Page 1

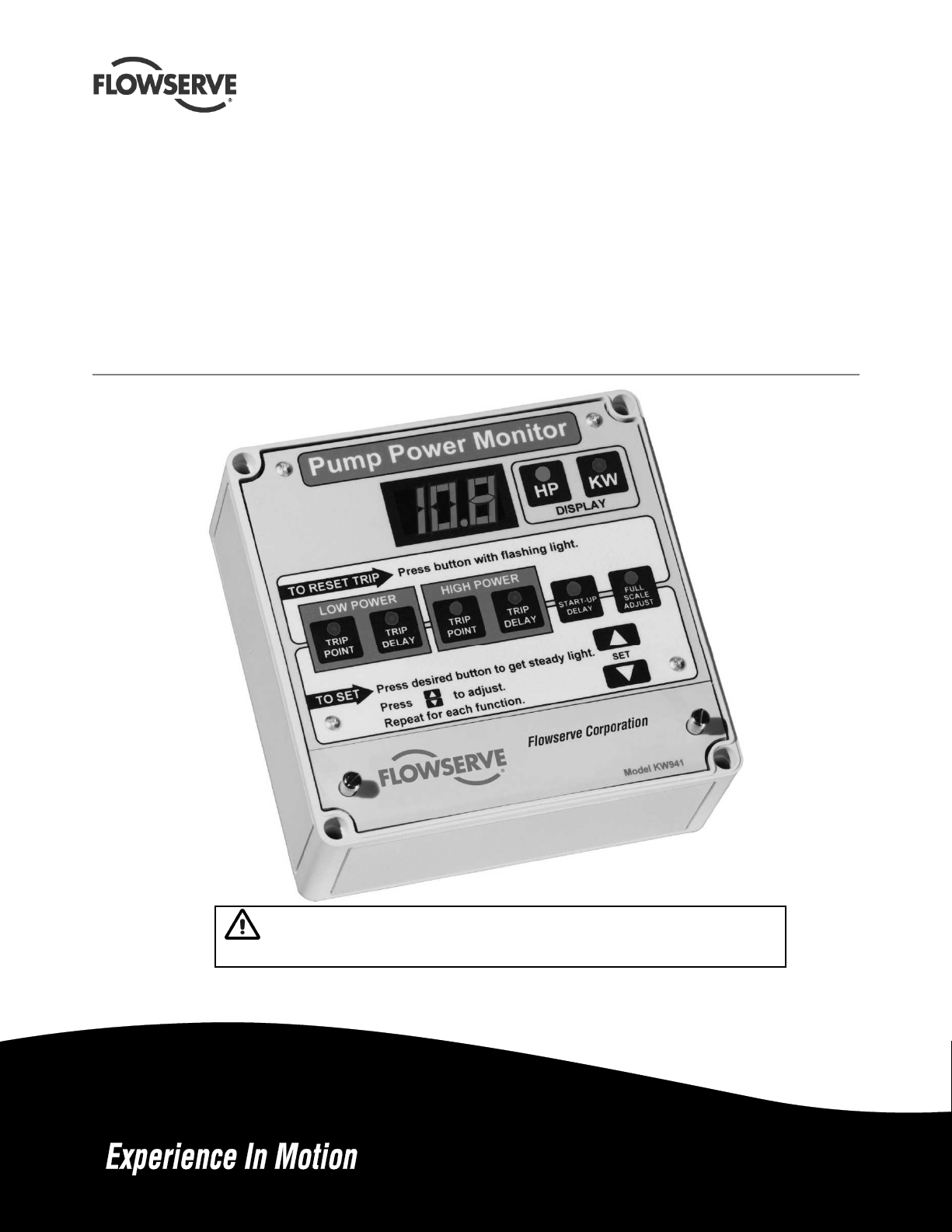

USER INSTRUCTIONS

Flowserve KW941

Pump Power Monitor™

Pump Power Monitor for protection against both under load and

over load conditions.

PCN= = 71569285 – 02-12 (E) (incorporates PM-200 & PM-201)

Original instructions.

Installation

Operation

Maintenance

These instructions must be read prior to installing,

operating, using and maintaining this equipment.

Page 2

KW941 Pump Power Monitor USER INSTRUCTIONS ENGLISH 71569285 02-12

CONTENTS

Page

1 INTRODUCTION AND SAFETY ............................ 3

1.1 General ........................................................... 3

1.2 CE marking and approvals .............................. 3

1.3 Disclaimer ....................................................... 3

1.4 Copyright ......................................................... 3

1.5 Duty conditions ................................................ 3

1.6 Safety .............................................................. 4

1.7 Nameplate and safety labels ........................... 5

1.8 Specific machine performance ........................ 5

2 TRANSPORT AND STORAGE .............................. 5

2.1 Consignment receipt and unpacking............... 5

2.2 Handling .......................................................... 5

2.3 Storage ............................................................ 5

2.4 Recycling and end of product life .................... 5

3 DESCRIPTION ...................................................... 6

3.1 Configurations ................................................. 6

3.2 Nomenclature .................................................. 6

3.3 Design of major parts ...................................... 6

3.4 Performance and operation limits ................... 7

4 INSTALLATION ...................................................... 8

4.1 Location ........................................................... 8

4.2 Electrical connections ..................................... 8

5 SETUP AND OPERATION .................................. 13

5.1 Display Mode – Power Units Selection ......... 13

5.2 Full Scale Adjust ............................................ 13

5.3 Alarms ........................................................... 14

5.4 Demo Mode ................................................... 16

5.5 Current Sensor Field Replacement ............... 16

6 MAINTENANCE ................................................... 17

6.1 Spare parts .................................................... 17

6.2 Tools required ................................................ 17

7 FAULTS: CAUSES AND REMEDIES .................. 17

8 PARTS LIST AND DRAWINGS ........................... 20

9 CERTIFICATION ................................................. 23

10 OTHER RELEVANT DOCUMENTATION AND

MANUALS ........................................................ 23

10.1 Supplementary user instructions .................. 23

10.2 Change Notes .............................................. 23

Page 2 of 24 flowserve.com

Page 3

KW941 Pump Power Monitor USER INSTRUCTIONS ENGLISH 71569285 02-12

1 INTRODUCTION AND SAFETY

1.1 General

These instructions must always be kept

close to the product's operating location or

directly with the product.

