD ................................ 2.3 - 12

Figure 2.3-12 Three Phase 240 VAC Supply – FE Petro

Variable Frequency Controller (VFC),

Motor Control Box – and IST Pump

Interface Schematic to TS-LLD ................................. 2.3 - 13

Figure 2.3-13 Control Unit Final Assembly ......................................... 2.3 - 14

Chapter 2 . Section 4

Figure 2.4-1 TS-1000 & TS-TGI Layout .............................................. 2.4 - 1

Figure 2.4-2 TS-1000 & TS-TGI – TS-LLD Wiring Diagram ............... 2.4 - 2

Figure 2.4-3 TS-2000 – TS-LLD Line Leak Detector Interface .......... 2.4 - 3

Figure 2.4-4 TS-1001 / 2001 Typical Hardware Layout ...................... 2.4 - 4

Figure 2.4-5 TS-1001 / 2001 LLD

I

Wiring Diagram ........................... 2.4 - 5

Chapter 3

Figure 3-1: Control Unit Cover – Component Location ....................... 3 - 2

Chapter 5

LSU Bottom & Side Views ........................................................................ 5 - 2

—

TOC Page TOC - 6 TS-LLD INSTALLATION GUIDE

❖

—

Page 9

P PREFACE

Contents:

Graphic Symbol Conventions (used in this manual)

Page Numbering and Layout Conventions

Components Included with Each TS-LLD System

Before You Begin

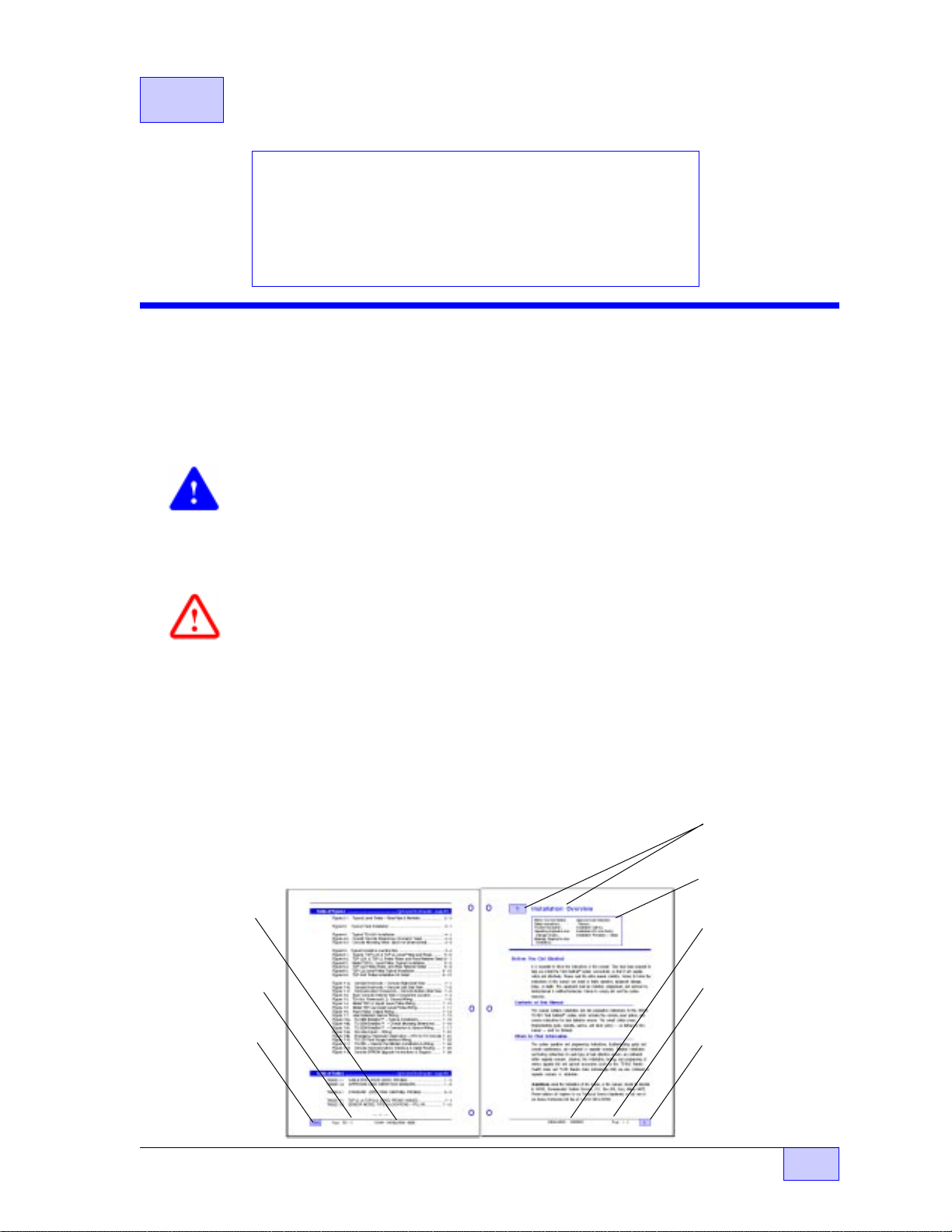

Graphic Symbol Conventions

NOTE

Important information, tips, and hints are highlighted by the NOTE graphic.

☞

CAUTION

graphic and contain instructions that must be followed to avoid faulty equipment

operation, or an explosion or shock hazards. If ignored, severe injury or death

result !

DANGER

instructions that must be followed to avoid an explosion or electrical shock

hazard. If ignored, severe injury or death

— ❖ — End of Chapter symbol

Page Numbering Convention – Example:

Page 4 – 1 = Chapter 4 page 1 and Page 6.1 – 2 = Chapter 6 . Section 1 – Page 2

Page Layout Convention – Example:

or

WARNING

messages are highlighted by the WARNING

messages are highlighted by the DANGER graphic and contain

will

result !

may

Chapter Number &

Name (

FIRST

Chapter Contents

TOP LEFT

PA GE

)

Manual Name

(

EVEN NUMBERED

PAGES

)

Page Number

Chapter Number

Chapter Name

ODD NUMBERED

(

PAGES

)

Page Number

Chapter Number

PREFACE Page P - i P

Page 10

Components Included with Each TS-LLD System

(TS-LLD Packing List)

(1) CU – Control Unit enclosure assembly (with stick-on CU Serial No. label)

(1) CU – Control Unit faceplate cover assembly

– (4) CU cover hold-down screws (4-40 x 1/4 inch)

*

(1) Bundle of different colored wire (Wire Bundle)

– (1) Spare 1/2 Micro Amp Fuse (F1)

*

– (1) Line Filter Capacitor, 1 µ Farad (for pump relay / motor control box)

*

(1) Sheet of (9) stick-on –

(1) LSU – Leak Sensing Unit (with stick-on LSU Serial No. label)

(1) Cable adapter (2 inch NPT) – (for Red Jacket Pumps)

– (1) Plug (1/4 inch NPT)

*

– (2) Wire Nuts (red) – (for connections at pump)

*

(1) Warranty Registration Card (write / stick-on CU & LSU Serial No. labels)

(1) TS-LLD Installation Guide Manual

(1) Read Me First – Installation Guide (Supplement Sheet)

(1) TS-LLD Quick Reference Guide (for the station owner / customer)

– Denotes parts in the supplied Hardware Kit (within plastic accessory bag)

*

DANGER

labels

Before you Begin

NOTES

☞

Refer to all applicable Local and State codes before beginning this installation. If a

conflict exists between the information presented in this manual, and the local

codes, then follow the local codes.

Maintenance, Service, and Installation of the TS-LLD system is to be performed by

Factory Trained and Certified personnel only.

Heed all

attempting any installation, maintenance, or service work.

This manual is your reference guide for the INCON TS-LLD line leak detector. It

includes typical installation details, which may vary depending on the actual

equipment at the site. Reference the Submerged Turbine Pump (STP) or

submersible pump, and pump relay (Motor Control) box — manufacturers’

documentation — for the installation details and requirements of this equipment.

CAUTIONS

and

WARNINGS

! See Chapter 2.1 about Safety, before

—

P Page P - ii TS-LLD INSTALLATION GUIDE

❖

—

Page 11

1 TS-LLD Electronic

Line Leak Detector system –

Overview

Contents:

• Overview and theory of

Operation

• Leak Test Requirements

and Length

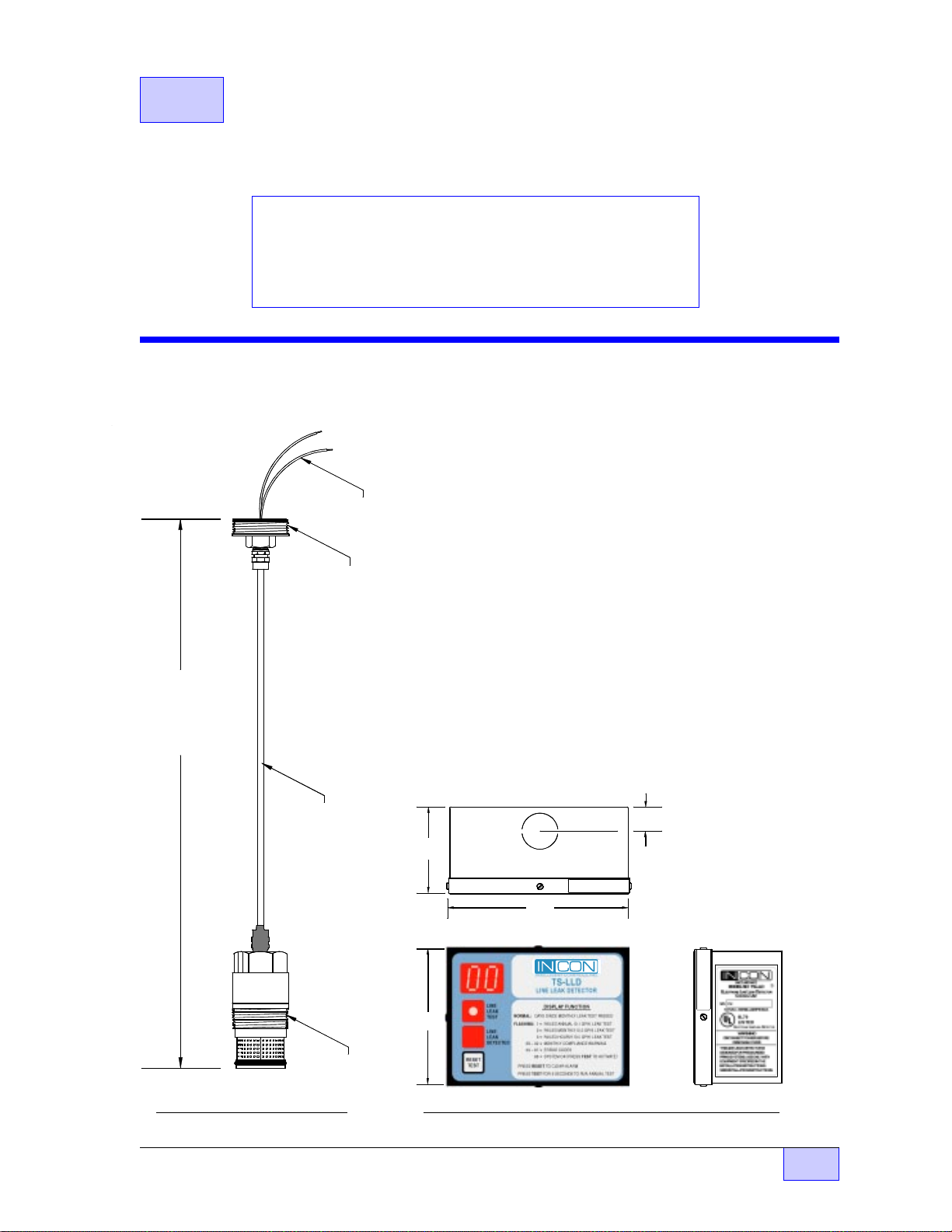

Overview and Theory of Operation

- JU N C T IO N

BOX SIDE

8 INCH

LEADS

M I CABLE

ADAPTER

• The LSU (Leak Sensing Unit)

• Communications

• The CU (Control Unit)

• Operator Interface

The INCON TS-LLD is an electronic line leak detector

system. It has two components: a Control Unit (or CU)

and a Leak Sensing Unit (or LSU). The CU is mounted in

the station near the pump control relay box, and the LSU is

installed in the line leak detector port at the submersible

pump housing. One system per pump is required to detect

leaks from a pressurized fuel line.

