Page 1

LS500 Auto Learn

Line Leak Detection

Installation & User’s Guide

Manual # Revision date Changes from Previous Revision

000-2145 E August 2012 Updated to Incude TS-550evo

Franklin Fueling Systems • 3760 Marsh Rd. • Madison, WI 53718 USA

Tel: +1 608 838 8786 • 800 225 9787 • Fax: +1 608 838 6433 • www.franklinfueling.com

Page 2

Notice

Franklin Fueling Systems (FFS) strives to produce the nest manual possible and to ensure that the information that

it contains is complete and accurate. However, FFS reserves the rights to change this document and specications at

any time without notice. FFS makes no expressed or implied warranty with regard to the contents of this manual. FFS

assumes no liability for errors, omissions or for any damages, direct or consequential, that may result from the use of this

document or the equipment that it describes.

This manual is for use expressly with the TS-550, TS-550evo and TS-5000 at their approved specications.

For further information, installation and programming instructions, please refer to the T5 Series Installation Guide (p/n

000-2150), T5 Series Programming Guide (p/n 000-2142) or the TS-550evo FMS Programming Guide (p/n 000-2173).

Trademarks

INCON®, Tank Sentinel®, System Sentinel®, System Sentinel AnyWare® and Tank Sentinel AnyWare® are registered

trademarks of Intelligent Controls. All brand and product names are trademarks or registered trademarks of their

respective companies.

Inspection of Materials

Visually inspect all components for defects or damage prior to installation. If any defect or damage is found, do not use the

product and contact Franklin Fueling Systems for further assistance.

Warranty Information

Please refer to the FFS Fuel Management Systems & Product Warranty Policy for all warranty information.

Contacting Franklin Fueling Systems (FFS)

Please feel free to contact us by mail at:

Franklin Fueling Systems

3760 Marsh Rd.

Madison, WI 53718 USA

Or contact us by phone, fax or e-mail:

Tel: +1 800 225 9787 E-mail: sales@franklinfueling.com

Fax: +1 608 838 6433 techserve@franklinfueling.com

Ofce and Sales Hours: 8 a.m. to 5 p.m. CST - Monday through Friday

Technical Support Hours: 7 a.m. to 7 p.m. CST - Monday through Friday

Please visit our website at www.franklinfueling.com

Copyright ©2008 by Franklin Fueling Systems (FFS). No part of this publication may be reproduced in any form without the prior written consent of FFS.

2

All rights reserved.

Page 3

Contents

Notice................................................................................................................................2

Important Safety Messages ............................................................................................ 4

Overview...........................................................................................................................5

Site Requirements .................................................................................................................. 5

Transducer Installation ............................................................................................................ 6

Denitions and Acronyms .......................................................................................................6

Intrinsically Safe LS500 Installation ..............................................................................7

Explosion Proof LS500E Installation ............................................................................. 8

LS-500 Setup (Console Programming) .......................................................................... 9

4-20mA Input Module ............................................................................................................10

Relay Module ........................................................................................................................ 11

Turbine Pump Interface (TPI) Applications ........................................................................... 12

Fuel Management Systems (FMS) Line Application Set-Up ................................................. 13

Line Status and Control Screens ................................................................................. 14

Control Indicator Table .......................................................................................................... 15

Learn Indicator Table ............................................................................................................ 15

Pre-Operational LS500 Testing .................................................................................... 16

Required Equipment ............................................................................................................. 16

Line Stability Test .................................................................................................................. 16

Learn Process ................................................................................................................ 17

When to Learn / Re-Learn ..................................................................................................... 17

Procedure ............................................................................................................................. 17

Learn Messages ................................................................................................................... 18

LS-500 Reports .............................................................................................................. 19

LS-500 Line Leak Reports .................................................................................................... 19

Alarms ............................................................................................................................ 19

LS-500 Alarms and Warnings ............................................................................................... 20

Clearing Alarms ....................................................................................................................22

LS-500 Functional Testing ............................................................................................ 23

Enabling / Disabling Lines ............................................................................................. 23

3

Page 4

Important Safety Messages

INCON equipment is designed to be installed in association with volatile hydrocarbon liquids such as gasoline and diesel

fuel. Installing or working on this equipment means working in an environment in which these highly ammable liquids

may be present. Working in such a hazardous environment presents a risk of severe injury or death if these instructions

and standard industry practices are not followed. Read and follow all instructions thoroughly before installing or working

on this, or any other related, equipment.

As you read this guide, please be aware of the following symbols and their meanings:

Warning

Caution

Danger

Warning

Warning

This symbol identies a warning. A warning sign will appear in the text of this document when a potentially

hazardous situation may arise if the instructions that follow are not adhered to closely. A potentially hazardous

situation may involve the possibility of severe bodily harm or even death.

This is a caution symbol. A caution sign will appear in the text of this document when a potentially hazardous

environmental situation may arise if the instructions that follow are not adhered to closely. A potentially

hazardous environmental situation may involve the leakage of fuel from equipment that could severely harm

the environment.

This symbol identies an electrical danger. An electrical danger sign will appear in the text of this document

when a potentially hazardous situation involving large amounts of electricity may arise if the instructions that

follow are not adhered to closely. A potentially hazardous situation may involve the possibility of electrocution,

severe bodily harm, or even death.

Follow all applicable codes governing the installation and servicing of this product and the

entire system. Always lock out and tag electrical circuit breakers while installing or servicing

this equipment and any related equipment. A potentially lethal electrical shock hazard and the

possibility of an explosion or re from a spark can result if the electrical circuit breakers are

accidentally turned on during installation or servicing. Please refer to the Installation and Owner’s

Manual for this equipment, and the appropriate documentation for any other related equipment, for

complete installation and safety information.

Follow all federal, state and local laws governing the installation of this product and its associated

systems. When no other regulations apply, follow NFPA codes 30, 30A and 70 from the National Fire

Protection Association. Failure to follow these codes could result in severe injury, death, serious

property damage and/or environmental contamination.

Warning

Warning

Warning

Warning

Warning

Always secure the work area from moving vehicles. The equipment in this manual is usually

mounted underground, so reduced visibility puts service personnel working on this equipment in

danger from moving vehicles entering the work area. To help eliminate these unsafe conditions,

secure the area by using a service truck to block access to the work environment, or by using any

other reasonable means available to ensure the safety of service personnel.

When the Tank Sentinel system is used to monitor tanks containing gasoline or other ammable

substances, you may create an explosion hazard if you do not follow the requirements in this

manual carefully.

