Page 1

Colibri

Tank Monitoring System

CL6 Series

Set-Up and Operator’s Guide

Franklin Fueling Systems • 3760 Marsh Rd. • Madison, WI 53718 USA

Tel: +1 608 838 8786 • 800 225 9787 • Fax: +1 608 838 6433 • www.franklinfueling.com

Page 2

Important Safety Messages

This equipment is installed close to gasoline and diesel fuel. Working in such a hazardous environment presents a

risk of severe injury or death if these instructions and standard industry practices are not followed. Read and follow all

instructions thoroughly before installing or working on this, or any other related, equipment.

Be aware of the following symbols and their meanings:

A warning sign will appear in the text of this document when a potentially hazardous situation may arise if the

Warning

Caution

Danger

instructions that follow are not adhered to closely. A potentially hazardous situation may involve the possibility

of severe bodily harm or even death.

A caution sign will appear in the text of this document when a potentially hazardous environmental situation

may arise if the instructions that follow are not adhered to closely. A potentially hazardous environmental

situation may involve the leakage of fuel from equipment that could severely harm the environment.

An electrical danger sign will appear in the text of this document when a potentially hazardous situation

involving large amounts of electricity may arise if the instructions that follow are not adhered to closely. A

potentially hazardous situation may involve the possibility of electrocution, severe bodily harm, or even death.

Alarms and warnings alert you with specic details when a problem occurs so you can take corrective

action. System hardware failure warnings and tank leak alarms can be programmed to do many things.

The events that require programming are denoted by a (p) below:

- cause the red Alarm light or yellow Warning light to ash (standard)

- activate / sound the console annunciator alarm horn (p)

- activate internal output relays for external alarm devices (p)

- print alarm reports automatically via attached USB printer (USB - HP compatible printer) (p)

- send alarm and test reports to a specied email address (p)

Warning

Warning

Warning

Warning

Warning

Warning

Follow all applicable codes governing the installation and servicing of this product and the

entire system. Always lock out and tag electrical circuit breakers while installing or servicing

this equipment and any related equipment. A potentially lethal electrical shock hazard and the

possibility of an explosion or re from a spark can result if the electrical circuit breakers are

accidentally turned on during installation or servicing. Please refer to the Installation and Owner’s

Manual for this equipment, and the appropriate documentation for any other related equipment, for

complete installation and safety information.

Follow all federal, state and local laws governing the installation of this product and its associated

systems. When no other regulations apply, follow NFPA codes 30, 30A and 70 from the National Fire

Protection Association. Failure to follow these codes could result in severe injury, death, serious

property damage and/or environmental contamination.

Always secure the work area from moving vehicles. The equipment in this manual is usually

mounted underground, so reduced visibility puts service personnel working on this equipment in

danger from moving vehicles entering the work area. To help eliminate these unsafe conditions,

secure the area by using a service truck to block access to the work environment, or by using any

other reasonable means available to ensure the safety of service personnel.

When the Fuel Management System is used to monitor tanks containing gasoline or other

ammable substances, you may create an explosion hazard if you do not follow the requirements in

this manual carefully.

All wiring must enter the console’s enclosure through the designated knockouts. An explosion

hazard may result if other openings are used.

You must run wiring from probes to the Fuel Management System console in conduits which are

separate from all other wiring. Failure to do so will create an explosion hazard.

2

Page 3

Contents

Important Safety Messages ............................................................................................2

Basic Console Operation ................................................................................................3

LCD Layout ............................................................................................................................. 3

Set up Preferences ..........................................................................................................6

Set up Conguration .......................................................................................................6

Entering Setup .................................................................................................................8

System ID ...............................................................................................................................8

System Conguration .............................................................................................................8

Probe Modules ........................................................................................................................8

Relay Modules ........................................................................................................................ 8

Dispenser Interface .................................................................................................................9

Setup-Fuel Management System ................................................................................. 11

Static Tank Testing ................................................................................................................ 12

Tanks ....................................................................................................................................12

Tank# Probe ................................................................................................................................ 13

Tank# Limits ................................................................................................................................ 13

Special tanks ........................................................................................................................13

Manifolds ..............................................................................................................................14

Products ................................................................................................................................14

Grades .................................................................................................................................. 14

Reconciliation .......................................................................................................................14

Autocalibration ...................................................................................................................... 14

E-mail Setup ...................................................................................................................15

System Sentinel AnyWare ............................................................................................15

Rules ...............................................................................................................................16

List of Default Rule Entries ................................................................................................... 16

Operation ........................................................................................................................17

Check Inventory .................................................................................................................... 17

Check Deliveries ................................................................................................................... 17

Alarms ...................................................................................................................................18

Print Reports ......................................................................................................................... 18

Web Browser Interface ..................................................................................................19

Connecting to the Console ...................................................................................................19

Web Interface Available Pages ............................................................................................. 21

Appendix A: List of Alarms ...........................................................................................22

Appendix B: Standard Tank Table ............................................................................... 25

Appendix C: Compatible Printers ................................................................................ 27

Appendix D - Standard Products Table ....................................................................... 27

Appendix E - Typical Tank Leak Test Times ................................................................27

Appendix F - Using the Console’s Autocalibration Feature ...................................... 28

3

Page 4

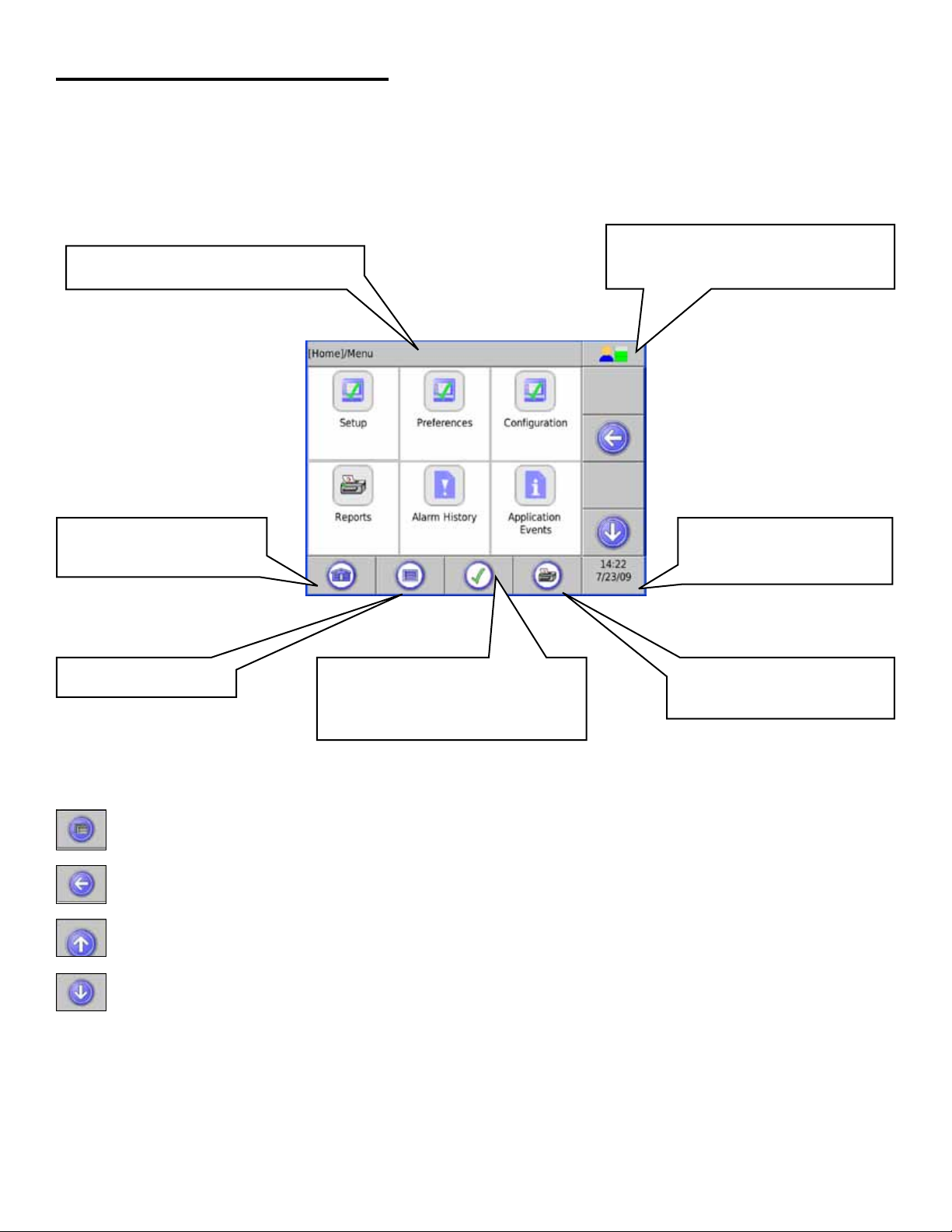

Basic Console Operation

The console can be operated through the LCD touch screen or the Web Browser Interface via a Personal Computer.

Refer to to page 16 for Web Browser Interface setup.

LCD Layout

The LCD interface allows the user to enter on-screen information.

User Role – Displays and allows

Path Bar – Shows the path / description

of information displayed.

changing the access level of the

current user

Home – Goes to the home

summary screen.

