Page 1

Fuel Management System

Operator’s Guide

T5 Series

Franklin Fueling Systems • 3760 Marsh Rd. • Madison, WI 53718 USA

Tel: +1 608 838 8786 • 800 225 9787 • Fax: +1 608 838 6433 • www.franklinfueling.com

Page 2

Notice

Franklin Fueling Systems (FFS) reserves the right to change this document and specications at any time without notice.

FFS makes no expressed or implied warranty with regard to the contents of this manual. FFS assumes no liability for

errors or omissions, or for any damages, direct or consequential, that may result from the use of this document or the

equipment that it describes.

Trademarks

INCON®, Tank Sentinel®, System Sentinel®, SCALD®, Brite®, BriteBox®, BriteBus®, and BriteSensors® are registered

trademarks of Intelligent Controls. All brand and product names are trademarks or registered trademarks of their

respective companies.

Inspection of Materials

Visually inspect all components for defects or damage prior to installation. If any defect or damage is found, do not use the

product and contact FFS for further assistance.

Return Shipping Charges

FFS will not accept shipments of returned products without a Return Material Authorization (RMA) number. RMA’s are

obtained by contacting FFS’s Technical Service division — NO RMA’s will be given without the unit’s serial number(s).

Returned material remains the property of the buyer until replaced or repaired.

Contacting Franklin Fueling Systems (FFS)

Please feel free to contact us by mail at:

Franklin Fueling Systems

3760 Marsh Rd.

Madison, WI 53718 USA

Or contact us by phone, fax or e-mail:

Tel: 1 608 838 8786 E-mail: sales@franklinfueling.com

Fax: 1 608 838 6433 techserve@franklinfueling.com

Tel: US & Canada 1 800 225 9787

Tel: México 001 800 738 7610

Tel: Europa +49 6571 105 380

Ofce Hours: 8am to 5pm CST - Monday through Friday

Technical Service Hours: 7am to 7pm CST - Monday through Friday

Please visit our web site at www.franklinfueling.com

No part of this publication may be reproduced in any form without the prior written consent of FFS. All rights reserved.

ii

Copyright ©2007 by Franklin Fueling Systems (FFS).

Page 3

Contents

Important Safety Messages .............................................................................................. 1

Related Documentation ............................................................................................................ 2

Introduction ........................................................................................................................3

Denitions and Acronyms .........................................................................................................3

Applications ..............................................................................................................................4

Standard Sensors .....................................................................................................................4

BriteSensors™ ..........................................................................................................................4

Modules .................................................................................................................................... 4

Standard Modules ........................................................................................................................... 4

Optional Modules ............................................................................................................................ 5

User Interface ........................................................................................................................... 5

Alarms and Warnings ...................................................................................................................... 5

Basic Console Operation .................................................................................................. 6

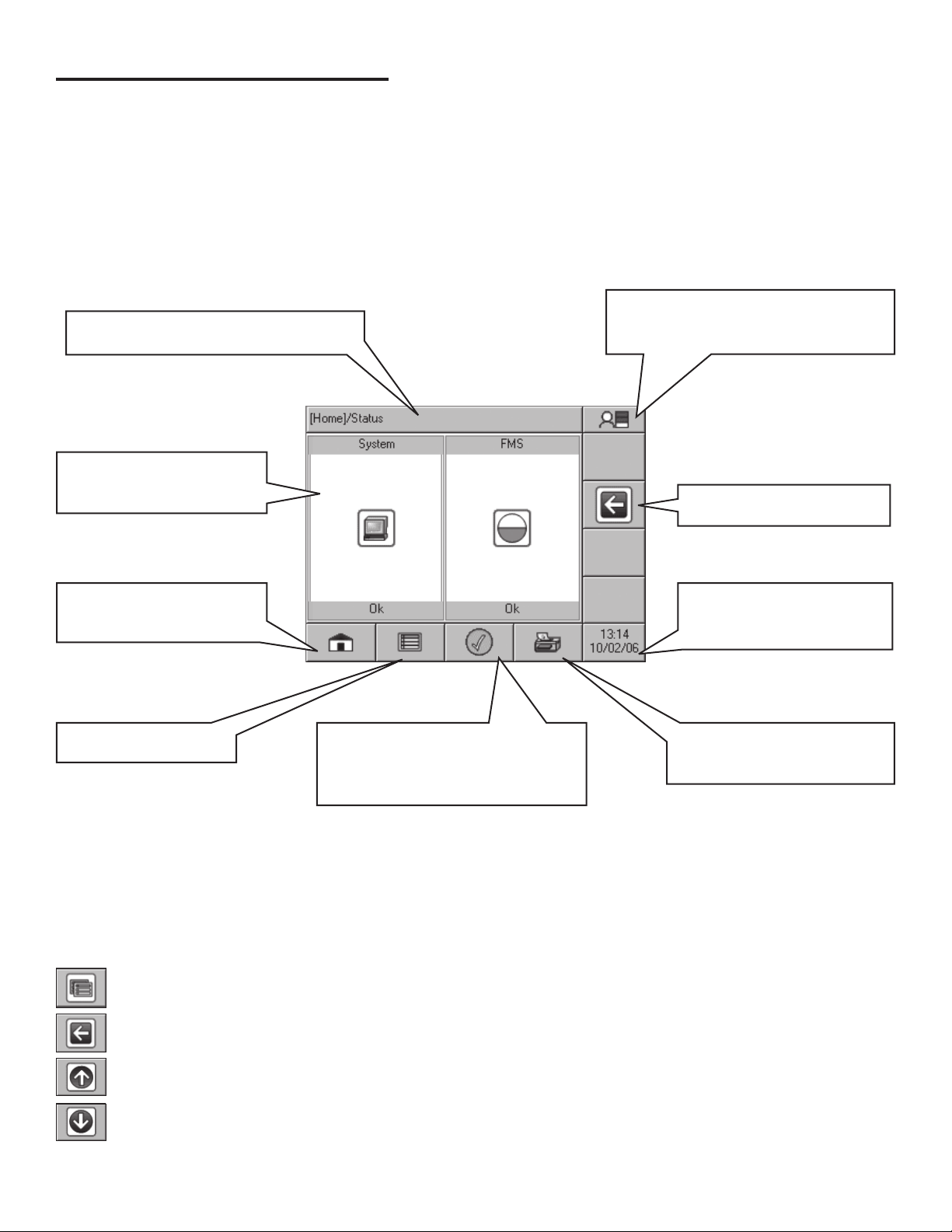

LCD Layout ............................................................................................................................... 6

Home Row ....................................................................................................................................... 6

Navigation Buttons .......................................................................................................................... 6

Data Entry ....................................................................................................................................... 7

User Role - Access Control ............................................................................................................. 7

System Identication .................................................................................................................7

Main (Home) Menu Options ............................................................................................................ 8

Preferences Menu .................................................................................................................................... 8

Conguration Menu .................................................................................................................................. 8

Reports Menu...........................................................................................................................................9

Diagnostics Menu.....................................................................................................................................9

Tools Menu ...............................................................................................................................................9

Fuel Management System Application ..................................................................................... 10

FMS Inventory Summary Menu....................................................................................................... 10

FMS Inventory Detail Menu ............................................................................................................. 10

FMS Application Menu .................................................................................................................... 10

Printing Reports ................................................................................................................11

Internal Printer .......................................................................................................................... 11

External Printers ....................................................................................................................... 11

Print Button ...............................................................................................................................11

Reports Options ........................................................................................................................ 11

System Reports ............................................................................................................................... 11

