Page 1

Tank Sentinel Operator’s Guide

®

TS-1001, 2002, 504, 508 & 750

Automatic Tank Gauge/ Leak Detection System

3760 Marsh Road ● Madison, WI 53718 U.S.A.

Tel: +1 608 838 8786 ● Fax: +1 608 838 6433 ● www.franklinfueling.com

Tel: USA & Canada 1 800 225 9787 ● Tel: Mexico 001 800 738 7610

Part Number: 000-1052, Rev. D

©

Copyright

August 2011

Page FC - 1

Page 2

NOTICE

Franklin Fueling Systems has strived to produce the nest possible manual for you, and to ensure

that the information contained in it is complete and accurate. However, Franklin Fueling Systems

makes no expressed or implied warranty with regard to its contents. Franklin Fueling Systems

assumes no liability for errors or omissions, or for any damages, direct or

consequential, that result from the use of this document or the equipment which

it describes.

This document contains proprietary information and is protected by copyright. All

rights are reserved. No part of this document may be reproduced in any form

without the prior written consent of Franklin Fueling Systems.

Franklin Fueling Systems reserves the right to change this document at any time without notice.

Need Help ? Contact Franklin Fueling Systems at:

Franlin Fueling Systems

3760 Marsh Road

Madison, WI 53718

Office Hours: 7 a.m. to 7 p.m. Central Time Monday through Friday

- ecivreS lacinhceT

Phone: (608) 838-8786

Fax: (608) 838-6433

Visit our Website at:

Phone: (800) 984-6266

E-mail:

techserve@franklinfueling.com

www.franklinfueling.com

INCON is a wholly owned subsidiary of Franklin Electric and is a member of the

Franklin Fueling Systems Group

Tank Sentinel ® SCALD® Brite BriteBox® Britebus® BriteSensors

and INCON® are registered trademarks of Intelligent Controls, Inc.

System Sentinel™ and System Sentinel

™ are trademarks of

Intelligent Controls, Inc.

Copyrighted 1997, 1998, 2003, 2011 Intelligent Controls, Inc. All rights reserved.

®

—

Tank Sentinel Setup Programming Guide

—

Page 3

T able of Contents

P Preface................................................................................................... P - i

Graphic Symbol Conventions ............................................................................... P - i

Page Numbering Conv ention – Example:....................................................... P - i

Page Layout Convention – Example: .............................................................. P - i

Product Overview ................................................................................................. P - ii

Alarms and Warnings...................................................................................... P - iii

Tank Sentinel® Features...................................................................................... P - iii

Safety .................................................................................................................. P - iv

Approvals ...................................................................................................... P - iv

Need Help ? – Names and Phone Numbers to Contact.......................... P - iv

1 Console – Basic Operation .................................................................. 1 - 1

General.................................................................................................................. 1 - 1

Operating Modes................................................................................................... 1 - 1

Console Component Location ............................................................................... 1 - 2

Display .................................................................................................................. 1 - 2

Run Mode Display ........................................................................................... 1 - 2

Sentinel Mode Display..................................................................................... 1 - 3

Tank or Line Testing Display ........................................................................... 1 - 3

Tank & Line Display Notes: .......................................................... 1 - 3

Menu keys (M1 thru M4) ....................................................................................... 1 - 3

Status Row (with Alarm Test Key) ......................................................................... 1 - 4

Keypad Keys ......................................................................................................... 1 - 4

Report Printer........................................................................................................ 1 - 4

Paper Advance Button .......................................................................................... 1 - 4

RS232 Communication Ports ................................................................................ 1 - 4

TS-FM2 Receptacle .............................................................................................. 1 - 5

Model & Serial Number Label................................................................................ 1 - 5

Product & Tank Related Keys................................................................................ 1 - 5

Menu Related Keys ............................................................................................... 1 - 6

Changing the Display and Report Language ............................................... 1 - 8

Special Keys ......................................................................................................... 1 - 9

Selecting A Report .......................................................................................... 1 - 9

Report Features ............................................................................................ 1 - 10

Check Date &Time ..................................................................................... 1 - 10

Check Display, Printer, or Dialtone .......................................................... 1 - 10

Check Software & Hardware Options ........................................................ 1 - 10

Starting a tank or Line Leak Test: ............................................................ 1 - 11

Testing Note:............................................................................................ 1 - 11

Showing the Status of Tank or Line Leak Tests ....................................... 1 - 11

Indications of Active Tests:...................................................................... 1 - 11

Aborting a Tank or Line Leak Test............................................................ 1 - 12

ACK Shift key uses: .................................................................................... 1 - 13

Upgrade Menu..................................................................................................... 1 - 14

Sample Upgrade Instructions .............................................................................. 1 - 16

Table of Contents Page TOC - 1

TOC

Page 4

2 Acknowledging Alarms ........................................................................ 2 - 1

Purpose of Audio / Visual Alarms.......................................................................... 2 - 1

Audio Alarm Annunciator (& Output Relays)......................................................... 2 - 1

Visual Alarm Indications ........................................................................................ 2 - 2

Alarm Types........................................................................................................... 2 - 3

System Warnings ............................................................................................ 2 - 3

Tank Alarms..................................................................................................... 2 - 3

Sensor Alarms................................................................................................. 2 - 3

Line Alarms...................................................................................................... 2 - 3

Alarm Status.......................................................................................................... 2 - 3

Acknowledge Password........................................................................................ 2 - 4

Acknowledging Alarms / Silencing Alarms ............................................................ 2 - 4

Starting a Grace Period................................................................................... 2 - 4

Leak Detection Sensors .................................................................................. 2 - 5

3 T ank Sentinel Reports.......................................................................... 3 - 1

Reports Overview................................................................................................. 3 - 1

Report Types......................................................................................................... 3 - 1

How to Print a Report...................................................................................... 3 - 2

FAXing a Report .............................................................................................. 3 - 2

Where are Fax’d Reports Sent ? ............................................................... 3 - 2

Example – Automatic Alarm Reports .............................................................. 3 - 3

Typical Information Shown On Reports..................................................... 3 - 3

Product Inventory Detail REPORT ................................................................. 3 - 4

Product Inventory Summary REPORT ........................................................... 3 - 4

Tank Inventory Detail REPORT ...................................................................... 3 - 5

Tank Inventory Summary REPORT................................................................ 3 - 5

Product Delivery Detail REPORT ................................................................... 3 - 6

Product Delivery Summary REPORT............................................................. 3 - 6

Product Delivery History REPORT................................................................. 3 - 6

Product Usage Detail REPORT..................................................................... 3 - 7

Product Usage Summary REPORT ............................................................... 3 - 7

Product Usage Reconcile REPORT ............................................................... 3 - 8

Product Usage Sales REPORT...................................................................... 3 - 9

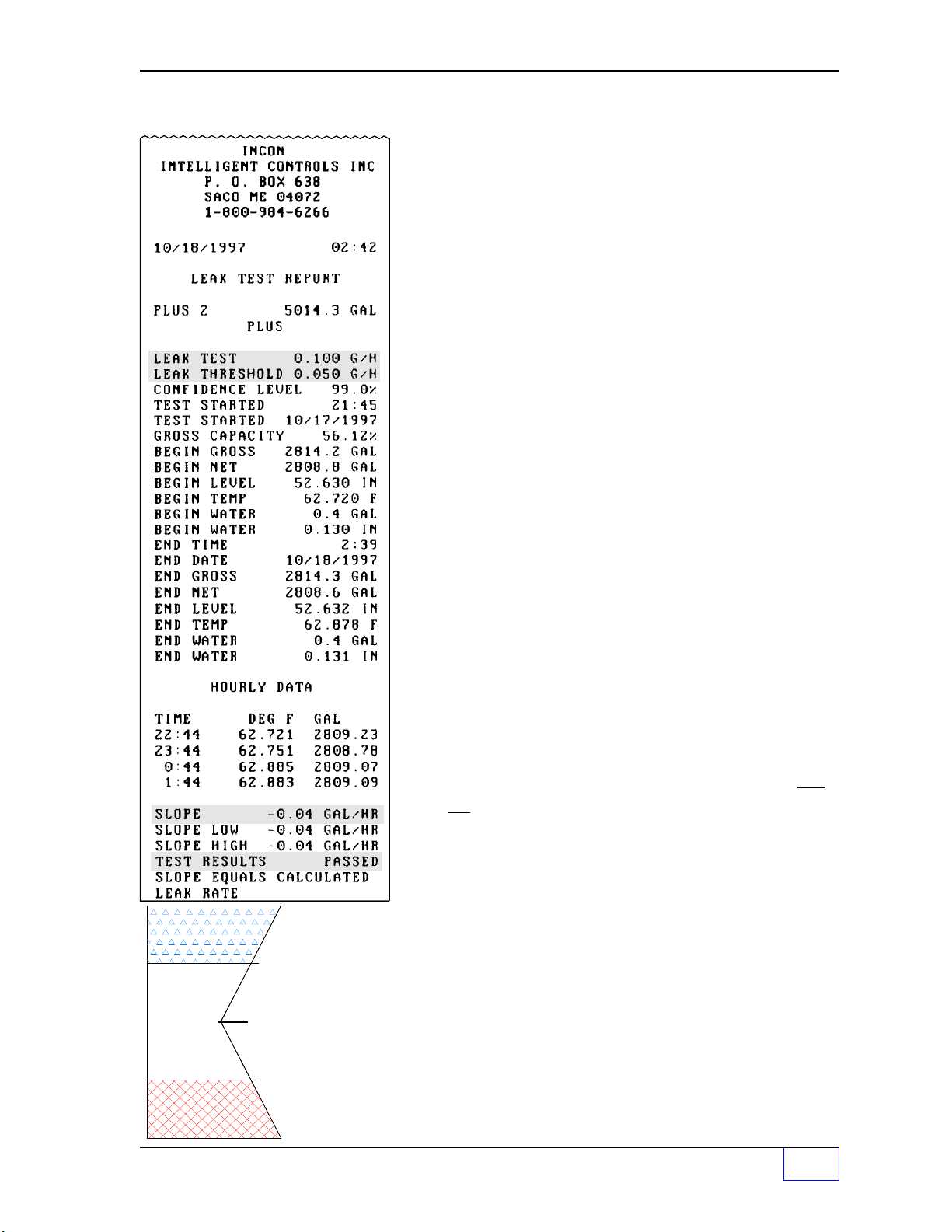

Tank Leak Test Estimate REPORT ............................................................... 3 - 10

Standard (Static) Tank Leak Test REPORT .................................................. 3 - 11

Slope & Leak Test Results ............................................................................ 3 - 11

SCALD Leak Test REPORT....................................................................... 3 - 12

Line Compliance Test REPORT .................................................................... 3 - 13

Line Leak T est REPORT ............................................................................... 3 - 14

Line Leak Diagnostic REPORT..................................................................... 3 - 14

Line Leak Test History REPORT................................................................... 3 - 15

Report(s) Sent to Remote Fax Machines:............................................... 3 - 16

Sensor Status REPORT ............................................................................... 3 - 17

V apor Sensor REPORT ................................................................................ 3 - 17

Alarm Reports ............................................................................................... 3 - 18

Active System Alarms REPORT .................................................................. 3 - 18

Cleared System Alarms REPORT................................................................ 3 - 18

System Alarm History REPORT................................................................... 3 - 18

Active Tank Alarms REPORT ....................................................................... 3 - 18

TOC

Page TOC - 2 Tank Sentinel Operator’s Guide

Page 5

Cleared Tank Alarms REPORT..................................................................... 3 - 18

Tank Alarm History REPORT ....................................................................... 3 - 18

Active Sensor REPORT ............................................................................... 3 - 19

Cleared Sensor Alarms REPORT................................................................. 3 - 19

Sensor Alarm History REPORT .................................................................... 3 - 19

Active Line Alarms REPORT ........................................................................ 3 - 19

Cleared Line Alarms REPORT...................................................................... 3 - 19

Line Alarm History REPORT ........................................................................ 3 - 19

All Active Alarms REPORT........................................................................... 3 - 20

All Cleared Alarms REPORT ....................................................................... 3 - 20

All Alarm History REPORT ........................................................................... 3 - 21

Changing the Number of Alarms to Print ....................................................... 3 - 21

System Setup REPORT ............................................................................... 3 - 22

Tank Setup REPORT .................................................................................... 3 - 22

Setup Report example............................................................................. 3 - 23

Regulatory REPORT..................................................................................... 3 - 27

CPM Alarm REPORT.................................................................................... 3 - 28

CPM Status REPORT................................................................................... 3 - 28

CPM Monthly REPORT ................................................................................ 3 - 29

Generator Run REPORT .............................................................................. 3 - 30

Print Test REPORT ....................................................................................... 3 - 30

4 Leak Testing.......................................................................................... 4 - 1

Overview............................................................................................................... 4 - 1

Tank Leak Tests – Type and Frequency ................................................................ 4 - 2

Before Starting a Standard (static) Tank Leak Test ......................................... 4 - 2

When to Run Tank Leak Tests......................................................................... 4 - 2

Starting Tank Leak Tests: ................................................................................ 4 - 3

Tank Leak Test Results ................................................................................... 4 - 3

Reasons Why Tank Leak Tests Fail:................................................................ 4 - 3

When a Leak Test Fails.................................................................................... 4 - 4

TS-LLD Line Leak Tests: ....................................................................................... 4 - 5

Type and Frequency.............................................................................................. 4 - 5

Before Starting a Line Leak Test:..................................................................... 4 - 5

When to Run Line Leak Tests.......................................................................... 4 - 5

Starting Line Leak Tests .................................................................................. 4 - 6

When a Line Leak Test Fails / Line Leak is Detected ...................................... 4 - 6

Steps to take When a Line Leak is Detected:........................................................ 4 - 7

Need help ? ........................................................................................................... 4 - 7

5 T roubleShooting & Routine Maintenance ........................................... 5 - 1

TroubleShooting..................................................................................................... 5 - 1

Site Policy:............................................................................................................. 5 - 8

• Silencing Alarms ........................................................................................... 5 - 8

• Acknowledging Alarms.................................................................................. 5 - 8

• Grace Periods (Allowed when, number of times, etc.) .................................. 5 - 8

• Troubleshooting Alarms & Error Messages ................................................... 5 - 9

• Line and Tank Leak Test Failures................................................................. 5 - 10

• Call Numbers for Help................................................................................. 5 - 11

Site Sketch / paste-in area: ................................................................................. 5 - 12

Table of Contents Page TOC - 3

TOC

Page 6

Routine Maintenance........................................................................................... 5 - 14

• External Cleaning ..................................................................................... 5 - 14

• Replacing the Printer P aper Roll............................................................... 5 - 14

• Lubricate Printer: ...................................................................................... 5 - 14

• Replacing Fuses, Memory-backup Battery , & Interior Cleaning:.............. 5 - 15

FCC Information & Requirements ........................................................ FCC - 1

Overall Information & Requirements ................................................................ FCC - 1

INDUSTRY CANADA Information & Requirements ...................................... FCC - 2

CP-01 Issue 8, Part I, Section 14.1.................................................................. FCC - 2

CP-01, Issue 8, Part I, Section 14.2................................................................. FCC - 2

G Glossary .............................................................................................. G - 1

CFF Customer Feedback Form....................................................... CFF - 1

W Warranty .............................................................................................. W - 1

T able of FIGURES and T ABLES

Graphic Symbol Conventions .................................................................... P - i

Page Numbering Convention – Example:................................................. P - i

Page Layout Convention – Example: ........................................................ P - i

Figure P - 1 TS-1001 & TS-2001 Model ATG Consoles......................... P - iii

Figure 1 - 1 Console Component Identification...................................... 1 - 2

TABLE 2.1 Output Groups (A — FF)..................................................... 2 - 6

Figure 2.1 External BriteBoxes to Console ......................................... 2 - 7

Figure 2.2 Typical Station Partial Side-view with One Tank................. 2 - 7

TABLE 2.1 Output Groups (A — FF)..................................................... 2 - 8

Setup Report (example) .......................................................................... 3 - 23

TABLE 5 - 1 Alarms & Error messages ................................................ 5 - 1

TABLE 5 - 2 SYSTEM TEST SCHEDULE ............................................ 5 - 7

TABLE 5 - 3 Fax Numbers & Location (Fill-in)....................................... 5 - 11

TOC

—

Page TOC - 4 Tank Sentinel Operator’s Guide

❖

—

Page 7

P PREF ACE

Contents:

Graphic Symbol, Page Numbering

and Layout Conventions

Product Overview

Alarms and Warnings

Graphic Symbol Conventions

NOTE

Important information, tips, and hints are highlighted by the NOTE graphic.

