Franklin Fueling Systems HEALY VP1000-220-IC User Manual

Vapor Recovery Assist System

Manual for 220 Volt Integrated Control Applications

VP1000-220-IC

Manual # Revision Date Changes from previous revision

405177002 3 March 2012 Removed pipe tape material brand reference

Franklin Fueling Systems • 3760 Marsh Rd. • Madison, WI 53718 USA

Tel: +1 608 838 8786 • 800 225 9787 • Fax: +1 608 838 6433 • www.franklinfueling.com

Contents

Important Safety Messages ............................................................................................ 3

Introduction ......................................................................................................................4

Description of Operation ................................................................................................4

Vacuum Pump Features ........................................................................................................4

Preparation.......................................................................................................................5

Parts List .................................................................................................................................5

Tools Required ........................................................................................................................ 7

Dispenser Access ................................................................................................................... 7

Before Mounting the Vacuum Pump ....................................................................................... 7

Installing the VP1000-220-IC System ............................................................................. 8

Mounting the Vacuum Pump & Electrical Conduit Assembly ..................................................8

Non-Hazardous Wiring Installation ............................................................................... 9

Installing Dispensing Hanging Hardware .................................................................... 11

Hose Adapters ...................................................................................................................... 11

Testing the System ........................................................................................................ 11

VP1000-220-IC Troubleshooting ..................................................................................11

VP1000-220-IC Vane & Rotor Service & Replacement Guide ....................................12

Start-Up / New Installation / Warranty / Annual Testing Form ..................................... 13

2

Important Safety Messages

Franklin Fueling Systems (FFS) equipment is designed to be installed with volatile hydrocarbon liquids such as gasoline.

Installing, servicing, or testing this equipment means working in an environment where these highly ammable liquids may

be present. Working in such a hazardous environment presents a risk of severe injury or death if these instructions and

standard industry practices are not followed. Read and follow all instructions thoroughly before installing or working on

this, or any other related, equipment.

Warning

Warning

Warning

Follow all applicable codes governing the installation and servicing of this product and the entire system.

Always lock out and tag electrical circuit breakers while installing or servicing this equipment and any

related equipment. A potentially lethal electrical shock hazard and the possibility of an explosion or re from

a spark can result if the electrical circuit breakers are accidentally turned on during installation or servicing.

Please refer to the appropriate documentation for any other related equipment for complete installation and

safety information.

Follow all federal, state and local laws governing the installation of this product and its associated systems.

When no other regulations apply, follow NFPA codes 30A and 70 from the National Fire Protection

Association. Failure to follow these codes could result in severe injury, death, serious property damage

and/or environmental contamination.

Always secure the work area from moving vehicles. The equipment in this manual is usually mounted in

dispensers, so reduced visibility puts service personnel working on this equipment in danger from moving

vehicles entering the work area. To help eliminate these unsafe conditions, secure the area by using a

service truck to block access to the work environment, or by using any other reasonable means available to

ensure the safety of service personnel.

3

Introduction

This procedure describes the tools, methods, and skill

levels required to install a Healy Systems, Inc. Model

VP1000-220-IC Vapor Recovery Pump in existing or

reconditioned dispensers. Only Healy trained and certied

contractors may perform these retrots or the warranty will

be voided. The installer must also be a skilled petroleum

technician and thoroughly familiar with federal and local

code requirements for the installation and repair of

gasoline dispensing equipment. In addition, they shall be

aware of all the necessary safety precautions and site

safety requirements in order to assure a safe, trouble-free

installation.