2 3 .5 IN CH E S

APPROX.

OVERALL

LENGT H

ASSEMBLED

M I CABLE

The TS-LLD detects leaks in the pipeline leading from the

submersible pump to the dispenser. To comply with

current EPA regulations, three types tests are provided.

These are: a 0.1 gph annual test, a 0.2 gph monthly test,

and a 3.0 gph hourly test, which run at full line pressure.

Note: All Dimensions are in inches, and are approximate

0.60

2.25

Line #:

Product:

4.35

TOP & BOTTOM VIEW - C ONTROL UNIT (CU )

3.35

Knoc kout f or

1/2 inch f itting

- Ty pic a l -

x x x x x x x x

TS-LL D C U S eri al Numb er

xxxxxxxx

- LINE LEAK

P O RT S ID E

2 INCH NPT

FR ON T VIEW

RIGHT SIDE VIEW

Figure 1.1 LSU Outline Figure 1.2 CU Outline Dimensions

Overview Page 1 - 1 1

Page 12

Overview and Theory of Operation (Continued... )

The 0.1 gph annual test is started manually from the control unit (also known as a

manual test). On the other hand, the gross 3.0 gph hourly test and the

intermediate precision 0.2 gph monthly-compliance test both start and run

automatically.

and finish any line leak test.

Leak Test Requirements and Length

The 3.0 gph hourly test starts after every dispense and takes about 3 minutes

of

quiet-time

The 0.2 gph monthly-compliance test automatically starts after a 3.0 gph test

passes

hours. The monthly compliance test either runs, passes, and resets the day-count

to 00, or, advances a day if no test has passed after 24 hours. Depending on

conditions of the line and product, the 0.2 gph monthly-compliance test needs

13 minutes to 4 hours of

unless

Quiet-times, where no dispensing occurs, are required to start

to finish.

a previous 0.2 gph test has already passed within the last 24

quiet-time

to finish.

The manual 0.1 gph annual test needs 4 hours of

started, and takes about 13 minutes of

The LSU (Leak Sensing Unit)

The LSU (Leak Sensing Unit) has an O-Ring sealed valve at its base, which forces

all of the fuel flowing from the submersible pump through the LSU. A

microprocessor based printed circuit board is contained in the LSU. It uses a

proprietary technique to measure the actual product flow rate through a sensor

tube within the LSU, which can indicate a leak.

In most cases, the only required field wiring connections are two wires that are

connected in parallel to the existing Submersible Turbine Pump (STP) power-feedlines. A special copper sheathed, Mineral Insulated Cable (MI Cable) connects the

LSU to the electrical junction box at the pump discharge head.

Communications

The LSU not only receives power from the existing pump power-lines, but it

transmits data (communicates) over these lines. One of the power lines is routed

through a communications

pickup coil

quiet-time

quiet-time

inside the Control Unit (CU).

to finish after it starts.

before it’s

1 Page 1 - 2 TS-LLD INSTALLATION GUIDE

Page 13

The CU (Control Unit)

The CU monitors data that it receives from the pickup coil. The control unit

automatically turns on the pump when no one is dispensing product and calculates

accurate liquid flow rates to determine if a line leak exists or not.

The dispense signal is also monitored to identify when a customer is about to

dispense product. The CU is tied directly to the existing Pump Relay (Motor

Control) Box that is inside the station. The control unit activates the pump relay,

which turns the pump on and permits product dispensing when no line leak or

errors exist.

When a leak or error is detected, the pump relay is deactivated, which

keeps the pump turned off and prevents product dispensing.

Operator Interface

Two lights, a 2 digit display, and a reset-test touch button are provided for operator

interface. One light turns on when leak tests run, and the other flashes when a line

leak is detected. The two digit display shows operational status codes / day counts

(since the last monthly 0/2 gph line leak test passed), or flashes line leak alarms,

warnings, and error codes when and if they occur.

Brief operating instructions, and a list of codes and display functions are printed on

the control unit faceplate. See Chapter 3 for complete details.

Overview Page 1 - 3 1

Page 14

— Your Notes —

—

1 Page 1 - 4 TS-LLD INSTALLATION GUIDE

❖

—

Page 15

2.0 TS-LLD Materials & Tools

Required

Contents:

• Do a Site Survey Before Attempting the Installation

• Materials Required

• Tools Required

Do a Site Survey Before Attempting the Installation

Submersible Turbine Pumps:

What is the Motor Control / Pump Relay Box or Starter Type ? and

What is the Model Number, HP, Manufacturer, and age of all Turbine Pumps ?

Electrical Supply:

What is the Voltage and Phase (240 VAC – Single or Three Phase ? ) of all

Turbine Pumps ?

Materials Required

❒

Petroleum absorbent / absorbing rags

❒

Pipe Dope — Non-hardening (Soft-Set), UL Classified, gas/oil resistant —

to seal the Leak Sensing Unit, and the 1/4 inch Tank Test Port plug at the pump

❒

MI Cable Adapter — for installation on the TS-LLD Leak Sensing Unit (LSU). The

TS-RJ 2" NPT Cable Adapter for Red Jacket® submersible pumps is

with the TS-LLD),

Order INCON part number:

TS-FE 3" straight Cable Adapter for FE Petro® STPs

❒

Stick-on

❒

(1) 1/4 inch NPT pipe plug for the tank test port at the pump head

the TS-LLD)

❒

Red wire nuts for LSU wiring at the pump head

❒

(1) 1µ Farad Line Filter capacitor for the pump relay box

– supplied with the TS-LLD)

❒

Wire: 14 AWG, 3 feet

DANGER

(supplied

the adapter for FE Petro® STPs must be ordered separately...

*

labels

(INCON P/N 240-1175 – supplied with the TS-LLD)

(supplied with

(supplied with the TS-LLD)

(INCON P/N 020-0028

(supplied with the TS-LLD)

❒

(6) spade lugs for #8 studs to connect the 14 AWG wire at the pump relay box

Materials and Tools Required Page 2.0 - 1 2.0

Page 16

Materials Required

❒

(1) ring lug for the 14 AWG earth ground connection at the pump relay box

❒

(1) short 1/2 inch nipple — 2-1/2 to 3 inches long, or 1/2 inch 90 degree, and

hardware fittings to mount the CU to the relay box. (Or you may wall-mount the

control unit with appropriate fasteners, and use 1/2 inch EMT and fittings.)

❒

Steel stem Replacement Check Valve Kit (RedJacket P/N 144-184-5) to

*

replace older all plastic check valves – for older RedJacket pumps only

❒

Approved Pump Relay (Motor Control) Box – to comply with codes, retrofit

*

system to add a motor control box inside of the station

= Occasionally Required

*

❒

this Installation Manual – INCON P/N 000-1359 most current revision

❒

(1) Completed Warranty Registration Card –

❒

TS-LLD Quick Reference guide – INCON P/N 000-1447

TS-LLD).

station owner, shift managers / personnel

❒

Also, for use by the station owner, shift managers / personnel, provide the

name(s), phone number(s) of the local inspection agency and other applicable

information, instructions and regulations should a line leak be detected.

Leave all TS-LLD Quick Reference guide(s) on-site for use by the

(continued... )

(supplied with each TS-LLD)

(supplied with each

!

❒

Regulations and documentation: Applicable Local and State Codes, the

Manufacturers’ manuals and wiring diagrams of the — Dispenser, Submersible

Pump, and Relay Box (including other equipment not listed here and the sites’

electrical power distribution).

Tools Required

❒

Digital multimeter and test leads (high quality professional instrument)

❒

One each: wire strippers, cutters, and crimp splice tool

❒

Various sizes of flat and phillips bladed screwdrivers

❒

One 12 inch long adjustable wrench

❒

One 2 inch open end hex wrench

❒

Two 7/8 inch open end hex wrenches

❒

One socket set, extension, and square socket for a 1/4 inch NPT square headed

hole plug

—

2.0 Page 2.0 - 2 TS-LLD INSTALLATION GUIDE

❖

—

Page 17

2.1 TS-LLD SAFETY

Contents:

• Important Safety Notes and Warnings...

Read and follow these DANGER, WARNING, and CAUTION

messages before starting any installation or service.

Important Safety Notes and Warnings

DANGER

servicing, or working on this equipment, make sure you turn off all

submersible pump power (240 VAC) and pump relay coil /

dispenser power at the electrical panel. Tag, secure / lockout

these circuit breakers in the off position to prevent accidental or

unauthorized circuit breaker closure. Failure to turn off power

will result in severe injury or death !

DANGER

on, or wiring-to a circuit – a lethal electrical-shock-hazard could

exist, which would kill you.

in the on position, even when the circuit breaker lever is turned off.

DANGER

pump to run leak-tests at full line pressure between periods of

product dispensing (while the dispense switch is off). BEFORE

performing any installation or service (such as replacing fuelfilters) – turn off / lockout all electrical power sources to the

submersible pump(s), and relieve fuel-line pressure. Failure to

turn off power, and relieve fuel-line pressure before work is started,

may cause a pressurized fuel spill.

create a fire or explosion hazard that could result in injury or death.

Electrical Shock Hazard. Before installing,

Verify that no voltage exists before working-

Note: circuit breaker contact(s) can fail

The TS-LLD automatically starts the submersible

A pressurized fuel spill would

NOTE

☞

INCON Danger stickers (see above left) are supplied with the

TS-LLD line leak detector. Apply these stickers on the pump relay

box cover, in locations near dispenser fuel-line filters, plugs,

emergency safety-shut-off valves, on the TS-LLD Leak Sensing

Unit (at the submersible pump housing), and other serviceable

components of a fuel line (where a spill would occur if the line

became pressurized). The selected surfaces must be clean, dry,

and in plain sight so that the warning can be read, and followed.

SAFETY Page 2.1 - 1 2.1

Page 18

Safety Notes and Warnings (continued... )

DANGER

After any installation or service of the submersible pump or its

housing, inspect the MI Cable at the LSU (Leak Sensing Unit) for

damage, twists, kinks, or breaks... 240 VAC power flows through

this cable to the LSU.

damaged, twisted, kinked, or broken.

this area could cause an explosion, injury or death.

