Page 1

DC400 Dispensing Cutoff System

404-4 Controller

Installation Instructions

Franklin Fueling Systems • 3760 Marsh Rd. • Madison, WI 53718 USA

Tel: +1 608 838 8786 • 800 225 9787 • Fax: +1 608 838 6433 • www.franklinfueling.com

Page 2

Important Safety Messages

Franklin Fueling Systems (FFS) equipment is designed to be installed in association with volatile hydrocarbon liquids such

as gasoline and diesel fuel. Installing or working on this equipment means working in an environment in which these highly

ammable liquids may be present. Working in such a hazardous environment presents a risk of severe injury or death

if these instructions and standard industry practices are not followed. Read and follow all instructions thoroughly before

installing or working on this, or any other related, equipment.

As you read this guide, please be aware of the following symbols and their meanings:

Warning

This symbol identies a warning. A warning sign will appear in the text of this document when a potentially

hazardous situation may arise if the instructions that follow are not adhered to closely. A potentially hazardous

situation may involve the possibility of severe bodily harm or even death.

Caution

Warning

Warning

Warning

Warning

This is a caution symbol. A caution sign will appear in the text of this document when a potentially hazardous

environmental situation may arise if the instructions that follow are not adhered to closely. A potentially

hazardous environmental situation may involve the leakage of fuel from equipment that could severely harm

the environment.

Follow all applicable codes governing the installation and servicing of this product and the

entire system. Always lock out and tag electrical circuit breakers while installing or servicing this

equipment and any related equipment. A potentially lethal electrical shock hazard and the possibility

of an explosion or re from a spark can result if the electrical circuit breakers are accidentally

turned on during installation or servicing. Please refer to the Installation and Owner’s Manual for

this equipment, and the appropriate documentation for any other related equipment, for complete

installation and safety information.

Follow all federal, state and local laws governing the installation of this product and its associated

systems. When no other regulations apply, follow NFPA codes 30A and 70 from the National Fire

Protection Association. Failure to follow these codes could result in severe injury, death, serious

property damage and/or environmental contamination.

Always secure the work area from moving vehicles. The equipment in this manual is usually mounted

underground, so reduced visibility puts service personnel working on this equipment in danger from

moving vehicles entering the work area. To help eliminate these unsafe conditions, secure the area

by using a service truck to block access to the work environment, or by using any other reasonable

means available to ensure the safety of service personnel.

Use circuit breakers for multiple disconnect to turn off power and prevent feedback from other dispensers.

List of Parts

Description Part Number

QTY QuickON Wire connectors 210-0083

Controller 404-4

List of Tools

• Industry-standard, non-sparking tools

• Allen wrench, 19mm

• Conduit and ttings as required, must be UL

listed for use in Class I, Div 1 locations

Junction Box internal volume requirements per conductor:

Size of Conductor (AWG) Free space required for

each conductor (in3)

18 1.5

16 1.75

14 2.0

12 2.25

10 2.5

Determine volume of Junction box. This information may be on the

junction box itself usually expressed in cubic inches. If not, measure the

inside length, width, and depth of the box and multiply these numbers

together. This gives you the free volume of the junction box.

If the junction box is round measure the inside diameter and multiply this

number by itself. Multiply this number by 0.78 and record this answer.

Then measure the depth of the junction box and multiply it by the sum of

your rst answer. This gives the free volume of a cylindrical junction box.

Using the table above, subtract the cubic inches per each conductor

which originates outside the junction box and terminates or is spliced

within the junction box. Each conductor that passes through the junction

box without splice or termination shall be counted once. Refer to

National Electric Code 2011, article 314.16 (B).

2

Page 3

Product Description

The DC400 system uses a sump sensor to detect the

presence of liquid in the STP (Submersible Turbine Pump)

or dispenser sump. If liquid is detected, the system will

shut down power to the STP or dispenser.