FMS Reports ................................................................................................................................... 11

Tank Testing .......................................................................................................................12

Static Testing .............................................................................................................................12

Terms ............................................................................................................................................... 12

Tank Testing Requirements ............................................................................................................. 13

How to Manually Start Static Tests .................................................................................................. 14

Static Test Results ........................................................................................................................... 14

Statistical Continuous Automatic Leak Detection (SCALD) ..................................................... 15

Why Continuously Test the Integrity of the Tank ............................................................................. 15

Terms ............................................................................................................................................... 15

SCALD Testing Requirements ......................................................................................................... 15

When SCALD Tests ......................................................................................................................... 15

SCALD Results ............................................................................................................................... 16

Reasons Why SCALD May Not Complete ..............................................................................................16

Tank Leak Test Reports ............................................................................................................ 16

Printing Tank Leak Test Reports ...................................................................................................... 16

LCD ..........................................................................................................................................................16

iii

Page 4

Line Leak Testing ..............................................................................................................19

Overview ................................................................................................................................... 19

Terms ............................................................................................................................................... 19

Certications – 3rd Party Approvals ................................................................................................. 19

National Work Group Leak Detection Evaluations (NWGLDE) ....................................................... 19

Line Leak Testing Requirements ..................................................................................................... 19

Test Cycles & Types ..................................................................................................................20

How to Manually Start Line Leak Tests ..................................................................................... 20

Line Test Results .......................................................................................................................21

Line Leak Test Reports .............................................................................................................22

Printing Tank Leak Test Reports ...................................................................................................... 22

LCD ..........................................................................................................................................................22

Example Line Leak Test Reports from TSA ............................................................................................. 23

Web Browser Interface ...................................................................................................... 24

Using the Web Interface ........................................................................................................... 24

Navigating Pages ......................................................................................................................24

Home – Status Page ....................................................................................................................... 24

Available Pages ............................................................................................................................... 25

Home ........................................................................................................................................................25

System .....................................................................................................................................................25

FMS ..........................................................................................................................................................25

Setup/Cong ............................................................................................................................................25

Preferences .............................................................................................................................................. 25

How to Manually Start Leak Tests Using Web Browser Interface ............................................. 25

Tank Leak Tests ............................................................................................................................... 25

Line Leak Tests ............................................................................................................................... 25

Routine Maintenance ........................................................................................................26

Console Care ............................................................................................................................ 26

LCD Touch Screen ....................................................................................................................26

Contrast Adjustment ........................................................................................................................ 26

Calibration ....................................................................................................................................... 26

Internal Printer .......................................................................................................................... 26

Changing Paper .............................................................................................................................. 26

Ink Ribbon Replacement ................................................................................................................. 26

Thermal Printer ................................................................................................................27

Appendix A – Compatible Printers ...................................................................................27

T5 Series Fuel Management Systems – Hewlett Packard Compatible Printers ....................... 27

Appendix B – Alarm Table ................................................................................................28

Appendix C – Third Party Certications ..........................................................................35

iv

Page 5

Important Safety Messages

Franklin Fueling Systems (FFS) equipment is designed to be installed in association with volatile hydrocarbon liquids

such as gasoline and diesel fuel. Installing or working on this equipment means working in an environment in which these

highly ammable liquids may be present. Working in such a hazardous environment presents a risk of severe injury or

death if these instructions and standard industry practices are not followed. Read and follow all instructions thoroughly

before installing or working on this, or any other related, equipment.

As you read this guide, please be aware of the following symbols and their meanings:

Warning

Caution

Danger

Warning

This symbol identies a warning. A warning sign will appear in the text of this document when a potentially

hazardous situation may arise if the instructions that follow are not adhered to closely. A potentially hazardous

situation may involve the possibility of severe bodily harm or even death.

This is a caution symbol. A caution sign will appear in the text of this document when a potentially hazardous

environmental situation may arise if the instructions that follow are not adhered to closely. A potentially

hazardous environmental situation may involve the leakage of fuel from equipment that could severely harm

the environment.

This symbol identies an electrical danger. An electrical danger sign will appear in the text of this document

when a potentially hazardous situation involving large amounts of electricity may arise if the instructions that

follow are not adhered to closely. A potentially hazardous situation may involve the possibility of electrocution,

severe bodily harm, or even death.

Alarms and warnings are designed to alert you with specic details when a problem occurs so you can take

appropriate corrective action.

Follow all applicable codes governing the installation and servicing of this product and the

entire system. Always lock out and tag electrical circuit breakers while installing or servicing

this equipment and any related equipment. A potentially lethal electrical shock hazard and the

possibility of an explosion or re from a spark can result if the electrical circuit breakers are

accidentally turned on during installation or servicing. Please refer to the Installation and Owner’s

Manual for this equipment, and the appropriate documentation for any other related equipment, for

complete installation and safety information.

Warning

Warning

Warning

Warning

Warning

Warning

Follow all federal, state and local laws governing the installation of this product and its associated

systems. When no other regulations apply, follow NFPA codes 30, 30A and 70 from the National Fire

Protection Association. Failure to follow these codes could result in severe injury, death, serious

property damage and/or environmental contamination.

Always secure the work area from moving vehicles. The equipment in this manual is usually

mounted underground, so reduced visibility puts service personnel working on this equipment in

danger from moving vehicles entering the work area. To help eliminate these unsafe conditions,

secure the area by using a service truck to block access to the work environment, or by using any

other reasonable means available to ensure the safety of service personnel.

When the Fuel Management System is used to monitor tanks containing gasoline or other

ammable substances, you may create an explosion hazard if you do not follow the requirements in

this manual carefully.

All wiring must enter the console’s enclosure through the designated knockouts. An explosion

hazard may result if other openings are used.

You must run wiring from probes or sensors to the Fuel Management console in conduits which are

separate from all other wiring. Failure to do so will create an explosion hazard.

Substituting components could impair intrinsic safety. T5 series consoles are intrinsically safe

for sensors installed in – Class I, Division 1, Group D – hazardous locations. Substitution of

components could make the energy limiting circuitry in the system ineffective and could cause

an explosion hazard. Repairs to a T5 series console or attached components should only be

performed by a qualied, factory-trained technician.

1

Page 6

Certied Programmer/Service Person: Only an FFS certied programmer or service person is allowed to access both

the user interface keypad and areas internal to the Fuel Management System console.

Station Owner/Operator: The station owner or operator of the Fuel Management System console is only allowed to

access the user interface keypad. Access to areas internal to the console is strictly prohibited.

Approvals

All Fuel Management System models are UL and cUL listed 6L79 as Liquid Level Gauge / Leak Detection

Systems. Third party approved leak detection — Pd (probability of detection) = 99.2 % for 0.1 or 0.2 GPH leak

tests (0.1 = annual precision test, 0.2 is the monthly regulatory compliance test).

*The static tank test does not support Manifolded tanks.

**SCALD is 3rd party approved for ONLY two Manifolded tanks.

Related Documentation

The system installation and programming instructions are provided for your use in separate documents. Detailed

installation and testing instructions for each type of leak detection sensor are present in the relevant manual, and,

likewise, the installation, testing and programming of various upgrade kits and optional accessories are also contained in

separate manuals, addenda or in one of this document’s appendices.

T5 Series Fuel Management Systems Installation Guide (000-2150)

T5 Series Fuel Management Systems Programming Manual (000-2142)

2

Page 7

Introduction

The purpose of this manual is to guide installers, operators and technicians through the operation of a T5 series console.

