Page 1

Fuel Management System

Programming Guide

T5 Series

Software Revision 1.7.4

Franklin Fueling Systems • 3760 Marsh Rd. • Madison, WI 53718 USA

Tel: +1 608 838 8786 • 800 225 9787 • Fax: +1 608 838 6433 • www.franklinfueling.com

Page 2

Notice

Franklin Fueling Systems (FFS) strives to produce the nest manual possible and to ensure that the information that it

contains is complete and accurate FFS periodically review the manuals. However, FFS reserves the rights to change this

document and specications at any time without notice. FFS makes no expressed or implied warranty with regard to the

contents of this manual. FFS assumes no liability for errors, omissions or for any damages, direct or consequential, that

may result from the use of this document or the equipment that it describes.

This manual is for use expressly with the T5, T550, and T5000 at their approved specications. No part of this document

may be reproduced in any form without the prior written consent of FFS.

Open Source Notice

The T5 series consoles implement open source software released under the General Public License (GPL) as well as

other open source licenses. As a customer, you are entitled to receive a copy of the licensed source code used within our

product, if so desired. Please contact our sales staff for more information.

Trademarks

FFS®, Tank Sentinel®, System Sentinel®, SCALD®, Brite®, BriteBox®, BriteBus®, and BriteSensors® are registered

trademarks of Intelligent Controls. All brand and product names are trademarks or registered trademarks of their

respective companies.

Inspection of Materials

Visually inspect all components for defects or damage prior to installation. If any defect or damage is found, do not use the

product and contact FFS for further assistance.

Warranty Information

Please refer to the FFS Fuel Management Systems & Product Warranty Policy for all warranty information.

Contacting Franklin Fueling Systems (FFS)

Please feel free to contact us by mail at:

Franklin Fueling Systems

3760 Marsh Rd.

Madison, WI 53718 USA

Or contact us by phone, fax or e-mail:

Tel: +1 800 984 6266 E-mail: sales@franklinfueling.com

Fax: +1 608 838 6433 techserve@franklinfueling.com

Ofce and Sales Hours: 8am to 5pm CST - Monday through Friday

Technical Support Hours: 7am to 7pm CST - Monday through Friday

Please visit our website at www.franklinfueling.com

Copyright ©2011 by Franklin Fueling Systems. No part of this publication may be reproduced in any form without the prior written consent of FFS. All

ii

rights reserved.

Page 3

Contents

Notice..................................................................................................................................ii

Important Safety Messages ..............................................................................................1

Introduction ........................................................................................................................3

FMS Functions ..........................................................................................................................3

Denitions and Acronyms ......................................................................................................... 4

Related Documentation ............................................................................................................ 4

General ............................................................................................................................... 5

User Interfaces (UI) ..................................................................................................................5

LCD Touch Screen Interface .......................................................................................................... 5

Touch Screen Calibration .........................................................................................................................5

Web Browser Interface .................................................................................................................... 5

Access Control ................................................................................................................................ 5

Password Input................................................................................................................................ 6

Modifying Passwords ...................................................................................................................... 6

Connecting a PC or Laptop Computer ...................................................................................... 6

Conguring IP Settings for Communication .................................................................................... 7

Check Status of Connection ............................................................................................................ 9

Connecting a PC to the T5 series RS-232 Port ........................................................................ 10

Connecting a PC to the T5 series COMM 1 Port ............................................................................ 10

Conguring COMM 1 Settings for Communication ......................................................................... 11

Check Operation of Connection ...................................................................................................... 13

Initial Console Conguration ...........................................................................................13

Console Build Characteristics ................................................................................................... 13

Conguration and Preferences ................................................................................................. 14

Preferences Menu ........................................................................................................................... 14

Conguration Menu ..................................................................................................................16

Conguration Options...................................................................................................................... 16

Network Parameters ........................................................................................................................ 16

Date/Time Set ................................................................................................................................. 16

Time Zone ....................................................................................................................................... 17

Remote Logging Host ..................................................................................................................... 17

Modem ..............................................................................................................................17

Programming and Navigation ..........................................................................................18

Console Navigation ...................................................................................................................18

Navigation Buttons .......................................................................................................................... 18

Character Navigation Buttons ......................................................................................................... 19

Application Menus ............................................................................................................ 19

Programming System Parameters ............................................................................................20

System ID ........................................................................................................................................ 20

System Conguration ...................................................................................................................... 20

Programming Modules .................................................................................................................... 21

IO Modules .............................................................................................................. 21

AC Input Modules.....................................................................................................................................21

Probe Modules ......................................................................................................................................... 22

2-Wire Sensor Modules............................................................................................................................22

3-Wire Sensor Modules............................................................................................................................22

4-20 mA Input Modules ........................................................................................................................... 23

Power Supply ........................................................................................................................................... 24

Relay Modules .........................................................................................................................................26

Dispenser Interface .................................................................................................................................. 27

iii

Page 4

Programming Parameters ............................................................................................................... 28

Fuel Management System .......................................................................................................................28

Special Tanks ...........................................................................................................................................29

Manifold Tank System ..............................................................................................................................29

Vapor Recovery Monitoring .....................................................................................................................31

Secondary Containment Monitoring .......................................................................................................31

E-Mail ....................................................................................................................................................... 32

Events ......................................................................................................................................................32

Web Browser Interface ......................................................................................................33

Navigating Applications Remotely ............................................................................................ 33

Accessing Web Browser Interface .................................................................................................. 33

Making Changes to System Parameters .................................................................................. 33

Password Prompting .................................................................................................................33

Setup ........................................................................................................................................33

Backup Setup Files ...................................................................................................................34

Leak Testing .......................................................................................................................36

Leak Testing .............................................................................................................................. 36

Overview ......................................................................................................................................... 36

Tank Leak Tests – Type and Frequency .......................................................................................... 36

Static Tank Testing Requirements ............................................................................................................ 36

When to Force Static Tank Leak Tests ..................................................................................................... 36

Manually Forcing Static Leak Tests ..........................................................................................................37

Tank Leak Test Results ................................................................................................................... 38

Reasons Why Tank Leak Tests Fail .........................................................................................................38

Steps to Take When a Tank Leak Test Fails.............................................................................................38

SCALD Tank Leak Tests .................................................................................................................. 38

Reasons Why SCALD Tank Tests may Fail .............................................................................................38

TS-LS500 Auto Learn Line Leak Testing ......................................................................................... 39

Overview ..................................................................................................................................................39

Line Leak Test Requirements ...................................................................................................................39

When to Force Line Leak Tests ................................................................................................................39

Line Leak Test Results .............................................................................................................................39

Steps to Take When a Line Leak Test Fails .............................................................................................39

DTU (Data Transfer Unit) Setup and Programming ........................................................ 40

DIM Programming ..............................................................................................................42

Dual DIM Installation .................................................................................................................46

Hardware Conguration ............................................................................................................ 46

Device Address .........................................................................................................................46

Communication Settings ........................................................................................................... 46

TS-TPI Overview and Functionality .................................................................................47

TPI Setup ..................................................................................................................................48

List of Alarms and Troubleshooting ................................................................................ 49

System Alarms ..........................................................................................................................49

VRM Alarms ..............................................................................................................................51

FMS Alarms .............................................................................................................................. 52

SCM Alarms ..............................................................................................................................55

Wire Sensor Alarms .................................................................................................................. 55

Line Leak Detector (LLD) Alarms .............................................................................................. 56

TPI Alarms ................................................................................................................................ 57

Printer Alarms ........................................................................................................................... 58

Appendix A - Standard Tanks Table .................................................................................59

Appendix B - Standard Products Table ........................................................................... 61

Appendix C - Typical Tank Leak Test Times ...................................................................61

iv

Page 5

Important Safety Messages

FFS equipment is designed to be installed in association with volatile hydrocarbon liquids such as gasoline and diesel

fuel. Installing or working on this equipment means working in an environment in which these highly ammable liquids

may be present. Working in such a hazardous environment presents a risk of severe injury or death if these instructions

and standard industry practices are not followed. Read and follow all instructions thoroughly before installing or working

on this, or any other related, equipment.

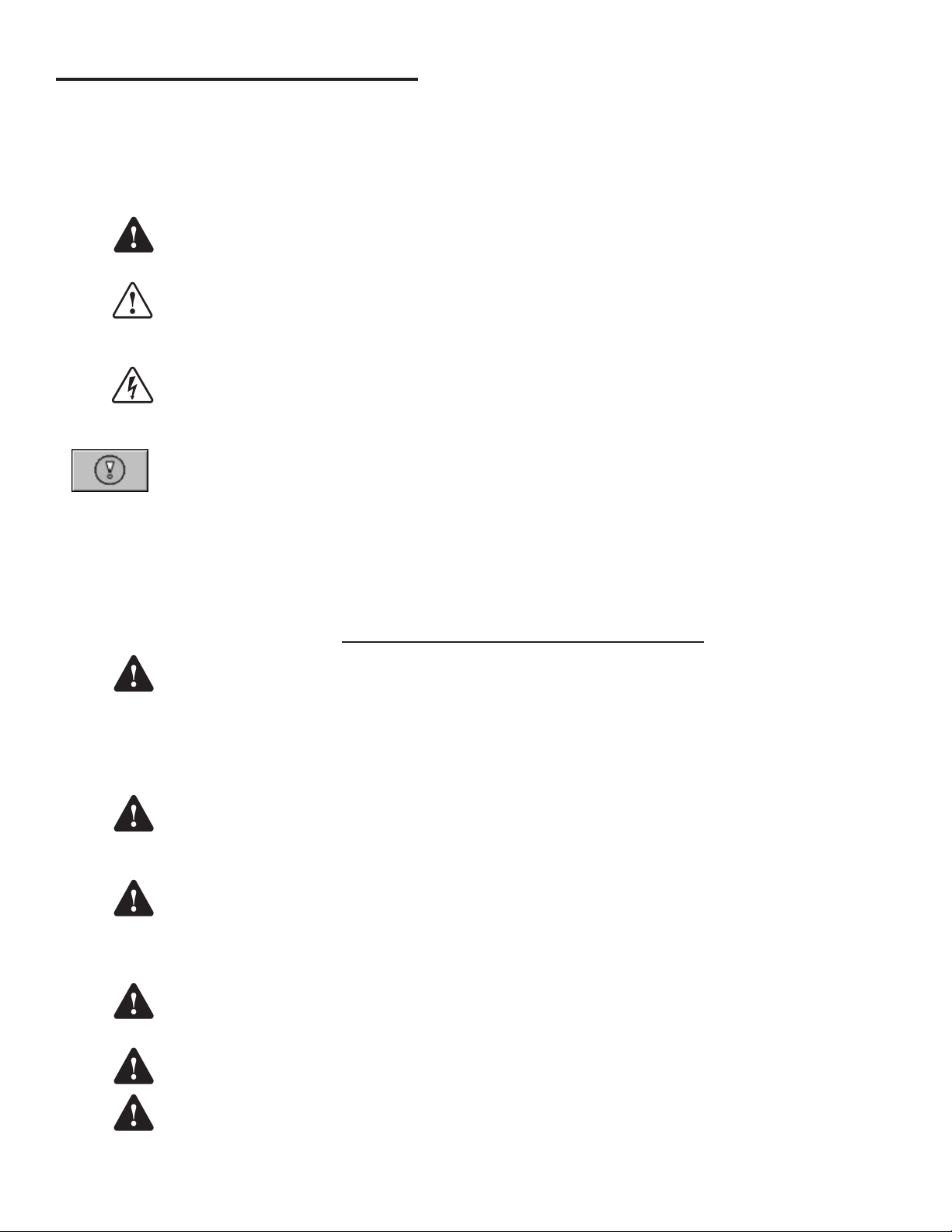

As you read this guide, please be aware of the following symbols and their meanings:

Warning

Caution

Danger

Warning

This symbol identies a warning. A warning sign will appear in the text of this document when a potentially

hazardous situation may arise if the instructions that follow are not adhered to closely. A potentially hazardous

situation may involve the possibility of severe bodily harm or even death.