Main Menu – Access the

Application Menu.

Status:

ü = No Alarms.

! = Alarm. For alarms: press this to

go to the alarms page.

Date/Time – Press this to

change Time / Date settings.

Print Report – Pressing this

button will take you to a menu

of reports.

Navigation Buttons

The navigation buttons are on the right side of the LCD touch screen. These change depending upon the application.

FMS: FMS Function Menu

Back: Reverts to the previous screen.

Scroll Up: Indicates that more menu options are available above current view.

Scroll Down: Indicates that more menu options are available below current view.

4

Page 5

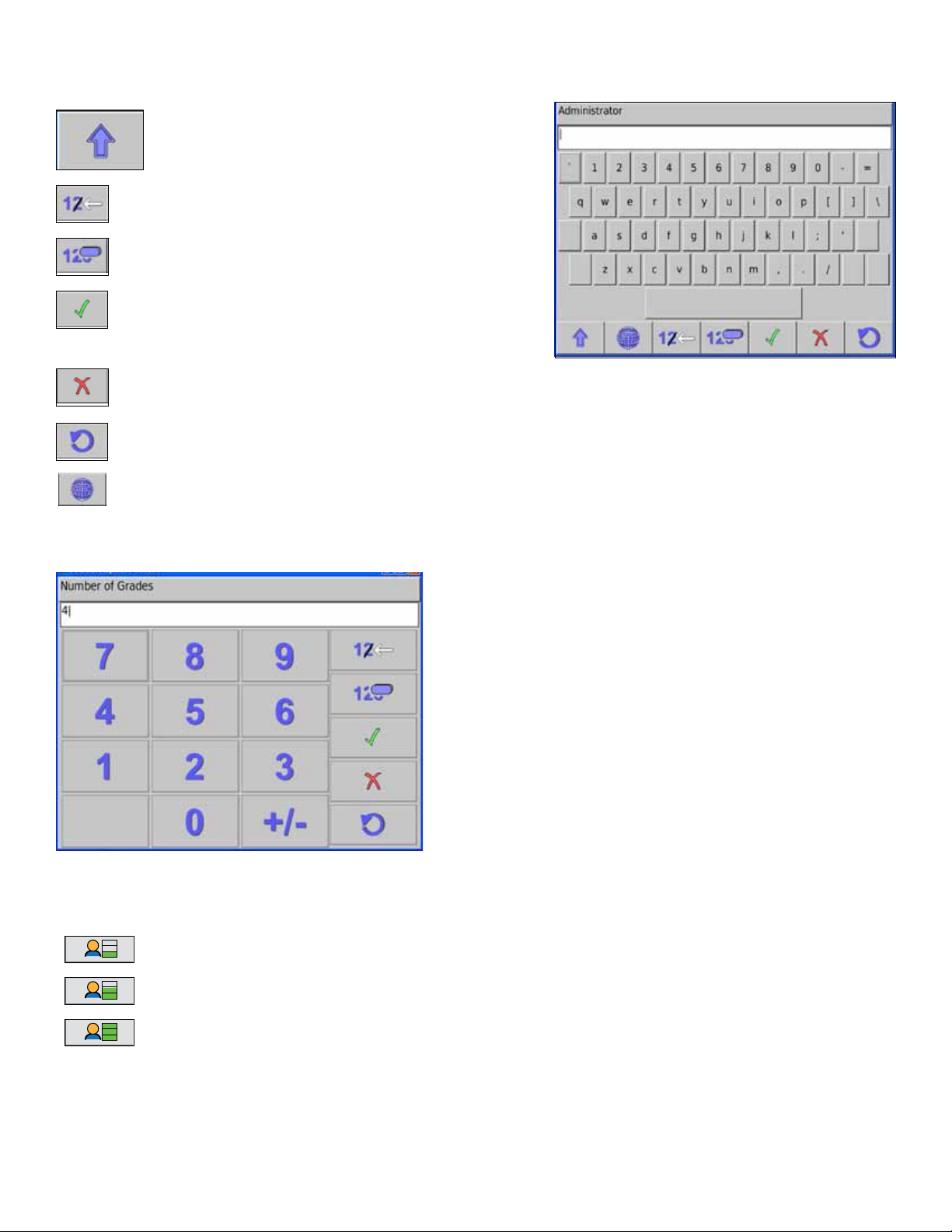

Data Entry

If you are prompted to enter information, a keypad and edit buttons will be displayed.

Character Selection: Selects between upper case

letters, lower case letters and numerals.

Backspace: Deletes the previous character.

Clear: Deletes data from the entry line.

Enter: Accepts the choice.

Cancel: Returns to the application and no changes will be made to console settings.

Restore Default: This will restore the original settings programmed into the console.

Alternate Characters: Shows accented characters

Number Entry

A screen like that below is used when number information is needed.

Security Access Control

Guest Monitor system status

User Perform system control.

Administrator Modify system setup, plus all

functions listed above

Note: For increased security, it is strongly suggested to change the default passwords (see page 6).

5

Page 6

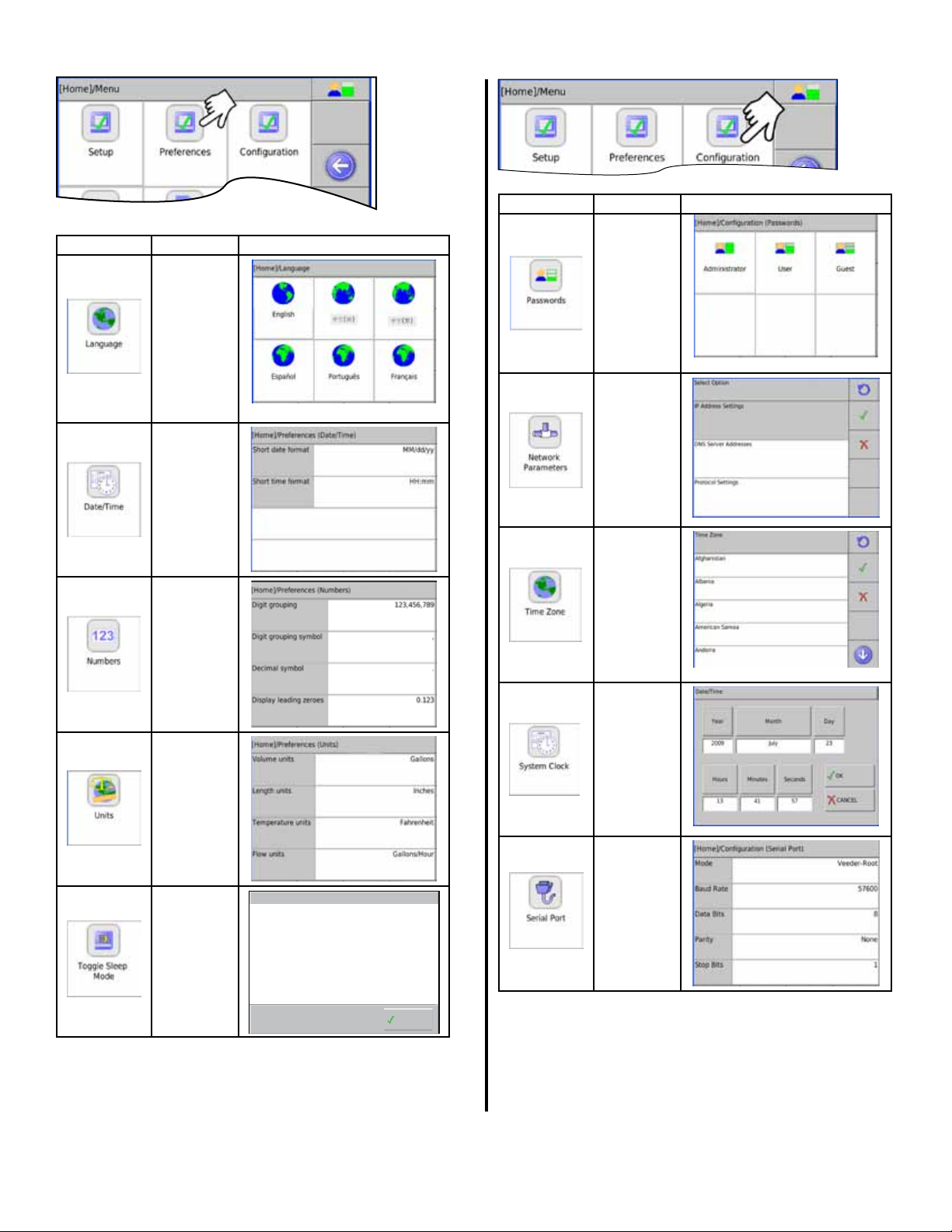

Set up Preferences

Set up Conguration

Display Description Values

Choose

language

for console

menus.