Flowserve products are designed, developed and

manufactured with state-of-the-art technologies in

modern facilities. The unit is produced with great

care and commitment to continuous quality control,

utilizing sophisticated quality techniques and safety

requirements.

Flowserve is committed to continuous quality

improvement and being at service for any further

information about the product in its installation and

operation or about its support products, repair and

diagnostic services.

These instructions are intended to facilitate

familiarization with the product and its permitted use.

Operating the product in compliance with these

instructions is important to help ensure reliability in

service and avoid risks. The instructions may not

take into account local regulations; ensure such

regulations are observed by all, including those

installing the product. Always coordinate repair

activity with operations personnel, and follow all plant

safety requirements and applicable safety and health

laws and regulations.

These instructions must be read prior to

installing, operating, using and maintaining the

equipment in any region worldwide. The

equipment must not be put into service until all

the conditions relating to safety, noted in the

instructions, have been met. Failure to follow and

apply the present user instructions is considered

to be misuse. Personal injury, product damage,

delay or failure caused by misuse are not covered

by the Flowserve warranty.

1.2 CE marking and approvals

It is a legal requirement that machinery and equipment

put into service within certain regions of the world shall

conform with the applicable CE Marking Directives

covering Machinery and, where applicable, Low Voltage

Equipment, Electromagnetic Compatibility (EMC),

Pressure Equipment Directive (PED) and Equipment for

Potentially Explosive Atmospheres (ATEX).

Where applicable, the Directives and any additional

Approvals, cover important safety aspects relating to

machinery and equipment and the satisfactory provision

of technical documents and safety instructions. Where

applicable this document incorporates information

relevant to these Directives and Approvals.

To confirm the Approvals applying and if the product is

CE marked, check the product identification label and

the Certification. (See section 9, Certification.)

1.3 Disclaimer

Information in these User Instructions is believed to

be complete and reliable. However, in spite of all of

the efforts of Flowserve Corporation to provide

comprehensive instructions, good engineering and

safety practice should always be used.

Flowserve manufactures products to exacting

International Quality Management System Standards

as certified and audited by external Quality

Assurance organizations. Genuine parts and

accessories have been designed, tested and

incorporated into the products to help ensure their

continued product quality and performance in use.

As Flowserve cannot test parts and accessories

sourced from other vendors the incorrect

incorporation of such parts and accessories may

adversely affect the performance and safety features

of the products. The failure to properly select, install

or use authorized Flowserve parts and accessories is

considered to be misuse. Damage or failure caused

by misuse is not covered by the Flowserve warranty.

In addition, any modification of Flowserve products or

removal of original components may impair the safety

of these products in their use.

1.4 Copyright

All rights reserved. No part of these instructions may

be reproduced, stored in a retrieval system or

transmitted in any form or by any means without prior

permission of Flowserve.

1.5 Duty conditions

This product has been selected to meet the

specifications of your purchase order. The

acknowledgement of these conditions has been sent

separately to the Purchaser. A copy should be kept

with these instructions.

The product must not be operated beyond

the parameters specified for the application.

If there is any doubt as to the suitability of the

product for the application intended, contact

Flowserve for advice, quoting the part number.

Page 3 of 24 flowserve.com

Page 4

KW941 Pump Power Monitor USER INSTRUCTIONS ENGLISH 71569285 02-12

If the conditions of service on your purchase order are

going to be changed (for example supply voltage or

frequency) it is requested that the user seeks the

written agreement of Flowserve before start up.

