Page 1

Data Transfer Unit

Dispenser Retrofi t Manual

Model TS-DTU

Franklin Fueling Systems • 3760 Marsh Rd. • Madison, WI 53718 USA

Tel: +1 608 838 8786 • 800 225 9787 • Fax: +1 608 838 6433 • www.franklinfueling.com

Page 2

Important Safety Messages

Franklin Fueling Systems (FFS)/Healy equipment is designed to be installed in association with volatile hydrocarbon

liquids such as gasoline and diesel fuel. Installing or working on this equipment means working in an environment in which

these highly fl ammable liquids may be present. Working in such a hazardous environment presents a risk of severe injury

or death if these instructions and standard industry practices are not followed. Read and follow all instructions thoroughly

before installing or working on this, or any other related, equipment.

As you read this guide, please be aware of the following symbols and their meanings:

Warning

Caution

Warning

Warning

Warning

This symbol identifi es a warning. A warning sign will appear in the text of this document when a potentially

hazardous situation may arise if the instructions that follow are not adhered to closely . A potentially hazardous

situation may involve the possibility of severe bodily harm or even death.

This is a caution symbol. A caution sign will appear in the text of this document when a potentially hazardous

environmental situation may arise if the instructions that follow are not adhered to closely. A potentially

hazardous environmental situation may involve the leakage of fuel from equipment that could severely harm

the environment.

Follow all applicable codes governing the installation and servicing of this product and the

entire system. Always lock out and tag electrical circuit breakers while installing or servicing

this equipment and any related equipment. A potentially lethal electrical shock hazard and the

possibility of an explosion or fi re from a spark can result if the electrical circuit breakers are

accidentally turned on during installation or servicing. Please refer to the Installation and Owner’s

Manual for this equipment, and the appropriate documentation for any other related equipment, for

complete installation and safety information.

Follow all federal, state and local laws governing the installation of this product and its associated

systems. When no other regulations apply, follow NFPA codes 30A and 70 from the National Fire

Protection Association. Failure to follow these codes could result in severe injury, death, serious

property damage and/or environmental contamination.

Always secure the work area from moving vehicles. The equipment in this manual is usually

mounted underground, so reduced visibility puts service personnel working on this equipment in

danger from moving vehicles entering the work area. To help eliminate these unsafe conditions,

secure the area by using a service truck to block access to the work environment, or by using any

other reasonable means available to ensure the safety of service personnel.

Warning

Important: All electrical and hydraulic plumbing fi ttings referred to in these instructions must be UL “listed” or

Important: The TS-DTU will increase the current draw of the dispenser by 0.25 amps. Use the label supplied to note this

Use circuit breakers for multiple disconnect to turn off power and prevent feedback from other

dispensers.

“recognized” for the purpose.

change.

2

Page 3

Contents

Important Safety Messages ............................................................................................2

Purpose: .................................................................................................................................4

Specifi cations: .........................................................................................................................5

Tools Required .......................................................................................................................6

Installing the TS-DTU in the Dispenser .........................................................................6

Mounting the TS-DTU module ........................................................................................6

Intrinsically Safe Wiring ..................................................................................................6

Connecting the Vapor Flow Meter and Vapor Pressure Sensor..................................7

TS-VFM Splice ..............................................................................................................................7

TS-VPS Splice ...............................................................................................................................7

Dispenser Specifi c Installation ......................................................................................7

Gilbarco Advantage Narrow Frame ........................................................................................8

Gilbarco Encore 300 and 500 Series ....................................................................................12

Tokheim Premier B ...............................................................................................................16

Tokheim Premier C ...............................................................................................................20

Wayne Vista 1 .......................................................................................................................28

Wayne Vista 2 .......................................................................................................................32

Wayne Vista 3 .......................................................................................................................36

3

Page 4

Purpose:

This procedure describes the tools, methods and skill levels required to install an INCON/Franklin Fueling Systems model

TS-DTU, Data Transfer Unit in UL Approved Dispensers. Each installation of a TS-DTU in a dispenser requires that a TSDRK, dispenser installation kit, be used. The TS-DRK is ordered by specifi c dispenser types. Please refer to the Table

1 for the correct TS-DRK model. Only INCON/Franklin Fueling Systems trained and certifi ed contractors will be able to

perform these retrofi ts or warranty will be void. The installer shall be a skilled petroleum technician and thoroughly familiar

with the requirements of State, Federal and local codes for installation and repair of gasoline dispensing equipment. Also,

they shall be aware of all the necessary safety precautions and site safety requirements to assure a safe and trouble free

installation. NOTE: All electrical fi ttings referred to in these instructions must be UL “listed” or “recognized” for the purpose.

Important Safety Messages

Before installing the equipment, read, understand and follow:

- The National Electrical Code (NFPA 70)

- The Automotive and Marine Service Code (NFPA 30A)

- Any national, state and local codes that may apply.

The failure to install the equipment in accordance with NFPA 30A and 70 may adversely affect the safe use and operation

of the system. Accurate, sound installations reduce service calls: Use experienced, licensed contractors that practice

accurate, safe installation techniques. Careful installation provides a sound troubleshooting framework for fi eld repairs and

can eliminate potential problems.

1. Read all instructions before beginning.

2. Follow all safety precautions:

• Barricade the area.

• Do not allow vehicles or unauthorized people in the area.

• Do not smoke or allow open fl ames in the area.

• Do not use power tools in the work area.

• Wear eye protection during installation.

3. Use circuit breaker for multiple disconnects to turn off power and prevent feedback from other dispensers.

4 General Information

Page 5

Specifi cations:

Power 100-240 VAC, 60 Hz, 0.25 A

Parts List

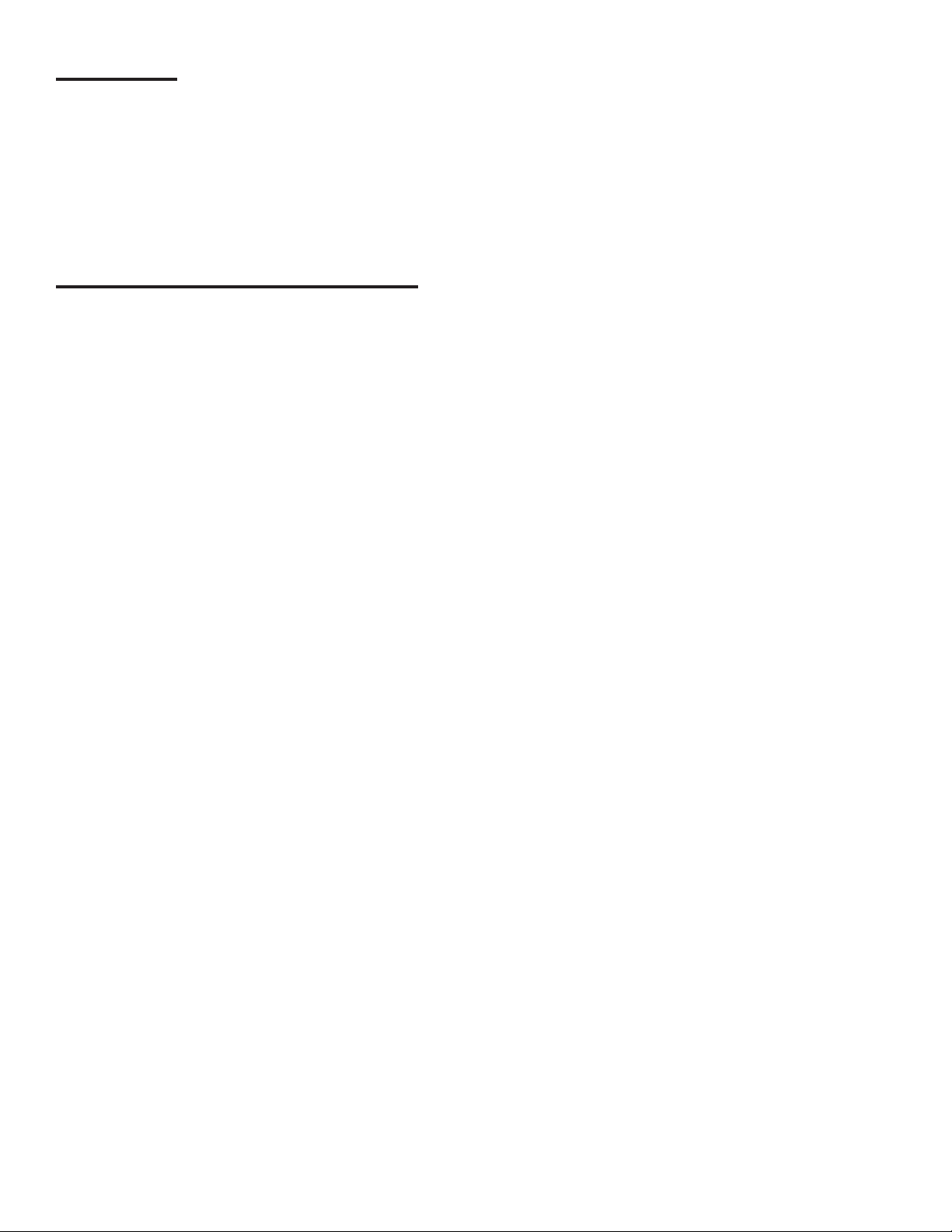

The TS-DTU and TS-DRK installation kit consists of the

following major components. Make sure you have these

parts before installing the DTU.