The DC400 system consists of the 404-4 Controller and

either a 2-Wire or 3-Wire sensor. Follow these instructions

for installation of the 404-4 Controller. Franklin Fueling

Systems sensors approved for use with the DC400 system

come with their own installation instructions.

Specications:

Input line voltage: 90 – 250VAC 50/60 Hz

404-4 power consumption: 2W

Relay switch conguration: SPST

Relay switch contact rating: 12A continuous, 250VAC

maximum

Operating temperature: -20 to 60 degrees C

Hazardous location

Class I, Div 1, Group D

category:

Refer to Franklin Fueling Systems control drawing 000-1737

Installation for Dispenser Cutoff

Notice! Only qualied service

Warning

Warning

Note: Install this kit ONLY in a UL listed dispenser.

Note: If the is no junction box or open port on the junction

box, you cannot install this kit.

1. Shut off all power to the dispenser. Lock out and

tag the corresponding dispenser circuit breaker.

2. Open / remove the dispenser lower panel for

access to the dispenser hazardous area. Inspect

the hazardous area to locate the dispenser

explosion proof power entry junction box. The 4044 controller will be wired into the dispenser via a

spare conduit hub located on the dispenser power

entry junction box.

3. Determine where to best locate the 404-4

controller and how best to plumb conduit from

the dispenser spare conduit hub to the 404-4

controller. The 404-4 controller must be located

so that regular servicing of the dispenser (such as

changing of fuel lters) will not be impeded. The

404-4 controller can be located in the dispenser

hazardous area or suspended down below the

dispenser in the dispenser sump as room dictates.

Refer to gure 1.

technicians experienced with petroleum

dispensing and pumping systems

should install the DC400 system.

Notice! Do NOT exceed the 12A

(continuous), 250VAC relay contact

rating of this controller. Relay contacts

are not fused.