This is a caution symbol. A caution sign will appear in the text of this document when a potentially hazardous

environmental situation may arise if the instructions that follow are not adhered to closely. A potentially

hazardous environmental situation may involve the leakage of fuel from equipment that could severely harm

the environment.

This symbol identies an electrical danger. An electrical danger sign will appear in the text of this document

when a potentially hazardous situation involving large amounts of electricity may arise if the instructions that

follow are not adhered to closely. A potentially hazardous situation may involve the possibility of electrocution,

severe bodily harm, or even death.

Alarms and warnings are designed to alert you with specic details when a problem occurs so you can

take appropriate corrective action. System hardware failure warnings, tank related alarms, leak detection

sensor alarms, and line leak alarms can be custom programmed to do many things. The events that require

programming are denoted by a (p) below:

- cause the red Alarm light or yellow Warning light to ash (standard)

- activate / sound the console annunciator alarm horn (p)

- activate internal output relays for external alarm devices (p)

- print alarm reports automatically, either locally (internal printer), or remotely (USB - HP compatible printer) (p)

- send alarm and test reports to a specied e-mail address (p)

- send reports to remote location(s), via internal data/fax modem (p)

Follow all applicable codes governing the installation and servicing of this product and the

entire system. Always lock out and tag electrical circuit breakers while installing or servicing

this equipment and any related equipment. A potentially lethal electrical shock hazard and the

possibility of an explosion or re from a spark can result if the electrical circuit breakers are

accidentally turned on during installation or servicing. Please refer to the Installation and Owner’s

Manual for this equipment, and the appropriate documentation for any other related equipment, for

complete installation and safety information.

Warning

Warning

Warning

Warning

Warning

Follow all federal, state and local laws governing the installation of this product and its associated

systems. When no other regulations apply, follow NFPA codes 30, 30A and 70 from the National Fire

Protection Association. Failure to follow these codes could result in severe injury, death, serious

property damage and/or environmental contamination.

Always secure the work area from moving vehicles. The equipment in this manual is usually

mounted underground, so reduced visibility puts service personnel working on this equipment in

danger from moving vehicles entering the work area. To help eliminate these unsafe conditions,

secure the area by using a service truck to block access to the work environment, or by using any

other reasonable means available to ensure the safety of service personnel.

When the Fuel Management System is used to monitor tanks containing gasoline or other

ammable substances, you may create an explosion hazard if you do not follow the requirements in

this manual carefully.

All wiring must enter the console’s enclosure through the designated knockouts. An explosion

hazard may result if other openings are used.

You must run wiring from probes or sensors to the Fuel Management System console in conduits

which are separate from all other wiring. Failure to do so will create an explosion hazard.

1

Page 6

Warning

Certied Programmer/Service Person: Only an FFS certied programmer or service person is allowed to access both

the user interface keypad and areas internal to the Fuel Management System console.

Station Owner/Operator: The station owner or operator of the Fuel Management System console is only allowed to

access the user interface keypad. Access to areas internal to the console is strictly prohibited.

Substituting components could impair intrinsic safety. T5XXXs are intrinsically safe for sensors

installed in – Class I, Division 1, Group D – hazardous locations. Substitution of components could

make the energy limiting circuitry in the system ineffective and could cause an explosion hazard.

Repairs to a T5XXX console or attached components should only be performed by a qualied,

factory-trained technician.

Approvals

All Fuel Management System models are UL and cUL listed 6L79 as Liquid Level Gauge / Leak Detection

Systems. Third party approved leak detection — Pd (probability of detection) = 99.2 % for 0.1 or 0.2 gph leak tests

(0.1 = annual precision test, 0.2 is the monthly regulatory compliance test).

*The static tank test does not support Manifolded tanks.

**SCALD is 3rd party approved for ONLY two Manifolded tanks.

2

Page 7

Introduction

The purpose of this manual is to guide installers, operators and technicians through programming and troubleshooting

the T5 series console, so that it’s congured based on a site’s specic needs. The Fuel Management Systems (FMS)

application within the T5 Series consoles tie together the monitoring and alarm capabilities of preceding automatic tank

gauges with advanced technologies to supply tank and level data more accurately and efciently. This manual is also

designed to introduce technicians to the optional LCD Graphical User Interface, which is used as an input device to

program system conguration and maintain all applications from the front panel of the console as well as through a web

interface. Overall safety issues, troubleshooting information, warranty, service and return policies, as dened in this

manual, must be followed.

FMS Functions

The main function of the Fuel Management System is to represent levels for inventory and tank leak testing by monitoring

probe inputs and performing calculations based on those inputs. Line leak sensing devices also provide input signals.

Results from these calculations may be used for system monitoring and/or regulatory compliance. The console, in

conjunction with external fuel system equipment, may provide positive system shutdown, based on programmed rules.

Sites that utilize Fuel Management Systems have the ability to monitor and perform:

• Tank Inventory Level Information

• Tank Leak Detection

• Sensor Conguration

• Line Leak Detection

• Sump Leak Detection

• Compliance Line and Leak Testing

FMS also allows sites to generate and print the following reports:

• Inventory Reports

• Delivery Reports

• Tank Test Results

• SCALD Testing Reports

• Regulatory Reports

• Sensor Reports

3

Page 8

Denitions and Acronyms

Module – A module is a plug-in card within the T5 series console that is used to perform various functions of the console.

The modules are used for eld wiring of the input and / or output of electrical signals between different functional

equipment pieces.

RS-232 – An IEEE standard for serial communication using a 9-pin connector.

RS-485 – An IEEE standard for serial communication using Shielded Twisted Pair or Unshielded Twisted Pair wiring.

RJ-45 – An IEEE standard connector for use in communications with Shielded Twisted Pair wiring. Usually data.

RJ-11 – An IEEE standard connector for use in communications using Shielded Twisted Pair wiring. Usually voice and fax.

2SM – 2-Wire Sensor Module (Intrinsically Safe)

ACIM – AC Input Module

AIM – 4-20mA Analog Input Module (Intrinsically Safe)

AST – Aboveground Storage Tank

ATG – Automatic Tank Gauge

CARB – California Air Resources Board

CM – Controller Module

DCE – Data Communication Equipment

DIM – Dispenser Interface Module

DTE – Data Terminal Equipment

DTU – Data Transfer Unit

DW/DWT – Double Wall/Double Wall Tank

EVR – Enhanced Vapor Recovery

FMS – Fuel Management Systems

IS – Intrinsically Safe

ISD – In-Station Diagnostic

LCD – Liquid Crystal Display

LIM – LonWork Interface Module

LLD – Line Leak Detection

PC – Personal Computer

PM – Probe Module (Intrinsically Safe)

PSM – Power Supply Module

RTD – Resistance Temperature Detectors

RM – Relay Module

SCM – Secondary Containment Monitoring

SLLD - Statistical Line Leak Detection

STP – Submersible Turbine Pump

TPI – Turbine Pump Interface

TS-5 – T5 Series FMS Consoles (T5/608, T550/EMS, T5000/EXPC)

TS-EMS – Environmental Monitoring System

TS-EXPC – Expansion Console

URL – Uniform Resource Locator for the internet

USB – Universal Serial Bus

UST – Underground Storage Tank

VFM – Vapor Flow Meter

V/L – Vapor to Liquid ratio

VRM – Vapor Recovery Monitoring

XML – eXtensible Markup Language

Related Documentation

The system installation and operation instructions, troubleshooting guide and console maintenance manual are provided

for your use in separate documents. Detailed installation and testing instructions for each type of leak detection sensor

are present in the relevant manual, and, likewise, the installation, testing, and programming of various upgrade kits and

optional accessories are also contained in separate manuals, addenda or in one of this document’s appendices.

T5 Series Fuel Management Systems Installation Guide (000-2150)

T5 Series Fuel Management Systems Operators Guide (000-2151)

4

Page 9

General

After the Fuel Management System has been installed, typically your interaction with the system will be from the LCD

display, on-board printer; or using the Web Browser software to program and monitor the console remotely. Remote

operation can be performed from a PC, either attached directly or through a network connection to the console. All of the

features of the console are available through these input / output devices. Also, the console may be set up to generate and

send automated reports to e-mail accounts or print reports at a programmed time.

Occasionally you may need console information, such as model and serial numbers. The model number is located on the

face of the console. The serial number is located on a small plaque placed on the bottom of the left panel. This label also

shows the model number, voltage, manufacturer’s address, a warning symbol and the unit’s voltage specications.

User Interfaces (UI)

LCD Touch Screen Interface

An LCD touch screen is included with the T5 (TS-608) consoles and can be ordered as an option on the T550

(TS-EMS) and T5000. The “D” designation in the console’s model number indicates that a LCD display was ordered

with the system. This bright display, with an adjustable contrast setting, allows easy viewing in any lighting condition. A

programmable screen saver can be selected to automatically turn the backlight off after 5 minutes. This extends the life of

the display. To enable or disable the sleep mode select: Menu > Preferences > Toggle Sleep Mode

Touch Screen Calibration

During initial setup, it will be necessary to calibrate the touch screen function of the LCD display. Calibrating the

touch screen will enable the console to better recognize the area that you “touch,” so that you can accurately enter in

information. To calibrate the touch-screen function of the display, you must rst access the calibration application.

1. From the HOME MENU, press MAIN MENU > DOWN > TOOLS > TOUCHSCREEN CALIBRATION.

2. The console will ask if you are sure that you want to proceed, answer Yes.

3. Follow the on-screen instructions to complete the calibration process.

Web Browser Interface

Each T5 Series console includes an Ethernet port and programming options to eliminate the need for an Ethernet port

server or a external / internal modem (although both options are still available). The advantages to using an Ethernet

connection are: faster connection speeds, quicker data transfer rates, less data errors or quicker recovery of data when

errors occur, and it does not require extra software or drivers to be loaded. This means that console parameters can be

modied and that status/alarm reports can be printed from virtually anywhere.

Access Control

There are three access levels programmed into the console’s operating system: Guest, User, and Administrator. Each

level will allow an operator to access different features or change specic settings on the console. This security feature

prevents unauthorized tampering of console congurations.

The User Role icon will appear in the upper-right corner of the LCD display as one of the following:

• ONE BAR lled operates at the GUEST level. Guests are allowed to access menu options and check the system

congurations. The GUEST will not be able to modify the console settings.

• TWO BARS lled operates at the USER level. Users are given limited access to certain areas of the operating

system to make changes or print reports.

• THREE BARS lled operates as an ADMINISTRATOR. This level grants access to all areas of programming and

setup conguration. The administrator privilege is usually assigned to the designated technician of a site.

5

Page 10

Password Login

1. Press the User Roll icon

2.

Enter Password for the desired level as described in the Access Control section on page 5.

Default passwords are as follows:

Guest: guest

User: user

Administrator: admin

Tapping twice on the User Role Icon will reset to guest level access.

Modifying Passwords

For initial settings and continuous security purposes, the console will allow you to change any password used for

accessing console functions. When changing passwords, make note of the password and keep it in a secure, memorable

place. The password you choose must be at least two characters long with a maximum of 16 characters — spaces and

special characters are allowed as part of your password.

The Administrator status is required to change passwords.

From the touch screen display, changing access passwords is done by navigating through menus to modify a password.