☞

CAUTION

WARNING

DANGER

must be followed.

— ❖ — End of Chapter (or Section) symbol

or

messages are highlighted by this graphic.

messages are highlighted by this graphic and contain instructions that

Tank Sentinel Features

Safety

Approvals

Need Help ? Names and Phone Numbers to

Contact

Page Numbering Convention – Example:

•

Page 2 - 1 = Chapter 2 page 1• Page 6.1 - 2 = Chapter 6 . Section 1 – Page 2

Page Layout Convention – Example:

Manual Name

EVEN NUMBERED

(

PAGES

)

Page Number

Chapter Number

Chapter Number &

Name (

FIRST

Chapter Contents

TOP LEFT

PAGE

)

Chapter Name

(

ODD NUMBERED

PAGES

)

Page Number

Chapter Number

PREFACE Page P - i P

Page 8

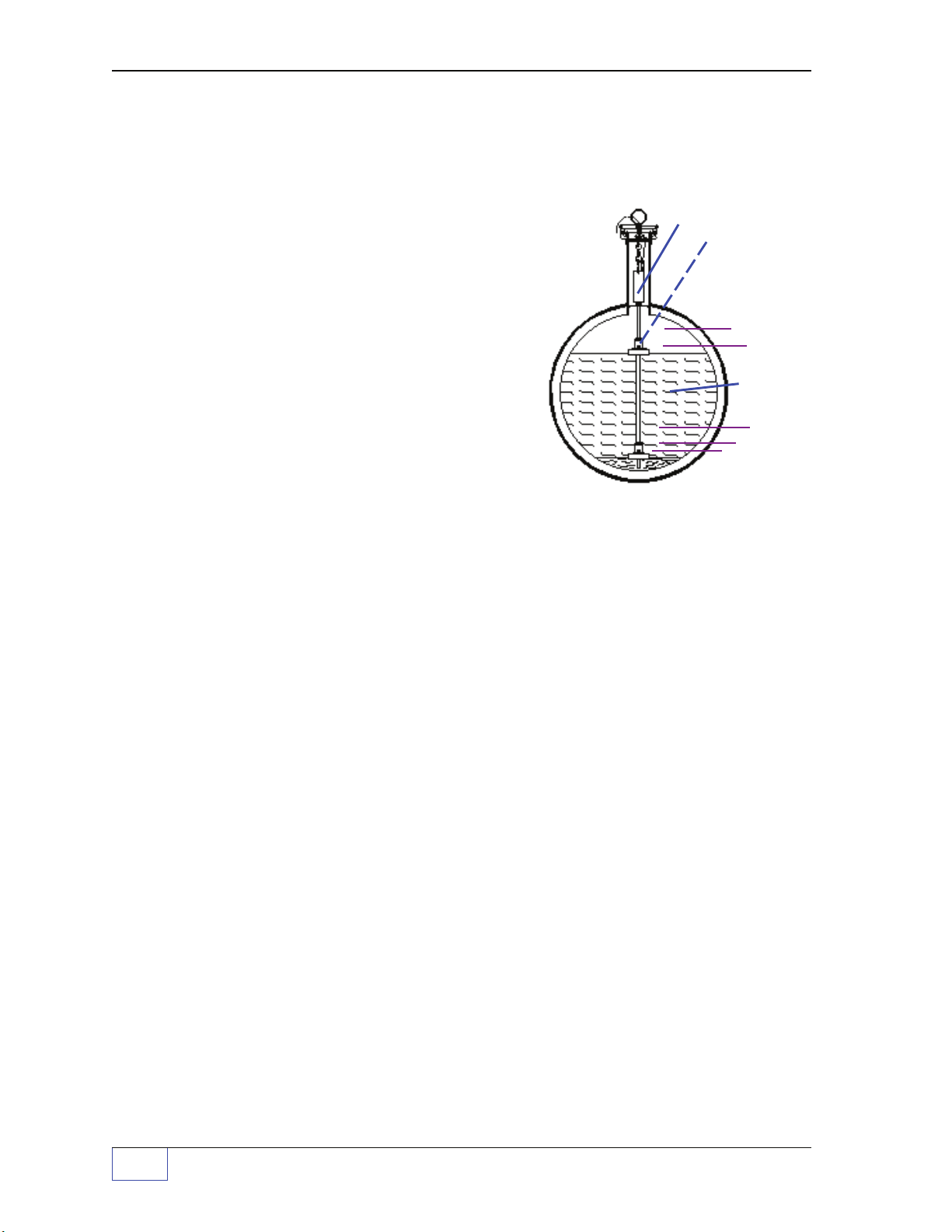

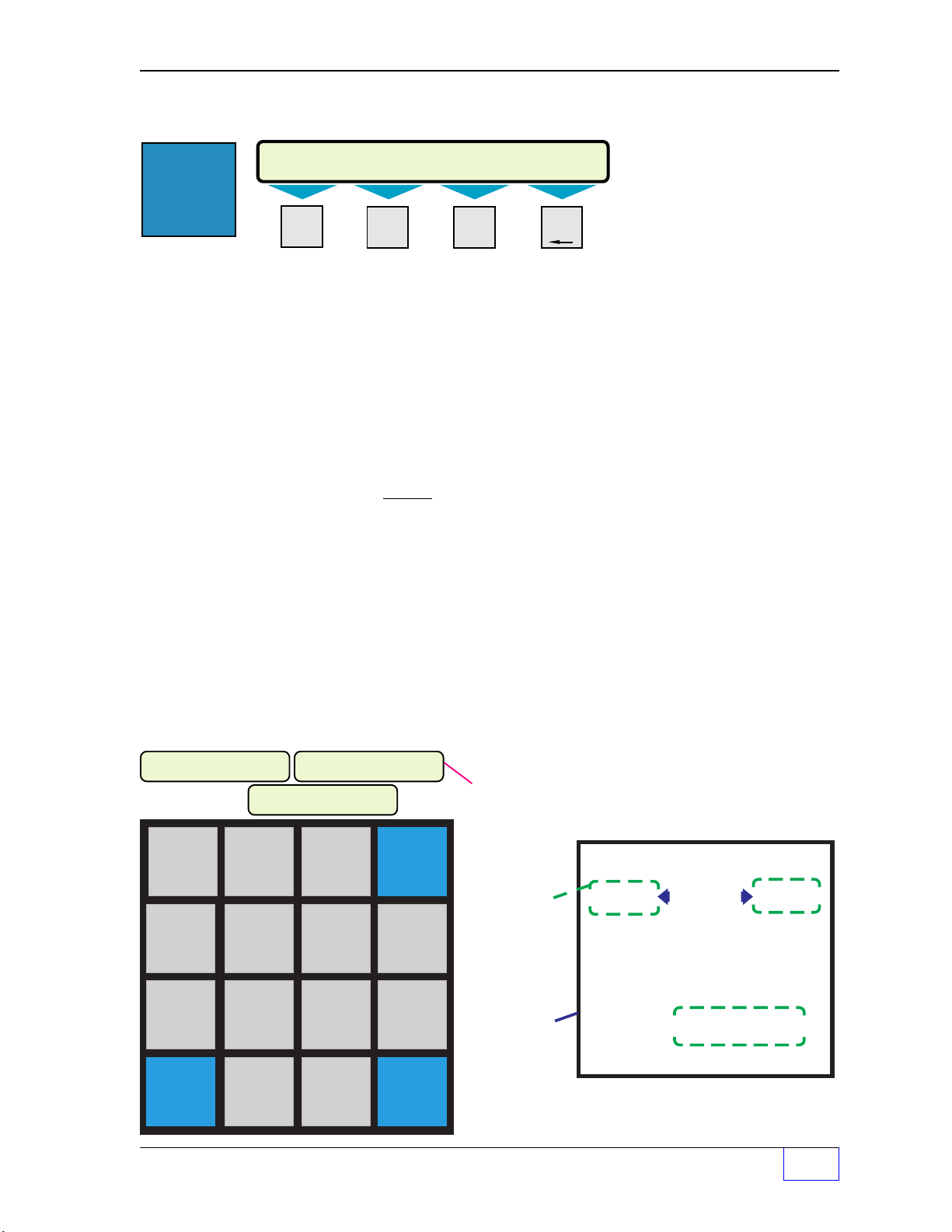

Product Overview

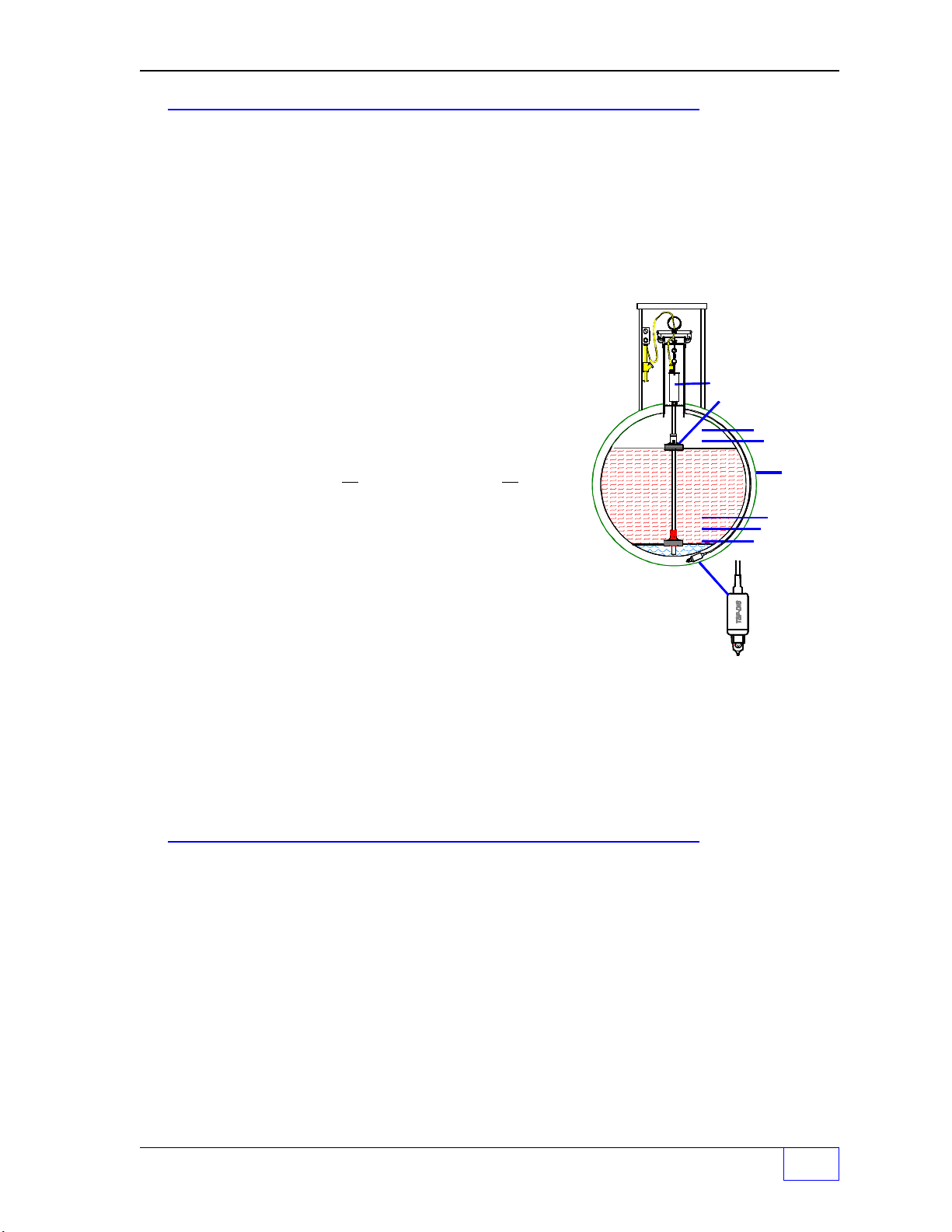

The INCON TS-1001 / 2001 /504 / 508 / 750 Tank Sentinel® consoles are complete leak detection

and inventory monitoring systems. The TS-750 / 1001 / 2001 models run in-tank leak tests

with exceptionally high accuracy. The TS-504 / 508 models are designed for monitoring and

controlling liquid levels in aboveground storage tanks.

The tests meet or exceed all current EPA standards.

Liquid Level Probe &

Floats

A broad range of liquid products can be leaktested and inventory-monitored (or gauged)

simultaneously in many storage tanks.

PROGRAMMED

TANK RELATED

ALARM LIMITS

HIGH HIGH

HIGH

:

Inventory monitoring is done with a very

special sensor called a

Liquid Level Probe

Product

that has a product float. With petroleum

products, water floats are used. When a

programmed limit is reached, then a tank-

LOW

LOW LOW

HIGH WATER

related alarm will be produced at the console

for that specific tank.

Additionally, these consoles can monitor a wide variety of leak detection sensors which

are installed within – the walls of double-walled tanks (DW or DWTs), containment sumps,

dispenser pans, and groundwater or vapor monitoring wells near USTs. Leak detection

sensors produce alarms when exposed to liquids such as product. Some produce alarms

at various liquid levels, or when water is absent (as with a ground water monitoring well

sensors), or when they are exposed to hydrocarbon vapors (as with a vapor sensor).