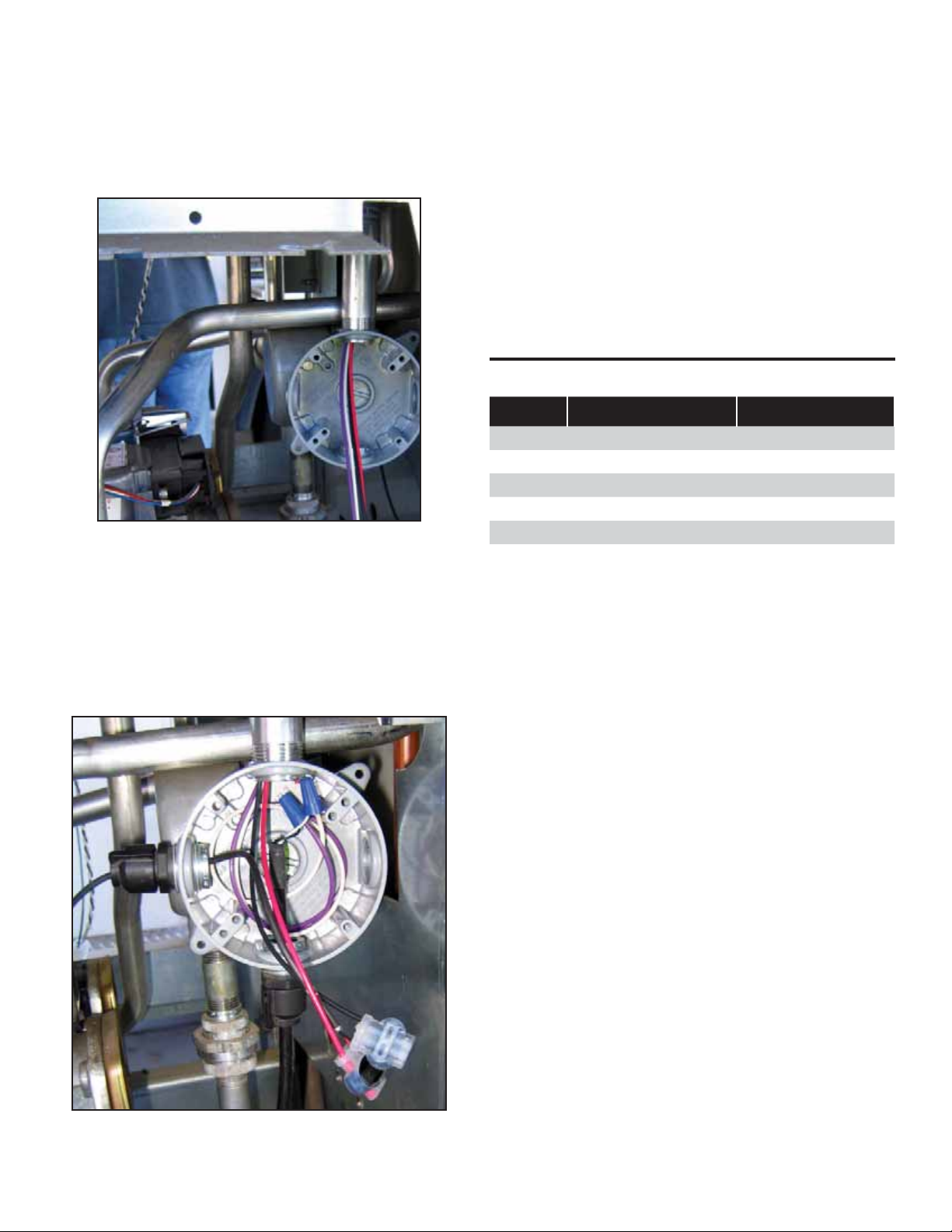

Figure 3: 131610 Potted Nipple Assembly

Wayne Dispenser

Power Harness

600-0166

Figure 1: TS-DTU / P Data Transfer Unit

• TS-DTU

• Mounting Plate

• Fasteners (5 screws, nuts, and washers)

Gilbarco Encore

Dispenser Power

Harness 600-0167

Gilbarco Advantage

Dispenser Power

Harness 600-0168

Tokheim Dispenser

Power Harness

600-0165

Figure 2: 020-1513 IS Conduit Kit

• Straight Conduit Fitting

• 90degree Conduit Fitting

• Conduit Reducer

• Flexible Conduit (1/2”PVC)

• Two splice connectors

Figure 4: Power Harness Kits

5General Information

Page 6

General Instructions

Tools Required

(This applies to all dispenser installation procedures)

Assorted Open End Wrenches 1/4” through 3/4”

Wire Cutters/Strippers 16 AWG to 26 AWG

3/8” Drill Assembly

Assorted Drill Bits 1/16” through 7/16”

Assorted Screwdrivers (Flat blade-one must be 1/8” wide)

3/4" Conduit Hole Punch (For potted nipple assembly)

Electrical Multi-meter

12” adjustable Wrench

18” Channel lock Pliers

Attaching the Mounting Bracket

For each dispenser installation, the mounting bracket will

need to be attached to the back side of the TS-DTU. Refer

to each dispenser installation instruction as it will specify

the correct orientation of the bracket

1. Remove the TS-DTU enclosure cover and set it

aside.

2. Find the correct orientation for the mounting

bracket in the dispenser-specifi c instructions.

3. Find two screws, washers, and star nuts from the

TS-DTU/P kit. Insert the two screws into the two

mounting holes of the front face of the TS-DTU

enclosure.

4. Put the mounting bracket on the side of the DTU

enclosure and install a washer and star nut.

Figure 6: Mounting Bracket On Bottom Of Unit

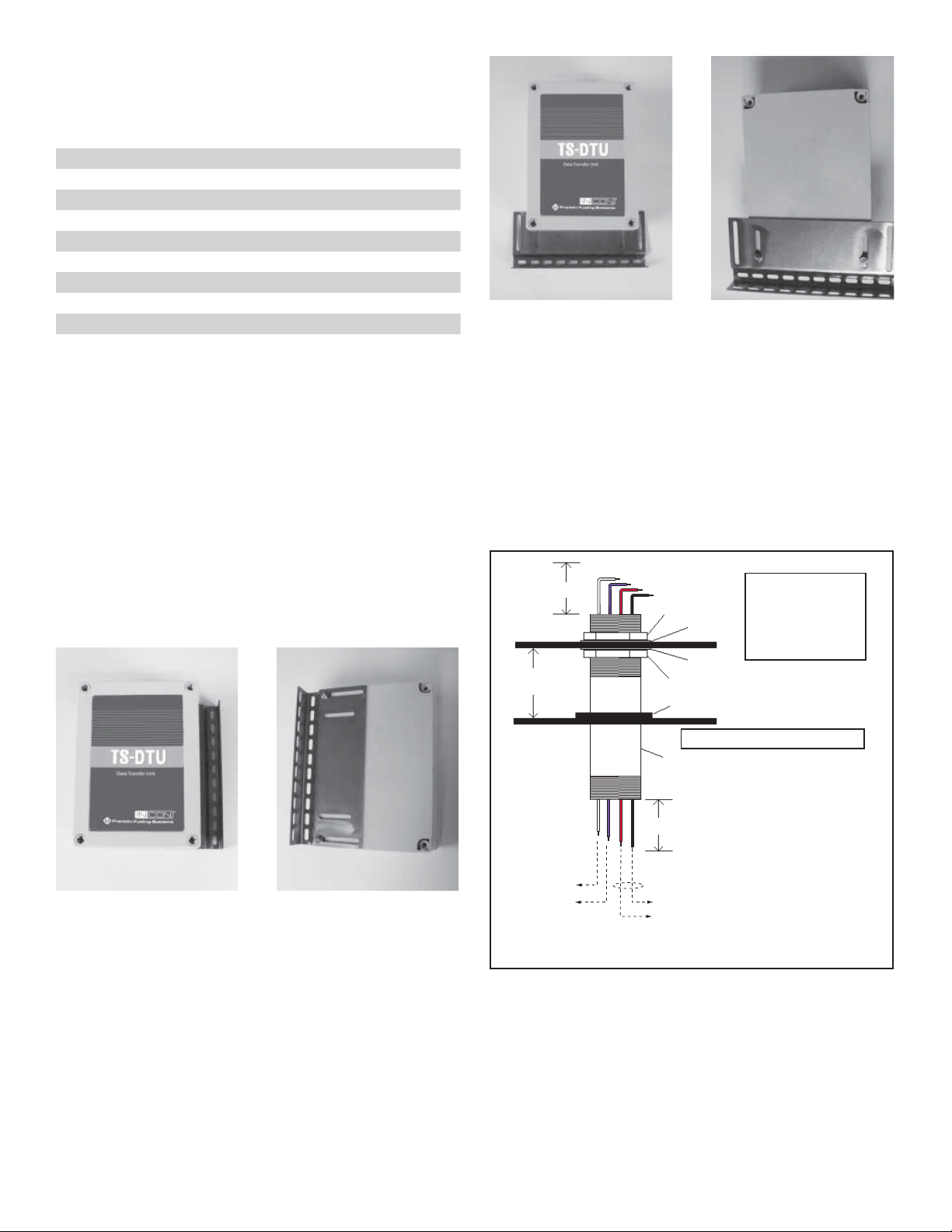

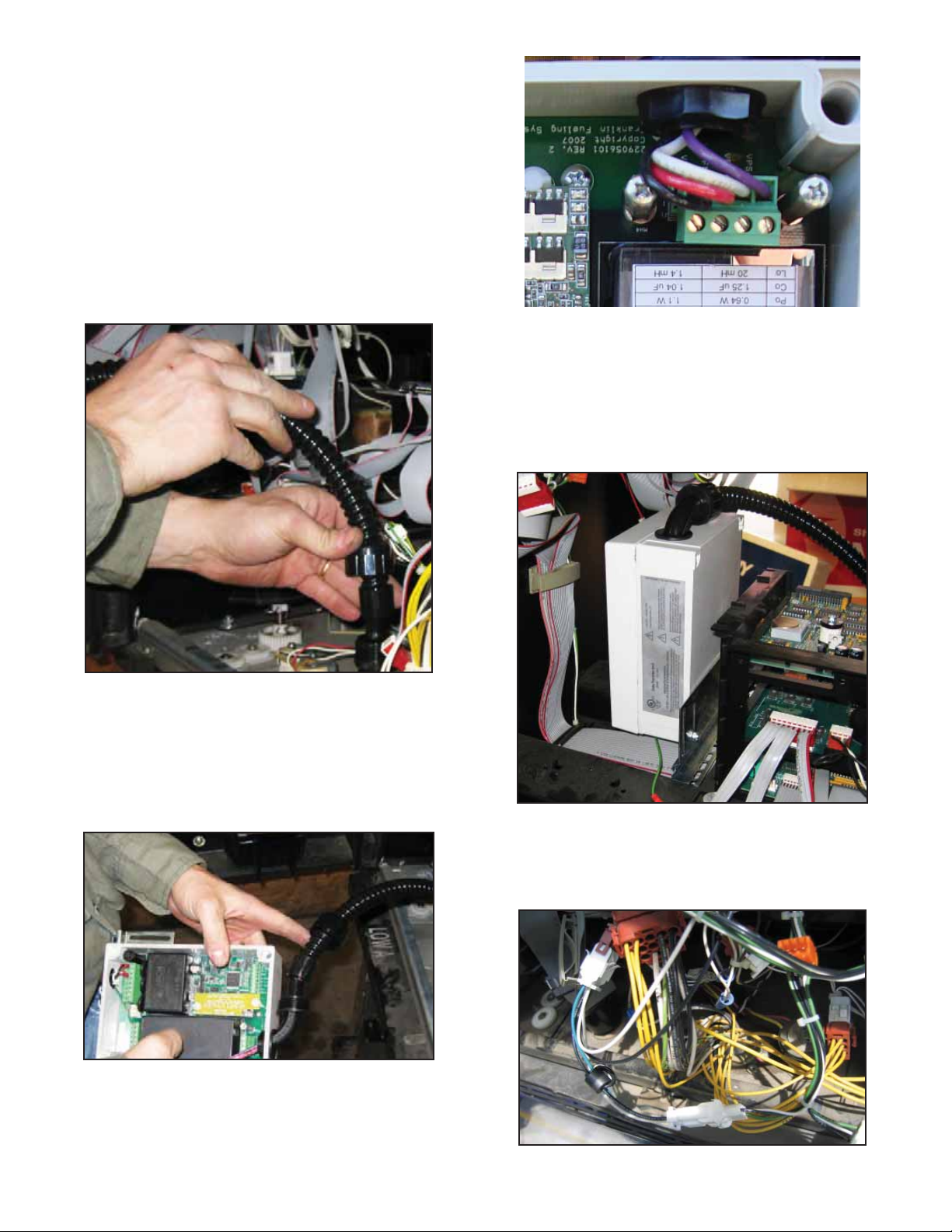

Intrinsically Safe Wiring

The Intrinsically safe wiring is the same for all type of

dispensers. The wires from the top end of a potted nipple

should be connected to the TS-DTU module and from the

bottom end to the TS-VFM and TS-VPS. These wires

connect intrinsically safe devices (TS-VFM and TS-VPS) to

the associated apparatus (TS-DTU) and therefore must be

protected in non-hazardous area where TS-DTU is

located.