The T5 series consoles incorporate the monitoring and alarm capabilities of preceding automatic tank gauges with

advanced technologies to supply tank and level data more accurately and efciently. This manual is also designed to

introduce technicians to the optional LCD Graphical User Interface, which is used as an input device to program system

conguration and maintain all applications from the front panel of the console. Overall safety issues, troubleshooting

information, start-up procedures, warranty, service and return policies, as dened in this manual, must be followed.

The TS-5 (TS-608) / 550 / 5000 Fuel Management System consists of an open architecture, modular console that can

run multiple Fuel Management Applications simultaneously. It typically contains an LCD touch screen user interface and a

built-in printer, but it can also be operated by a web-based remote interface. Magnetostrictive Liquid Level Probes inside

of the tanks provide the console with inventory and leak detection information. A variety of optional sensors can be used

to monitor containment spaces. T5 series consoles combine the power and exibility of computer-based open architecture

with a high speed modular bus design.

Note: The TS-5 (TS-608) comes standard with an LCD touch screen display and does not accommodate for an internal

printer. An internal printer and touch screen display are optional on all other systems.

Denitions and Acronyms

TS-2WSNS – 12 input, 2-Wire Sensor Module (Intrinsically Safe)

TS-3WSNS – 8 input, 3-Wire Sensor Module (Intrinsically Safe)

TS-ACI – 12 input, AC Input Module

TS-420IB – 4-20mA Analog Input Module (Intrinsically Safe)

AST – Aboveground Storage Tank

CARB – California Air Resources Board

TSSP-CM – Controller Module

Console – The enclosure that houses the Modules.

DHI – Dispenser Hook Isolation

TS-DIMIB – Dispenser Interface Module

DW/DWT – Double Wall/Double Wall Tank

EVR – Enhanced Vapor Recovery

FMS – Fuel Management Systems

IS – Intrinsically Safe

LCD – Liquid Crystal Display

LON – Echelon Communication Module

LLD – Line Leak Detection

Module – A plug-in card within a T5 series console that is used to perform various functions for a console. Modules are

used for eld wiring the input and/or output of electrical signals between different functional equipment pieces.

NWGLDE – The National Work Group Leak Detection Evaluations

PC – Personal Computer

TS-PRB – Probe Module (Intrinsically Safe)

TSSP-PS – Power Supply Module

RS-232 – An EIA standard for serial communication using either a 9 or 25-pin connector or adapter.

RS-485 – An EIA standard for serial communication.

RTD – Resistance Temperature Detector

RJ-45 – An EIA standard connector for use in communications with an eight conductor cable. Usually used in data

transmission applications.

RJ-11 – An EIA standard connector for use in communications using STP wiring. Usually used in voice and fax

applications.

TS-RLY – Relay Module

STP – Submersible Turbine Pump

TPI – Turbine Pump Interface

TS-EMS – Environmental Monitoring System

TS-EXPC – Expansion Console

USB – Universal Serial Bus

UST – Underground Storage Tank

VRM – Vapor Recovery Monitoring

XML – eXtensible Markup Language

3

Page 8

Applications

Applications are programs designed to function as a platform for specic Inputs/Outputs. There are two different applications available to the T5 series consoles:

System – This application is standard on all systems and monitors the console’s operational status and manages software

options and upgrades. All preferences and conguration settings are controlled by this application (e.g., display

options, clock and calendar). The system application is standard on every console.

Fuel Management System (FMS) – The Fuel Management System application provides inventory management and leak

detection for tanks, lines and sensors as well as tank, line and sensor control. This

application also allows users to print reports, tank tests and line tests.

A broad range of liquid products can be leak-tested and inventory-monitored using Magnetostrictive LL2 probes. These

probes come in a variety of lengths and typically contain two oats for indicating both product and water levels inside the

of tank. Programmable limits can be set to indicate high and low conditions.

Containment sumps, interstitial spaces, monitoring wells and other areas can be monitored for water and hydrocarbon

intrusion using a wide range of optional Standard and BriteSensors. These sensors come in 2-wire (non-discriminating)

and 3-wire (typically discriminating) versions. These models are listed below and can be used in any combination

depending on site specications.

Standard Sensors

Standard sensors do not discriminate between liquid and hydrocarbons and are typically 2-wire sensors.

TSP-EIS – Electro-optic Interstitial Sensors (3-wire, infrared, liquid sensor)

TSP-HLS – High product Level Sensor (2-wire, oat switch, liquid level sensor)

TSP-ULS – Universal Liquid Sensor (2-wire, oat switch, liquid level sensor)

TSP-UHS – Universal Hydrostatic Sensor (2-wire, oat switch, liquid sensor)

BriteSensors™

BriteSensors™ are 3-wire, discriminating sensors (many of which may generate multiple alarms).

TSP-DIS – Discriminating Interstitial Sensor (infrared and conductivity, liquid and vapor sensor)

TSP-HIS – Hydrostatic Interstitial Sensor (oat switches, liquid level sensor)

TSP-DDS – Discriminating Dispenser sump Sensor (conductivity strip and oats, liquid and vapor sensor)

TSP-DTS – Discriminating Turbine sump Sensor (conductivity strip and oats, liquid and vapor sensor)

TSP-MWS – Discriminating ground water Monitoring Well Sensor (oat and conductivity strip, liquid and vapor sensor)

TSP-DVS – Discriminating Vapor well Sensor (vapor sensor)

TSP-DMS – Discriminating Magnetostrictive Sensor

Modules

A modular bus consists of modules connected by a bus backplane. Some modules are standard in all units, while the type

and number of other modules are dependent on the site conguration and options purchased. Most systems have empty

slots available for future expansion. TS-5 (TS-608) consoles are not compatible with the TS-EXPC expansion console.

Standard Modules

Controller Module – Contains the primary controller and software applications as well as the user interface and printer

controls. The module contains the Ethernet port, USB port (for external printer only), COMM port 1,

audible horn and an optional internal modem card.

Power Supply Module – Contains a self-switching (110 & 220 VAC) input and provides power to the rest of the system. I/O

ports include two output relays, two backup generator inputs, a Turbine Pump Interface (TPI) RS485 connection and the COMM 2 communications port. An optional Dispenser Interface Module

(TS-DIMIB) or Echelon Communications Module (TS-LON) can also be added. The Power Supply

Module also has a bus expansion port that can connect a T5 series console to a TS-EXPC

Expansion Console.

4

Page 9

Optional Modules

2-Wire Sensor Module Provides 12 inputs for 2-wire Standard sensors.

3-Wire Sensor Module Provides 8 inputs and supports both 3-wire and 2-wire sensors.

4-20 mA Input Module Provides 8 inputs that can be used for TS-LS500 line leak detection transducers.

4-20 mA EXP Explosion-proof module. Otherwise the same as the 4-20 mA Input Module.

AC Input Module Provides 12 inputs for dispenser hook signals, which are also required for LLD. This module

replaces external DHI boxes.

Probe Module Provides 12 inputs (8 in the TS-608) for LL2 probes.

Relay Module Provides 8 relay outputs (2-Amp) which are typically used to control the submersible pump

relays to provide pump or dispenser shutdown when line leak detection or other applications

are used. Not used in combination with TPI.

10-Amp Relay Module Provides 6 relay outputs which are typically used to control the submersible pump relays to

provide pump or dispenser positive shutdown upon alarm conditions.

Input / Output Module Provides 8 AC or DC voltage inputs that can range from 3 to 240 volts. Typically used for

vapor processors and generic devices, but not for dispenser hook signals. In addition, this

module also includes four 4-20 mA signal outputs which are typically used to interface to

an external device, such as a SCADA (Supervisory Control and Data Acquisition), building

monitoring system or fuel level monitoring.