Of the many types of leak detection sensors that are available from INCON, these can be

divided into two basic types — one is called a Standard Sensor and the other is called a

BriteSensor™.

BriteSensors™ are sensors with built-in intelligence. Within them is a small computer that

uses digital data to communicate with the system console. The data sent identifies the

sensor-type and status of each alarm that it can detect. Some BriteSensors can tell the

difference (discriminate) between water and a hydrocarbon (product) and will produce

different alarm-codes for each of these.

On the other hand, Standard Sensors do not use digital data. Instead, the Standard Sensor

operates like an ON–OFF switch that’s

closed when no liquid is present

a liquid is detected. When a liquid is detected, the loss of signal produces a standard

sensor alarm at the console.

P Page P - ii Tank Sentinel Operator’s Guide

– or – open when

Page 9

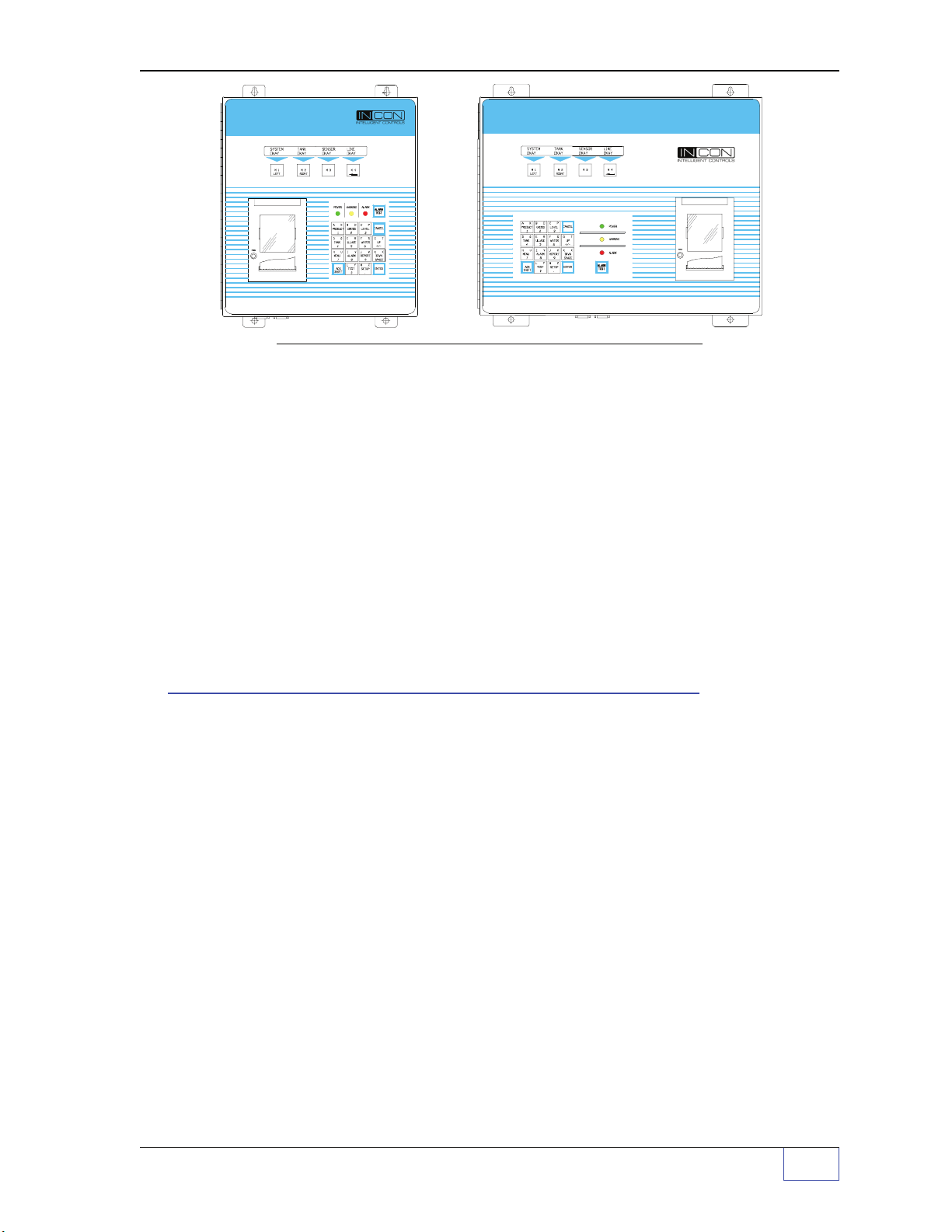

TS-1001 TANK SENTINEL

Figure P - 1 TS-1001 & TS-2001 Model ATG Consoles

®

Alarms and Warnings –

Alarms and warnings are designed to alert you / make you aware of a problem when it

occurs so you can take appropriate corrective action. System hardware fail warnings, tank

related alarms, leak detection sensor alarms, and line leak alarms can be customprogrammed to do many things. These events that require

a (p) below:

– cause the red Alarm light or yellow Warning light to flash (standard)

– activate / sound the console annunciator alarm horn (p)

– activate output relay(s) /

– print alarm reports automatically at the report printer (

– send reports to remote location(s) –

optional

TS-2001 TANK SENTINEL

®

programming

external alarm device (p)

)

p

optional

TS-FM2 fax/data modem req’d (p)

are denoted by

Tank Sentinel® Features

•

The Models TS-1001, 504 & 750 can monitor product in up to 4 tanks

•

The Models TS-2001 & 508 can monitor product in up to 8 tanks

•

The TS-1001 can monitor up to 12 leak detection sensors internally

•

The TS-2001 can monitor up to 24 leak detection sensors internally

•

The TS-504 , 508 & 750 can monitor up to 8 leak detection sensors internally

•

External sensor expansion capability — all consoles can be expanded with 1 or 2

external TS-SEM sensor expansion modules — for an additional 8 or 16 sensors inputs

•

All consoles use advanced technology and can be custom programmed to operate per

your specific needs and management style

•

All models can be programmed to create logical groups of sensors or tank limits

(i.e. by tank, by monitoring well fields, by product type, or by product limits)

•

TS-1001/2001 consoles can be programmed for automatic operation and generation

of reports, and to comply with your local EPA regulatory requirements – for leak testing

and leak detection

•

All consoles can be equipped with an

alarms, reports, and test data can be sent to remote locations

optional

TS-FM2 internal fax-modem — deliveries,

PREFACE Page P - iii P

Page 10

Tank Sentinel® Features (

•

All consoles can communicate with remote computers for off-site notification, management,

and dispatch requests with the

•

Access to the Tank Sentinel console door is key-locked for security, and the database /

setup-configuration program mode can be protected by security passwords to protect

the operation and function of the tank gauge.

•

The Tank Sentinel systems can be equipped with many optional accessories or

programs such as: Tank Overfill Alarm and Acknowledge units, SCALD (Statistical and

Continuous Automatic

•

TS-1001/2001 consoles can be upgraded with a unique input code after receipt of a

purchase order and the console serial number. For instance, a 2 tank TS-1001 can be

upgraded to 4 tanks, or SCALD upgrade added either locally on-site, or remotely (remote

upgrade is possible with the

•

All consoles can monitor product lines for leaks when the INCON

Detector) Interface is used. Many line reports can be produced from the collected data,

such as the versatile Regulatory Report.

•

All models can be programmed to use either:

– SI Units ( litres = liters / l / L, centimeters / cm / CM, Celsius /°C/C )

English System of Units ( gallons / GAL / G, inches / IN, Fahrenheit / °F / F )

Throughout this manual, the volume length and temperature values are shown in US

Units.

CONTINUED

optional

tank

Leak Detection

optional

... )

data or fax modem.

testing

).

data / fax-modem).

1)

Metric International System of Units

TS-LLDI

or 2)

(Line Leak

US

.

Safety

Intrinsically safe circuits for liquid level probes, and leak detection sensors mounted in:

Class I, Division 1, Group D hazardous locations.

Approvals

All Tank Sentinel models are UL and cUL Listed 6L79 as Liquid Level Gauge / Leak

Detection Systems. Third party approved leak detection — Pd (probability of detection) =

99.2 % for 0.1 or 0.2 gph leak tests (0.1 = precision test, 0.2 is the monthly regulatory

compliance test)

Need Help ? – Names and Phone Numbers to Contact

See the inside front cover of this manual. When you first read this manual, please take

time to fill-in the Contact Names, Phone Numbers and when to contact these people or

organizations (i.e.: local / State EPA Regulatory Agency).

NOTE

☞

...Reference the Table of Contents for specific topics, and the Glossary for technical

definitions and explanations.

and all corrective actions to take should a problem, alarm, or warning occur.

Also be familiar with the Policy and Procedures at your site

—

P Page P - iv Tank Sentinel Operator’s Guide

❖

—

Page 11

1 Console – Basic Operation

Contents:

Operating Modes,

Component Location

Display (Run Mode, Normal

Warning and Alarm

Indications, Sentinel Mode,

Tank or Line Testing)

Menu Keys (M1 – M4),

Status Row & Alarm Test key,

Keypad Keys,

Optional Report Printer,

General

Once the Tank Sentinel console has been

interaction with the system is through the keypad, display and printer. All of the basic

features of the system are available through these input / output devices.

Operating Modes

There are three operating modes of the Tank Sentinel console, these are:

the RUN mode, the SENTINEL mode, and the SETUP programming mode.

Paper Advance-Button,

RS232 CommunicationPorts,

TS-FM1/TS-DOM Receptacle,

Model & Serial No. Label,

Product & Tank-Related

Keys:

PRODUCT, GROSS, LEVEL,

TANK, ULLAGE, WATER

Menu-Related Keys:

CANCEL, UP, DOWN,

ENTER, MENU

installed, programmed, and tested

Special Keys:

ALARM, REPORT... Selecting

a Report, Report Features

CHECK Date & Time,

Display, Printer, Dialtone,

Software & Hardware

Options

TEST, Starting tests, test

Status, Aborting tests

ACK-SHIFT Key & Uses

Upgrade Menu

most of your

1) The RUN mode is the normal operating mode when product dispensing is expected (the

site is open for business). Inventory levels and deliveries are monitored and all leak

detection sensors are active during this time.

2) The SENTINEL mode is the after-hours watch mode when dispensing is not expected,

and the site is not open for business. Deliveries and unauthorized dispensing (thefts)

are monitored, and coarse leak tests or compliance leak tests run during this time (after

normal business hours). The start and stop time of the sentinel mode must be

scheduled in the setup programming mode.

3) The SETUP programming mode is where automatic operation, configuration, alarmlimits, and the overall system operation is defined and set. This mode can be

password protected — this is highly recommended to protect the system-operation

from unintentional changes or acts of vandalism. Inventory levels, delivery detection,

and all leak detection sensors are not active during this mode.

WARNING

it is possible to alter the system and make it nonfunctional, unable to detect

leaks, or be out of compliance with EPA rules and regulations.

INCON does not recommend changing the system-setup because

NOTE

☞

Let your authorized INCON service-provider do the setup programming – look at the inside of the

front cover for contact name(s) and phone number(s).

Console – Basic Operation Page 1 - 1

1

Page 12

®

SYSTEM TANK SENSOR LINE

OKAY OKAY OKAY OKAY

Tank Sentinel

AUTOMATIC

ODEL

120

:

TS-1001

121795

VAC, 50 / 60 Hz

A

MPS MAX

:1

TANK GAUGE

&

LEAK

DETECTION

SYSTEM

MADE IN

USA

M

S/N:

INTELLIGENT CONTROLS, INC. SACO, ME 04072 USA

®

PN 240-1187

TS -1001

TANK SENTINEL

Door hinge

(left side)

