Page 1

TS-550evo & TS-5000evo Modbus Interface

Franklin Fueling Systems • 3760 Marsh Rd. • Madison, WI 53718 USA

Tel: +1 608 838 8786 • 800 225 9787 • Fax: +1 608 838 6433 • www.franklinfueling.com

Page 2

Contents

Important Safety Messages ................................................................................................. 3

Overview ................................................................................................................................ 4

Installation ............................................................................................................................. 4

Modbus RTU ................................................................................................................................. 4

Connecting a PC or Laptop Computer................................................................................4

Conguring IP Settings for Communication .................................................................................. 5

Obtain an IP Address Automatically .............................................................................................. 7

Check Status of Connection .......................................................................................................... 7

Network Parameters ...................................................................................................................... 8

Modbus Register Map...........................................................................................................9

Register Mapping Overview .......................................................................................................... 9

System Units ............................................................................................................................... 10

Tank Data ............................................................................................................................ 11

Manifold Data ......................................................................................................................12

Sensor Data ......................................................................................................................... 13

Mag Sensor Register Set ................................................................................................... 14

Relay Data ...........................................................................................................................14

Turbine Pump Interface (TPI) Data .................................................................................... 15

Input Data ............................................................................................................................15

Low Voltage Inputs Status Register ............................................................................................ 15

GIO Inputs Status Register ......................................................................................................... 16

Current Alarms Register Set .............................................................................................. 16

Alarm Code Table ........................................................................................................................ 16

2

Page 3

Important Safety Messages

FFS equipment is designed to be installed in association with volatile hydrocarbon liquids such as gasoline and diesel

fuel. Installing or working on this equipment means working in an environment in which these highly ammable liquids

may be present. Working in such a hazardous environment presents a risk of severe injury or death if these instructions

and standard industry practices are not followed. Read and follow all instructions thoroughly before installing or working

on this, or any other related, equipment.

As you read this guide, please be aware of the following symbols and their meanings:

This symbol identies a warning. A warning sign will appear in the text of this document when a

Warning

Caution

potentially hazardous situation may arise if the instructions that follow are not adhered to closely. A

potentially hazardous situation may involve the possibility of severe bodily harm or even death.

This is a caution symbol. A caution sign will appear in the text of this document when a potentially

hazardous environmental situation may arise if the instructions that follow are not adhered to closely.

A potentially hazardous environmental situation may involve the leakage of fuel from equipment that

could severely harm the environment.

Danger

Warning

This symbol identies an electrical danger. An electrical danger sign will appear in the text of this

document when a potentially hazardous situation involving large amounts of electricity may arise if

the instructions that follow are not adhered to closely. A potentially hazardous situation may involve

the possibility of electrocution, severe bodily harm, or even death.

Alarms and warnings are designed to alert you with specic details when a problem occurs so you

can take appropriate corrective action. System hardware failure warnings, tank related alarms, leak

detection sensor alarms, and line leak alarms can be custom programmed to do many things. The

events that require programming are denoted by a (p) below:

- Cause the red Alarm light or yellow Warning light to ash (standard)

- Activate / sound the console annunciator alarm horn (p)

- Activate internal output relays for external alarm devices (p)

-

Print alarm reports automatically, either locally (internal printer), or remotely (USB - HP compatible printer) (p)

- Send alarm and test reports to a specied e-mail address (p)

- Send reports to remote location(s), via internal data/fax modem (p)

Follow all applicable codes governing the installation and servicing of this product and the

entire system. Always lock out and tag electrical circuit breakers while installing or servicing

this equipment and any related equipment. A potentially lethal electrical shock hazard and the

possibility of an explosion or re from a spark can result if the electrical circuit breakers are

accidentally turned on during installation or servicing. Please refer to the Installation and Owner’s

Manual for this equipment, and the appropriate documentation for any other related equipment, for

complete installation and safety information.

Warning

Warning

Warning

Warning

Warning

Follow all federal, state and local laws governing the installation of this product and its associated

systems. When no other regulations apply, follow NFPA codes 30, 30A and 70 from the National Fire

Protection Association. Failure to follow these codes could result in severe injury, death, serious

property damage and/or environmental contamination.

Always secure the work area from moving vehicles. The equipment in this manual is usually

mounted underground, so reduced visibility puts service personnel working on this equipment in

danger from moving vehicles entering the work area. To help eliminate these unsafe conditions,

secure the area by using a service truck to block access to the work environment, or by using any

other reasonable means available to ensure the safety of service personnel.

When the Fuel Management System is used to monitor tanks containing gasoline or other

ammable substances, you may create an explosion hazard if you do not follow the requirements in

this manual carefully.

All wiring must enter the console’s enclosure through the designated knockouts. An explosion

hazard may result if other openings are used.

You must run wiring from probes or sensors to the Fuel Management System console in conduits

which are separate from all other wiring. Failure to do so will create an explosion hazard.

3

Page 4

This manual describes the installation and setup of the Modbus interface on the TS-550evo & TS-5000evo (evo). Included

are protocol descriptions, register mapping, and data descriptions for the data supported. This document is intended for

users who will be conguring the Modbus feature, and some understanding of Modbus protocol is required.

Overview

Modbus is a serial communication protocol that allows for simple system integration across various devices all on the

same network. This will allow the evo to be connected to a host system that supports Modbus TCP or RTU.

Modbus TCP is available via the evo’s Ethernet ports and Modbus RTU is available via Comm Port 1.

Installation

Modbus communication is a standard feature on the evo with software versions 2.3.0 or higher. It is available over the

standard Ethernet and RS-232 Comm Port 1. No additional hardware installation required. To use Modbus communication

you must connect to either the RS-232 or Ethernet port. For details on establishing these connections please refer to the

following manuals (000-2170 Installation Manual & 000-2173 Programming Manual).