All wiring must enter the Tank Sentinel console’s enclosure through the designated knockouts. An

explosion hazard may result if other openings are used.

All wiring from probes or sensors to the Tank Sentinel console must be run in conduit separate

from all other wiring. Failure to do so will create an explosion hazard.

Substituting components could impair intrinsic safety. The Tank Sentinel 5 (T5) series consoles

are intrinsically safe for sensors installed in – Class I, Division 1, Group D – hazardous locations.

Substitution of components could make the energy limiting circuitry in the system ineffective and

could cause an explosion hazard. Repairs to a T5 Series console or attached components should

only be performed by a qualied, factory-trained technician.

4

Page 5

Overview

The TS-LS500 is a continuous product line leak detection system that monitors the primary pipe. This product is an

available option of Franklin Fueling Systems’ TS-550 and TS-5000 FMS consoles.

The TS-LS500 system includes the FMS application running on a T5 series console and a transducer. One transducer

is required per product line, which measures the line pressure. Line Pressure is created by the pump and static seating

pressure is metered by a pressure relief valve. Transducers (TS-LSU500) use the AutoLearn technology to continuously

evaluate the line conditions.

Note: The TS-LS500 requires pressure for leak tests and should only be installed in systems that are designed to obtain

and hold this minimum static pressure. The system will report “learned with errors” if tests are run at less than

optimum pressure.