1.6 Safety

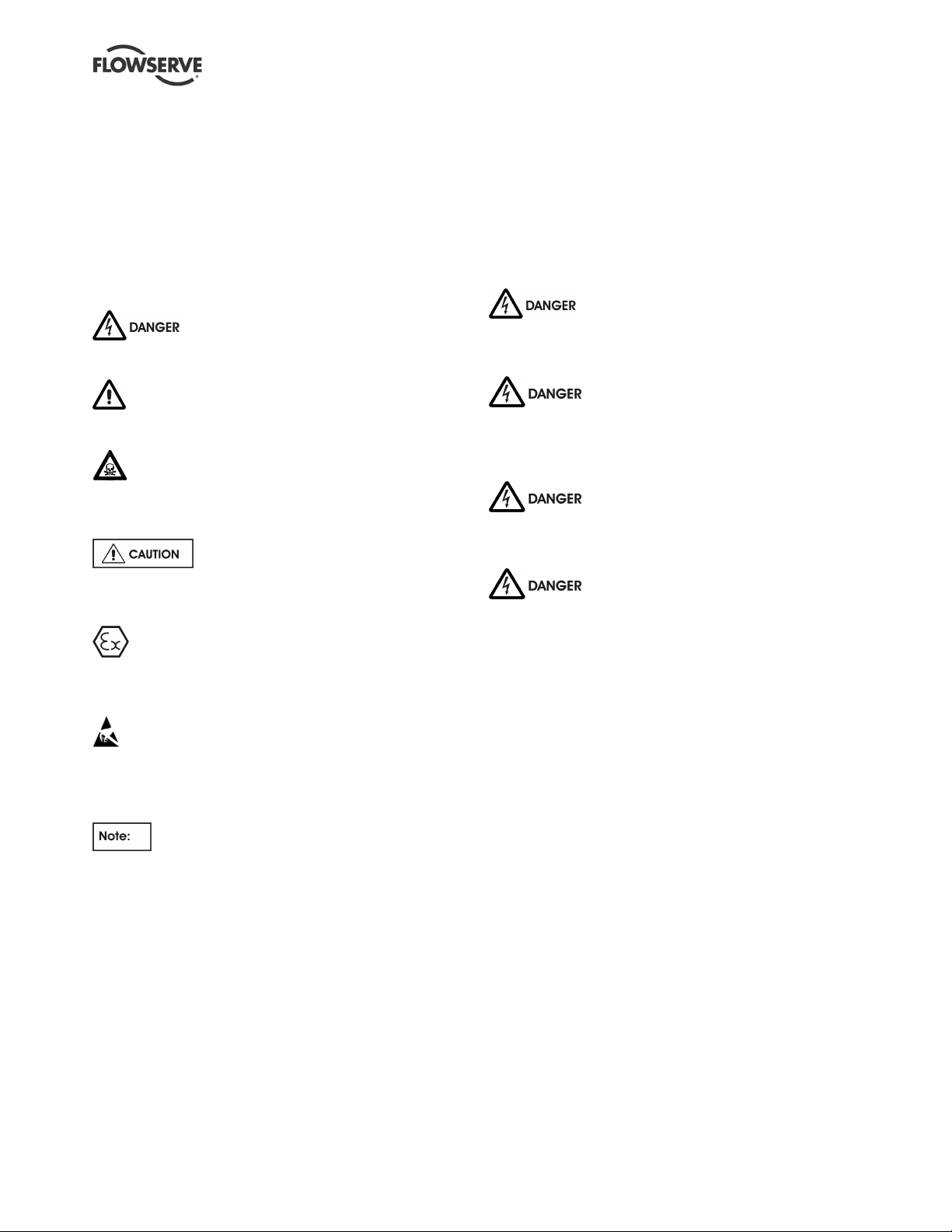

1.6.1 Summary of safety markings

These User Instructions contain specific safety

markings where non-observance of an instruction would

cause hazards. The specific safety markings are:

This symbol indicates electrical safety

instructions where non-compliance will involve a high

risk to personal safety or the loss of life.

This symbol indicates safety instructions where

non-compliance would affect personal safety and could

result in loss of life.

This symbol indicates “hazardous and toxic

substances” safety instructions where non-compliance

would affect personal safety and could result in loss of

life.

This symbol indicates safety instructions

where non-compliance will involve some risk to safe

operation and personal safety and would damage the

equipment or property.

This symbol indicates explosive atmosphere zone

marking according to ATEX. It is used in safety

instructions where non-compliance in the hazardous

area would cause the risk of an explosion.

This symbol is used in safety instructions to

remind not to rub non-metallic surfaces with a dry

cloth; ensure the cloth is damp. It is used in safety

instructions where non-compliance in the hazardous

area would cause the risk of an explosion.

Always coordinate repair activity with operations and

health and safety personnel, and follow all plant

safety requirements and applicable safety and health

laws and regulations.

1.6.3 Safety action

This is a summary of conditions and actions to help

prevent injury to personnel and damage to the

environment and to equipment.