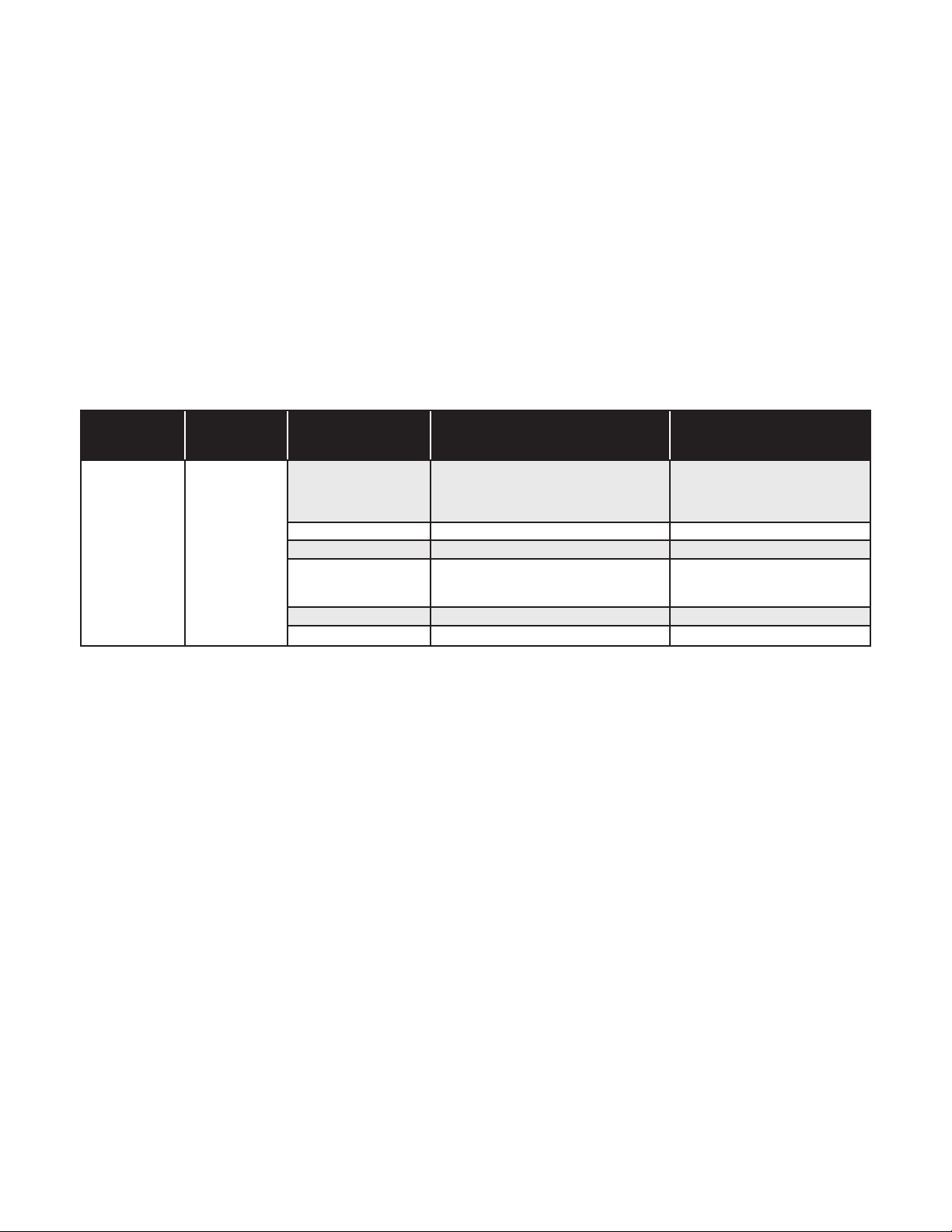

Modbus RTU

To setup the Modbus RTU format you will need to edit the Comm 1 serial port setting in the evo system parameters. First,

select the Mode Modbus and then dene the additional parameter as required for your conguration.

Group Name

Serial Ports

Parameter

Name

COMM 1

Description

Mode Network Connection (PPP)

Baud Rate 57600 1200 - 115200

Data Bits 8 7 or 8

Parity None

Stop Bits 1 1 or 2

Modbus Address 1 1 to 247

Default

Range of Values

Values

Network Connection (PPP)

Veeder-Root

Franklin Fueling System (XML)

Modbus

odd

even

none

Modbus TCP

Modbus TCP is enabled by default on Ethernet Port 502. Establish an Ethernet connection between the Master device

and the evo over port 502 to access the Modbus registers. Refer to the TS-550evo Programming Guide (000-2173) for

details regarding Ethernet connections to the systems.

Connecting a PC or Laptop Computer

To access the console using the Web Browser interface, connect a PC to the console through either the Ethernet port or

the COMM 1 serial port. If the console is connected to a local network, you can perform this setup from any PC on that

network by using a web browser, such as Microsoft’s Internet Explorer or Mozilla’s FireFox, or Safari for a Mac.

Note: The PC or laptop will recognize this serial connection as a network connection and will not allow the use of a Local

Area Connection simultaneously. While it is not necessary to disconnect the Local Area Connection to connect

using the Serial port, it will be necessary to disconnect the Serial Connection through the computers operating

system in order to use the Local Area Connection again.

The following instructions are written specically for Microsoft’s Windows 7 operating system. For assistance with other

operating systems, please contact Franklin Fueling Systems Technical Services.

Connecting a PC to the TS-550 evo Ethernet Port

1. Using an Ethernet Crossover, 10 Base-T cable, plug the RJ-45 connector on one end of the cable into the

Ethernet port of the console.

2. Plug the RJ-45 connector on the opposite end of the cable to the Network Interface Card of the computer.

3. Power up and log onto your PC.

Note:

You may need to re-congure your TCP / IP settings to allow the computer to communicate with the console.

Note: Some modern laptop computers have automatically switching Network Interface Cards and as such, will require the use

of a standard cat 6 cable instead of a crossover.