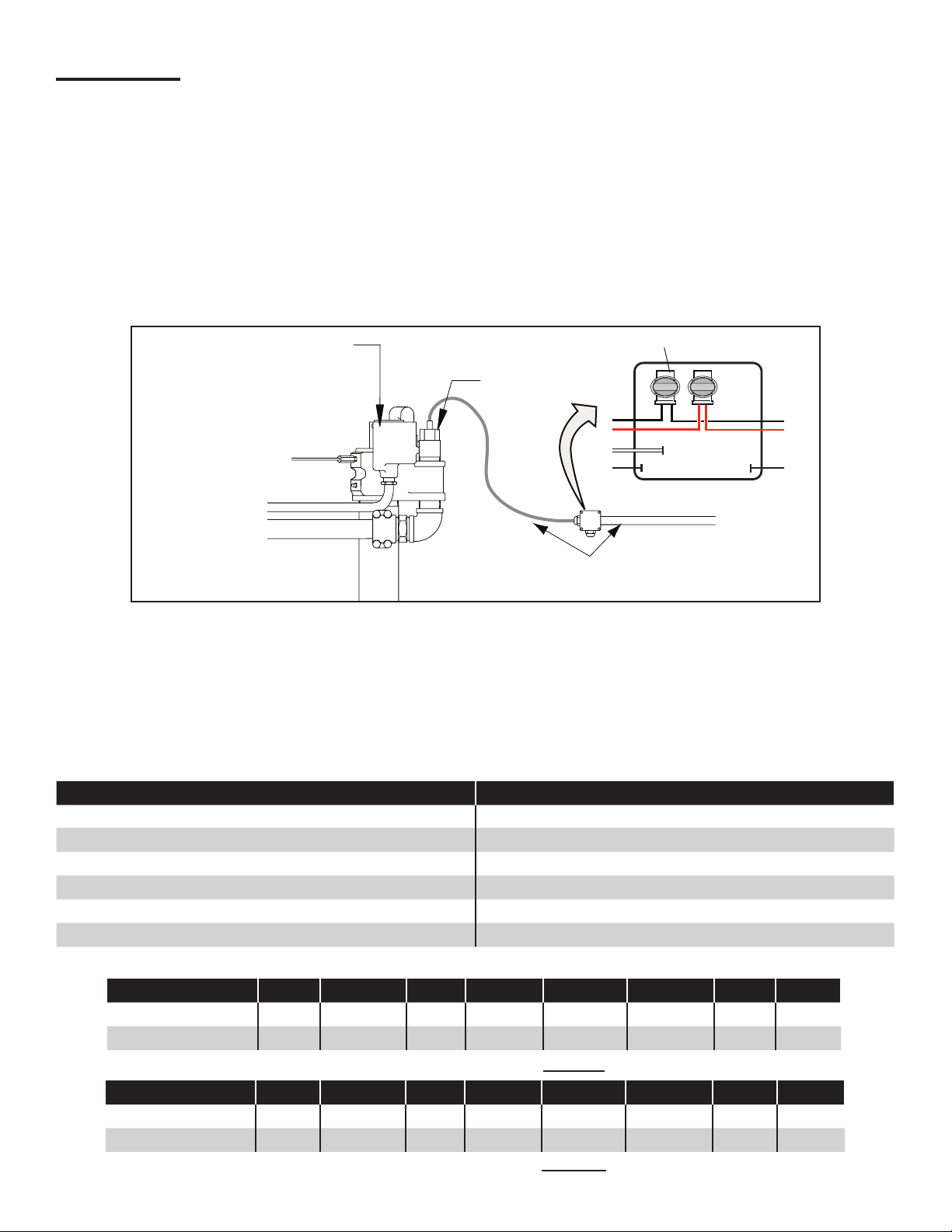

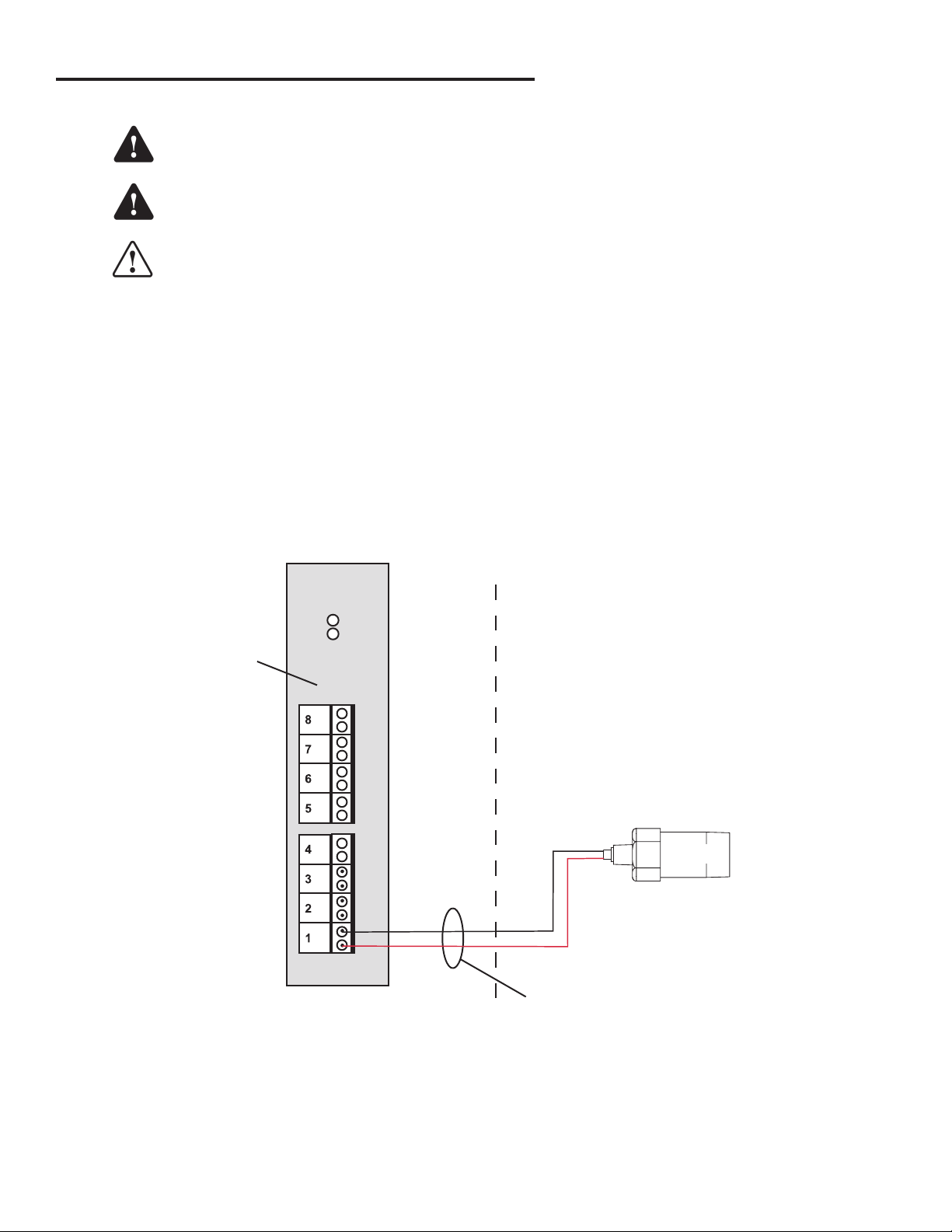

Applications

The following diagram illustrates a typical installation of the LS500 equipment inside of a STP sump.

FE Petro

Submersible

Pump

TS-LSU500

Intrinsically safe wiring or explosion-proof

conduit, depending upon application

Figure 1: LS500 Install Overview

Wire Splices

Black

Red

White (capped)

Shield (Not connected)

To maintain optimal line pressure, Franklin Fueling makes the following recommendations for submersible pumps:

• For FE Petro Submersible Pumps, use a Standard Check Valve (part # 400988931).

• For Red Jacket Submersible Pumps, use an adjustable functional element, adjusting the pump OFF pressure to be at

least 2 psi below the pump ON pressure.

Newer style Red Jacket Submersible Pumps do not have an adjustable functional element as an option. These

submersible pumps have a check valve that meets the LS500 pressure requirements.

Site Requirements

Item Value

Minimum Static Pressure 18 PSI for precision testing

15 PSI for gross leak testing

20 PSI for learning lines

Maximum line volume for rigid pipe 312.2 gallons

Maximum line volume for exible pipe 95.4 gallons

Minimum volume for rigid or exible pipe 2.5 gallons

Table 1: Capacity Table

Pipe Diameter I.D. 1" 1 ½" 1 ¾" 2" 2 ½" 3" 4" 5"

Flex Length 61' 27' 20' 15' 10' 7' 4' 2'

Rigid Length 61' 27' 20' 15' 10' 7' 4' 2'

Table 2: Pipe Length Required for Holding Minimum Line Volume

Pipe Diameter I.D. 1" 1 ½" 1 ¾" 2" 2 ½" 3" 4" 5"

Flex Length 2339' 1040' 764' 585' 374' 260' 146' 94'

Rigid Length 7656' 3403' 2500' 1914' 1225' 851' 479' 306'

Table 3: Pipe Length Required for Holding Maximum Line Volume

5

Page 6

6.25"

(159 mm)

3/4" NPT

2-3/8" (70mm)

across ats

5.13"

(130 mm)

2" NPT

Figure 2: TS-LSU500 Dimensions

Transducer Installation

1. Apply UL Classied Gasoline / Oil resistant pipe dope thread sealant to the threads of the LSU500 Transducer and

use a 2 3/8” open-end wrench to install it in the Leak Detector Port of the STP housing

(see Figure 1).

2. Install Couplings, threaded Rigid Metal Conduit (RMC), and Explosion / Weather Proof Junction Boxes (J-Boxes)

in the STP sumps. For intrinsically safe wiring, run the transducer lead to the junction box. For explosion-proof

installations, run conduit to the top of the transducer.

3.

Install threaded RMC and EYS ttings along with Transducer Cables (Belden #9365) from LS500 console to

the Explosion / Weather Proof J-Boxes. A licensed electrician should splice the cables together. If this wiring is

Intrinsically Safe it MUST NOT be run with any Explosion-Proof wiring or other non-Intrinsically safe wiring!

Alpha cable #58411 (INCON #600-0062) must be used if using nonmetallic (PVC) conduit as allowed by local code.

Denitions and Acronyms

AIM – 4-20mA Analog Input Module (Intrinsically Safe)

FMS – Fuel Management Systems

IS – Intrinsically Safe

ISD – In-Station Diagnostic

LCD – Liquid Crystal Display

LED – Light Emitting Diode

LLD – Line Leak Detection

PC – Personal Computer

PM – Probe Module (Intrinsically Safe)

RM – Relay Module

SCM – Secondary Containment Monitoring

STP – Submersible Turbine Pump

TPI – Turbine Pump Interface

T5 – T5 Series FMS Consoles

(TS-5 / 608, TS-550 EMS, TS-5000 / EXPC

/ TS-550evo)