Description of Operation

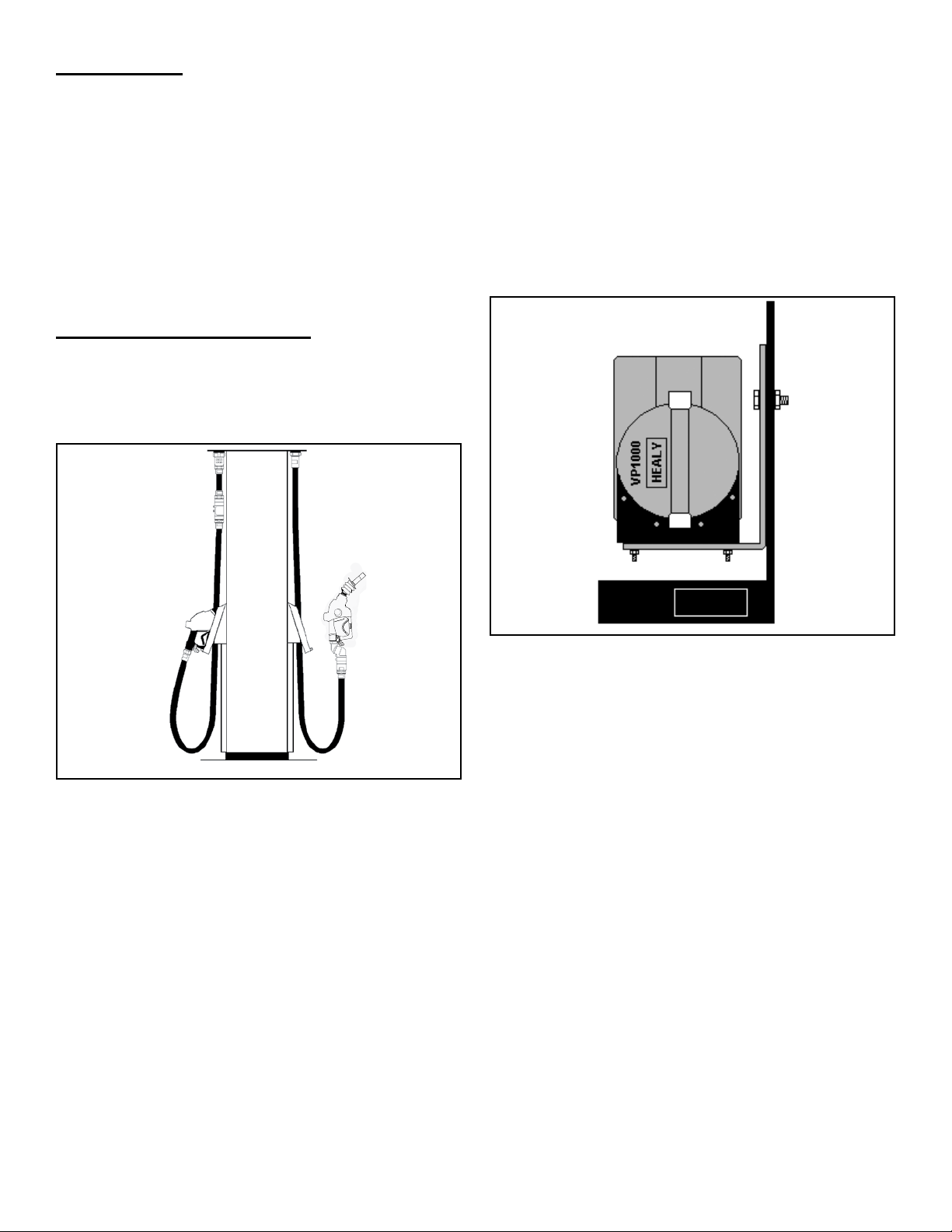

The Healy Systems VP1000-220-IC Vacuum Pump

is typically mounted in the lower hydraulic area of a

dispenser or self-contained gasoline pump. It works as

a component of a complete Stage II system which also

includes Healy hanging hardware (Figure 1).

Vacuum Pump Features

• Operates at two speeds: Low Speed if one fueling point

has been activated, or High Speed if both fueling points

are activated simultaneously.

• Contains performance protection devices that will shut

off the vacuum pump and disable dispensing if the

vacuum pump is not operating properly.

• Contains internal control and operates as a ‘stand alone’

Vacuum pump.

• Contains low temperature activation circuits that turn the

vacuum pump on at slow speed when the temperature

drops below 40° F (4º C) to prevent freezing.

IN

Figure 1: Hanging Hardware

It is intended for use by either OEM dispenser / pump

manufactures or as an aftermarket retrot to make existing

equipment compatible with Healy Systems technology.

Specications: 1/8 Hp, 220 VAC input, 2 Amp AC

Note: All electrical and hydraulic plumbing ttings referred

to in these instructions must be UL “listed” or

“recognized”.

OUT

Figure 2: VP1000-220-IC Typical Mounting

Note: The VP1000-220-IC will increase the current draw

of the dispenser by 2 amps.

The preferred mounting position of the VP1000-220-IC

Vacuum Pump is with the vacuum pump inlet and electrical

connections facing upwards, towards the top of the

dispenser (see Figure 2 below). If other mounting positions

are desired because of mechanical constraints within

the dispenser, please contact FFS Technical Services at

1-800-984-6266.