Choose date

and time

display format

Choose

format of

numbers

Display Description Values

Choose

passwords for

access

Set Network

Parameters

Choose

location for

correct time

zone

Set system

time and date

Choose units

of measure

Enables

blank screen

saver

Notification

Sleep Mode is now Enabled

OK

Set Serial

Port

Parameters

6

Page 7

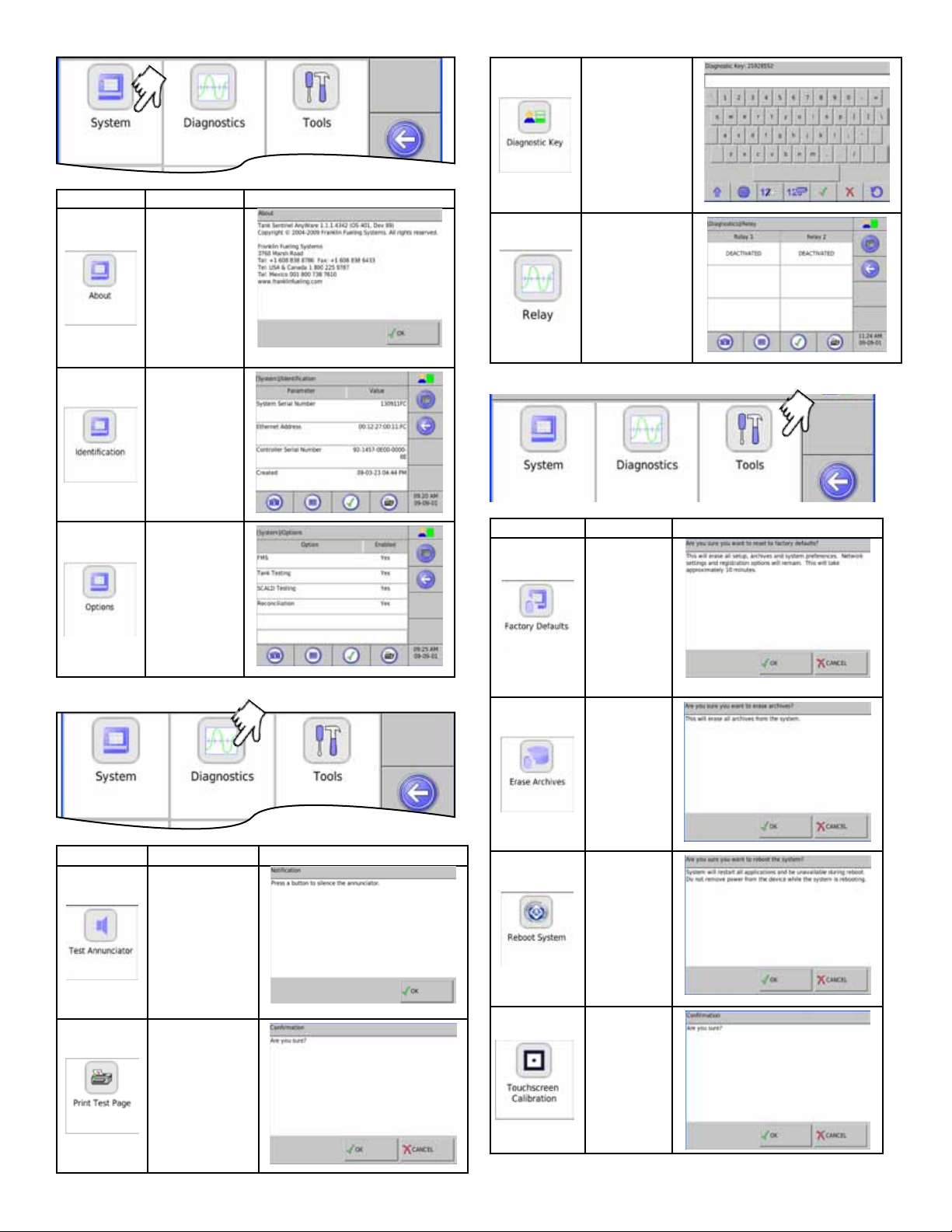

Display Description Values

Allows technicians

access to

diagnostic

functions*

Lists detail

about the

Console

Lists System

Parameters

Lists options

enabled

View relay state

and test operation

(read screen

caution notice)!

* Call FFS Tech Support for the password

Display Description Values

Restore

factory default

settings

Display Description Values

To Silence the

annunciator

To print or e-mail

a test page

Will erase all

archived data

Will reboot

system

Re-calibrates

screen

7

Page 8

Entering Setup

Always enter information starting from the top of the menu. Later menus use this information.

Note that the tables are formatted to correspond to the Web Browser Interface. Information shown is also valid for the

LCD touch screen.

[Setup] / System ID

Parameter Name Parameter Value Description Max Characters

Site Name (Site Name) Name of site. 40

Web UI URL (http://localhost/tsa) URL address of site. 40

ID Line 1 (blank)

ID Line 2 (blank) 40

ID Line 3 (blank) 40

ID Line 4 (blank) 40

ID Line 5 (blank) 40

These lines should contain the physical address of the site. This

information is used in reports and to identify site properties when

using Web User Interface.

40

[Setup] / System Configuration

Parameter Name Parameter Value Description Value

Technical Support

Key

Enable Log Files (No) Enables the logging option. Yes/No

(0) Enter the appropriate key number. #

Note: The System Conguration entries are for use by Franklin Fueling Systems for diagnostic purposes.

[Setup] / Probe Modules

Parameter Name Parameter Value Description Value

Module # Channels (0)

Channel # Name (Probe 1) Given Name of Probe. abc#

Number of channels in use per

module.

1-6

(30 characters

maximum)

[Setup] / Relay Modules

Parameter Name Parameter Value Description Value

Module # Channels (2) Number of channels in use per module.

Channel # Name (Relay 1) Given name of the channel. abc#

Enabled (Yes) Yes if the channel is in use.

Polarity (Normal) Allows the polarity to be inverted.

Physically Wired As (Normally Open) How the relay is wired internally. NO, NC

1 or 2

(30 characters

maximum)

Yes / No

Normal, Invert

8

Page 9

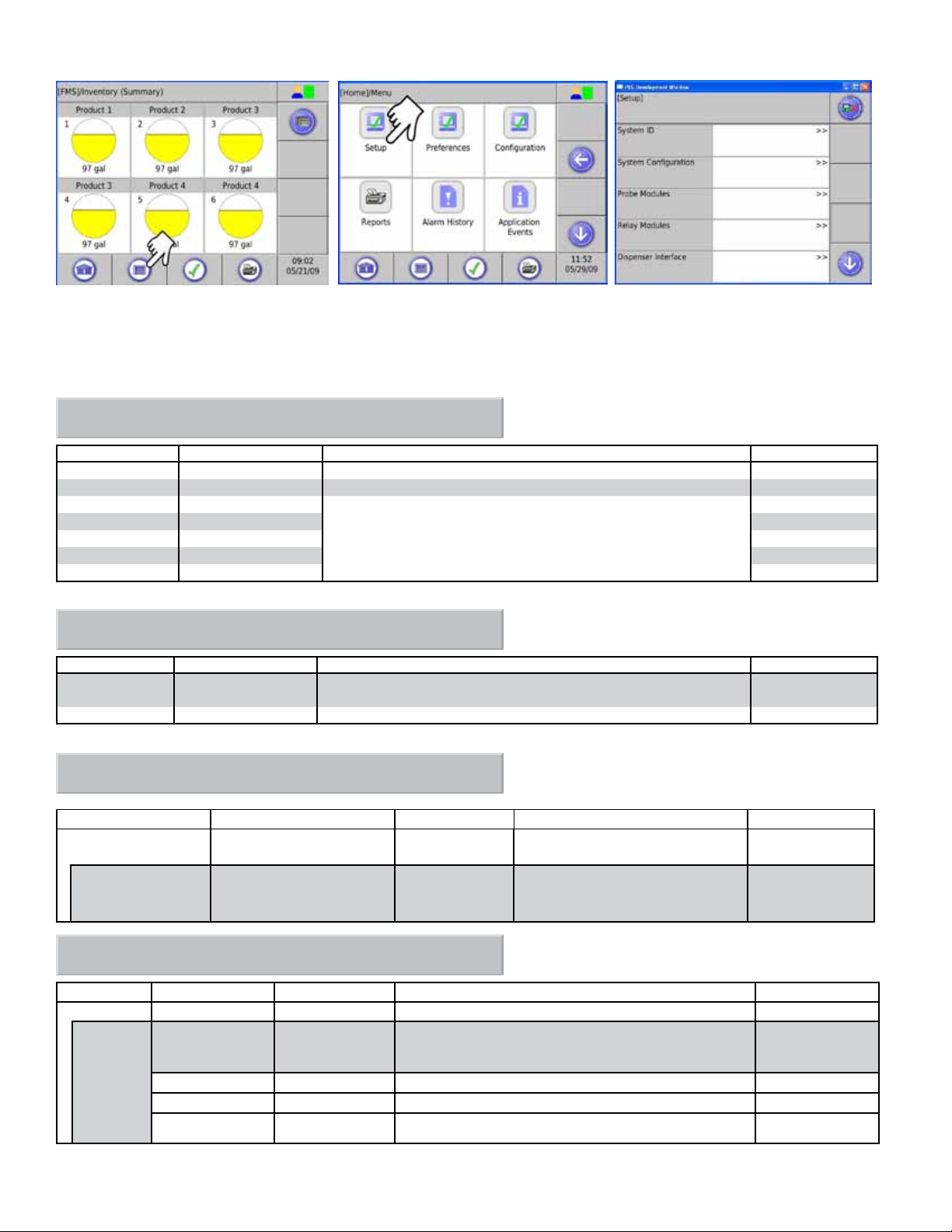

[Setup] / Dispenser Interface

Note: The Dispenser Interface allows the console to read dispensing information and requires the TS-TRAC option.