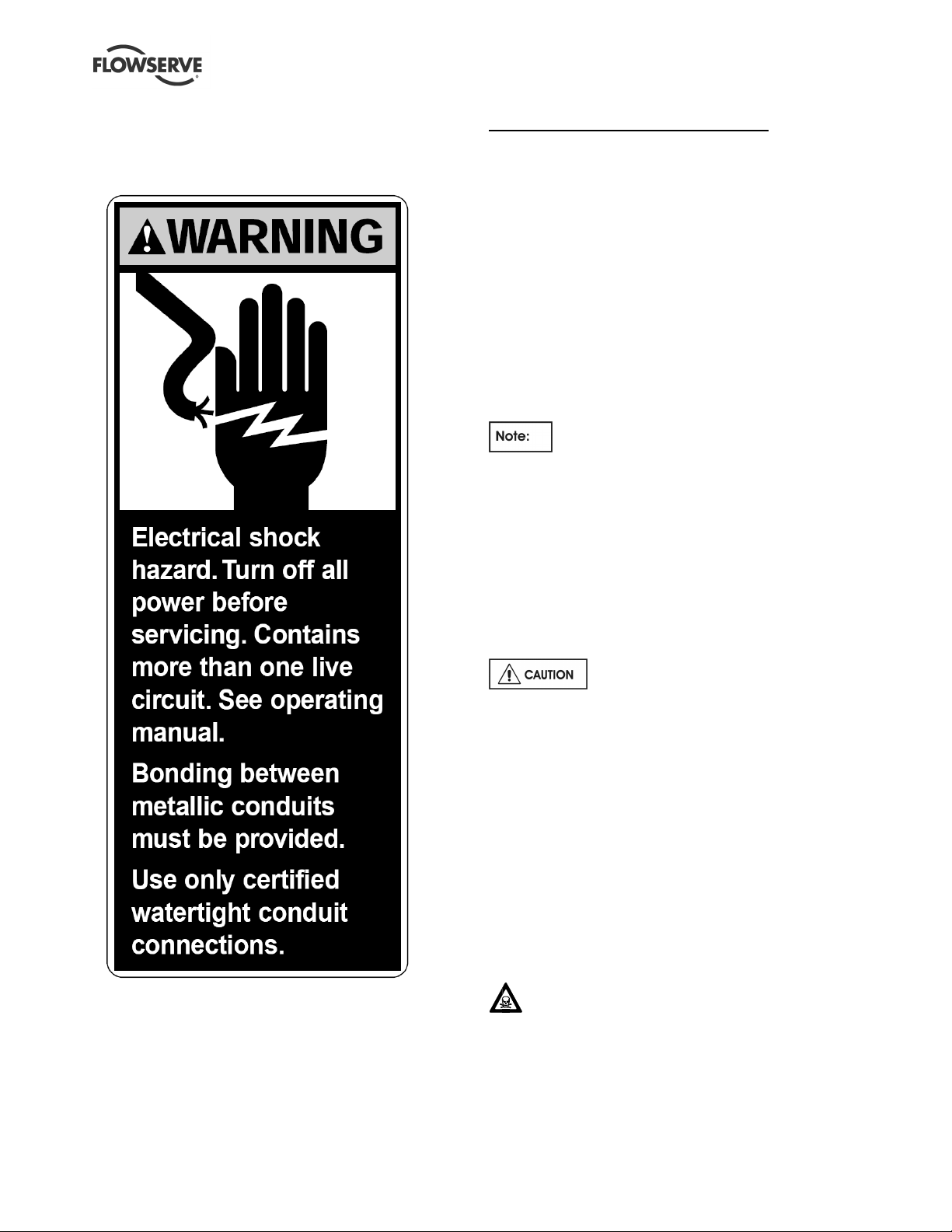

NEVER DO MAINTENANCE WORK

WHEN THE UNIT IS CONNECTED TO POWER.

LOCK OUT THE POWER SUPPLY.

Dangerous voltages are present in

motor control panels and circuits. INSTALLATION

MUST BE PERFORMED BY QUALIFIED

PERSONNEL!

Improper installation or operation can

cause damage to the unit and can result in an

unprotected pump or nuisance tripping of the pump.

The current transformer/toroid

secondary leads must always be shorted together or

connected to an appropriate measuring device to

provide a suitable burden whenever the primary

circuit is energized. Operation of a current

transformer/toroid with an open secondary will result

in hazardous voltages and destruction of the device!

This sign is not a safety symbol but indicates

an important instruction in the assembly process.

1.6.2 Personnel qualification and training

All personnel involved in the operation, installation,

inspection and maintenance of the unit must be

qualified to carry out the work involved. If the personnel

in question do not already possess the necessary

knowledge and skill, appropriate training and instruction

must be provided. If required the operator may contact

the manufacturer/supplier to provide applicable

training/technical support.

Page 4 of 24 flowserve.com

Page 5

KW941 Pump Power Monitor USER INSTRUCTIONS ENGLISH 71569285 02-12

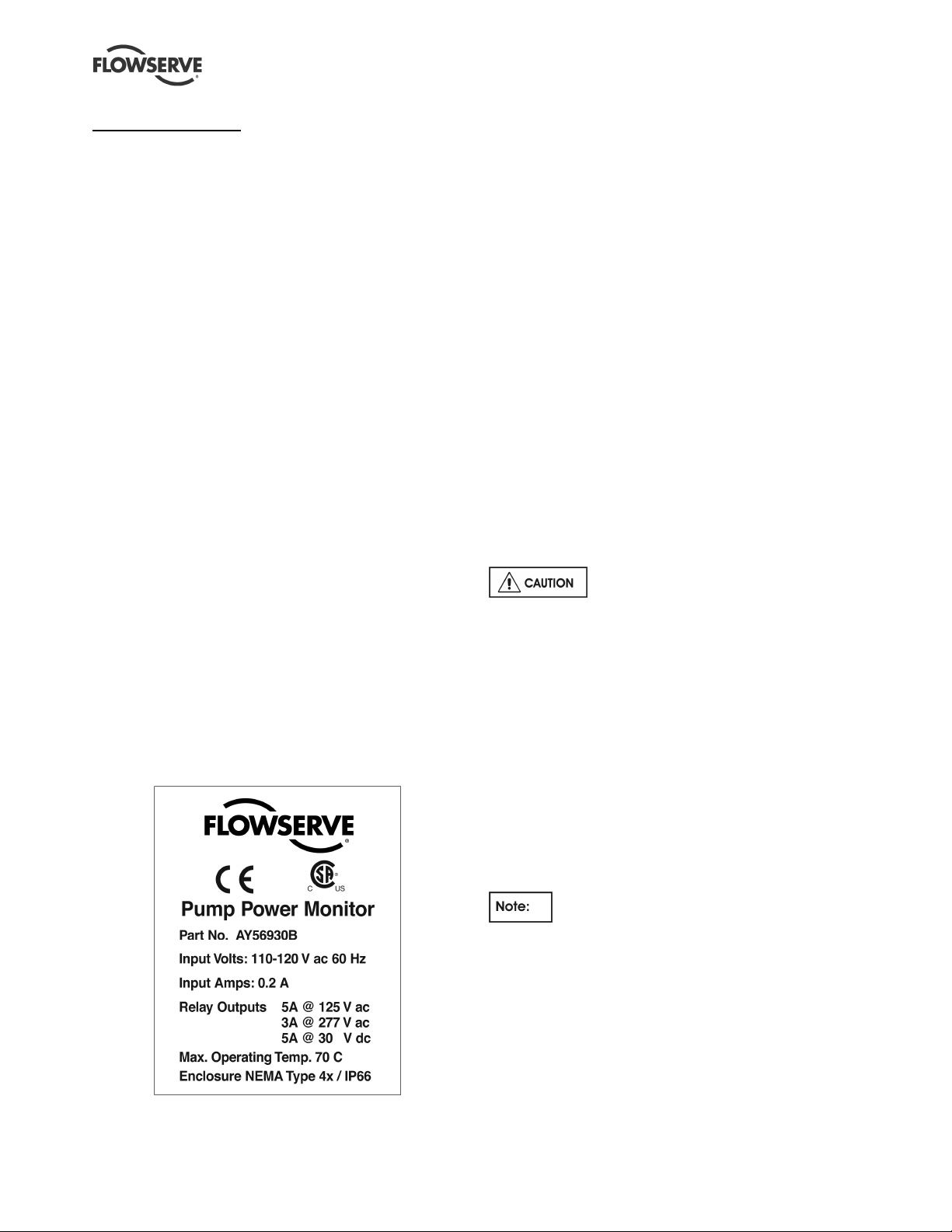

1.7 Nameplate and safety labels

1.7.1 Safety labels

2 TRANSPORT AND STORAGE

2.1 Consignment receipt and unpacking

Immediately after receipt of the equipment it must be

checked against the delivery/shipping documents for

its completeness and that there has been no damage

in transportation. Any shortage and/or damage must

be reported immediately to Flowserve Pump Division

and must be received in writing within ten days of

receipt of the equipment. Later claims cannot be

accepted.