TS-EMS – Environmental Monitoring System

TSA – TankSentinel Anywhere

6

Page 7

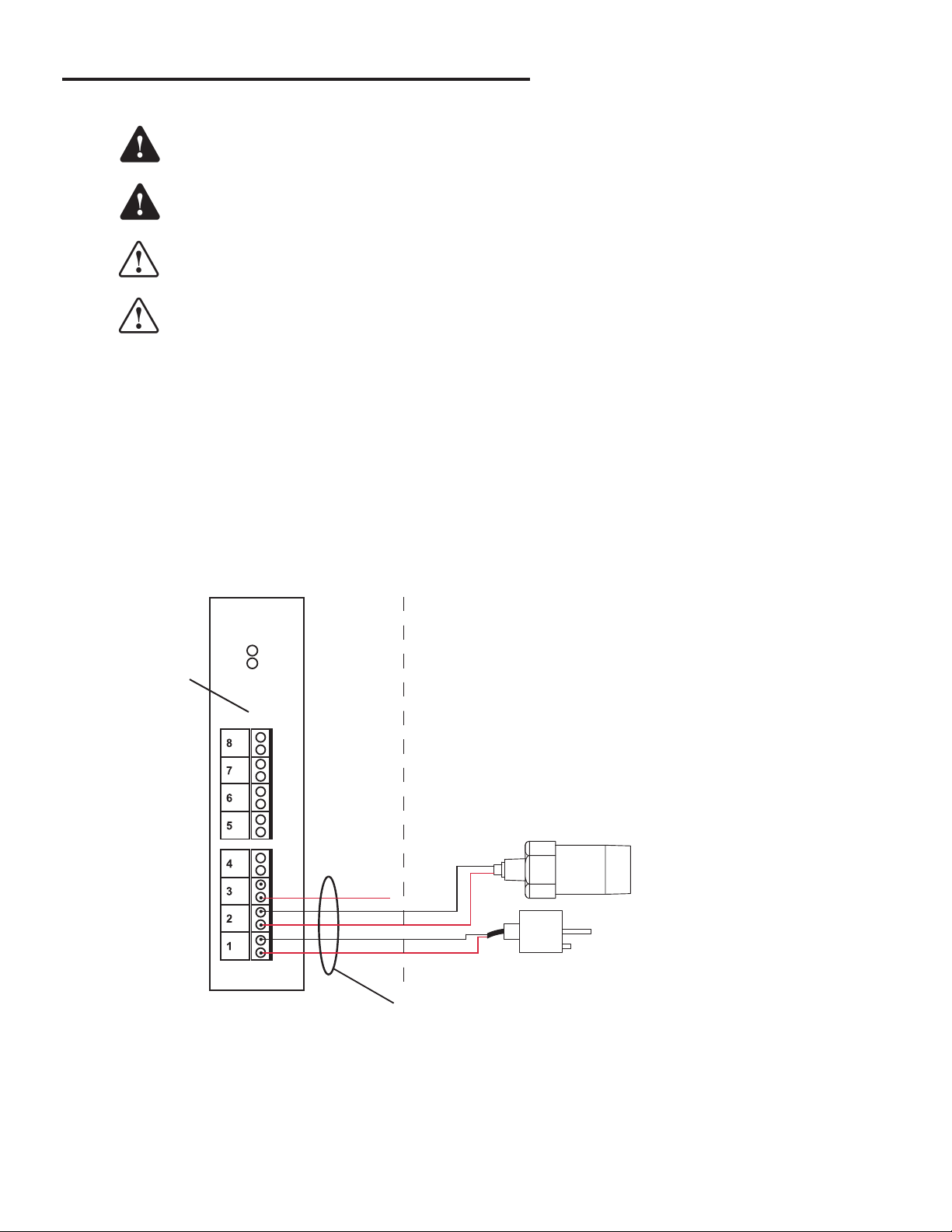

Intrinsically Safe LS500 Installation

Note: The Intrinsically Safe 4-20mA Input Module has a BLUE face.

Warning

Warning

Caution

Caution

Lockout and tag circuit breakers, and disconnect console power wiring before installing or servicing

any system wiring.

DO NOT make transducer wiring connections with power connected to the console or any module.

Do not run intrinsically safe (IS) wiring and non-intrinsically safe (non-IS) wiring in the same conduit.

Do not use explosion-proof transducers (TS-LS500E) with intrinsically safe LS500.

Note: LS500 must be installed in accordance with the national electrical code, ANSI / NFPA 70, CEC or other applicable

national or local codes.

1. Pull the wiring through the intrinsically safe conduits that will be used for the TS-LSU500 transducers.

2. Mount the TS-LSU500 in the Leak Detector Port of the STP housing. (As outlined in the Transducer Installation

Section above).

3. The TS-LSU500 wiring must enter the console in IS conduit through a knockout on the IS side of the barrier.

Secure each pair of transducer wires to a single channel on the 4-20mA Input Module. Always start at the rst

available channel and do not skip channels. For example, if channels one through three are already being used

for another application channel 4 must be used. Be sure to connect the wires to the correct polarity (+/-). If the

transducer is wired backwards it will not function.

(Blue)

4-20mA Input

Module

RUN

ERR

–

+

–

+

–

+

–

+

–

+

–

+

–

+

–

+

Non-Hazardous

Location

- (BLK)

+ (RED)

Hazardous Location

Class I, Division 1, Group

D, Group IIA, Zone 0

- (BLK)

+ (RED)

Tank Pressure Sensor

Intrinsically Safe Conduit

LS-500

Figure 3 – 4-20 mA Input Module Wiring

7

Page 8

Explosion Proof LS500E Installation

Note: The Explosion Proof 4-20mA Input Module has a RED face.

Warning

Warning

Caution

Lockout and tag circuit breakers, and disconnect console power wiring before installing or servicing

any system wiring.

DO NOT make transducer wiring connections with power connected to the console or any module.

Do not run intrinsically safe (IS) wiring and non-intrinsically safe (non-IS) wiring in the same

conduit.

Note: LS500E must be installed in accordance with the national electrical code, ANSI / NFPA 70, CEC or other applicable

national or local codes.

Note: The explosion-proof transducer needs to have explosion-proof conduit to the head of the transducer.

1. Pull the wiring through the explosion proof conduit that will be used for the TS-LSU500 transducers.

2. Mount the TS-LSU500E in the pump manifold.

3. The TS-LSU500E wiring must enter the console in Explosion Proof conduit through a knockout on the Hazardous

side of the barrier. Secure each pair of transducer wires to a single channel on the 4-20mA Input Module. Always

start at the rst available channel and do not skip channels. For example, if channels one through three are

already being used for another application channel 4 must be used. Be sure to connect the wires to the correct

polarity (+/-). If the transducer is wired backwards it will not function.