Dispenser information is sent through the Serial Port.

Parameter

Name

Grades Number of grades (0)

Fueling Points Number of fueling

Hoses Number of hoses (0) The number of grades available at a specic fueling point

Parameter Name Parameter Value Description Max Value

The number and name of products used at the site.

(0)

points

Anywhere on site where a vehicle can get fueled.

Dispenser Interface: Example of site set-up

There are 4 grades in this example:

• Unleaded

• Mid-grade

• Premium

• Diesel

Site Top View Dispenser Detail View

Dispenser 1 Dispenser 2

FP2

Dispenser 1 Dispenser 2

FP1

FP4

FP3

U M P U M P D

U = Unleaded

M = Mid-Grade

P = Premiuml

(0-32)

(0-32)

(0-8)

U = Unleaded

M = Mid-Grade

P = Premium

D = Diesel

FP = Fueling Point

There are 3

grades available

at Fueling Points

1 and 2. Number

of hoses = 3

There are 4

grades available

at Fueling Points

3 and 4. Number

of hoses = 4

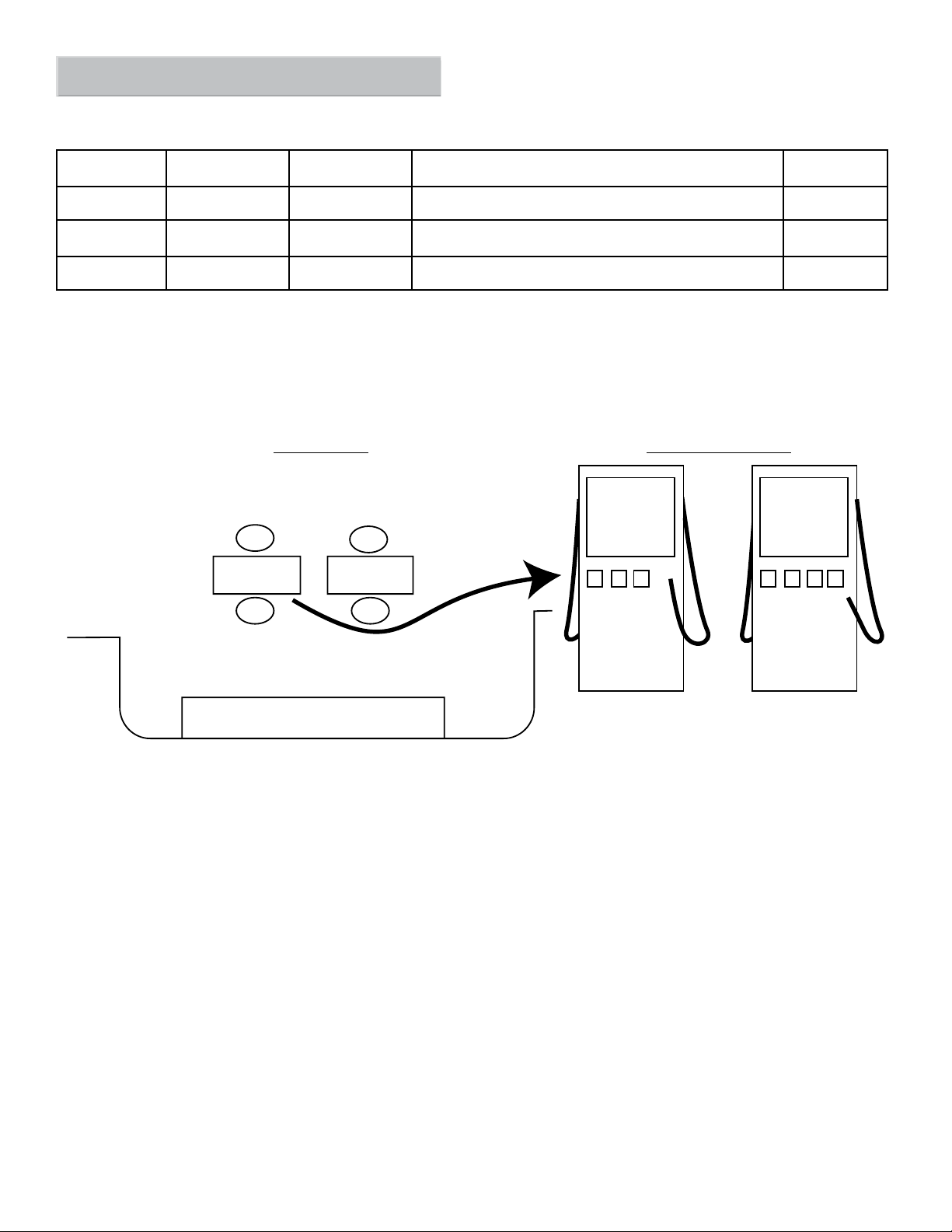

To Setup Dispensing Information:

1. Connect the RS232 serial cable from the distribution box (D-box) to the RS232 port on the Colibri.

2. Verify that the RS232 Communication port settings on the console match the D-box communication settings.

Refer to Page 6 of this manual for Serial Port Setup options.

3. On the Colibri console, enter the number of grades. For this example (page 10), there are 4 grades.

9

Page 10

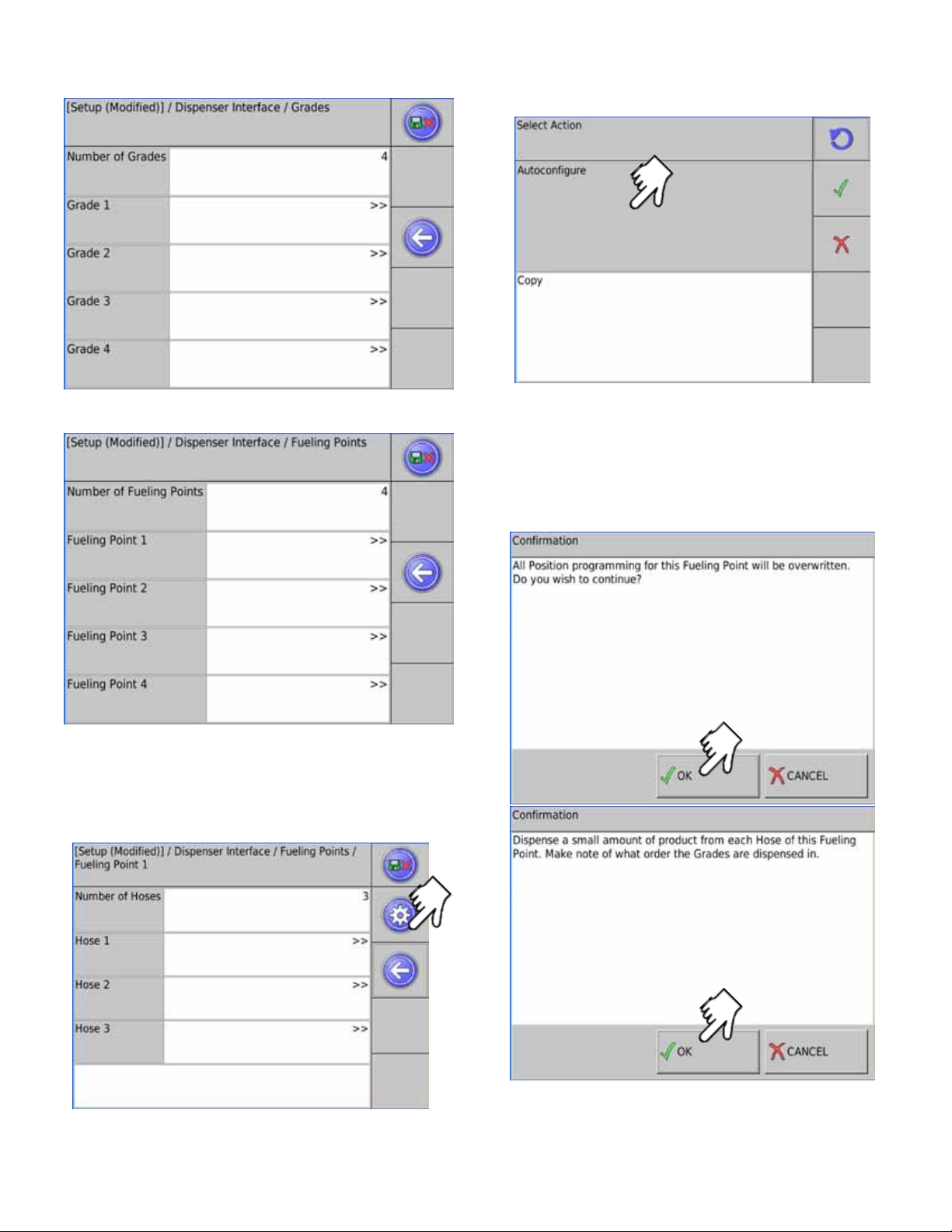

Select each grade and assign a name (i.e. Unleaded

Regular).