36"

Free space

between decks

To TS-DTU

1

2

2

1

3

Wire Color Codes

Red......... VFM+

Black....... VFM–

Purple ..... VPS +

White ...... VPS–

Some dispensers have two decks

between hydraulics and electronics

Wires from

potted conduit to

sensors

Figure 5: Mounting Bracket On Side Of Unit

Follow the dispenser-specifi c instructions for the

installation location and procedure of the potted nipple on

the dispenser vapor barrier.

6 General Information

List of Items Included with Assembly

1. Hex jam nut (2 required)

4

2. Metal washer (2 required)

3. Rubber washer (1 required if

dispenser has two decks between

hydraulic & electronic areas)

4. 3/4" x 6" potted conduit

42"

(36" of wires at module end,

42" of wires vapor signals)

VPS

Shielded cable

VFM

Figure 7: Potted Nipple Assembly

Page 7

Connecting the Vapor Flow Meter and Vapor

Pressure Sensor

The connection of potted nipple to the TS-VFM and TSVPS in the lower section of the dispenser is the same for all

dispensers. For ease of installation, a junction box may be

connected directly to the bottom of the potted nipple. Note,

the potted nipple is a ¾” conduit thread, see Figure 8.

Figure 8: Junction Box Connected to Potted Nipple

TS-VFM Splice

1. Find two-splice connectors in the IS Wiring Kit, 020-

1513.

2. Make the following splice connections:

• Red wire of potted nipped to Red wire of TS-VFM

cable.

• Black wire of potted nipple to Black wire of TS-VFM

cable.

TS-VPS Splice

1. Find two wire nuts in the Power Harness Kit, 600016X.

2. Make the following splice connections:

• Purple wire of potted nipped to Black wire of TSVPS cable.

• White wire of potted nipple to White wire of TS-VPS

cable (Refer to Figure 9).

Dispenser Specifi c Installation

This manual covers the following types of dispensers:

Make Type Installation Kit

Gilbarco Advantage TS-DRK/A

Encore 300 & 500 TS-DRK/E

Tokheim Premier B TS-DRK/T

Tokheim Premier C TS-DRK/T

Wayne Ovation TS-DRK/W

Vista 1V, 2V, 3V TS-DRK/W

Table 1: Dispenser Kits

Figure 9: VFM and VPS Spices

7General Information

Page 8

Gilbarco Advantage Narrow Frame

This section illustrates the basic components needed

to retrofi t a TS-DTU module into an existing or UL

remanufactured dispenser. This system can be installed

in any “Non-Vapor or Vapor Ready” dispenser including

dispensers with existing “Balance” or “VacAssist” piping.

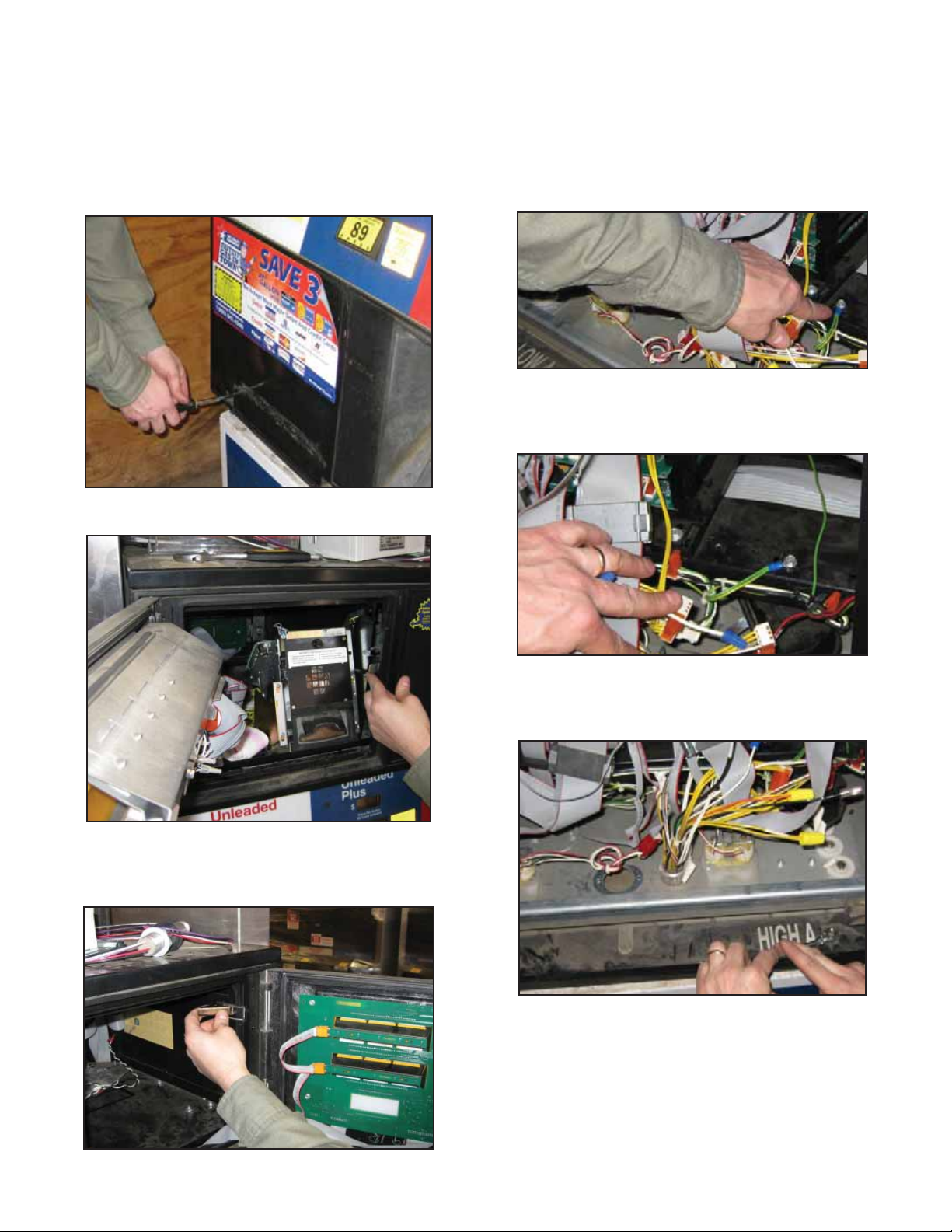

1. Loosen three bolts at the bottom of each main

door assembly.

Figure 1: Loosen Bolts

2. Unlock the left options door on each main door.

4. Disengage two latches, one in each right and left

options door openings, and open main door on

both sides of dispenser.

5. Move to side A of dispenser. Side A can be

determined by the side that the credit card reader

(crind) tray pops out.

6. Find ground wire mounting location shown and

remove screw and star washer.

Figure 4: Find Ground Wire

7. Reinstall ground with ring terminal screw and star

washer in alternate location shown. Tighten screw

securely.

Figure 2: Open Options Door

3. Lift latch on right side of left options door opening

to release right options door on each side of the

dispenser.

Figure 5: Reinstalled Ground Wire

8. Find shield covering opening in air gap and

remove two bolts from shield. Retain shield and

bolts for future reassembly.

Figure 6: Air Gap Shield

Figure 3: Release Options Door

8

Gilbarco Advantage Narrow Frame - DTU Installation

Page 9

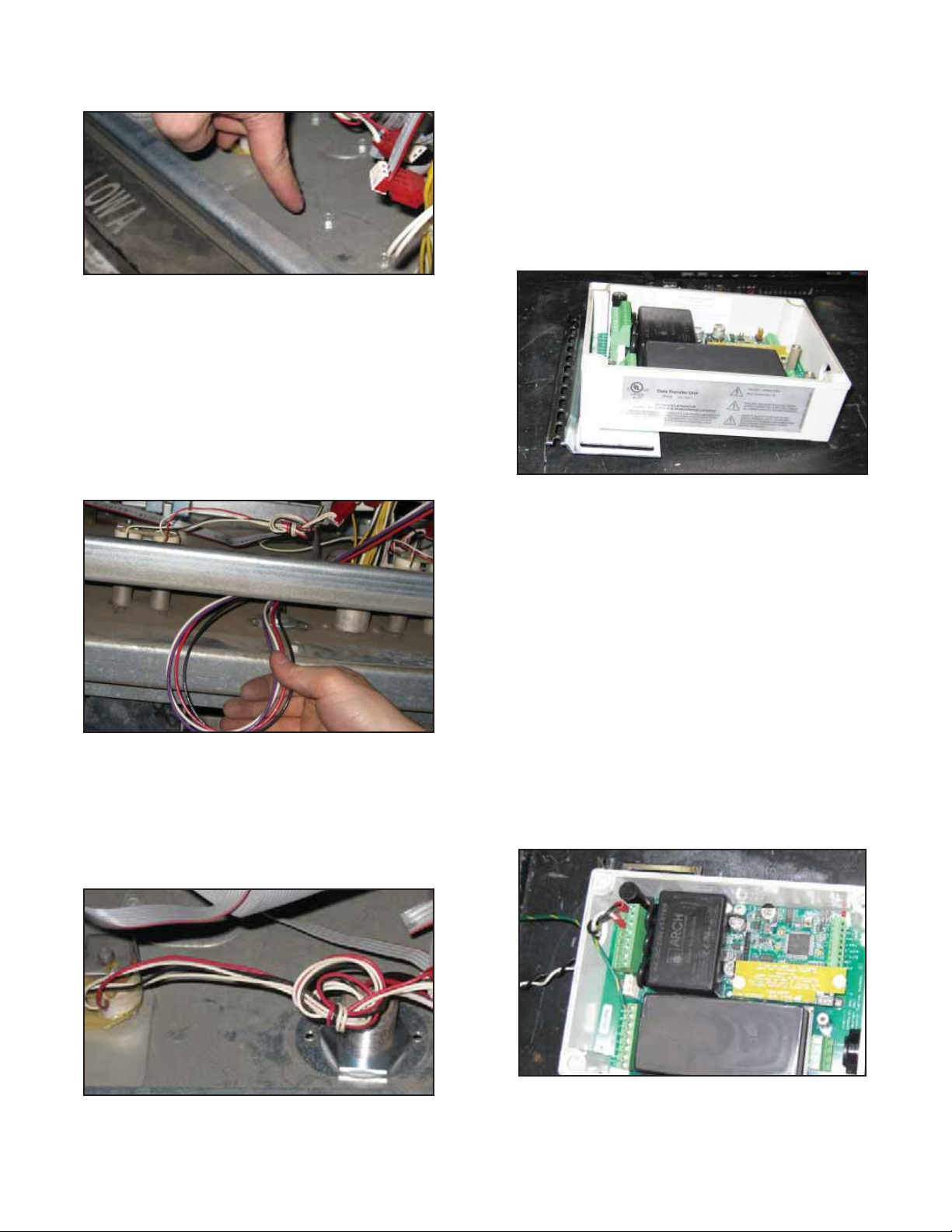

9. Remove two screws from upper air gap knock-out

cover and remove. Discard cover but keep screws

for reuse.