Check all crates, boxes or wrappings for any

accessories or spare parts that may be packed

separately from the equipment or attached to side

walls of the box or equipment.

The current senor (toroid) is shipped inside

the KW941 underneath the wiring compartment

cover.

2.2 Handling

The KW941 Power Monitor is small and light so

handling and mounting are easy. The unit weighs

approximately 2.3 kg (5 lbs).

2.3 Storage

1.8 Specific machine performance

For performance parameters see section 1.5, Duty

conditions. Where performance data has been supplied

separately to the purchaser these should be obtained

and retained with these User Instructions.

Store the pump in a clean, dry location

away from vibration. If kept in its original packaging

and protected from excessive environmental effects

like continuous high humidity or corrosive gases the

shelf life would be decades.

2.4 Recycling and end of product life

At the end of the service life of the product or its

parts, the relevant materials and parts should be

recycled or disposed of using an environmentally

acceptable method and in accordance with local

regulations. If the product contains substances that

are harmful to the environment, these should be

removed and disposed of in accordance with current

local regulations. This also includes the liquids

and/or gases that may be used in the "seal system"

or other utilities.

Make sure that hazardous substances are

disposed of safely and that the correct personal

protective equipment is used. The safety

specifications must be in accordance with the current

local regulations at all times.

Page 5 of 24 flowserve.com

Page 6

KW941 Pump Power Monitor USER INSTRUCTIONS ENGLISH 71569285 02-12

3 DESCRIPTION

3.1 Configurations

The KW941 Pump Power Monitor provides a power

measurement, display and trip-point system to detect

and protect against both UNDERLOAD and

OVERLOAD conditions. The KW941 monitors

MOTOR POWER by sensing both VOLTAGE and

CURRENT. By factoring in motor efficiency, the

KW941 can be scaled to display PUMP POWER. The

adjustable trip-points can be set using power

information provided by the Flowserve Pros+

software for Flowserve pumps.

The KW941 consists of a current sensor and a

Display/Control module. The sensor, through which

one motor power lead passes, normally is located

inside the motor starter panel and provides a sample

of motor current to the Display/Control module. A

voltage sample is provided by a control voltage

transformer (not supplied) located between two of the

three motor power phases. The Display/ Control

module (located outside the starter panel) processes

the current and voltage sample information, contains

the LED display, alarm relays, and provides operator

interface.

Three models of the KW941 Power Monitor are

available based upon the supply voltage at the

customer’s site. The part numbers are listed below:

AY56930B = 110-120v, 60Hz

AY56930C = 220-240v, 50Hz

AY56930D = 220-240v, 60Hz

3.2 Nomenclature

3.2.1 Product Identification Label

3.2.2 Abbreviations

TS = terminal strip

TS1 = terminal strip screw position #1

Jp = jumper

NO = normally open

NC = normally closed

FS = full scale (power)