WARNING

dispenser, may be under pressure. Turn off all pump power and

relieve pipeline pressure (reference and follow the pump

manufacturer’s directions about how to do this). If the line leak

detector/plug (or any other part of the submersible pump and fuel

line) is removed without first relieving pressure, then a product

leak will occur. This could cause an environmental, fire, or

explosion hazard, and may result in injury or death.

WARNING

fuel dispensing equipment (volatile fuel may be within the pump’s

leak detector port). Allow no source of combustion near the work

area. Failure to follow these directions may cause an explosion

hazard, which could result in property damage and death.

Explosion Hazard — Flammable Vapor Area.

DO NOT apply power if the MI Cable is

Electrical sparks or fire in

The fuel line from the submersible pump to the

Be careful not to cause sparks when working on

CAUTION

codes, the National Electric Code (NEC), and the Automotive and

Marine Service Station Code (NFPA 30A) before installation or

maintenance.

Refer to all applicable Federal, State and local

This installation is designed for submersible pumps

which have a pump relay box in the station.

does not exist, then the system must be retrofitted to add a

pump relay (motor control) box in the facility to comply with

Codes.

CAUTION

not recommend operating the LSU while submerged for long

periods of time (drain sump and manhole immediately).

2.1 Page 2.1 - 2 TS-LLD INSTALLATION GUIDE

Although the LSU is water resistant, INCON does

—

❖

—

If a pump relay box

Page 19

2.2 TS-LLD LSU Installation

Contents:

• LSU Installation Steps

(Typical in Pump Housing)

• Overall Site Installation Diagrams (typical Site,

in Angle Check Valve, RedJacket “BigFlo,” & FE

PETRO STP / IST pumps)

LSU Installation Steps

Follow the steps (below) in the order that they appear:

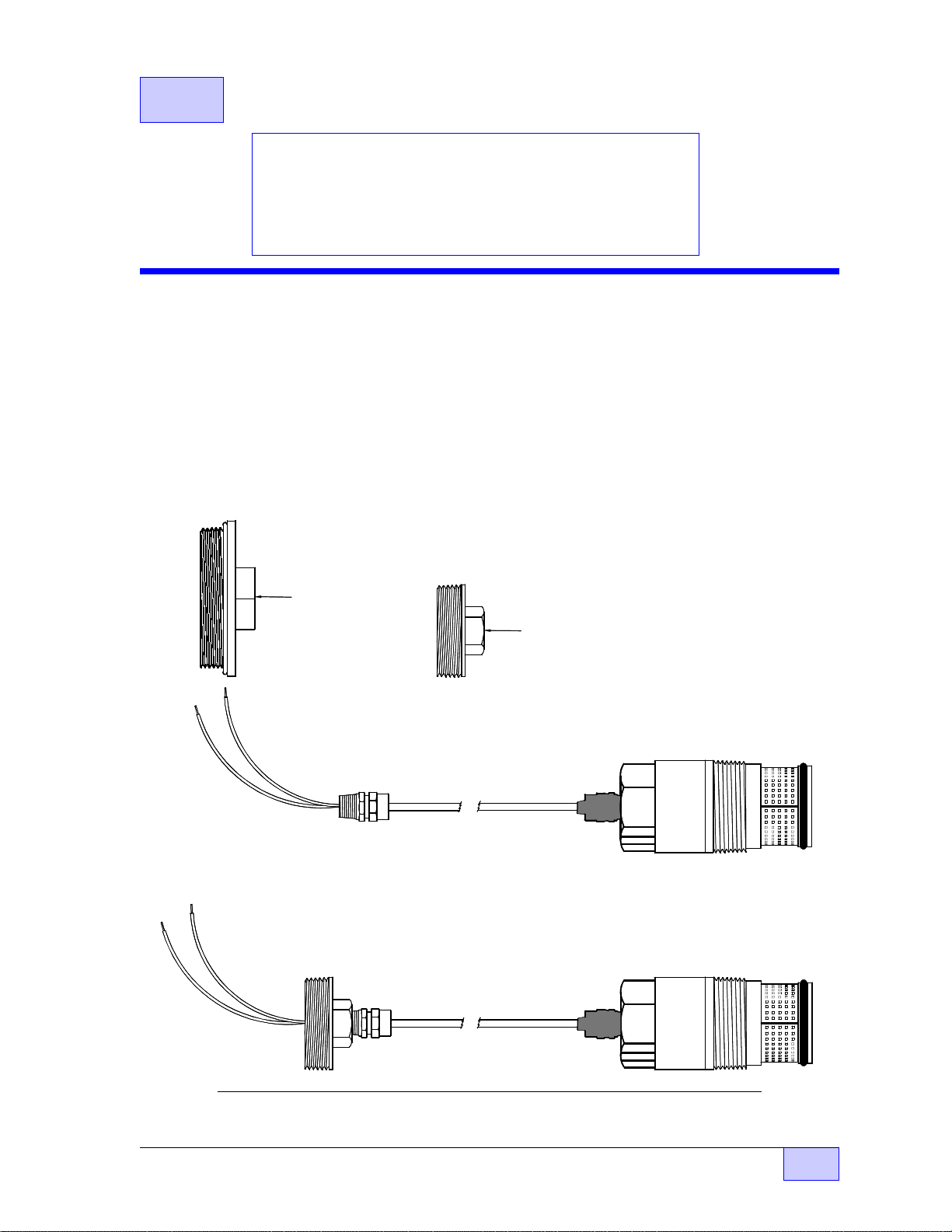

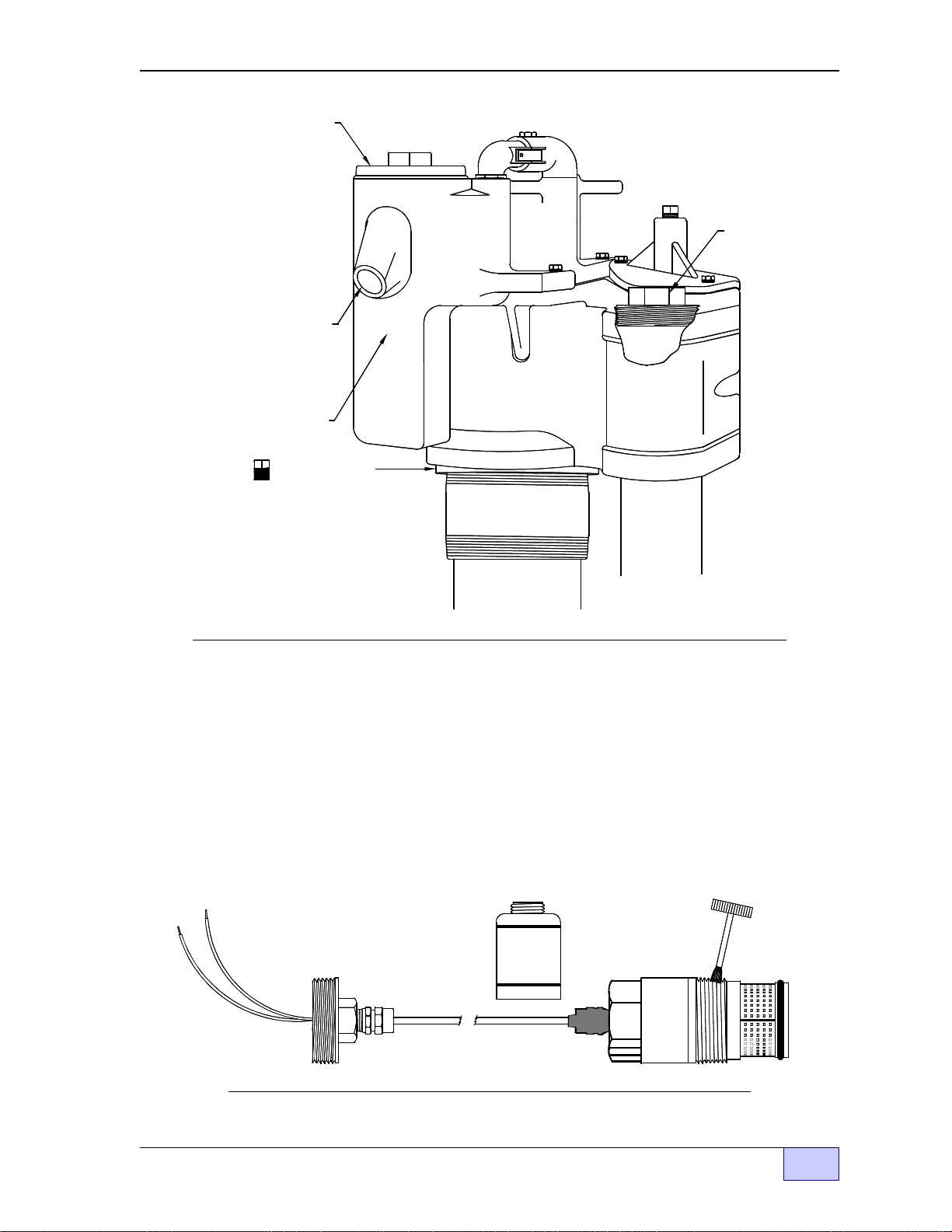

1) Install the appropriate size MI Cable Adapter on the LSU. Use an adjustable

wrench and a 7/8 inch wrench to tighten the MI cable adapter onto the TS-LLD as

shown in Figure 2.2-1. NOTE: The cable adapter that you install must match the

size of the junction box plug at the submersible pump housing (two different cable

adapters are shown in Figure 2.2-1). The 3 inch straight TS-FE cable adapter

must be ordered separately because the pump type and manufacturer varies.

TS- F E

3 INCH

M I CA BL E

ADAPTER

For FE Petro

Pumps

TS- RJ

2 INCH NPT

M I CA BL E

ADAPTER

For Red Jacket

Pumps

TS-LLD

LINE LEAK DETECTOR

LEAK SENSING UNIT

(LSU)

Figure 2.2-1 MI Cable Adapter Installation (before and after)