Figure 7: Remove Screws

10. Remove two screws from lower air gap knockout

cover and remove. Discard cover and screws.

11. Remove lower door from side A of dispenser using

key lock on right side of door. Save door for future

reassembly

12. Find potted nipple assembly, 131610. Remove all

washers and nuts and set aside.

13. Pull wires from top side of potted nipple assembly

through dispenser hydraulics enclosure up through

opening in lower air gap knock-out.

Figure 8: Potted Conduit wires

14. Attach one nut and washer onto the potted nipple

assembly before pushing wires up through electrical

enclosure.

15. Pull wires and then nipple assembly up into electronics

enclosure. Fit washer and nut over wires and tighten

nut securely in place, as shown in Figure 9.

17. Reinstall the screws previously retain in step 9.

These screws seal the holes left behind by the air

gap knockout.

18. Find TS-DTU / P kit and remove brackets, DTU,

and hardware from box.

19. Remove cover from DTU.

20. Install mounting bracket to DTU with two screws,

nuts and washers from hardware provided with

DTU as described in the General Information

section. Ensure that bracket is installed on correct

side as shown.

Figure 10: Mounting Bracket on DTU

21. Remove two screws from IS wiring cover inside

the DTU and remove cover. Retain cover and

screws for reassembly

22. Find the 90 degree fi tting from IS wiring kit,

020-1513. Remove nut from 90 degree fi tting.

Attach fi tting to opening nearest IS wiring terminal

block of DTU using nut previously removed.

23. Find power harness kit part number 600-0168.

Find the Gilbarco Advantage power harness and

ground with ring terminal as shown in fi gure 4 of

the Parts List.

24. Put wiring harness end with crimp connector

through opening in DTU nearest terminal block

J1. Attach white lead to terminal block position

labeled NEUTRAL and black lead to terminal

block position labeled L1 on terminal block J1 of

DTU. Attach ground wire to terminal block position

labeled GND of J2 on DTU.

Figure 9: Potted Nipple Installed

16. Reattach air gap shield using screws previously

retained in step 8.

Gilbarco Advantage Narrow Frame - DTU Installation

Figure 11: DTU Power Connections

25. Move DTU assembly to dispenser nearest

intended mounting location

9

Page 10

26. Find reducer from IS wiring kit, 020-1513. From

electrical enclosure, pull wires from potted nipple

assembly through 3/4” opening of reducer and

attach reducer to the top of the nipple assembly.

27. Find straight conduit fi tting from IS wiring kit,

020-1513. From electrical enclosure, pull wires

from the potted nipple assembly through opening

of straight conduit fi tting. Attach straight conduit

fi tting onto the reducer.

28. Remove nut and bushing from straight conduit

fi tting. Place bushing on one end of fl exible

conduit. Push wires from nipple assembly through

bushing / fl exible conduit and secure fl exible

conduit to straight conduit fi tting using nut.

Figure 14: Attach Wiring to DTU

31. Reinstall barrier cover using screws that were

removed in step 23.

32. Replace DTU cover.

33. Install the DTU assembly on the horizontal cross

bracket as shown in Figure 15. Use the two

screws, washers, and nuts as supplied in the TSDTU/P hardware kit.

Figure 12: Attaching Flexible Conduit

29. Remove nut and bushing from 90 degree conduit

fi tting and push fl exible conduit through nut. Put

bushing on unattached end of fl exible conduit.

Push wires from fl exible conduit through the 90

degree conduit fi tting and pull excess wire into

DTU. Attach fl exible conduit to 90-degree fi tting

with nut.

Figure 13: Attach Flexible Conduit to DTU

30. Cut excess wire inside DTU allowing a length of 2”

for terminal block wiring. Strip insulation 3/8” from

ends of wire. Attach wires to DTU terminal block

as follows (DIAGRAM)

10

Gilbarco Advantage Narrow Frame - DTU Installation

Figure 15: Attach DTU Mounting Bracket

34. Find input connector on AC distribution wiring

harness and disconnect.

35. Insert new power harness with ferrites between

input power and AC distribution harness.

Figure 16: Connecting to Dispenser Power

Page 11

36. Attach ring terminal of DTU ground wire to

dispenser with bolt, nut and star washer.

Figure 17: Attach Ground Wire

37. Use wire-wrap ties to attach excess wires from AC

wiring harness together.

38. Use wire-wrap ties to attach excess wire from DTU

power harness and ground away from door and

gears.

39. Find cable assembly extending from TS-VFM

vapor meter in dispenser hydraulics enclosure.

40. Find wiring from previously installed potted nipple

assembly inside hydraulics enclosure.

41. Find two wire-splice connector kits. Inside hydraulics

enclosure, connect black wire from potted nipple

assembly to black wire from TS-VFM fl ow meter by

placing each lead into an opening in the wire splice

connector and push fi tting closed to lock.

42. Find cable extending from TS-VPS inside

hydraulics enclosure. Cut yellow and blue leads

from end of cable.

43. Find purple and white wires from potted nipple

assembly in hydraulics enclosure. Strip wiring

3

insulation

/8" from end of wire.

44. Using wire nuts provided with kit, attach purple

wire from potted nipple assembly to black wire

of TS-VPS and white wire from potted nipple

assembly to white wire of the TS-VPS.

45. Close main doors on Side A and Side B.

46. Engage main door latches located in both option

openings for each side. Refer to fi gure 2 & 3.

47. Tighten the three bolts at the bottom of each main

door assembly. See fi gure 1.

48. Reinstall side A lower dispenser door. Firmly

attach using key lock on right side of door.

Gilbarco Advantage Narrow Frame - DTU Installation

11

Page 12

Gilbarco Encore 300 and 500 Series

This section illustrates the basic components needed

to retrofi t a TS-DTU module into an existing dispenser.

This system can be installed in any “Non-Vapor or Vapor

Ready” dispenser including dispensers with existing

“Balance” or “VacAssist” piping.

1. Unlock interface doors on both sides of dispenser.

Open two latches on left side of interface door and

open main doors.

Figure 1: Open Doors

2. Find TS-DTU/P from kit and remove brackets,

DTU, and hardware from box.

3. Remove cover from DTU.

4. Install mounting bracket to DTU using two screws,

nuts and washers from hardware provided with

DTU as described in the General Information

section. Make sure the bracket is installed on

correct side as shown.

Figure 3: Mount DTU in Dispenser

6. Find power harness kit part number, 600-0167. Find

the Gilbarco power harness as shown in fi gure 4 of

the Parts List. Remove tie-wraps and uncoil. The

Gilbarco cable will have green ground wire.

7. Inside dispenser, fi nd the incoming power

connection. Attach the new power extension

cable between the original dispenser power

connectors. Notice that the wire colors

match up with the original connection.

Figure 2: Install Mounting Bracket

5. Install the DTU assembly on the horizontal

cross bracket as shown in Figure 3. Use

the two screws, washers, and nuts as

supplied in the TS-DTU/P hardware kit.

12

Figure 4: Power Distribution Wires

8. Carefully route DTU power wiring harness to DTU.

Figure 5: Power Wiring

9. Route crimp terminal end of harness through

opening in the bottom of the DTU and connect

white lead to terminal block position labeled

NEUTRAL and black lead to terminal block

position labeled L1 on terminal block J1 of DTU.

Gilbarco Encore 300 and 500 - DTU Installation

Page 13

Figure 6: Connect Power Leads

10. Find ground wire from power harness kit

600-0165. Remove ties and uncoil. From end

without ring coil, strip insulation 3/8” from end of

wire.

11. Route ground wire end with out ring terminal

through DTU and secure to terminal block.

12. Attach ring terminal of ground wire to dispenser

bracket using screw and nut as shown. Coil

excess wiring and tie it to ensure that it does not

interfere with door closing.

Figure 7: Attach Ground Wire

13. Find side of dispenser opposite of power supply.

Remove lower door on that side of dispenser by

loosening two screws.

14. Remove lower doors on both sides of dispensers.

Set doors aside and save for later assembly

15. Find knockout panel on the bottom of the electrical

enclosure closest to the DTU (See Figure 7).

16. Using screwdriver, remove one knockout plug from

knockout panel.

17. Find potted nipple assembly, 131610.

Undo wire ties and uncoil wiring.

18. Remove top nut from potted nipple and remove

one washer by pulling over wire leads. Keep nut

and washer for future use.

19. Pull wires from top of potted nipple assembly up

through the opening created in step 16 from the

hydraulics enclosure to the electrical enclosure.

Ensure that wiring is not damaged by sharp edges.

Figure 8: Pulling Wires Through Opening

20. Pull top of potted nipple assembly through the

bottom of the electrical enclosure as shown in

Figure 9.

Figure 9: Potted Nipple in Position

21. Put wires in electrical enclosure through washer

and nut that were removed from potted nipple

assembly in step 18.

22. Tighten nut to tightly hold potted nipple assembly.

23. Find reducer from IS wiring kit, 020-1513. From

electrical enclosure, pull wires from the potted

nipple assembly through ¾” opening of reducer

and attach reducer to the top of the nipple

assembly.

Gilbarco Encore 300 and 500 - DTU Installation

13

Page 14

24. Find straight conduit fi tting from IS wiring kit

020-1513. From electrical enclosure, pull wires

from the potted nipple assembly through opening

of straight conduit fi tting. Attach straight conduit

fi tting onto the reducer. Refer to Figure 10.

Figure 10: Reducer Installed

25. Remove two screws from IS wiring cover inside

the DTU and remove cover. Keep cover and

screws for future reassembly.

26. Find the 90-degree fi tting from IS wiring kit,

020-1513. Remove nut from 90-degree fi tting.

Attach fi tting to opening of DTU nearest the IS

connector using nut previously removed.

Figure 12: Flexible Conduit Installation

28. Pull wires from potted nipple assembly through

fl exible conduit.