Figure 1 - 1. Console Component Identification – TS-1001 shown typical

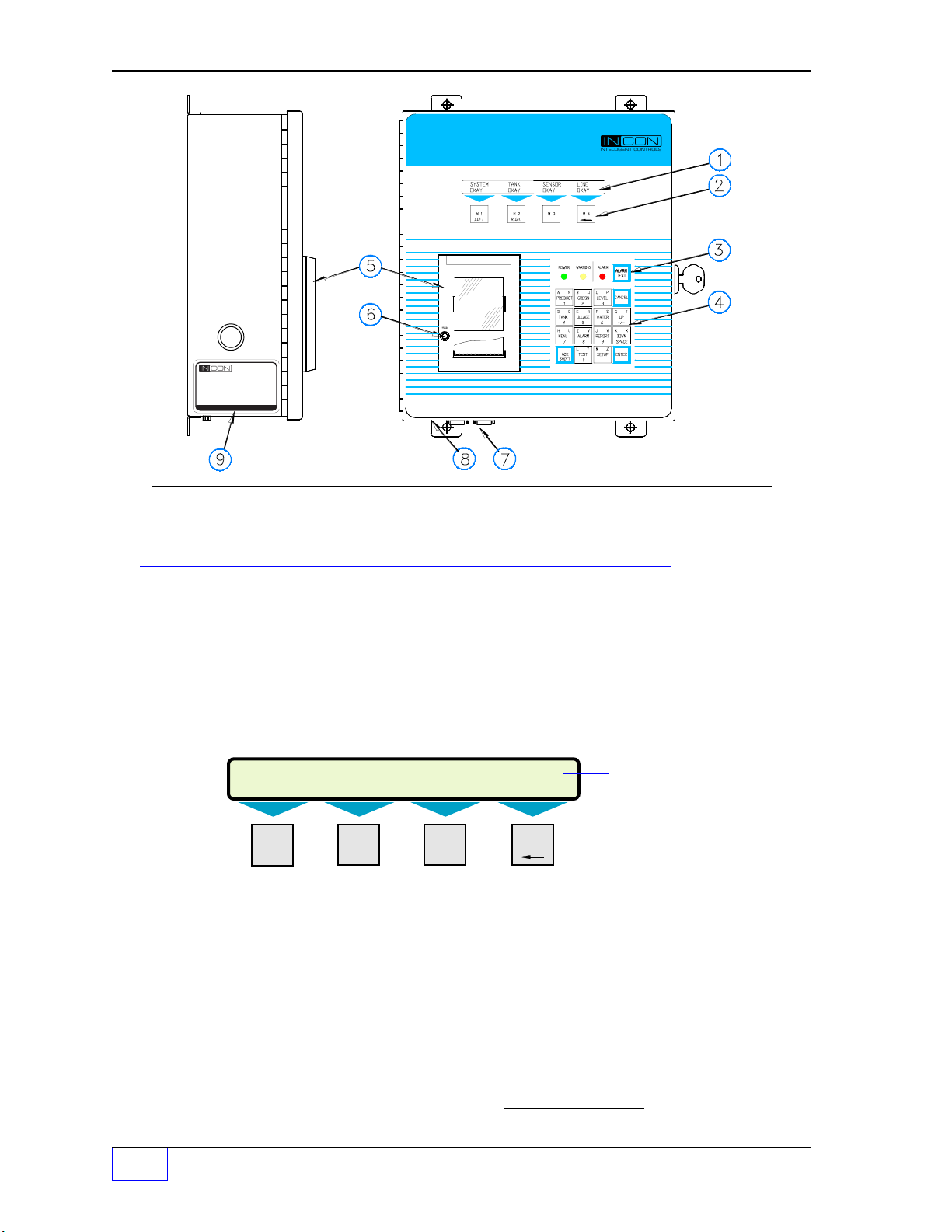

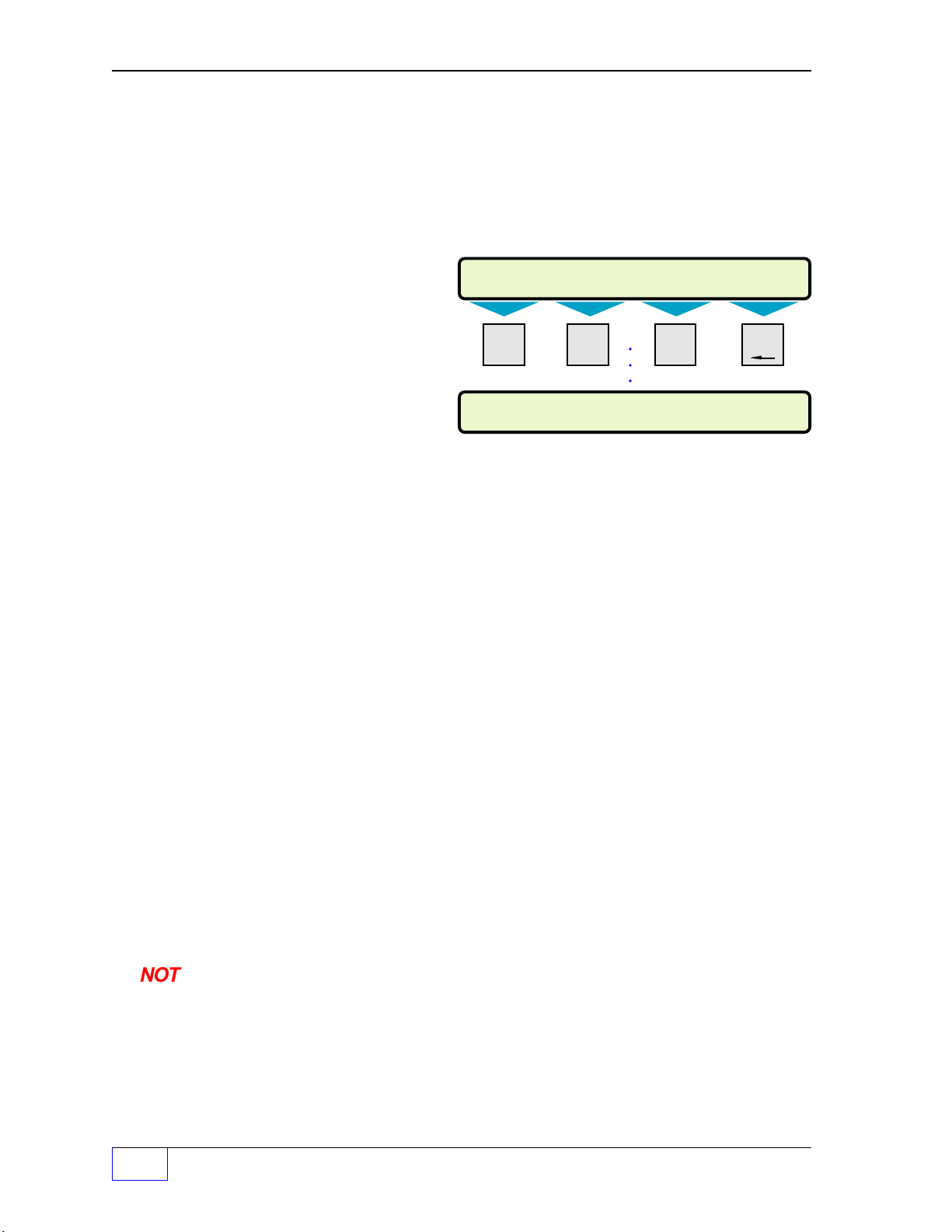

Console Component Location – see Figure 1-1 above

➀

Display

The light-green backlit display consists of two rows that are 40 characters long.

Run Mode Display

The Tank Sentinel console shows up to four status-display columns in the normal run

mode. The heading names of these are: System, Tank, Sensor, and Line.

Display Normal Indications

OKAY is shown under each status-display column.

Display WARNING Indications ( also see Status Row ➂ )

WARNING is shown under the SYSTEM display column when a system software or

hardware failure occurs ( i.e. FAX HARDWARE FAILURE )

Display ALARM Indications ( also see Status Row ➂ )

M1 M2 M3 M4

LEFT RIGHT

See Tank and Line

Display Notes

a & b (next page)

ALARM is shown under a

occur ( i.e.

1

Page 1 - 2 Tank Sentinel Operator’s Guide

TANK

HIGH LIMIT

, HIGH BRINE, 0.2 GPH LINE LEAK )

, SENSOR, or LINE display column(s) when alarms

Page 13

Sentinel Mode Display

SYSTEM TANK SENSOR LINE

OKAY SENTINEL OKAY TESTING

SYSTEM TANK SENSOR LINE

WARNING TESTING ALARM OKAY

Under the word TANK, SENTINEL is alternately displayed with OKAY or ALARM when the

Sentinel mode is running. Sentinel-mode is programmed to run after business hours and

will monitor for product thefts and gross tank leaks.

M1 M2 M3 M4

LEFT RIGHT

Tank or Line Testing Display

Under the word TANK or LINE, TESTING is alternately displayed with OKAY or ALARM

when leak test(s) are running. Tests can either be started manually, or scheduled (setup)

to run at certain times of the month, week, or day. A tank leak test estimate report can be

printed by using the

REPORT

be (aborted), by using the

See Tank and Line

Display Notes

a & b (below)

key. A leak test status can be displayed, and a leak test can

TEST

key.

See Tank and Line

Display Notes

a & b (below)

M1 M2 M3 M4

LEFT RIGHT

Tank & Line Display Notes:

a.) The tank-status display and any tank-related menus or reports do not appear unless

the number of tanks are setup / programmed for 1 or more tanks. A Leak Detection

System (tanks set to Ø) can monitor leak detection sensors, but does not monitor intank product levels.

b.) The line-status display, and any line-related menus or reports will not appear unless

INCON Line Leak Detectors are connected to the TS-LLDI interface terminals, and the

number of lines are setup (programmed) for 1 or more lines.

➁

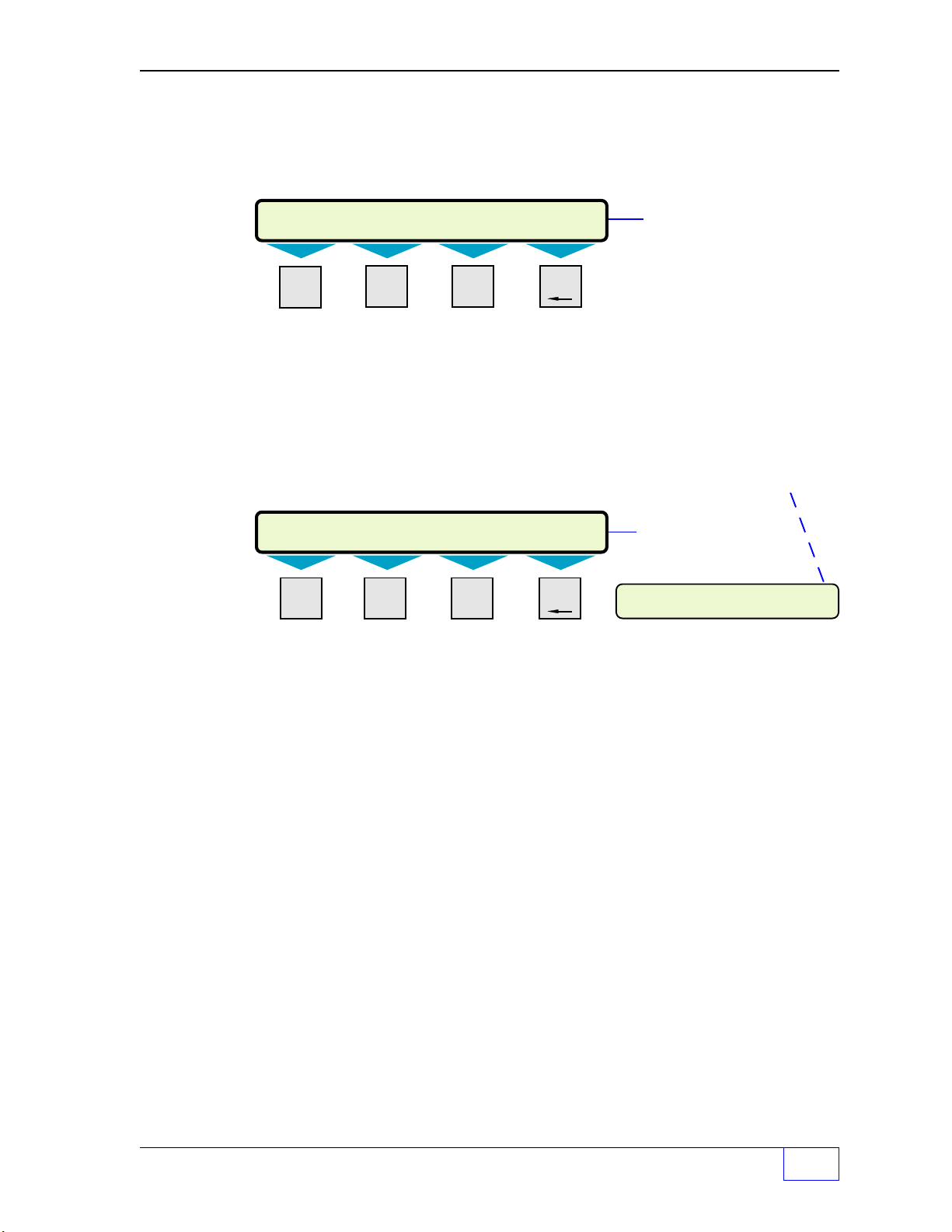

Menu keys (M1 thru M4)

Menu keys

are used to: make menu selections (see the

information (see above... press a

control the cursor, or delete a character when a number or letter input is required from the

keypad

left and

{

M4

M2

moves the cursor right }.

SELECT LEAK TEST OPTION

STATUS START ABORT

...see graphic above

ALARM

Menu key

to display current alarms). Menu keys can

can backspace / delete a input character ( xxx_ï),

key) and to display

M1

moves the cursor

Console – Basic Operation Page 1 - 3

1

Page 14

Component Location ( Continued... see Page 1 - 2 Figure 1 - 1 )

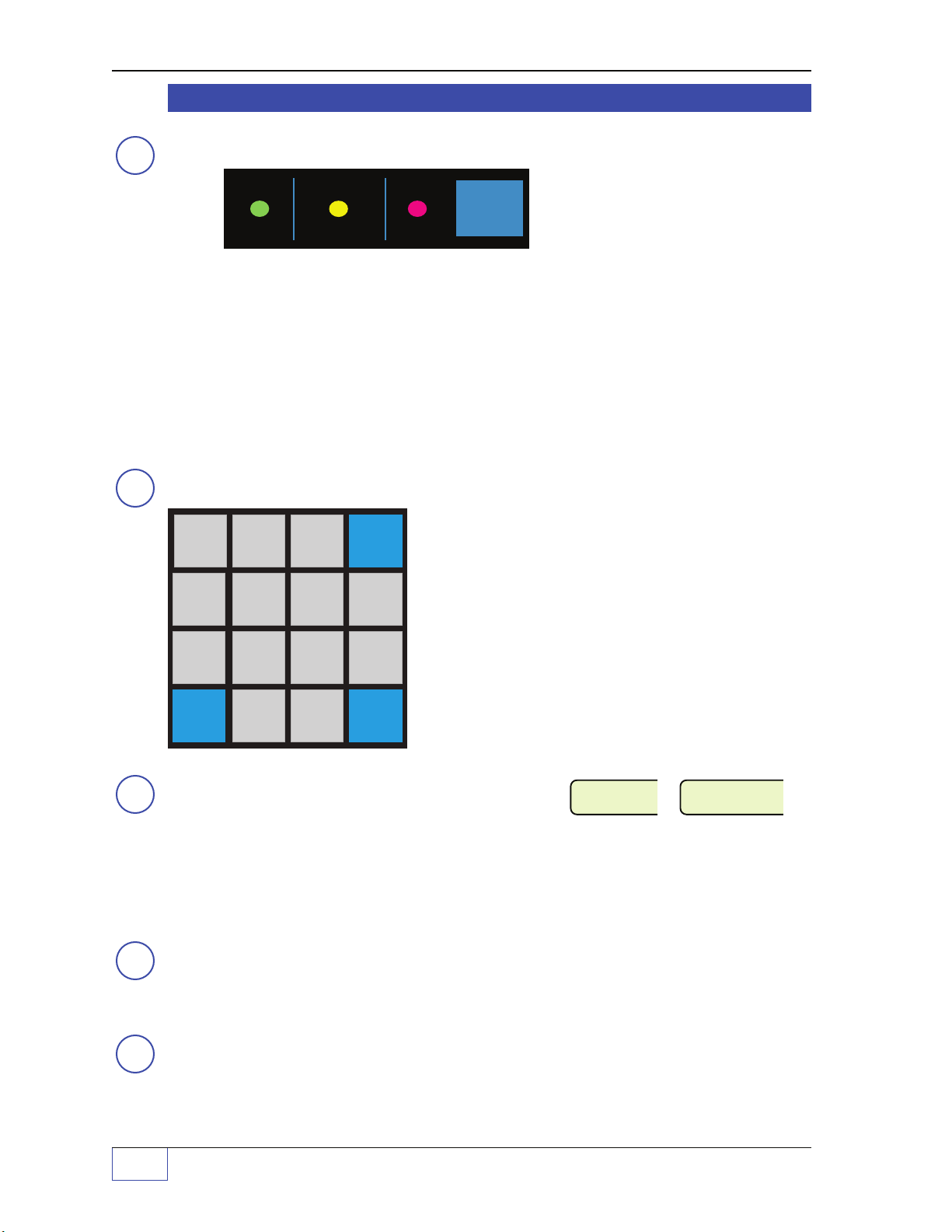

Status Row

3

NOTE

Keypad Keys

4

A N

PRODUCT

1

D Q

TANK

4

H U

MENU

7

ACK

SHIFT

(with Alarm Test Key)

POWER

WARNING ALARM

ALARM

TEST

TS-1001/ 750 / 504 Status Row shown

( TS-2001/508 is vertical )

GreenPOWER on Light: On steady when the console power is on

Yellow WARNING Light: Flashes for System fail warnings

RedALARMLight: Flashes for Tank, Sensor, or Line alarms

ALARM TEST Key: Press to test the annunciator alarm horn

After a warning or alarm is acknowledged, the flashing yellow-warning light or

red-alarm light will stop flashing and will stay on continuously (solid) until the condition

clears or no longer exists, which will cause it to turnoff (see Chapter 2).