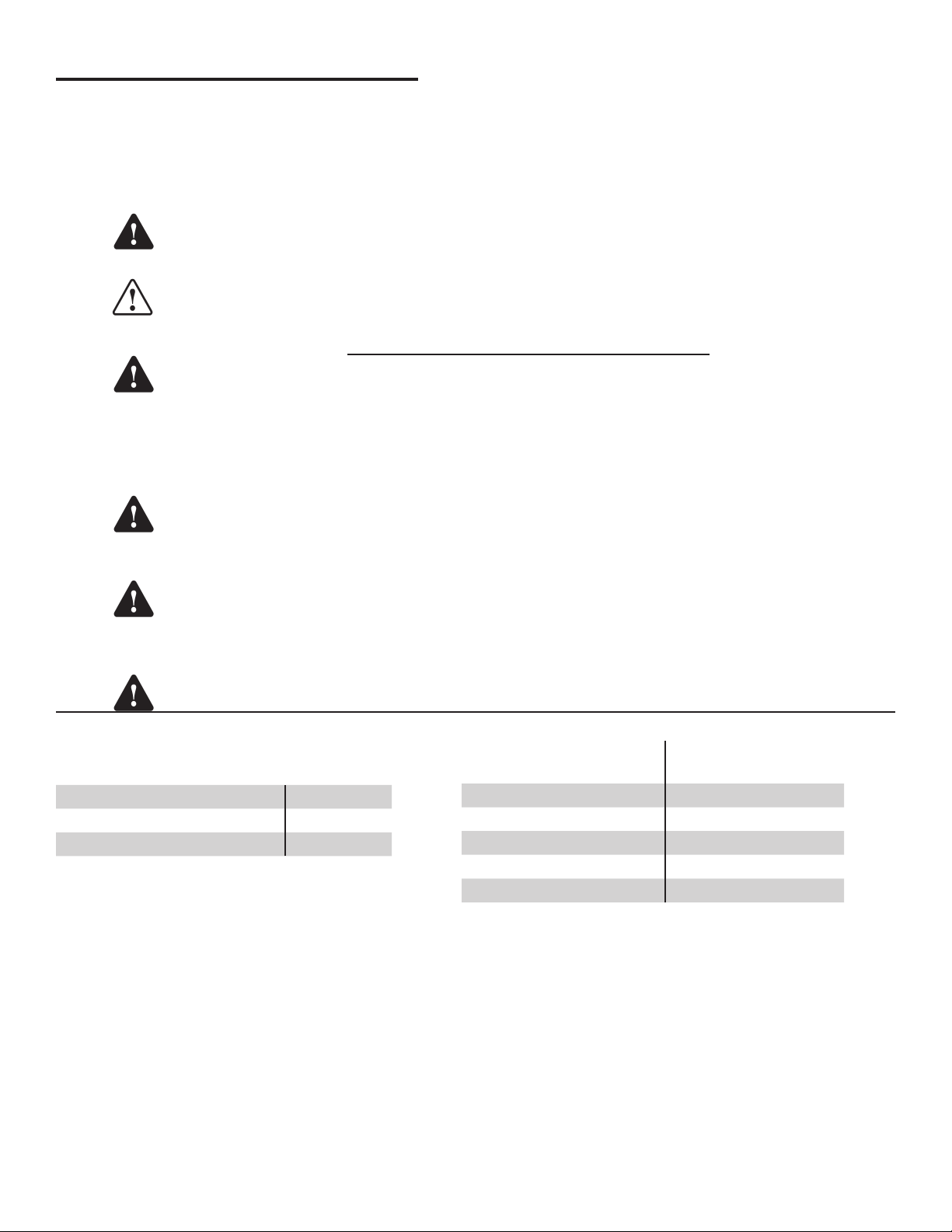

Dispenser

404-4

Controller

Cable Connection

2-Wire or

3-Wire sensor

Figure 1: Typical System Installation in a Dispenser Sump

Note:

Because each dispenser installation is unique it is

Junction Box

EYS

Dispenser

Base

Dispenser

Sump

EYS

impossible to provide a “one size ts all” conduit

tting kit. Necessary explosion-proof conduit and

conduit ttings must be determined and supplied by

the installer. The 404-4 controller conduit size is 3/4”

NPT. Simple ttings such as elbows, sweeps, unions,

and nipples should be used and must be UL listed and

suitable for use in Class I, Div 1, Group D locations.

4. Open the dispenser power entry junction box

cover and retain hardware for later use. Remove

spare junction box plug and plumb explosion-proof

conduit from the spare conduit entry hub to the

404-4 controller power port (the port with 6 wires

protruding). Thread the 6 wires coming out of the

power port of the 404-4 controller through the

conduit to the dispenser power entry junction box.

Important! Be sure installation of conduit, ttings and

wiring is in accordance with local, State and

National electrical codes. A conduit seal must be

installed between the dispenser J-box and the

controller. The conduit seal must be within 18" of

the dispenser J-box and the 404-4 controller. Refer

to NEC NFPA 70, article 501.15 (A) (3), 2011. Make

sure the dispenser power entry junction box has

enough spare room to accommodate the additional

404-4 controller wires (see the table on page 2).

Important! When tightening the conduit to the 404-4

controller, use a wrench on the conduit ttings and

not the 404-4 controller body.

5. Wire the 404-4 power wiring per the schematic

that matches your dispenser listed in Figures

7 - 14. Contact your dispenser manufacturer for a

wiring diagram if you are unsure of the dispenser

input power wiring.

Make sure to connect both ground

Warning

wires and verify they are connected

to earth ground. Failure to do so may

result in a re or explosion hazard in

case of a fault condition.