4

Page 5

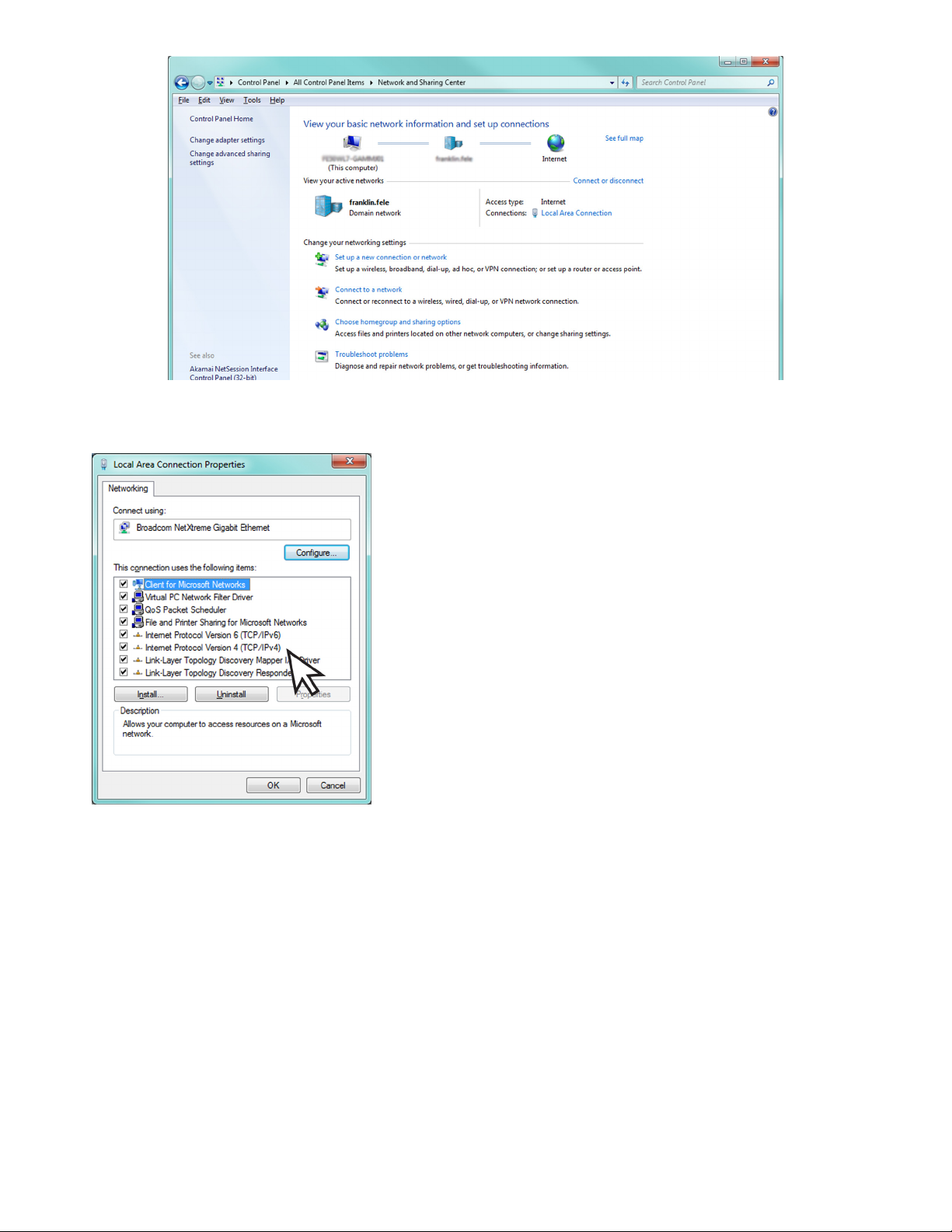

Conguring IP Settings for Communication

Before attempting to modify any computer settings, contact

the Information Technologies department of your business,

if available. Some computer accounts may have restricted

permissions to overcome before any changes are allowed

to be made to TCP / IP settings.

At the PC:

1. Power up the PC and log into your Windows

operating system.

2. Click on Start, then select Control Panel.

3. There are (2) two views settings possible when

using Windows 7:

• In Category View, click on Network and Internet,

then click View Network Status and tasks under

Network and Sharing Center.

↓

• In Icon View, click on Network and Sharing

Center.

4. Click on the Change adapter settings in the left hand column.

5

Page 6

5. Right-click on Local Area Connection and select Properties.

6. In the Local Area Connection Properties dialog box, under “This connection uses the following items,” select

Internet Protocol Version 4(TCP / IPv4) and click Properties.

There are various ways to congure a computer to

communicate with a TS-550 evo console. These factors

depend upon the user’s computer knowledge and how the

computer is currently congured.

To determine which method is best for your site, read the

instructions in the following section carefully. Make detailed

notes on the current conguration of the TCP / IP settings on

the PC you are using. Read both the “Obtain an IP address

automatically” and the “Use the following IP address” methods

before making a choice between the two.