1. When the console is powered up, press the Main Menu button .

2. Press the Conguration Application button.

3. Press Passwords in the application window, and then press the corresponding button to change the password for that

access level.

4. Verify the correct password has been entered, and then press the Checkmark button.

Connecting a PC or Laptop Computer

To access the console using the Web Browser interface, connect a PC to the console through either the Ethernet port or

the COMM 1 serial port. If the console is connected to a local network, you can perform this setup from any PC on that

network by using a web browser application, such as Microsoft’s Internet Explorer or Mozilla’s FireFox (the console’s IP

address may need to be modied — see Conguration in Section 2).

The following instructions are written specically for Microsoft’s Windows XP operating system. For assistance with other

operating systems, please contact Franklin Fueling Systems Technical Services.

Connecting a PC to the T5 series Ethernet Port

1. Using an Ethernet Crossover, 10 Base-T cable, plug the RJ-45 connector on one end of the cable into the Ethernet

port of the console.

2. Plug the RJ-45 connector on the opposite end of the cable to the Network Interface Card of the computer.

3. Verify that the green POWER LED on the front panel of the console is lit, which indicates that the console has power.

4. Power up and log onto your PC.

Note: You may need to recongure your TCP / IP settings to allow the computer to communicate with the console.

6

Page 11

Conguring IP Settings for Communication

Before attempting to modify any computer settings, contact the Information Technologies department of your business, if

available. Some computer accounts may have restricted permissions to overcome before any changes are allowed to be

made to TCP / IP settings.

Note: If setting up a connection with a newer operating system (i.e. MS Vista or Widows 7), contact FFS Technical

Support for assistance.

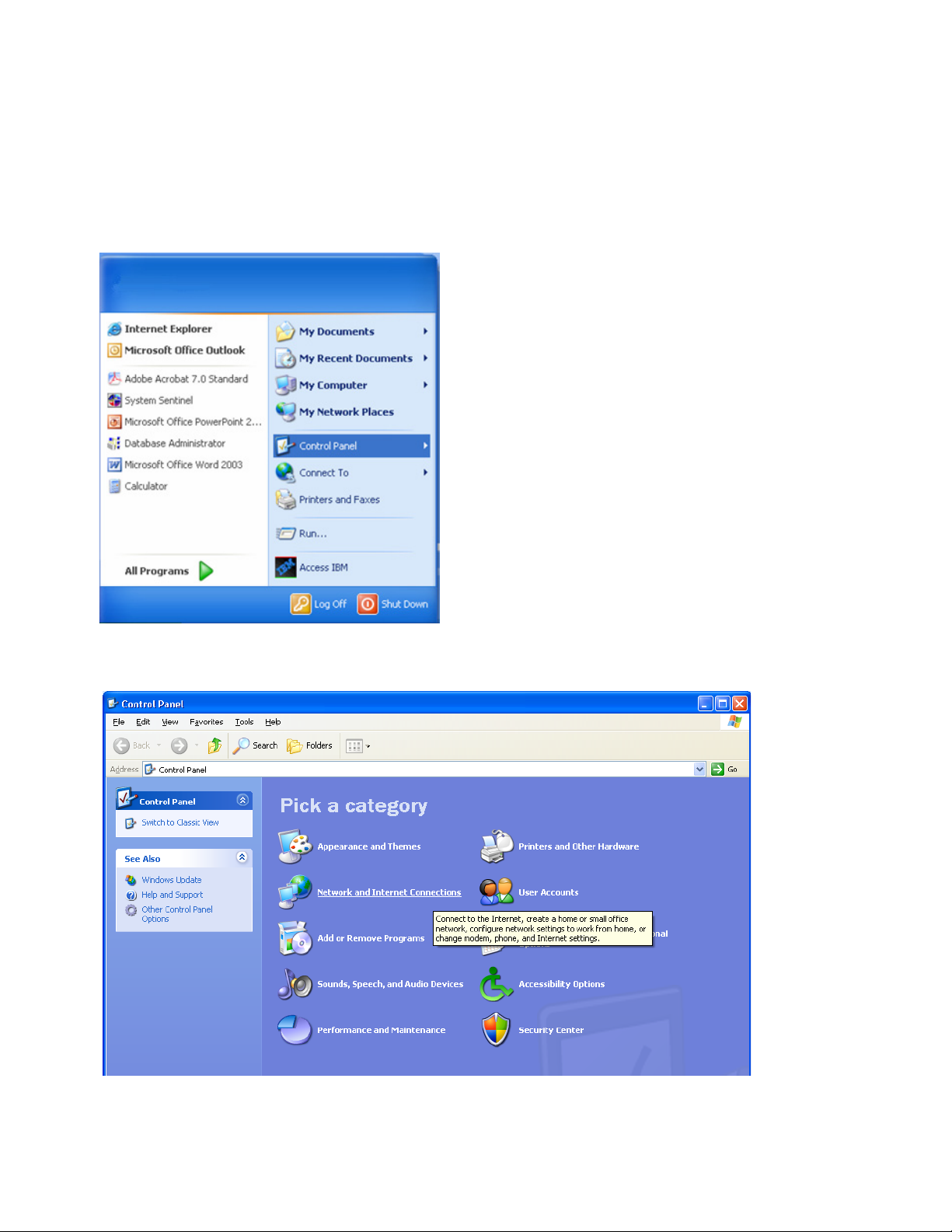

At the PC:

1. Power up the PC and log into your Windows operating system.

2. Click on Start, then select Control Panel.

3. There are (2) two views settings possible when using Windows XP:

• In Category View, click on Network and Internet Connection, then click Network Connections.

7

Page 12

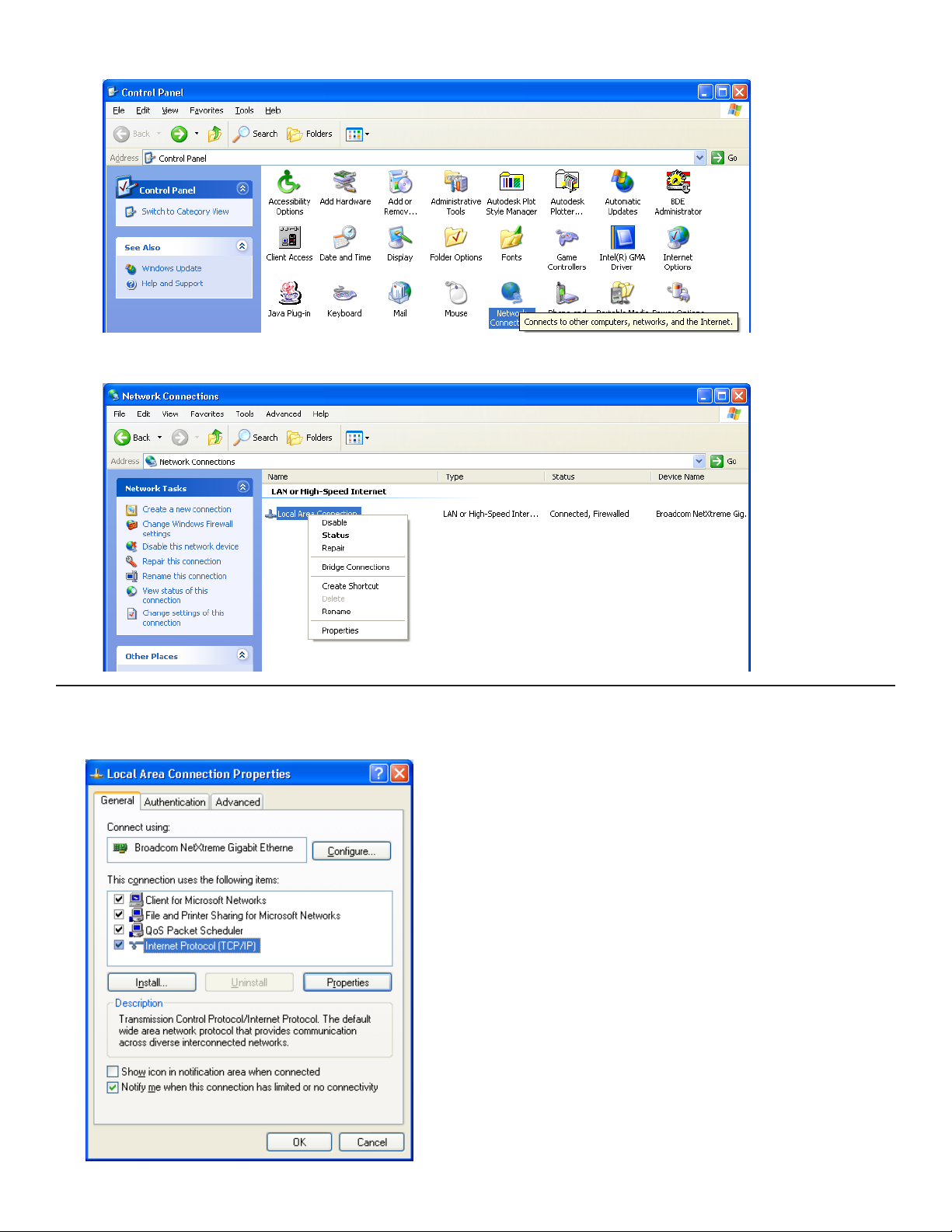

• In Classic View, click on Network Connections.

4. Right-click on Local Area Connection and select Properties.

5. In the Local Area Connection Properties dialog box,

under “This connection uses the following items,” select

Internet Protocol (TCP / IP) and click Properties.

There are many ways to congure a computer to

communicate with a T5 series console. These factors are

dependent on the user’s computer knowledge and how the

computer is currently congured.

To determine which method is best for your site, read the

instructions in the following section carefully. Make detailed

notes on the current conguration of the TCP / IP settings on

the PC you are using. Read both the “Obtain an IP address

automatically” and the “Use the following IP address”

methods before making a choice between the two.