4 - 20mA EXP

INPUT MODULE

(Red)

RUN

ERR

–

+

–

+

–

+

–

+

–

+

–

+

–

+

–

+

Non-Intrinsically

Safe Side of

Console

Hazardous Location

Class I, Division 1, Group

D, Group IIA, Zone 0

- (BLK)

+ (RED)

Explosion-Proof Conduit

Figure 4 – 4-20 mA Input Module Wiring

LS-500E

8

Page 9

LS-500 Setup (Console Programming)

The following instructions are a guide to programming the LS-500 only. The administrator password will be necessary to

save the programming changes. For instruction on FMS programming, or how to obtain the Administrator access level,

please refer to the T5 Series FMS Programming Guide (p/n 000-2142) or the TS-550evo FMS Programming Guide (p/n

000-2173).

Access the T5 Series FMS console (via the LCD touch screen or by the web) and navigate to the Setup Menu, Go to each

of the following parameters, shown in the next tables, and set them accordingly per the site. You will be prompted to enter

the Administrator password when it is required.

Note: Site setups vary depending on the products used and other equipment installed. Setup information in the sections

of this chapter depicts a typical site and are meant as examples only.

AC Input Module

One of the functions of the AC input module is to accept incoming dispenser hook signals. The hook signal tells the

console which product the dispenser is requesting, then turns the appropriate Submersible Turbine Pump (STP) on using

either a relay (from the relay board or from the power supply board) or the turbine pump interface (TPI). The LS500 is

constantly monitoring the pressure on the line, and testing accordingly. To perform tests properly, the LS500 needs to

know when the pumps are being used by other applications.

Parameter Parameter value

Number of Gasoline Hooks

per Dispenser

Channels Select the number of inputs in use.

Name Text box, name each channel to easily identify in the mapping.

The number of product hook signal inputs to the console from each dispenser.

Enabled Select YES. This will allow the channel to be mapped to another module. Other modules

need this signal to trigger events.

Active State Select HIGH. A high signal level will activate the channel and a low signal will deactivate

the channel. If set to low, then the channel is inverted and will only become active when

a signal is absent and inactive when a signal is present.

Action Select NONE

Example: AC Input Module FMS Setup

Group Name Parameter Name Parameter Value

AC Input Modules Number Gasoline Hooks per Dispenser 2

Module 1 Channels 3

Channel 1 Name Disp 1 Unleaded Hook Signal

Enabled Yes

Active State High

Action None

Channel 2 Name Disp 2 Unleaded Hook Signal

Enabled Yes

Active State High

Action None

Channel 3 Name Disp 3 Unleaded Hook Signal

Enabled Yes

Active State High

Action none

9

Page 10

4-20mA Input Module

TS-LSU500 Transducers use a single 4-20mA channel per product line which allows the console to monitor the pressure

on each product line.

Parameter Parameter Value

Channels Select the number of channels used for LLD.

Name

Enabled Select Yes.

Service Type Select Line Leak Detector. This indicates that the type of device connected to the channel to indicate that the device

Example: 4-20mA Input Module LS-500 Setup

Group Name Parameter Name Parameter Value

4-20mA Input Modules

Module 1 Channels 1

Text box, name each channel to easily identify in the mapping.

is a TS-LSU500 transducer.

Channel 1 Name Unleaded Transducer

Enabled Yes

Service Type Line Leak Detector

10

Page 11

Relay Module

The 2A relay module contains 8 separate relays, called relay channels. The 10A relay module contains 6 relay channels.

Each relay is used by the console to turn a specic STP on or off in applications where Turbine Pump Interface (TPI) is not

used.

Parameter Parameter Value

10 Amp Select either yes or no depending upon which type of relay module is used

Channels Select the number of channels that will be used

Name Text box, name each channel to easily identify in the mapping

Enabled Select Yes

Type Submersible Pump

Polarity Normal

Logic OR logic

Physically Wired As Normally Open

Number of Inputs*

Type Module type that the input is on

Channel Specic channel the input is wired to.

* Calculate the total number of inputs that need to turn on the STP:

1 transducer

+ Number of AC inputs for the specic line

+ Any other inputs to operate the STP

= Total number of inputs

1 for transducer plus number of AC inputs for this product, plus any other inputs to operate the submersible pump

Example: Relay Module Setup for STP Control

Group Name Parameter Name Parameter Value

Relay Modules

Module 1 Channels 1

Channel 1 Name Unleaded STP

Enabled Ye s

Type Submersible Pump

Polarity Normal

Logic OR Logic

Physically Wired As Normally Open

Number of inputs 4

Input 1 Type 4-20mA Input Module

Channel Unleaded Transducer

Input 2 Type AC Input Module

Channel Dispenser 1 Unleaded Hook Signal

Input 3 Type AC Input Module

Channel Dispenser 2 Unleaded Hook Signal

Input 4

Type AC Input Module

Channel

Dispenser 3 Unleaded Hook Signal

11

Page 12

Turbine Pump Interface (TPI) Applications

In systems where TPI is used, the relays are not needed for line leak or STP operation. Communication with the FFS

smart controllers is done exclusively by the RS-485 connection. Refer to the Programming Manual for full TPI instructions.

Example: TPI Setup

Group Name Parameter Name Parameter Value

Power Supply

RS-485 Enable Interface Yes

TS-TPI Enable Interface Yes

Controllers A Number of Controllers 3

Controller 1 Name Unleaded Controller

Enabled Ye s

Type Mag/Eco

Address 1

Group 0

Tank 1

Height 5.00 in

* Number of inputs 4

Input 1 Type 4-20 mA Input Module

Channel Unleaded Transducer

Input 2 Type AC Input Module

Channel Dispenser 1 Unleaded Hook Signal

Input 3 Type AC Input Module

Channel Dispenser 2 Unleaded Hook Signal

Input 4 Type AC Input Module

Channel Dispenser 3 Unleaded Hook Signal

* Calculate the total number of inputs that need to turn on the STP:

1 transducer

+ Number of AC inputs for the specic line

+ Any other inputs to operate the STP

= Total number of inputs

Note: Height is the estimated distance from PMA bottom to tank bottom. This distance is used for empty tank and high

water conditions.

12

Page 13

Fuel Management Systems (FMS) Line Application Set-Up

Setting up the lines establishes which transducer and relay is used on the specic line and allows the user to change

certain parameters in the operation of the line leak testing. Make sure the line is holding at or above the minimum required

pressure (see page 5). If the pressure is too low, review the check-valve used, and adjust the pump / pump controller for

proper pressure.

Parameter Parameter Value

Number of lines Number of product lines

Name Text box, name each channel to easily identify in the mapping.

Submersible Pump Module Select either power supply module or relay module depending upon which relay is being used for

pump control, or if TPI is being used. If Power Supply Board is selected and a relay from this power

supply board was associated to a pump, an additional option will show up to indicate if TPI or relay

will be used.