6

Page 7

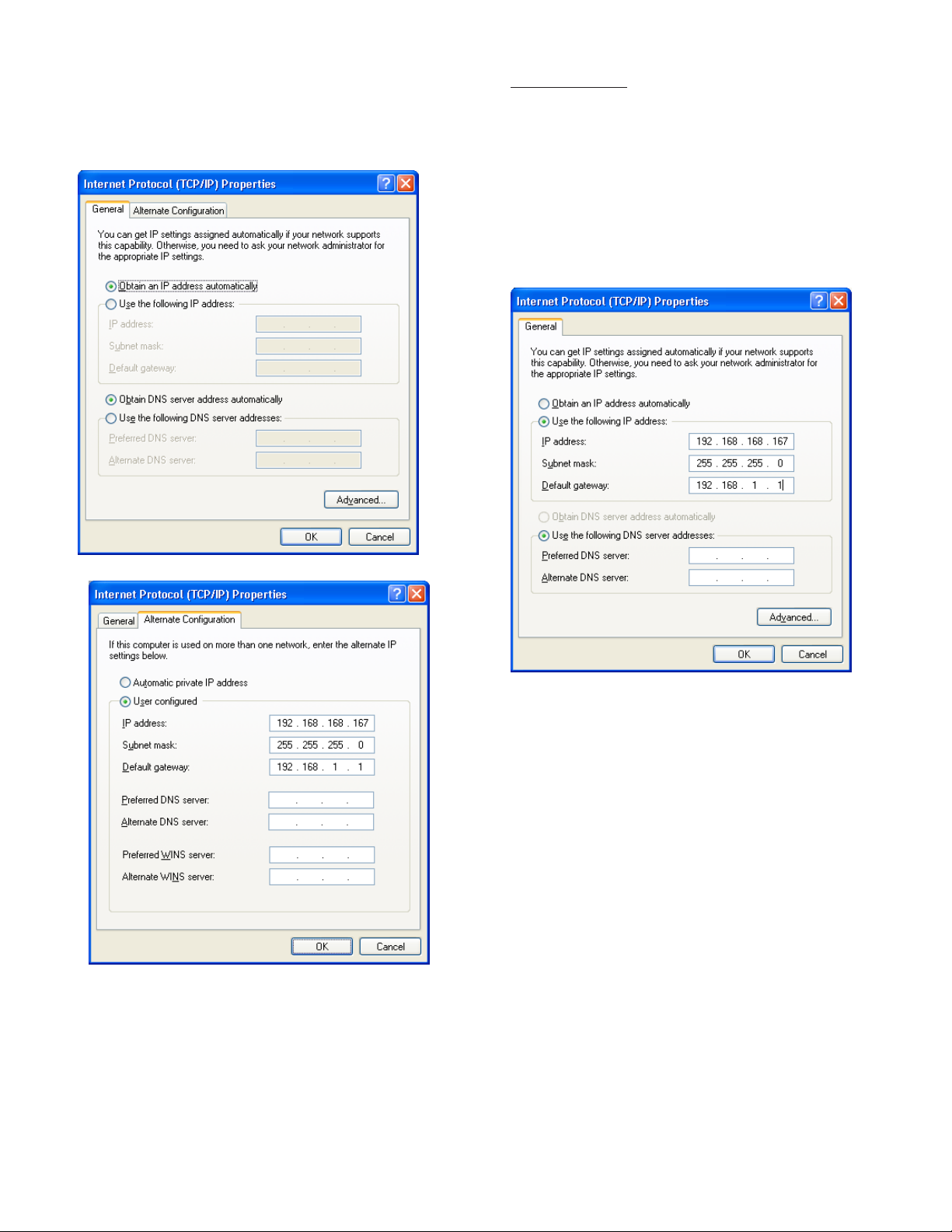

Obtain an IP Address Automatically

Computers commonly use this setting to obtain an IP

address automatically.

1. If Obtain an IP address automatically is

selected, it may be best to click the Alternate

Conguration tab.

Note: The consoles default IP address is

192.168.168.168. If the PC is normally congured

to acquire an IP address automatically, Alternate

Conguration may be used, as mentioned above, to

allow a connection to be enabled without the necessity

of reconguring the computer each time it will be used

to connect to this console.

Use the Following IP Address

1.

If Use the following IP address is selected and

the entry boxes contain any information, record this

information for use when console programming is

complete.

2. Select User Congured.

3. Enter an IP address. For simplicity, make the last

segment of the IP one number different than the IP

address of the console. Upon initial setup ONLY,

the numbers used in the gure may be used to

congure the TCP / IP settings of your PC. After

initial startup the programmed parameters should

be veried through the touchscreen

4. Leave all other information blank and click OK.

5. Close the Local Area network for changes to take

place.

2. Enter an IP address. For simplicity, make the last

segment of the IP one number different than the IP

address of the console. Upon initial setup ONLY,

the numbers used in the gure may be used to

congure the TCP / IP settings of your PC.

3. Leave the DNS information blank.

Note: The consoles default IP address is

192.168.168.168. If the PC is normally congured

to Use the following IP address, make sure that

all displayed information is recorded and kept prior

to making any changes. It may be necessary to use

this information to re-congure the console once

programming is complete.

Check Status of Connection

1. Check the status of your connection by going to

the Network Connections window.

2. If the connection status is disabled, enable it by

right-clicking on the Local Area Connection and

selecting Enable.

3. Verify link light is lit under Ethernet on Controller

module is lit and RX light is ashing.If technical

difculties arise, please contact Franklin Fueling

Systems Technical Support before proceeding.

7

Page 8

Network Parameters

To communicate with your network equipment (i.e. router,

switch, hub, etc.) you will need to modify the TS-550evo or

TS-5000evo console’s network parameters.

IP Address Settings:

IP Address – This is a logical (electronic) address, like a

street address, that the console uses to route

information. This address will have to match

your network, if connected to a network, in

order to ‘talk’ to a remote communication

device, or your PC.

Network Mask – Masking is a way to diversify the use

of multiple subnets. The mask must match

that of the network the console is connected

to. Masks are used in networking to create

‘sub-networks’ within a whole, like slicing and

apple. You have separate slices that may be

in different locations, but they are still from the

same apple. Administrators use this to make

separate networks, to maximize bandwidth or

capacity of medium resources (cables or ber).

Therefore, when your network uses static IP

addressing (assigned by an administrator),

this mask must match the Network Mask of the

router port that it is attached to. If the network

uses a DHCP server (automatically assigns

IP addresses) then the mask should meet the

specications set by your administrator.

Gateway – The Gateway is the logical address to the

nearest router port, commonly the one that

is connected to the console. Consult your

administrator for details on this and other

network parameters.

DNS Server Address:

Preferred DNS Server / Alternate DNS Server – The

domain name system (DNS) is the way that internet domain

names are located and translated into Internet Protocol

addresses. A domain name is a meaningful and easyto-remember tag for an internet address (used for e-mail

functions).

8

Page 9

Modbus Register Map

Register Values

Little Endian Ordering

All 32-bit values are stored such that the least signicant bits are in the lower of the 2 register addresses (a.k.a. Little

Endian). For example, Tank 1 Product level is stored in registers 204 and 205. If the value happened to be large enough

that it spanned 2 registers, say 9876.5 gallons, the values would be stored as follows:

Gallons resolution is 0.1, so the oating point value is multiplied by 10 and converted to the integer value 98765. In hex,

this value is 0x000181CD. Mapping this into registers:

Address 204: 0x81CD

Address 205: 0x0001

Two’s Complement Integer Representation

Negative values are stored as 2’s complement values. So, for the sake of a simple example let’s say we had -9876.5

gallons. The 2’s complement value of -98765 in hex is 0xFFFE7E33. By noting the highest bit is a 1, you know the

number is signed. To get the positive value you simply invert the bits and add 1, getting you back to 0x000181CD. This will

be set up in the Modbus client software.

The following is a table of Input Register addresses that can be accessed using function code 0x04.