LSU Installation Page 2.2 - 1 2.2

Page 20

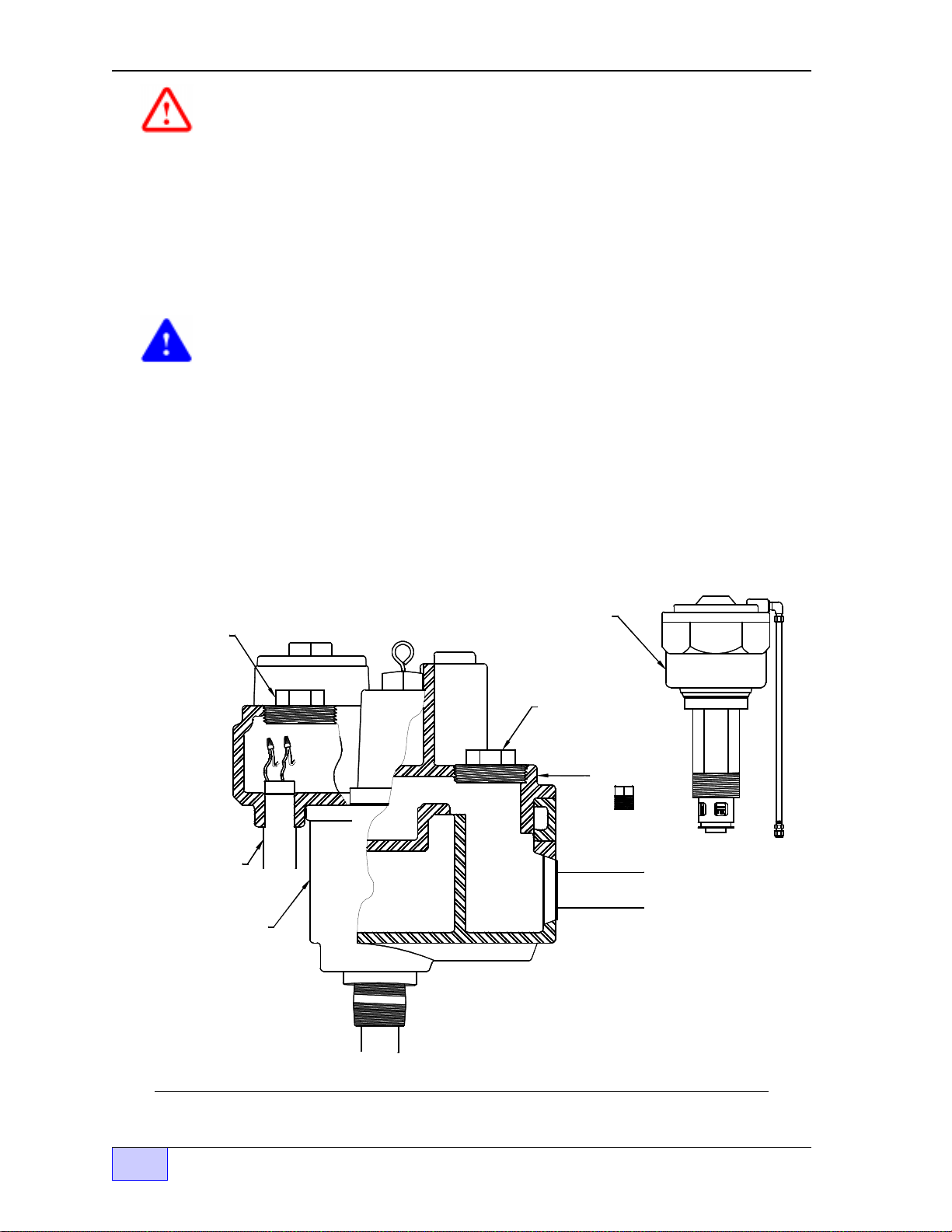

DANGER

Fire, Explosion, & Electrical Shock Hazard. Before installing,

servicing, or working on this equipment, make sure all submersible pump power

and pump relay coil / dispenser power is turned off & locked out at the electrical

panel.

lines, and electrical shocks.

Prevent automatic or unauthorized pump start-ups, spills from pressurized

See Chapter 2.1 follow all Safety advise.

2) Relieve pipe line pressure. Reference the detailed instructions found in the

submersible pump manufacturers’ documentation about relieving pressure in the

pipe line.

WARNING

The pipe line is under pressure – relieve line pressure. If the

line leak detector / plug is removed before the pipe line pressure is relieved, then a

product leak will occur ! A explosion, fire, or environmental hazard may be created.

3) Remove the 2 or 3 inch junction box plug and the 2 inch line leak plug, or

mechanical line leak detector (if present), from the pump housing per Figure 2.2-2

or 2.2-3. Use petroleum absorbent / absorbing rags to collect and contain spills if

they occur (be sure to properly dispose of these afterwards). If a mechanical line

leak detector was removed, then apply pipe dope on the threads of the

supplied 1/4 NPT hole plug, and install this plug into the tank test port.

MECHANICAL

2" PLUG

LINE LEAK

DETECTOR

2" PLUG

1/4" PLUG

STATION

CONDUIT

PUMP HOUSING

Figure 2.2-2 Plug Location – RedJacket® Submersible Pump Housing

PIPELINE

2.2 Page 2.2 - 2 TS-LLD INSTALLATION GUIDE

Page 21

3" PLUG

STATION

CONDUIT

PORT

PUMP HOUSING

1/4" PLUG

2" PLUG

PIPELINE

Figure 2.2-3 Plug Location – FE Petro Submersible Pump Housing

4) Apply Pipe dope to the line leak detector threads per Figure 2.2-4.

TS-LLD

LINE LEAK DETECTOR

LEAK SENSING UNIT

(LSU)

e

Pip

Dope

Pipe dope

only these

thre ads

Figure 2.2-4 TS-LLD Leak Sensing Unit – Thread Doping

LSU Installation Page 2.2 - 3 2.2

Page 22

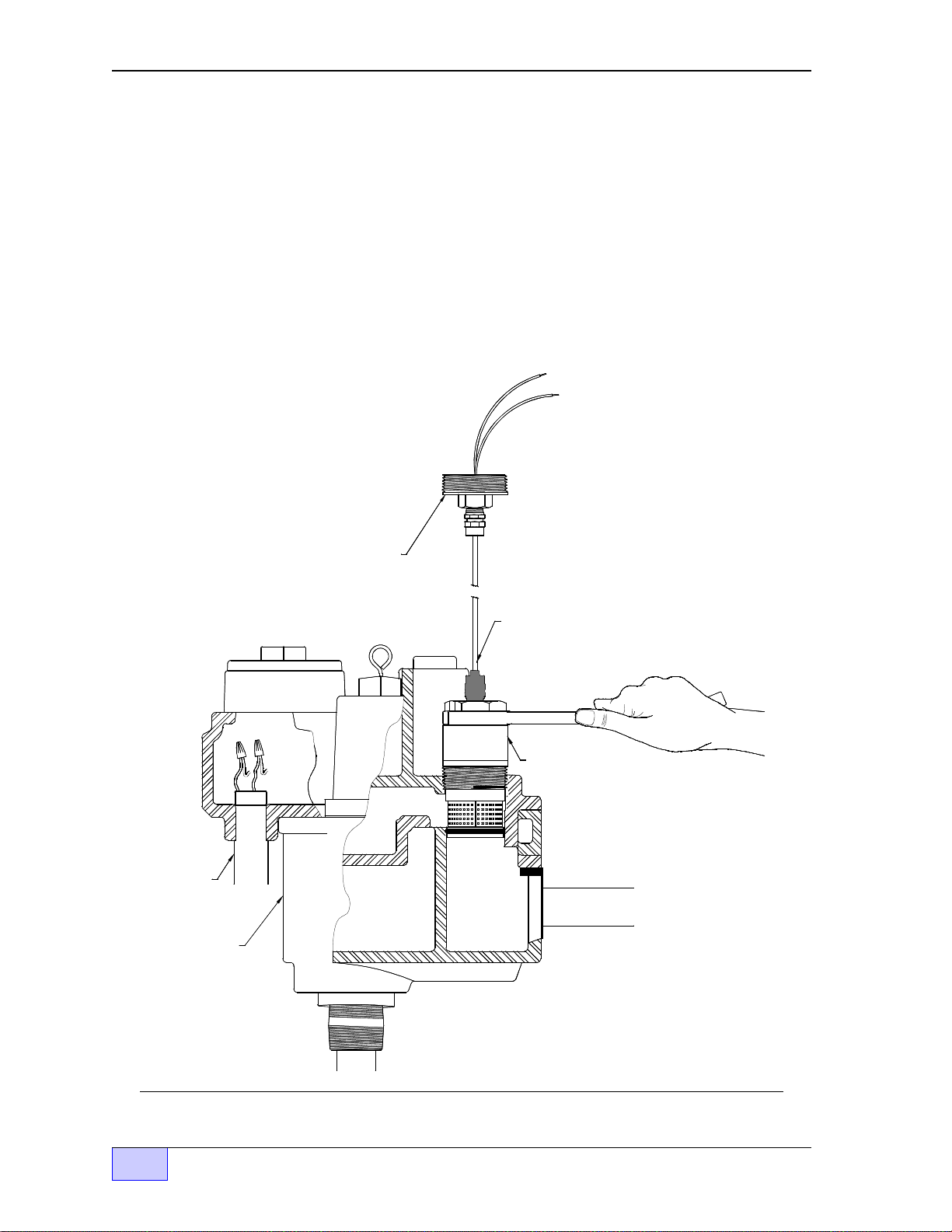

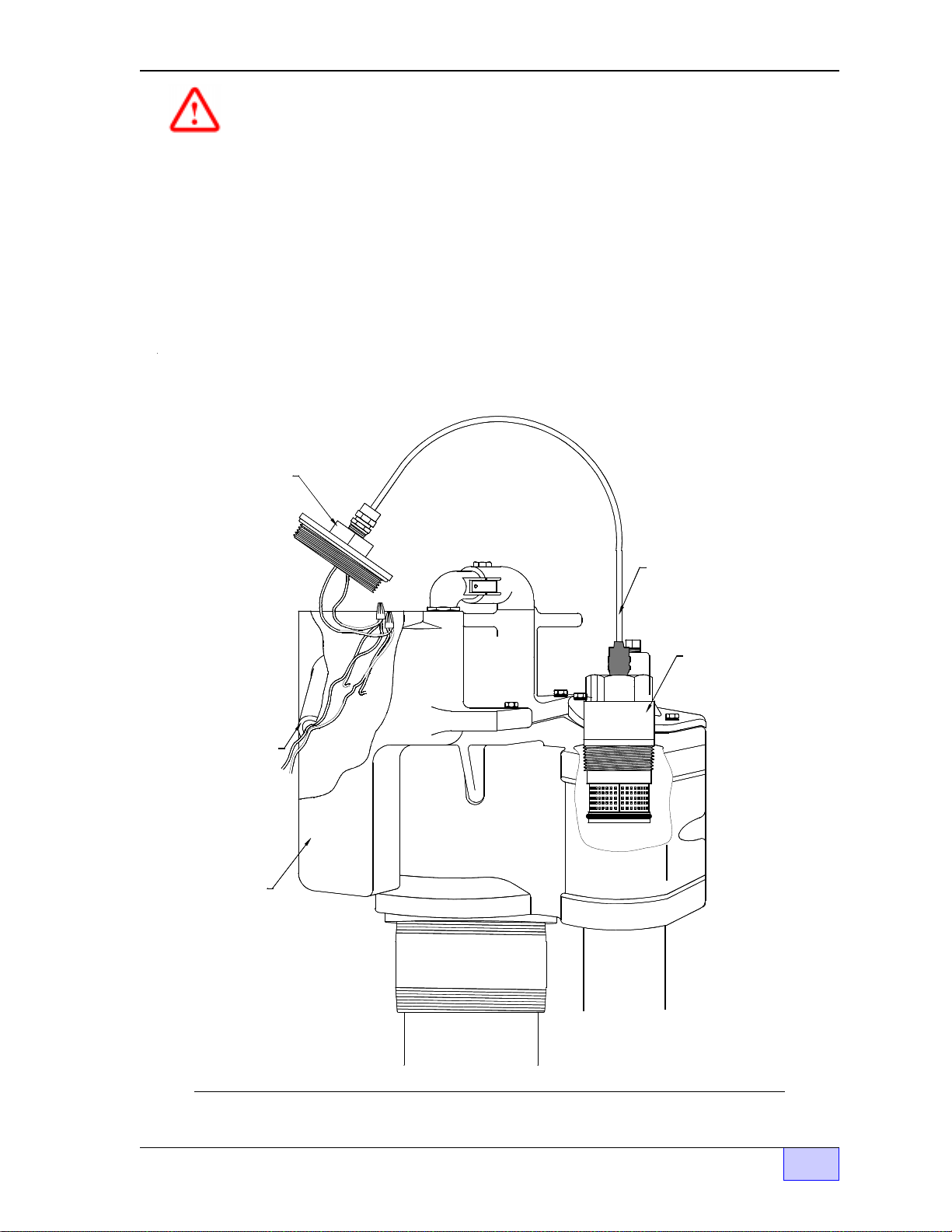

5) Insert the Leak Sensing Unit into the line leak port at the pump housing. See

Figure 2.2-5, or 2.2-6, and tighten the detector with a 2 inch hex – open end

wrench (no larger than 12" long to prevent overtightening and possible pump

housing damage or leaks). DO NOT overtighten the LSU in the pump head !