3

Page 4

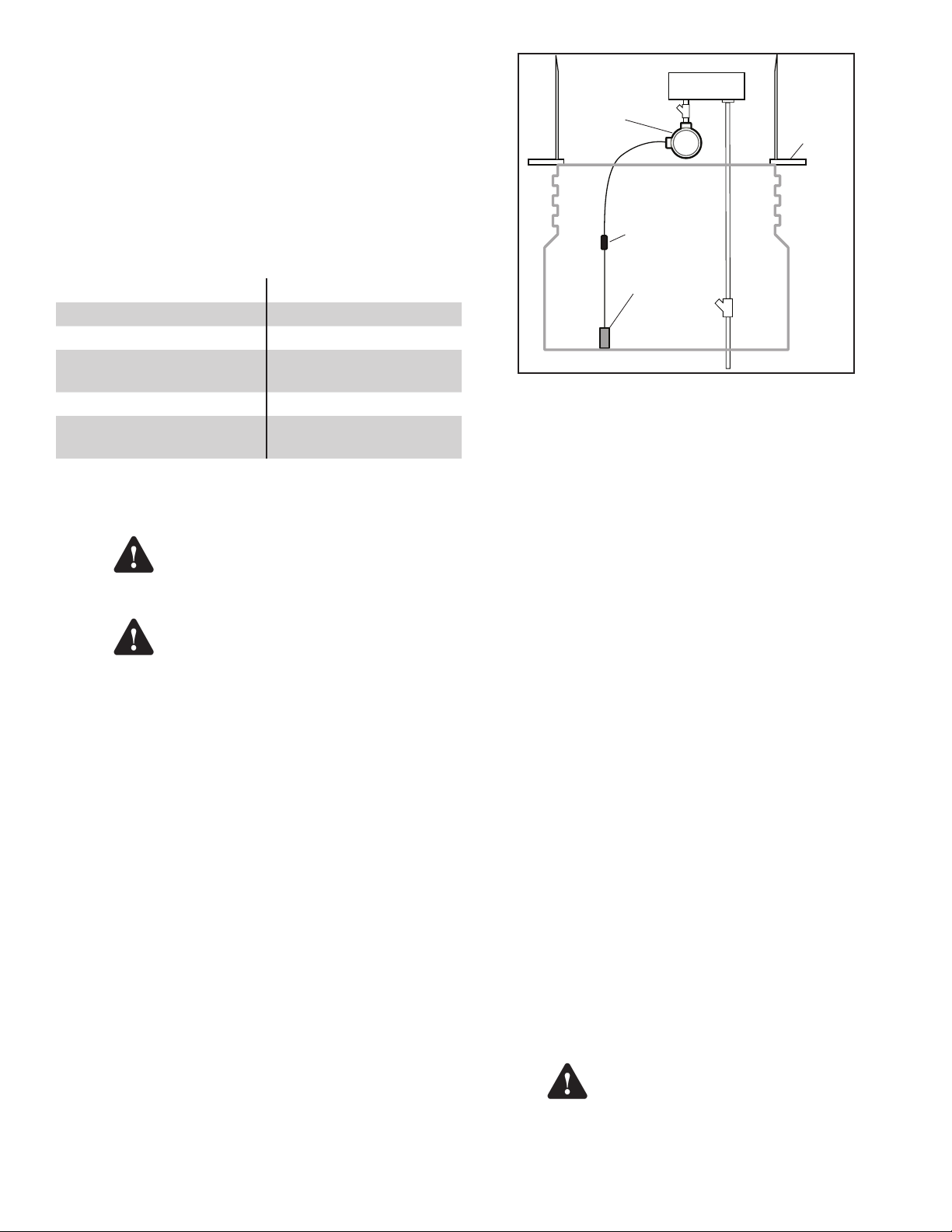

404-4

Controller

To Sensor

Connection

Explosion Proof Union

STP Junction Box Cover

NOTE: Use reducer to connect ¾" conduit

to ½" cover opening.

EYS

6. Connect the sensor wire cable coming from the 404-4 controller to the appropriate Franklin Fueling Systems

sensor. Refer to the sensor’s installation instructions for installation, wiring and testing of the sensor.

The sensor must be installed in accordance with the sensor’s control drawing and with Franklin Fueling System’s control

drawing 000-1737.

7. Double check all dispenser & controller power wiring to be sure it is correct then replace the dispenser power

entry junction box cover. Secure the cover with all of the bolts previously retained.