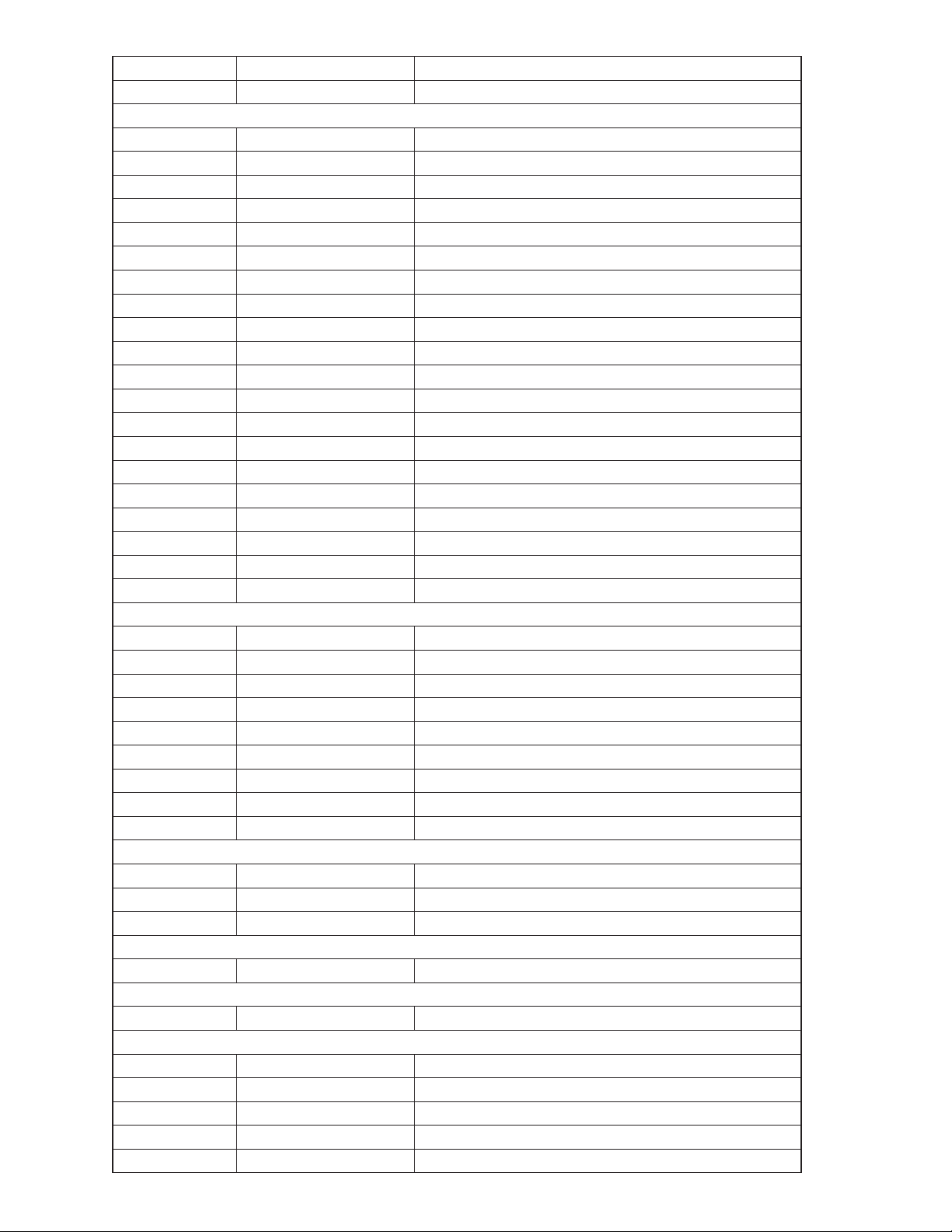

Register Mapping Overview

Register Addresses Data Set Data Type

100-107 System Units System Unit Setting

200-235 Tank 1 Tank 1 Data

236-271 Tank 2 Tank 2 Data

272- …. Tank 3 … Tank 3 Data …

2756-2791 Tank 72 Tank 72 Data

2792-3199 Reserved

3200-3225 Manifold 1 Manifold 1 Data

3226-3251 Manifold 2 Manifold 2 Data

3252-…. Manifold 3… Manifold 3 Data…

4110-4135 Manifold 36 Manifold 36 Data

4136-4499 Reserved Reserved

4500-4501 2-Wire Sensor 1 2-Wire Sensor 1 Data

4502-4503 2-Wire Sensor 2 2-Wire Sensor 2 Data

4504-…. 2-Wire Sensor 3… 2-Wire Sensor 3 Data …

4642-4643 2-Wire Sensor 72 2-Wire Sensor 72 Data

4644-4799 Reserved Reserved

4800-4802 3-Wire Sensor 1 3-Wire Sensor 1 Data

4803-4805 3-Wire Sensor 2 3-Wire Sensor 2 Data

4804-…. 3-Wire Sensor 3... 3-Wire Sensor 3 Data …

4941-4943 3-Wire Sensor 48 3-Wire Sensor 48 Data

4944-4999 Reserved Reserved

5200-5206 Mag Sensor 1 Mag Sensor 1 Data

5207-5213 Mag Sensor 2 Mag Sensor 2 Data

5214-…. Mag Sensor 3… Mag Sensor 3 Data

5697-5703 Mag Sensor 72 Mag Sensor 72

5704-5899 Reserved Reserved

5900-5901 PS Relay 1 PS Relay 1 Status

5902-5903 PS Relay 2 PS Relay 2 Status

5904-5999 Reserved Reserved

9

Page 10

6000-6001 Relay 1 Relay 1 Status

6002-6003 Relay 2 Relay 2 Status

6003 -…. Relay 3… Relay 3 Status…

6166-6167 Relay 84 Relay 84 Status

6168-6399 Reserved Reserved

6400-6401 TPI 1 Controller 1 Status

6402-6403 TPI 2 Controller 2 Status

6404 -…. TPI 3 … Controller 3 Status …

6462-6463 TPI 32 Controller 32 Status

6464-6599 Reserved Reserved

6600-6601 LVI 1 Low Voltage Input 1 Status

6602-6603 LVI 2 Low Voltage Input 2 Status

6604-6699 Reserved Reserved

6700-6701 AC Input 1 AC Input 1Status

6702-6703 AC Input 2 AC Input 2 Status

6704-…. AC Input 3… AC Input 3 Status …

6842-6843 AC Input 72 AC Input 72 Status

6844-7099 Reserved Reserved

7100-7101 GIO 1 IO Input 1 Status

7102-7103 GIO 2 IO Input 2 Status

7104-…. GIO 3… IO Input 3 Status

7194-7195 GIO 48 IO Input 48 Status

7196-7399 Reserved Reserved

7400-7404 Current Alarms 1

7405-7409 Current Alarms 2

…

7645-7649 Current Alarms 50

7650-9999 Reserved Reserved

System Units

Units Data Register Set

Address Offset Unit Type Data Type

5-7 Reserved NA

Length Units Table

Register Value Unit Type Units Precision

10

0 Length See Length Units Table

1 Volume See Volume Units Table

2 Temperature See Temperature Units Table

3 Density See Density Units Table

4 Mass See Mass Units Table

0 Millimeters 1 mm

1 Centimeters 0.1 cm

2 Meters 0.001 m

3 Inches 0.1 in

Page 11

Volume Units Table

Register Value Unit Type Units Precision

0 Liters 0.1 L

1 Gallons 0.1 gal

2 Imperial Gallons 0.1 imp gal

Temperature Units Table

Register Value Unit Type Units Precision

0 Centigrade 0.1 C

1 Fahrenheit 0.1 F

Density Units Table

Register Value Unit Type Units Precision

0 Kilograms per cubic meter 0.1 kg/m^3

1 Grams per cubic centimeter 1 g/cm^3

2 Pounds per cubic foot 0.001 lbs/ft^3

Mass Units Table

Register Value Unit Type Units Precision

0 Kilograms 0.1 kg

1 Grams 1 g

2 Pounds 0.01 lbs

Tank Data

Tank Data Register Set

Tank Register Start Address = (TankNumber-1)*36+200

Register Description Address Offset Data Format Resolution

Tank Status Register 0, 1 See Tank Status Register

Tank Alarms Register* 2,3 See Tank Alarms Register

Product Level 4,5 Signed 32-bit Integer See Length Units