NOTE

☞

The MI Cable should be straight, vertical and able to rotate

freely with the LSU during the insertion or removal process.

M I CABLE

ADAPTER

M I CABLE

LINE LEAK

DETECTOR

STATION

CONDUIT

PIPELINE

PUMP

HOUS ING

Figure 2.2-5 Line Leak Detector Installation – RedJacket® Pump Housing

2.2 Page 2.2 - 4 TS-LLD INSTALLATION GUIDE

Page 23

STATION

CONDUIT

PORT

PUMP

HOUSING

M I CABLE

ADAPTER

MI CABLE

LINE LEAK

DETECTOR

Figure 2.2-6 Line Leak Detector Installation – FE Petro Pump Housing

LSU Installation Page 2.2 - 5 2.2

Page 24

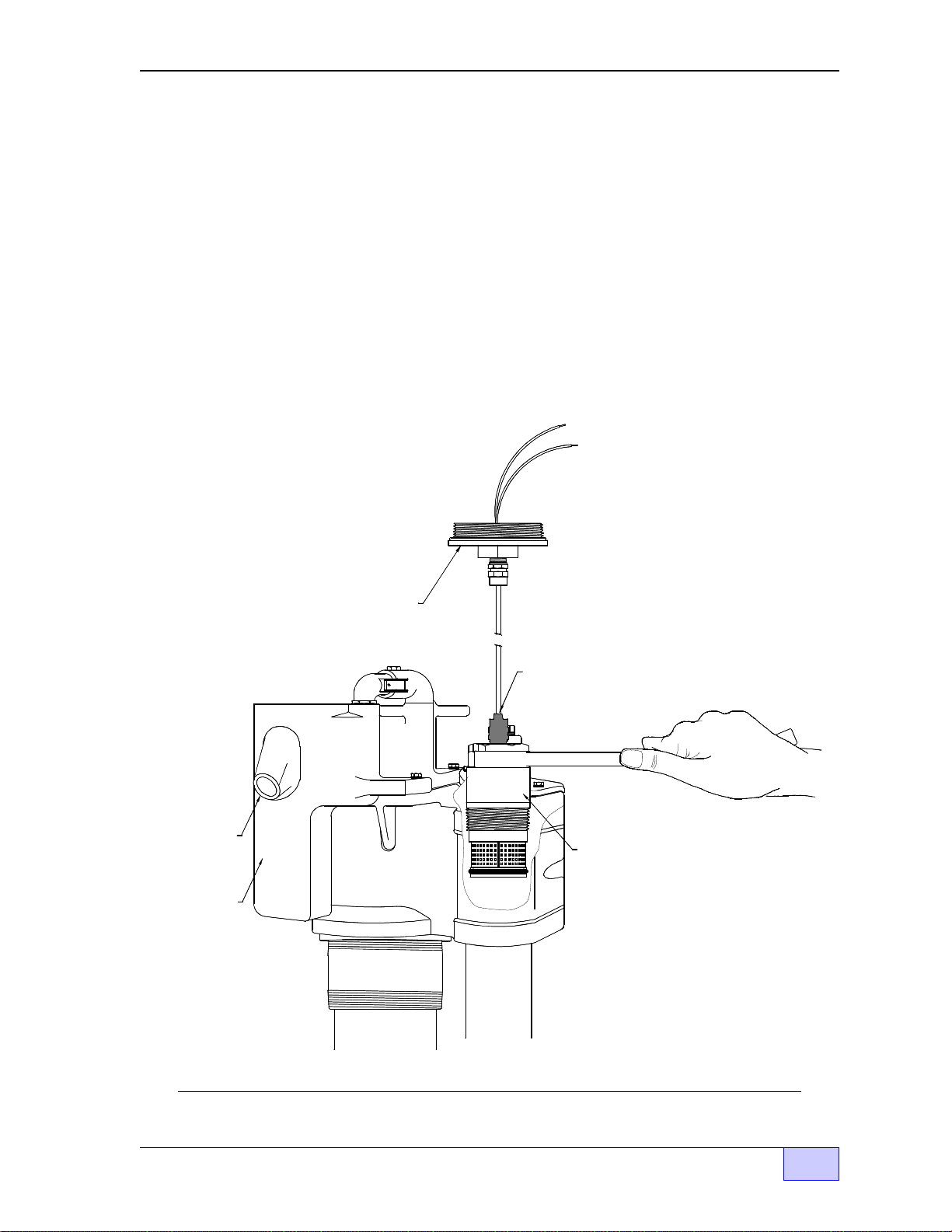

6) Carefully bend the thin-wall MI cable by hand and align the 2 or 3 inch cable

adapter fitting with the

hands when bending to fit. DO NOT force or bend the MI cable against the

compression fittings. Be sure you leave enough room to work (as shown in Figure

2.2-7, or 2.2-8).

junction box

plug opening. Support the MI cable with both

NOTE

☞

Avoid breaking the MI cable — DO NOT bend the MI cable too

close to the fittings. An LSU that has a damaged MI Cable is

unusable and must be replaced before power is applied.

7) Carefully remove each wirenut, one at a time and check each for the absence of

power (see Figure 2.2-7, or 2.2-8).

M I CABLE

LINE LEAK

DETECTOR

STATION

CONDUIT

PUMP

HOUSING

Figure 2.2-7 Line Leak Detector Wiring – RedJacket® Pump Housing

2.2 Page 2.2 - 6 TS-LLD INSTALLATION GUIDE

PIPELINE

Page 25

DANGER

Make sure you check these wires for the absence of power

before proceeding. All pump power (240 VAC) and pump relay / dispenser power

must be off before this installation is started, otherwise a lethal hazard will be

created which could kill you or others.

Note:

A circuit breaker contact(s) can

stick closed even when the circuit breaker is in the off position.

8) Leak Sensing Unit Wiring – Reference Figure 2.2-7, or 2.2-8.

a) Use one of the supplied red wire nuts, and twist one wire lead from pump

together with one of the black wire leads from the LSU.

b) Again use a red wire nut, and twist the remaining lead from pump together

with the remaining black wire lead from the LSU.

c)

For Canadian TS-LLD leak sensing units only:

connect the green (ground)

wire from the pump to the green LSU wire.