8

Page 13

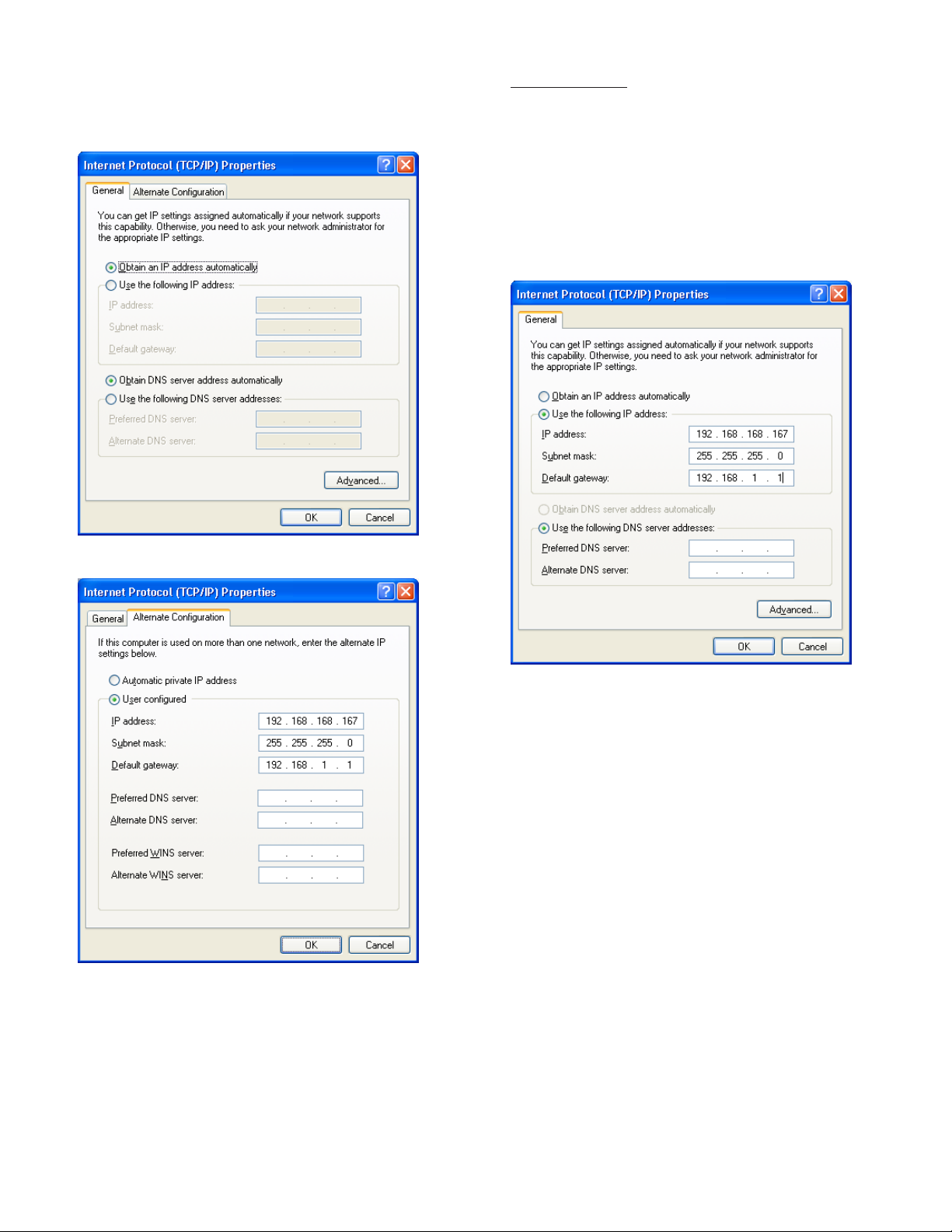

Obtain an IP Address Automatically

Computers commonly use this setting to obtain an IP

address automatically.

1. If Obtain an IP address automatically is selected, it

may be best to click the Alternate Conguration tab.

Note: The consoles default IP address is

192.168.168.168. If the PC is normally congured

to acquire an IP address automatically, Alternate

Conguration may be used, as mentioned above, to

allow a connection to be enabled without the necessity

of reconguring the computer each time it will be used

to connect to this console.

Use the Following IP Address

1.

If Use the following IP address is selected and the entry

boxes contain any information, record this information for

use when console programming is complete.

2. Select User Congured.

3. Enter an IP address. For simplicity, make the last

segment of the IP one number different than the IP

address of the console. Upon initial setup ONLY, the

numbers used in the gure may be used to congure

the TCP / IP settings of your PC.

4. Leave all other information blank and click OK.

5. Close the Local Area network for changes to take place.

2. Enter an IP address. For simplicity, make the last

segment of the IP one number different than the IP

address of the console. Upon initial setup ONLY, the

numbers used in the gure may be used to congure

the TCP / IP settings of your PC.

3. Leave the DNS information blank.

Note: The consoles default IP address is

192.168.168.168. If the PC is normally congured

to Use the following IP address, make sure that

all displayed information is recorded and kept prior

to making any changes. It may be necessary to use

this information to recongure the console once

programming is complete.

Check Status of Connection

1. Check the status of your connection by going to the

Network Connections window.

2. If the connection status is disabled, enable it by rightclicking on the Local Area Connection and selecting

Enable.

3. Verify link light is lit under Ethernet on Controller

module is lit and RX light is ashing.If technical

difculties arise, please contact Franklin Fueling

Systems Technical Support before proceeding.

More information on the Web Browser Interface is located

on page 33 of this manual.

9

Page 14

Connecting a PC to the T5 series RS-232 Port

COMM 1 is used to connect a PC or laptop with the console via the Web Browser Interface for programming or remote

monitoring. COMM 2 is used only for VRM to retrieve ullage data from an external ATG.

If serial connection to Point-Of-Sale (POS) is desired for report retrieval, then we suggest using COMM 1 in Veeder-Root

(VR) mode.

Note: The PC or laptop will recognize this serial connection as a network connection and will not allow the use of a Local

Area Connection simultaneously. While it is not necessary to disconnect the Local Area Connection to connect

using the Serial port, it will be necessary to disconnect the Serial Connection through the computers operating

system in order to use the Local Area Connection again.

Connecting a PC to the T5 series COMM 1 Port

1. Using a female to male DB-9 straight serial cable, connect the female end of the serial cable to the serial

communication (COM) port of the computer.

2. Connect the male end of the serial cable to COMM 1 on the bottom of the console.

Console Conguration

Mode: Network Connection (PPP)

Baud Rate: 57600

→

→

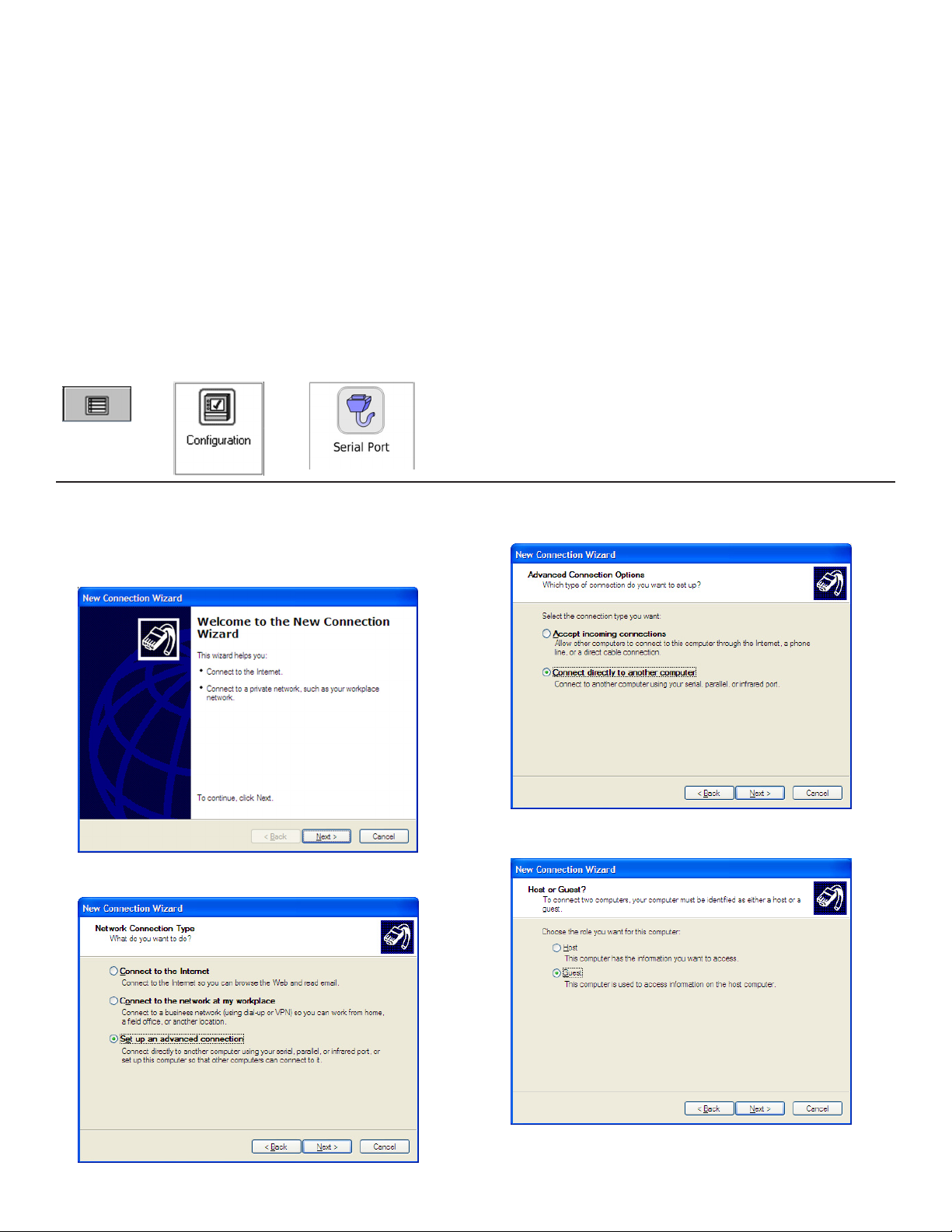

Conguring COMM 1 Settings for

Communication

1. Select Start > All Programs > Accessories >

Communications > New Connection Wizard.

→

Data Bits: 8

Parity: None

Stop Bits: 1

3. Select Connect Directly to Another Computer.

2. Select Set up an Advanced Connection.

10

4. Select Guest.

Page 15

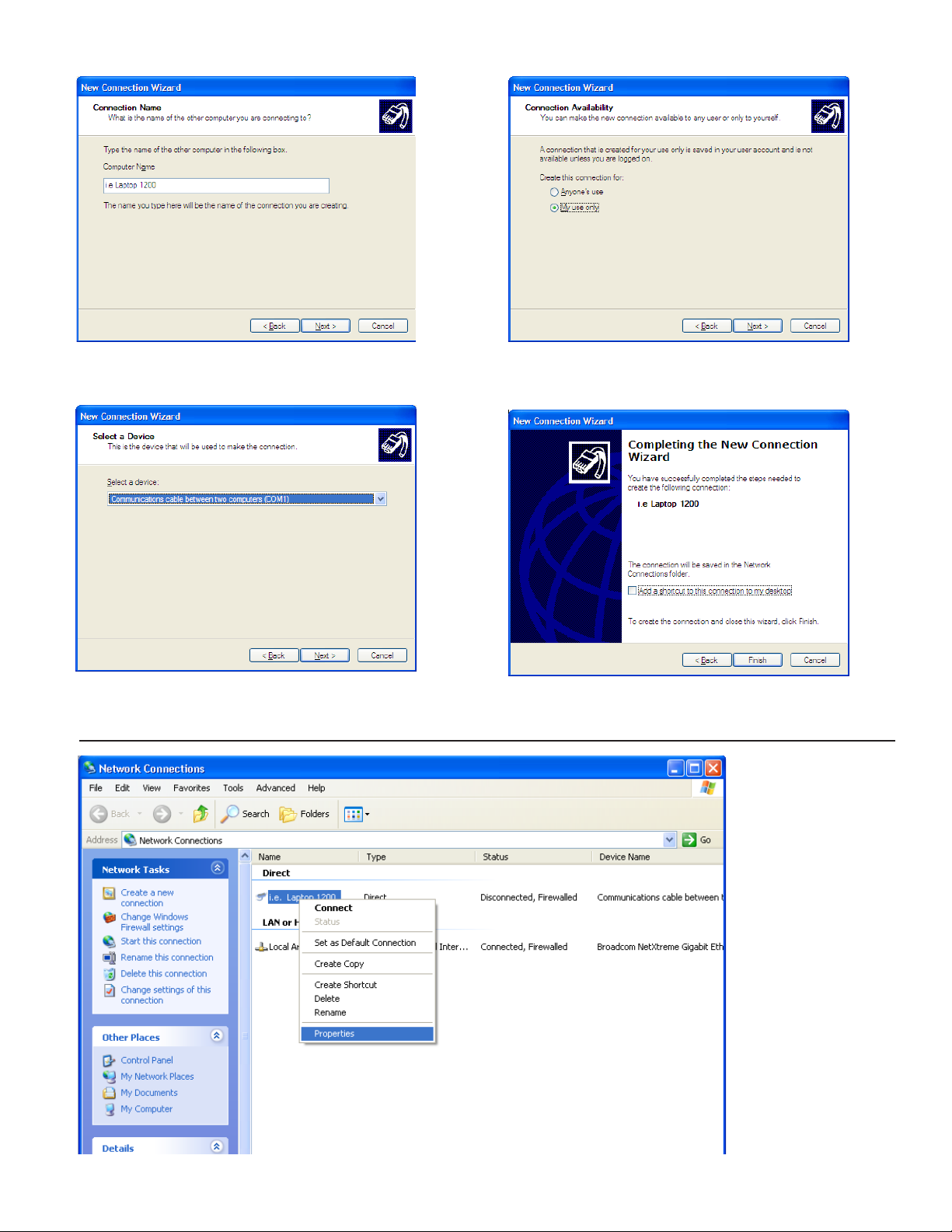

5. Enter a Computer Name (it can be the site name).

7. Select My use only.

6. Select the communication port to be used from the

Select a Device drop-down list.