Water Level 6,7 Signed 32-bit Integer See Length Units

Temperature 8,9 Signed 32-bit Integer See Volume Units

Gross Product Volume 10,11 Signed 32-bit Integer See Volume Units

Net Product Volume 12,13 Signed 32-bit Integer See Volume Units

Water Volume 14,15 Signed 32-bit Integer See Volume Units

Ullage Volume 16,17 Signed 32-bit Integer See Volume Units

Density 18,19 Signed 32-bit Integer See Density Units

Net Density 20,21 Signed 32-bit Integer See Density Units

Mass 22,23 Signed 32-bit Integer See Mass Units

Reserved 24-31 N/A

*Note that this register does not contain all possible alarms for a tank.

Tank Status Register

Bit # Status Bit

0 Tank in Alarm

1 Delivery in Progress

2 Static Tank Test in Progress

3-31 Reserved

11

Page 12

Tank Alarms Register

Bit # Status Bit

0 High High Product

1 High Product

2 High Water

3 Low Product

4 Low Low Product

5 Precision Leak Detected

6 Gross Leak Detected

7 SCALD Leak Detected

8 Product Density High Limit Exceeded

9 Product Density Low Limit Exceeded

10 Float Missing

11 Probe Synchronization Error

12 No Probe Detected

13 Float Height Error

14-31 Reserved

Manifold Data

Manifold Data Register Set

Manifold Register Start Address = (ManifoldNumber-1)*26+3200

Register Description Address Offset Data Format Resolution

Manifold Status Register 0, 1 See Manifold Status Register

Manifold Alarms Register* 2,3 See Manifold Alarms Register

Temperature 4,5 Signed 32-bit Integer See Volume Units

Gross Product Volume 6,7 Signed 32-bit Integer See Volume Units

Net Product Volume 8,9 Signed 32-bit Integer See Volume Units

Water Volume 10,11 Signed 32-bit Integer See Volume Units

Ullage Volume 12,13 Signed 32-bit Integer See Volume Units

Reserved 14-20 N/A

*Note that this register does not contain all possible alarms for a tank.

Manifold Status Register

Bit # Status Bit

0 Manifold in Alarm

1 Delivery in Progress

2-31 Reserved

Manifold Alarms Register

Bit # Status Bit

0 Low Product

1 Low Low Product

2 SCALD Leak Detected

3-31 Reserved

12

Page 13

Sensor Data

2-Wire Sensor Status Register

2-Wire Sensors Start Address = (SensorNumber-1)*2+4500

Bit # Status Bit

0 Sensor State

1-31 Reserved

2-Wire Sensor State Table

Bit Value Sensor State

0 Ok

1 Alarm

3-Wire Sensor Register Set

3-Wire Sensors Start Address = (SensorNumber-1)*3+4800

Register Description Address Offset Data Format

Sensor Type 0 See 3-Wire Sensor Type Table

Sensor State 1 See 3-Wire Sensor State Table

Reserved 2

3-Wire Sensor Type Table

Register Value Sensor Type

0 Unknown Sensor

1 Interstitial (EIS) OR 2-Wire Sensor

2 Discriminating Interstitial Sensor (DIS)

3 Discriminating Dispenser Sump Sensor (DDS)

4 Discriminating Turbine Sump Sensor (DTS)

5 Monitoring Well Sensor (MWS)

6 Hydrostatic Interstitial Brine Reservoir Sensor (HIS)

7 Discriminating Monitoring Well Vapor Sensor (DVS)

3-Wire Sensor State Table

Register Value Sensor State

0 Ok

1 Alarm

2 Sensor On

3 Product Detected

4 Water Detected

5 Sump Full

6 Dry Well

7 High Brine

8 Low Brine

9 Vapor Detected

10 Vapor Sensor Malfunctioning

11 Temperature Error

12 Synchronization Error

13 Signal Lost

14 ID Error

15 Data Error

13

Page 14

Mag Sensor Register Set

Mag Sensors Start Address = (SensorNumber-1)*7+5200

Register Description Address Offset Data Format

Product Level 0,1 Signed Integer (See Length Units)

Water Level 2,3 Signed Integer (See Length Units)