8. Turn the dispenser power back on. The dispenser should operate normally.

9. Replace and secure lower dispenser door(s).

10. Test the DC400 dispenser cutoff by submerging the sensor in water. The dispenser should shut off and remain off

as long as the sensor is submerged.

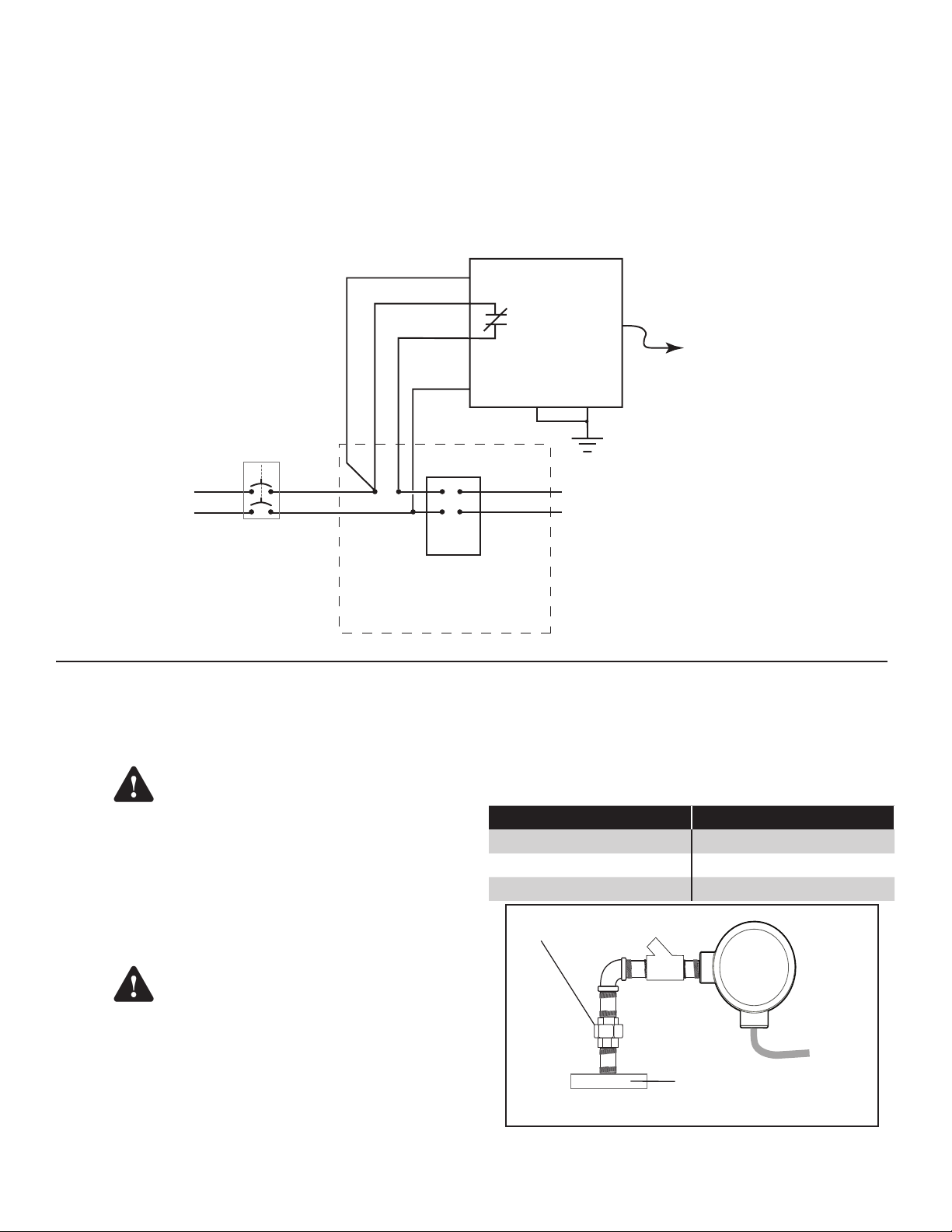

BLK

ORG/BLK

ORG

WHT

Dispenser

Breaker

404-4 Controller

12A, 240VAC

GRN

To Dispenser

Inputs

Sensor

GG

GRN/YEL

To Dispenser Earth Ground terminal

Installation for Submersible Pump Cutoff

Notice! Only qualied service technicians experienced

with petroleum dispensing and pumping systems

should install the DC400 system.