M I CABLE

ADAPTER

STATION

CONDUIT

PORT

PUMP

HOUSING

M I CABLE

LINE LEAK

DETECTOR

PIPELINE

Figure 2.2-8 Line Leak Detector Wiring – FE Petro Pump Housing

LSU Installation Page 2.2 - 7 2.2

Page 26

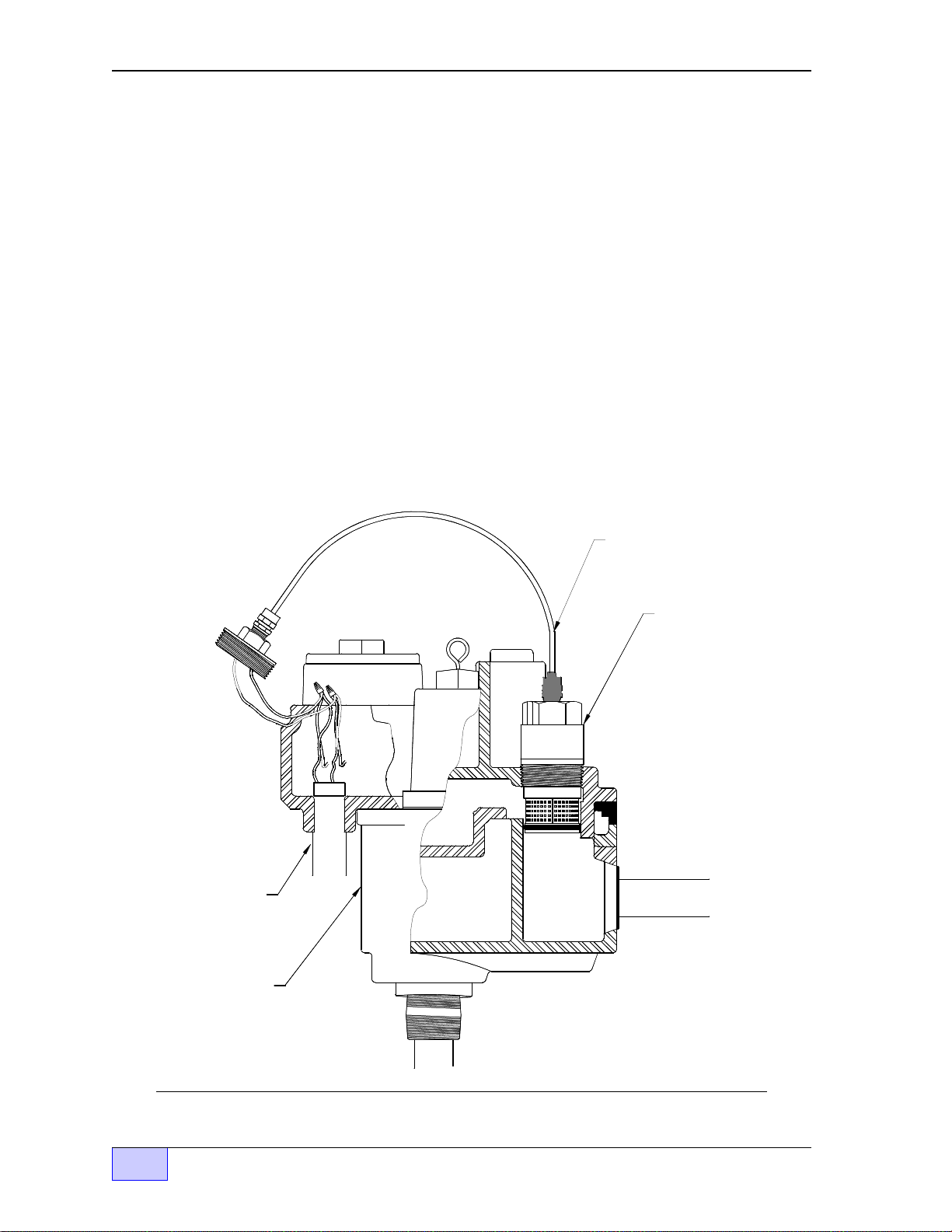

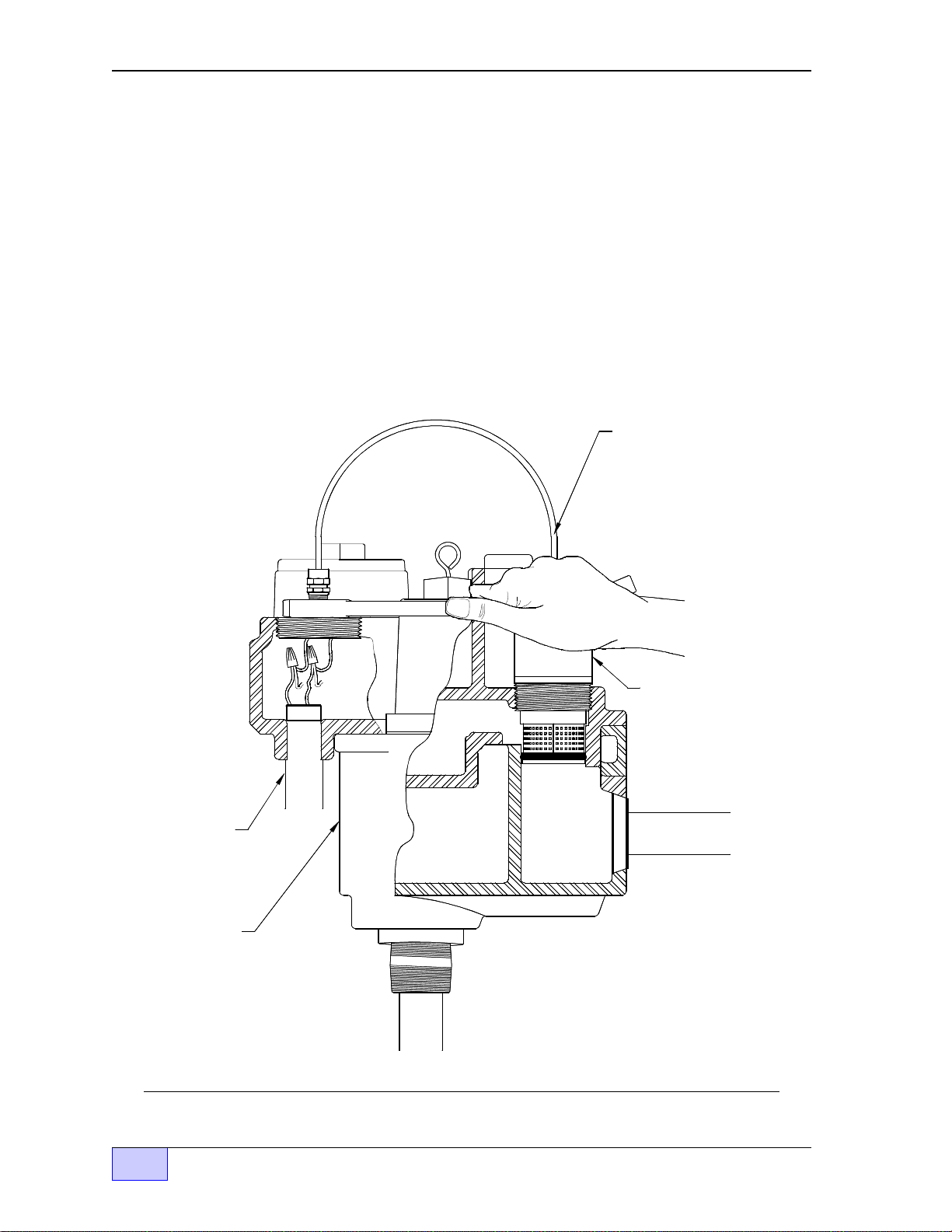

9) Stuff the wires back into the pump housing and carefully finish bending the MI

cable so that the cable adapter engages the threaded opening of the junction box.

Make sure to push the wires down enough to avoid pinching, or cutting through

the wire insulation from the cable adapter when it is tightened down.

Reference

Figure 2.2-9, or 2.2-10.

10) Tighten the MI cable adapter (new junction box cover) after making sure that

compression fitting is loose and is able to rotate freely — to prevent bending

and twisting damage to the MI Cable. Apply electrically conductive pipe dope to

the cover or the junction box. Use a 12 inch adjustable wrench. Reference Figure

2.2-9, or 2.2-10.

M I CAB LE

STATION

CONDUIT

PUMP

HOUSING

Figure 2.2-9 MI Cable Adapter Installation – RedJacket® Pump Housing

LINE LEAK

DETECTOR

PIPELINE

2.2 Page 2.2 - 8 TS-LLD INSTALLATION GUIDE

Page 27

M I CABLE

ADAPTER

STATION

CONDUIT

PORT

PUMP

HO USING

M I CABLE

LINE LEAK

DETECTOR

PIPELINE

Figure 2.2-10 MI Cable Adapter Installation – FE Petro Pump Housing

LSU Installation Page 2.2 - 9 2.2

Page 28

11) Tighten the MI cable compression fitting with a 7/8 inch wrench. Be careful

g

g

not to overtighten the compression fitting –

damage and failures

– torque to 25 lbs/ft. Reference Figure 2.2-11, or 2.2-12.

avoid MI cable twisting / bending

12) Recommended for Red Jacket installations: inspect and replace the check valve

under the functional element – IF – it doesn’t have a stainless steel stem. Use

Red Jacket replacement part number: 144-184-5.

13) Finally, inspect the MI Cable at the LSU (Leak Sensing Unit) for damage, twists,

kinks, or breaks —

replaced before power is applied.

M I Cable

Upper

Compression Fittin

Lower Junction Box /

Cable Adapter Fittin

DETAIL A

a LSU that has a damaged MI Cable is unusable and must be

Install a new LSU if the MI Cable is damaged.

Stainless

Steel

st em

Plastic

Check Valve

Detail

M I CABLE

STATION

CO NDUIT

PUMP

HO USING

PIPELINE

Figure 2.2-11 Tightening MI Cable Adapter Compression Fitting – RedJacket® Pump

2.2 Page 2.2 - 10 TS-LLD INSTALLATION GUIDE

Page 29

DETAIL A

g

g

DANGER

After any installation or service of the submersible pump or its

housing, inspect the MI Cable at the LSU (Leak Sensing Unit) for

damage, twists, kinks, or breaks... 240 VAC power flows through

this cable to the LSU.

damaged, twisted, kinked, or broken.

this area could cause an explosion, injury or death.

M I C ab le

Upper

Compression Fittin

Low er Junc tion Box /

Cable Adapter Fittin

Explosion Hazard — Flammable Vapor Area.

DO NOT apply power if the MI Cable is

Electrical sparks or fire in

M I CABLE

AD AP TE R

STATION

CONDUIT

PORT

PUMP

HOUSING

M I C AB LE

LINE LEAK

DETECTOR

PIPELINE

Figure 2.2-12 Tightening MI Cable Adapter Compression Fitting – FE Petro Pump

LSU Installation Page 2.2 - 11 2.2

Page 30

2.2 Page 2.2 - 12 TS-LLD INSTALLATION GUIDE

g

g

Reference Schematic Figure 2.3 - 8

Electrical

Power Panel

Pump

Relay

Boxes

INCON TS-LLD Line Leak Detector

Typical Installation in Leak Detector Port

TS-LLD CUs

(Control Units):

# 2 and # 1

2

1

TS-LLD LSU # 1

(Leak Sensing Unit # 1)

at submersible

pump housin

Dispenser

# A

Dispenser

TS-LLD LSU # 2

(Leak Sensing Unit # 2)

at submersible

pump housin

# X

NOTE:

NOTE:

A TS-TGI Tank Gauge Interface

A TS-TGI Tank Gauge Interface

module is required to connect

module is required to connect the

the TS-LLD Line Leak Detector

TS-LLD Line Leak Detector system

system to an INCON TS-1000

Tank Sentinel console.

to an INCON TS-1000 Tank Sentinel console. See the TS-TGI Install

See the TS-TGI Install Manual.

Manual.

For TS-1001/2001 Tank Sentinel

consoles, use the LLD /

...see the OPTIONAL TS-LLD TANK

SENTINEL ATG CONSOLE

INTERFACE chapter in this manual.

Existing

Conduit

(Pump 1)

Submerged

Turbine

Pump

Tank - Pump # 1

I

interface

Existing

Conduit

(Pump 2)

Figure 2.2-13 Typical Installation INCON TS-LLD Line Leak Detector

Epoxy

Filled

EYS

Seal

Fitting

Explosionproof

Junction

Box

Tank - Pump # 2

Page 31

LSU Installation Page 2.2 - 13 2.2

g

g

g

g

g

g

Reference Schematic Figure 2.3 - 8

Electrical

Power Panel

Pump

Relay

Boxes

INCON TS-LLD Line Leak Detector

External Leak Detector Port Installation

TS-LLD CUs

(Control Units):

# 2 and # 1

2

1

TS-LLD LSU (#1)

(Leak Sensin

at STP housin

Standard

Single Phase Installation

Dispenser

Unit)

# A

Dispenser

# X

TS-LLD LSU (#2)

(Leak Sensing Unit)

at External Leak Detector Port

NOTE:

A TS-TGI Tank Gauge Interface

module is required to connect the

TS-LLD Line Leak Detector system

to an INCON TS-1000 Tank Sentinel console. See the TS-TGI Install

Manual.

For TS-1001/2001 Tank Sentinel

consoles, use the LLD /

...see the OPTIONAL TS-LLD TANK

SENTINEL ATG CONSOLE

INTERFACE chapter in this manual.

Epoxy

Filled

Fittin

I

interface

Existin

Conduit

(Pump 2)

Existin

Conduit

(Pump 1)

Submer

Turbine

Pump (STP)

ed

("Standard" Single Phase

Tank - Pump # 1

Installation)

Figure 2.2-14 INCON TS-LLD Installation at External Leak Detector Port

EYS

Seal

Explosionproof

Junction

Boxes

Tank - Pump # 2

Installation within an

External Leak Detector Port

( not pump housing)

Page 32

2.2 Page 2.2 - 14 TS-LLD INSTALLATION GUIDE

g

g

y

y

g

g

g

y y

Electrical

Power Panel

Pump

Relay

Boxes

3 Phase

Pump

Motor

Starter

INCON TS-LLD Line Leak Detector

BigFlo & Diaphragm Valve Installation

TS-LLD CUs

(Control Units):

# 2 and # 1

2

1

Epoxy

Filled

2

EYS

Seal

TS-LLD LSU (#1)

(Leak Sensing Unit)

at pump housing

Standard Single

Phase Installation

Fittings

Dispenser

# A

Dispensers

TS-LLD LSU (#2)

# B thru # X

(Leak Sensing Unit)

at Diaphragm Valve

see Detail A - A

NOTE:

1)

An additional Sin

Rela

Control Box (panel), two additional

wires, and possibl

le Phase 230 VAC

an additional conduit run to

the LSU, are required for 3 Phase Applications.

The INCON TS-LLD LSU MUST be installed

2)

so the fasteners are ali

ned in a 12 & 6 o'clock

(vertical) position as shown in Detail A - A.

Tighten the LSU to meet this requirement.

Existing

Conduit

(Pump 2)

Submerged

Pump (STP)

Detail A - A

Overhead Top View

(correct ali

nment)

Partial

Enlar

ed

Side View

Existing

Conduit

(Pump 1)

Turbine

Tank - Pump # 1

("Standard" Sin

Installation)

le Phase

BigFlo Pump

(BigFlo Three Phase Pump and

Diaphragm Valve Installation)

BigFlo

STP

Pump

Explosionproof

Junction

Box . . . . .

Tank - Pump # 2

Note:

Use two

conduits

when

conduit

fill exceeds

40% full as

specified

b

our

National

Electric

Code.