Status Register 4 See Mag Sensor Status Register

Reserved 5-8

Mag Sensor Status Register

Bit # Status Bit

0 Water Warning Active

1 Water Alarm Active

2 Product Alarm Active

3 Installation Alarm Active

4 Sensor Missing Alarm Active

5 Sensor Sync Alarm Active

6 Sensor Float Missing Active

7-15 Reserved

Relay Data

Relay Status Register

PS Relay Start Address = (PSRelay-1)*2+5900

Relay Start Address = (Relay-1)*2+6000

Bit # Status Bit

0 Relay Status

1-15 Reserved

Relay Status State Table

Bit Value Relay State

0 Deactivated

1 Active

14

Page 15

Turbine Pump Interface (TPI) Data

TPI Controller Status Register

TPI Start Address = (TPINum-1)*2+6400

Bit # Status Bit

0 Pump Status

1 Pump Forced Off

2 Pump Controller Faulted

3-15 Reserved

Pump Status Table

Register Value Pump Status State

0 Idle

1 Running

Pump Forced Off State Table

Register Value Pump Forced Off State

0 Ok

1 Force Off

Pump Controller Faulted Table

Register Value Pump Controller Faulted State

0 Ok

1 Controller Faulted

Input Data

Low Voltage Inputs Status Register

LVI Start Address = (LVINum-1)*2+6600

Bit # Status Bit

0 Input Status

1-15 Reserved

Low Voltage Input Status Table

Bit Value Low Voltage Input State

0 In-Active

1 Active

AC Input Status Register

DHI Start Address = (DHI Num-1)*2+6700

Bit # Status Bit

0 Input On

1-15 Reserved

AC Input Bit Value Table

Register Value AC Input State

0 In-Active

1 Active

15

Page 16

GIO Inputs Status Register

GIO Start Address = (GIO Num-1)*2+7100

Bit # Status Bit

0 Input On

1-15 Reserved

GIO Input Bit Value Table

Register Value GIO Input State

0 In-Active

1 Active

Current Alarms Register Set

Alarms Start Address = (Alarm Num-1)*5+7400

Register Description Address Offset Data Format

Alarm Code 0 See Alarm Code Table

Alarm Data 1 Integer, typically device number

Reserved 2-5

Alarm Code Table

Alarm Code Device Type Alarm Name

-2 None Unknown

-1 None Any

0 None No error

1 Slot Test Alarm

SYSTEM ALARMS (0900-1999)

1001 None Probe module number mismatch

1002 None Probe module number mismatch

1003 None 4-20mA module number mismatch

1004 None Relay module number mismatch

1005 None AC Input module number mismatch

1006 None 4-20mA module number mismatch

1007 None 4-20mA module number mismatch

1008 None 2-Wire Sensor module number mismatch

1009 None 3-Wire Sensor module number mismatch

1010 None Power Supply module number mismatch

1011 None IO module number mismatch

1012 None DIM module number mismatch

1013 None LON module number mismatch

1014 None Printer module number mismatch

1015 None Console DTU number mismatch

1018 None IS Barrier Violation

1022 Slot Console DTU is ofine

1023 Slot Probe module is ofine

1024 Slot 4-20mA module is ofine

1025 Slot Relay module is ofine

1026 Slot AC Input module is ofine

1027 Slot 2-Wire Sensor module is ofine

16

Page 17

1028 Slot 3-Wire Sensor module is ofine

1029 Slot Power Supply module is ofine

1030 Slot IO module is ofine

1031 Slot Controller module is ofine

1032 None System Bus Error

1033 None Power Supply Setup Error

1034 None AC Input Setup Error

1035 None Relay Module Setup Error

1036 None Probe Module Setup Error

1037 None 4-20mA Module Setup Error

1038 None 2-Wire Sensor Module Setup Error

1039 None 3-Wire Sensor Module Setup Error

1040 None Vapor Recovery Monitor Setup Error

1041 None Fuel Management System Setup Error

1042 None Secondary Containment Monitor Setup Error

1043 None System Setup Error

1044 None Invalid Registration

1045 None Invalid Conguration

1046 None Internal Error #1 - contact technical support

1047 None Auto Detect Setup Error

1048 None Set Date and Time

VAPOR RECOVERY MONITORING ALARMS (2000-2499)

2001 aldHose Daily Vapor Collection Warning

2002 aldHose Daily Vapor Collection Failure

2003 aldHose Weekly Vapor Collection Warning

2004 aldHose Weekly Vapor Collection Failure

2005 aldHose ORVR Vehicle Limit Reached

2040 aldChannelPRB VFM Missing

2041 aldChannelPRB VFM Error

2042 aldChannelPRB VFM No Data

2050 None Weekly Ullage Pressure Warning

2051 None Weekly Ullage Pressure Failure

2053 None Weekly Ullage Pressure Leak Test Warning

2054 None Weekly Ullage Pressure Leak Test Failure

2056 None Ullage Volume Insufcient

2057 None Pressure Out of Range for Ullage Pressure Leak Test

2058 None Monthly Ullage Pressure Warning

2059 None Monthly Ullage Pressure Failure

2070 None Pressure Sensor Error

2071 None Pressure Sensor Open Circuit

2080 None Vapor Processor Input

2081 None Vapor Processor Failure

2082 None Vapor Processor Warning

2083 None Vapor Processor Failure

2090 None Conguration Error

2091 None TS-DIM Read Data Error

2092 None External ATG Connection Down Error

17

Page 18

2093 None TS-DIM Connection Down

2095 None Development Test Alarm

2096 None External ATG Connection Down Warning

FUEL MANAGEMENT SYSTEM ALARMS (2500-2999)