29. Remove nut and bushing from straight conduit

fi tting.

30. Push bushing onto end of fl exible conduit and

reattach to straight fi tting using nut.

31. Remove bushing and nut from 90-degree conduit

fi tting on DTU and pull wiring / fl exible conduit

through.

32. Route wires through 90-degree conduit fi tting and

pull into the DTU enclosure.

Figure 11: 90-degree Fitting Installed

27. Find the fl exible conduit from the IS Wiring Kit,

020-1513. Using 90-degree fi tting and straight

fi tting installed earlier, determine length of fl exible

conduit assembly needed and cut to fi t. Refer to

Figure 12.

14

Gilbarco Encore 300 and 500 - DTU Installation

Figure 13: Wires in Flexible Conduit

33. Using nut and then bushing, attach fl exible conduit

to 90-degree conduit fi tting.

Page 15

34. Cut excess wire inside DTU allowing a length of

2” for terminal block wiring. Strip wire insulation

3/8” from the end. Connect wires to DTU terminal

block.

Figure 14: Wiring Connection to DTU

35. Reinstall barrier cover using screws from step 23.

37. Find cable assembly extending from TS-VFM

vapor meter in dispenser hydraulics enclosure.

38. Find wiring from previously installed potted nipple

assembly inside hydraulics enclosure.

39. Find two wire splice connector kits. Inside

hydraulics enclosure connect black wire from

potted nipple assembly to black wire from TS-VFM

fl ow meter by putting each lead into an opening in

the wire splice connector and push fi tting closed to

lock.

40. Find cable extending from TS-VPS inside

hydraulics enclosure. Cut yellow and blue leads

from end of cable.

41. Find purple and white wires from potted nipple

assembly in hydraulics enclosure. Strip wiring

insulation 3/8” from end of wire.

42. Using wire nuts provided with kit, attach purple

wire from potted nipple assembly to black wire

of TS-VPS and white wire from potted nipple

assembly to white wire of the TS-VPS.

43. Attach lower hydraulics covers to dispenser and

secure each using key lock.

44. Close both main doors of dispenser. Securely

attach the two latches on the left side of each

interface door.

45. Close both interface doors and lock.

Figure 15: Reinstall Barrier

36. Replace DTU cover.

Figure 16: Replace Cover

Gilbarco Encore 300 and 500 - DTU Installation

15

Page 16

Tokheim Premier B (422B)

This section illustrates the basic components needed

to retrofi t a TS-DTU module into an existing dispenser.

This system can be installed in any “Non-Vapor or Vapor

Ready” dispenser including dispensers with existing

“Balance” or “VacAssist” piping.

Note: Conduit knockouts measure 1 1/4”. Holes are too

small for conduits to make a good seal. These

knockouts cannot be used. New conduit knockouts

will need to be made.

1. Open right options door with key on Side A of

dispenser. Side A has manufacturer’s nameplate.

Remove door and set aside for future installation.

dispenser.

Figure 4: Lower Display Assembly

5. Loosen two screws on display assembly and

lower it.

6. Remove lower hydraulics door from side A of

dispenser by releasing key lock on either side of

door.

7. From side A of dispensers, examine opening on

right side of electrical enclosure. Choose drilling

location ensuring that components in electrical

enclosure and hydraulics enclosure will not be

disturbed by the drilling. Use washer to insure

proper clearance after install.

Figure 1: Unlocking door

2. Open printer door on B side of dispenser.

Figure 2: Unlock Printer Door

3. Unlock right options door on B side of dispenser.

Figure 5; Mark Drilling Location

8. Using a low speed pneumatic drill, drill a small

pilot hole through the bottom of the electrical

enclosure.

Note: During drilling, put a catch pan under the drilling

location to catch shavings and metal fi ling during

drilling operation.

9. Carefully remove all metal fi ling and shavings from

inside of electrical enclosure.

Figure 3: Release Latch

4. Release latch on display cover on B side of

16

Tokheim Premier B DTU Installation

Page 17

10. Using a ¾” conduit hole punch, open hole

previously drilled.

Figure 6: Use Hole Punch

11. Find potted nipple assembly, 131610.

Undo wire ties and unwind wiring.

12. Remove and dispose of rubber washer from

assembly.

13. Remove top nut and washer from potted nipple.

Keep nut and washer for future use.

14. Pull wires from top of potted nipple assembly up

from the hydraulics enclosure to the electrical

enclosure. Make sure wiring is not damaged by

sharp edges.

15. Pull top of potted nipple assembly through opening

in electrical enclosure. Push wires inside electrical

enclosure through washer and nut retained in step

13. Securely attach potted nipple assembly by

tightening nut.

Figure 8: DTU Open

20. Install mounting bracket to DTU with two screws,

nuts and washers from hardware provided with

DTU as described in the General Information

section. Ensure that bracket is installed on correct

side as shown.

21. Remove two screws from IS wiring cover inside

the DTU and remove cover. Retain cover and

screws for future reassembly

22. Find 90-degree fi tting from IS wiring kit. Remove

nut from 90-degree fi tting. Attach fi tting to opening

nearest IS wiring terminal block of DTU using nut

previously removed.

Figure 7: Potted Nipple Assembly Attached

16. Find reducer from IS wiring kit 020-1513. From

electrical enclosure, pull wires from the potted

nipple assembly through ¾” opening of reducer

and thread reducer to the top of the nipple

assembly.

17. Find straight conduit fi tting from IS wiring kit. From

electrical enclosure, pull wires from the potted

nipple assembly through opening of straight

conduit fi tting. Attach straight conduit fi tting onto

the reducer.

18. Find TS-DTU/P kit and remove brackets, DTU,

and fasteners from box.

19. Remove cover from DTU.

Tokheim Premier B DTU Installation

Figure 9: Attach 90-degree Fitting

23. Find power harness kit part number 600-0165.

Find the Tokheim power harness and ground wire

with ring terminal as shown in fi gure 4 of the Parts

List. Remove tie-wraps and uncoil.

24. Route wiring harness end with crimp connector

through opening in DTU nearest terminal block

J1. Attach white lead to terminal block position

labeled NEUTRAL and black lead to terminal

block position labeled L1 on terminal block J1 of

DTU. Attach ground wire to terminal block position

labeled GND of J2 on DTU.

17

Page 18

25. Remove nut and bushing from straight conduit

fi tting. Place bushing on one end of fl exible

conduit. Push wires from nipple assembly through

bushing / fl exible conduit and attach fl exible conduit

to straight conduit fi tting using nut.

Figure 10: Attach Flexible Conduit to Potted Nipple

26. Remove nut and bushing from 90-degree conduit

fi tting and pull fl exible conduit through nut. Attach

bushing on unattached end of fl exible conduit. Pull

wires from fl exible conduit through the 90-degree

conduit fi tting and pull excess wire into DTU.

27. Attach fl exible conduit to 90-degree fi tting with nut.

Figure 12: Wiring Connection to DTU

29. Reinstall barrier cover using screws uninstalled in

step 23.

Figure 11: Attach Flexible Conduit to 90-Degree Fitting

28. Cut excess wire inside DTU allowing a length of

2” for terminal block wiring. Strip wire insulation

3/8’ from the ends of wire. Attach wires to DTU

terminal block as follows.

Figure 13: Reinstall Barrier Cover

30. Replace DTU cover.

31. Install the DTU assembly on the dispenser vertical

bracket as shown in Figure 14. Use the two

screws, washers, and nuts as supplied in the TSDTU/P hardware kit.

Figure 14: DTU Attached to Dispenser

18

Tokheim Premier B DTU Installation

Page 19

32. Route power cable along bottom of electrical

enclosure and attach to AC power distribution

board as shown. Ensure that wiring is kept away

from sharp edges and will not interfere with door

closing.

33. Plug the connector from the Tokheim power

harness into available connector on AC power

distribution board.

37. Find two wire splice connector kits. Inside

hydraulics enclosure, connect black wire from

potted nipple assembly to black wire from TS-VFM

fl ow meter by putting each lead into an opening in

the wire splice connector and push fi tting closed to

lock.

37. Find cable extending from TS-VPS inside

hydraulics enclosure. Cut yellow and blue leads

from end of cable.

37. Find purple and white wires from potted nipple

assembly in hydraulics enclosure. Strip wiring

insulation 3/8”from end of wire.

40. Using wire nuts provided with kit, attach purple

wire from potted nipple assembly to black wire

of TS-VPS and white wire from potted nipple

assembly to white wire of the TS-VPS.

41. Replace lower hydraulics door to side A and lock

with key.

42. Lift the display assembly back to normal position

and tighten with two attached screws.

43. Lock latch on display cover on B side of dispenser.

44. Close right options door on B side and lock.

45. Close printer door on B side and lock.

46. Close right options door on A side and lock.

Figure 15: Connect to AC Power Board

34. Attach ring terminal of ground wire to dispenser

bracket using screw and nut as shown. Coil

excess wiring and secure with tie-wraps to ensure

that it does not interfere with door closing.

Figure 16: Attach Ground Wire

35. Find cable assembly extending from TS-VFM in

dispenser hydraulics enclosure.

36. Find wiring from previously installed potted nipple

assembly inside hydraulics enclosure.

Tokheim Premier B DTU Installation

19

Page 20

Tokheim Premier C

This section illustrates the basic components needed

to retrofi t a TS-DTU module into an existing dispenser.

This system can be installed in any “Non-Vapor or Vapor

Ready” dispenser including dispensers with existing

“Balance” or “VacAssist” piping.

1. Unlock left door from each side of dispenser and

open the door.

Figure 1: Unlock Door

2. Release inside latch from left door assembly and

open center door.

Figure 2: Release Inside Latch

3. Repeat step 2 for right door assembly.

5. Find TS-DTU/P kit and remove brackets, DTU,

and fasteners from box.

6. Remove cover from DTU.

7. Install mounting bracket to DTU with two screws,

nuts and washers from hardware provided with

DTU as described in the General Information

section. Ensure that bracket is installed on correct

side as shown.

Figure 4: Attaching DTU

8. Remove two screws from IS wiring cover inside

the DTU and remove cover. Keep cover and

screws for future reassembly.

9. Find 90-degree fi tting from IS wiring kit 020-1513.

Remove nut from 90 degree fi tting. Attach fi tting to

opening nearest IS wiring terminal block of DTU

using nut previously removed.

10. Find power harness kit part number 600-0165.

Find the Tokheim power harness and ground wire

with ring terminal as shown in fi gure 4 of the Parts

List. Remove tie-wraps and uncoil.

11. Pull wiring harness end with crimp connector

through opening in DTU nearest terminal block

J1. Attach white lead to terminal block position

labeled NEUTRAL and black lead to terminal

block position labeled L1 on terminal block J1 of

DTU. Attach ground wire to terminal block position

labeled GND of J2 on DTU.

12. Find vapor barrier plug on bottom of dispenser

electronics barrier enclosure.