8. For convenience, a shortcut may be created on your

desktop. Click Finish to complete the wizard.

9. In the Network Connections window, right-click the

new direct connection that was created and select

Properties.

11

Page 16

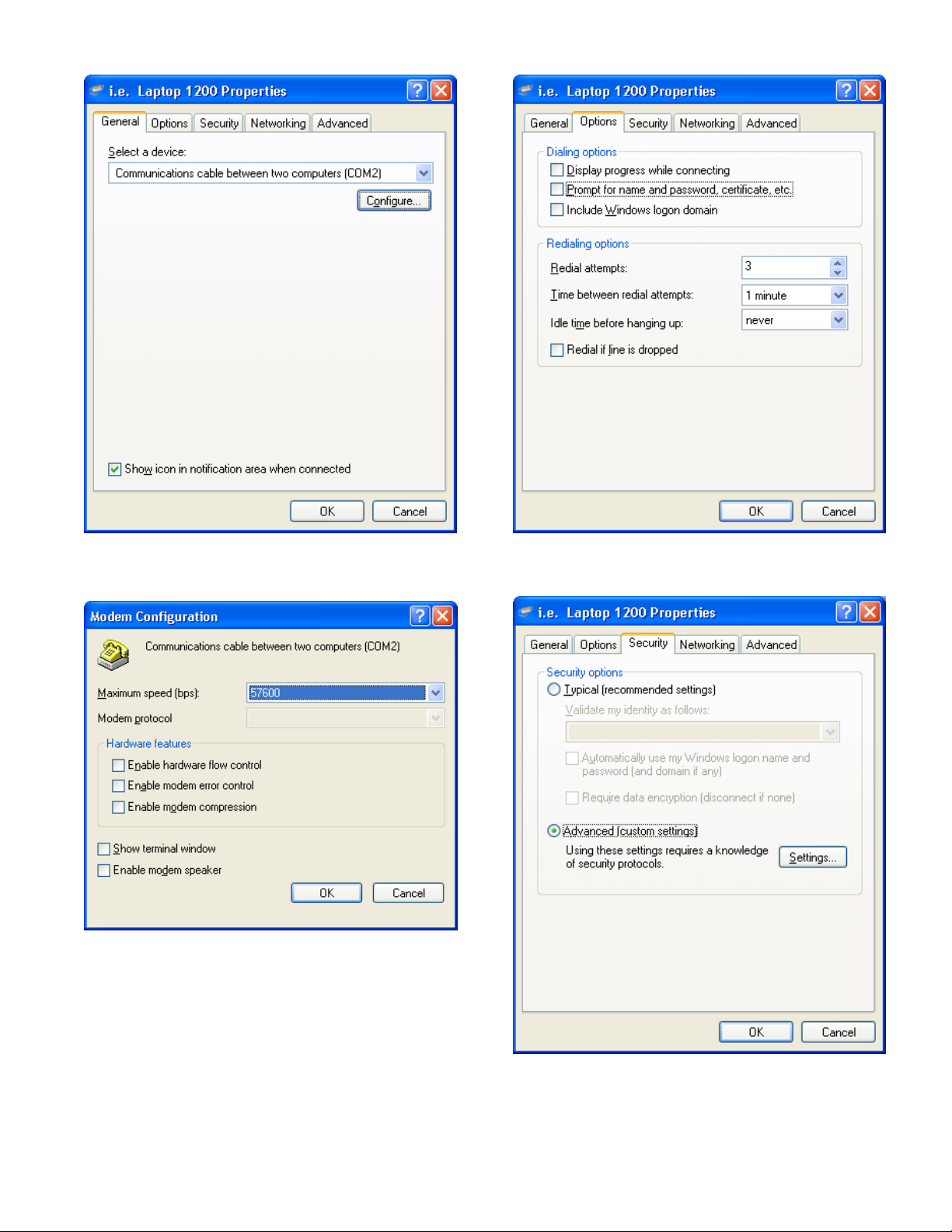

10. Under the General tab, select Congure.

15. Leave the existing Redialing Options as they are.

11. Change the Maximum speed (bps) to 57600.

12. Disable all of the Hardware Features and click OK.

13. Select the Options tab.

14. Disable all of the Dialing Options.

16. Select the Security tab.

17. Select Advanced (custom settings).

12

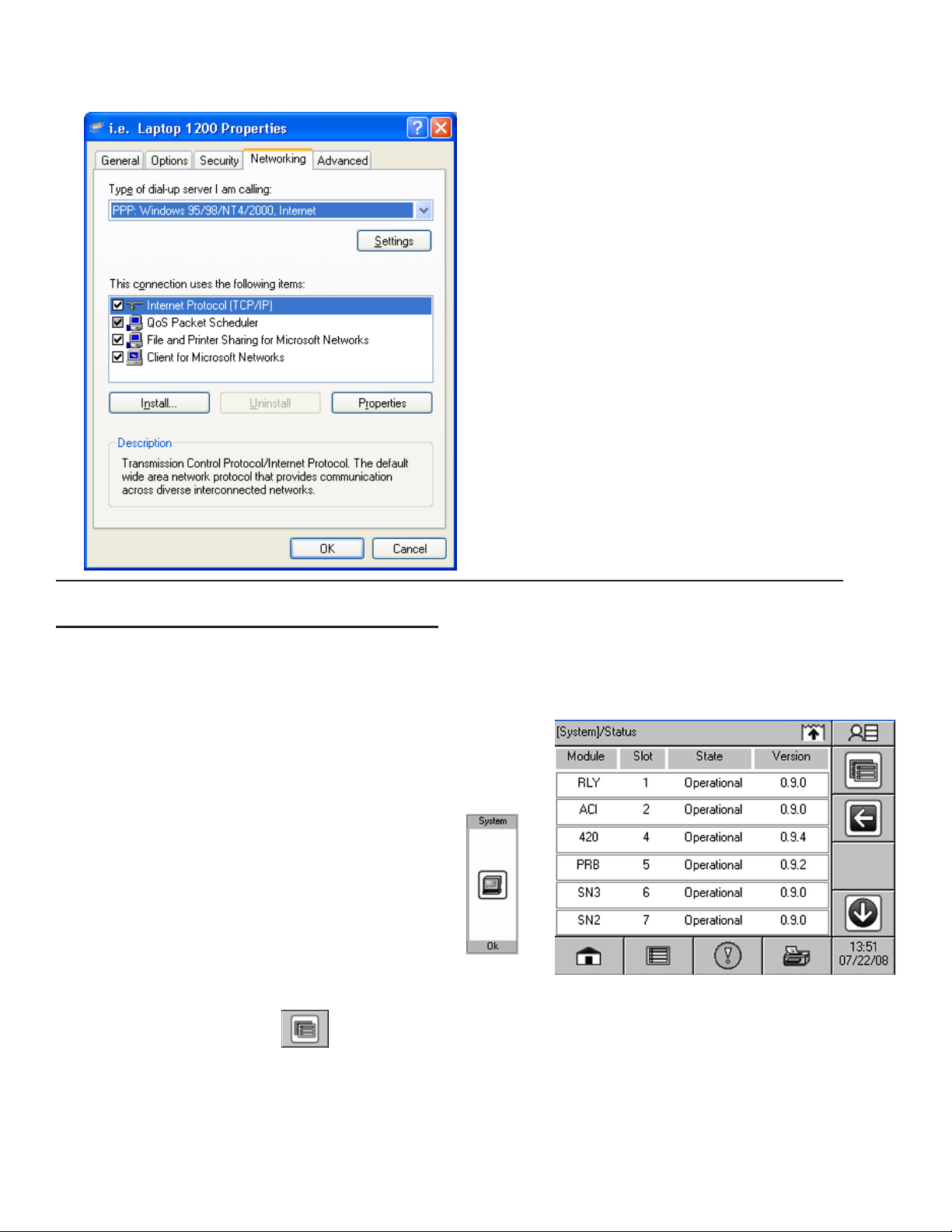

18. Select the Networking tab.

Page 17

19. In the Type of dial-up server I am calling, select

PPP: Windows 95 / 98 / NT4 / 2000, Internet from the

drop-down list then click OK.

Check Operation of Connection

1. As before, open Network Connections.

2. Right-Click the new direct connection and select

Connect. The status should change to connected. At

this point, the computer is connected to the console.

If you experience technical difculties, please contact

Franklin Fueling Systems Technical Support before

proceeding.

At this point, more information on navigating the Web

Browser Interface is provided in Section 4: Web Browser

Interface of this manual.

Initial Console Conguration

Initial setup must be completed before the console can be used. This section will show how to set custom parameters by

navigating through the programming options and set up the T5 series console for the rst time.

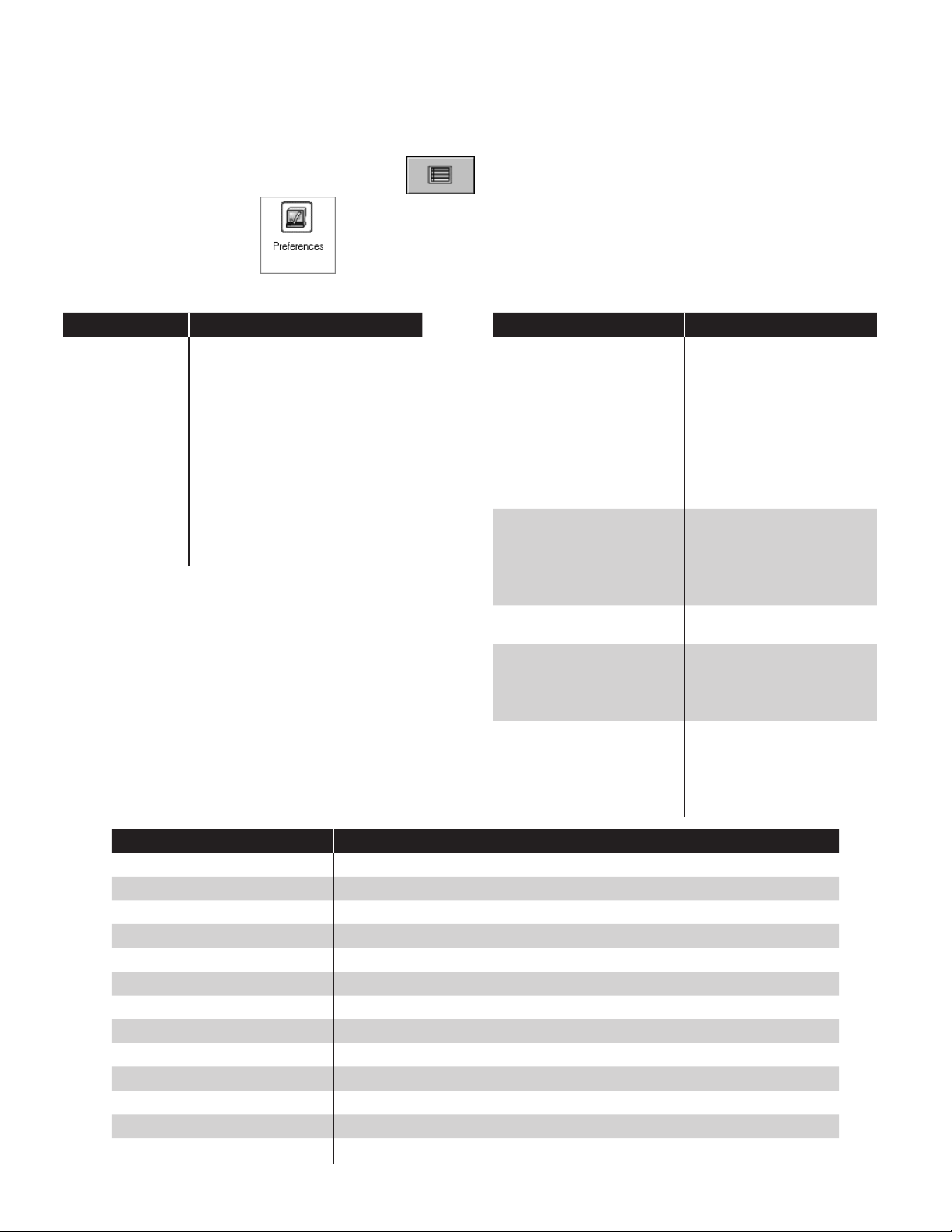

Console Build Characteristics

Each console is custom ordered and built to customer specications.