This will allow the console to automatically program hose

information (grade association and position) for the Fueling

points based on information received from the D-box.

4. Enter the number of fueling points. In this example

there are 4.

5.

Select Fueling Point 1 and program the number of

hoses. For this example there are 3 available grades

at FP1 and FP2. (number of hoses =3)

and 4 grades available at FP 3 and 4 (number of

hoses = 4). Continue to enter the number of hoses

for each fueling point.

7. Follow the instructions on the screen.

Note: Dispensing small amounts of fuel from each hose

is required before copying the information to other

fueling points that have the same number of hoses.

Run Autocongure before copy.

Conrmation Screens:

10

6. After the number of hoses are programmed, push

the auto-conguration button for fueling point 1.

This will allow the console to verify grade and fueling point

assignments.

Page 11

This action will copy the grade association and position

information to the other Fueling points.

Next Screen

[Setup] / Fuel Management System

Parameter Name Parameter Value Description Value

Ullage Percent (95) Percent of tank level used to calculate space left. 70-100 %

Delivery Delay (15 min) Time after delivery when increase is reported. 1 - 240 min.

Correction

Temperature

High Product Limit Level

Static Tank Testing See Below

Tanks See Below Choose number and types of tanks

Special Tanks See Below Congure non-standard tanks

Manifolds See Below

Products See Below Choose name and type of products

Grades* See Below

Reconciliation* See Below

Autocalibration* See Below

(15.50 °C) Product temperature correction. -15 to 37.78 °C

Choose Volume or Level. This will inuence how

high product alarm is programmed.

Level or volume

* Requires TS-TRAC option

11

Page 12

[Setup] / Fuel Management System / Static Tank Testing

Parameter Name Parameter Value Description Value

Region United States Choose United States, Spain or Other (regulatory) abc#

Monthly Leak Test

Threshold

Yearly Leak Test

Threshold

Sentinel Mode

Threshold

Condence (99%) Leak testing condence. 90, 95, 97.5,

Minimum Leak Test

Time

Maximum Leak Test

Time

Alarm On Precision

Leak Test Failure

[Setup] / Fuel Management System / Tanks

Parameter Name Parameter Value Description Value

Name (Tank 1) Given name of tank. abc#

Type (Special 1) Type of tank. Std./Spcl.

Manifolded (No)

Product # (1) Product # In tank 1-48

Delivery Threshold (757.1 liter) Level increase needed to signal delivery >0.3

Theft Threshold (18.9 liter)

Monthly Compliance Yes

Annual Compliance Yes

Probe

Limits

(0.21) Set static leak tolerance for monthly testing tanks. # cc/sec

(0.11)

(3.15)

(2 hr)

(8 hr)

(No)

Set static leak tolerance for yearly testing tanks.

Set static leak tolerance for Sentinel Mode.

Minimum amount of time used to test.

Maximum amount of time used to test.

Yes will produce an alarm upon leak test failure.

Part of a tank Manifold?

Level decrease needed to signal theft. Note: console

must be in Sentinel Mode

Track this tank under monthly section of compliance

page.

Track this tank under annual section of compliance

page.

(See below)

(See below)

# cc/sec

# cc/sec

99 %

0-8

1-8

Yes/No

Yes / No

>0.3

Yes / No

Yes / No

12

[Setup] / Fuel Management System / Tanks /

Tank 1 / Probe

Parameter

Name

Channel (Probe 1) Channel used for the probe in tank. Probe

Type (Standard 29) Type of probe used in this tank. Std./Spcl.

Ratio (1 to 1 tip to head) Ratio of product level movement in proportion to

Float Type (4 in gas) Type of oat(s) used on probe. 4, 3, or 2 in.

Water Float Yes Indicates if water oat is on probe. Yes / No

Gradient (8.99046 µs/mm) Speed of probe wire. # µs/mm

Product Offset (0.00 mm) Used for compensation of tank tilt. # mm

Water Offset (0.00 mm) Used to compensate for debris on tank bottom. # mm

Parameter Value Description Value

1:1; 7:1; 9:1

the oat

Gas/Diesel,

Stainless,

LPG, Density

Page 13

[Setup] / Fuel Management System / Tanks /

Tank 1 / Limits

Parameter Name

High High Product

(Level) Limit

High Product

(Level) Limit

High Water Level

Limit

Low Product

Volume Limit

Low Low Product

Volume Limit

Parameter

Value

(63.5 liter) (cm)

(58.4 liter) (cm)

(5.1 cm)

(847.9 liter)

(832.8 liter)

Description Value

Product level needed to cause alarm. Units depend on

whether Level or Volume was chosen for high product limit.

Product level needed to produce alarm. Units depend on

whether Level or Volume was chosen for high product limit.

Water level needed to produce alarm.

Product level needed to produce alarm. Units depend on

whether Level or Volume was chosen for low product limit.

Product level needed to produce alarm. Units depend on

whether Level or Volume was chosen for low product limit.

[Setup] / Fuel Management System / Special Tanks

Special #

Parameter Name Parameter Value

Shape

Length (160)

Diameter (28)

End Type (Cylinder)

Correction Table

(Horizontal

Cylinder)

Choose tank shape Horizontal or

Enter Tank Length

Enter Tank Diameter

Describe tank end type Cylinder, one or

Number of points

Description

# liters (cm)

# liters (cm)

# cm

# Liters (cm)

# Liters (cm)

Value

Vertical Cylinder,

Rectangular

0-1200 in.

0-1200 in.

two domed ends

0-100

The Correction Table is used to adjust tank

characteristics by correlating known volume with

a known level. The table is more reliable when

more points are known.

Note: For the following information, Setup / Fuel Management System / Tanks / Manifolded must be set to Yes.

[Setup] / Fuel Management System / Manifolds

Manifold #

Parameter Name Parameter Value

Name (Manifold 1)

Product # (1)

Delivery Threshold (757.1)

Theft Threshold (18.9)

Monthly Compliance Yes

Limits

SCALD

Enter manifold name

Product # In tank

Level increase needed to signal delivery

Level decrease needed to signal theft. Note: console must be in

Sentinel Mode

Track this manifold under monthly section of compliance page

Sets high and low level limits (see table top of page 11)

Enable, Qualify and Diagnostic Modes

Description

Value

abc#

1 - 48

# liters

# liters

Yes / No

Note: SCALD (Statistical Continuous Automatic Leak Detection) tank test runs continuously and requires and detects

quiet times of no dispensing or deliveries.

13

Page 14

[Setup] / Fuel Management System / Products

Product #

Name (Product 1)

Type (Unleaded

Regular)

Enter Product name

Select type of fuel Unleaded Regular, Plus,

[Setup] / Fuel Management System / Grades

Grade #

First Tank (Tank 1)

Second tank (none) Select tank number for second tank

Select tank number for rst tank

[Setup] / Fuel Management System / Reconciliation

abc#

Extra, Super, Diesel,

Kerosene, #2 Fuel Oil,

Ethanol, Special #

(20 Characters maximum)

Tank 1-6

None, Tank 1-6

Parameter Parameter Value

Over Short Limit

Percent

Over Short Limit

Volume

Sales yes

Deliveries Yes

Tank Volume Yes

(1.00)

(130)

Enter short limit percent

Enter short limit volume

Include Sales

Include Deliveries

Include tank volume

Description

Value

0-100

#

Yes / No

Yes / No

Yes / No

[Setup] / Fuel Management System / Autocalibration

Note: Must have Dispenser Interface connected for Autocalibration to work

Parameter Parameter Value

Autostop Volume

Coverage

Autostop Level

Coverage

Autostop Number of

Points Coverage

(100)

(80)

(100)

Enter volume percent at which the Autocalibration

will automatically stop.

Enter level percent at which the Autocalibration

will automatically stop.

Enter number of points required at which the

Autocalibration will automatically stop.

Any of these parameters values can be set separately. If any of the values are met the autocalibration will stop.

• If you want a certain volume coverage, set volume to desired percentage and level and number of points to 100.

• If you want a certain level coverage, set level to desired percentage and set volume and number of points to 100.

If you want so many points in the table, set number of points to desired number and set volume and level coverage to 100.

•

Description

Value

0-100

0-100

0-100

If you have accurate tank dimensions entered, you may not need Autocalibration. Refer to Appendix F for detailed

information on setting up and running Autocalibration.

14

Page 15

E-Mail Setup

[Setup] / E-Mail

Note: This is only needed if you have an Ethernet connection and want the system to send e-mail messages.

Parameter Parameter Value

“From” Address

SMTP Host

SMTP Port 25

Enable Authentication No

Maximum Queue Size 20

Retry Timeout 3600

Watchdog Timeout 30

Enable Debugging No Keeps record of communication attempts Yes / No

your_from@

address.com

Your SMTP host

address

Enter e-mail address of sender (console) abc#

Enter I.P. address of SMTP host

Port address of SMTP

Data authentication (if required)

Maximum size of queue in Megabytes

Time, in seconds, that the console will wait before

attempting to resend the message.

Time, in seconds, that the console self-monitoring

program waits when it expects an error due to

software or power quality problems.