Page 33

BIG-FLO PUMP & DIAPHRAGM VALVE

Reference Schematic Figures 2.3 - 9 & 10

Detail A

Installation (2 Explosion proof Conduit Outlet

Boxes & Hardware and 1 conduit run)

BIG-FLO PUMP & DIAPHRAGM VALVE

Detail B Alternate

Installation (2 Explosion proof Conduit Outlet

Boxes & Hardware and 2 conduit runs)

LSU Installation Page 2.2 - 15 2.2

3/4 inch

Conduit

& EYS

Epoxy filled

" Y " Seal

fitting

Crouse-Hinds:

GUAD

or GUAM

& GUJC

A

BigFlo

STP

Pump

UL approved

Explosion Proof

Junction Boxes

Class 1, Div's 1 & 2

Groups C, D

MI Cable

INCON

TS-LLD

A

Line Leak

Detector LSU

Diaphram

Valve

3/4 inch Conduit

& EYS Epoxy filled

" Y " Seal fittings

BigFlo

or

To / From

Pump Control

Relay Box &

3 Phase

Motor

Starter

Underground

Containment / Storage Tank

To Dispenser

Note: Use two conduits when conduit fill exceeds 40% full as specified by your National Electric Code.

Use recommended components or equivalent

To

Pump

Control

Relay

Box

From #

3 Phase

Motor

Starter

STP

Pump

Crouse-Hinds:

GUJC Explosionproof Junction Box

A 3/4 TO 1/2 inch

bushing is also

required for the

TS-LLD LSU fitting

A

A

Figure 2.2-15 INCON TS-LLD Installation at BigFlo Diaphragm Valve

Page 34

2.2 Page 2.2 - 16 TS-LLD INSTALLATION GUIDE

g

Reference Schematic Figures 2.3 - 11 & -12

❖

—

—

Electrical

Power Panel

Motor

Control

Panels

3 Phase

Starter

- or Variable

Frequency

NOTE:

An additional Single Phase 230 VAC

1)

Relay Control Box (panel), and two additional

wires for the LSU, are required for

Three Phase pump Applications.

Motor Control Panels may be either:

2)

Single Phase 230 VAC Relay Control Boxes,

- or - Single or Three Phase 230 VAC

Variable Frequency Controllers (VFCs).

Controller (VFC)

2

1

2

INCON TS-LLD Line Leak Detector

FE PETRO STP and IST (or STP-VS2 VFC)

Installation

TS-LLD CUs

(Control Units):

# 2 and # 1

TS-LLD LSU (#1)

(Leak Sensing Unit)

at STP housing

Existin

Conduit

(Pump 1)

Existing

Conduit

(Pump 2)

Submerged

Turbine

Pump (STP)

Dispenser

# A

TS-LLD LSU (#2)

(Leak Sensing Unit)

at IST pump housing

Epoxy

Filled

EYS

Seal

Fitting

Dispenser

# X

Explosionproof

Junction

Boxes

Tank - Pump # 1

( "Standard" STP Single Phase

Installation )

( FE PETRO Three Phase:

IST pump or STP Installation )

Figure 2.2-16 INCON TS-LLD Installation at FE PETRO STP or IST pumps

Single or Three Phase 240 VAC Applications

Tank - Pump # 2

Page 35

2.3 TS-LLD CU Installation & Wiring

Contents:

• Control Unit Installation Steps (Location, Product Configuration,

TS-2000 Configuration, Mounting the Control Unit, Relay Box &

Control Unit Wiring TABLE 2.3-1)

• Wiring Diagrams & Schematics (Pump Control Relay Box,

Single Phase 240 VAC, 3 Phase 240 VAC, 3 Phase RedJacket BigFlo,

3 Phase 240 VAC - FE Petro - STP & IST applications)

• Final Installation Steps

Control Unit ( CU ) Installation Steps

Follow the installation steps (below) and in the order that they appear:

NOTE

☞

DANGER

Electrical Shock Hazard. BEFORE installing, servicing or

working on this equipment, turn off all submersible pump power (240 VAC) and

pump relay coil / dispenser power at the electrical panel. Tag, secure / lockout

these circuit breakers in the off position to prevent accidental or unauthorized

circuit breaker closure. Failure to turn off power will result in severe injury or

death ! Check all wiring terminals for the absence of power before proceeding.

Note: Circuit breaker contact(s) can stick closed even when the circuit breaker

lever is in the off position.

You must know the dispense line number, product dispensed, and which pump

relay box (motor control box) is associated with this line.

1) Select an accessible mounting location for the control unit (see Figures 2.3-1 &

2.3-3), and remove the appropriate conduit knockouts. The CU is usually

mounted above the pump relay box (shown here)... other locations are possible.

1 485A

INTERNAL VIEW

UP

TB 2

TB 1

2 485B

3 DSY1

4 DSY2

5 ALAR M

1 110V

2 NEU

3 P-OUT

4 P-IN

SIG RTN

F1

KNOCKOUT S FOR ELECTRICAL FIT TINGS

TOP VIEW SHOWN

CU ENCLO SURE

BOTTOM VIEW

REM O V E

KNOCKOUT

FOR 1/2 INCH

ELECTRICAL

FITTING

AT BOT TOM

Figure 2.3-1 CU Internal & Bottom Views, and Relay Box Top View

Control Unit Installation Page 2.3 - 1 2.3

Page 36

BOX

UP

Printed Circuit

Board

(P C B o a rd )

TS-LLD CO NTRO L UNIT (CU) ENCLOSURE

1 485A

2 485B

TB 2

3 DSY1

4 DSY2

Donut shaped

Pic ku p Coil

TB 1

5 ALARM

1 110V

2 NEU

3 P-O UT

4 P-IN

SIG RTN

F1

COVER (SHIELD ON)

P L AS TIC S H IEL D SH O W N

MOUNTED OVER PC BOARD.

R E M O VE TH E S H IEL D TO SE T

THE JUMPER LINK POSITION

AS S H OW N BE L O W .

TH IS S H IE L D M U S T B E

IN PLACE BEFORE TH E

COVER IS RE-INSTALLED.

GREEN C ONNEC TOR (J1)

= 1/4 inch hole

lo c a tio n s fo r

w a ll mounting.

Alternate

Jum per

Link Position:

for Diesel, or

Fuel Oils

DIESEL

1

GAS

Standard

Jum per

L i n k P o si ti o n s:

for Gas olin e

DIESEL

J2

Standa rd TGI

Interface

Alternate

Jum per

Link Position:

for Gas olin e

DIESEL

for

TS-2000 Interface

Jumper Link

Side V ie w

Standa rd TGI

Interface

Alternate

Jum per

Link Position:

for Diesel, or

Fuel Oils

DIESEL

for

TS-2000 Interface

2

GAS

Figure 2.3-2 CU Component Location - Internal View

Control Unit Installation Steps (continued... )

GAS

J2

GAS

J2J2

3

GREEN C ONNEC TOR (J1)

J1

J2

DIESEL

C ontrol Unit cover

COVER (SHIELD OFF)

GAS

PC BOARD

S h ie ld

Bottom View

2) Product Configuration (Top Jumper Link) — required only for Diesel, Fuel Oil,

or Kerosene — skip this step if gasoline will be monitored. Remove the plastic

shield in back of the control unit cover. Pull up and reposition the top blue jumperlink at J2, so that it is installed over the left two pins. See Figure 2.3-2 and

reinstall the plastic shield when done.

3) INCON TS-2000 Configuration (Bottom Jumper Link) — this step is required

only when the TS-LLD will be wired to or interfaced to an INCON model TS-2000

ATG console. Remove the plastic shield from the control unit cover. At J2, pull up

and reposition the bottom jumper-link so that its installed over the left two pins.

See Figure 2.3-2 and the applicable INCON Application Note about wiring to

a TS-2000. Reinstall the plastic shield when done.

2.3 Page 2.3 - 2 TS-LLD INSTALLATION GUIDE

Page 37

(

p

p

p

(es)

g

NIPPLE

PUMP RELAY BOX

WARNING: DISCONNECT POWER

BEFORE REMOVING COVER

To 208/230 VAC

single phase

Power Source

electr ical power

anel) - circui t

breakers

90° FITTING

PUMP RELAY BOX

WARNING: DISCONNECT POWER

BEFORE REMOVING COVER

- - Al ter nate Mounti n

To Di s

Switch

enser

To Submersibl e

Pump explosion

roof Junction Box

WALL

MOU N TED

& EMT

PUMP RELAY BOX

WARNING: DISCONNECT POWER

BEFORE REMOVING COVER

- - Alternate Mounti ng B - -

WARNING Avoid electrical shock hazards. Disconnect all electrical power

source s BEFORE removing any enclosure cover !

NOTE: Ground equipment as required by your local and National Electric Codes.

A - -

Figure 2.3-3 TS-LLD CU Typical Mounting and Conduit Routing

NOTE

☞

4) Mount the CU to the pump relay box (see Figure 2.3-3 above for typical

mounting methods). You may mount the control unit to a wall through the two 1/4

inch mounting holes — use fasteners that are appropriate for the wall

construction. The centers of these holes are shown on the inside label of the

control unit. In addition, make sure that the UP arrow is pointing up as shown in

Figure 2.3-2.

Control Unit Installation Page 2.3 - 3 2.3

Page 38

Control Unit Installation Steps (continued...

}

5) Wiring at the Pump Control Relay Box:

a) Remove the wire from S2 to the relay coil

b) Remove the wire from M2 to the relay N.O. contact

c) Install the 1µ Farad “Line Filter” capacitor (INCON P/N 020-0028) between

terminals L1 and L2

d) Wire the CU to the pump relay box as described below TABLE 2.3-1 and as

shown in Figures 2.3-4 & 2.3-5. Strip 1/4 inch of insulation off each end (for

termination at the control unit and for the spade crimp connectors at the pump

relay box). Use connectors sized for 14 AWG wire.

NOTE

☞

Other pump relay boxes may have different terminations, and/or may

be wired differently than what is shown in this manual.

Typical Single Phase Wire Connection List TABLE 2.3 -1

PUMP RELAY BOX — to — TS-LLD CONTROL UNIT ( CU )

)

From

L2 BLK 14 AWG (supplied) 110 V (AC Line Power input) TB1 - 1

N WHT 14 AWG (supplied) Neu (Line Power Neutral) TB1 - 2

Relay Coil RED 14 AWG (supplied) P-OUT (Pump On - output signal, TB1 - 3

S2 BRN 14 AWG (supplied) P-IN (Pump On - input signal, TB1 - 4

M2

Relay N.O.

Ground Stud GRN 14 AWG (supplied) GND (Equipment Ground) Ground Stud

Wire

Color

ORG 14 AWG (supplied) 240 VAC (Pump Motor Power) { see below }

Wire Gauge Circuit (Description) To

110 V AC, to Pump Relay Coil)

{ Pump Motor Power - the 14 gauge

orange wire is pre-routed through the

N O T E -

N O T E -

pick-up coil at the Control Unit.

relay box

terminal, & wire the other end to the

pump relay N.O. contact (Figure 2.3-

4)... no wiring/connection at CU

{ Ground according to

, wire one end to the M2

your

National Electric Codes.