CR = control relay

MOL = motor overload

3.3 Design of major parts

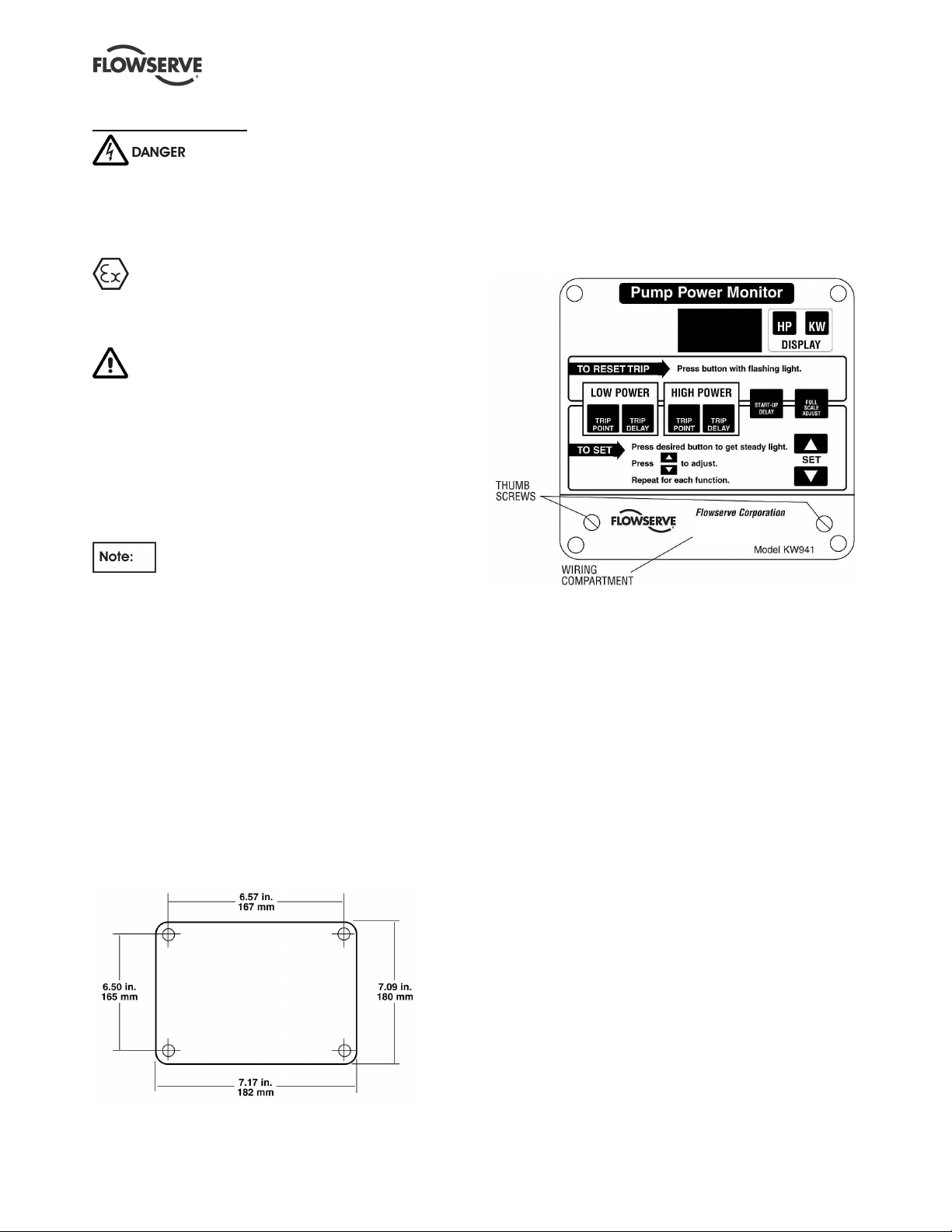

3.3.1 Enclosure

• Material: polycarbonate, with see-through cover.

• Protection rating: NEMA 4X / IP66. Use only

certified liquid-tight access hole fittings/conduit

hubs to maintain enclosure protection rating.

• Overall dimensions: 182 mm W x 180 mm L x 90

mm H (7.17"W x 7.09"L x 3.54"H).

• Mounting hole spacing: 167 mm W x 173 mm H

(6.57"W x 6.81"H).

• Mounting screws: 4 mm (#8), quantity of four.

• Enclosure can be drilled, sawed or punched for

wiring access holes.

Do not damage the internal

components of the KW941 unit while making access

holes.

3.3.2 Power Requirements

• 110 Vac Model (110/115/120 nominal Vac),

60 HZ @ 0.100 amps

• 220 Vac Models (220/230/240 nominal Vac),

50/60 HZ @ 0.05 amps

• Fuse: (Internal to TS1 #2 VAC connection, not

user accessible.)

• For 110 Vac Models: 200 mA, 125 Vac, Slo

Blo, 5 x 20 mm

• For 220 Vac Models: 100 mA, 250 Vac, Slo

Blo, 5 x 20 mm

Power to the KW941 is supplied by a

(customer-supplied) control voltage transformer

connected between two of the three motor power

supply phases. Power may be supplied by an

existing appropriately connected transformer with

adequate capacity. Consult area codes/regulations

for transformer fusing and grounding requirements.

Page 6 of 24 flowserve.com

Page 7

KW941 Pump Power Monitor USER INSTRUCTIONS ENGLISH 71569285 02-12

Fusing of the control voltage transformer primary

and/or secondary circuit supplying power to the

KW941 may be required. Please consult local area

electrical codes/regulations.

• Control Voltage Transformer: (Not Supplied)

Rating: 15 VA (Volt Amps) or greater.

• Power On/Off Switch: (Not Supplied)

No On/Off switch is provided with the

KW941. It is intended to be On (operational)

whenever power is supplied to the motor starter

control circuits, whether or not the motor is running,

so that it can be set up prior to starting the equipment

and provide protection on startup. The transformer

supplying power to the KW941 is normally installed

ahead of the motor starter contactor but after the

starter power disconnect switch, so that power can be

turned off with the disconnect switch. If required, the

control transformer circuit supplying power to the

KW941 can be switched.

3.3.3 Wiring and Grounding

• Maximum TS1 connection wire size: #14 AWG.

• Use wire with adequate insulation and current

carrying capability for the application.

• Terminal TS1 #1 is internally connected to the

KW941's metal chassis. Connect this point to

earth ground.

• Use of metallic conduits will require bonding

between the conduits.

PLEASE FOLLOW ALL AREA

ELECTRICAL CODES/REGULATIONS!

3.3.4 Full Scale Range

• 0.7 to 112 KW (1 to 150 HP) @ 460 Vac, 50/60

Hz three phase power with the supplied current

sensor (toroid).

• Contact Flowserve Engineering for higher power

capabilities (to 999 hp with auxiliary current

sensor) and for special applications.

3.3.5 Current Sensor (also known as a toroid or

current transformer)

• 200 amp (primary), current sensing toroid

• 12" #24 AWG leads

• Max lead extension length = 30.5 m (100 feet).

• O.D: 51 mm (2.0 in.)

• I.D.: 18 mm (0.7in.) – this limits the maximum

wire size that can go through current sensor.

• Ht.: 20 mm (0.8 in.)

3.3.6 Alarm Output Relay Contacts

5 amps @ 125 VAC

3 amps @ 277 VAC

5 amps @ 30 VDC

3.3.7 Analog Output

• 4 to 20 milliamp source, proportional to full

scale.

• Maximum loop load resistance = 600 Ohms.

3.3.8 Digital Display

• 3 digit, 0.6" high, seven segment, red LED.

• Displays 0.0 to 999

3.3.9 Timers

• Start-Up Delay Timer: Adjustable 0 to 999

seconds.

• Trip Delay Timers: Adjustable 0 to 999 seconds.

3.3.10 Remote Reset

• Momentary external mechanical or solid state

switch to conduct < 200 microamps DC between

"RESET +" and "RESET -" terminals.

• Reset input specifications (for use with solid

state logic switch resets)

• For NORMAL operation: +2 to +5 VDC

between reset terminals

• For RESET: -0.3 to +0.8 VDC between reset

terminals (minimum pulse width 20

milliseconds).

3.4 Performance and operation limits

Operating Temperature: -40 to 70 °C (-40 to 158 °F) .

Effective toroid power limit = 112 KW (150 HP)

Power monitoring using only the supplied

current sensor is limited by its 200 amp current limit

and the size of the motor lead that can fit through the

toroid’s internal diameter (18 mm (0.7 in.)).