B O

GROSS

2

E R

ULLAGE

5

I V

ALARM

8

L Y

TEST

0

C P

LEVEL

3

F S

WATER

6

J W

REPORT

9

M Z

CHECK

.

CANCEL

G T

UP

+ / –

K X

DO WN

SPACE

ENTE R

The Keypad Keys and Menu keys are used to:

Display product and tank data, access the setup program,

view alarms, select reports (to print or Fax), navigate

through menus and make choices, silence alarms,

acknowledge alarms, start or stop (abort) leak tests, and

to check the system time, display, printer operation, and

to check options (such as the tank gauge part and

version number, and the operational status of all

connected hardware).

Report Printer

5

The printer requires a special roll of thermal printer paper to produce scheduled reports,

automatic alarm reports, and reports selected from the keypad. Reports cannot print

without paper. See Chapter 5 Routine Maintenance about replacing the roll of paper when

the Paper Out warning is flashed (above).

Paper Advance Button

6

Press to advance the printer paper (use when replacing the paper roll).

RS232 Communication Ports

7

Two RS232 ports are supplied for remote communications and interfacing with other

equipment (card readers, POS terminals... also see # ).

1

Page 1 - 4 Tank Sentinel Operator’s Guide

SYSTEM......

WARNING

SYSTEM

PAPER OUT

Page 15

➇

SELECT PRODUCT

REGULAR XTRA PLUS

REGULAR GROSS NET WTR VOL ULLAGE

MAN 1 5960 6860 93.3 4087

GROSS TANK 1 TANK 2 TANK 3 TANK 4

GALLONS 22080 12080 8080 2480

LEVEL TANK 1 TANK 2 TANK 3 TANK 4

INCHES 98.25 86.10 64.53 24.71

REGULAR GROSS NET WTR VOL ULLAGE

TANK 1 3813 3770 33.3 1510

REGULAR GROSS NET WTR VOL ULLAGE

TANK 2 3147 3090 60.0 2577

TS-FM2 Receptacle

Remote communications (telephone) port for the

Modem (TS-FM2). After a fax/modem is installed and the communications program is

setup, modem data can be sent to up to 4 different numbers in response to deliveries,

alarms, or leak test results. With the

can also be faxed on a automatic schedule, or manually on-demand using the keypad, to

1 to 4 different fax machine numbers (programmed in the FAX – REPORTS setup menu).

➈

Model & Serial Number Label

This label also specifies the Voltage, Hertz, and Amperage rating of the console.

Product & Tank Related Keys (ALSO SEE THE GLOSSARY)

Depending on which units have been selected, level units are in inches (or centimeters),

volume units in gallons (or liters), and temperature units in Fahrenheit (or Celsius).

AN

PRODUCT

1

optional

optional and enabled

internal Data Only Modem or Fax

TS-FM2 Fax Modem, reports

Manifold tanks display the

TOTAL

...press DOWN to display

individual tank data when tanks

are manifold

...The last two displays are

typical for non-manifold tanks

values initially

PRODUCT

the WTR VOL (water volume), and ULLAGE of all tanks containing that product (press

DOWN to display by tank or manifold). REGULAR shown above.

BO

GROSS

2

GROSS

NET, the GROSS product volume is not temperature compensated.

Gross volume changes as the product temperature changes

contraction or expansion). After a delivery, the fluctuations in gross volume will subside

as temperature stabilizes

CP

LEVEL

LEVEL

3

same as an electronic dipstick reading. Also see TANK.

shows the PRODUCT name, the total GROSS volume, the total NET volume,

Press DOWN for other tanks.

shows the physical product volume in each tank minus any water volume. Unlike

(because of thermal

(see Chpt 4 about Tank Leak Test Requirements).

Press DOWN for other tanks.

shows the actual physical height of the liquid in each tank. The level display is the

Console – Basic Operation Page 1 - 5

1

Page 16

Product & Tank Related Keys ( CONTINUED... )

WATER TANK 1 TANK 2 TANK 3 TANK 4

INCHES 1.8 1.6 1.5 1.0

ULLAGE TANK 1 TANK 2 TANK 3 TANK 4

GALLONS 2020 1020 383 220

SELECT TANK

TANK 1 TANK 2 TANK 3 TANK 4

REGULAR GROSS NET WTR VOL ULLAGE

TANK 1 22080 21855 93.3 2020

REGULAR LEVEL TEMP WTR LVL PERCENT

TANK 1 98.25 67.8F 1.8 93.5

DQ

T ANK

4

TANK

(which is temperature-compensated), WTR VOL (water volume), ULLAGE (gross volume

that could be added to fill the tank), actual product LEVEL, product TEMP (temperature),

WTR LVL (water level), and PERCENT full (capacity) values of the selected tank.

ER

ULLAGE

5

FS

Ullage shows the

(to 95 % full / capacity).

Press DOWN for other tanks &

Press a menu key to select a tank

Press DOWN to see additional tank

data

...(product level, temperature,

water level, and percent full)

shows the PRODUCT name, the GROSS product-volume, NET product-volume

Press DOWN for other tanks.

gross volume

that could be added to fill a tank without overfilling it

Press DOWN for other tanks.

W ATER

6

Displays the actual

WTR VOL (water volume) and WTR LVL (water level).

Menu Related Keys

The

CANCEL

•

•

•

•

GT

UP

+

/ –

KX

The

UP

The

Press

DOWN

be pressed repeatedly (it will not scroll through a menu if it’s held-down).

SP A CE

water level

CANCEL

key (upper right key) has many uses. Press

cancel a menu choice (before the

in each tank. Press the TANK key to display both

ENTER

CANCEL

key is pressed)

to:

return to default status display

exit out of and to return to a previous upper level menu or parent menu

cancel an input (before the

UP

key is used to travel up through a menu.

ENTER

key is pressed)

must be pressed repeatedly (it will not scroll through a menu if it’s held-down).

DOWN

key is used to travel down through a menu.

DOWN

when a menu is first accessed or entered. The

DOWN

key must also

1

Page 1 - 6 Tank Sentinel Operator’s Guide

Page 17

Menu Related Keys ( CONTINUED... )

SELECT MENU OPTION

SETUP UPGRADE LANGUAGE DATALOG

The

ENTER

•

•

•

HU

MENU

ENTER

key has many uses. Press

ENTER

to:

accept a setup menu choice or input value for storage into memory

accept or to change the number of reports to print (to save paper)

accept an alphanumeric code input... Examples uses are:

1) accept an alarm acknowledge password

2) accept an upgrade password and string sequence to upgrade the system

(when adding equipment or enhancing the system operation)

7

M1 M2 M3 M4

LEFT RIGHT

The

MENU

•

access the SETUP program mode

•

access the UPGRADE menu (to expand the system or add/enable optional

key is used to:

(access should be password protected)

, or

features). Upgrades are optional extra cost features that expand the number of tanks

monitored, add the FAX/Modem, or add software capabilities. Please contact your

Authorized INCON tank gauge distributor for pricing and availability. See the warning

below.

•

access the LANGUAGE menu (to change the display and report language)

•

to datalog (this is a technical diagnostic menu only)

AN

PRODUCT

1

BO

GROSS

CP

LEVEL

2

CANCEL

3

DQ

TANK

HU

MENU

ACK

SHIFT

4

7

ER

ULLAGE

5

IV

ALARM

8

LY

TEST

0

Console – Basic Operation Page 1 - 7

FS

WATER

6

JW

REPORT

9

MZ

CHECK

.

GT

UP

+/–

KX

DOWN

SPACE

ENTER

1

Page 18

Menu Related Keys ( CONTINUED... )

SELECIONE

LINGUAGEM

INGLES FRANCES ESPANHOL

PORTUGUES

SELECCIONAR

IDIOMA

INGLES FRANCES

ESPANOL

PORTUGUES

SELECTIONNER

LANGUE

ANGLAIS

FRANCAIS

ESPAGNOL PORTUGAIS

SELECT

LANGUAGE

ENGLISH

FRENCH SPANISH PORTUGUESE

SELECT MENU OPTION

SETUP UPGRADE

LANGUAGE

DATALOG

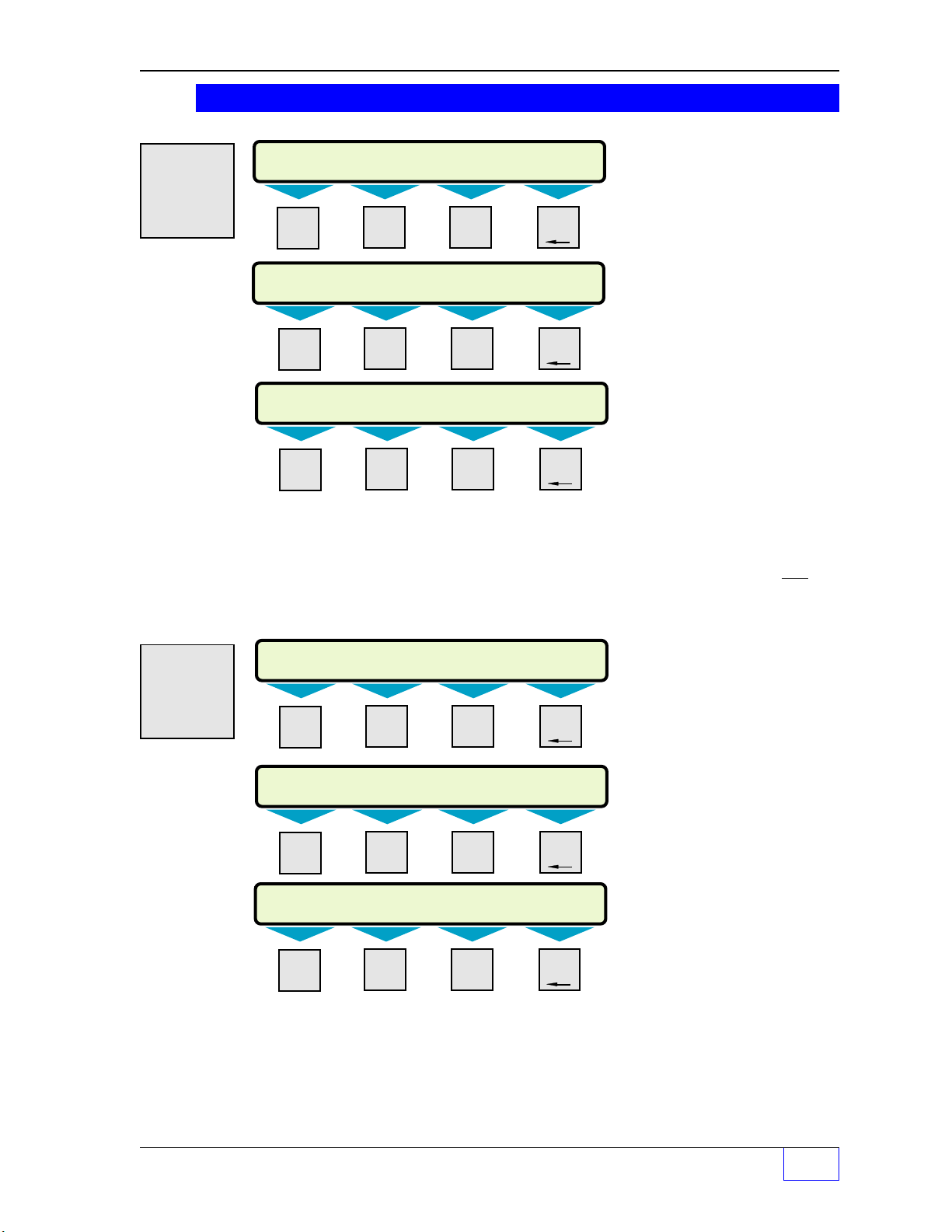

Changing the Display and Report Language

HU

MENU

use (English is the

directly under the desired language ...changes are immediate.

7

Press the

MENU

key and then the M3 menu key. Choose the language that you want to

default

M1 M2 M3 M4

LEFT RIGHT

language), and then press the menu key (

M1 M2 M3 M4

LEFT RIGHT

M1 M2 M3 M4

LEFT RIGHT

M1 M2 M3

English

default

selected

French selected

or M4)

M1 M2 M3 M4

LEFT RIGHT

M1 M2 M3 M4

LEFT RIGHT

Spanish selected

Portuguese selected

AN

PRODUCT

1

DQ

TANK

4

HU

MENU

7

ACK

SHIFT

BO

GROSS

ER

ULLAGE

IV

ALARM

LY

TEST

2

5

8

0

CP

LEVEL

3

FS

WATER

6

JW

REPORT

9

MZ

CHECK

.

CANCEL

GT

UP

+/–

KX

DOWN

SPACE

ENTER

1

Page 1 - 8 Tank Sentinel Operator’s Guide

Page 19

Special Keys ( ALSO SEE THE GLOSSARY )

REGULATORY REPORT

PRINTER FAX

SELECT REPORT GROUP (MORE)

SENSOR ALARM SETUP REGULATORY

SELECT REPORT GROUP (MORE)

INVENTORY DELIVERY USAGE TEST

SELECT SENSOR ALARM STATUS

ACTIVE CLEARED HISTORY

SELECT ALARM TYPE (MORE)

ALL

SELECT ALARM TYPE (MORE)

SYSTEM TANK SENSOR LINE

IV

ALARM

8

NOTE

☞

The annunciator may be programed to pulse (modulated) or to output a continuous

(solid) tone for certain alarms.

could be sent to remote locations IF the console is properly programmed and has

an

M1 M2 M3 M4

LEFT RIGHT

M1 M2 M3 M4

LEFT RIGHT

M1 M2 M3 M4

LEFT RIGHT

In addition, alarms, deliveries, and leak test results

optional

internal TS-FM2 Data or Fax Modem ➇.

Pressing the

ALARM

key will

display the types of alarms:

SYSTEM TANK SENSOR LINE

and ALL alarms (ALL is shown if

the

DOWN

key is pressed).

Press a menu key under one of

these types to display a status

group to choose from (Active,

Cleared, or History).

Also see the

ACK

SHIFT

key

about how to acknowledge

alarms.