That means that all of the hardware (modules) and software options

needed for your site are installed and tested. Before programming,

check the status and version of each module and verify that your

purchased options are present.

1. At the Home Status screen, press System Application.

2. The System Status screen will appear. Here you can see a

module’s description, installed slot, operational status, and version.

3. Press the Application Menu button.

Identication – View to locate the System Serial Number, Ethernet Address (not the same as IP address) Controller

Serial number and Date/Time of manufacture.

Options – Displays the current installed software options.

13

Page 18

Conguration and Preferences

Conguration and Preferences include how information will be displayed and conguring the console for its location and

communication and access options.

Preferences Menu

Starting at the Home Menu, press the Main Menu button.

And then select Preferences .

Use the Preference tables on the following pages to select the menu options to be changed.

Translation Options

Language English

Spanish

Russian

Chinese (Simplied)

Chinese (Traditional)

French

Portuguese

German

Russian

Polish

Slovakian

Hebrew

Date/Time Options

MM/dd/yyyy

M/d/yyyy

M/d/yy

MM/d/yy

Short date format

Long date format

Year/month date format

Short time format

Long time format

MM/dd/yy

Yy/MM/dd

yyyy-MM-dd

dd-MMM-yy

User Dened

EEEE, MMMM dd, yyyy

MMMM dd, yyyy

EEEE dd MMMM, yyyy

dd MMMM, yyyy

User Dened

MMMM, yyyy

User Dened

HH:mm

H:mm

hh:mm a

h:mm a

HH:mm:ss

H:mm:ss

hh:mm:ss a

h:mm:ss a

User dened

14

Symbol Representation

MM Two-digit month with leading zero (i.e. 01 for Jan…).

M Two-digit month, no leading zero (i.e. 1 for Jan…).

MMM Three-letter month (i.e. JAN, FEB, AUG…).

dd Two-digit day with leading zero (i.e. 01, 02…).

d Two-digit day, no leading zero (i.e. 1, 2…).

yyyy Four-digit year (i.e. 2006…).

yy Two-digit year (i.e. 06, 07…).

HH Two-digit hour with leading zero; 24-hour format.

hh Two-digit hour, no leading zero; 24-hour format.

mm Two-digit minute, with leading zero.

ss Two-digit second, with leading zero.

a A.M. or P.M. indicator.

EEEE

Page 19

Numbers Options

Digit grouping

Group digits by 103 using specied symbol (i.e. either “123456789” or

“123,456,789”).

Digit grouping symbol Symbol used to group digits (i.e. ‘, ’; ‘ _ ‘…). User dened option.

Decimal symbol Symbol used to separate decimal units (i.e. ‘.’; ‘,’). User dened option.

Display leading zeroes Displays decimals with leading zero (i.e. with ‘0.123’; without ‘.123’).

Units Options

Liters

Volume

Gallons

Imperial Gallons

Millimeters

Length

Centimeters

Meters

Inches

Temperature

Centigrade

Fahrenheit

Liters/Hour

Cubic Centimeters/Second

Flow

Cubic Feet/Hour

Gallons/Minute

Gallons/Hour

Pascal

Bar

FMS - Line Pressure

Pounds per square inch

Inches of Water

Inches of Mercury

Pascal

Bar

VRM-Tank Ullage

Pounds per square inch

Inches of Water

Inches of Mercury

Pascal

SCM - Containment

Vacuum

Bar

Pounds per square inch

Inches of Water

Inches of Mercury

Kilograms per Cubic Meter

Density Units

Grams per cubic centimeter

Pounds per cubic foot

Kilograms

Mass Units

Grams

Pounds

Other Options

Refresh Rate (web interface only) How often the systems information is updated.

Show XML Tool (web interface only) Displays the Tool in the upper right corner of the browser window.

Sleep Mode (console screen only) Toggles display sleep mode on or off

Printer Options (console screen only) Set external printer paper size

15

Page 20

Conguration Menu

Conguration Options

Using the options in this menu, you can change:

• Console passwords • COM 1 parameters

• Network parameters • Modem Parameters

• Current time and date and set an accurate time zone.

For instructions on setting passwords, see pages 5 & 6: Access Control.

Once the console has been powered up, navigate the console by pressing the screen on the appropriate button.

1. Starting at the Home Status Menu, press the Main Menu button.

2. Select the Conguration button.

3. Select from the options in the Network Parameters section that follows to view or change console conguration settings

Network Parameters

To communicate with your network equipment (i.e. router, switch, hub, etc.) you will need to modify the network

parameters.

IP Address Settings:

IP Address – This is a logical (electronic) address, like a street address, that the console uses to route information.

This address will have to match your network, if connected to a network, in order to ‘talk’ to a remote

communication device, or your PC.

Network Mask – Masking is a way to diversify the use of multiple subnets. The mask must match that of the network the

console is connected to. Masks are used in networking to create ‘sub-networks’ within a whole, like slicing

and apple. You have separate slices that may be in different locations, but they are still from the same apple.

Administrators use this to make separate networks, to maximize bandwidth or capacity of medium resources

(cables or ber). Therefore, when your network uses static IP addressing (assigned by an administrator),

this mask must match the Network Mask of the router port that it is attached to. If the network uses a DHCP

server (automatically assigns IP addresses) then the mask should meet the specications set by your

administrator.

Gateway – The Gateway is the logical address to the nearest router port, commonly the one that is connected to the

console. Consult your administrator for details on this and other network parameters.

DNS Server Address:

Preferred DNS Server / Alternate DNS Server – The domain name system (DNS) is the way that internet domain names

are located and translated into Internet Protocol addresses. A domain name is a meaningful and easy-to-remember tag for

an internet address (used for e-mail functions).

Protocol Settings – Veeder Root, port 8001: Port used to connect to a network that uses VR Protocol

– Web Server Secondary Port, 10001: Port used for network as port to forward

Date / Time Set

To set the date and time, click the button that corresponds with your selection and then select the correct option from the

list. If your choice does not appear on the rst screen, use the up and down navigation buttons to scroll through more

options. When nished, conrm your selection by pressing the checkmark or OK button. It is important to enter the date

and time information correctly to ensure reports and alarms can be accurately tracked.

.

16

Page 21

Time Zone

Set the Time Zone according to your geographical location. If your choice does not appear on the rst screen, use the

navigation up and down buttons to scroll through more options. When nished, conrm your selection by pressing the

check-mark or OK button.

Remote Logging Host

Logging event information can be done remotely by using this option. Type the address of the remote host that the

console will communicate with.

Modem

Type:

External USB

External Serial

Mode:

Network Connections (PPP)

Veeder Root

Franklin Fueling (XML)

Data Bit: 5 to 8

Parity: Odd, Even or None

Stop Bits: 1 or 2

Country Code: (Country)

Serial Port (Comm 1)

Mode:

Network Connections (PPP) Point-to-Point Protocol is a commonly used data link protocol.

Veeder Root

Franklin Fueling (XML)

Baud Rate: 300 - 57600

Data Bit: 5-8

Parity: Odd, Even or None

Stop Bits: 1 or 2

17

Page 22

Programming and Navigation

Console Navigation

The operating system is designed for easy navigation. Applications allow the user to modify programming options by

responding to on-screen commands. The following instructions show various operating system functions, so that issues

can be corrected efciently without interrupting dispensing or sales.

Access application sub-menus within the console by pressing the corresponding menu option button on the display.

Graphical icons are used to navigate the console. Console application menus / sub-menus are outlined in the next section

of this manual.

User Role – Displays the access level

Path Bar – Shows the path/description

of information displayed.

Application Window –

Displays the current

application content.

Form Feed Button

of the current user (determined by the

password input).

Back – Returns you to the

previous screen.

Home – This button will bring

you back from any application

to the home status screen.

Main Menu – Access the

Main Menu application.

Status – Displays a check for OK

or an exclamation for alarm. When

alarms exist, pressing this will bring

you to an alarms page.

Date/Time – The current date

and time. This will let you

congure Time/Date settings.

Print Report – Pressing this

button will take you to a menu

of reports.

Navigation Buttons

There are many ways to navigate the applications of the T5 series console. Listed below are buttons that will help you

navigate the functions of the console.

Exit: Takes you back to the Main Menu.

Scroll Up: When this button appears on the right side of the screen it indicates more menu options are available

and pressing this button will scroll up through the options.

Scroll Down: When this button appears on the right side of the screen it indicates more menu options are

available and pressing this button will scroll down through the options.