Use of a second current transformer in series with the

supplied toroid can allow the KW941 to monitor

power levels up to 745 KW (999 HP).

Supply voltage should not exceed 230 Vac at 50 Hz

or the internal fuse may blow.

Unbalanced power line/load conditions will affect

power readings.

The motor efficiency value used during initial setup

(Section 4 Installation) affects the KW941 power

reading displayed.

Page 7 of 24 flowserve.com

Page 8

KW941 Pump Power Monitor USER INSTRUCTIONS ENGLISH 71569285 02-12

4 INSTALLATION

Dangerous voltages are present in

motor control panels/circuits. Make sure power is off

and locked out during installation.

INSTALLATION MUST BE PERFORMED BY

QUALIFIED PERSONNEL!

The KW941 Pump Power Monitor and its

current sensing toroid must not be installed in a

potentially explosive atmosphere.

It is important to be aware of the EUROPEAN

DIRECTIVE on electromagnetic compatibility when

wiring up and installing equipment on site. Attention

must be paid to ensure that the techniques used

during wiring/installation do not increase

electromagnetic emissions or decrease the

electromagnetic immunity of the equipment, wiring or

any connected devices. If in any doubt, contact

Flowserve for advice.

The Flowserve KW941 Pump Power

Monitor has a CE Mark approval for EMC and Low

Voltage Directive Compliance.

4.1 Location

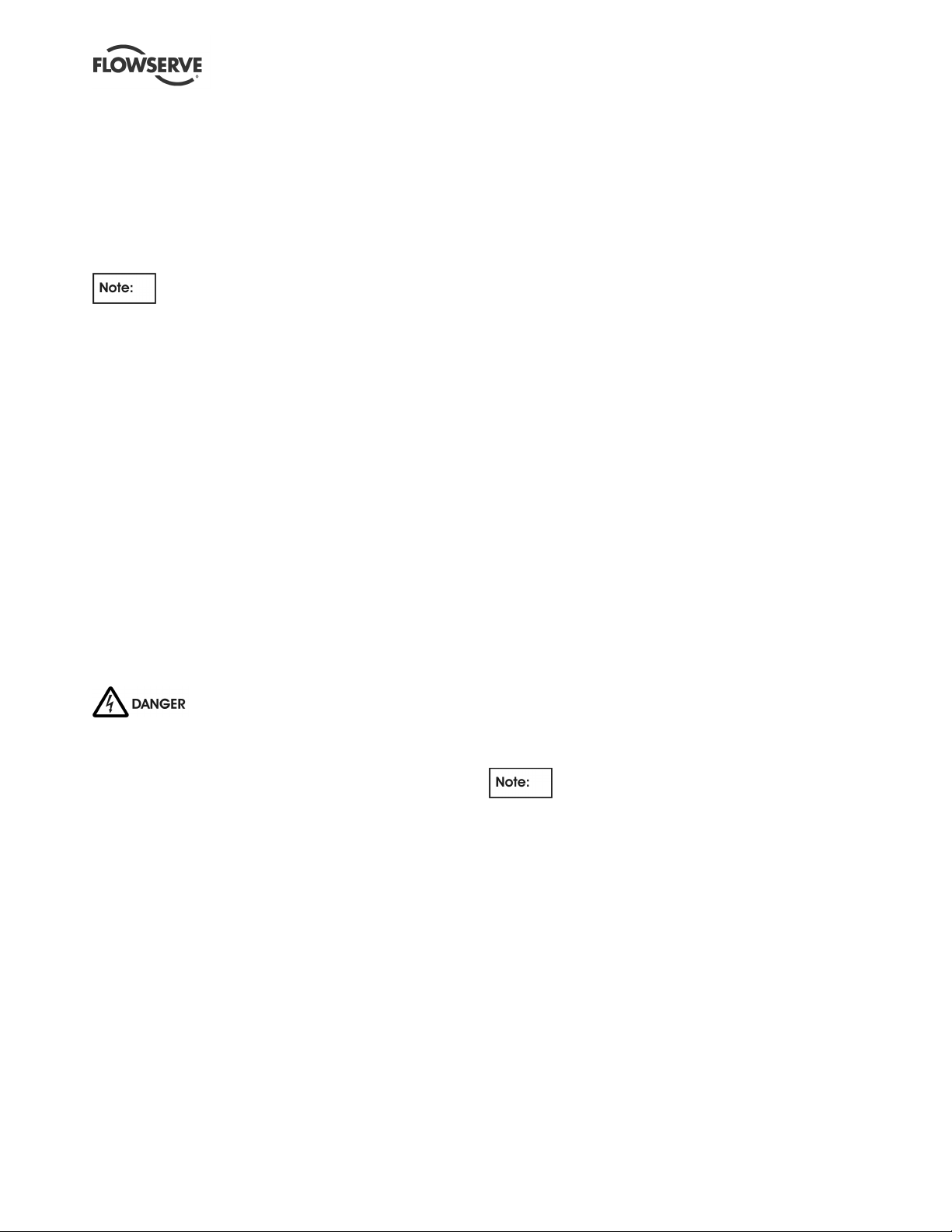

The KW941 Display/Control module can be mounted

on the outside of the motor starter panel or a nearby

wall or structure. Use the four corner mounting screw

holes located below the see - through front cover

screws. Refer to Figure 4.1 for mounting dimensions.

The KW941 Display/Control module can be located

up to 30.5 m (100 ft.) from the motor lead that must

run through the current sensor (toroid). This is the

length limit for extending the toroid leads.

Figure 4.1

4.2 Electrical connections

Connections are made in the wiring compartment,

accessible by removing the separate cover plate on

the lower portion of the KW941. Loosen the two

thumbscrews to remove the cover plate (see Figure

4.2).

Figure 4.2

Entry for wiring/conduit is made by drilling, sawing or

punching the required hole(s) into the wiring

compartment area. Use caution when making access

holes to prevent damage to the internal components.