JW

REPORT

9

(MORE) =

press the

DOWN

key to

display more

choices

Selecting A Report

Press the

a report that you want to print or fax. For example, to print a SENSOR ALARM HISTORY

report, press the following keys:

(under SENSOR), and finally

M1 M2 M3 M4

LEFT RIGHT

M1 M2 M3 M4

LEFT RIGHT

M1 M2 M3 M4

LEFT RIGHT

REPORT

key to display the report groups: Press the appropriate menu key under

REPORT DOWN

M3

(under HISTORY).

The report key can send reports

to either the

optional

console

printer ➄, or to fax machines if

the console is equipped with the

optional

➇ TS-FM2 Fax Modem.

The number of available reports

is extensive and the choices are

presented in a multilevel fashion.

See Chapter 3 Tank Sentinel

Reports for example reports

and descriptions.

M2

(under the ALARM text)

M3

Console – Basic Operation Page 1 - 9

1

Page 20

Report Features

SELECT FUNCTION 07:16:47 PM 12-23-1997

DISPLAY PRINTER DIALTONE OPTIONS

See Chapter 3 ...Reports may be programmed or scheduled to print automatically at certain

times (for example, during work shifts, every day, every week on a particular day, or every

month on a particular day). Other reports can be automatically fax’d or printed when an

alarm occurs, or when a non-alarm event happens (for example, when the result of a Leak

Test is available).

MZ

CHECK

.

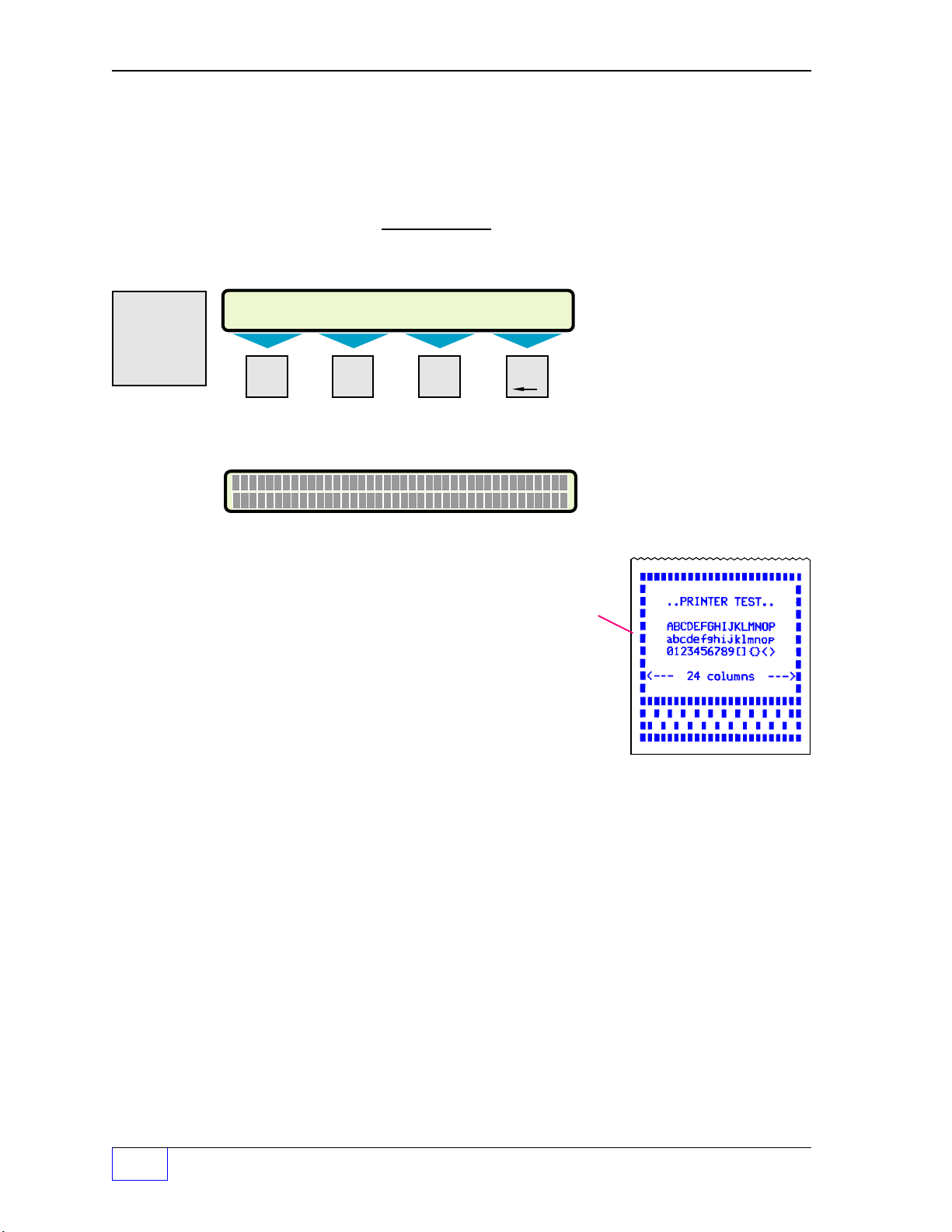

Check Display, Printer, or Dialtone

Press the

—

Press the

to check the Printer / printout a test report. The report

should be uniformly dark, clear, & legible.

Press the

DIALTONE to check for a Dialtone. Either a

NO DIALTONE DETECTED message is shown, or a

DIALTONE DETECTED message appears when both the

internal Fax / Modem hardware and the phone line are

installed and working correctly.

M1 M2 M3 M4

LEFT RIGHT

CHECK

PPP P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P

P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P

press the

CHECK

key and then

CANCEL

key and then

CHECK

M1

to check the Display (shown below). NOTE:

key to show / go back to the

Menu

key under PRINTER

key and then

Menu

key under

CHECK Date &Time

Press the

CHECK

key to show

the time and date.

NOTE: DIAL T ONE appears

when an internal TS-FM2

Fax / Data Modem is installed.

the 40 segments of each row

should show a reversed P

CHECK

menu (above).

Check Software & Hardware Options

Press the

CHECK

go through the list (below):

(Software Options) ______________________ Part Number

(Software Options) ______________________ Version Number

(Hardware Option): PROBES, TS-CIM, TS-ROM, TS-SEM 1, TS-SEM 2, and

(Hardware Option) TS-IEM — TS-2001/508 consoles only, and

(Hardware Option): LINES, PRINTER, and FAX MODEM

NOTE

Each hardware option / status-check will display one of the four following

messages: OPERATIONAL, NOT INSTALLED, OUT OF PAPER, or TROUBLE

☞

1

(also see Chapter 5 ).

Page 1 - 10 Tank Sentinel Operator’s Guide

key,

Menu

key under OPTIONS, and then press the

DOWN

key to

Page 21

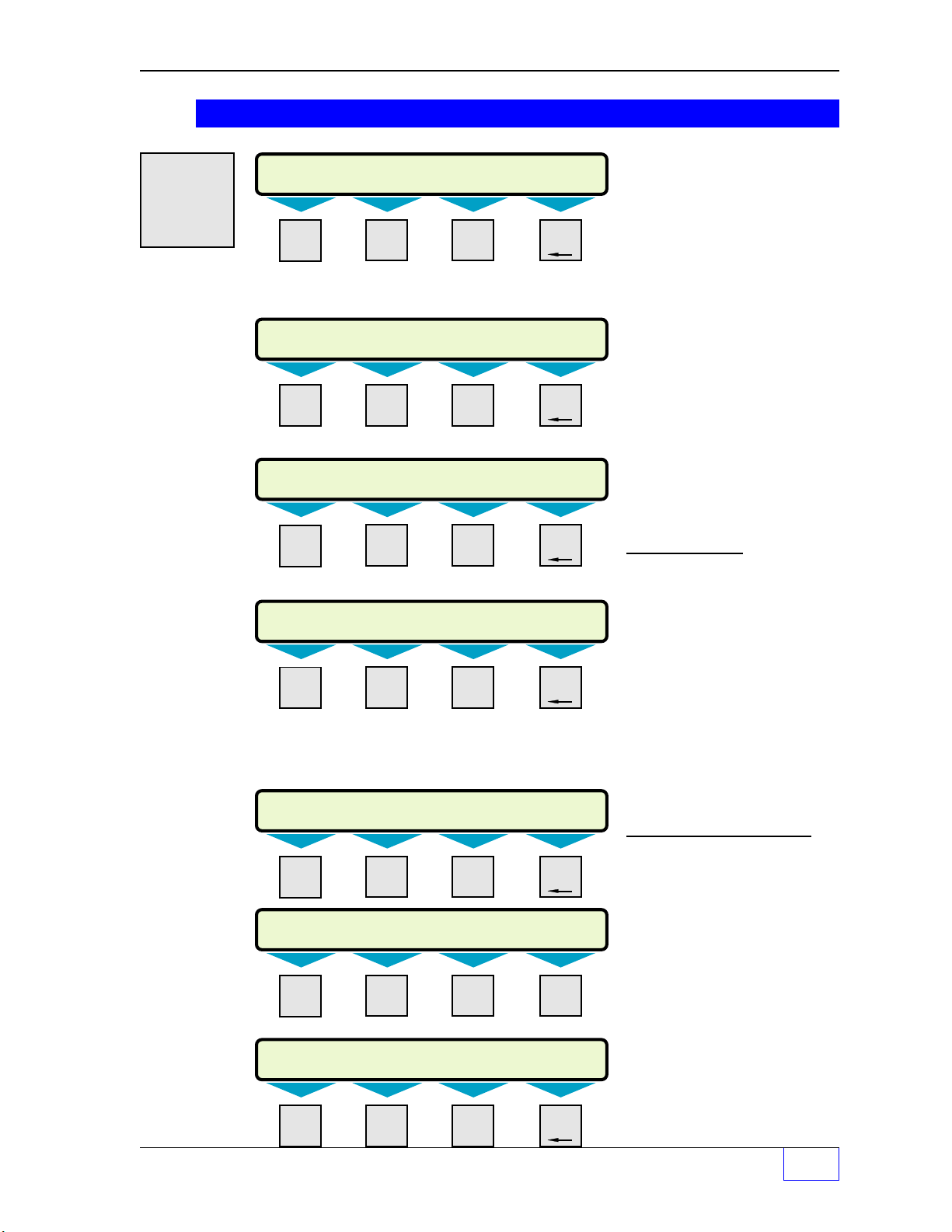

Special Keys ( Continued... )

SELECT LEAK TEST OPTION

STATUS START ABORT

SELECT LEAK TEST TO START

0.1 TANK 0.2 TANK

SELECT TANK TO START 0.2 TEST (MORE)

TANK 1 TANK 2 TANK 3 TANK 4

SELECT TANK TO START 0.2 TEST (MORE)

ALL TANKS (or ALL LINES for Line Leak Tests)

ACTIVE LEAK TESTS (UP/ DN)

TANK 1 0.2 GPH STARTED 08:53:54PM

ACTIVE LEAK TESTS (UP/ DN)

TANK 3 0.2 GPH STARTED 09:12:04PM

NO ACTIVE LEAK TESTS (are running)

LY

TEST

0

M1 M2 M3 M4

LEFT RIGHT

The

TEST

key is used to: check

the Status of running tank or line

leak tests, or to Start or Abort a

test.

NOTE

Because

SCALD® is a

S tatistical

C ontinuous

A utomatic

L eak

D etection

program

that runs

Tank-LeakTests

continuously,

SCALD leak

tests are

not

included

with

standard

Active Leak

Tests.

1) Press the

2) Choose the type of test below (press a

LEFT RIGHT

3) Choose the Tank or Line # (press a

LEFT RIGHT

4) Choose ALL – press

LEFT RIGHT

Press the

or

DOWN

TEST

key and then the

M2

key (above)

menu key

M1 M2 M3 M4

menu key

M1 M2 M3 M4

DOWN

M1 M2 M3 M4

TEST

key, the

M1

and then the

key, and then the

key to show the Status of other Leak

M1

Tests.

M1 M2 M3 M4

LEFT RIGHT

M1 M2 M3 M4

LEFT RIGHT

– or –

M1 M2 M3 M4

LEFT RIGHT

UP

Starting a tank or Line

)

Leak Test:

Follow the steps to the left &

follow test requirements in

Chapter 4.

)

Once a Tank or Line is chosen, it

is removed from the start-test

display.

T esting Note:

A tank leak test, time-estimate

key

report can be printed by pressing

the REPORT key – M4 key –

under TEST and then M1 under

ESTIMATE.

Showing the Status of

Tank or Line Leak Tests

Indications of Active

T ests:

•

The word TESTING is slowly

flashed under the TANK or LINE

when one or more tests are

running. See the normal statusdisplay ➀ text that is shown on

page 1 - 3 of this Chapter.

•

The INCON TS-LLD Line Leak

Test light will also be on at the

TS-LLD Control Unit when a Line

Leak Test is running.