User Interface

LED Indicators – Three LEDs on the left side of the front panel give an “at-a-glance” indication of the system status. These

LEDs are standard on all systems. The green Power LED indicates that the system power is on. The yellow Warning LED

gives indication that the console has detected a malfunction or condition that has been deemed a Warning. The red Alarm

LED indicates that the system has detected an alarm condition.

LCD Touch Screen – The optional LCD touch screen (standard on the TS-5 (TS-608)) is the most commonly used user

interface for the Fuel Management System. This bright display allows easy viewing in any lighting condition. Touching

certain buttons or segments of the screen will allow access to menus or more detailed information. Do not use sharp or

pointed objects to operate the touch screen or damage may result. A “Sleep Mode” screensaver can be activated under

Preferences to automatically turn off the back light after 5 minutes to extend the life of the display. If improper operation

of the touch screen is noted, it may be necessary to calibrate the touch screen. Please refer to the Routine Maintenance

chapter of this manual for calibration procedures.

Alarms and Warnings

Alarms and warnings are designed to alert you with specic details when a problem occurs so that you can take appropriate corrective action. System hardware failure warnings, tank related alarms, leak detection sensor alarms, and line leak

alarms will always notify the user in certain ways, other notication options are programmable.

Alarms and Warnings will always:

• Cause the red Alarm light or yellow Warning light to ash (standard).

• Change the alarm button from to .

Optionally they may:

• Sound the console’s internal alarm horn.

• Activate relay outputs and sound external alarm devices.

• Print alarm reports.

• E-mail alarm reports to a specied destination.

• Notify remote monitoring software via optional internal modem or Ethernet.

For help with troubleshooting alarms, refer to the Troubleshooting chapter of the T5 Series Programming

Manual (000-2142).

5

Page 10

Basic Console Operation

Once the Fuel Management System has been installed, programmed and tested, you will interact with the system via

the LCD touch screen and printer or the Web Browser Interface via a PC. This section of the manual will describe the

operation of the console using a touch screen. Information on the Web Browser Interface can be found in later chapters.

LCD Layout

The LCD interface is designed so that a user may navigate the system with ease. Manageable applications allow the user

to modify programming options by responding to on-screen commands. The following instructions will give you a good feel

for the operating system functions, so that issues can be corrected efciently without interrupting dispensing or sales.

To navigate the console, it’s necessary to become familiar with the layout of the LCD and its graphical icons.

User Role – Displays the access level

Path Bar – Shows the path/description

of information displayed.

Application Window –

Displays the current

application content.

of the current user (determined by the

password input).

Back – Returns you to the

previous screen.

Home – This button will bring

you back from any application

to the home status screen.

Main Menu – Access the

Application Menu.

Status – Displays a checkmark for

OK or an exclamation for alarm. If

an alarms exist, pressing this will

bring you to an alarms page.

Date/Time – The current date

and time. This will let you

congure Time/Date settings.

Print Report – Pressing this

button will take you to a menu

of reports.

Home Row

The buttons along the bottom row of the LCD touch screen (see above for details) are always present and will always take

you to the same location.

Navigation Buttons

The buttons on the right side of the LCD touch screen will appear when applicable and are for navigating through the various menu items in the different applications.

Application Menu: Once an application has been selected, this button will take you to the menu choices for that

application.

Back: This button will take you to the previous screen.

Scroll Up: When this button appears on the right side of the screen, it indicates that more menu options are

available above your current viewable threshold; pressing this button will scroll up through the options.

Scroll Down: When this button appears on the right side of the screen, it indicates that more menu options are

available below your current viewable threshold; pressing this button will scroll down through the options.

6

Page 11

Data Entry

If you are prompted to enter information, a keypad and edit buttons will be displayed.

Character Selection: Selects between upper case

letters, lower case letters and numerals.

Backspace: Deletes the previous character.

Clear: Deletes all of the data on the entry line.

Enter: Allows the data to be accepted. When this button is

pushed, the conguration will be set for the item you are

changing.

Cancel: Will return to the application you were changing. No changes will be made to console settings.

Restore Default: This button will restore the original settings programmed into the console during manufacture.

Alternate Characters: Shows accented characters

User Role - Access Control

There are three levels of access into the console’s operating system: Guest, User, and Administrator. Each level will

allow an operator to access different features and controls of the console. This security feature prevents unauthorized

access to critical information and settings. The password for each access level can be adjusted by the Administrator. The

Administrator level is typically reserved for an FFS certied technician.

The User Role icon displays the current access level allowed. White bars displayed in this icon indicate the access level.

Pressing the User Role indicator on your LCD display will return the system to Guest access level.

One white bar operates at the GUEST level. Guests are allowed to access menu options, check the system

conguration and print reports. A GUEST will not be able to modify the console’s settings.

Two white bars operates at the USER level. Users are given access to more functions of the operating

system so that they can perform line/tank leak tests and reset line alarms.

Three white bars operates as an ADMINISTRATOR. This level grants access to all areas of programming

and setup conguration. The administrator privilege is usually reserved for FFS certied technicians.

System Identication

In order to understand what sections of this manual apply to your system, you must be able to identify what Fuel Management System you have and what Options and Applications it is running.

Model Number – Located on the front of the console.

Serial Number – Located on a sticker on the left side panel (along with Model number).

Options – To see what Applications and Options the system is running, press System Application > Application Menu

(button) > Options.

7

Page 12

Main (Home) Menu Options

The Main Menu button will take you to the Home/Menu screen where you can select from several different options. The

rst six are displayed; use the Down button to see the rest of the choices.

Setup Performing console setup and programming

(Administrator Use Only).

Preferences Congure the way information will be displayed.

Conguration Set certain system parameters.

Reports Print various reports when an optional printer is

attached.

Alarm History Displays a list of alarms that have occurred.

Application Events Displays a list of all application events.

Diagnostics Functions to check and

test the operation of the

system.

Tools For resetting and

controlling the console.

Preferences Menu

Use the Preferences Menu to congure:

Language Displayed language for console applications.

Date/Time Set the date/time formats.

Numbers Format the way numbers will be displayed.

Units Select from different units of measurement.

Sleep Mode Turn the screen saver mode off and on.

Conguration Menu

Use the Conguration Menu to congure:

Passwords Set the passwords for all access levels

(Administrator Use Only).

Network Parameters Congure IP connection settings

(Ethernet connection).

Time Zone Set the system’s time zone.

System Clock Set the system date and time.

8

Page 13

Reports Menu

Use the Reports Menu to generate a variety of reports and access report menus for all available applications.

Alarm History Print a history of alarms.

FMS Access the FMS reports menu.

System Print system status reports.

Diagnostics Menu

Use the Diagnostics Menu to test the operation of certain components of the system.

Test Annunciator Tests the operation of the internal alarm.

Print Test Page Sends a test page to any optional printer.

Diagnostic Key Enters Diagnostic Mode (Certied technician

access only).

Relay Tests the operation of the relays

Tools Menu

Use the Tools Menu to perform various resets of the system and perform certain control functions.

Reboot System Cycles power to the system, all data is

retained.

Touch Screen Calibration Recalibrate the operation of the touch

screen.

Printer Utility View and control certain printer functions

9

Page 14

Fuel Management System Application

The Fuel Management Systems application provides inventory

management, optional tank and line leak detection features and

sensor monitoring. Select FMS in the Application window of the Home

screen.