Description

Value

(40 Characters Maximum)

abc#

(40 Characters Maximum)

0-65535

Yes / No

0-200

86400 max

0-300

System Sentinel AnyWare

[Setup] / System Sentinel AnyWare

Note: This section of Set-up is only required if the console is going to transmit data to SSA. It will require the assistance

of the SSA Administrator to set up.

Setup would require:

1. Contact an SSA Administrator.

2. The console must be connected through an Ethernet connection.

3. The SSA Administrator must create a site on SSA.

4. On the SSA Site / Setup page there is an EPS option.

5. Click on EPS.

6. You will be prompted with a note “Program EPS for this site?”

7. Click yes, and the program will automatically enter the values in the table below.

Parameter Parameter Value

IP Address

Port 80

IP address of SSA server abc#

The port that the SSA server uses

Description

Value

(40 Characters Maximum)

#

Path

Priority Highest

Database Connection SSA1

Database User Name SSAADMIN

Database User

Password

Site ID (0) Can leave this at 0. #

/ssa/_data/ssa_

webdata.dll

This is the Web Data URL located on the SSA

server but without the http:// and the domain

name.

Sets communication priority. Leave this at High or

Highest.

Name of Database. For most applications this is

left blank.

Name used to access the database abc#

Password of the user above to access the

database.

(40 Characters Maximum)

Highest, High, Normal, Low

(40 Characters Maximum)

(40 Characters Maximum)

(40 Characters Maximum)

abc#

abc#

abc#

15

Page 16

Rules

Rules associate an event (i.e. alarm, delivery, tank test, etc.) with an action (i.e. activate relay, e-mail, sound, etc.).

[Setup] / Rules

List of Default Rule Entries

These rules can be enabled or modied as needed for local conditions.

Rule - Power On Sound

Rule - Application Event Sound

Rule - New Alarm Sound

Rule - Print Inventory Daily

Rule - Print Tank Test Weekly

Rule - Print SCALD Test Weekly

Rule - Print Regulatory Monthly

Rule - Print on Delivery

Rule - Print on Alarm

Rule - Start Tank Test

Rule - E-mail Alarms

Rule - Set Reconciliation Period

[Setup] / Rules / Rule - Any

Rules

The table below lists parameters for rule making.

Note: The values shown will change depending upon the selection made.

Group Name Parameter Name Parameter Value Description Options

Rules

Rule – New Rule # Name (New Rule #) Given name of rule. abc#

Events

Event

Action

Action Type (e-mail) Action that will occur upon event E-mail, Report, Relay, Tank

Enabled

Type (Alarm Occurred) Event type that triggers action. Alarm Occurred;

Category (Any) System that event occurs in to trigger

Code (Any) Error/Trouble Event Code that

Device (Any) Device that created the alarm

State (Any) State of alarm to trigger action. Various

Address your,email@address.com Where it will send e-mail

Contact Generated What e-mail format is used Generated, Text, HTML, Other

Template Text E-mail Template HTML, Text, short text

(No)

Yes to enable rule.

action.

triggers action.

condition.

Testing, Sentinel mode,

Reconciliation, sound, Notify

SSA, Sample input

Yes/No

Alarm Cleared;

Application Event;

Schedule

Any;

System;

FMS;

(see below)

Various

You can nd samples of creating rules (in English) on the internet. Sign in at http://techlab.franklinfueling.com and locate

FMS/Colibri, or search video libraries

16

Page 17

Operation

Check Inventory

Select the tank.

View or print tank information.

Check Deliveries

Choose the tank or manifold (Tanks shown)

17

Page 18

Alarms

This will bring up a list of current or active alarms. Refer to

Appendix A, Alarm Table.

Print Reports

This shows manifolds. Separate tanks will be listed if tanks

are not connected together with manifolds.

Choose the type of report.

18

Page 19

Web Browser Interface

Connecting to the Console

To use the Web Browser Interface, the console must be connected to a computer. You can connect to the console’s

Ethernet connection using an RJ-45 cable.

Ethernet Connection:

Router or Hub

Use network

cross-over cable

Use network

straight cable

To set up a connection, from the console:

Changing IP settings require administrator sign-on.

The numbers you get may be different than shown. Copy these

numbers for the next step.

Connect the PC to the console with an Ethernet cable.

In M.S. Windows, click on Start:

19

Page 20

Click

Right Click and select Properties

Enter the numbers from the [Home] Conguration IP Address Settings

Page of the console, EXCEPT: Change the IP Address to a different

value (i.e. 192.168.168.167)

Select Properties

Click OK after setting properties

Click OK

Open the computer’s internet browser and put the console’s IP address into the address bar of the browser.

A screen should open similar to that below.

Access Level

Alarm Indicator

The menu selections are the same as shown earlier for the console.

20

Software Version

Page 21

Web Interface Available Pages

The following pages can be viewed in order to see data and perform control functions. Several pages and functions are

controlled by access level. If the Auto Refresh action is listed on the Action Bar of a page, then the data on the page does

not refresh automatically. Click Refresh on your browser to update the page or click on Auto Refresh to have the screen

updated continuously.

Auto refresh

Menu

System

Page Description

Status Displays alarm status for all applications.

Alarms Shows a detailed list of all active Alarms and Warnings.

Reports Make alarm and application event reports.

Conguration Edit the access level passwords and IP information. (Administrator Only)

Registration View the installed options.

Diagnostics Displays SCALD status and Relay status

Tools Allows rebooting system, erase archives or restore factory defaults

About Lists manufacturer contact information

FMS

Page Description

Status Third navigation line appears showing tank inventory information and alarm status.

Alarms Lists all active alarms and the date and time they occurred.

Control Start tank tests, Set Auto-Calibration and calibrate probes.

Compliance Displays compliance information for all tanks.

Reports Make various reports like Inventory, Delivery, Tank Tests and Regulatory.

Setup / Cong

Refer to pages 8-14 for information. This menu and should only be used by a certied technician. See your Franklin

Fueling distributor for assistance.

Preferences

Change the way that data is displayed, change the units of measure and adjust the Auto Refresh rate. There are two

levels of preferences:

Preference Description

Personal These settings are saved and viewed only on your computer.

System Changes the way data is displayed for all Web Browser Interfaces and touch screen users.

Tank Leak Testing Using the Web Browser Interface

Before starting a tank leak test, wait 6 hours after the last delivery and 2 hours after last dispense in order for the tank to

become stable.

There must be no dispense during a tank leak test.

Tank leak tests can take from 2-8 hours to complete. (See Appendix E)

1. Open your web browser and connect to the site.

2. On the Primary Navigation Bar, select FMS.

3. On the Secondary Navigation Bar, select Control.

4. Select Tanks.

Tank Leak Tests

1. Check the box next to the Tank(s) you want to test.

2. From the drop-box, select the type of test (Monthly or Annual) you want to perform for each tank, .

3. Click on Start Leak Tests on the Action Bar.

21

Page 22

Appendix A: List of Alarms

FMS

Tank/Manifold Alarms

Displayed Alarm Description Recommended Actions

Correction Table

Error

Manifold Gross Leak

Detected

Manifold Leak

Detected

Manifold SCALD Leak

Detected

Manifold Theft

Detected

Tank Gross Leak

Detected

Tank Leak Detected The tank listed with the alarm has

Tank SCALD Leak

Detected

Tank Theft Detected Product level in the tank listed with

Correction points for the special tank

listed with the alarm were not entered

or were entered incorrectly.

The manifold listed with the alarm has

failed a Gross Leak Test.

The manifold listed with the alarm has

failed a Monthly Leak Test.

The manifold listed with the alarm has

failed a SCALD Leak Test.

Product level in the manifold listed

with the alarm has dropped below the

programmed Theft Limit.

The manifold listed with the alarm has

failed a Gross Leak Test.

failed a Monthly Leak Test.

The tank listed with the alarm has

failed a SCALD Leak Test.

the alarm has dropped below the

programmed Theft Limit.

Verify that the correction table points for the tank listed with the

alarm are entered sequentially in ‘Special Tanks’ Programming.

Review manifold leak test history and programming. It may be

necessary to manually start a Gross Leak Test to keep the manifold

in compliance.

Review manifold leak test history and programming. It may be

necessary to manually start a Monthly Leak Test to keep the

manifold in compliance.

Review manifold leak test history diagnostic web page and

programming.

Verify that the programmed Theft limit is correct. Verify that the

values of product loss on the console correspond with actual

product loss in the tank.

Review manifold leak test history and programming. It may be

necessary to manually start a Gross Leak Test to keep the tank in

compliance.

Review tank leak test history and programming. It may be

necessary to manually start a Monthly Leak Test to keep the tank in

compliance.

Review tank leak test history and programming. Test to keep the

tank in compliance.

Verify that the programmed Theft Limit is correct. Verify that the

values of product loss on the console correspond with actual

product loss in the tank.

22

Page 23

FMS

Probe Alarms

Displayed Alarm Description Recommended Actions

Float Height

Error

Float Missing A oat on the probe listed with the alarm

High Water

Level

High Product

Level

High High

Product Level

Low Product

Level

Low Low

Product Level

No Probe

Detected

Probe

Synchronization

Error

RTD Table Error The RTD Table programmed for the probe

Temperature

Error

Unstable Probe This alarm indicates inconsistent data from

A oat on the probe listed with the alarm is

being monitored at a varying height outside

of thresholds. Causes can include broken

oat and programming, or mistakenly

associating a gasoline and diesel oat.

has not been detected or the probe was

programmed with the incorrect number of

oats.