At the

Local and

- N O T E

- N O T E

NOTE

☞

Electricians: All AC wiring at the control unit (TB1-1 110V and TB1-4 P-IN)

must be in-phase and read 0 VAC in respect to each other and must read

from 110 to 130 VAC in respect to ground. Reference Figures 2.3-4 thru

2.3-10. These are “typical” diagrams and may not represent the actual wiring.

A 0 VAC potential must exist from TB1-1 to the hot side of dispenser on switch S1

( or to S2 ) with the dispense switch on. Take voltage readings at the pump relay

box. Use the leg that is in-phase with S1 ( L1 or L2 that reads 0 VAC) and wire it

to TB1-1 ( 110V ). For 3 phase applications — DO NOT use any leg that

reads more than 130 VAC to Ground

!

2.3 Page 2.3 - 4 TS-LLD INSTALLATION GUIDE

Page 39

g

g

g

No termination - wire runs through

the d onut-s hap e d P ic kup Coil

Figure 2.3-4 Typical Single Phase 240 VAC Pump Relay Box & Control Unit

RLY N.O. CONTACT (ORG)

Pickup Coil

M2 (ORG)

TS-LLD Control Unit

1 485A

2 485B

3 DSY1

4 DSY2

5 ALARM

F1

TB2

Control Unit Installation Page 2.3 - 5 2.3

Wiring Diagram

Remove wires

(shown as

dashed lines)

NO TE : Only the

new wirin

that's required

within the

Pump Relay

Box, is shown

in this d ia

ram .

Pump Relay Box

PUMP RELAY

- - COM - -

- - - COIL - - -

N.O.

S1 M2S2 M1 N L2L1

RLY COIL (RED)

GROUND

STUD/SCREW

L2 (BLK)

N (WHT)

1 110V

2 NEU

3 P-OUT

S2 (BRN)

GROUND

(GRN)

#8-32 Ground S tud

4 P-IN

SIG RTN

Install the 1uF Line Filter

Capacitor (INCON PN 020-0028)

Be tween L1 & L2

DANGER Electrical shock hazards!

Turn off and lock-out the submersible

pump power source (terminated at

L1 and L2), and the pump relay power

source (terminated at S2, from the

dispenser switch) BEFORE workin

on this equipment. Failure to turn off

these power sources will result in

severe injury or death.

TB1

Page 40

L1

Reference Site Layout

Figures 2.2 - 13 & 14

L2

From: 208/230 Volt, Single Phase,

Electrical Power Source

Neutral Bus

LINE

LOAD

COM

N.O.

L1

COM

N.O.

M1

Remove

Original

Wiring

BLK

TS-LLD Leak

Sensing Unit

(Installed at

the pump

housing.)

L2

M2

BLK

ON

OFF

Line Filter Cap

(See Note 1)

Dispenser

Switch

(or switches)

GROUND

208/230 Volt, Single Phase,

Electrical Power Panel

3 Pole Switched-Neutral

Circuit Breaker

N

COIL

S2S1

115 V.

No connection

at CU -- wire is

run through the

donut-shaped

Pickup Coil

RLY N.O. Contact

M2 (ORG)

L2 (BLK)

N (WHT)

RLY COIL (RED)

S2 (BRN)

GROUND (GRN)

Remove

Original

Wiring

208/230 Volt, Single Phase Submersible Pump Motor

Relay Box

TS-LLD Control Unit

(use bottom, 1/2 inch

conduit knockout)

Pickup Coil

F1

#8-32 Ground Stud

1 485A

2 485B

3 DSY1

4 DSY2

5 ALARM

1 110V

2 NEU

3 P-OUT

4 P-IN

SIG RTN

TB2

TB1

NOTES:

Single Phase

OL

DANGER ELECTRICAL SHOCK HAZARDS. TURN OFF AND LOCK-OUT THE

SUBMERSIBLE PUMP POWER SOURCE, AND THE PUMP RELAY POWER SOURCE

AT THE CIRCUIT BREAKER - BEFORE - WORKING ON THIS EQUIPMENT. FAILURE

TO TURN OFF THESE POWER SOURCES WILL RESULT IN SEVERE INJURY OR DEATH.

Submersible

Pump Motor

with

Thermal

Overload

MI Cable

Adapter

(cover) for

Explosion

Proof

junction box

1) Install the 1uF Line Filter Capacitor (INCON

PN 020-0028) between input AC line terminals at

the Relay Box.

2) The TS-LLD is installed at the submersible pump

housing (see Chapter 2.2 for details).

3) Follow your local and National Electrical Codes

for electrical grounding requirements.

4) If three phase is available, see Figure 2.3-6.

2.3 Page 2.3 - 6 TS-LLD INSTALLATION GUIDE

Figure 2.3-5 Typical Single Phase 240 VAC Pump & Control Unit

Interface Schematic

Page 41

g

g

1 110V

2 NEU

TB1

4 P-IN

3 P-OUT

TB2

1 485A

3 DSY1

2 485B

5 ALARM

4 DSY2

F1

Power Source = L1

TS-LLD Control Unit (CU)

ram

SIG RTN

Dia

NOTES

GND

No connection.

Wire is routed

through the

donut-shaped

Pickup Coil

Pickup Coil

RLY N.O. (ORG)

GND

N

Neutral (WHT)

M1 (ORG)

L1 Line (BLK)

RLY COIL (RED)

Dispense ( BRN)

Pump On Sig.

1) The Leak Sensing Unit (LSU) is installed at STP # 1

2) In line check valves are required at the output of

each RedJacket Submerged Turbine Pump

3) All ancillary pumps must be controlled / enabled

by the Aux. Relay Box as shown.

4) Only STP #1 Runs during line leak tests

DANGER ELECTRICAL SHOCK HAZARDS. TURN OFF AND LOCK-OUT THE

SUBMERSIBLE PUMP POWER SOURCE AT THE CIRCUIT BREAKER - BEFORE -

WORKING ON THIS EQUIPMENT. FAILURE TO TURN OFF PUMP & DISPENSER

POWER SOURCE WILL RESULT IN SEVERE INJURY OR DEATH.

GND

N

M2

L1 L2 S2 S1

M1

L2 S2 S1

L1

Aux. Relay Box

N

GND

Dispense

Switch(es)

M2

M1

Relay Box # 2

Pump Control

GND

(dashed lines)

N

Remove Wires

Conduit

to pump

Junction

Box

STP # 2 Motor

OL

INCON TS-LLD - 1 LSU Multiple Pumps & Manifolded Lines - Wirin

Electrical

Power

Panel

L1 L2

L1 L2 S1S2

P/N

020-0028

Cap at L1 and L2

M1 M2

Install Line Filter

STP #1 Motor & LSU

TS-LLD LSU

at Leak Detection Port:

STP # 1 Pump Housing

(remove dashed wires)

Relay Box # 1

Pump Control

Figure 2.3-6 Single Phase 240 VAC Multiple Pump & Manifolded Line with Single LSU & CU

Interface Schematic

Control Unit Installation Page 2.3 - 7 2.3

Page 42

TS-LLD Line Leak Detector —

g

g

g

Mechanical Blender Interface

When connecting a TS-LLD line leak detector to systems with mechanical

blenders, tie the: premium, all mid-grades, and regular dispenser switch signals

together (electric blenders can be wired normally). Wire both premium and

regular TS-LLD Control Units at TB1-4 (P-IN). See the typical (partial) wiring

diagram below. Because the mid-grades are blended mixtures of the premium

and regular octanes, any product dispense will abort leak tests at the premium

and regular Control Units.

CAUTION

The

dispense on

signals must be

in phase

to avoid electrical shorts

and damage. Verify that all dispenser switch signals are in phase before you tie

them together (in phase = 0 Volts AC in respect to each other and 120 Volts AC in

respect to Neutral or ground). Note that both pumps will be active on any

dispense.

F1

F1

1 485A

2 485B

3 DSY1

4 DSY2

5 ALARM

1 110V

2 NEU

SIG RTN

1 485A

2 485B

3 DSY1

4 DSY2

5 ALARM

1 110V

2 NEU

SIG RTN

S1

C

N.O.

PREMIUM

Dispense

Switch (es)

S1

C

N.O.

MID-GRADE

Dispense

Switch (es)

S1

C

N.O.

REGULAR

Dispense

Switch (es)

Dispense

(on) si

(on) signal

(on) si

nal

Dispense

Dispense

nal

TB2 -

PREMIUM

TS-LLD

Control Unit

TO: PREMIUM MOTOR

START RELAY COIL

Tie

to

ether

TB2 -

REGULAR

TS-LLD

Control Unit

TO: REGULAR MOTOR

START RELAY COIL

TB1 -

TB1 -

Figure 2.3-7 Blended Dispensers to TS-LLD Control Unit – Interface Schematic

2.3 Page 2.3 - 8 TS-LLD INSTALLATION GUIDE

Page 43

L1 ( or L3)

Reference Site Layout

Figures 2.2 - 13 & 14

See

Note

L2

From: 208/230 Volt, Three Phase, Electrical Power Source,

utilizing two lines to power a Single Phase load.

(See Note 1)

1

Neutral Bus

LINE

LOAD

COM

N.O.

See

Note

1

L1

(or L3)

COM

N.O.

Remove

Original

Wiring

BLK

TS-LLD Leak

Sensing Unit

(Installed at

the pump

housing.)

L2

M2M1

BLK

ON

OFF

Line Filter Cap

(See Note 2)

Dispenser

Switch

(or switches)

GROUND

OL

MI Cable

Adapter

(cover) for

Explosion

Proof

junction box

DANGER ELECTRICAL SHOCK HAZARDS. TURN OFF AND LOCK-OUT THE

SUBMERSIBLE PUMP POWER SOURCE, AND THE PUMP RELAY POWER SOURCE

AT THE CIRCUIT BREAKER - BEFORE - WORKING ON THIS EQUIPMENT. FAILURE

TO TURN OFF THESE POWER SOURCES WILL RESULT IN SEVERE INJURY OR DEATH.

208/230 Volt, Single Phase,

Electrical Power Panel

3 Pole Switched-Neutral

Circuit Breaker

N

COIL

Remove

Original

Wiring

Single Phase

Submersible

Pump Motor

with

Thermal

Overload

115 V.

S2S1

NOTES:

1) Only use phases L1 & L2, or L3 & L2. DO NOT use

phase L1 & L3.

2) Install the 1uF Line Filter Capacitor (INCON PN 020-0028)

between AC input line terminals at the Relay Box.

3) The TS-LLD is installed at the submersible pump housing

(see Chapter 2.2 for details).

4) Follow your local and National Electrical Codes for

electrical grounding requirements.

5) 230 VAC must not enter the Control Unit! All Control Unit

AC wiring must be 110 volts (110V power = TB 1-1, dispenser

switch [ S2 ] on signal = TB 1-4, and pickup coil [ M2 ] sense

lead all must be derived from the same phase [ L2 ] ).

208/230 Volt, Single Phase Submersible Pump Motor

Relay Box

No connection

at CU -- wire is

run through the

donut-shaped

Pickup Coil

RLY N.O. Contact

Pickup Coil

M2 (ORG)

L2 (BLK)

N (WHT)

RLY COIL (RED)

S2 (BRN)

GROUND (GRN)

TS-LLD Control Unit

(use bottom, 1/2 inch

conduit knockout)

1 485A

2 485B

3 DSY1

4 DSY2

5 ALARM

F1

1 110V

2 NEU

3 P-OUT

4 P-IN

SIG RTN

#8-32 Ground Stud

TB2

TB1