Warning

Notice! Do not exceed the 12 A (continuous), 250 VAC relay

contact rating of this controller. Relay contacts are not

fused. This controller is suitable for most submersible

pumps rated up to 2 hp @ 250 VAC and 1½ hp @

120 VAC. provided the maximum pump motor

service factor amperage is 12A or less. Contact the

submersible pump manufacturer if in doubt.

Warning

1. Shut off power to the STP. Lock out and tag the

2. In pump cutoff installations the 404-4 controller

4

Refer to MFG

wiring schematic

for terminal block /

wire connections

Dispenser Main Junction Box

Figure 2: Power Wiring Schematic for Controller Dispenser Connection

This controller is NOT for use with

3-phase pumps or Variable Frequency

Drive pump installations.

Remove power to avoid possible

electrocution or ignition of explosive

gasoline vapors.

corresponding STP circuit breaker.

will be connected directly to the integral electrical

junction box on the STP via rigid explosion proof

conduit. Since STP sump installations can vary,

the installer will need to determine where best to

place the controller in the sump and then procure

the necessary conduit and ttings.

A typical means of connecting the controller to

an STP via an explosion proof union is shown in

Figure 3. All ttings must be UL listed and suitable

for use in a Class I, Div 1, Group D environment.

If the STP junction box does not have a removable plug or

opening, installation adapters are available as listed below.

Installed STP Installation Adapter

FE Petro TS-FE

Red Jacket TS-RJ

Red Jacket Quantum TS-RJQ

Figure 3: Typical Connection to STP

Page 5

3. Remove the STP junction box cover / plug. Make

Orange / Black

sure the STP junction box has enough room to

accommodate the additional 404-4 controller wires

(see the table on page 2). Thread the six 4044 power wires from the power port through the

conduit ttings and plumb the conduit ttings to

the 404-4 controller. Connect the controller power

wires to the STP wiring as shown in gure 4.

Make sure to connect both ground

Warning

4.

Join the controller conduit to the STP junction

box cover and replace the cover on the STP

and securely tighten. A union will be required to

do this, (see Figure 3). A conduit seal must be

installed between the electrical junction box and the

controller. The conduit seal must be within 18” of

the electrical junction box and the 404-4 controller.

Multiple conduit seals may be required for some

installations, depending upon the ditance between

the electrical junction box and the 404-4 controller.

Refer to NEC NFPA 70, article 501.15 (A) (3), 2011.

5. Connect the sensor wire cable coming from

the 404-4 controller to the appropriate Franklin

Fueling Systems sensor. Reference the sensors

installation instructions for installation, wiring and

testing of the sensor.

6. Turn the STP circuit breaker back on and test

the DC400 system for proper operation. With the

sensor dry, the STP should operate normally.

wires and verify they are connected

to earth ground. Failure to do so may

result in a re or explosion hazard in

case of a fault condition.

7. Next, test the DC400 pump cutoff by submerging

the sensor in water. The pump should shut off and

remain off as long as the sensor is submerged.

(Note: if the pump is controlled and monitored by

an external pump controller or tank gauge, this

device may need to be reset when the sensor is

removed from the water).

STP Electrical

Junction Box

STP Sump

404-4 Controller

2-Wire or

3-Wire Sensor

Figure 5: Typical STP Sump Installation

EYS

L1

From pump

control relay

or contactor

(220 VAC)

L2

Black

Controller

/Relay

White

404-4 Controller

Figure 4: Power Wiring Schematic for STP Connection

N.C.