The water oat on the Tank/Manifold listed

with the alarm is above the programmed

High Water Level Limit.

The product oat on the Tank/Manifold listed

with the alarm is above the programmed

High Product Level Limit. Tank may be close

to an overfull condition.

The product oat on the Tank/Manifold listed

with the alarm is above the programmed

High High Product Level Limit. Tank may be

near an overfull condition.

The product oat on the Tank/Manifold listed

with the alarm is below the programmed Low

Product Level Limit. Tank may be close to an

empty condition.

The product oat on the Tank/Manifold listed

with the alarm is below the programmed Low

Low Product Level Limit. Tank may be near

an empty condition.

This alarm indicates a communication error

between the console and the probe listed

with the alarm.

This alarm indicates a communication error

between the console and the probe listed

with the alarm.

listed with the alarm is incorrect.

This alarm indicates a temperature sensor

error or failure inside the probe shaft of the

probe listed with the alarm.

the probe listed with the alarm.

Verify Probe programming. Visually inspect that the probe oat type

matches the type of product. Inspect magnet and probe shaft for

cracks or debris and clean if necessary.

Verify the ‘number of oats’ in Probe programming. Number of

oats must match number of oats installed. Float must be lower

than 5" from the bottom of the probe head.

Verify that the programmed limit is correct. Verify that the Water

Level values on the console correspond with the actual water level

in the tank.

Verify that the programmed limit is correct. Verify that the Gross

Product Level values on the console correspond with actual product

level in the tank.

Verify that the programmed limit is correct. Verify that the Gross

Product Level values on the console correspond with actual product

level in the tank.

Verify that the programmed limit is correct. Verify that the Gross

Product Level values on the console correspond with actual product

level in the tank.

Verify that the programmed limit is correct. Verify that the Gross

Product Level values on the console correspond with actual product

level in the tank.

Verify Probe programming. Inspect the probe wiring from the probe

module to the probe.

Verify Probe programming. Inspect the probe wiring from the probe

module to the probe.

Verify the RTD Table programming.

Verify the RTD Table programming. Visually inspect probe shaft for

defects and cracks.

Inspect the probe wiring from the probe module to the probe. Verify

that the product in the tank is both physically and thermally stable.

23

Page 24

FMS

Special Product Alarms

Displayed Alarm Description Recommended Actions

Alpha Volume

Correction Error

API Volume

Correction Error

Level Error The level of the product oat on the probe

Net Error The net volume of the product oat on the

Product Volume

Error

Ullage Error The Ullage level on the tank/manifold listed

Water Volume

Error

If the tank is not listed as a standard tank in Appendix B: Standard Tanks Table, use the tank chart from the manufacturer to create a

custom correction table.

These Alarms refer to temperature correction

coefcients used by the console to calculate

Net Volume. When these values are entered

too high or too low, an alarm condition will

occur.

These Alarms refer to temperature correction

coefcients used by the console to calculate

Net Volume. When these values are entered

too high or too low, an alarm condition will

occur.

listed with the alarm has exceeded a possible

level according to the programming.

probe listed with the alarm has exceeded

a possible volume according to the

programming; related to Volume Correction.

The volume of the product oat on the probe

listed with the alarm has exceeded a possible

volume according to the programming.

with the alarm has exceeded a possible level

according to the programming.

The Water Volume on the tank/manifold listed

with the alarm has exceeded a possible level

according to the programming.

Verify that the Volume in the Correction Type matches the

specications of the product used in ‘Special Products’

Programming. These values should be listed in the product

manufacturer’s Spec Sheets.

Verify that the Volume in the Correction Type matches the

specications of the product used in ‘Special Products’

Programming. These values should be listed in the product

manufacturer’s Spec Sheets.

Verify that the following parameters are programmed correctly

according to site specications: Correction Table, Gradient, Probe

Type, and Product Offset.

Verify that the following parameters are programmed correctly

according to site specications: Correction Table, Gradient, Probe

Type, and Product Offset.

Verify that the following parameters are programmed correctly

according to site specications: Correction Table, Gradient, Probe

Type, and Product Offset.

Verify that the following parameters are programmed correctly

according to site specications: Correction Table, Gradient, Probe

Type, and Product Offset.

Verify that the following parameters are programmed correctly

according to site specications: Correction Table, Gradient, Probe

Type, and Product Offset.

24

Page 25

Appendix B: Standard Tank Table

Legend

O/C = Owens Corning / FC Fluid Containment

D = Diameter (Dia.)

L = Length

S = Single Wall

DW = Double Wall Tank (DWT)

Type #

01 O/C Tanks D5

02 O/C Tanks D-5

03 O/C Tanks D-2B

04 O/C Tanks DWT-2 (6) 2,500 75 x 151 DW

05 O/C Tanks D-6

06 O/C Tanks G-5

07 O/C Tanks G-3 4,000 92 x 165 S

08 O/C Tanks D-6

09 O/C Tanks G-3 6,000 92 x 231 S

10 O/C Tanks DWT-2 (8) 6,000 95 x 237 DW

11 O/C Tanks G-3 8,000 92 x 300 S

12 O/C Tanks G-5

Manufacturer Model Capacity

(Gallons)

550

DWT-4 (4)

DWT-4 (4)

D-6

DWT-2 (6)

G-6

DWT-2 (6)

550

1,000

1,000

2,000

2,000

4,000

4,000

4,000

4,000

6,000

6,000

8,000

Dimensions

D x L (inches)

48 x 78

51 x 83

50 x 132

53 x 138

74 x 133

74 x 133

74 x 236

75 x 239

92 x 167

95 x 167

74 x 354

75 x 357

92 x 299

S / DW

Wall

S

DW

S

DW

S

S

S

DW

S

S

S

DW

S

G-6

DWT-2 (8)

13 O/C Tanks DWT-2 (6) 8,000 75 x 472 DW

14 O/C Tanks G-3 10,000 92 x 362 S

15 O/C Tanks G-5

G-6

16 O/C Tanks D-6 10,000 120 x 245 S

17 O/C Tanks DWT-2(6) 10,000 75 x 570 DW

18 O/C Tanks G-3 12,000 92 x 432 S

19 O/C Tanks G-5

G-6

DWT-2(8)

20 O/C Tanks DWT-2(10) 15,000 124 x 348 DW

21 O/C Tanks DWT-2(10) 20,000 124 x 458 DW

22 O/C Tanks DWT-2(10) 25,000 125 x 554 DW

23 Xerxes DWT-2(10) 30,000 124 x 656 DW

24 Xerxes — 2,000 96 x 108 S

8,000

8,000

10,000

10,000

12,000

12,000

12,000

95 x 299

95 x 303

92 x 365

95 x 365

92 x 431

95 x 431

95 x 435

S

DW

S

S

S

S

DW

25

Page 26

Type #

25 Xerxes — 2,000 76 x 166 DW

26 Xerxes — 2,000 75 x 144 S

27 Xerxes — 3,000 96 x 147 S

28 Xerxes — 4,000 75 x 263 S

29 Xerxes — 4,000 96 x 180 S

30 Xerxes — 4,000 76 x 252 DW

31 Xerxes — 6,000 75 x 353 S

32 Xerxes — 6,000

33 Xerxes —

Manufacturer Model Capacity

(Gallons)

6,000

8,000

Dimensions

D x L (inches)

96 x 246

97 x 251

96 x 312

S / DW

Wall

S

DW

S

—

34 Xerxes —

—

35 Xerxes —

—

36 Xerxes —

—

37 Xerxes —

—

38 Xerxes —

—

39 Xerxes —

—

40 Corespan — 4,000 99 x 162 DW

41 Corespan — 5,000 99 x 192 DW

42 Corespan — 6,000 99 x 216 DW

43 Corespan — 8,000 99 x 282 DW

44 Corespan — 10,000 99 x 342 DW

45 Corespan — 12,000 99 x 402 DW

46 Corespan — 15,000 99 x 576 DW

47 — — 275 44 Vertical S

48 — — 550 44 Vertical (Dual

49 — — 275 44 Horizontal S

8,000

10,000

10,000

10,000

10,000

12,000

12,000

12,000

12,000

15,000

15,000

20,000

20,000

97 x 317

96 x 378

97 x 383

124 x 257

125 x 262

96 x 444

97 x 449

124 x 288

125 x 293

124 x 353

125 x 359

124 x 452

125 x 458

275 gal.)

DW

S

DW

S

DW

S

DW

S

DW

S

DW

S

DW

S

26

Page 27

Appendix C: Compatible Printers

Hewlett Packard Compatible Printers

Colibri consoles have a standard Type-A USB socket on the bottom of the console. The console uses Printer Control

Language (PCL) version 3 or higher protocol developed by Hewlett Packard (HP) to print to external printers.

Colibri consoles have two standard Type-A USB sockets on the bottom of the console. The console uses Printer Control

Language (PCL) versions 3 through 5 protocols developed by Hewlett Packard (HP) to print to external printers.

PCL 6 is not compatible with the Colibri consoles. However, many printers with PCL 6 can also support PLC 5. It is also

important to note that PCL 3 GUI is a subset of PCL 3 and is not compatible with the Colibri consoles.

Franklin Fueling Systems recommends the following HP printers:

• HP Deskjet 6940

• HP LaserJet P1505n.

Important Note

• Do not use printers with a power save feature

• Start the printer before starting the console

Appendix D - Standard Products Table

Product Name API Gravity (6B Compensation)

Leaded Regular 63.5

Unleaded Regular 63.5

Unleaded Plus 62.8

Unleaded Extra 62.8

Unleaded Super 51.3

Diesel 32.8

Kerosene 41.8

#2 Fuel Oil 32.8

Appendix E - Typical Tank Leak Test Times

For 7 Tank Sizes at Half Capacity ( Worst Case is 50% Full )

Tank Size in Gallons Typical - Tank Leak Test Times (to Finish)

4,000 2.0 hours

6,000 3.0 hours

8,000 4.0 hours

10,000 5.0 hours

12,000 6.0 hours

15,000 7.5 hours

20,000 8.0 hours

Note: The Leak Threshold value is one half of the Leak Test value.

27

Page 28

Appendix F - Using the Console’s Autocalibration Feature

Using the Autocalibration Feature on an FFS

Tank Gauge

Introduction

Autocal is a feature of the Colibri Tank Monitoring Systems

which generates a tank strapping chart in order to

accurately calibrate and reconcile your fuel management

system automatically. Autocal compares sale of product

from dispensers with changes in tank volume.

Autocal corrects discrepancies in delivery reporting and

daily reconciliations that are caused by inaccurate tank

information programmed into the ATG. Incorrect tank

information can come from:

• Lack of a tank chart

• Wrong tank chart

• Tank that deforms over time and no longer represents

its tank chart

Autocal Requirements

A high variance on a tank’s Daily Reconciliation Reports,

means that the amount of product owing through the

dispensers appears to be different from the amount leaving

the tank. This could mean that the manufacturer’s tank

chart programmed into the ATG is not accurate, but it can

also be caused by several other things. The following

items should always be checked by a certied service

professional before starting Autocal:

• Autocal cannot be performed on manifolded tanks

• Probes must be properly installed

• Tank tilt calculations must be correct (or 0 if the probe is

at tank center)

• The tank charts provided must be correct

• The tank must be programmed correctly (length,

diameter, correction points)

• Make sure that probe alarms or TS-DIM (Dispenser

Interface Module) problems are not the reason for the

Over / Short status

• Recently passed tank tests and line tests are on le

• The dispenser meters are calibrated

• Your FFS ATG has the Reconciliation option and is

interfaced with a POS / dispenser

• Your FFS ATG has the correct Reconciliation

programming

Note: Calibrating a tank with Autocal that does not meet

the above criteria could potentially cover up a

problem or leak.

Hardware and Software Requirements

An Colibri gauge must have the TS-TRAC internal

software option to perform the Autocal feature. The Colibri

Tank Monitoring System must be doing accurate dispenser

reconciliation.

Autocal Preparation

Determining Sites That May Require Autocal. The following

steps will help determine if an Autocalibration may be

necessary

1. Generate a DIM Reconciliation Report for the last

30 days. Look for tanks that have Over or Short

status on the report.

2. Take note if any days show missing sales or sales

numbers that are unrealistic. These days may

be the reason that the status may show OVER

or SHORT, but they are not reasons for using

Autocal. It is possible that the tank still needs to

be calibrated even if it has some missing days

or data. The “good” days need to be examined

to see if the Daily Variance is usually high. If the

Daily Variance is greater than 10% of the sales

on “good” days, then there is another problem in

the system that needs to be xed prior to starting

Autocal.

28

Page 29

To See If a Tank Is Autocal Ready

• Use the previous month’s DIM Reconciliation Report to

look for explanations for the Over / Short status. A typical

tank that needs calibration will show a consistently

high variance, but not very high. If the Daily Variance

is higher than 10% of the sales for that day, then the

problem is probably being caused by something that will

not be resolved by using Autocal.

• Check the Active Alarms and Alarm History for probe

problems on the tank to be calibrated.

• Check the tank setup. Each tank must have its own

Special Tank, and each tank type must be the Special

Tank of the same number (e.g. Tank 1 type = Special 1,

Tank 2 type = Special 2).

• Make sure that the Tank Length (or estimated Length

for berglass) is programmed correctly. If it is not, there

may be a false delivery recorded at the time between

the old tank chart being cleared and the rst point being

put in. To see how to adjust the length of your tank

correctly, refer to the following section called Adjusting

Length rst.

• Are there any known problems at the site in the past that

might effect variance?

• Record the daily usage from the ATG in order to

estimate how long Autocal will take to complete.

• If Autocal has been attempted before, make sure that it

was stopped and that the original tank information was

programmed back in prior to starting Autocal again.

If the above bulleted points have all been addressed, then

you are ready to start Autocal.

Calibration Procedure

FFS recommends that calibration be started with the

tank lled to more than 90% of its total volume, and that

the tank be then allowed to drain down to at least 10% of

its total volume. When the Autocal program senses 80%

volume coverage, it will end automatically, but it can also

be stopped manually at any time.

As long as the coverage is around 70%, it should be

sufcient. The key is that the new tank chart covers the

level range that the tank stays in during normal operation.

Delivery during Calibration

If a delivery occurs during the Autocal process that raises

the fuel level to a point above the calibration starting point,

Autocal will STOP.

Adjusting Length First

If the Tank Length (or estimated Length for berglass) isn’t

programmed correctly, then there may be a false delivery

recorded at the time between the old tank chart being

cleared and the rst point being entered in. Make sure that

your Tank Length is programmed correctly, and refer to the

appropriate section below based on your tank type.

Flat Ends (Steel)

If the ends of the tank are at so that the tank is a true

cylinder, then the ATG should only need to know the

length and diameter and should not need to be calibrated.

Adjusting the Length may correct the problem.

If the Daily Variance is always negative or always positive,

then it is likely that the Length is wrong. Check the delivery

accuracy, and it will likely show an error also, though

probably in the opposite direction of the variance.

If the Daily Variance is consistently NEGATIVE (with

positive deliveries), then the tank is TOO BIG and the

Length should be shortened and vice versa. Adjust the

Length of the tank. As a rule of thumb, calculate the

average variance for the past ve days. Figure out what

percentage of the total tank volume this average variance

is equal to, and modify the length of the tank by the same

percentage. Monitor the Daily Variance of the modied

tank for several days to see what the effect has been.

Dome Ends (Fiberglass)

If the tank is berglass with domed ends, then there is no

set Length. An approximate Length should be calculated

based on the Diameter and Volume capacity of the tank by

using this formula: Length = 231 (4V/πD2) (for metric units

replace 231 with 10,000,000). Enter the Correction Points

from the manufacturer’s tank chart at least every 5 inches

(12.7 cm) - the more points entered the better.

Length and Volume Unknown

If the Length and Volume of the tank are unknown and you

don’t have a tank chart, then the default reference volume

will not be accurate enough. Follow these steps to obtain,

and enter, an accurate reference volume in the tank:

1. Enter an approximate length.

2. Drain the tank completely dry (the product drop in

the next step will be off by whatever amount is not

removed).

3. Drop an accurately measured amount of fuel into

the tank — the more measured fuel added, the

better.

4. Adjust the Length until the ATG reads about the

same amount as was dropped.

5. Enter the amount dropped as the reference

volume when prompted during the Autocal start.

29

Page 30

Starting Autocal

When Autocal starts, it will need a reference volume as

the starting point for the calibration. The default reference

volume will be what the tank gauge is reading at the

time that Autocal is started. This reading needs to be as

accurate as possible and not higher than the initial

volume read by the ATG, in order to produce a quality

chart. The Diameter, Length, and Correction Points are

what contribute to the default volume’s accuracy. The

diameter of the tank should be listed on the tank chart, but,

if it’s not, then it can be easily measured.

To begin the Autocal process;

1. Select a tank from the Inventory Summary Screen.

2. After selecting the tank, press the (MENU) key in

the upper right hand corner.

3. Next, select Control/Tanks/Autocalibration.

4. Select the tank and this message should

appear “Are you sure you want to perform the

autocalibration on this tank?” Select OK.

30

Page 31

5. The following message will be displayed “Do

you want to enter a reference volume for the

autocalibration?”

6. Select OK and enter a reference volume to start.

The reference volume needs to be slightly less

than the current volume.

After the reference volume is entered, the tank should

have an ACTIVE indication in the (FMS) / Autocalibration

(Tank) screen.

Reasons Why Autocal Would Stop

• Power failure

• Setup entered

• Probe failure

• TS-DIM failure

• Delivery in Tank under Autocal.

Autocal Completion

1. The Autocalibration procedure will stop when the

Percent Coverage is reached.

2. Monitor the Daily Reconciliation and Delivery

Reports for a few weeks to ensure that they are

within tolerance.

Note:

If Autocal stops collecting points for any reason, stop

it, reprogram the original tank chart, and start over.

31

Page 32

©2009 FFS 000-2155 RevA

Loading...

Loading...