2500 None FMS conguration error

2501 Tank No data available

2502 Tank Float missing

2503 Tank Probe synchronization error

2504 Tank No probe detected

2505 Tank Temperature Error

2506 Tank RTD table error

2507 Tank API volume correction error

2508 Tank Alpha volume correction error

2509 Tank Level error

2510 Tank Product volume error

2511 Tank Water volume error

2512 Tank Ullage error

2513 Tank Correction table error

2514 Tank Net error

2515 Tank Low battery

2516 Tank System memory error

2517 Tank Float height error

2519 Tank Line monitor disabled

2520 Tank Open analog input

2521 Tank Unstable probe

2522 Tank High high product level

2523 Tank High product level

2524 Tank High water level

2525 Tank Low product volume

2526 Tank Low low product volume

2527 Manifold Manifold Low product volume

2528 Manifold Manifold Low low product volume

2529 Tank High product volume

2530 Tank High High product volume

2540 Tank Density error

2541 Tank High water/Phase sep

2650 Tank Tank Theft Detected

2651 Manifold Manifold Theft Detected

2652 Tank Tank Leak Detected

2653 Manifold Manifold Leak Detected

2654 Tank Tank Gross Leak Detected

2655 Manifold Manifold Gross Leak Detected

2656 Tank Tank Scald Leak Detected

2657 Manifold Manifold Scald Leak Detected

2658 Tank Tank Scald Compliance Warning

2659 Manifold Manifold Scald Compliance Warning

18

Page 19

2660 Tank Tank Water/Phase Sep Float Disabled

2680 Tank Tank Product Density High Limit Exceeded

2681 Tank Tank Product Density Low Limit Exceeded

2682 Tank Density oat error

2690 Mag Sensor Mag sensor conguration error

2691 Mag Sensor Mag sensor not learned error

2692 Mag Sensor Mag sensor oat missing

2693 Mag Sensor Mag sensor synchronization error

2694 Mag Sensor Mag sensor missing

2695 Mag Sensor Mag sensor data error

2696 Mag Sensor Mag sensor oat height error

2697 Mag Sensor Mag installation error

2698 Mag Sensor Mag water warning

2699 Mag Sensor Mag water alarm

2700 Mag Sensor Mag product alarm

SECONDARY CONTAINMENT MONITORING ALARMS (3000-3499)

3000 Containment Vacuum Too High

3001 Containment Low Vacuum

3002 Containment Failed to Reach Target Vacuum

3003 Containment Failed to Hold Vacuum

3004 Containment Unstable Vacuum

3005 Containment Containment Not Learned

3006 Containment Vacuum Sensor Failed

3007 Containment Vacuum Sensor Failed/Not Connected

3008 Containment Containment Pump Request Ignored

3009 Containment Low Vacuum And Pump Request Ignored

3010 None Containment Program Error Warning

3011 None Containment Program Error Detected

3012 Containment Not Congured

3013 Containment Disabled

ANA ALARMS (3500-3599)

3500 4-20mA Channel 4-20mA Input Error

SENSOR ALARMS (3600-3699)

3600 2-Wire Sensor SN2 Sensor On

3601 Slot SN2 Fuse Blown

3602 3-Wire Sensor SN3 Sensor On

3603 Slot SN3 Fuse Blown

3604 Slot SN3 Pwr Short

3605 3-Wire Sensor SN3 Data Error

3606 3-Wire Sensor SN3 Water

3607 3-Wire Sensor SN3 Product

3608 3-Wire Sensor SN3 Sump Full

3609 3-Wire Sensor SN3 Dry Well

3610 3-Wire Sensor SN3 High Brine

3611 3-Wire Sensor SN3 Low Brine

3612 3-Wire Sensor SN3 Vapor

3613 3-Wire Sensor SN3 No Signal

19

Page 20

20

3614 3-Wire Sensor SN3 Id Error

3615 3-Wire Sensor SN3 Sync Error

LINE LEAK DETECTION ALARMS (3700-3799)

3700 Line Gross Leak Test Failed

3701 Line Monthly Leak Test Failed

3702 Line Precision Leak Test Failed

3703 Line Failed to Pressure Up

3704 Line Failed to Catch Pressure

3705 Line Sudden Pressure Loss

3706 Line Dispensing Pressure Test Failed

3707 Line High Line Pressure

3708 Line Extended Hook Signal

3709 4-20mA Channel Pressure Transducer Fail

3710 Line Line is not congured

3711 Line Line Program Error Detected

3712 Line Air in Line

3713 Line Line Not Enabled

3714 Line Line Not Learned

3715 Line 3 GPH Compliance Expired

3716 Line 0.2 GPH Compliance Expired

3717 Line 0.1 GPH Compliance Expired

3718 Line Marginal Pass of Gross Leak Test

3719 Line Line Pump Request Ignored

PRINTER ALARMS (3800-3899)

3800 System Printer Paper Jam

3801 System Printer Paper Jam

3802 System Printer Solenoid Stuck

3803 System Printer Solenoid Stuck

3804 None Printer Door Open

3805 None Check Printer

3806 None Printer Motor Temperature

3807 None Printer Head Temperature

3808 None Check Paper

MODEM ALARMS (3900-3999)

3900 None Modem Error

3901 None Cellular Modem Error

3902 None Dynamic DNS Error

VR EMULATION ALARMS (4000-4049)

4000 None VR Dim Data Lost

DISPENSER INTERFACE MODULE ENGINE ALARMS (4050-4099)

4050 None Dim Communications Failure

TURBINE PUMP INTERFACE ALARMS (4100-4199)

4100 None Communication Failure

4101 Pump Pump Communication Fail

4102 Pump Clogged Intake

4103 Pump Dry Tank

4104 Pump Pump In Water

Page 21

4105 Pump Under Voltage

4106 Pump Locked Rotor

4107 Pump Open Circuit

4108 Pump Capacitor Failing

4109 Pump Short Circuit

4110 Pump High Temperature

4111 Pump Not Calibrated

4112 Pump Extended Run

4113 Pump Relay Fault

4114 Pump L2 Open

4115 Pump Over Voltage

4116 Pump Unbalanced Voltage

4117 Pump Unbalanced Load

4118 Pump Unknown Fault

4119 Pump Underload

4120 Pump Over Speed

4121 Pump Long Flash

4122 Pump Hardware Fault

4123 Pump Controller Type Error

INPUT ALARMS (4200-4299)

4200 GIO Input IO Input Alarm

4201 PS Input Power Supply Input Alarm

4202 DHI Input AC Input Alarm

PLC ALARMS (4300-4399)

4300 None DTU FFS Interference

4301 None DTU Non FFS Interference

4302 PLC Remote DTU is ofine

COMPLIANCE ALARMS (4400-4499)

4401 Tank Monthly Compliance Alarm

4402 Tank Monthly Compliance Warning

4403 Tank Annual Compliance Alarm

4404 Tank Annual Compliance Warning

4405 Manifold Monthly Compliance Alarm

4406 Manifold Monthly Compliance Warning

4407 Line Monthly Compliance Alarm

4408 Line Monthly Compliance Warning

4409 Line Annual Compliance Alarm

4410 Line Annual Compliance Warning

4411 2-Wire Sensor Monthly Compliance Alarm

4412 2-Wire Sensor Monthly Compliance Warning

4413 3-Wire Sensor Monthly Compliance Alarm

4414 3-Wire Sensor Monthly Compliance Warning

4415 Mag Sensor Monthly Compliance Alarm

4416 Mag Sensor Monthly Compliance Warning

21

Page 22

©2013 FFS 000-0536 Rev A

Loading...

Loading...