4

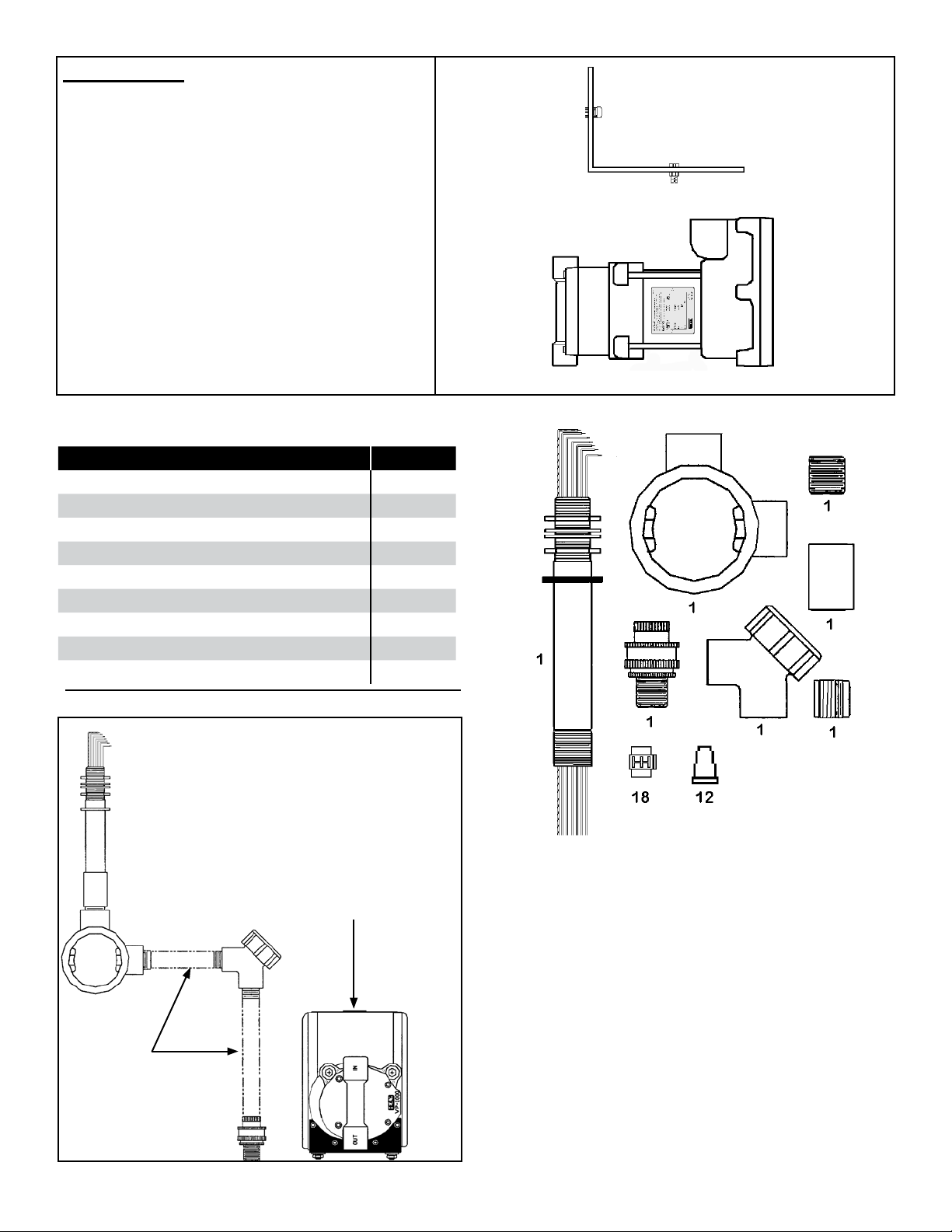

Preparation

Parts List

This section illustrates the basic components needed

to retrot a VP1000-220-IC Vacuum Pump into any

new, replaced, retrotted, or reconditioned dispenser.

This system can be installed in any “Non-Vapor

or Vapor Ready” dispenser including dispensers

with existing “Balance” or “VacAssist” piping. Three

items are required for complete retrot installations:

VP1000-220-IC, Vapor kit, and Electrical kit. Other

supplies beyond these items may also be needed to

complete your installation (i.e. electrical nipples and,

possibly, additional vapor connections).

Assorted lengths of “UL Listed” electrical nipples as

well as pipe or electrical elbows and couplings will be

required to complete vacuum pump installation.

Figure 3: VP1000-220-IC Mounting Parts

Electrical Kit Z069E for 220VAC Applications

Part Quantity

Explosion Proof Junction Box 1

Capped 90° Elbow 1

1/2" Union 1

Potted Conduit Nipple 1

1/2" x 3/4" Reducing Bushing 1

3/4" Coupling 1

3/4" Close Nipple 1

Electrical Wire Nuts 12

Scotchlok

™

Wire Connectors 18

Mounting Bracket & Hardware

VP1000-220-IC Vacuum Pump

1/2" Conduit

supplied by the

Installing Contractor

Electrical Conduit

Connection to the

VP1000-220-IC

Vacuum Pump

Figure 4: Electrical Parts

Figure 5: Universal Electrical Kit Z069E

5

Loading...

Loading...