13. Remove lower door on side A of dispenser (side

with AC distribution board).

Figure 3: Right Door Assembly

4. Find side B of dispenser. Side B will be the side

without the AC distribution board. Unit will be

installed on the right side of side B

20

Figure 5: Remove Lower Door

Tokheim Premier C DTU Installation

Page 21

14. Remove nut from top of plug using wrench.

15. Remove plug, washers, and nuts and discard all

hardware.

Figure 6: Remove Nut

16. Find potted nipple assembly 131610.

Untie wire ties and unwind wiring.

17. Remove and dispose of rubber washer from

assembly.

18. Remove top nut from potted nipple and remove

nut and one washer by pulling over wire leads.

Keep nut and washer for future use.

19. Put wires from top of potted nipple assembly up

from the hydraulics enclosure to the electrical

enclosure. Ensure that wiring is not damaged by

sharp edges.

Figure 7: Potted Nipple Location

20. Push top of potted nipple assembly through

opening in electrical enclosure. Pull wires inside

electrical enclosure through washer and nut kept

in step 8. Secure potted nipple assembly by

tightening nut.

21. Find reducer from IS wiring kit, 020-1513. From

electrical enclosure, pull wires from the potted

nipple assembly through ¾” opening of reducer

and attach reducer to the top of the nipple

assembly.

Figure 9: Attach Reducer

22. Find straight conduit fi tting from IS wiring kit. From

electrical enclosure, pull wires from the potted

nipple fi tting through opening of straight conduit

assembly. Attach straight conduit fi tting onto

reducer.

23. Remove two screws from IS wiring cover inside

the DTU and remove cover. Keep cover and

screws for future reassembly.

24. Find 90-degree fi tting from IS wiring kit. Remove

nut from 90-degree fi tting. Attach fi tting to top

opening of DTU using nut previously removed.

25. Find fl exible conduit from IS wiring kit 020-1513.

Using 90-degree fi tting and straight fi tting installed

earlier, determine length of fl exible conduit needed

and cut to fi t.

26. Pull wires inside electrical enclosure through

fl exible conduit.

Figure 8: Potted Nipple Installed

Tokheim Premier C DTU Installation

Figure 10: Wire in Flexible Conduit

27. Remove nut and bushing from straight conduit

fi tting.

21

Page 22

28. Push bushing onto end of fl exible conduit and

reattach to straight fi tting using nut.

Figure 11: Flexible Conduit Connected

29. Remove bushing and nut from 90-degree conduit

fi tting on DTU and pull wires through the bushing.

30. Pull wires through 90-degree conduit fi tting.

32. Cut excess wire inside DTU allowing a length of 2”

for terminal block wiring. Strip wire insulation 3/8”

from ends of wire. Attach wires to DTU terminal

block as follows.

Figure 14: Wiring Connection to DTU

33. Reinstall barrier cover using screws that were

removed in step 23.

34. Replace DTU cover.

Install the DTU assembly on the supporting studs

located on the vertical side of the dispenser

as shown in Figure 15. Use two 10-24 locking

nuts to secure the assembly to the dispenser.

Figure 12: Pull wires through 90-degree fi tting

31. Using nut, fi rmly attach fl exible conduit to 90

degree conduit fi tting.

Figure 13: 90-Degree Conduit Connected

22

Figure 15: DTU Attached to Dispenser

35. Route power cable along bottom of electrical

enclosure to AC power distribution board as shown.

Ensure that wiring is kept away from sharp edges

and will not interfere with door closing.

Tokheim Premier C DTU Installation

Page 23

Figure 16: Power Cable Installation

36. Attach connector from the Tokheim power harness

into available connector on AC power distribution

board.

Figure 17: Attach White Connector

37. Attach ring terminal of ground wire to dispenser

bracket using screw and nut as shown. Coil excess

wiring with tie wraps to ensure that it does not

interfere with door closing

Figure 18: Ground Wire Attached

38. Find cable assembly extending from TS-VFM vapor

meter in dispenser hydraulics enclosure.

39. Find wiring from previously installed potted nipple

assembly inside hydraulics enclosure.

40. Find two wire splice connector kits. Inside

hydraulics enclosure connect black wire from potted

nipple assembly to black wire from TS-VFM fl ow

meter by placing each lead into an opening in the

wire splice connector and push fi tting closed to lock.

41. Find the cable extending from TS-VPS inside

hydraulics enclosure. Cut yellow and blue leads

from end of cable.

42. Find purple and white wires from potted nipple

assembly in hydraulics enclosure. Strip wiring

insulation 3/8” from end of wire.

43. Using wire nuts provided with kit, attach purple wire

from potted nipple assembly to black wire of TSVPS and white wire from potted nipple assembly to

white wire of the TS-VPS.

44. Close right door assembly and tighten latch. Refer

to Figure 3.

45. Close center door assembly and tighten latch.

Refer to Figure 2.

46. Close and lock left options door.

47. Repeat steps 45 through 47 for opposite side of

dispenser.

Tokheim Premier C DTU Installation

23

Page 24

Wayne Ovation

This section illustrates the basic components needed to

retrofi t a TS-DTU module into an existing dispenser. This

system can be installed in any “Non-Vapor or Vapor Ready”

dispenser including dispensers with existing “Balance” or

“VacAssist” piping.

1. Open the upper dispenser door on both sides by

loosening two screws on each door.

Figure 3: Attach DTU to Dispenser

6. Find power harness kit part number 600-0166. Find

the Wayne power harness as shown in Figure 4 of

the Parts List. Remove tie-wraps and uncoil.

7. Pull wiring harness end with crimp connector

through bottom of DTU. Attach white lead to

terminal block position labeled NEUTRAL and

black lead to terminal block position labeled L1 on

terminal block J1 of DTU.

Figure 1: Open Dispenser

2. Find TS-DTU/P kit and remove brackets, DTU, and

hardware from box.

3. Remove cover from DTU.

4. Install the mounting bracket on DTU with two

screws, nuts and washers from hardware provided

with DTU as described in the General Information

Section. Ensure that bracket is installed on correct

side as shown.

Figure 4: Attach Power Wiring

8. Inside dispenser, fi nd the incoming power

connection on the dispenser power supply board

and disconnect.

9. Attach the Wayne power extension cable between

the incoming power connector and the power

supply board (Figure 5).

Figure 2: Mounting Bracket Installed

5. Install the DTU assembly in the vertical

dispenser bracket as shown in Figure

3. Use the two screws, washers, and nuts

as supplied in the TS-DTU/P hardware kit.

24

Figure 5: Attach Power extension Cable

Wayne Ovation - DTU Installation

Page 25

Figure 6: Attach Power Connector to Board

10. Pull wires away from door using positioning

devices included with dispenser

11. Find ground wire from power wiring harness kit.

From end without ring terminal, strip 3/8” of wiring

insulation.

12. Attach ground wire to terminal block position

labeled GND of J2 on DTU.

13. Attach ring terminal of ground wire to dispenser

bracket using screw and nut as shown. Wind

excess wiring and attach with tie wraps to ensure

that it does not interfere with door closing.

Figure 8: Remove Hole Plug

16. Find potted nipple assembly, 131610.

17. Remove and dispose of rubber washer from

assembly.

18. Turn top nut from potted nipple counter-clockwise

and remove nut and one washer by pulling it over

wire leads. Keep nut and washer for future use.

19. Using ¾” conduit hole punch, increase size of 1/2”

hole exposed after following step 14.

Figure 7: Attach Ground Wire to Frame

14. Find the side of dispenser opposite of power

supply. Remove lower door on that side by

loosening two screws. Set door aside and save for

later assembly.

15. Remove nut from hole plug located at the bottom

of the electrical enclosure using two wrenches.

Remove bolt, nut, and washers and dispose of

them.

Wayne Ovation - DTU Installation

Figure 9: Increase Hole Size

20. Push wires from top of potted nipple assembly

up from the hydraulics enclosure through to the

electrical enclosure. Make sure that wiring is not

damaged by sharp edges.

25

Page 26

Figure 10: Push Wire to Electrical Enclosure

21. Push top of potted nipple assembly through

opening in electrical enclosure. Pull the wires

inside electrical enclosure through washer and

nut retained in step 18. Tighten potted nipple

assembly nut.

Figure 11: Install Potted Nipple

22. Find reducer in IS conduit kit. From electrical

enclosure, pull wires from the potted nipple

assembly through ¾” opening of reducer and

thread reducer to the top of the nipple assembly.

23. Find straight conduit fi tting from IS wiring kit.

From electrical enclosure, pull wires from the

potted nipple assembly through opening of

straight conduit fi tting. Turn straight conduit fi tting

clockwise onto reducer.

24. Remove two screws from IS wiring cover inside

the DTU and remove cover. Retain cover and

screws for future reassembly.

Figure 12: Remove Wiring Cover

25. Find 90-degree fi tting from IS conduit kit. Remove

nut from 90-degree fi tting. Attach fi tting to top

opening of DTU using nut previously removed.

Figure 13: Attach 90-Degree Fitting

26. Find fl exible conduit fi tting in IS conduit kit, 020-

1513. Using 90-degree fi tting and straight fi tting

installed earlier, determine length of fl exible

conduit needed and cut to fi t.

27. Pull wires inside electrical enclosure through IS

conduit assembly.

28. Remove nut and bushing from straight conduit

fi tting.

26

Wayne Ovation - DTU Installation

Page 27

29. Push bushing onto end of fl exible conduit and

reattach to straight fi tting using nut.

Figure 14: Attach Flexible Conduit to Potted Nipple

30. Remove bushing and nut from 90-degree fi tting on

DTU and pull wiring and fl exible conduit through.

31. Pull wires through 90-degree fi tting and pull into

the DTU enclosure.

32. Use nut and attach fl exible conduit to 90-degree

fi tting.

Figure 15: Attach Flexible Conduit to 90-Degree Fitting

33. Cut excess wire inside DTU allowing a length of 2”

for terminal block wiring. Strip insulation 3/8” from

end of wire. Attach wires to DTU terminal block as

follows

34. Reinstall barrier cover using screws removed in

step 24.

35. Replace DTU cover.

Figure 17: Attach Cover to DTU

36. Find cable assembly extending from TS-VFM

vapor meter in dispenser hydraulics enclosure.

37. Locate wiring from previously installed potted

nipple assembly inside hydraulics enclosure.

38.

Find two-wire splice connector kits. Inside hydraulics

enclosure connect black wire from potted nipple

assembly to black wire from TS-VFM fl ow meter by

placing each lead into an opening in the wire splice

connector and push fi tting closed to lock.

39. Find cable extending from TS-VPS inside

hydraulics enclosure. Cut yellow and blue leads

from end of cable.

40. Find purple and white wires from potted nipple

assembly in hydraulics enclosure. Strip wiring

insulation at end 3/8”.