18

Page 23

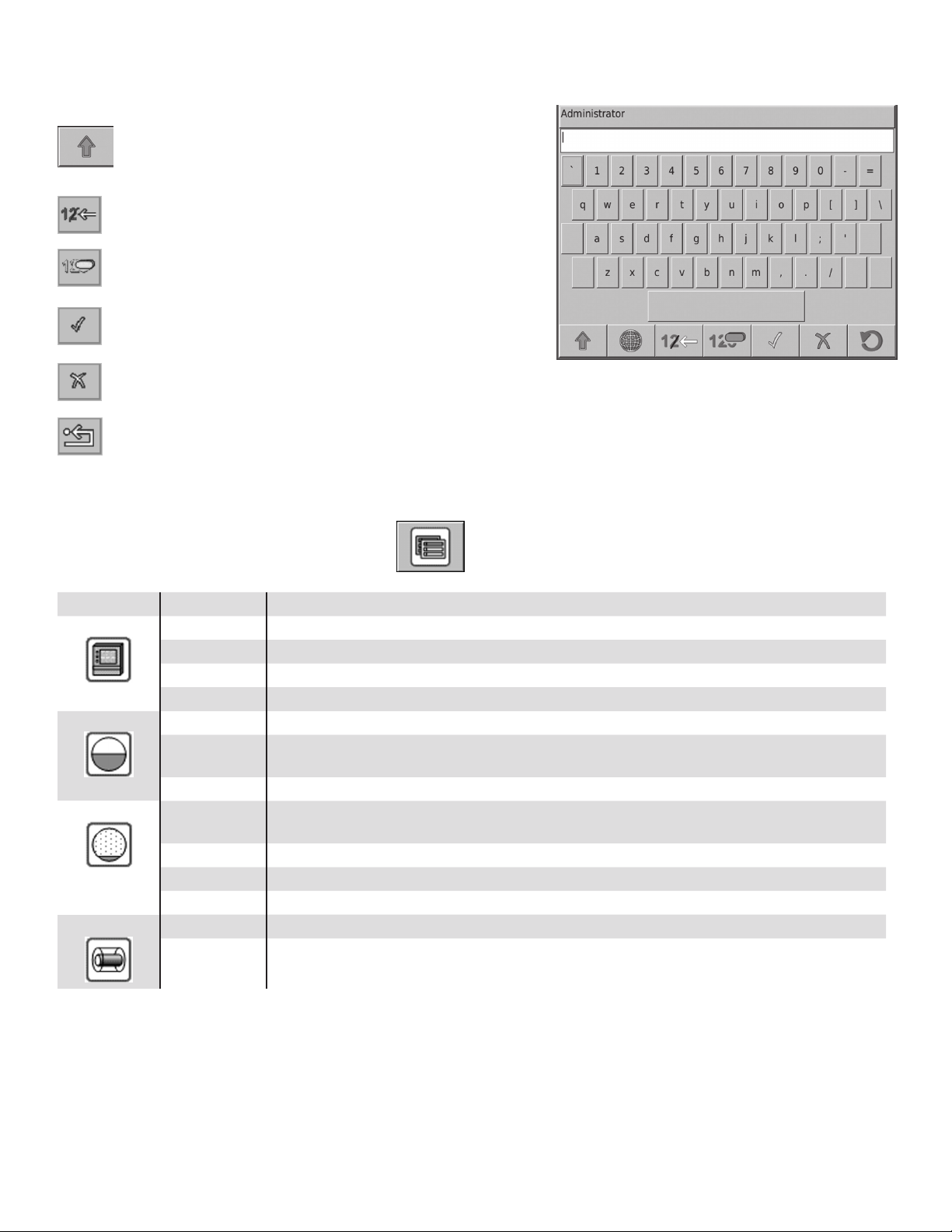

Character Navigation Buttons

When prompted to enter system information, press the corresponding keys.

Character Selection: Selects between upper case letters,

lower case letters and numerals. Note how the characters

on the input buttons change as you scroll through the

options.

Backspace: This will move the cursor one space to the left

and delete the last character.

Clear: Deletes all of the data on the entry line.

Enter: Allows the data to be accepted. When this button is

pushed, the conguration will be set for the item you are

changing.

Cancel: Will return to the application you were changing. No changes will be made to console settings.

Restore Default: This button will restore the original settings programmed into the console during manufacture.

Application Menus

Each Application has an application menu button

application have selected. These are listed below:

Application Menu Topic Description

System Status Shows status of installed modules including slot#, state and software version

About Shows system software version and copyright information

Identication Shows system and controller serial #, Ethernet address, and date created

Options Shows which options are installed

FMS Status Show status of Tanks, Lines, Sensors, Pumps and Deliveries

Control Allows controlling Tanks, Lines, Sensors, Pumps and Probes including initiating test and

to re-enable retest condition

Reports Allows printing various FMS reports

VRM Ullage

Pressure

Dispensers Shows status of the dispensers

Control Allows running manual tests, calibrating sensors and clearing monitoring

Reports Allows printing, e-mailing or faxing of Monthly and Daily Vapor Recovery reports

SCM Status Shows pressure reading and enabled status of each containment area

Control Allows controlling the Secondary containment, including resetting alarms and

Shows current ullage pressure as well as Operational Statistics and Compliance status

re-enabling containment.

This will bring up different options depending upon which

.

19

Page 24

Programming System Parameters

Using the touch screen function of the console to program, navigate from the Home Status screen by pressing the Main

Menu button.

At the Main Menu, press the Setup button, and select System ID.

The System ID screen looks like this:

To make a modication, select the parameter that you want to change.

Type the new setting in using the characters available. When nished,

press the check-mark. When Conrmation is displayed, press Yes to

save and apply, or No to exit without saving — you may press cancel

to continue making changes. Changes will not be applied until you

return to the main menu.

Refer to the programming tables on the following pages for a more

descriptive representation of each option including the submenus of

each menu item. The console will update the menus as additional

data or information is required during programming.

Please note, features appearing in this guide may not be available,

unless the option is purchased with your console. Default parameters

are noted by the use of parentheses ().

You should have the following items ready before beginning console programming:

• Site location information to setup Site ID

• Communications parameters for external equipment to match console settings

• Wiring diagrams of site if necessary; to identify sensor and/or probe location

• Manufacturers Tank Charts for “special” tank correction tables

• Probe stickers with gradient and RTD location for “special” probes

System ID

Group Name

System ID

Parameter

Name

Site Name (Site Name) Physical name of site. 40

Web UI URL (http://localhost/tsa) URL address of site. 40

ID Line 1 (blank)

ID Line 2 (blank) 40

ID Line 3 (blank) 40

ID Line 4 (blank) 40

ID Line 5 (blank) 40

Parameter

Value

Description

These lines should contain the physical address of the site. This

information will be used in the header of reports and to identify

site properties when using web UI.

Max

Characters

40

System Conguration

Group Name Parameter Name

System Conguration

Modules Expected

20

Technical Support Key (0) Enter the appropriate key number. 0-1

Enable Log Files (No) Enables the logging option. Yes/No

IO (0) These settings are preset by ordered options. This

AC Input (0) 0-6

Relay (0) 0-6

Probe (0) 0-6

2-Wire Sensor (0) 0-6

3-Wire Sensor (0) 0-6

4-20mA Input (0) 0-6

Printer (0) 0-1

LON (0) 0-1

DIM (0) 0-2

Console DTU (0) 0-1

Parameter

Default

Description

value represents the number of each module installed.

When a module is installed, the console will open more

options base on which module will be utilized.

Parameter

Input

0-6

Page 25

Programming Modules

The Fuel Management System is composed of a custom set of modules. Each module maintains individual characteristics.

Parameters must be set to match the site conguration. The programming table below will assist in this setup.

Remote Data Transfer Units (DTU’s)

Remote Data Transfer Units (DTU’s) are used in California for the purpose of relaying information from various sensors

mounted in dispensers to the FFS console.

Group Name Parameter Name

Remote Data Transfer Units

Parameter

Default

Description

Parameter

Input

DTU 1 Unit ID (0) Insert the Serial number of the rst DTU. abc#

Network ID (1) The I.D. of the network. #

Number of units (0) The number of DTUs in the eld. 1-16

For Further DIM or DTU Setup information, refer to the Web Browser Interface Section.

IO Modules

The Low Voltage Input / Output Module is a non-intrinsically safe module that provides eight separate AC or DC voltage inputs

that can range from 0 to 240 volts. In addition to the AC / DC inputs, the IO module also includes four 4-20mA signal outputs.

Group Name

IO Modules

Module #

Inputs Channels (0) The number of A/C or D/C inputs physically wired to the gauge. 0-8

Channel #

Outputs Channels (0) Number of 4-20mA channels in use per module. 0-4

Channel #

Parameter

Name

Name (Input 1) Descriptive name used to identify the input. abc#

Enabled (Yes) Enables the input.

Active State (High)

Action (None) Create an alarm or event timestamp . None

Name (output 1) Descriptive name used to identify the output

Enable (Yes) Yes if the channel is in use

Parameter

Default

Description Parameter Input

High will activate channel when high voltage is present.

Low will activate channel with no voltage present.

Yes / No

High / Low

Alarm

Event

abc

Yes / No

AC Input Modules

The AC Input Module is a non-intrinsically safe module that has 12 identical optically isolated AC input channels that can

be used for dispenser hook isolation, vapor processor input, or as generic AC inputs.

Group Name Parameter Default

AC Input Modules

Module # Channels (0) Number of channels in use per module. 0-12

Channel #

Number Gasoline Hooks per

Dispenser

Name (AC Input 1) Given name of channel. abc#

Enabled (Yes) Yes if channel is used. Yes / No

Active State (High)

Action Setup None Create an alarm or event timestamp None, Alarm,

Parameter

Default

(0)

Description

Including diesel. This is for reference only

except on VRM applications.

High will activate channel when high voltage

is present. Low will activate channel with no

voltage present.

Parameter

Input

0-8

High / Low

Event

21

Page 26

Probe Modules

The Probe Module gather data from probes, vapor ow meter and TS-DMS sensors. This information is processed by

the Controller Module for use in inventory, reconciliation, V/L Ratio calculation, TS-DMS sensor alarms and to provide

information for reports.

If a DTU is being used there will be an option for a “virtual module” labeled Remote Module. The Remote Module gathers

information from the vapor ow meter when a DTU is used. (see DTU Programming for further details on page 31 in this manual.)

Group Name Parameter Name

Probe Modules

Module # Channels (0)

Channel #

Remote Module 2 Channels (6) Number of DTU devices in use 0-12

Channel 1 (TS-DTU 1) Name DTU 1-VFM 1 Unique name given to channel abc#

Name (Probe 1) Given Name of Probe. abc#

Type (TS-LL2) Type of device connected.

Type TS-VFM Type of device connected. TS-VFM

Parameter

Default

Description

Number of channels in use per module.

Parameter

Input

0-12

TS-VFM

TS-LL2

TS-DMS

2-Wire Sensor Modules

The 2-Wire Sensor Module is designed to accept 12 sensor inputs per module, and the system as a whole can accept a

total of 36 sensors (3 modules with 12 inputs each). The module only supports standard sensors, and does not accept

inputs from 3-wire BriteSensors®.

Group Name Parameter Name

2-Wire Sensor Modules

Module # Channels (0) Number of channels in use per module. 0-12

Channel #

Name

Monthly Compliance (Yes)

Parameter

Default

(2-Wire Sensor

1)

Description

Given name of channel. abc#

Select Yes if this sensor is to appear on the

Compliance page and in the Regulatory report

Parameter

Input

Yes/No

3-Wire Sensor Modules

The 3-Wire Sensor Module is designed to accept 8 sensor inputs per module, and the system as a whole can accept a

total of 24 sensors (3 modules with 8 inputs each). The 3WSNS can support standard sensors and BriteSensors®.

Note: When the number of 3-wire sensor channels is selected, the system will automatically detect the connected

sensors and populate the setup with the detected types.

Group Name

3-Wire Sensor Modules

Module # Channels (0)

Channel #

Parameter

Name

Name

Type

Monthly

Compliance

Parameter

Default

(3-Wire Sensor 1)

(Interstitial

(EIS) or 2-Wire

Sensor)

(Yes)

Description Parameter Input

Number of channels in use

per module.

Given name of channel. abc#

Unknown,

The type of sensor

connected to the channel.

After the Channels are

entered this will ll in

automatically.

Select Yes if this sensor

is to appear on the

Compliance page and in

the Regulatory report

Interstitial (EIS) or 2-Wire Sensor

Discriminating Interstitial Sensor (DIS)

Discriminating Dispenser Sump Sensor (DDS)

Discriminating Turbine Sump Sensor (DTS)

Monitoring Well Sensor (MWS)

Hydrostatic Interstitial Brine Reservoir Sensor (HIS)

Discriminating Monitoring Well Vapor Sensor (DVS)

0-12

Yes / No

22

Page 27

4-20 mA and 4-20 mA EXP Input Modules

The Analog Input Module has 8 identical channels for loop powered IS sensors with a 4-20 mA interface.