(When Dry)

* Safety Ground

Orange

Green

STP

* Yellow/Green

Black

5

Page 6

Installation for Alarm Wiring

Important! For all applications, do not exceed the relay

contact rating of 250VAC, 12A.

The relay contacts (Orange / Black and Orange wires)

on the 404-4 controller are normally closed dry contacts

(when power to the controller is applied) that will open

when liquid is detected. This enables the DC400 to be

wired for various alarm notication and monitoring.

Figure 6 shows an example of alarm wiring for applications

that do not require positive shutdown but simply some sort

of visual and / or audible notication. In this example the

alarm light illuminates when the DC400 detects liquid.

404-4 Controller

Contacts

120 VAC

Testing

Test the function of the system according to applicable

codes. Test immediately after installation, and at least

annually to verify proper system operation.

Troubleshooting

If the controller relay repeatedly cycles or oscillates

when the sensor is tripped, it is likely that the controller is

switching its own power. Check the wiring diagram and

conrm that the controller is wired properly. Make sure that

the orange / black, red and black wires are tied to power

from the breaker and the orange wire feeds the dispenser.

If problems continue, please contact FFS Technical

Support at 800-984-6266.

N.C.

Orange / Black

120 VAC

Neutral

Figure 6: Wiring Example for Non-Positive Shutdown

Orange

External

120 VAC

Relay Coil

120 VAC

Alarm Pilot Light

N.C.

Neutral

6

Page 7

Dispenser-Specic Wiring

404-4 Controller

12A, 240VAC

H

120-240VAC

N

GRN

Dispenser

Breaker

ORG/BLK

ORG

BLK

WHT

1

2

3

4

5

6

7

8

9

10

11

12

W-V

Main Junction Box

Figure 7: 404-4 Wired to a 120V Dresser-Wayne Vista 3 Series Dispenser

Sensor

GG

GRN/YEL

Sensor

404-4 Controller

12A, 240VAC

120-240VAC

GG

GRN/YELGRN

H

N

ORG/BLK

ORG

BLK

WHT

Junction Box

W-BN

W-R

BK

W-BK

Line

N

Dispenser Control

Power

Figure 8: 404-4 Wired to a Dresser Wayne Ovation Dispenser

W

BNVV

Y

7

Page 8

Dispenser

Breaker

404-4 Controller

ORG/BLK

12A, 240VAC

ORG

BLK

H

120-240VAC

WHT

Line

N

GRN

Neutral

Earth Ground

Main Junction Box

Figure 9: 404-4 Wired to a Gilbarco Eclipse Dispenser

GG

GRN/YEL

Sensor

Line

Neutral

Earth Ground

Dispenser

Breaker

Field Conduit

BLK

WHT

GRN/YEL

Main Junction Box

ORG/BLK

ORG

WHT

BLK

H

N

A-10

404-4 Controller

12A, 240VAC

120-240VAC

GRN

A-2

A-13

Sensor

GG

GRN/YEL

Main Conduit

BLK

WHT

GRN/YEL

Electronics Cabinet

(CD Module)

Figure 10: 404-4 Wired to a Gilbarco Encore 300 or 500 Dispenser

8

Page 9

Dispenser

Breaker

Main Junction Box

BLK - ACH

BLK

ORG/BLK

ORG

WHT

BLK - ACH

404-4 Controller

12A, 240VAC

120-240VAC

GRN

Sensor

GG

GRN/YEL

Dispenser

Breaker

WHT - ACC

WHT - ACC

Figure 11: 404-4 Wired to a Tokheim 262 or 262A Dispenser

Dispenser Junction Box

BLK

ORG/BLK

ORG

WHT

UDC - ACH

9

120-240VAC

404-4 Controller

12A, 240VAC

GRN

Sensor

GG

GRN/YEL

UDC - ACC

10

Figure 12: 404-4 Wired to a Tokheim Premier Dispenser

9

Page 10

Page intentionally blank

10

Page 11

Page intentionally blank

11

Page 12

©2011 000-0316 Rev A

Loading...

Loading...