41. Using wire nuts provided with kit, attach purple

wire from potted nipple assembly to black wire of

TS-VPS and attach white wire from potted nipple

assembly to white wire of the TS-VPS.

42. Replace lower hydraulics door using two screws

on door.

43. Close dispenser doors on each side of the unit and

fi rmly attach with two screws located in each door.

Figure 16: Terminal Block Wiring

Wayne Ovation - DTU Installation

27

Page 28

Wayne Vista 1

This section illustrates the basic components needed

to retrofi t a TS-DTU module into an existing dispenser.

This system can be installed in any “Non-Vapor or Vapor

Ready” dispenser including dispensers with existing

“Balance” or “VacAssist” piping.

1. Remove lower brand panel door using key locks.

2. Remove two thumb screws from each side of

bezel and pull bezel off of dispenser

3. Remove product select connector from center

bezel.

Figure 1: Lower Door Panel Open

4. Remove keypad data P2 cable, and LCD power

connectors from door

Figure 3: Remove Hole Plug

8. Find potted nipple assembly, 131610.

Open wire ties and unwind wiring.

9. Remove and dispose of rubber washer from

assembly.

10. Remove top nut from potted nipple and remove

nut and one washer by pulling over wire leads.

Keep nut and washer for future use.

11. Pull top wires of potted nipple assembly from the

hydraulics enclosure to the electrical enclosure.

Ensure that wiring is not damaged by sharp edges.

12. Pull top of potted nipple assembly through

opening in electrical enclosure. Route wires inside

electrical enclosure through washer and nut

retained in step 10. Attach potted nipple assembly

by tightening nut.

NOTE: Alternate display assembly will require the removal

of a fourth connector from the LCD/keypad

assembly.

Figure 2: 4th Connector

5. Remove bezel and retain for future reassembly

6. Repeat steps 2 through 5 for other side

7. Using two wrenches, remove nut from hole plug

found at the bottom of the electrical enclosure.

Remove bolt, nut, and washers and dispose of

them.

Figure 4: Potted Nipple Installed

13. Find reducer from IS conduit kit, 020-1513. From

electrical enclosure, pull wires from the potted

nipple assembly through ¾” opening of reducer

and attach reducer to the top of the nipple

assembly.

14. From electrical enclosure, pull wires from the

potted nipple assembly through opening of straight

conduit. Attach straight conduit fi tting onto reducer.

28

Wayne Vista 1 - DTU Installation

Page 29

Figure 5: Straight Conduit Installed

15. Find TS-DTU/P kit and remove brackets, DTU,

and hardware from box.

16. Remove cover from DTU.

17. Attach mounting bracket to DTU with two screws,

nuts and washers from hardware provided with

DTU as described in the General Information

Section. Ensure that bracket is installed on correct

side as shown in Figure 6.

Note: The installation of the DTU in the dispenser will

occur after all connections have been made to the

DTU.

20. Find power harness kit part number 600-0165.

Find the Wayne power harness and ground wire

with ring terminal as shown in fi gure 4 of the Parts

List. Remove tie-wraps and uncoil.

21. Push wiring harness end with crimp connector

through opening in DTU nearest power terminal

block J1. Attach white lead to terminal block

position labeled NEUTRAL and black lead to

terminal block position labeled L1 on terminal

block J1 of DTU. Attach ground wire to terminal

block position labeled GND of J2 on DTU.

Figure 6: Mounting Bracket on DTU

18. Remove two screws from IS wiring cover inside

the DTU and remove cover. Keep cover and

screws for reassembly.

19. Find 90-degree fi tting in IS conduit kit, 020-1513.

Remove nut from 90-degree fi tting. Attach fi tting

to opening nearest IS wiring terminal block of DTU

using nut previously removed.

Figure 8: DTU Wiring

22. Cut connector off the Wayne power harness kit.

Strip wire insulation 3/8” from the end of the wire.

23. Pull wire underneath bracket, along bottom of

dispenser and through wire bushing in display

assembly.

Figure 9: Power Harness Wiring

24. Find black/white pair of twisted wires inside display

assembly. Cut wires, forming four leads and

uncoil. Strip wire insulation 3/8” from the end of

the wire.

Figure 7: 90-Degree Fitting Installed

Wayne Vista 1 - DTU Installation

29

Page 30

25. Using wire nuts provided, connect all three white

wires together. Connect three black wires together.

30. Find straight conduit fi tting and fl exible conduit

from IS conduit kit, 020-1513. Remove nut and

bushing from straight conduit fi tting. Push bushing

on one end of fl exible conduit. Pull wires from

nipple assembly through bushing / fl exible conduit

and attach fl exible conduit to straight conduit fi tting

using nut.

Figure 10: Connect Wires

26. Use tie-wrap to attach connections together.

Figure 11: Wrap Wires

27. Attach wiring from power wiring harness to the

side of the display assembly using adhesive

backed anchor and wire tie.

Figure 13: Attach Flexible Conduit

31. Remove nut and bushing from the 90-degree

conduit fi tting and feed fl exible conduit through

nut. Put bushing on unattached end of fl exible

conduit. Pull wires from fl exible conduit through

the 90-degree conduit fi tting and pull excess wire

into DTU. Use nut to attach fl exible conduit to

90-degree fi tting.

Figure 12: Attach Power Wiring Harness

28. Close display assembly and fi rmly attach using

two screws. Ensure that all wiring is free of sharp

edges and pinching when doors close. If sharp

edges or pinching is observes, use additional tie

wraps and anchors to reroute wiring as necessary.

29. Attach ring terminal of ground wire to dispenser

bracket using screw and nut as shown. Wind

excess wiring and fi rmly attach with tie wraps to

ensure that it does not interfere with door closing.

30

Figure 14: Flexible Conduit DTU Connection

32. Cut excess wire inside DTU allowing a length of 2”

for terminal block wiring. Strip wire insulation 3/8”

from the end of the wire.

Wayne Vista 1 - DTU Installation

Page 31

33. Attach wires to DTU terminal block as follows

Figure 15: Wires Connected to DTU

34. Reinstall barrier cover using screws that were

removed in step 20.

35. Replace DTU cover.

36. Install the DTU assembly on the horizontal cross

bracket as shown in Figure 16. Use the two

screws, washers, and nuts as supplied in the TSDTU/P hardware kit. Take care that the fl exible

conduit does not interfere with the electronics on

the side of the dispenser.

39. Find two wire splice connector kits. Inside

hydraulics enclosure, connect black wire from

potted nipple assembly to black wire from TS-VFM

fl ow meter by placing each lead into an opening in

the wire splice connector and push fi tting closed to

lock.

40. Locate cable extending from TS-VPS inside

hydraulics enclosure. Cut yellow and blue leads

from end of cable.

41. Find purple and white wires from potted nipple

assembly in hydraulics enclosure. Strip wire

insulation 3/8” from the end of the wire.

42. Using wire nuts provided with kit, attach purple

wire from potted nipple assembly to black wire

of TS-VPS. Attach white wire from potted nipple

assembly to white wire of the TS-VPS.

43. Reinstall lower hydraulic door using key-lock

44. Reinstall all connectors removed in step 3 & 4.

45. Close the bezel on the dispenser and secure using

two thumb screws from each side of the bezel.

46. Repeat steps 44 & 45 for the opposite side of the

dispenser.

Figure 16: DTU Installed with Cover On

Note: Moving the 90-degree conduit fi tting on DTU

slightly away from the dispenser PCB board will aid

in separating the conduit from the that board.

37. Find cable assembly extending from TS-VFM

vapor meter in dispenser hydraulics enclosure.

38. Find wiring from previously installed potted nipple

assembly inside hydraulics enclosure.

Wayne Vista 1 - DTU Installation

31

Page 32

Wayne Vista 2

This section illustrates the basic components needed

to retrofi t a TS-DTU module into an existing dispenser.

This system can be installed in any “Non-Vapor or Vapor

Ready” dispenser including dispensers with existing

“Balance” or “VacAssist” piping.

1. Using key-lock, remove lower door on B side of

dispenser. B side of the dispenser does not have

dispenser marking at the base.

2. Open upper dispenser door on both sides by

loosening two screws on each door.

Figure 1: Open Upper Dispenser Door

3. On “B” side, remove two screws holding display

assembly and carefully lower into resting position.

Figure 2: Carefully Lower Door

4. DTU will be installed in the location shown below.

(The DTU will not be installed until step 21)

Examine the bottom of the electrical enclosure

to determine location of unused hole plugs and

choose the appropriate side of dispenser.

Note: Hole plugs beneath plastic catch pans cannot be

used as there is not enough clearance to install

conduit fi ttings.

5. Remove lower dispenser door using key lock

closest to the hole plug chosen in step 2.

6. Using two wrenches, remove nut from hole plug

found at the bottom of the electrical enclosure.

Remove bolt, nut, and washers and dispose of

them.

Figure 4: Remove Hole Plug

7. Find potted nipple assembly, 131610.

Open wire ties and unwind wiring.

8. Remove and dispose of rubber washer from

assembly.

9. Remove top nut from potted nipple and remove

nut and one washer by pulling over wire leads.

Keep nut and washer for future use.

10. Pull top wires of potted nipple assembly from the

hydraulics enclosure to the electrical enclosure.

Ensure that wiring is not damaged by sharp edges.

11. Pull top of potted nipple assembly through

opening in electrical enclosure. Route wires inside

electrical enclosure through washer and nut

retained in step 9. Attach potted nipple assembly

by tightening nut.

32

Figure 3: DTU Installed

Figure 5: Potted Nipple Installed

12. Find reducer from IS conduit kit, 020-1513. From

electrical enclosure, pull wires from the potted

nipple assembly through ¾” opening of reducer and

attach reducer to the top of the nipple assembly.

Wayne Vista 2 - DTU Installation

Page 33

13. From electrical enclosure, pull wires from the

potted nipple assembly through opening of straight

conduit. Attach straight conduit fi tting onto reducer.

Figure 6: Straight Conduit Installed

14. Find TS-DTU/P kit and remove brackets, DTU,

and hardware from box.

15. Remove cover from DTU.

16. Install mounting bracket to DTU with two screws,

nuts and washers from hardware provided with

DTU, as described in the General Information

Section. Make sure that bracket is installed on

correct side as shown in Figure 7.

Figure 8: 90-Degree Fitting Installed

19. Find power harness kit part number 600-0165.

Find the Wayne power harness and ground wire

with ring terminal as shown in fi gure 4 of the Parts

List. Remove tie-wraps and uncoil.

20. Push wiring harness end with crimp connector

through opening in DTU nearest power terminal

block J1. Attach white lead to terminal block

position labeled NEUTRAL and black lead to

terminal block position labeled L1 on terminal

block J1 of DTU. Attach ground wire to terminal

block position labeled GND of J2 on DTU.

Figure 7: Mounting Bracket on DTU

17. Remove two screws from IS wiring cover inside

the DTU and remove cover. Keep cover and

screws for reassembly.