FMS Inventory Summary Menu

The FMS Inventory Summary displays a graphical representation

of the product and water levels in the tank and indicates any alarm

conditions. The Product name and current Volume are also displayed

for each tank. Pressing the print button while on this screen will print

an Inventory Report for all tanks.

FMS Inventory Detail Menu

Selecting a single tank will show the FMS Inventory Detail for that

tank, which will provide detailed information on product volume, level,

temperature and ullage space available. The level and volume of any

water will also be displayed. The hash marks on the graphic indicate

the various programmed high and low alarm limits. An alarm condition

on the tank is also indicated here, if present.

FMS Application Menu

Pressing the Application Menu button will display the FMS Menu.

From here you will be able to view various FMS information, execute

certain control functions and print reports.

Status Displays the current status of all devices (tanks, line,

sensors and others).

Control Allows you to start and monitor tank and line tests as well

as learn lines and sensors.

Reports Prints various FMS related reports.

10

Page 15

Printing Reports

Internal Printer

An internal printer is optional on TS-550 / 5000 FMS consoles, but not available on the TS-5 (TS-608) console. Older

units used an impact style printer that uses standard printer paper and has a replaceable ribbon cartridge. Newer units

use a thermal printer that requires no ribbon. For paper loading and ribbon replacement instructions, refer to the Routine

Maintenance chapter in this manual.

External Printers

External printing is accomplished via USB. No software drivers need to be installed to print via USB. Connect the USB

cable to the printer and the USB port on the console. The unit is now ready to print. For a list of approved printers, refer to

Appendix A.

Note: The setup will need to be changed so the printer option is 0, save the conguration, connect the printer and cycle

the power of the tank gauge.

Print Button

Pressing the print button from the Home screen will bring up a list of some of the Applications that are

running on the system. Select the Application that you want to print from and a list of available reports for

that Application will be displayed. If you are already inside of an Application, then its report options will be

displayed immediately. There are some screens, like the Inventory Summary, where selecting the print

button will not provide additional options, like date range.

Reports Options

The following reports are available for the different optional Applications. Each report allows you to select the date range

of data you wish that report to contain.

System Reports

Report Description

Alarm History A history of the Alarms that have occurred.

Application Event History A history of the Application Events that have occurred.

Setup A printout of the system programming.

FMS Reports

Report Description

Inventory Complete level, volume, temperature and ullage info for each tank.

Delivery Start and ending level and volume information and total amount delivered.

Tank Test Annual and monthly static tank testing results. (tank testing option required)

SCALD 24hr continuous monthly tank testing results. (tank testing option required)

Lines Gross, monthly and annual line tests. (line leak option required)

Regulatory Complete compliance report for all tanks, lines, sensors.

Sensor Alarm status of all monitoring sensors.

11

Page 16

Tank Testing

Why Test the Integrity of a Tank

In compliance with federal, state and local regulatory policies, all tanks must be monitored for leaks due to environmental

and public safety/health concerns. Tank tightness testing determines if there is a leak.

There are two types of Tank Testing available in the Fuel Management Systems: Static and SCALD.

SCALD Testing

Static tests are run during quiet times when the tank is thermally stable and the site is closed so that no dispensing or

deliveries will occur. There are two types of Static tests: Monthly (0.2 gph) and Annual (0.1 gph). Static tests can be

scheduled to run on a Daily, Weekly or Monthly basis in the Setup menu (Administrator use only). They can also be

started on demand from the FMS > Control menu. Make sure that all testing conditions are met before starting a Static

Tank Test.

SCALD (Statistical Continuous Automatic Leak Detection) tests run 24 hours a day and look for periods of quiet time when

the tank is thermally stable and no dispensing or deliveries are occurring. These quiet periods are collected and analyzed

and the tightness of the tank is determined. SCALD tests will update whenever possible and can be setup to print

automatically when they do. The more common method is to schedule the latest SCALD test to print out once a week,

saving a signicant amount of paper because SCALD tests can be generated multiple times a day on a quiet tank.

Static and SCALD tests run independently of each other and can be run at the same time. A SCALD test will likely

complete during the time that the Static test is running. See page 15 for further SCALD information.

Tank Pre-qualication for SCALD

It is important to pre-qualify a site before making the decision to order the SCALD software. A site not meeting the

following parameters would not be able to use SCALD.

For a tank or manifold (two connected tanks) to routinely complete SCALD tests, there must be an average of at least:

• 4 Quiet Intervals (QIs) lasting an average of 20 minutes when no dispensing occurs from the tank or manifold. The data

collected during these QIs, must be thermally stable. Tanks that receive frequent deliveries, especially where there are

large differences in temperature between the fuel coming off the truck and the fuel in the ground, will have a hard time

collecting enough QIs to get a completed SCALD test.

• 48 hours between deliveries to that tank or manifold. This time period may need to be extended to 72 hours in areas

that experience periods of extreme temperatures.

Sites that barely qualify under both instances above may still experience periods where SCALD is unable to collect QIs

because of thermal instability. Rescheduling the deliveries to the tank(s) may improve the generation of QIs. Filling a tank

as full as possible in the morning and allowing as many nights, when most QIs occur, as possible to elapse before lling

the tank again, will improve the chances of completing a SCALD test.

All FFS Fuel Management Systems meet the requirements of the U.S. Environmental Protection Agency (EPA/530/UST90/006 test protocol) for Automatic Tank Gauging Systems (ATGS). The system(s) also meet the requirements for Annual

Tank Tightness Testing for 0.1 gal/hr leaks of the National Work Group on Leak Detection Evaluations (NWGLDE). Third

Party Testing Laboratory test results (for standard static tank leak tests) are also available at http://nwglde.org/.

Static Testing

Terms

Threshold – Test results must be within these programmable limits to pass a leak test. There are Monthly, Annual and

Sentinel Mode Thresholds.

Sentinel Mode – Sentinel mode is designed to monitor the product levels in your tank(s) when there isn’t supposed to be

any dispensing.

Condence – Level of testing sensitivity indicating the probability that the test will detect a leak.

Higher condence percentages will produce more sensitive test results. Check local regulations to

verify acceptable condence levels.

Slope (Tank Testing Reports) – A ratio of the calculated rate of change to the time the rate is

measured. Slope is affected by leaks and by many other sources of interference. A negative slope

or decrease indicates loss of product volume. A positive slope or increase indicates a rise in product

volume.

12

Flow

(+) slope

Time

(–) slope

No Leak

Page 17

Tank Testing Requirements

Static Tank Testing is available only if the option for Tank Testing is enabled. This option can be ordered when purchasing

the console or after initial purchase by using the part number TS-TT. The software option includes both Static and SCALD

(continuous) leak testing. For TS-5 and TS-608 consoles, Static Tank Testing is included as standard programming.

SCALD is an option.

To perform tank testing, the Tank Testing software must be enabled. To verify that the software is enabled:

1. Starting at the Home/Status screen, press the

System Application button.

2. Press the Application Menu button.

3. Press the Options button.

4. Under Option, a Tank Testing row will appear.

A “Yes” in the Enabled column indicates that

the software has been purchased and is

enabled.

Step 1

Step 3

Step 2

Step 4

Test Types

This system is designed to perform two types of static tests to comply with regulatory policies.

• 0.1 GPH Annual Leak Test — Detects a rate increase or decrease of product in the tank, other than dispensing

(no testing during dispensing), at a rate greater than 0.1 gallons per hour.

• 0.2 GPH Monthly Leak Test — Detects a rate increase or decrease of product in the tank, other than dispensing

(no testing during dispensing), at a rate greater than 0.2 gallons per hour.