The 4-20 mA EXP module is programmed in the same manner. The 420 EXP module is located on the hazardous side of

the console, must have the wires enclosed in explosion-proof conduit, and has a red front. If a DTU is being used there

will be an option for a “virtual module” labeled Remote Module. The Remote Module gathers information from the vapor

pressure sensor when a DTU is used. (see DTU Programming for further details on page 31 in this manual.)

Group Name

4-20mA Input Modules

Module # Channels (0) Number of channels in use per module. 0-8

Channel #

#3 Remote

Module 2 (DTU)

Parameter

Name

Name (4-20mA Input 1) Given name of the channel. abc#

Service Type (Analog) Determines the input signal.

Low Range -8.00 Low range of mA input - #

High Range 8.00 High range of mA input + #

Channels (0) Number of channels in use 0-5

Name 4-20 mA input 6 Given name of the channel abc#

Service Type (Vapor Recovery) Determines the output signal Vapor Recovery Monitoring

Parameter

Default

Description Parameter Input

Analog

Secondary Containment Monitoring

Line Leak Detection

Vapor Recovery Monitoring

FMS Level Probe

23

Page 28

Power Supply Module

The Power Supply is a non-intrinsically safe module that provides power to the T5 series console from line voltage rated 110 - 240

VAC. This module is two inches wide, occupies two slots and is located immediately to the right of the Controller Module.

The Power Supply Module has two AC / DC switching power supplies: one power supply is +5 V and the other is +24 V.

The Power Supply also has two relay outputs for use with remote annunciators and two low voltage inputs for emergency

generator applications.

Group Name Parameter Name

Power Supply

RS-485 Enable Interface (Yes) Enables RS-485 options Yes / No

TS-TPI

Controllers

Controller #

Groups

Group #

Comm 2

Enable Interface (Yes)

Number of Controllers (0)

Name Pump 1

Enabled (Yes)

Type (Unknown)

Address (0)

Group (0)

Tank (0) The tank number (where this Pump is located). 0 - 29

Height (5.00)

Number of inputs (0)

Number of groups (0)

Name Group 1

Mode (None)

Mode: None

Master / Slave (No)

Alternating (No)

Fault Shutdown (No)

Mode: Leveling

Master / Slave (No)

Fault shutdown (No)

Mode: Priority

Reserve (20)

Master / Slave (No)

Fault shutdown (No)

Baud rate (9600) Data transmission speed in bits per second. 1200-57600

Data Bits (8) Number of bits that represent data. 7-8

Parity (None) Value of parity (error check) bit. None, Even, Odd

Stop Bits (1)

Response Time-out (8)

Parameter

Default

Description

Enables TS-TPI options.

The number of controllers being monitored

Descriptive name used to identify input

Enables the output

The type of FE Petro Smart Controller • Variable

The slave address of the controller as congured by the

DIP switches on the Smart Controller.

The Group number this pump is in. Put Pumps located

in similar products into the same group for Leveling or

Priority mode.

The height of the Pump Motor Assembly off of the bottom

of the tank in inches.

The number of inputs that will have control over activating

and deactivating this Pump.

The number of Groups as assigned under controllers.

Descriptive name used to identify input.

Select the mode you want. (Refer to the TPI section for

more details).

Select yes if you want both pumps to run during periods of

high demand.

Select yes if you want the pumps to alternate when hook

signals drop out.

Select yes if you want both pumps to shutdown upon an

alarm.

Select yes if you want both pumps to run during periods of

high demand.

Select yes if you want both pumps to shutdown upon an

alarm.

The percent of volume that the pump will switch to the

next in the group.

Select yes if you want all pumps to run during periods of

high demand.

Select yes if you want all pumps to shutdown upon an

alarm.

Number of stop bits, noties receiving device of end of

data packet.

Period of time the device will wait until transmission stops

in seconds.

Parameter

Input

Yes / No

1-31

abc#

Yes / No

Frequency

• Smart

• Smart 1

• 3 Phase Smart

208/380V

• Mag/Eco

• Unknown

0 - 30

0 - 15

#

0 - 32

0 - 15

abc#

Leveling

Priority

None

Yes / No

Yes / No

Yes / No

Yes / No

Yes / No

# %

Yes / No

Yes / No

1-2

1-10

24

Page 29

Group Name Parameter Name

RS-232

Relays

Channel #

Input # Type (Unknown

Low Voltage Inputs

Channel #

LON

Baud Rate (9600) Data transmission speed in bits per second. 1200-57600

Data Bits (8) Number of bits that represent data. 7-8

Parity (None) Value of parity (error check) bit. None, Even, Odd

Stop Bits (1)

Response Time-out (8)

Name (Relay 1) Given name of the relay. abc#

Enabled (Yes) Whether the Relay is Enabled or not. Yes/No

Type (Unknown) Equipment connected to the relays output. Unknown

Polarity (Normal) Allows the polarity to be inverted. Normal, Invert

Logic (OR Logic) The type of logic that the gate will use to process incoming

Physically Wired As

Number of inputs (0) Number of devices that can control the relay. 0-32

Name (LV Input 1) Given name of input. abc#

Enabled (Yes) Whether the input is Enabled or not. Yes/No

Active State (high)

Action (None)

IFSF Node ID (1)

Parameter

Default

(Normally

Module)

Open)

Description

Number of stop bits, noties receiving device of end of

data packet.

Period of time the console will wait for a response from a

remote device.

signals. In OR, if any combination of inputs is active, the

relay is active. With AND, when all inputs are active, the

relay is active. In XOR, if all inputs are in the same state

(on / off), the relay is inactive.

How the relay is wired internally.

Chooses which module is inputting the signal to the relay. Unknown

High will activate channel when high voltage is present.

Low will activate channel with no voltage present.

Create an alarm or event timestamp None

Allows the T5 Series console to communicate with an

IFSF POS (Point of Sale) System

Parameter

Input

1-2

0-10

Submersible

Alarm

Solenoid

Dispenser

Other

OR, AND, XOR

NO, NC

Controller

Power Supply

IO

AE

4-20

Probe

2-wire Sensor

3-wire Sensor

High / Low

Alarm

Event

0-127

25

Page 30

Relay Modules

The Relay Module is a non-intrinsically safe module that has 8 identical Form C output channels. Each channel has a fuse

and three terminals. Each channel can be congured as NO or NC with the power off by wiring to the appropriate terminals.

Group Name Parameter Name

Relay Modules

Module # 10 Amp

Channel #

Input # Type (Unknown) Type of module that is sending the signal. Unknown

Channels

Name (Relay 1) Given name of the channel.

Enabled (Yes) Yes if the channel is in use.

Type (Unknown) Equipment connected to the relays output. Unknown

Polarity (Normal) Allows the polarity to be inverted.

Logic (OR Logic)

Physically Wired As (Normally Open) How the relay is wired externally.

Number of inputs (0) Number of devices that can control the relay.

Parameter

Default

(No)

(0)

Description

Select Yes if this is the 10 Amp relay module.

Number of relays used on this module.

The type of logic that the gate will use to process incoming signals.

Parameter

Input

Yes / No

0-8 (2 Amp

module)

0-6 (10 Amp

Module)

abc#

Yes / No

Submersible

Alarm

Solenoid

Dispenser

Other

Normal, Invert

OR, AND, XOR

NO, NC

1-32

Controller

Power Supply

AC Input

IO

Probe

2-wire Sensor

3-wire Sensor

4-20 mA

26

Page 31

Dispenser Interface

The Dispenser Interface is used in VRM and Reconciliation applications to communicate sales data from the dispensers

to the console.

Group Name

Dispenser Interface

Precision

Grades

Dispenser Interface Modules: DIM 1

Parameter

Name

Volume Precision (3) The number of digits to the right of the decimal point. 0-6

Dispenser Volume (Gross) Select Gross if the dispenser volume is not temperature

Number of Grades (0) The number of grades that are on site. 0 - 32

Name (1) Given name of Grade abc#

Include in Vapor

Recovery

Type (Wayne) The type of communication from the dispensers. None

Communication (Currant Loop) The communication protocol of the distribution box. None

Fueling Points

Number of fueling

points*

Number of hoses (0) The number of grades on this dispenser. 0 - 8

Hose # (1)

Grade

Association

Position (0) The number that was detected from the Query function after a

Parameter

Default

compensated.

(Yes) Select yes if this grade will be used in VRM.

(0) The number of possible fueling points on site

(Unknown) The grade that is associated with the rst hose you dispensed

from.

dispense.

Description Parameter Input

Gross / Net

Yes / No

Gilbarco

Wayne

Tokheim

G Site

Bennett 515

Current Loop

RS422 / 485

Tokheim STD

RS232 Duplex

RS232 RxD x 1

RS232 RxD x 2

0 - 32

Select the correct

grade from the

Grades menu.

0 - 9

* Q The query function is used to determine the Position number from the dispensers.

C Will copy the Position numbers and Grade associations to all like number of hoses fueling points.

The copy and query functions are available only via the Web Browser Interface.

If using the console touch-screen, the “Auto-congure” button

will initiate the query function.

27

Page 32

Programming FMS Parameters

Here is where specic equipment parameters will be modied to match the site setup.

Fuel Management System

Group Name Parameter Name

Ullage Percent (95) Percent of tank level used to calculate space left. 70-100 %

Fuel Management

System

Static Tank Testing

Tanks Number of Tanks (0) Number of tanks in fuel system. 0-48

Tank #

Probe Channel (Probe 1) Channel used for the probe in tank. Probe

Generator

Mode

SCALD

Delivery Delay (15 min) Time after delivery when increase is reported. # min.

Correction Temperature (60.00 °F) Product temperature correction. # °

High Product Limit (Level)

Region (United States) The region in which the gauge is located

Monthly Leak Test Threshold (0.20 gph) Static leak tolerance for testing tanks. # gph

Yearly Leak Test Threshold (0.10 gph) Static leak tolerance for testing tanks. # gph

Sentinel Mode Threshold (3.00 gph)

Condence (99%) Leak testing condence.

Minimum Leak Test Time (2 hr) Minimum amount of time used to test. 0-8

Maximum Leak Test Time (8 hr) Maximum amount of time used to test. 1-8

Alarm On Precision Leak Test

Failure

Name (Tank 1) Given name of tank. abc#

Type (Special 1) Type of tank. Std./Spcl.

Manifolded (No) Used for Manifolded tanks. Yes / No

Manifold # (1)

Product # ( 1) Type of product in tank. 1-48

Delivery Threshold (200.0 gal) Amount of increase to report delivery. # gal

Theft Threshold (5.0 gal) Amount of decrease to report theft. # gal

4-20 mA Output (None)

Monthly Compliance (Yes)

Annual Compliance (Yes)

Type (Standard 101) Type of probe used in this tank. Std./Spcl.

Ratio

Float Type (4 in gas) Type of oat(s) used on probe. 4, 3, or 2 in.

Water Float (Yes) Select Yes if water oat is present. Yes /No

Gradient

Product Offset (0.00 in)

Water Offset (0.00 in) # in

Enable (No) If generator testing is being used, select yes. Yes / No

Enable (No) Enables SCALD tank testing. Yes / No

Qualify (14 %) Required percent full to run SCALD test. # %

Parameter

Default

(No)

(1 to 1 tip to

head)

(9.03000 µs / in)

Description

Select whether the High Product alarm will be triggered

by high product Level or high product Volume.

If Sentinel Mode is congured, this is the amount of

volume that would trigger an alarm.

Used to produce an alarm upon failure.

If Manifold is selected, this option will allow you to

select a manifold number. Tanks that are Manifolded

should have the same manifold number.

If an IO module is used and the outputs are congured,

this option will appear. Select the correct output that

correlates to this tank.

Select Yes if this tank is to appear on the Compliance