Submersible Pump Channel Select the channel that the submersible controller is connected to.

Transducer Select the transducer installed in the line.

Enabled Select yes

Pressure Up Test Wait Time * Default is 4 Seconds. This is the time that the gauge waits for the line to pressure up above 12 PSI.

Catch Pressure Wait Time * Default is 2 seconds. This is the time the gauge waits after the pump turns off to make sure the

pressure is at least 12 PSI.

Dispenser Pressure Test When selected, this gauge monitors the line pressure while dispensing. If the pressure decreases to

7.5 PSI, the line goes into alarm mode. The pump shuts off and is disabled.

Gross / Monthly / Annual Tests

Enable

Wait Period Between Tests Default setting is 0 days. (This is the scheduling for line test after the test passed).

Shutdown on Test Fail If selected, this will shut down the submersible if that line fails that type of test

Select Yes. This allows the LS500 to run the tests.

* These settings typically will not need to be changed. Contact FFS tech support before changing these settings.

Example: LS500 Application Setup

Group Name Parameter Name Parameter Value

Lines Number of lines 3

Line 1 Name Unleaded Line

Submersible Pump Module Relay Module

Submersible Pump Channel Unleaded STP

Transducer Unleaded Transducer

Enabled Ye s

Pressure Up Test Wait Time 4 Sec

Catch pressure Wait Time 2 Sec

Dispenser Pressure Test Yes

Gross Tests Enable Yes

Monthly Tests Enable yes

Wait Period Between Passed Tests 0 Days

Shutdown on Failed Test

Enable Yes

Annual Tests

Wait Period Between Passed Tests 0 Days

Shutdown on Failed Test

Note: Do not enable the line in set-up until the transducers have been properly connected to the 4-20 Input Module.

13

Page 14

Line Status and Control Screens

The status of each line channel can be viewed at any time by navigating to the Line Status or Control screens. To get to

the Line Status or Control screens, go to FMS > Status > Lines or FMS > Control > Lines.

LS500 Status Screen

The status of each line can be viewed at any time by navigating to the line status or control screens.

Status and alarm Indicators Description

Status Indicates the condition of the line

Line Pressure Indicates the current line pressure

Enabled Green, enabled. Red, disabled

Not Learned Red, if not learned. Gray, if learned

Pump Shutdown Red, if pump is shutdown. Gray, if not shutdown

Alarm Red, if in alarm. Gray, if not in alarm

Running Gross Leak Test Green, if running test. Gray, if not running test

Running Monthly Leak Test Green, if running test. Gray, if not running test

Running Annual Leak Test Green, if running test. Gray, if not running test

Between Test Green, if running test. Gray, if not running test

Waiting out Thermal Green, if waiting out thermal, Gray, if not

Transducer Failure Red, if the LS-500 is not communicating with the transducer

Pump On Green, if the STP is on

Pump Request The LS-500 is attempting to turn the STP on

When viewing the Line Status Summary screen, remember to enable Auto Refresh. The Auto Refresh button will allow the

on-screen results to be automatically updated. The screen update depends on the user-dened parameter Refresh Rate

found on the Conguration page.

The Line Control screen will automatically update line information. Administrator privileges will be necessary to use the

Line Control screen. For instructions on FMS programming or on how to obtain an Administrator access level, please refer

to the T5 Series FMS Programming Guide (p / n 000-2142) or the TS-550evo FMS Programming Guide (p/n 000-2173).

14

.

Page 15

LS500 Control Screen

Status Section

Indicator Description

Line Pressure Indicates the current line pressure

Enabled Green, enabled. Red, disabled

Not Learned Red, if not learned. Gray, if learned

Pump On Green, if the STP is on

Alarm Red, if in alarm. Gray, if not in alarm

Control Section

Enable/Disable Manually enable or disable the line

Reset Alarm Manually reset an alarm on the line

Reset Line Manually reset line

Force Gross Leak Test Manually start a gross leak test

Force Monthly Leak Test Manually start a monthly leak test

Force an Annual Leak Test Manually start an annual leak test

Learn Section

Start/Stop Manually start or stop the learn cycle

Learn Message Indicates the status of the learn process

Learn Mode Active Green: The line is being learned

Learn Mode Error Red: An error has been detected in learning the line

Indicator Description

Indicator Description

15

Page 16

Pre-Operational LS500 Testing

The line stability test procedure assumes that all STP’s, pump controllers, and AC inputs have been installed,

wired, calibrated and are operational and in accordance with their respective installation and operation

procedures. It also assumes that all T5 Series FMS console programming has been completed accurately.

Caution

Note: State and / or local laws may require a separate, more stringent manual line tightness test.

Before installing the LS-500, ALWAYS verify and comply with local regulations.

Note: The STP connected to the line being tested will need to be activated by lifting the appropriate product dispenser

handle. Verify that all STP’s and pump controllers are installed, calibrated and operational.

Note: The lines must be able to reach 20 PSI. If the lines cannot reach 20 PSI, the issue needs to be resolved or the

LS500 will not work in that STP.

DO NOT proceed to the Learn Process until each line successfully completes pre-operational

testing. Failure to perform this test or ignoring any failed tests may prevent the FMS application

from detecting a line leak.

Required Equipment

• LS 500 3.0 GPH Leak Generator Kit (TSP-ALCAL)

• Needle Valve Kit (TS-ALNIP)

• Pressure gauge

• Approved safety container

Line Stability Test

Perform the following steps for each line.

1. Install the needle valve kit, pressure gauge and leak generator into the STP manifold. Purge the line by

dispensing from each fueling point starting with the dispenser furthest from the tank. The STP should be running

the full time that the line is purged.

2. Once the line is purged, turn the STP off and monitor the pressure on the pressure gauge. The pressure should

not change more than 5 PSI (34.5 Kpa) in 5 minutes. If it does not change more than 5 PSI in 5 minutes proceed

to the learn process. If the pressure changes more than 5 PSI purge the lines again, and re-test.

16

Page 17

Learn Process

Each line must be learned before the FMS system can continuously monitor it. Learning involves bleeding the line

pressure down to zero, with no air in the line, then introducing a calibrated leak, facilitated by the leak generating kit (TSALCAL). The system learns this pressure decay curve and uses it to compare test data during continuous operation to

determine if there is a leak in the line.

Note: All console programming must be completed prior to the learn process. Refer to the Setup (Console Programming)

chapter in this manual for details. Administrator privileges are necessary to Learn Lines. Refer to T5 Series FMS

Programming Guide (p / n 000-2142) or the TS-550evo FMS Programming Guide (p/n 000-2173). for information on

gaining Administrator privileges.