Ideal Testing Conditions

Tank and environmental conditions play an important role in passing results. Consider the following items when

scheduling or manually forcing a static leak test:

Variable Explanation

Product Level The level in the tank must submerge at least the lowest RTD (temperature sensor) inside the probe shaft.

Temperature Stability A tank with more product inside is likely to be stable thermally and allow for higher quality results.

This variable ties in with temperature stability. Though not likely, product in the tank may dramatically rise

Time of Day

Deliveries

Dispensing If dispensing occurs within two hours prior to or during a test, that test will be aborted.

Test Time

and fall in temperature from dawn to afternoon and then from dusk to night. Typically, thermal issues affect

Aboveground Storage Tanks more often than Underground Storage Tanks.

A period of time is required to wait without a delivery between the last delivery and testing. The time to wait

is 4 hr 9 min for a 0.2 GPH and 5 hr 18 min for a 0.1 GPH after a delivery (in accordance with third party

testing). This time will allow the product to settle. If the wait time is not observed, then the test may abort or

fail.

The test should be scheduled or manually forced when the test will not exceed the maximum leak test time.

If the maximum time is surpassed, an Incomplete result is likely to occur. If scheduling or manually forcing a

test, take into account what the sites hours of operation are to avoid a dispense during testing. Doing this will

prevent aborted and incomplete tests.

13

Page 18

How to Manually Start Static Tests

This procedure requires User level privileges.

1. Starting at the Home/Status screen, press the FMS application button.

2. Press the Application Menu button.

3. Press the Control button.

Step 1

4. Press the Tanks button.

5. Select the tank that will be tested. If the tank does not appear on the screen, use the Scroll Down button to view more

options.

6. Press the Test Type and choose either Monthly or Yearly.

Step 4

7. Press the Checkmark button to start the test.

Step 2

Step 5

Step 3

Step 6

Step 7

Static Test Results

Pass – A passing result ensures the integrity of the tank is good.

Fail – Test failure will be indicated by a Warning light and/or annunciator. Additionally, a report may print (if the console is

programmed to do so, see the T5 Programming Guide - p/n 000-2142).

Abort – The result has been stopped due to variations in oat level and/or product temperature that are outside of the leak

test threshold. This may be caused by:

• Dispensing • Loss of Probe Signal

• Delivery • Rapid Temperature Change

• Theft • Product Lower than the lowest RTD

• Pump Started

Incomplete – When the test does not collect enough data before the programmed time limit ends, the test will be

Incomplete. When it’s necessary to obtain valid results for compliance reasons, start the test manually.

14

Page 19

Statistical Continuous Automatic Leak Detection (SCALD)

SCALD (Statistical Continuous Automatic Leak Detection) runs 24hrs a day performing 0.2 GPH tests on tanks at sites

that do not have enough quiet time to complete static tests (some static tests may take up to eight hours to complete).

SCALD Testing is available only if the option for Tank Testing is enabled. This option can be ordered when initially

purchasing the console or afterwards. The part number for this option is TS-TT for TS-550 / 5000 systems or TS-SCALD

for TS-5 / 608 systems (TS-5 / 608 systems have Static Testing standard, but require the TS-SCALD option to perform

SCALD testing). The TS-TT option includes both Static and SCALD testing.

Why Continuously Test the Integrity of the Tank

In compliance with federal, state and local regulatory policies, all tanks must be monitored for leaks due to environmental

and public safety/health concerns. Tank Integrity Tests determine whether there is a leak.

Since SCALD continuously runs statistical tank leak tests during the inactive periods between product deliveries and

dispensing, it is particularly useful for:

• Operations that are open for business on a continuous (24 hours, 7 days a week) schedule

• Operations that are open for business on a two-shift schedule and where deliveries may occur at any time during nonbusiness hours (normally schedule tank leak tests may require up to 8 hours of inactivity).

Terms

Qualify – The percentage of product that the tank is required to contain prior to testing according

to the programmed “Qualify” parameter.

Slope (Tank Testing Reports) – A ratio of the calculated rate of change to the time the rate is

measured. Slope is affected by leaks and by many other sources of interference. A negative

slope or decrease indicates loss of product volume. A positive slope or increase indicates a rise in

product volume.

Time

Flow

(+) slope

No Leak

(–) slope

SCALD Testing Requirements

To perform SCALD testing, the SCALD software must be enabled. To verify that the software is enabled:

1. Starting at the Home/Status screen, press the System Application button.

2. Press the Application Menu button.

3. Under Option, SCALD Testing will appear. A “yes” in the Enabled column indicates that the software has been

purchased and is enabled.

Step 1 Step 2 Step 3

When SCALD Tests

SCALD works by collecting quiet intervals in-between dispensing. A “QI” is obtained when a thermally stable tank is idle

for 20 minutes with no dispensing, no deliveries and no other movement of the probe oats. Once four QIs are collected,

the console will analyze the data and either Pass, Fail, Incomplete, or Abort that test. The four QIs can be collected over a

period of several days or weeks.

15

Page 20

SCALD Results

Pass – A passing result ensures the integrity of the tank is good.

Fail – Test failure will be indicated by a Warning light and / or annunciator. Additionally, a report may print (if the console is

programmed to do so, see the T5 Programming Guide - p/n 000-2142)

Abort – The result is due to variations in oat level and / or product temperature that are outside the leak test threshold.

This may be caused by:

• Dispensing • Rapid Temperature Change

• Delivery • Product Lower than the lowest RTD (Resistance Temperature Detector)

• Theft • Pump Started

• Loss of Probe Signal

Incomplete – When the test does not collect enough data before the programmed time limit, the test is Incomplete. When

it is necessary to obtain valid results for compliance reasons, start the test manually.

Note: The SCALD report will only indicate either Pass or Fail.

Reasons Why SCALD May Not Complete

• No Quiet Time

◦ SCALD needs four 20 minute QIs in order to complete a test. These QIs are normally found in the early morning

hours. If the site is so busy that there are no 20 minute periods of no dispensing, then SCALD will not be able to

complete a test.

• Temperature Instability

◦ If a site is receiving deliveries frequently and the temperature of the fuel being delivered is several degrees hotter/

colder then the fuel in the tank, SCALD will not be able to collect data due to thermal instability interrupting quiet time.

The temperature of the fuel cannot change more than .01° F during a 20 minute QI.

◦ If a pump control relay is stuck closed and the pump is running all of the time, the temperature in the tank may be

much higher than in the other tanks. Due to this high temperature and the fact that the pump is running, no QIs will

be collected.

Note: On rare occasions conditions can arise that prevent SCALD from getting enough QIs to complete a test.

Tank Leak Test Reports

Reports that contain leak testing data and results may be printed from the console or generated / printed using TSA.

Printing Tank Leak Test Reports

LCD

1. Starting at the Home/Status screen,

press the Reports button.

2. Press the FMS button.

3. Press either the Tank Test (for static

reports) or SCALD for continuous

reports.

4. Select the Date Range desired.

5. Press the checkmark to start report

printing.