18. Find 90-degree fi tting in IS conduit kit, 020-1513.

Remove nut from 90-degree fi tting. Attach fi tting

to opening nearest IS wiring terminal block of DTU

using nut previously removed.

Note: The installation of the DTU in the dispenser will

occur after all connections have been made to the

DTU.

Wayne Vista 2 - DTU Installation

Figure 9: DTU Wiring

21. Cut both connectors off the Wayne power harness

kit. Strip wire insulation 3/8” from the end of the wire.

22. Pull wire underneath bracket, along bottom of

dispenser and through wire bushing in display

assembly.

Figure 10: Power Harness Wiring

23. Dispenser supply power wires from the potted

nipple. Cut wires 6 to 12 inches away from the

potted nipple, forming four leads and uncoil. Strip

wire insulation 3/8” from the end of each wire.

33

Page 34

24. Using wire nuts provided, connect the incoming

power, one end of the wire with the ferrite, and a

wire for the DTU power.

Figure 11: Connect Wires

25. Use tie-wrap to attach connections together.

28. Attach ring terminal of ground wire to dispenser

bracket using screw and nut as shown. Wind

excess wiring and fi rmly attach with tie wraps to

ensure that it does not interfere with door closing.

29. Find straight conduit fi tting and fl exible conduit

from IS conduit kit, 020-1513. Remove nut and

bushing from straight conduit fi tting. Push bushing

on one end of fl exible conduit. Pull wires from

nipple assembly through bushing / fl exible conduit

and attach fl exible conduit to straight conduit fi tting

using nut.

Figure 14: Attach Flexible Conduit

30. Remove nut and bushing from the 90-degree

conduit fi tting and feed fl exible conduit through

nut. Put bushing on unattached end of fl exible

conduit. Pull wires from fl exible conduit through

the 90-degree conduit fi tting and pull excess wire

into DTU. Use nut to attach fl exible conduit to

90-degree fi tting.

Figure 12: Wrap Wires

26. Attach wiring from power wiring harness to the

side of the display assembly using adhesive

backed anchor and wire tie.

Figure 13: Attach Power Wiring Harness

27. Close display assembly and fi rmly attach using

two screws. Ensure that all wiring is free of sharp

edges and pinching when doors close. If sharp

edges or pinching is observes, use additional tie

wraps and anchors to reroute wiring as necessary.

Figure 15: Flexible Conduit DTU Connection

31. Cut excess wire inside DTU allowing a length of 2”

for terminal block wiring. Strip wire insulation 3/8”

from the end of the wire.

34

Wayne Vista 2 - DTU Installation

Page 35

32. Attach wires to DTU terminal block as follows

Figure 16: Wires Connected to DTU

33. Reinstall barrier cover using screws that were

removed in step 20.

34. Replace DTU cover.

35. Install the DTU assembly on the horizontal cross

bracket as shown in Figure 17. Use the two

screws, washers, and nuts as supplied in the

TS-DTU/P hardware kit. Make sure the fl exible

conduit does not interfere with electronics inside

dispenser.

38. Find two wire splice connector kits. Inside

hydraulics enclosure, connect black wire from

potted nipple assembly to black wire from TS-VFM

fl ow meter by placing each lead into an opening in

the wire splice connector and push fi tting closed to

lock.

39. Locate cable extending from TS-VPS inside

hydraulics enclosure. Cut yellow and blue leads

from end of cable.

40. Find purple and white wires from potted nipple

assembly in hydraulics enclosure. Strip wire

insulation 3/8” from the end of the wire.

41. Using wire nuts provided with kit, attach purple

wire from potted nipple assembly to black wire

of TS-VPS. Attach white wire from potted nipple

assembly to white wire of the TS-VPS.

42. Reinstall lower hydraulic door using key-lock

43. Close upper dispenser door on each side by

tightening two screws, refer to fi gure 1.

Figure 17: DTU Installed with Cover On

Note: Moving the 90-degree conduit fi tting on DTU

slightly away from the dispenser PCB board will aid

in separating the conduit from the that board.

36. Find cable assembly extending from TS-VFM

vapor meter in dispenser hydraulics enclosure.

37. Find wiring from previously installed potted nipple

assembly inside hydraulics enclosure.

Wayne Vista 2 - DTU Installation

35

Page 36

Wayne Vista 3

This section illustrates the basic components needed

to retrofi t a TS-DTU module into an existing dispenser.

This system can be installed in any “Non-Vapor or Vapor

Ready” dispenser including dispensers with existing

“Balance” or “VacAssist” piping.

1. Open upper dispenser door on both sides by

loosening two screws on each door.

Figure 1: Open Door

2. Find the location where the DTU will be installed.

(The DTU will not be installed until step 21).

Examine the bottom of the electrical enclosure

to determine location of unused hole plugs and

choose the appropriate side of dispenser.

Figure 3: Unlock Lower Door

4. Using two wrenches, remove nut from

hole plug located at the bottom of the

electrical enclosure. Remove bolt, nut,

and washers and dispose of them.

Figure 2: DTU Location

Note: Hole plugs beneath plastic catch pans cannot be

used as there is not signifi cant clearance to install

conduit fi ttings.

3. Remove lower dispenser door using key lock

closest to the hole plug chosen in step 2.

Figure 4: Removing Hole Plug

Note: Opening created in the bottom of the electrical

enclosure may be ½” or ¾”. If hole is ½”, it will need

to be increased in ¾” in step 5. For openings that

are ¾”, skip to Step 6.

5. Using ¾” conduit hole punch, increase size of ½”

hole to ¾”.

6. Find and remove potted nipple assembly, 131610.

7. Remove wire ties and unwind wiring.

8. Remove and dispose of rubber washer from

assembly.

9. Remove top nut from potted nipple and remove

nut and one washer by pulling over wire leads.

Keep nut and washer for future use.

10. Pull top wires of potted nipple assembly from the

hydraulics enclosure to the electrical enclosure.

Ensure that wiring is not damaged by sharp edges.

11. Pull top of potted nipple assembly through opening

in electrical enclosure. Pull wires inside electrical

enclosure through washer and nut retained in

step 8. Firmly attach potted nipple assembly by

tightening nut.

36

Wayne Vista 3 - DTU Installation

Page 37

Figure 5: Potted Conduit Installed

12. Find reducer from IS conduit kit PN 020-1513.

From electrical enclosure, pull wires from the

potted nipple assembly through ¾” opening of

reducer and thread reducer to the top of the nipple

assembly.

13. Find straight conduit fi tting from IS conduit kit

020-1513. From electrical enclosure, pull wires

from the potted nipple fi tting through opening of

straight conduit fi tting. Turn straight conduit fi tting

clockwise onto reducer.

Figure 6: Straight Conduit Installed

14. Find TS-DTU / P from kit and remove brackets,

DTU, and hardware from box.

15. Remove cover from DTU.

16. Install mounting bracket to DTU with two screws,

nuts and washers from hardware provided with

DTU as described in the general Information

Section. Ensure that bracket is installed on correct

side as shown.

Figure 7: DTU Mounting Bracket Installed

17. Remove two screws from IS wiring cover inside

the DTU and remove cover. Keep cover and

screws for future reassembly.

18. Find 90-degree fi tting from IS wiring kit. Remove

nut from 90-degree fi tting. Attach fi tting to opening

nearest IS wiring terminal block of DTU using nut

previously removed.

Figure 8: 90-Degree Fitting Installed

Note: The installation of the DTU in the dispenser will

occur after all connections have been made to the

DTU.

19. Find power harness kit part number 600-0166.

Find the Wayne power harness and ground wire

with ring terminal as shown in fi gure 4 of the Parts

List. Remove tie-wraps and uncoil.

20. Push wiring harness end with crimp connector

through opening in DTU nearest power terminal

block J1. Attach white lead to terminal block

position labeled NEUTRAL and black lead to

terminal block position labeled L1 on terminal

block J1 of DTU. Attach ground wire to terminal

block position labeled GND of J2 on DTU.

Wayne Vista 3 - DTU Installation

37

Page 38

21. Find the incoming power connection on the

dispenser power supply board shown in Figure 9

Figure 9: Attach White Connector

22. Attach the new Wayne power extension cable

between the incoming power connector and the

power supply board.

Figure 11: Flexible Conduit Installation

26. Remove nut and bushing from 90-degree conduit

fi tting and push fl exible conduit through nut. Push

bushing on unattached end of fl exible conduit. Pull

wires from fl exible conduit through the 90-degree

conduit fi tting and pull excess wire into DTU.

Attach fl exible conduit to 90-degree fi tting with nut.

Figure 10: Attache Power Cable

23. Find straight conduit fi tting and fl exible conduit

from IS conduit kit, 020-1513. Remove nut and

bushing from straight conduit fi tting. Put bushing

on one end of fl exible conduit.

24. Determine length of fl exible conduit needed and

cut to fi t.

25. Push wires from nipple assembly through

bushing / fl exible conduit and attach fl exible conduit

to straight conduit fi tting using nut.

38

Figure 12: 90-Degree Fitting Installed

27. Cut excess wire inside DTU allowing a length of

2” for terminal block wiring. Strip wire insulation

3/8” from end of wire. Attach wires to DTU terminal

block as follows.

Figure 13: Wires attached to DTU

28. Reinstall barrier cover using screws set aside in

step 17.

29. Replace DTU cover.

Wayne Vista 3 - DTU Installation

Page 39

30. Install the DTU assembly on the horizontal cross

bracket as shown in Figure 14. Use the two

screws, washers, and nuts as supplied in the TSDTU/P hardware kit.

31. Attach ring terminal of ground wire to dispenser

bracket using screw and nut as shown. Coil

excess wiring and fi rmly attach with tie wraps to

ensure that it does not interfere with door closing.

Figure 14: DTU Mounted

Figure 15: Ground Wire Connected

32. Find cable assembly extending from TS-VFM vapor

meter in dispenser hydraulics enclosure.

33. Find wiring from previously installed potted nipple

assembly inside hydraulics enclosure.

34. Find two wire splice connector kits. Inside hydraulics

enclosure, connect black wire from potted nipple

assembly to black wire from TS-VFM fl ow meter by

putting each lead into an opening in the wire splice

connector and push fi tting closed to lock.

35. Find cable from TS-VPS inside hydraulics enclosure.

Clip yellow and blue leads from end of cable.

36. Find purple and white wires from potted nipple

assembly in hydraulics enclosure. Strip wiring

insulation 3/8” from end of wire.

37. Using wire nuts provided with kit connect purple wire

from potted nipple assembly to black wire of TS-VPS.

Connect white wire from potted nipple assembly to

white wire of the TS-VPS.

38. Reinstall lower hydraulic door using key-lock.

39. Close dispenser doors on each side of the unit and

fi rmly attach with two screws located in each door.

Wayne Vista 3 - DTU Installation

39

Page 40

©2008 FFS 000-2146 rev B

Loading...

Loading...