Note: Complete the Pre-Operation Line Testing chapter prior to starting the Learn Process.

Note: No dispensing can take place during the Learn Process. If product is dispensed while Learning, stop the process

by pressing the Stop button.

Note: DO NOT submerse or block the TS-ALCAL orice while learning the line. The orice MUST be kept free of dirt and

debris.

When to Learn / Re-Learn

• Line installation and start-up

• After repairs or modications that effect the operating or holding pressure of the line

• After 4-20mA Input Module replacement

• After certain 4-20mA Input Module rmware upgrades (consult FFS Technical Services Department)

• If moving the LS-500 to another 4-20mA channel

TS-ALCAL

TS-ALNIP

Place a container to

catch the product

Figure 4 – Leak Generator Kits

Procedure

1. The needle valve kit (TS-ALNIP) and 3.0 GPH Leak Generator (TSP-ALCAL) should be installed in the STP

manifold. The line must be purged of all air prior to learning the line.

2. Open the needle valve with the leak generator in an approved container to catch any product. Let the line

pressure bleed down to 0. Make sure that the pressure reads 0 on the pressure gauge installed on the needle

valve kit.

3. Navigate to the line control screen on either the touch screen or by the web page. Locate the learn section and

press start.

4. If the learn process is performed correctly the screen will show the events in the following sequence,

• Learning zero offset

• Turn the STP on

• Learn pump pressure

• Learn the pressure decay curve

17

Page 18

5. When nished, the message Learn Completed – No Errors is displayed on-screen and the Not Learned indicator

will become inactive.

Note: If any errors are encountered at any time during the Learn Process, the screen will display the applicable error

message and the Not Learned indicator will remain active. Refer to the Alarms chapter of this guide for information

on troubleshooting any errors that are displayed.

6. Once the line has been successfully learned, the line will automatically be enabled. Leave the leak generator

open. The console will automatically begin a gross leak test. If the line was learned properly it will detect the leak

and positive shutdown will occur after the 2nd failed 3 GPM test (Approximately 10 minutes)

7.

Close the needle valve. To clear the alarm, navigate to the line control screen and choose reset alarm. The console

will ask: Do you also want to enable this line? Select OK. (If you select CANCEL the line will not be enabled) This

will automatically start another gross line test. A 3 gph pass will allow the FMS to continue to monitor the line. If this

test fails, isolate why the test failed, make necessary repairs, and then reset the alarm again.

8. Remove the leak generator and replace the leak generator plug. The needle valve kit should be left installed in the

manifold to easily allow functional testing, and re-learning lines if needed.

Learn Messages

Learn Message Description

Learning 0 offset Displayed when the console is calibrating 0

Excessive Offset or

Unstable Pressure

Learning pump pressure Displayed when the console is learning the operating pressure

Insufcient pressure STP is not operating at a high enough pressure

No pressure loss Console does not detect a leak

Insufcient volume (line

too small)

Learning pressure decay

curve

Modulus out of range Console detects a pressure drop that is too small

Learned The line has been learned

Pressure is unstable

Console detects a pressure drop that is too great

Displayed during the learn process to indicate that the calibrated leak decay curve is

being recorded

18

Page 19

LS-500 Reports

Line test reports are available on demand from the console or using the web page. The reports can also be generated by

using the rules engine.

Several report options are available to print or save generated reports. For more information on reports in general, please

refer to either the T5 Series Programming Manual (p / n 000-2142) or the T5 Series Operator’s Guide (p / n 000-2151) or

the TS-550evo FMS Programming Guide (p/n 000-2173).

LS-500 Line Leak Reports

LS-500 Line Leak Reports include any line tests completed within the date range chosen by the user. An example of an

LS-500 report can be found below.

Alarms

When a T5 FMS console is in alarm, the Alarm LED on the front of the console will ash. If the line has been programmed

to shut down the pump on failed test (in the FMS Setup), the pump will be unavailable for all system tests and dispensing

until the line with the active alarm is manually reset. If the condition still exists after reset, the alarm will return. A service

visit may be required to identify and correct the condition.

Warning

Note: Refer to the Important Safety Messages outlined in the beginning of this manual before performing any console

maintenance.

Note: If this guide is not able to help you correct a Warning or Alarm, please contact FFS Technical Services

(1-800-984-6266).

Always REMOVE POWER from the console prior to installing/removing a module or performing any

maintenance while the console door is open.

19

Page 20

LS-500 Alarms and Warnings

Alarms During the Learn Process

Alarm Symptom Possible Cause Resolution

Failed to pressure up STP is not turning on Verify that the 4-20 transducer is

a relay / TPI input

Is the pump controller powered

on?

If controlled by a relay, is the

common of the relay wired to 110

Volts?

Is another STP turning on? Check the other STPs

STP is turning on, but

the LS500 doesn’t see

the pressure change

Line is not

congured

Program error

detected

Air in line Console has sensed line

Not learned Learn Line (FMS > Control

Insufcient volume Line is too small

Is the 4-20 transducer in alarm? Check alarms

Is the wrong transducer

mapped?

Is the clamp valve down? Look at the pressure gauge on

Program mapping error Verify programming

Console software error Reboot console

pressure variations

> Lines > Learn) follow learn

procedures

Leak generator not correct

Air in the line

Check the programming

Check the controller

Test the voltage on the relay

common

Check programming

the needle valve kit for operating

pressure

Investigate, then Purge Line Starting

at the Furthest Dispenser

Follow learn procedures

Check line size

Review leak generator set-up

Purge air from the line

Alarms During Operation

Alarm Symptom Possible Cause Resolution

Failed to pressure

up

Pressure was less

that 12 psi after

programmed delay

when STP turned on

STP is not turning on Verify that the transducer is

STP is turning on, but

the LS500 doesn’t see

the pressure change

Clogged STP intake Investigate, force a manual test

and observe pressure

Check the programming

programmed as an input for the

relay / TPI.