Console – Basic Operation Page 1 - 11

1

Page 22

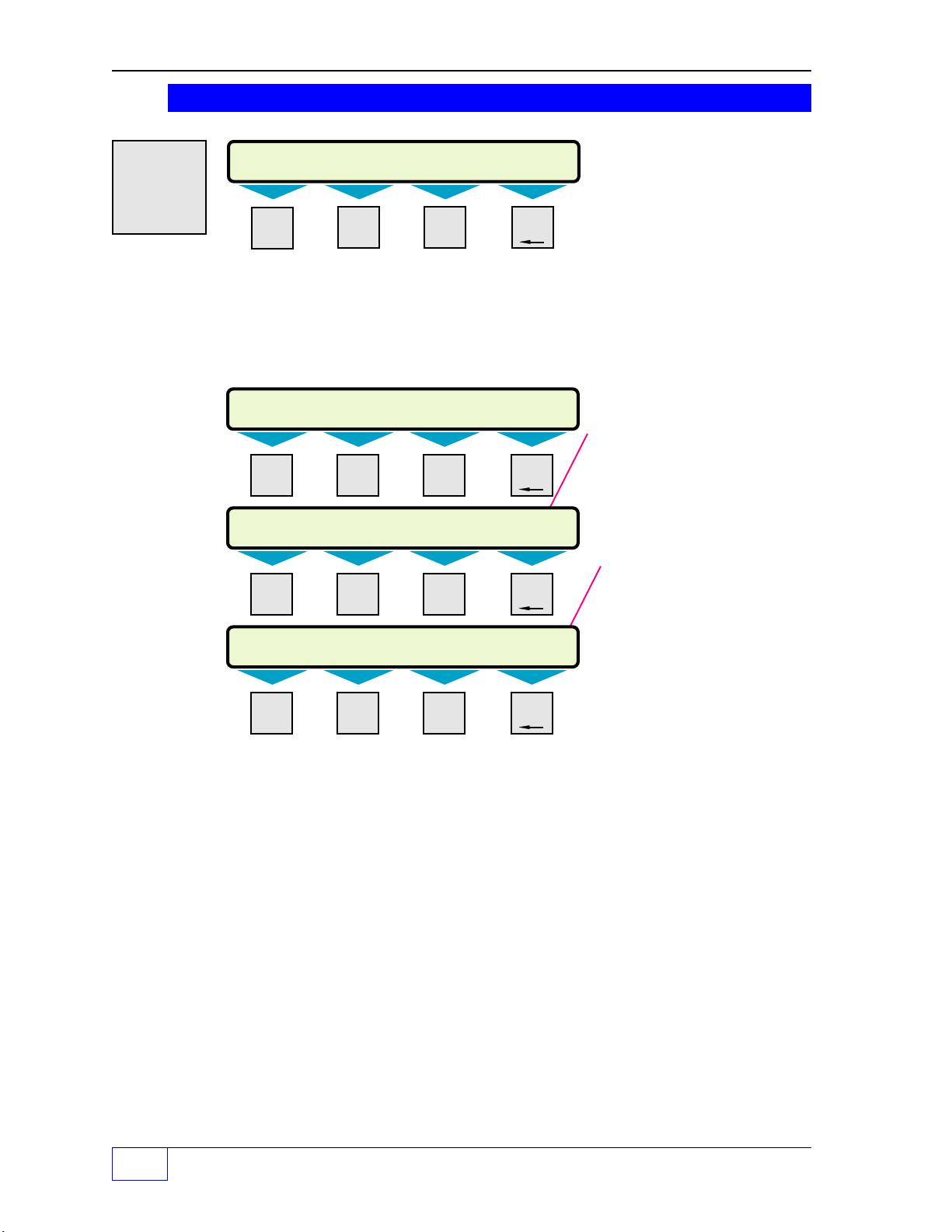

Special Keys ( Continued... )

SELECT LEAK TEST OPTION

STATUS START

ABORT

SELECT TANK TO ABORT

TANK 1 TANK 2 ALL TANKS

0.2 GPH TANK TEST ABORTED

SELECT TANK TO ABORT

TANK 1 ALL TANKS

LY

TEST

0

1) Press the

2) Press the

3) Press a

M1 M2 M3 M4

LEFT RIGHT

TEST

key and then the

UP

or

DOWN

key to show all Leak

M3

key (above).

Tests that can be aborted (below)

menu

key under your selection to choose

the Tank or Line test to abort (below)

M1 M2 M3 M4

LEFT RIGHT

M1 M2 M3 M4

LEFT RIGHT

Aborting a Tank or Line

Leak Test

An abort is used to cancel a

test... a test must be aborted

before a different type of leak

test can be started.

The display will show which test

(0.1 or 0.2 GPH) was aborted

once it has been chosen.

After a Tank or Line test is aborted

it is removed from the currentrunning, abort-test display as

shown to the left (in this case,

Tank 2 does not appear because

the test was aborted).

M1 M2 M3 M4

LEFT RIGHT

1

Page 1 - 12 Tank Sentinel Operator’s Guide

Page 23

ACK

(# 1 ) A...M

_

(# 2 ) N...Z

_

(# 3 ) NUMERIC

_

RELAYS AND ANNUNCIATOR ACKNOWLEDGED

GRACE PERIOD STARTED

SHIFT

M1 M2 M3 M4

LEFT RIGHT

ACK

is an abbreviation for

alarm acknowledge. The ACK

SHIFT key is a special key

with many uses.

ACK SHIFT

NOTE

☞

key uses:

1 ) Silence alarms (Press

ACK SHIFT

/ input an Alarm Acknowledge password if

required)

2) Acknowledge alarms (see Chapter 2)

3) Start a programmed Grace Period (if output modules are installed in the

console or a TS-CIM BriteBox, or if a TS-ROM BriteBox is installed... see

Figure 2.1 in Chapter 2)

4) Shift the keyboard input character type. Press

ACK SHIFT

to display or precondition

the input mode before a specific key is pressed (to input a letter, number, or special

character). Press

ACK SHIFT

key to change the input key position to: (# 1) (# 2)

or (# 3).

The input mode is displayed only when an input is expected

(when an alarm

acknowledge password or setup password code is required, or when an

upgrade password code is required).

AN

PRODUCT

1

DQ

TANK

4

HU

MENU

7

ACK

SHIFT

BO

GROSS

2

ER

ULLAGE

5

IV

ALARM

8

LY

TEST

0

Press the

N

times to DISPLAY the

input character type ( #__ )

then press the

(

)

# 1

A...M

COMMAND

(# 3)

number or special character

CP

LEVEL

3

FS

WATER

6

JW

REPORT

9

MZ

CHECK

CANCEL

GT

UP

+/–

KX

DOWN

SPACE

ENTER

Upper right

DISPLAY

shows the

input

selection

...shown

here

within

dashed

lines

T ypical

Key

.

Console – Basic Operation Page 1 - 13

ACK SHIFT

Key of choice.

(

input a

letter

N

UMERIC

# 2

N...Z

key

)

1

Page 24

Upgrade Menu

SELECT MENU OPTION

SETUP

UPGRADE

LANGUAGE DATALOG

Additional features can be added by Ordering a TS-UPGRADE (For example, a TS-FM2 Fax

Modem can be added). Hardware must be added to the Tank Sentinel system just before

the upgrade is performed. Because setup programming is required once an upgrade is

performed,

upgrades for you.

INCON recommends that you contact your service provider to perform all

HU

MENU

+

7

WARNING

and the 3 upgrade strings (codes). These will be sent to you (see example on the next

page).

unauthorized upgrade attempts !

Instructions and unique password and upgrade strings will be mailed to you on

receipt of:

M1 M2 M3 M4

LEFT RIGHT

DO NOT attempt an upgrade without the correct upgrade password

Repeated upgrade attempts that fail will damage the equipment – avoid

1) A valid Purchase Order

2) A console Model number and valid Serial Number (verify that it is correct)

3) Hardware requirement(s) ...what equipment is going to be added

4) Software requirement(s)

5) Your Name and Shipping Address

NOTE

☞

1

Note: a FAX-transmittal can be sent to you upon request... provide your Fax

number

The upgrade instruction document that is sent to you is serial-number specific (see the

sample on the next page). The upgrade will not work with any other console. Also,

upgrade codes can only be used once !

Once data entry has begun you may edit by pressing M1 and M2 to move left and right and

M4 to BACKSPACE. The shift key will change the keypad from NUMERIC to A...M for

entering the letters. See the previeous page for a review of the keypad and

ACK SHIFT

key.

Verify that the input password and the three upgrade strings are correct before you

press the

Page 1 - 14 Tank Sentinel Operator’s Guide

ENTER

key !

Page 25

Sample Upgrade Instructions (Page 1 of 2)

INTELLIGENT CONTROLS INC http://www.intelcon.com

74 INDUSTRIAL PARK RD SACO ME 04027 U S A

T ank Sentinel

Sample TS-UPGRADE

000-1368 Rev. B

Field Upgrade Instructions

Here is the field upgrade you purchased for the Tank Sentinel listed below. Please take a moment

to read the instructions before you begin the upgrade process.

Note: Some upgrades require new hardware to be installed in the Tank Sentinel (e.g. printer,

modem... etc.). This should be done prior to performing the upgrade.

REMEMBER: The number of attempts to upgrade is limited, and improper or unauthorized

attempts will damage your Tank Gauge.

This area will contain your:

MODEL:

SERIAL #:

OLD CONFIGURATION:

NEW CONFIGURATION:

UPGRADE PASSWORD:

UPGRADE STRING 1:

UPGRADE STRING 2:

UPGRADE STRING 3:

EXECUTING FIELD UPGRADE:

1.) Compare the model and serial number from these instructions to the ones shown on the label

on the left side of your unit. Make sure they are the same. Contact INCON if they are

different.

2.) Press the MENU key and select the UPGRADE option.

3.) The warning message will appear on the display for several seconds, and the unit will ask you

to enter a password. Enter the password shown in the box above and press the ENTER key.

M1

and

M2

Note: Once data entry has begun you may edit by pressing

M4

and

for entering the letters.

E-mail: tech@intelcon.com FAX 1-207-282-9002 TEL 1-800-984-6266 PAGE 1 of 2

to BACKSPACE. The

sales@intelcon.com FAX 1-207-283-0158 TEL 1-800-872-3455

ACK SHIFT

Continued next page...

key will change the keypad from NUMERIC to A...M

to move left and right

Console – Basic Operation Page 1 - 15

1

Page 26

— Your Notes —

—

1

Page 1 - 16 Tank Sentinel Operator’s Guide

❖

—

Page 27

2 Acknowledging Alarms

Contents:

Purpose of Audio / Visual Alarms

Audio Alarm Annunciator (& Output Relays)

Visual Alarm Annunciators (& Indications)

Alarm Types (System Warnings, Tank Alarms,

Sensor Alarms, Line Alarms)

Purpose of Audio / Visual Alarms

Audio / Visual alarm annunciators are designed to alert you of a problem so appropriate

and immediate corrective action can be taken. An overview of alarms and indications

will proceed the main topic of this chapter — Acknowledging Alarms. Once you are familiar

with these you can go directly to the Acknowledging Alarms topic.

Audio Alarm Annunciator (& Output Relays)

The Alarm annunciator horn and relay outputs #1 and # 2 are output devices that are

located within the console. Output devices are controlled (switched on / off) by one or more

output groups. One or more warnings / limits / alarms are programmed to an Output

Group, which control the output devices (see below).

Alarm Status, Acknowledge Password,

Acknowledging Alarms / Silencing Alarms

Starting a Grace Period

Leak Detection Sensors

Tables and Figures

The annunciator horn can be programmed to produce a continuous (solid) tone, or a

modulated (beeping) tone. Certain warning or alarm conditions can use a unique tone to

signal when these events have occurred.

Optionally, external alarm devices can be activated when they are wired to the console

alarm-relay-output # 1 or # 2.

These three output devices can also be programmed to silence or deactivate when a

certain time-out value is reached. This alarm time-out feature is used (programmed) when

an Alarm Acknowledge password is required before an alarm can be silenced. See Chapter

1 about how to use the ACK SHIFT key.

Simple

Alarm –

Output

Device

Diagram:

Alarm

Alarm

Alarm

Output

Group N

Output

Device

(Controlled)

Acknowledging Alarms Page 2 - 1

2

Page 28

Visual Alarm Indications

SYSTEM TANK SENSOR LINE

WARNING TESTING ALARM OKAY

The console has 4 visual output devices:

1) Light green, 80 character display

2) Yellow warning light (Status Row)

3) Red alarm light (Status Row)

4) Printer reports – printout if enabled / programmed

and if the printer has paper

The console display will show a

system fault occurs. An

ALARM

WARNING

message under the word SYSTEM when a

message will appear under one of the TANK or SENSOR

or LINE columns when one of those alarms happen.

The status row will indicate System faults by causing the yellow

/ turn-on. In addition, the

ALARM

light will flash when an alarm is detected. (See Status

WARNING

light to flash

Row indicators below.)

Visual warnings and alarms act independently from the custom-programmed audio or

printed alarms. The Status Row Indicator lights have 3 different states, they are:

1.) > Flashing < until active, cleared, or transient faults are acknowledged, then

2.) On-steady (solid) once active warnings or alarms are acknowledged, then

3.) Off after all active faults have cleared and have been acknowledged

NOTE: TANK AND

LINE STATUS COLUMNS

APPEAR ONLY IF THE

NUMBER OF TANKS OR

LINES ARE

M1 M2 M3 M4

LEFT RIGHT

PROGRAMMED TO A

VALUE OTHER THAN

ZERO.

➂

Status Row

indicators

NOTE

Depending on how the system was programmed, alarms may, or may not activate the audio

alarm horn when a warning or alarm occurs. Flashing Warning or Alarm lights indicate

☞

that at least one or more new alarms exist since the last time that alarms were

acknowledged. Routinely check the Status Row indicators and printed reports for new

alarms.

2

Page 2 - 2 Tank Sentinel Operator’s Guide

POWER

WARNING ALARM

ALARM

TEST

Page 29

Alarm Types

System Warnings

Are alarms that are caused by equipment failures or software malfunctions. These

could also be transient, instantaneous failures or warnings of impending failures.

Do not ignore system warnings!

See Chapter 5 for Site Policy &

SYSTEM warnings in TABLE 5 - 1.

Tank Alarms

Occur when a tank-related programmed limit is

reached. See Chapter 5 about Site Policy &

about TANK alarms (in TABLE 5 - 1).

Sensor Alarms

Leak Detection Sensors (Standard or

BriteSensor) or Aux. Input #1 or #2, or Solid

State Input Modules produce sensor alarms.

In Table 2.1 document the type, location, input-

channel, and the output-group name for each

sensor (sensor alarm). Standard sensors

produce only one alarm... BriteSensors can

produce two or more alarms. See Chapter 5 for

Site Policy & SENSOR alarms (TABLE 5 - 1).

Liquid Level

Probe &

Floats

TSP-DIS

PROGRAMMED

TANK-RELATED

ALARM LIMITS:

HIGH HIGH

HIGH

DW

TANK

LOW

LOW LOW

HIGH WATER

Leak

Detection

Sensor

TSP-DIS

Line Alarms

The INCON TS-LLD Line Leak Detectors can be interfaced to the system console

where line leak alarms and line leak detector status is monitored. See Chapter 5 about

Site Policy and about LINE alarms (shown in TABLE 5 - 1).

Alarm Status

An alarm or system warning can be either:

•

•

•

•

Transient an instantaneous fault that clears almost immediately

Cleared a previously active fault that no longer exists

Active a fault that exists when it was displayed or printed

Acknowledged a fault that was displayed or printed, and was acknowledged by

pressing the ACK SHIFT key. A grace period may also be started by pressing the

ACK SHIFT key.

Acknowledging Alarms Page 2 - 3

2

Page 30

Acknowledge Password

TANK ALARMS TRANSIENT 09-11-1963

SCALD DETECTED LEAK TANK 1 04:42:20AM

SYSTEM TANK SENSOR LINE

WARNING ALARM ALARM ALARM

For a variety of reasons, some sites may be programmed with a special Alarm

Acknowledge Password. This code must be entered correctly at the keypad before an

alarm can be acknowledged / silenced.

Acknowledging Alarms / Silencing Alarms

•

Status row lights are

flashing... To view the cause

of the alarm....

Press the menu key under

the column(s) that has the

WARNING or ALARM

display, to show the:

Type of Alarm, the Alarm Status, the Date and Time when it happened, and

the Cause / Location / Name of the Alarm

The Alarm key can also be used to select and display:

System, Tank, Sensor, Line, or All alarms. Active, Cleared, or a History of

alarms can be displayed or printed when this method is used.

M1 M2 M3 M4

LEFT RIGHT

(Alarms are displayed in order).