Step 1

Step 2

16

Step 3 Step 4

Page 21

Example Tank Leak Test Reports from Internal Printer

Site ID 1

Site ID 2

Site ID 3

Site ID 4

Site ID 5

Date Time

Tank Test Report SCALD Report

Specied Time Frame Specied Time Frame

Volume: (gal) programmed

Length: (in) programmed

Temperature: (F) programmed

TANKS

Tank #

Product #

Maximum Capacity

#.##

Begin Time

Date Time

Begin Gross

#.#

Begin Net

#.#

Begin Level

#.#

Begin Temperature

#.#

Begin Water Level

#.#

Begin Water Vol

#.#

End Time

Date Time

End Gross

#.#

End Net

#.#

End Level

#.#

End Temperature

#.#

End Water Level

#.#

End Water Vol

#.#

Last Delivery

Test Type

Monthly

Threshold

#.##

Leak Rate

#.##

Result

Pass/Fail/Abort/Incomplete

Capacity

#.##

Details

Time

Date Time

Net Volume

#.#

Temperature

#.#

Level

#.#

Time

Date Time

Net Volume

#.#

Temperature

#.#

Level

#.#

Site ID 1

Site ID 2

Site ID 3

Site ID 4

Site ID 5

Date Time

Volume: (gal) programmed

Length: (in) programmed

Temperature: (F) programmed

TANKS

Tank #

Product #

Maximum Capacity

#.##

Started

Date Time

Result

(Pass)

Slope

#.############

Status

#.#

Ended

Date Time

Vol %

#.##

Type

(Monthly)

17

Page 22

Example External Tank Leak Test Report from Web Browser Interface

Site ID 1

Site ID 2

Site ID 3

Site ID 4

Site ID 5

Name

Tank # #.##

Max

Capacity

Time

Started Date Time #.# #.# #.# #.# #.# #.#

Ended Date Time #.# #.# #.# #.# #.# #.#

Last Delivery Date Time Test Type (Monthly) Leak Rate #.## Result (Pass)

Threshold Programmed Capacity #.##

Net Volume Temperature Level Time

#.## ##.## #.## Date Time

#.## ##.## #.## Date Time

#.## ##.## #.## Date Time

Last Available

Tank Test Report

STATIC TEST

Gross

Volume

TANKS

Net Volume

Product

Level

Temperature

Water

Level

Date Time

Water Volume

Site ID 1

Site ID 2

Site ID 3

Site ID 4

Site ID 5

Name Product Max Capacity

Tank # Product # #.##

Last Available

Date Time

Tank Test Report

SCALD TEST

TANKS

Started Date Time Result (Pass) Slope #.# Status #.##

Ended Date Time Volume Quality Percent #.# Test Type (Monthly)

18

Page 23

Line Leak Testing

Overview

Line Leak Detection is available only if the option for Line Testing is enabled. This option can be ordered when purchasing

the console or after the initial purchase by using the part number TS-ELLD. Relay, AC Input and 4-20mA Modules will also

need to be ordered and installed, if not initially purchased with the console. The TS-5 and TS-608 FMS consoles do not

have line leak detection capabilities.

Line Leak Testing for all T5 series FMS consoles use software rules to automatically run tests. Tests may be started

manually from the console or remotely using TSA. AutoLearn software monitors line conditions by conducting a multitude

of electronic line pressure sensing tests.

Line Leak Detection is required in many areas to monitor for potentially hazardous environmental contamination. In

the event of a leak, the system may provide positive pump shutdown (to prevent further contamination) and display an

indicator light and on-screen description of the condition as console alarm notications. A high intensity remote alarm may

also be used if applicable. After installation, the user of the system must monitor the system to ensure that any leak alarm

and pump shutdown (indicating a line leak) is dealt with promptly.

The LS500 LLD system can detect a leak from the check valve in the pump to the solenoid valve at the dispenser —

assuming no other normally closed valve is in the pipeline system. This system does not detect leaks from the fuel storage

tank. The LS500 should be used in applications where site conditions are in accordance with Third Party testing (as listed

in the NWGLDE section of this chapter).

Terms

Piping Modulus – This is the maximum pipe capacity that may be tested in accordance with the 3rd Party Approval,

regardless of pipe diameter.

Transducer – An electronic pressure sensing device placed in the line that communicates with the console..

Certications – 3rd Party Approvals

TS-LS500 AutoLearn Pressurized Electronic Line Leak Detection as of May 19th, 2006 has been approved by a third party

for leak detection of rigid and exible piping.

National Work Group Leak Detection Evaluations (NWGLDE)

This data can be referenced on the abbreviated version of the 3rd Party Certication performed by Ken Wilcox Associates,

located on the NWGLDE site: http://nwglde.org/.

Line Leak Testing Requirements

To perform Line Leak testing, the Line Leak software must be enabled. To verify that the Line Leak software is enabled:

1. Starting at the Home/Status screen, press the System Application button.

2. Press the Application Menu button.

3. Under Option, a Line Testing row will appear. A “Yes” in the Enabled column indicates that the software has been

purchased and is enabled.

Step 1 Step 2 Step 3

19

Page 24

Test Cycles & Types

Once installed, calibrated and enabled, the LS500 will start a cycle of tests after the hook signal becomes inactive (i.e. a

nozzle is hung up). The transducers then monitor line pressure to ensure that pressure is sufcient to proceed with the

cycle. A Gross (3.0 GPH) Leak Test will begin immediately following the pressure test, if these options are enabled in

setup. When the Gross Test is complete with a pass result, the system will wait 30 minutes prior to monitoring the line for

thermal stability. When it determines that the line is stable, another Gross Test will be performed directly followed by a

Monthly (0.2 GPH) Leak Test. When the Monthly Test is complete with a pass result, the system then monitors the line for

thermal stability once again. When that the line is stable, another Gross Test will be performed followed by an Annual (0.1

GPH) Leak Test. When the Annual Test is complete with a pass result, the system then waits 45 minutes prior to restarting

the cycle again.

Test Type Description

Pressure Up A pressure up test will monitor line pressure from a static line to when the pump is turned on.

Dispenser Pressure

Catch Pressure

Gross (3.0 GPH) Leak

Thermal Wait Time

Monthly (0.2 GPH) Leak

Annual (0.1 GPH) Leak

Line Learned but Not Enabled

Sudden Pressure Loss

Extended Pump Run

High Pressure

Dispenser pressure is tested with the hook applied to ensure that line pressure does not drop too

low while dispensing. This feature can be enabled/disabled in the programming.

When the dispenser hook is dropped and the pump turns off, line pressure decay is monitored and

compared to a learned decay. This test will not cause the pump to shut down — alarm only.

The Gross Test will begin after every dispense when the line is enabled or after every 45 minutes

of quite time (no dispensing or pump running) following a line pressure test. In ideal conditions, this

test will take approximately 5 minutes to complete. In the event of a failure, the system will attempt

to run the test again after 5 minutes. After two failures an indicator light and alarm will turn on and

the pump will be shutdown. A dispense or pump shutdown by another application during this test

will cause an Abort Alarm. This test can be enabled / disabled in the programming.

Before initiating a precision test, the LS500 will monitor the line for thermal variations. Testing for

thermal variations takes 1½ to 10 hours of inactivity.

If this option is enabled in the programming, the test will follow a thermal wait period and line

pressure test. In the event of a failure, the system will attempt to run the test again without

waiting. Upon three failures, an indicator light and alarm will turn on and the pump will shutdown if

programmed. A dispense or pump shutdown by another application during this test will cause an

Abort alarm. This test can be enabled/disabled in the programming.

If a line is learned and not enabled within a preset amount of time, then the console will show a

warning that the line is not enabled. This is to show that the line is not being monitored for leaks.

This is a continuous test that runs in the background. An alarm will occur if line pressure drops too

fast.

The LS500 will detect all hook signals (if wired properly) and the time that they remain active. If

the hook signal is active for too long, the console will indicate this condition with an alarm light and

sound.

If line pressure exceeds the maximum allowable pressure, the pump will shut down and an alarm

will light and sound. This test will run continuously when the line is enabled.

How to Manually Start Line Leak Tests

This procedure requires User level privileges.

1. Starting at the Home/Status screen, press the FMS application button.

2. Press the Application Menu button.

3. Press the Control button.

Step 1

20

Step 2

Step 3

Page 25

4. Press the Lines button.

5. Select the line that will be tested. If the line does not appear on the screen, use the Scroll Down button to view more

options.

6. Press the Test Type, either Force Gross, Force Annual or Force Monthly.

7. Press the Checkmark button to start the test.

Step 4

Step 5

Steps 6 & 7

Line Test Results

Pass – A passing result ensures that the line is free of leaks; any variation in product stability is within permissible

thresholds.

Fail – Test failure will be indicated by an alarm light and/or annunciator. Additionally, a report may print (if the console is

programmed to do so, see the T5 Programming Guide - p/n 000-2142).

Abort – There may not be an indication of an abort for some tests. If a line is disabled manually or automatically by

another application, a test is manually initiated in the middle of a cycle or a dispense occurs, then the test cycle will abort

the results for the current test.

Incomplete – If there aren’t at least two hours of inactivity before a precision test, it may result in an incomplete test.

Pump Shutdown – Failing the maximum number of tests consecutively will shut the pump down. A single catch pressure

test failure or pressure up test failure will also shut the pump down.

Note: All conditions must be physically corrected to clear alarm conditions. To clear alarms after correcting the problem,

go to lines / control and click reset alarm. Alarms will clear automatically when conditions permit.

21

Page 26

Line Leak Test Reports

Reports that contain leak testing data and results may be printed from the console or generated/printed using TSA.

Printing Tank Leak Test Reports

LCD

1. Starting at the Home/Status screen,

press the Reports button.

2. Press the FMS button.

3. Press the Line Test row.

4. Select the Time Option desired.

5. Press the checkmark to start report

printing.

Step 1

Step 2

Example Line Leak Test Reports from Internal Printer

Step 3 Step 4

Site ID 1

Site ID 2

Site ID 3

Site ID 4

Site ID 5

Date Time

Line Leak Report

Specied Time Frame

‘TYPE’ TEST

Line #

‘Type’ Leak Test ‘Result’

Date Time

…..

Example Line Leak External Test Reports from Web Browser Interface

Site ID 1

Site ID 2

Site ID 3

Site ID 4

Site ID 5

Last Available

Line Leak Report

Date Time

Name Result Test Date

Line # Daily Total = #

Name Result Test Date

Line # Daily Total = #

Name Result Test Date

Line # Daily Total = #

Gross Leak Test ‘Result’ Date Time

Monthly Leak Test ‘Result’ Date Time

Annual Leak Test ‘Result’ Date Time

GROSS TEST

MONTHLY TEST

ANNUAL TEST

22

Page 27

Web Browser Interface

One of the most powerful advantages of a T5 series console is its standard Ethernet

port and ability to communicate with a web browser via web pages using standard

XML (eXtensible Markup Language) protocols. The Web Browser Interface allows

the Fuel Management System to directly connect to a PC through a local area

network or high speed internet connection. Using Web Browser Interface, your

console can be accessed from a PC with a web browser program (like Microsoft

Internet Explorer version 6.0 or later). Contact your local FFS distributor for more

information if you are not using this feature.

Using the Web Interface

To access the console using a remote PC you will need to know the IP address that

has been assigned to it. This address should be provided by the installer. For direct

connections not part of a network, the default IP address is 192.168.168.168. On

your PC, open your internet browser and, in the address bar, enter the IP address of

the console. The words Loading Page should appear in the upper left hand corner

and data will begin to be transferred. You will probably want to bookmark (or add)

this page to your Favorites in your browser.

Once the home page is loaded, you can navigate through the various web pages

Communication Ports

created by the console to view fuel management and compliance data, generate

reports that can be printed from your PC and access control functions for starting tank and line tests and dealing with

alarms. The information found in TSA (Tank Sentinel AnyWare) is the same data that can be accessed from the LCD touch

screen.

Navigating Pages

The Navigation Bars provide a list of pages that can be viewed. Clicking on each Primary choice will take you to a different

page and update the list of Secondary Navigation choices. The current choice is always highlighted. On occasion, a

third Navigation Bar will appear. The Data Window displays the appropriate information and the Action Bar allows you to

perform certain control functions like generating reports and starting leak tests.

Home – Status Page

Access Level – Displays the current access level.

Primary

Navigation Bar –

Displays top level

navigation choices.

The current choice

is highlighted.

Secondary

Navigation Bar –

Displays submenu

choices dependent

on Primary selection.

The current choice is

highlighted.

Data Window – Displays the

appropriate data depending on

what page is being viewed.

Action Bar – Lists possible actions that can

be performed. Actions are dependent on

Primary/Secondary choices.

23

Page 28

Available Pages

The following web pages can be browsed to in order to access data and perform various control functions. Some of the

pages are dependent on the version of console and the options installed. Several pages and functions are access level

controlled. If the Auto Refresh action is listed on the Action Bar of a page, then the data on the page does not refresh automatically. Click Refresh on your browser to update the page or click on Auto Refresh to do this continuously.

System

Web Page Description

Status Lists the installed modules, their current status and version.

Alarms Shows a detailed list of all active Alarms and Warnings.

Reports Generate Alarm and Application Event reports.

Conguration Edit the access level passwords and IP information. (Administrator Only)

Registration View system information and the installed options.

Diagnostic Shows Tank test status and Relay status

Tools Allows rebooting the System

FMS

Web Page Description

Status Third Navigation line appears. Choose the device to show status of Tanks, Lines, Sensors or Pumps.

Alarms Lists all active FMS alarms and the date and time they occurred.

Control Start line and tank tests, learn lines and sensors and auto congure sensors.

Compliance Displays compliance information for all FMS tanks, lines and sensors.

Reports Generate various FMS reports like Inventory, Delivery, Leak Tests, Regulatory.

Setup

This menu is limited to administrator access only, and should only be used by a certied technician. Contact your FFS

distributor for assistance.

Preferences

Modify the way that data is displayed, change the units of measure and adjust the Auto Refresh rate. There are two levels

of preferences:

Preference Description

Personal These settings are stored on your PC and apply to its use only.

System Adjusts the way data is displayed by default for all Web Browser Interface and touch screen users.

Other options (such as VRM and SCM) will display menu entries if those options are installed.

How to Manually Start Leak Tests Using Web Browser Interface

1. Open your web browser and connect to the site.

2. On the Primary Navigation Bar, select FMS.

3. On the Secondary Navigation Bar, select Control.

4. Select Tanks or Lines depending on what type of test you wish to start.

Tank Leak Tests

1. Check the box next to the Tank(s) you want to test.

2. From the drop-box, select the type of test (Monthly or Annual) you want to perform for each tank, .

3. Click on Start Leak Tests on the Action Bar.

Line Leak Tests

1. Press the button for Force Gross Leak Test under the line you wish to test.

24

Page 29

Routine Maintenance

As an end user/owner, there is a limited amount of maintenance that you may need to perform on the console. To keep

the unit in good, serviceable condition, follow the procedures outlined below.

Warning

Do not attempt to open the console unless you are a certied FFS technician. Electrical hazards

exist and injury or death may occur if the console interior is accessed by unauthorized personnel.

Console Care

Carefully wipe the outer areas of the console with a soft, damp cloth to remove any residue or build-up. Some chemicals

may damage the protective cover on the LCD display. Avoid spraying the console with anything directly. Cords and cables