Is the pump controller powered onCheck the controller

If controlled by a relay, is the

common of the relay wired to

110 V

Is another STP turning on? Check the other STPs

Is the 4-20 transducer in alarm? Check alarms

Is the wrong transducer mapped Check programming

Test the voltage on the relay

common

20

Page 21

Operating Alarms (Continued)

Catastrophic leak Investigate for leaks

Is the clamp valve down Look at the pressure gauge on

the needle valve kit for operating

pressure

Test Result Condition Possible Cause Resolution

Failed to catch

pressure

Sudden Pressure

Loss

Dispensing Pressure

Test Failed

High Pump Pressure Pressure was above

Extended Hook

Signal

Pressure Transducer

Fail

Air in line Console has Sensed

Not Enabled Line disabled Either manually, or by another

Marginal Pass of

Gross Leak Test

Pump Request

Ignored

4-20 mA Input error Contact Technical Support

Module is Ofine Communication failure

Pressure was less

that 12 psi after

programmed delay

when STP turned off

Pressure dropped to

less than 5 psi

Pressure dropped to

less than 7.5 psi while

dispensing

50 psi during the catch

pressure test 3 times

consecutively

Hook signal was applied

for more than 4 hours

Communication failure

to transducer

Line Pressure Variations

Passing result of gross

test, but marginally

STP did not turn on

when requested

between the control

module and the module

ofine

Check valve damaged Investigate, force a manual test

and observe pressure

Dispenser solenoid is still open

after hook signal is off

Catastrophic leak Investigate for a catastrophic leak

Catastrophic leak Monitor line pressure using a

Dispenser hook signal on steady Verify that all handles are down,

Wiring Check wiring connections at the

Transducer failure Direct connect, if still in alarm,

Line left open or air elimination

loop failing

application shut the STP down

Line is not thermally stable Force a gross leak test

Controller not functioning

System is busy

TPI problem Check RS485 communication

STP is disabled by another

application

Look at module LEDs Red, replace module.

Dispense, release hook, keep

nozzle open

such as a pipe breaking

pressure gauge, investigate for

leaks

Monitor line pressure using a

pressure gauge, investigate for

leaks

Monitor line pressure using a

pressure gauge, investigate for

faulty check valve

test AC inputs to determine which

is giving a signal

console, junction box and quick

disconnect.

replace.

Investigate, then Purge Line

Starting at the Furthest Dispenser

Check other alarms, nd source of

interruption

Green solid or ashing, power

down the console and re-seat the

module

21

Page 22

Test Result Alarms

Test Result Condition Possible Cause Resolution

Pass Line is tight

Fail Actual Leak Line pressure variations are outside

threshold

Temperature Instability Temperature uctuations cause

pressure variances

Inadequate learning Line not properly bled to zero during

learning

Air was not bled out of the line prior

to learning

Air in line Line left open or air elimination loop

failing

Abort (no

indication)

STP Shutdown 2 consecutive 3 GPH test

Dispensing A hook signal was detected, this

resets the testing

Line disabled Either manually, or by another

application shut the STP down

Manual test started User forced a line leak test Cycle resets after manual test

Possible gross leak Investigate, then Force a

failures

1-2 consecutive 0.2 GPH

test fails (depending on

programming)

1-3 consecutive 0.1 GPH

test fails (depending on

programming)

3 consecutive catch pressure

tests that over 50 psi

Catch pressure test failure Pressure was less that 12 psi after

Pressure up test failure Pressure was less that 12 psi after

Possible 0.2 GPH leak Investigate, then Force a

Possible 0.1 GPH leak Investigate, then Force a

High line pressure Investigate, adjust or replace

programmed delay when STP

turned off

programmed delay when STP

turned on

Check for leaks, force leak test

to verify

Check for leaks, force leak test

to verify

Re-learn the line, follow

procedures

Purge the line, re-learn

Purge the line

Allow test cycle to complete

before dispensing

Check other alarms, nd source

of interruption

completes

Manual Gross Test

Manual Monthly Test

Manual Annual Test

check valve or functional

element

Investigate, force a manual test

and observe pressure

Investigate, force a manual test

and observe pressure

Clearing Alarms

Clearing a console of alarms is important because, depending on how the T5 Series FMS console has been set up,

alarms can: disable channels, start an annunciator, or stop a line test under way.

Administrator privileges will be necessary to clear line alarms on the T5 Series FMS console. For instructions on how to

obtain an Administrator access level, please refer to the T5 Series FMS Programming Guide (p/n 000-2142) or the TS-

550evo FMS Programming Guide (p/n 000-2173).

1. Identify the alarm on the FMS Alarms screen.

2. Diagnose the condition using information found in the Alarms chapter of this guide.

3. Follow the troubleshooting steps in the previous section of this chapter to correct the issues indicated by the alarms.

4. Navigate to the Line Control screen.

5. Select Reset Alarms on the Control screen.

6. Select Enable/Disable on the Control screen if you were not given the choice to enable the line when the alarms were

reset.

If the condition still exists, the alarm can take up to several hours to reappear after the line is enabled.

22

Page 23

LS-500 Functional Testing

Perform a Functional Test annually. This test will verify that the LS-500 application will detect and alarm on a leak

condition. This test should be performed during times when there is no dispensing.

1. If the channel is Enabled, disable the channel. At the T5 Series FMS console (via LCD or by the web page), navigate

to the FMS > Lines Control screen. Press the Enable / Disable button to disable the line.

2. Remove the plug in the needle valve kit on the manifold. Connect the TS-ALCAL (Leak Generator Kit) to this port.

3. Open the needle valve.

4. Enable the line. This will initiate a gross line test.

5. Verify that the console displays a gross line test fail. This can take up to 10 minutes.

Note: The system must run two separate tests ve minutes apart and fail them both before a hard alarm occurs.

6. The channel will be disabled by the FMS application. Remove the TS-ALCAL. Replace and tighten the plug.

7. At the T5 Series FMS console (via LCD or by the web page), navigate to the FMS Lines Control screen. Press the

Reset Alarm button to clear the alarm and enable the channel.

8. Select OK when prompted.

9. If the Annual Functional Test passed by properly detecting the leak, please skip this step. If the system did not catch

the leak and the test failed, disable the channel and run the pre-operational tests. Perform the functional test again. If

the system still fails to detect the leak, please contact FFS Technical Support (1-800-984-6266).

Enabling/Disabling Lines

After learning the line(s), each line will need to be enabled to allow monitoring. The Line Status reects the current status.

Enabling Lines

At the T5 Series FMS console (LCD or by the web page), navigate to the FMS Control screen. Press the Enable / Disable

button to enable the line.

Only while the line is enabled will it continuously monitor and test pressure levels by activating the STP as necessary.

Disabling Line Channels

At the T5 Series FMS console (LCD or by the web page), navigate to the FMS>Lines Control screen. Press the

Enable / Disable button to disable the line.

Important: While the line is Disabled, FMS will neither maintain nor test line pressure levels.

If alarms or errors occur, please refer to the Alarms chapter of this guide.

23

Page 24

©2012 FFS 000-2145 Rev.E

Loading...

Loading...