○○○

•

Use the UP or DOWN key to display other warnings or alarms.

•

Record / Log Alarms and Warnings per the procedures at your site. This is

especially important when the printer is out of paper (a

the

WARNING

•

Press the ACK SHIFT key to acknowledge the existence of the alarm, which causes

the warning or alarm light to stop flashing (see Visual Alarms & Warnings page 2 - 1).

All transient or cleared alarms will disappear after acknowledged.

Site Policy — Reference Chapter 5 about Acknowledging Alarms.

Starting a Grace Period

Certain alarms (such as high water or low product levels in a tank) are frequently grouped

together and are used to prevent dispensing on alarm. When one of these alarms is active,

a control output relay in the optional TS-ROM BriteBox, or TS-IEM module (2001/508 only)

will activate and turn off the pump dispense circuit.

NOTE

The TS-ROM / output relay can be programmed with an alarm-override value or grace

period that allows for a return to normal operation at least temporarily. The grace period

☞

is started whenever an alarm is acknowledged (ACK SHIFT key is pressed), and continues

until the grace-period time has expired.

Site Policy — Reference Chapter 5 about Allowing Grace Periods.

NO PAPER

message replaces

display – under the system column – every 2 or 3 seconds).

2

Page 2 - 4 Tank Sentinel Operator’s Guide

Page 31

Leak Detection Sensors

TSP-EIS Electro-optic Interstitial (3 wire, infrared)

Standard Sensor detects liquids in spaces between the walls of DWTs

TSP-EIS

TSP-HLS High product Level (2 wire, float switch)

Standard Sensor used inside of tanks as an overfill alarm

detector (or in addition to the HIGH, and HIGH HIGH probe limits)

T SP-HLS

TSP-ULS Universal Liquid Sensor (2 wire, float switch)

Standard Sensor detects liquids in: spaces between the

walls of DWTs or Dispenser sumps

T SP-ULS

3 wire BriteSensors (below)

T SP-DIS

TSP-DIS Discriminating Interstitial (infrared & conductivity)

BriteSensor detects liquid WATER or PRODUCT in spaces between

the walls of DWTs

Hydrostatic Interstitial (float switches) TSP-HIS

BriteSensor detects HIGH Brine or LOW Brine levels in hydrostatic

reservoirs of DWTs.

TSP-DDS Discriminating Dispenser Sump (conductivity strip & floats)

TSP-DDS

BriteSensor detects liquid PRODUCT or WATER or SUMP FULL in

dispenser sumps

TSP-HIS

Discriminating Turbine Sump (conductivity strip & floats) TSP-DTS

BriteSensor detects liquid PRODUCT or WATER or SUMP FULL in

STP containment sumps

TSP-MWS

TSP-MWS Discriminating ground water monitoring well (float & conductivity strip)

BriteSensor – detects DRY WELL (no water in well) or PRODUCT floating

on water in monitoring wells

TSP-DVS Discriminating Vapor Well (vapor & conductivity strip)

BriteSensor detects liquid WATER or product VAPOR in vapor

monitoring wells

T SP-DVS

Acknowledging Alarms Page 2 - 5

TSP -DTS

2

Page 32

You must know what corrective actions / steps to take when a leak test fails, when a leak

detection sensor alarms, or when other problems or faults occur. These steps may differ

according to your location (Country, State, Province, City or local codes).

Alarms and limits may be programmed to one of the 32 available Output Groups (A thru

FF). Reference your system and tank Setup Report for these associations.

TABLE 2.1 – Output Groups (A — FF)

Probe / Sensor Limit

Name /Type Location Channel Alarm OG Group Action

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

2

Page 2 - 6 Tank Sentinel Operator’s Guide

Page 33

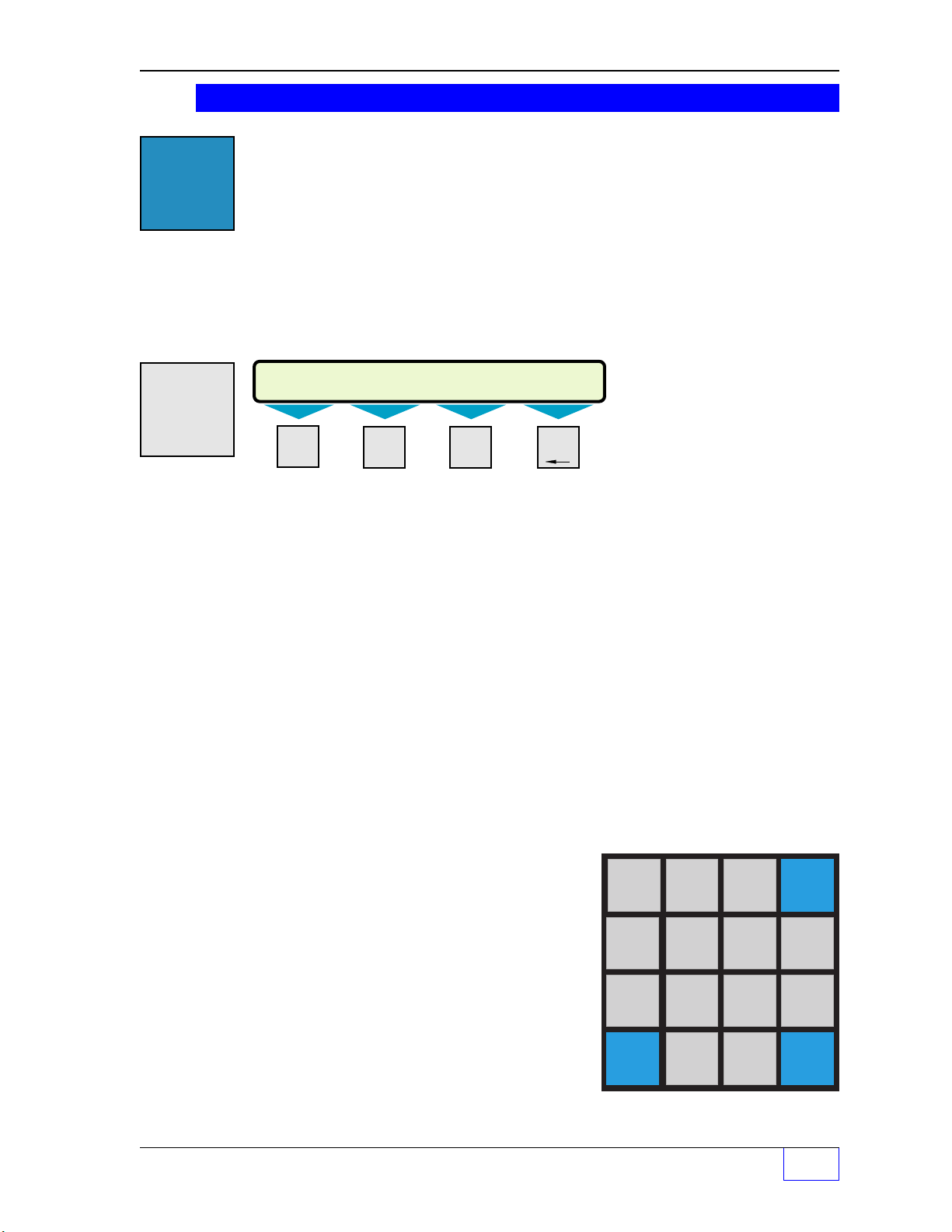

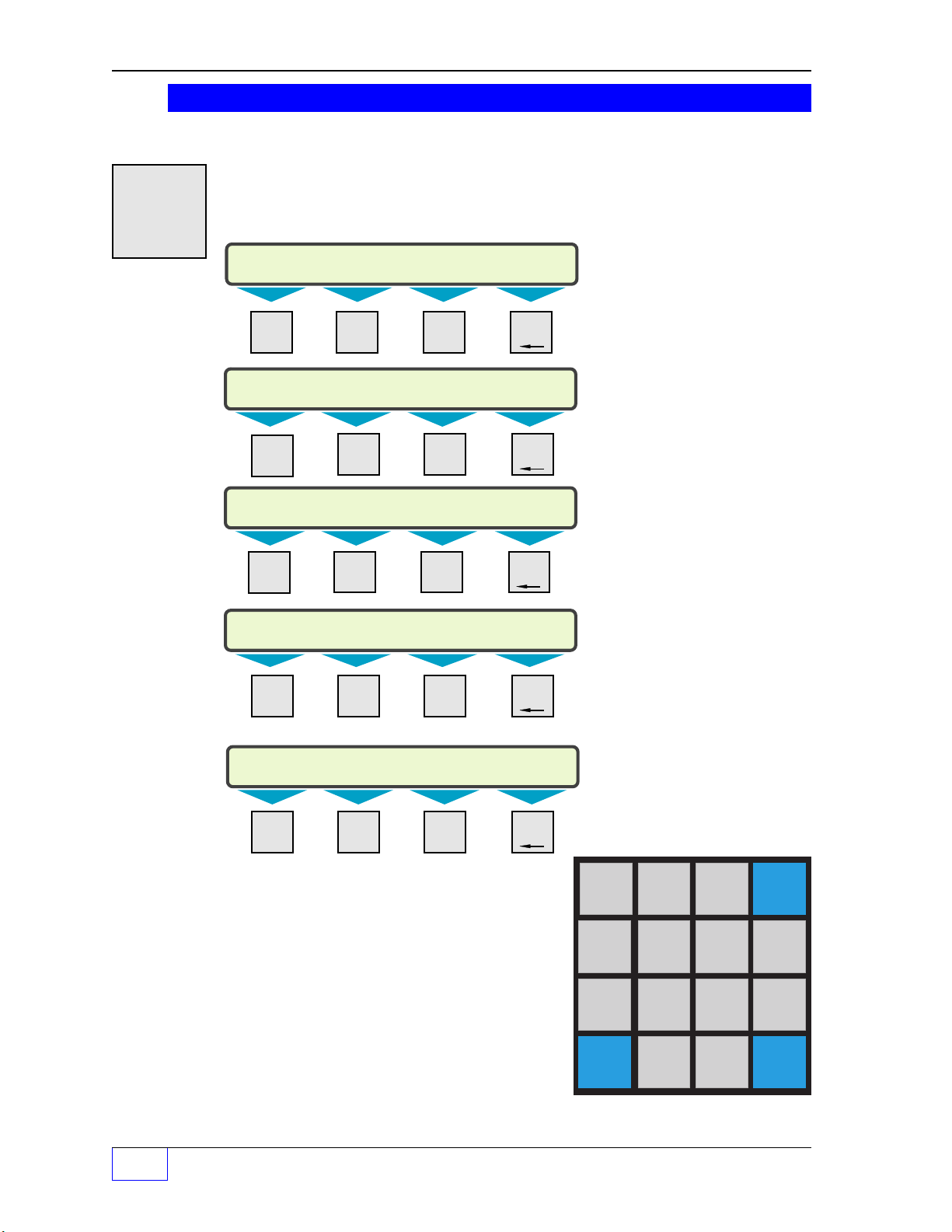

Of the 4 BriteBoxes that can connect to a Tank

Sentinel system:

1 or 2 can be TS-SEM Sensor Expansion Modules

1 can be a TS-ROM Relay Output Module, and

1 can be either a TS-TGI Tank Gauge Interface

module, or

a TS-CIM Control I/O Module

TS-2001

TANK SENTINEL

®

I/O MODULE

TS-CIM / TS-TGI

BRITEBOX

TANK GUAGE INTERFACE

M ODULE

TS-TGI

INPUTS

FROM SIGNAL DEVICES

OUTPUTS

TO LOAD DEVICES

TS- RA 1, or TS -RA 2

Tank Overfi ll Al arm

Ack nowl edge uni t

TS-ROM BRITEBOX

RELAY OUTPUT

M ODULE

TS-ROM

TO LOAD

DEVICES

Figure 2.1 External BriteBoxes to Console

(TS-RA 2 shown)

TS-RK Alarm

TS-SEM BRITEBO X

# 2

SENSOR EXPANSION

M ODULE

TS-SEM

# 33 - 36 # 37 - 40

# 21 - 24 # 25 - 28

TO LEAK

DET ECT IO N

SENSORS

TS-SEM BRITEBO X

# 1

SENSOR EXPANSION

M ODULE

TS-SEM

# 29 - 32 for TS-2001# 25 - 28

# 17 - 20 f or T S-1001# 13 - 16

TANK

SENTINEL

TANK SENTINEL

TS-20 01

TS P - D D S

Di s cri mi nati ng

Di sp ens er

Sump

BriteSensor

Console

TS - LLD

Line Leak Detector

TS P - D TS

Di s cri mi nati ng

STP

Turbi ne Sump

Br i t eSens or

TSP -LL2 Li qui d

Level Probe

TSP-DIS Di scriminating

Interstitial BriteSensor

TS P - MWS Di scri minat ing Ground

Water Moni tori ng Well Bri t eSensor

Figure 2.2 Typical Station Partial Side-view with One Tank

TS P - H L S

Std High

Level

Sensor

TS P - D V S

Di s cri m.

Vapor

Moni t ori ng

Wel l

Br i t eSens or

Acknowledging Alarms Page 2 - 7

2

Page 34

TABLE 2.1 – Output Groups (A — FF) Continued...

Probe / Sensor Limit

Name /Type Location Channel Alarm OG Group Action

20

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

example

TSP-DIS Tank 4 12 Product 12 C P Disp. Shut Down, Record, call EPA

TSP-DIS Tank 4 12 Water 12 C Record

2

Page 2 - 8 Tank Sentinel Operator’s Guide

Page 35

— Your Notes —

—

Acknowledging Alarms Page 2 - 9

❖

—

2

Page 36

3 T ank Sentinel Reports

Contents:

Reports Overview & Types

How to Print a Report

FAXing a Report

Sample Reports

Product Inventory (detail & summary)

Tank Inventory (detail & summary)

Product Delivery (detail, summary, history)

Reports Overview

Reports may be printed or fax’d manually from the keypad, or may be programmed to print

or fax on a schedule or automatically when certain events occur such as an alarm. Nonalarm reports also provide useful information to help run the business (examples of these

are: Inventory, Delivery, Usage, passed Leak Tests, Sensor, Alarm, Setup, CPM, CVS,

DIM or Regulatory reports). Leak Test and Regulatory reports are documented proof of

compliance and functional operation.

Alarm reports also provide hard copy documentation concerning system faults, tank –

sensor – line leak detector faults or detected leaks (see Chapter 2 about Alarms and

Warnings, and Chapter 4 about Leak Testing).

Product Usage (detail, summary, reconcile)

Tank Leak Test Estimate, Static Test, SCALD

Leak Test, Line Leak Test (compliance)

Sensor (status & vapor),

Alarm Reports (active cleared system line)

Setup (system, tank)

Regulatory, Generator Run, & Print Test

Report Types

Inventory:

Delivery:

Usage:

Test:

Sensor: