Fluke 702, 701 User Manual

Documenting Process Calibrator

November 1994, Rev. 4, 3/98

© 1994, 1995, 1996, 1998 Fluke Corporation. All rights reserved. Printed in U.S.A.

All product names are trademarks of their respective companies.

Visit the Fluke website at: www.fluke.com

701/702

Users Manual

¨

Table of Contents

Title Page

Introduction........................................................................................................ 1

Standard Equipment ..................................................................................... 4

Safety Information ............................................................................................. 10

Getting Acquainted with Your Calibrator ........................................................... 12

Input and Output Jacks................................................................................. 12

Keys.............................................................................................................. 14

Display .......................................................................................................... 17

Setting Up the Calibrator................................................................................... 17

Using the Strap and Bail ............................................................................... 17

Charging the Battery..................................................................................... 20

Battery Life.................................................................................................... 21

Automatically Saving Battery Life.................................................................. 23

Using the Optional Battery Eliminator ........................................................... 23

i

701/702

Users Manual

Selecting the Display Language .................................................................... 24

Adjusting the Display Contrast....................................................................... 24

Setting Up the Date and Time Display........................................................... 24

Using the Backlight........................................................................................ 25

Personalizing the Calibrator........................................................................... 26

Using Measure Mode......................................................................................... 27

Measurement Ranges.................................................................................... 27

Measuring Electrical Parameters................................................................... 28

Testing Continuity.......................................................................................... 30

Measuring Pressure....................................................................................... 30

Measuring Temperature ................................................................................ 33

Using Thermocouples................................................................................ 33

Using Resistance-Temperature Detectors (RTDs).................................... 36

Measurements in Percent of Scale................................................................ 40

Damping Your Measurements....................................................................... 40

Using Source Mode............................................................................................ 41

Sourcing Electrical Parameters...................................................................... 41

Simulating a 4 to 20 mA Transmitter.............................................................. 43

Providing Loop Power.................................................................................... 45

Sourcing Pressure ......................................................................................... 47

Simulating Thermocouples ............................................................................ 50

Simulating RTDs............................................................................................ 52

Sourcing in Percent of Scale.......................................................................... 54

Stepping and Ramping the Output Value ...................................................... 54

Stepping the Output....................................................................................... 54

ii

Contents

(continued)

Ramping the Output...................................................................................... 55

Simultaneous Measure/Source ......................................................................... 59

Calibrating a Process Instrument ...................................................................... 62

Generating “As Found” Test Data................................................................. 62

Adjusting the Transmitter.............................................................................. 66

“As Left” Test Run......................................................................................... 67

Memory Operations........................................................................................... 68

Saving Results .............................................................................................. 68

Reviewing Memory........................................................................................ 69

Data Logging (Model 702 Only).................................................................... 70

Observing Min and Max Measurements ....................................................... 72

Viewing the Task List (Model 702 Only)........................................................ 72

Clearing Memory........................................................................................... 73

Quick Guide to Applications .............................................................................. 73

Communicating with a PC (Model 702 Only)..................................................... 83

Maintenance...................................................................................................... 83

Replacing the Battery Pack........................................................................... 83

Internal Lithium Backup Battery .................................................................... 83

Cleaning the Calibrator ................................................................................. 83

Calibration Data ............................................................................................ 84

Service Center Calibration or Repair ............................................................ 84

Replacement Parts........................................................................................ 84

Specifications .................................................................................................... 86

DC Voltage Measurement............................................................................. 87

AC Voltage Measurement............................................................................. 88

DC Current Measurement............................................................................. 89

iii

701/702

Users Manual

Resistance Measurement.............................................................................. 89

Continuity Testing.......................................................................................... 90

Frequency Measurement............................................................................... 90

DC Voltage Output......................................................................................... 91

DC Current Output......................................................................................... 92

Resistance Sourcing...................................................................................... 93

Frequency Sourcing....................................................................................... 94

Temperature, Thermocouples ....................................................................... 95

Temperature, Resistance Temperature Detectors ........................................ 98

Loop Power Supply........................................................................................ 99

Top and Bottom Limits of Ranges with Auto Range On ................................ 100

General Specifications................................................................................... 102

Index

iv

List of Tables

Table Title Page

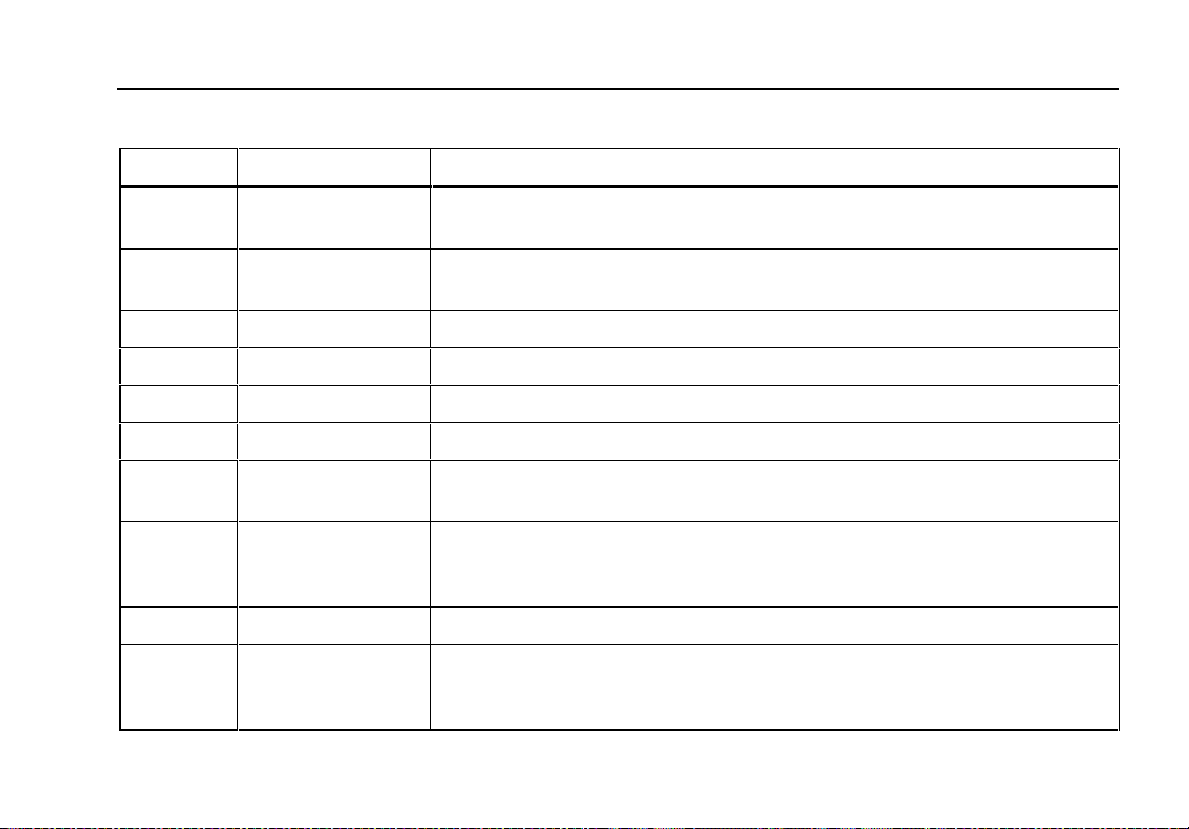

1. Summary of Source and Measure Functions......................................................... 3

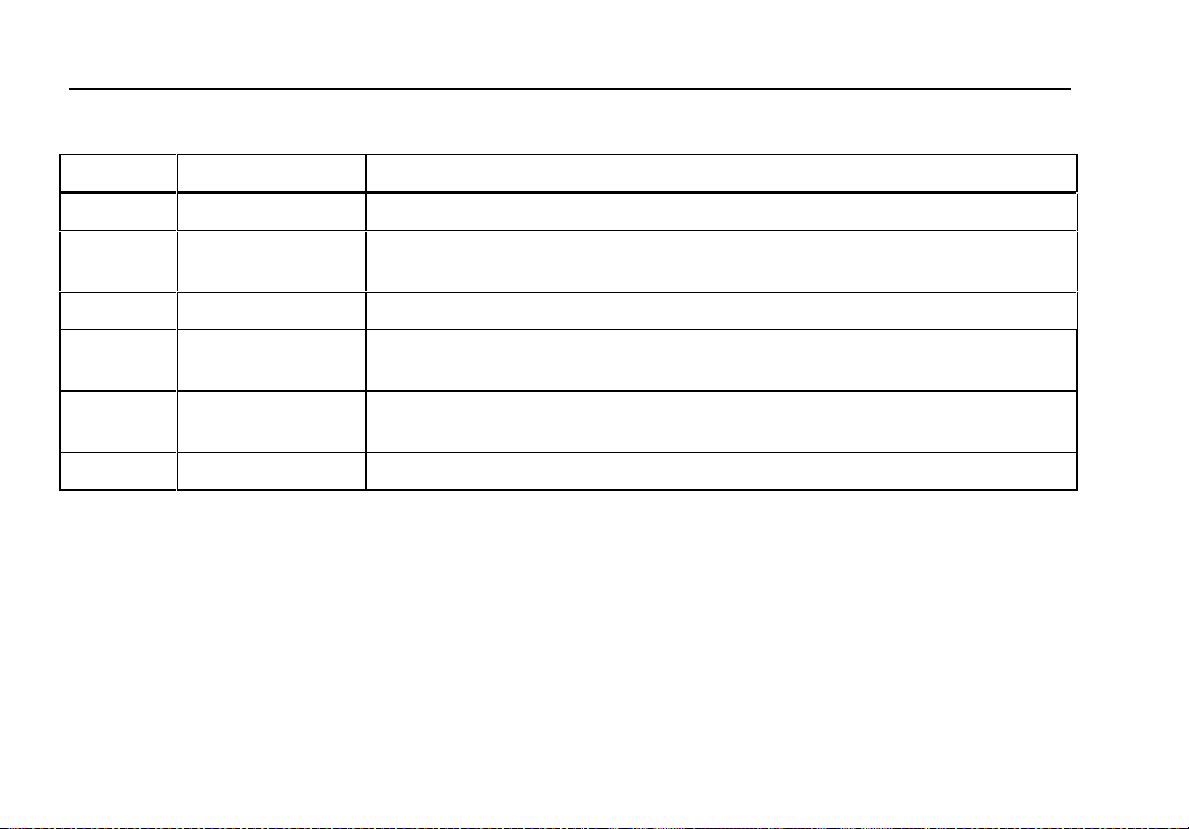

2. Input/Output Jacks and Connectors....................................................................... 12

3. Key Functions........................................................................................................ 15

4. Battery Life............................................................................................................. 22

5. Thermocouple Types Accepted............................................................................. 34

6. RTD Types Accepted............................................................................................. 36

7. Simultaneous MEASURE/SOURCE Functions with Loop Power Disabled........... 60

8. Simultaneous MEASURE/SOURCE Functions with Loop Power Enabled............ 61

9. Replacement Parts ................................................................................................ 85

v

701/702

Users Manual

vi

List of Figures

Figure Title Page

1. Standard Equipment.............................................................................................. 5

2. Accessories............................................................................................................ 8

3. Definition of Symbols............................................................................................. 10

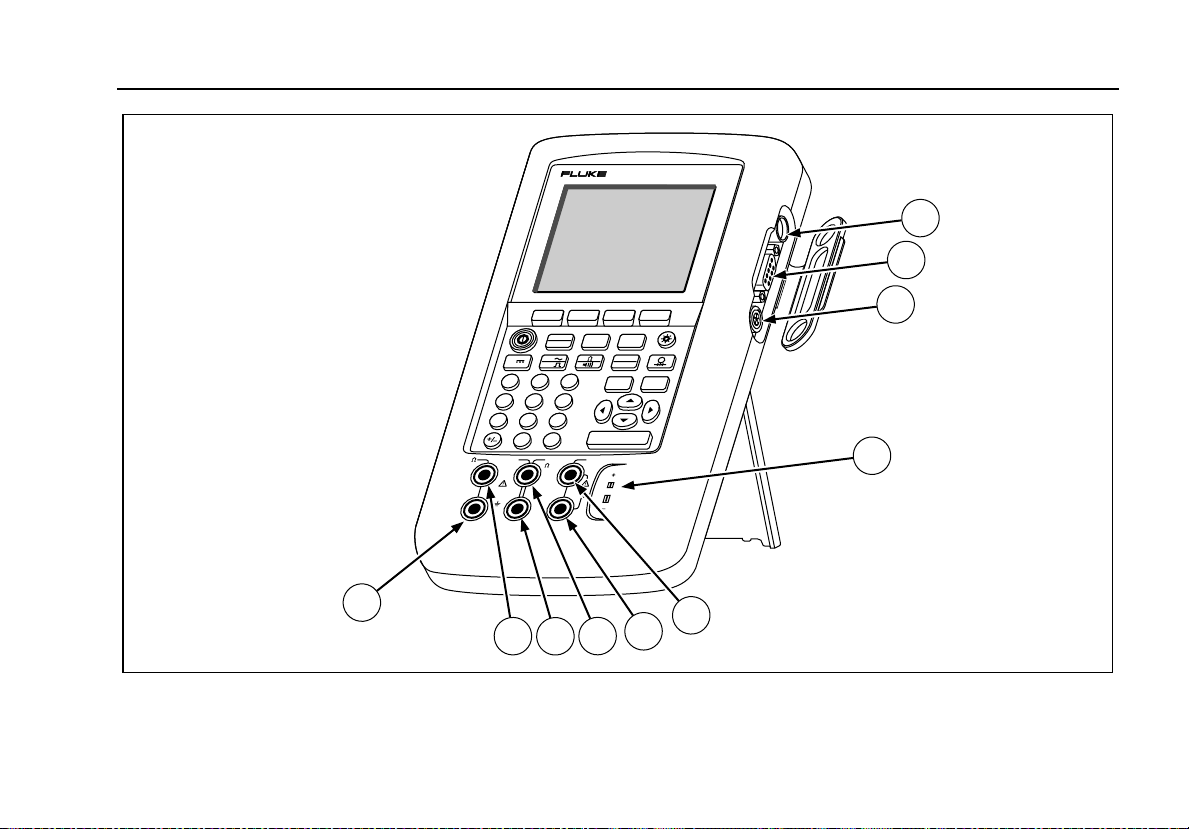

4. Input/Output Jacks and Connectors....................................................................... 13

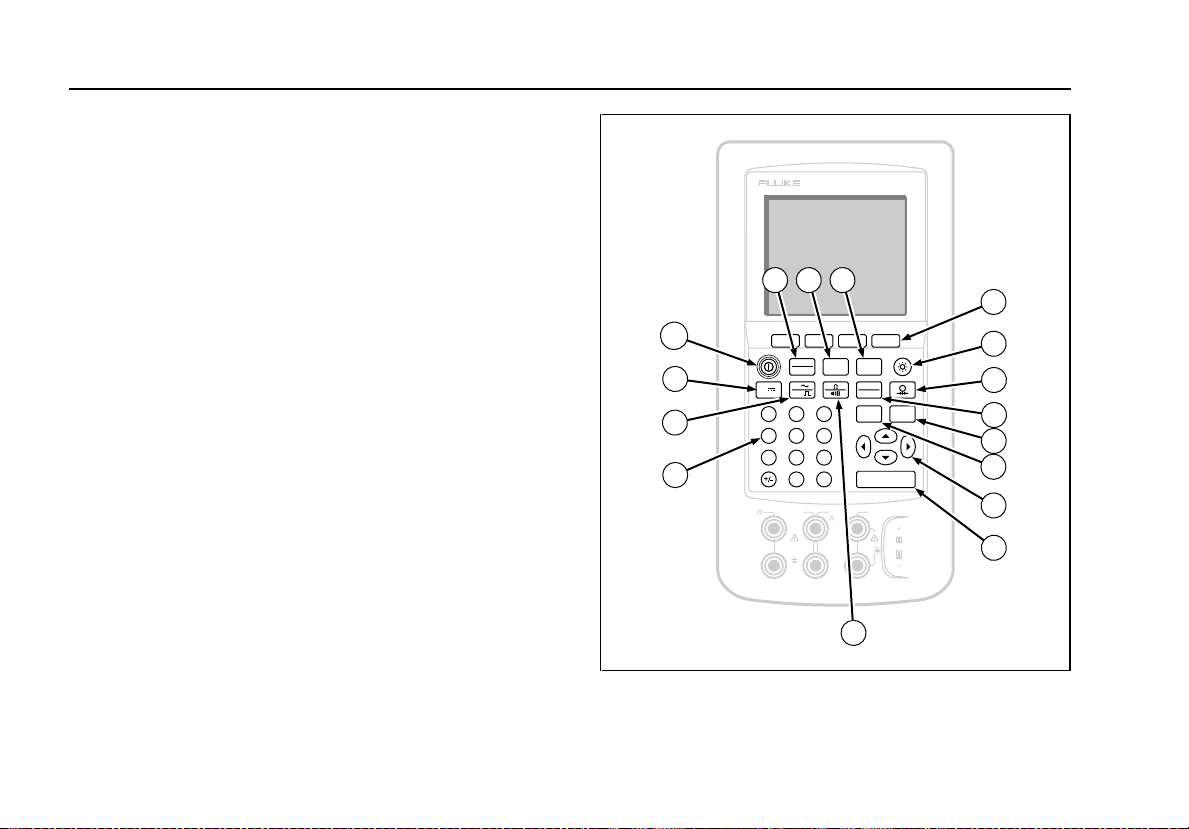

5. Keys....................................................................................................................... 14

6. Elements of a Typical Display................................................................................ 18

7. Installing the Strap and Using the Bail................................................................... 19

8. Removing the Battery and Using the Charger....................................................... 21

9. Electrical Measurement Connections .................................................................... 29

10. Gage and Differential Pressure Modules............................................................... 30

11. Connections for Measuring Pressure..................................................................... 32

12. Measuring Temperature with a Thermocouple...................................................... 35

13. Measuring Temperature with an RTD.................................................................... 39

vii

701/702

Users Manual

14. Electrical Sourcing Connections............................................................................. 42

15. Connections for Simulating a 4 to 20 mA Transmitter............................................ 44

16. Connections for Supplying Loop Power ................................................................. 46

17. Connections for Sourcing Pressure........................................................................ 49

18. Connections for Simulating a Thermocouple.......................................................... 51

19. Connections for Simulating an RTD....................................................................... 53

20. Checking a Relay Output Trip Alarm...................................................................... 58

21. Calibrating a Thermocouple Temperature Transmitter........................................... 63

22. Calibrating a Chart Recorder.................................................................................. 74

23. Measuring Voltage Drop......................................................................................... 74

24. Monitoring AC Line Voltage and Frequency........................................................... 75

25. Calibrating a Current-to-Pressure (I/P) Transducer................................................ 76

26. Measuring the Output Current of a Transmitter...................................................... 77

27. Measuring a Precision Resistor.............................................................................. 78

28. Sourcing Resistance............................................................................................... 78

29. Checking a Switch.................................................................................................. 79

30. Checking a Tachometer ......................................................................................... 79

31. Calibrating a Pressure-to-Current (P/I) Transducer................................................ 80

32. Calibrating a mV to Current Transmitter................................................................. 81

33. Checking a Vortex Shedding Flowmeter ................................................................ 82

34. Operting Environment Specification ....................................................................... 103

viii

Documenting Process Calibrator

Introduction

Fluke 701 and 702 Documenting Process Calibrators

(hereafter referred to as the calibrator) are batterypowered, hand-held instruments that measure and

source electrical and physical parameters. See Table

1. The calibrator lets you troubleshoot, calibrate,

verify, and document the calibration of process

instruments. See the back of this manual for

complete specifications.

In addition to the functions in Table 1, the 701 and

702 calibrators have the following features:

• General features:

Analog display in measurement mode to make it

easy to read the input level when the input is

unstable.

Display shows information in English, French,

German, Italian, or Spanish.

Thermocouple (TC) input/output jack that is

connected to an internal isothermal block with

automatic reference-junction temperature

compensation. Or, you can manually enter an

external temperature reference.

Stores results for later review.

Logs up to 8,000 data points (Model 702 with

PMLink software only.)

PC interface for uploading/downloading

procedures, lists, and results using PMLink

software (Model 702 only).

Automatic calibration procedures for transmitters

using split screen MEASURE/SOURCE mode.

Once you select the test parameters, you can

select an automatic procedure or you can

execute the test points one at a time.

• Features available in MEASURE mode:

1

701/702

Users Manual

Damping (smoothing of the last several

readings).

Display of measurements in engineering units or

percent of scale.

Data logging (Model 702 only).

• Features available in SOURCE mode:

An output ramp feature for testing limit switches.

Trip detect is either a 1V change or a continuity

status change (Open or Short) from one ramp

increment to the next.

An output step feature in which you set the step

size and press

uor dto step the output in

engineering units or percent of scale.

Unless stated otherwise, everything in this

manual applies to both the Fluke 701 and 702

Documenting Process Calibrators. For

maintenance, repair, performance testing, and

calibration instructions, order the 701/702

Service Manual (PN 944525). The phone

number in the USA and Canada for replacement

parts is: 1-800-526-4731. For service help in the

USA and Canada call 1-800-825-9810. For

application or operation assistance on Fluke

products call:

800-44-FLUKE (800-443-5853) in USA and

Canada

(31 40) 644200 in Europe

(206) 356-5500 from other countries

2

Documenting Process Calibrator

Introduction

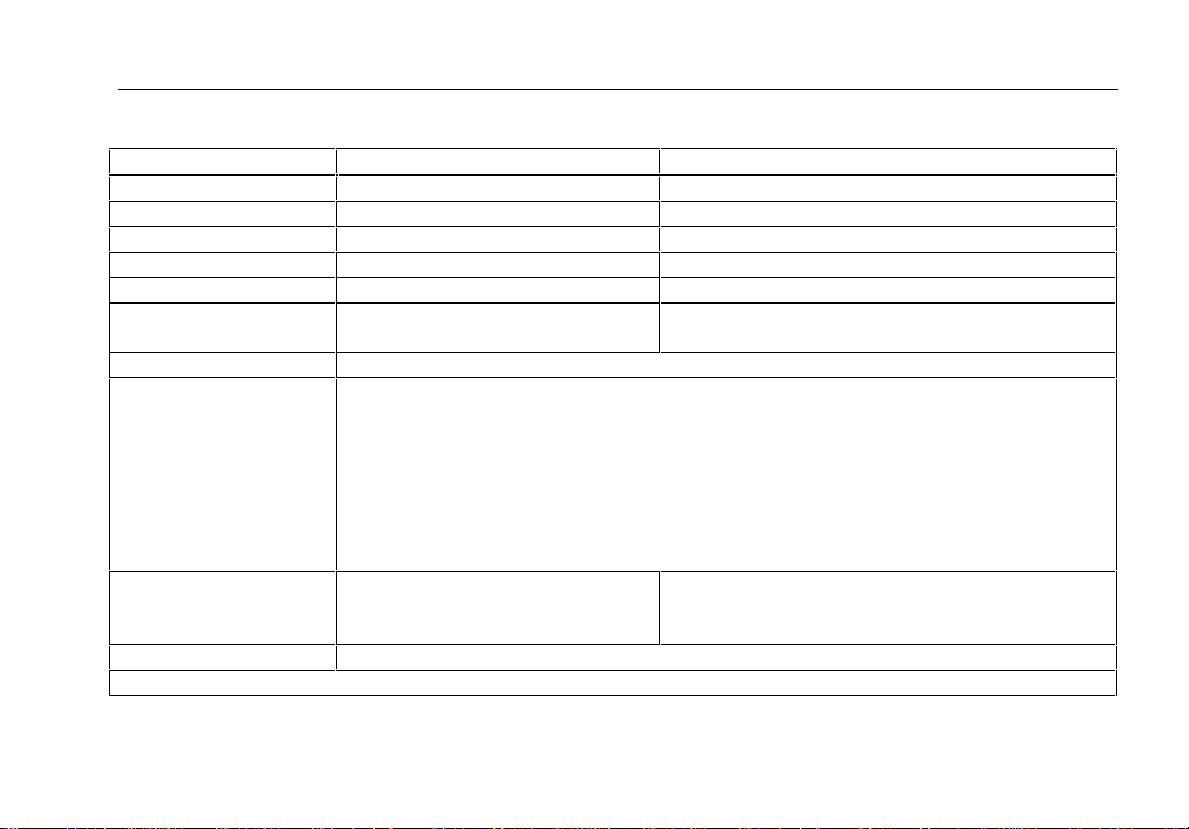

Table 1. Summary of Source and Measure Functions

FUNCTION MEASURE SOURCE

v dc V 0 to ±300V 0 to 11V in V or mV units (10 mA max)

h ac V 0 to 300V rms, 20 Hz to 5 kHz No sourcing

h Frequency 1 Hz to 50 kHz, 110 mV to 300V rms 1 mV to 10V pk square wave, 2 Hz to 50 kHz

q Resistance 0Ω to 11 kΩ 0Ω to 11 kΩ

m dc Current 0 to 110 mA 0 to 22 mA (28V max)

q Continuity Beep and the word Short indicates

continuity

t Thermocouple E, N, J, L, K, T, U, B, R, S, or C

t RTD

Measure 2,3, or 4 wire.

Source 2 Wire.

p Pressure 14 modules ranging from 0 to 10” H20

(2.5 kPa) to 0 to 10,000 psi (69,000

kPa)

s Loop Power 24 or 28V (22 mA max)

Note: Use an external hand pump or other pressure source as a pressure stimulus for the source pressure function.

No sourcing

100Ω Platinum (3926)

100Ω Platinum (385)

120Ω Nickel (672)

200Ω Platinum (385)

500Ω Platinum (385)

1000Ω Platinum (385)

10Ω Copper (427)

100Ω Platinum (3916)

Note

3

701/702

Users Manual

Standard Equipment

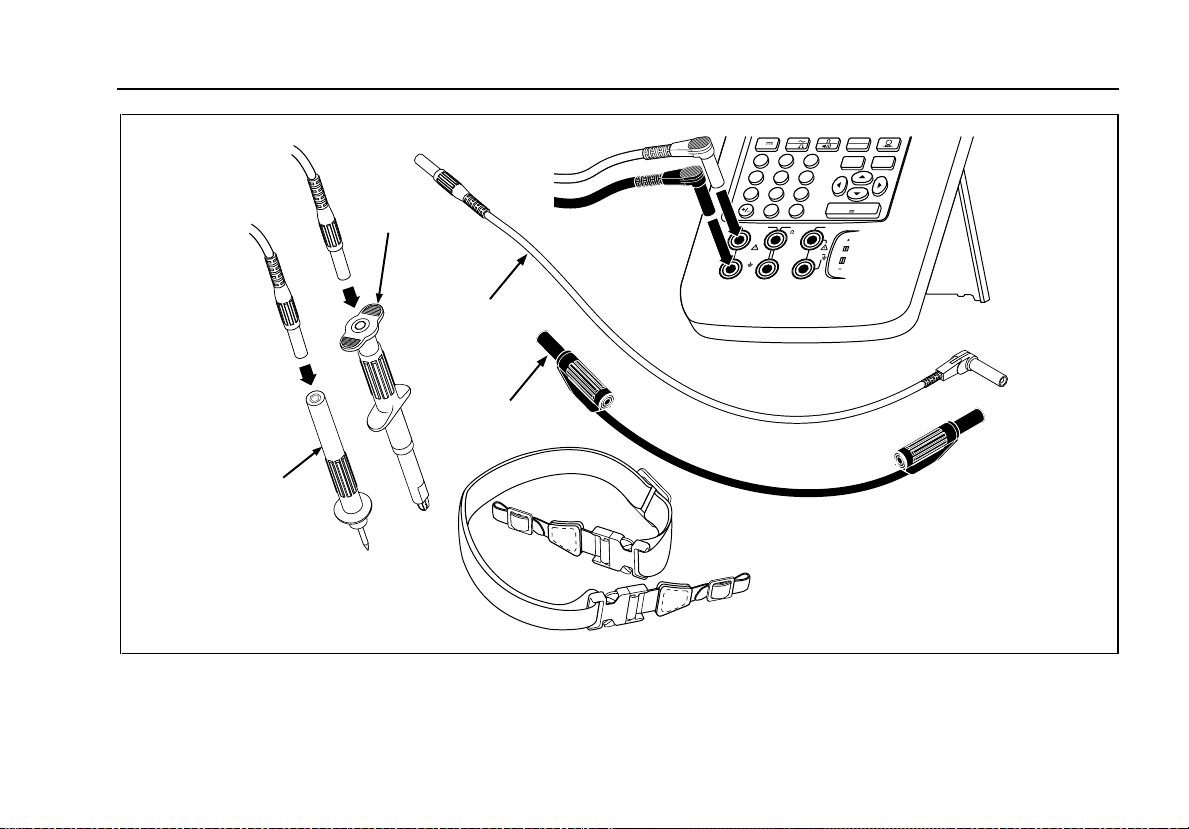

The items listed below and shown in Figure 1 are

included with your calibrator. If the calibrator is

damaged or something is missing, contact the place

of purchase immediately. To order replacement parts

or spares, see the user-replaceable parts list at the

end of this manual.

• TL24 industrial test leads (two sets).

• AC20 test clips (two sets).

• TP20 test probes (one set).

• Model BP7217 rechargeable nickel-cadmium

battery pack.

• Model BC7210 battery charger.

• Adjustable quick-release strap.

• Jumper for three-wire RTD measurement

connections (two included).

• 701/702 Users Manual.

• 701/702 Quick Reference Guide.

• Registration card.

4

Documenting Process Calibrator

Introduction

TP20

Test Probe

AC20

Test Clip

TL24

Test Leads

(2 Red and 2 Black)

Jumper

Figure 1. Standard Equipment

Strap

123

V

RTD

30V MAX

V

V

Hz

7

89

456

0

.

mA mA

RTD

MEASSOURCE

TC

RTD

CLEAR

RANGE

(ZERO)

ENTER

V

300V

TC

MAX

5

701/702

Users Manual

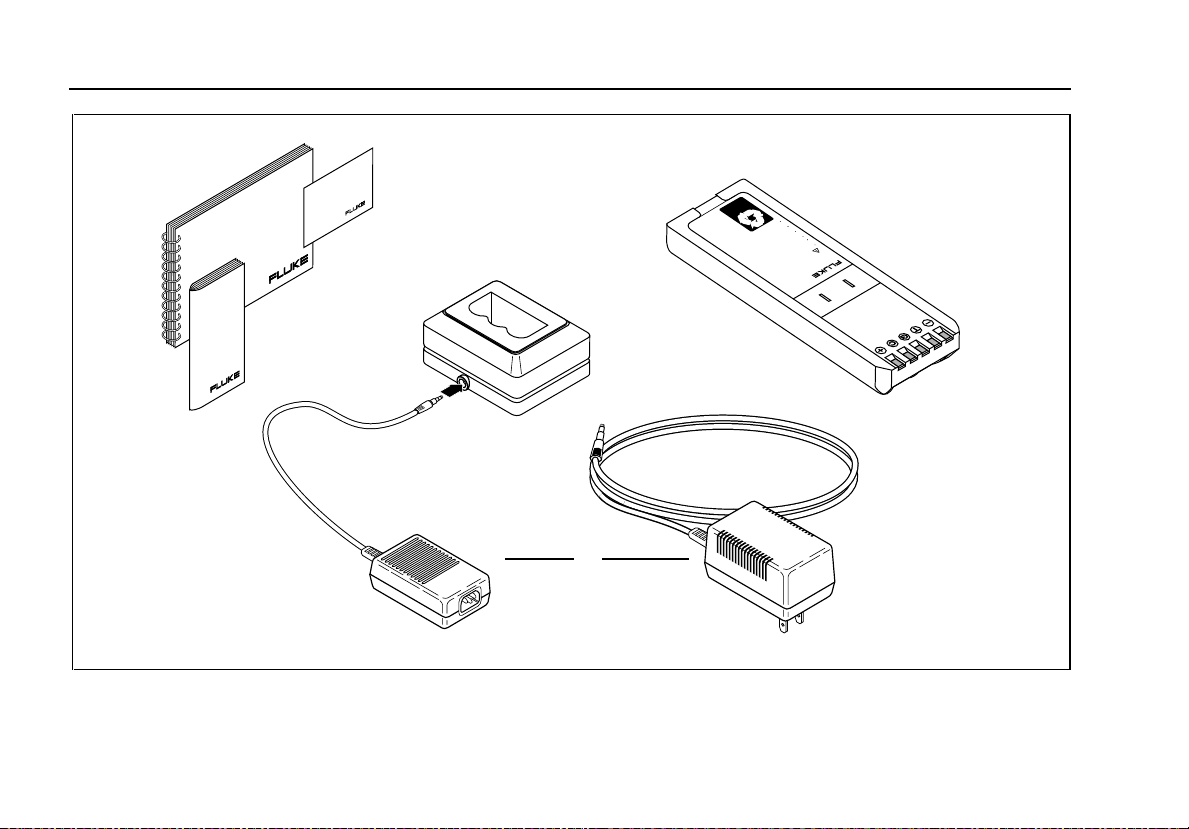

Users

Manual

Quick

Reference

Guide

Mail-in

Card

BC7210

Battery Charger

or

Figure 1. Standard Equipment (cont)

7.2V

1700 mAh

Ni-Cd

U.S.A.

CORPORATION

FLUKE

Nickel-Cadmium

Battery Pack

DO NOT EXPOSE TO FIRE

SPECIFIED IN MANUAL

USE CHARGING PROCEDURES

OF PROPERLY

MUST BE RECYCLED OR DISPOSED

DISASSEMBLE

DO NOT SHORT CIRCUIT OR

USE ONLY WITH FLUKE PRODUCTS

SAFE OPERATION

REFER TO USERS MANUAL FOR

RECHARGEABLE BATTERY

NICKEL-CADMIUM

BP7217

BP7217

6

Documenting Process Calibrator

Introduction

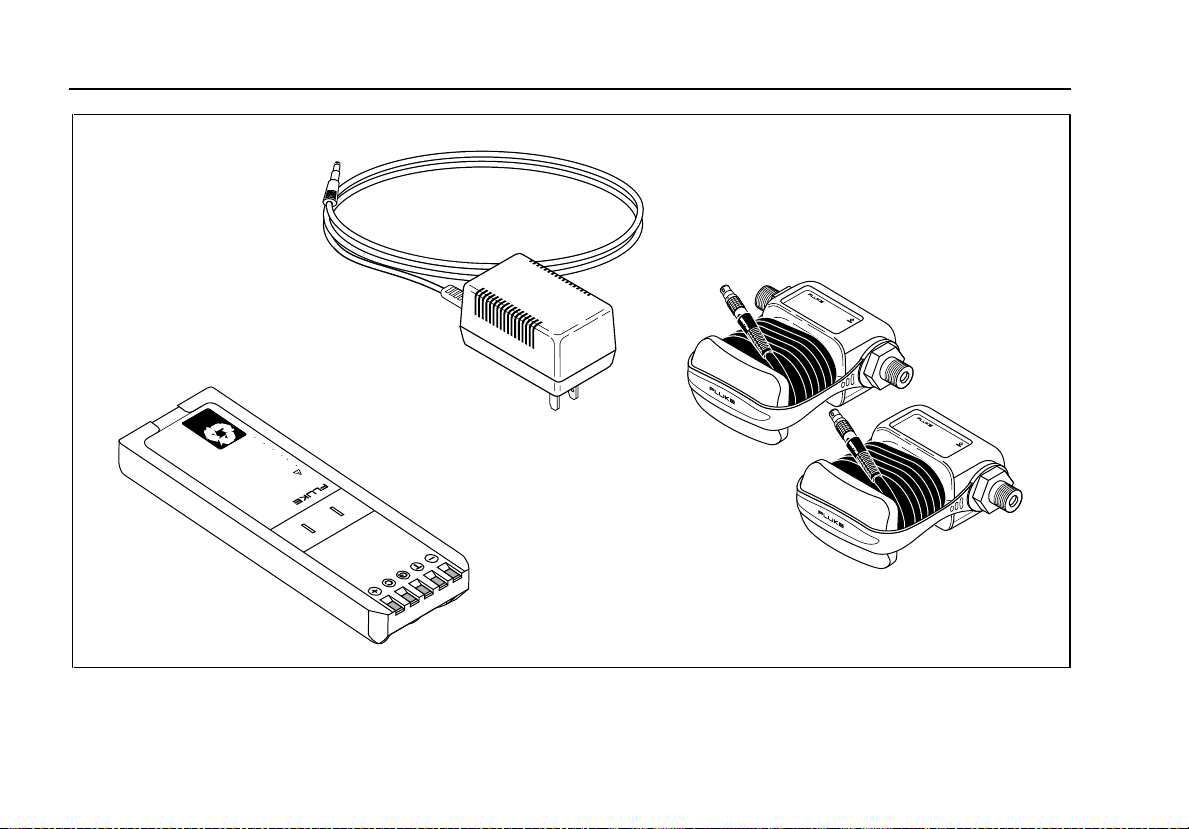

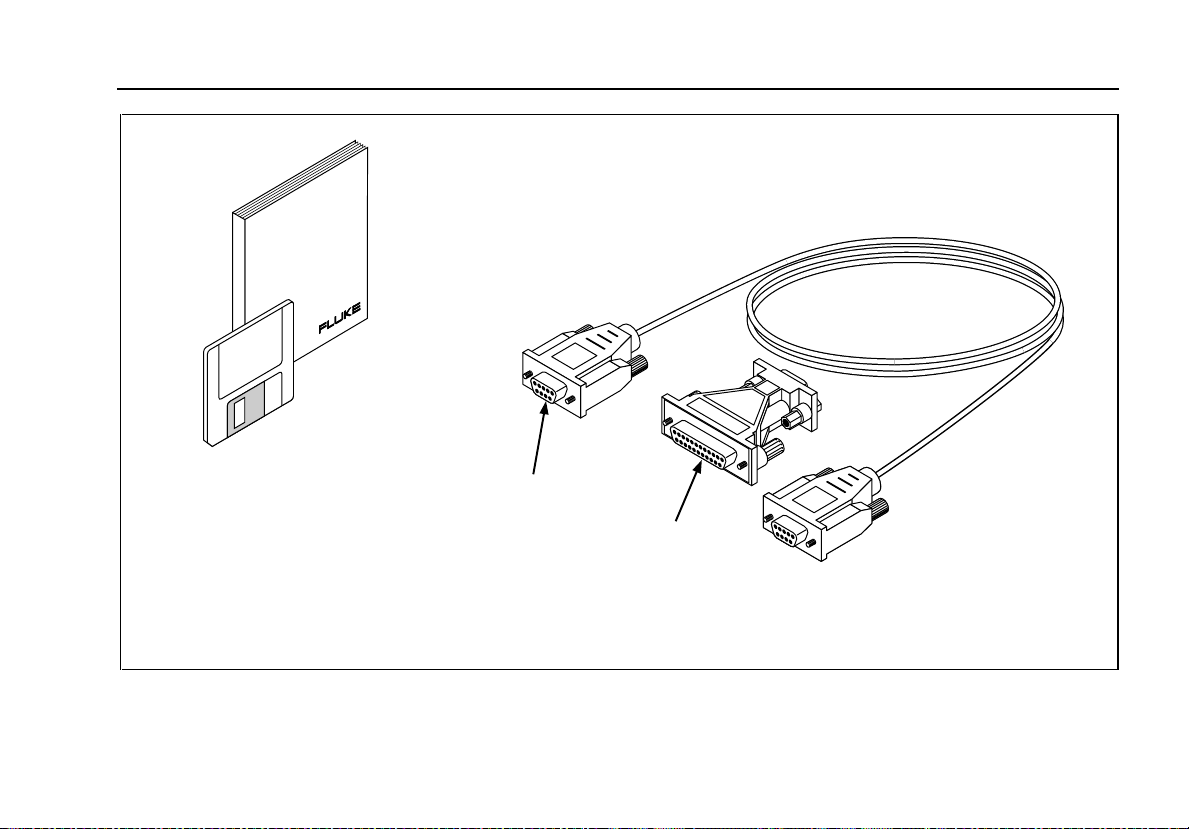

The accessories listed below and shown in Figure 2

are available from Fluke:

• Pressure Modules, Fluke model numbers listed

below. (Differential models also operate in gage

mode.)

700P01: 0 to 10 inches of H

O, or 2.5 kPa

2

(differential nonisolated)

700P02: 0 to 1 psi (differential, nonisolated)

700P03: 0 to 5 psi (differential, nonisolated)

700P04: 0 to 15 psi (differential, nonisolated)

700P22: 0 to 1 psi (differential, isolated)

700P23: 0 to 5 psi (differential, isolated)

700P24: 0 to 15 psi (differential, isolated)

700P05: 0 to 30 psi (gage, isolated)

700P06: 0 to 100 psi (gage, isolated)

700P07: 0 to 500 psi (gage, isolated)

700P08: 0 to 1000 psi (gage, isolated)

700P29: 0 to 3000 psi (gage, isolated)

700P30: 0 to 5000 psi (gage, isolated)

700P31: 0 to 10000 psi (gage, isolated)

• Model BE9005 Series Battery Eliminator for

bench-top use.

• PMLink software and cable for developing

procedures and transferring procedures and

data (for Model 702 only).

• Model BP7217 Nickel-Cadmium battery pack.

• Service Kit.

• C700 Carrying Case.

7

701/702

Users Manual

7.2V

U.S.A.

1700 mAh

Ni-Cd

CORPORATION

FLUKE

DO NOT EXPOSE TO FIRE

SPECIFIED IN MANUAL

USE CHARGING PROCEDURES

OF PROPERLY

MUST BE RECYCLED OR DISPOSED

DISASSEMBLE

DO NOT SHORT CIRCUIT OR

USE ONLY WITH FLUKE PRODUCTS

SAFE OPERATION

REFER TO USERS MANUAL FOR

RECHARGEABLE BATTERY

NICKEL-CADMIUM

BP7217

BE9005

Battery

Eliminator

BP7217

Nickel-Cadmium

Battery Pack

RANGE

700

PRESSURE MODULE

15 PSID/G

Fluke-700P0X

Gage Pressure Module

Fluke-700P0X

Differential

Pressure Module

P

04

1 bar100 kPa

RANGE

700

PRESSURE MODULE

P

100 PSIG

7 bar700 kPa

06

Figure 2. Accessories

8

PMLink

Manual

Documenting Process Calibrator

Introduction

PMLink Software

3.5-Inch Floppy Disk

PMLink Software

RS-232 Cable

DB9 to DB25

(9-Pin to 25-Pin)

Adapter

Figure 2. Accessories (cont)

9

701/702

Users Manual

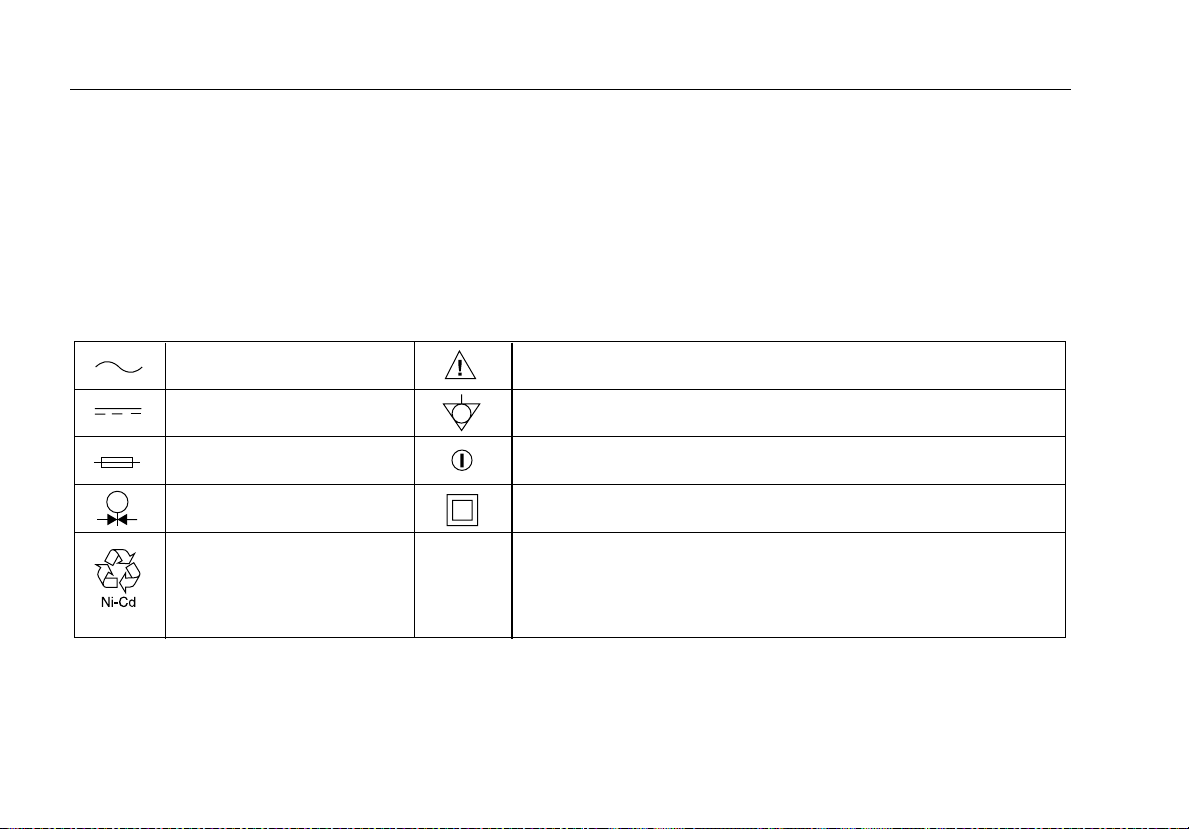

Safety Information

wThis calibrator is designed and tested in

accordance with IEC1010-1 and CAN/CSA C22.2

No. 1010.1-92. Use the calibrator only as specified in

this manual or in the Quick Reference Guide;

otherwise the protection provided by the calibrator

may be impaired.

AC-Alternating Current

DC-Direct Current

Fuse

Pressure

Recycling

CAT

II

Figure 3. Definition of Symbols

A WARNING identifies conditions and actions that

pose hazards to the user; a CAUTION identifies

conditions and actions that may damage the

calibrator or the equipment under test.

Symbols used on the calibrator and in this manual

are explained in Figure 3.

CAUTION see explanation in manual

Common (LO) Input equipotentiality

ON/OFF

Equipment protected throughout by DOUBLE INSULATION or

REINFORCED INSULATION

II

Overvoltage (Installation) Category

of Impluse Withstand Voltage protection provided. Typical locations

include; Mains Wall outlets, local appliances and PORTABLE

EQUIPMENT.

per IEC 1010-1 refers to the level

10

Documenting Process Calibrator

Safety Information

To protect yourself, follow these safety guidelines:

• Do not use the calibrator if it is damaged. Before

you use the calibrator, inspect the insulating

cover. Look for cracks or missing plastic. Pay

particular attention to the insulation surrounding

the connectors.

• Disconnect the power and discharge all high-

voltage capacitors in the equipment under test

before testing resistance or continuity.

• Inspect the test leads for damaged insulation or

exposed metal. Check test lead continuity.

Replace damaged test leads before using the

calibrator.

• Do not use the calibrator if it operates

abnormally. Protection may be impaired. When

in doubt, have the calibrator serviced.

• Select the proper function and range for your

measurement.

• Use caution when working above 42V pk, 30V

ac rms, or 60V dc. Such voltages pose a shock

hazard.

• When using the probes, keep your fingers away

from the probe contacts. Keep your fingers

behind the finger guards on the probes.

• Connect the common test lead before you

connect the live test lead. When you disconnect

test leads, disconnect the live test lead first.

• Do not operate the calibrator around explosive

gas, vapor, or dust.

• When using a pressure module, make sure the

process pressure line is shut off and

depressurized before you connect it to the

pressure module.

• Disconnect test leads before changing to

another measure or source function.

• When servicing the calibrator, use only specified

replacement parts.

11

701/702

Users Manual

Getting Acquainted with Your Calibrator

Input and Output Jacks

Figure 4 shows the calibrator input and output jacks.

Table 2 explains their use.

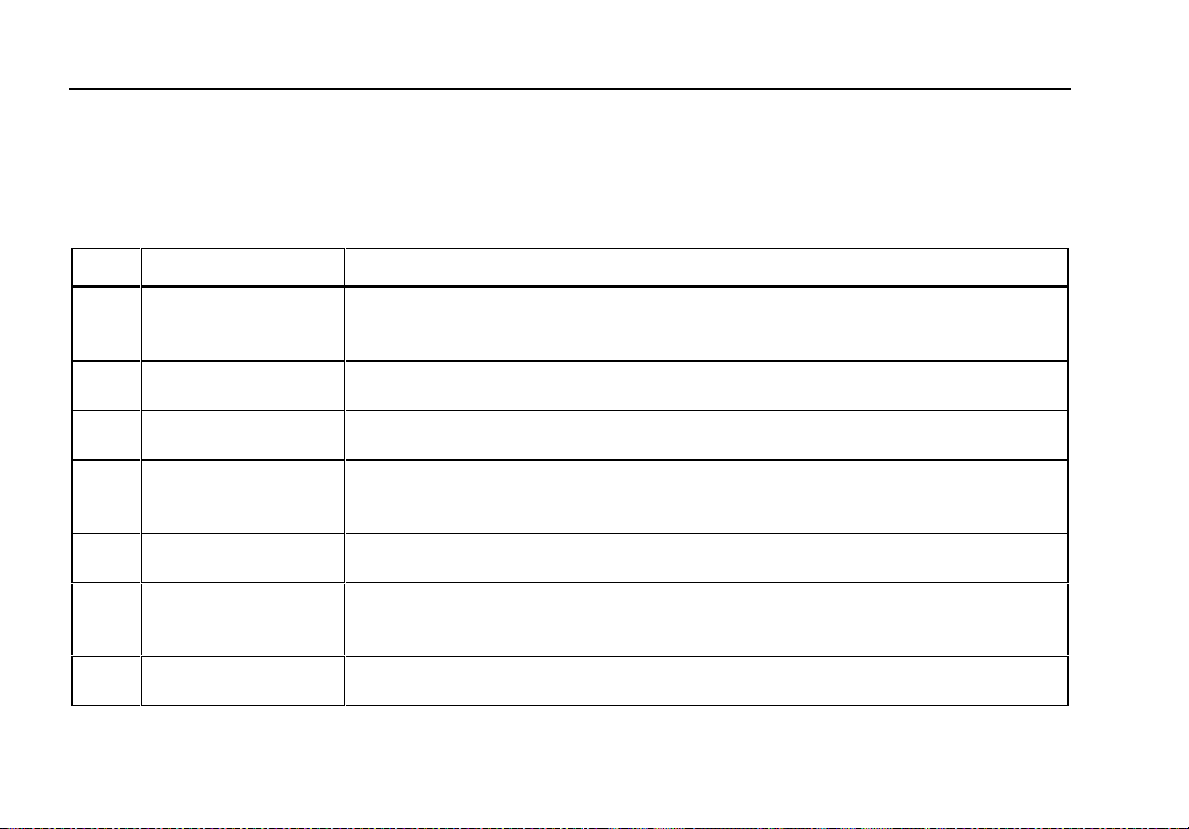

Table 2. Input/Output Jacks and Connectors

ITEM FEATURE DESCRIPTION

1 Battery Eliminator jack Jack for the Model BE9005 Battery Eliminator. Use the battery eliminator for bench-

top applications where ac line power is available. This input does not charge the

battery. The battery can only be charged in the external charger.

2 wSERIAL PORT (702

Only)

3 Pressure module

connector

4 TC input/output Jack for measuring or simulating thermocouples. This jack accepts a miniature

5, 6 w MEAS V jacks Input jacks for measuring voltage, frequency, or three- or four-wire RTDs (Resistance

7, 8 w SOURCE mA,

MEAS mA Ω RTD

jacks

9,10 w SOURCE V Ω RTD

jacks

Connects the calibrator to a personal computer. Instructions for communicating with the

calibrator are in the PMLink Software manual.

Connects the calibrator to a pressure module.

polarized thermocouple plug with flat, in-line blades spaced 7.9 mm (0.312 in) center to

center.

Temperature Detectors).

Jacks for sourcing or measur ing current, measuring resistance and RTDs, and

supplying loop power.

Output jacks for sourcing voltage, resistance, frequency, and for simulating RTDs

12

123

V

RTD

30V MAX

MEAS

SOURCE

V

V

Hz

7

89

456

0

.

mA mA

RTD

300V

MEASSOURCE

MAX

702

702

mA

SETUP

TC

RTD

CLEAR

(ZERO)

ENTER

V

TC

DOCUMENTING PROCESS CALIBRATOR

DOCUMENTING PROCESS CALIBRATOR

RANGE

Documenting Process Calibrator

Getting Acquainted with Your Calibrator

1

2

3

4

10

5

9

8

6

7

Figure 4. Input/Output Jacks and Connectors

13

701/702

Users Manual

Keys

Figure 5 shows the calibrator keys and Table 3

explains their functions. The softkeys are the four

unmarked blue keys just below the display. Softkey

functions are defined by the labels that appear above

the softkey during operation. Softkey labels and

other display text are shown in this manual in bold

type, for example, Choices.

DOCUMENTING PROCESS CALIBRATOR

702

21

3

4

16

MEAS

15

14

13

SOURCE

V

V

Hz

789

456

123

0

V

mA mA

RTD

30V MAX

SETUPmA

TC

RTD

CLEAR

RANGE

(ZERO)

ENTER

.

V

RTD

300V

MEASSOURCE

TC

MAX

5

6

7

8

9

10

11

12

Figure 5. Keys

14

Documenting Process Calibrator

Getting Acquainted with Your Calibrator

Table 3. Key Functions

ITEM FEATURE DESCRIPTION

1 M key Cycles the calibrator through MEASURE, SOURCE, and MEASURE/SOURCE

modes.

2 m key Selects mA (current) measure or source function. For loop power on/off, go to the

s mode.

3 s key Enters and exits the s mode to modify operating parameters.

4 Softkeys Perform the function defined by the label above each key on the display.

5 C key Turns the backlight on and off.

6 p key Selects the pressure measurement or sourcing function.

7 t key Selects TC (thermo couple) or RTD (resistance temperature detector) measurement

or sourcing functions.

8 r key Toggles between autorange and locked range, and increments range. Each time

you press r, the calibrator locks on the next range. Press this key again for 2

seconds to resume autorange.

9 c key Clears a partial data entry, or zeros the output when in the SOURCE mode.

10 u, d, L, R keys Adjust the display contrast. Also, use these keys to make selections when

prompted. These keys also increase or decrease the output in SOURCE mode

when using the step feature.

15

701/702

Users Manual

Table 3. Key Functions (cont)

ITEM FEATURE DESCRIPTION

11 e key Terminates a numeric entry when setting a source value, or selects entries from lists.

12 q key Toggles between resistance and continuity functions in MEASURE mode, or selects

the resistance function in SOURCE mode.

13 Numeric keypad Used whenever a numeric entry is required.

14 h key Toggles between ac voltage and frequency functions in MEASURE mode, or selects

frequency output in SOURCE mode.

15 v key Selects the dc voltage function in MEASURE mode, or selects dc voltage in SOURCE

mode.

16 o key Turns the power on and off.

16

Documenting Process Calibrator

Setting Up the Calibrator

Display

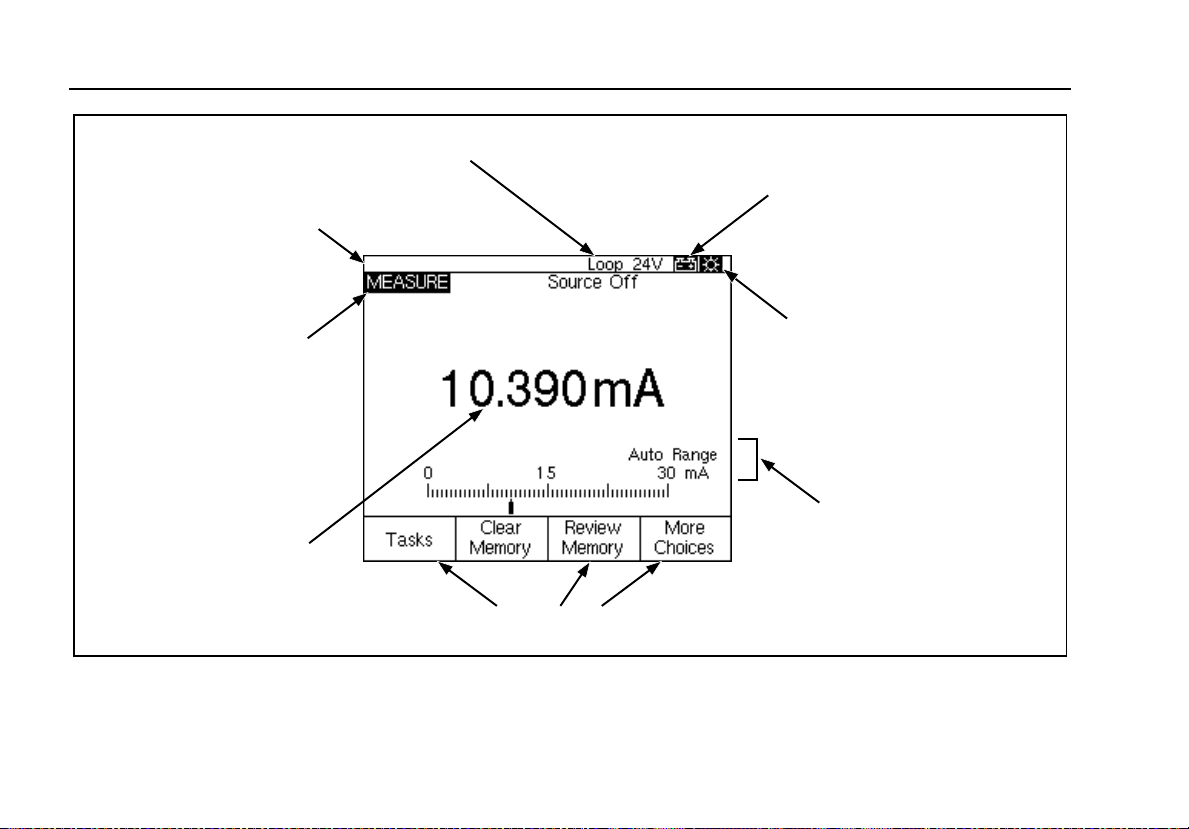

Figure 6 shows the features of a typical display. The

display shown is MEASURE mode. Near the top of

the display is “Source Off.” This is the area of the

display that shows what is happening in the other

mode (SOURCE or MEASURE). The other parts of

the display are as follows:

Status Bar: shows the time and date (if set in

•

Setup mode), and shows the status of Loop

Power, Battery Save, and Backlight Timeout; all

of which are set in Setup mode. The low battery

and backlight on annunciators also appear here.

Mode Indicator: Shows whether the calibrator is

•

in MEASURE or SOURCE mode. In split screen

MEASURE/SOURCE mode, there is a Mode

Indicator for each window.

Measured Value: Shows the measured value in

•

your choice of engineering units or percent of

scale.

Range Status: Shows whether Auto Range is on,

•

and what range is currently being used.

Setting Up the Calibrator

This section consists of general information that

should be read before you use the calibrator.

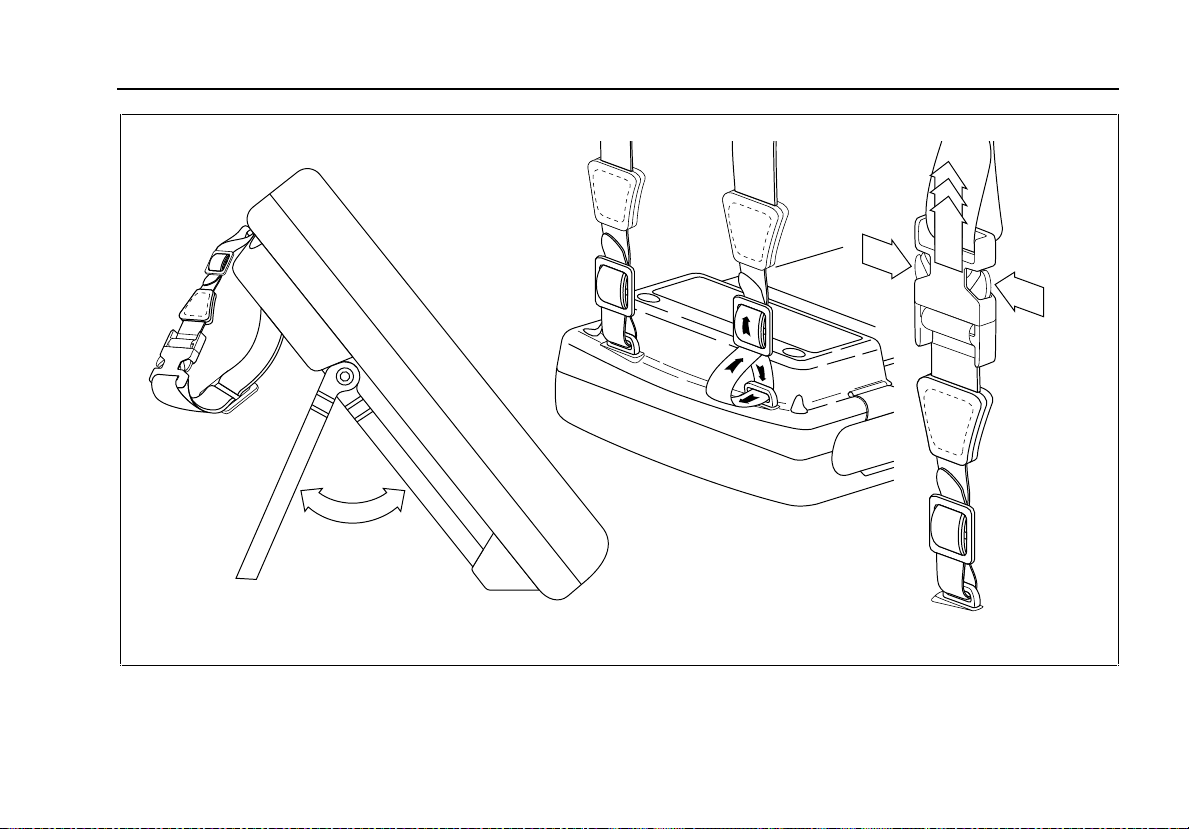

Using the Strap and Bail

After you unpack the calibrator, attach its carrying

strap as shown in Figure 7. You can adjust the strap

as necessary to hang the calibrator on any sturdy

support. Figure 4 also shows you how to prop open

the bail to stand the calibrator at a comfortable

viewing angle for benchtop use.

17

701/702

Users Manual

Status Bar

Mode Indicator

Measured Value

Loop Power Annunciator

Battery Save Annunciator

Backlight Timeout

Annunciator

Range Status

Softkey Labels

18

Figure 6. Elements of a Typical Display

Documenting Process Calibrator

Setting Up the Calibrator

Figure 7. Installing the Strap and Using the Bail

19

701/702

Users Manual

Charging the Battery

wBefore you use the calibrator for the first time,

charge its battery pack for 2 hours. Due to safety

requirements, the battery must be charged outside

the calibrator.

Figure 8 shows how to remove the battery. Remove

the battery door and tap the calibrator with your hand

to get the battery out. Place the battery in the

charger and connect the charger to line power. The

charger automatically senses line voltage and

adjusts itself accordingly.

A discharged battery is fully charged in 2 hours or

less in fast-charge mode (steady indicator light on

the charger). Full charge is maintained after that time

in trickle-charge mode (blinking indicator light on the

charger). Switching between charging modes is

automatic. You can leave the battery pack on trickle

charge indefinitely without damage.

NOTE

When you remove a charged battery from

the charger, wait for the blinking indicator to

go off before you insert a discharged battery.

It takes about 2 seconds for the battery

charger to reset.

20

Loading...

Loading...