The following information is required for installation:

1) Motor Nameplate Full Load Power

2) Motor Nameplate Voltage and Hertz (Hz)

3) Control Volts (110 or 220/240 VAC) from

transformer between motor power phases.

4) Motor efficiency.

Record this information on the worksheet provided in

Section 8 of this manual.

4.2.1 Control Voltage

Refer to the product identification label on the outside

of the KW941 enclosure for the selected factory

preset VAC and HZ options (110/120 or 220/240

VAC, 50 or 60 HZ).

Page 8 of 24 flowserve.com

Page 9

KW941 Pump Power Monitor USER INSTRUCTIONS ENGLISH 71569285 02-12

can be used to supply the voltage. Otherwise, a

Never move jumpers when power is

on! It can damage the unit.

The Control Voltage (110 or 220/240 VAC) is

required to power the KW941 as well as to provide a

voltage sample for power computation.

The voltage (VAC) MUST be obtained

from a voltage transformer connected between

two phases of the three phase motor power leads.

If a control voltage transformer (with at least 15 VA

capacity) is already present between two phases, it

Figure 4.3

suitable transformer must be installed.

In the case of a 220/240 VAC three phase motor, the

voltage (VAC) can be obtained directly across two of

the phases, provided that the Display/Control module

is set for 220/240 VAC voltage operation.

The control voltage is connected to the KW941

Display/Control module using properly sized wires in

an appropriate conduit. Wire the control voltage

(VAC) to the KW941 terminal strip (TS1) as shown in

Figure 4.3. Table 4.1 describes the function of each

of the terminal strip positions.

Page 9 of 24 flowserve.com

Page 10

KW941 Pump Power Monitor USER INSTRUCTIONS ENGLISH 71569285 02-12

Screw #

Description

Notes

91.0

Table 4.1 Display/Control Unit Connection Terminals (TS1)

1 Ground Safety ground to connect units metal frame to earth ground

2 VAC Input

3 VAC Input

4 Hi Alarm NO

5 Hi Alarm NC

6 Hi Alarm common The common screw # for the HI Alarm relay contacts.

7 Lo Alarm NO

8 Lo Alarm NC

9 Lo Alarm common The common screw # for the LO Alarm relay contacts.

10 Reset +

11 Reset -

12 4-20 mA + Positive connection for the 4-20 mA output function (optional).

13 4-20 mA - Negative connection for the 4-20 mA output function (optional).

14 Current Sensor Input Current sensing toroid lead connection.

15 Current Sensor Input Current sensing toroid lead connection.

4.2.2 Current Sensor Set Up

The current senor (toroid) is shipped inside

the KW941 underneath the wiring compartment

cover.

NEVER MOVE JUMPERS WHEN

POWER IS ON!

When properly installed, the current sensing toroid

(see figure 4.4) normally is located inside the motor

starter panel with one of the three phase motor power

leads passing through its center one or more times.

The sensor's output leads are then connected to the

KW941 Display/Control module using an appropriate

conduit. Figure 4.4

AC control voltage, 110 VAC from control voltage transformer (220/240

VAC optional)

AC control voltage, 110 VAC from control voltage transformer (220/240

VAC optional)

The normally open (power on, not tripped) Hi Alarm relay contact

between TS1 screw # 4 and # 6. This contact will be closed upon a Hi

Alarm condition or loss of control voltage.

The normally closed (power on, not tripped) Hi Alarm relay contact

between TS1 screw # 5 and # 6. This contact will open upon a Hi

Alarm condition or loss of control voltage.

The normally open (power on, not tripped) LO Alarm relay contact

between TS1 screw # 7 and # 9. This contact will close upon a LO

Alarm condition or loss of control voltage.

The normally closed (power on, not tripped) LO Alarm relay contact

between TS1 screw # 8 and # 9. This contact will open upon a LO

Alarm condition or loss of control voltage.

Remote reset terminal. A momentary contact between TS1 # 10 and #

11 will reset the alarm relay contacts.

Remote reset terminal. A momentary contact between TS1 # 10 and #

11 will reset the alarm relay contacts.

To install the current sensor:

1) Determine the required KW941 Full Scale Power

(FS) by calculating your motor's required INPUT

Power:

PowerNameplateMotor

2)

EXAMPLE:

3) Locate your motor voltage in Table 4.2 by

reading down the Motor Volts column.

4) Read across the table row identified by your

motor voltage to locate the smallest KW941 Full

Scale Power value that is greater than or equal

to the motor's Input Power found in step 1. This

will be the KW941 Full Scale Power (FS).

Record this value on the configuration worksheet

in Section 8 of this manual.

If the motor's Input Power exceeds the FS

values listed in Table 4.2, use Table 4.3.

PowerInput

_ =

PowerInput =

10_HP

EfficiencyMotor

_

= 10.98 HP

__

Page 10 of 24 flowserve.com

will result in decreased sensitivity.

Using a FS value larger than required

Page 11

KW941 Pump Power Monitor USER INSTRUCTIONS ENGLISH 71569285 02-12

5) Determine the number of "turns" required by the

motor power lead through the toroid inner

diameter. Read up the table column from the

selected Full Scale Power (FS) found in step 3.

The number of turns shown in that column

header is the required number of passes the

motor power lead must make through the current

sensing toroid. Record the number of turns on

the installation and configuration worksheet in

Section 8 of this manual.

6) Loop the motor power lead the required number

of turns through the toroid. THIS LEAD MUST

NOT BE EITHER OF THE LEADS USED FOR

THE CONTROL VOLTAGE TRANSFORMER.

Turns are counted by the number of times the

motor lead passes through the toroid center.

See Figure 4.3 for an example of one turn

through the current sensing toroid. If the motor

power lead is too large to obtain the required

number of turns, select the next larger KW941

Full Scale Power (FS) and its corresponding

number of turns. The smallest possible FS at

the required motor voltage will give best results.

7) Connect the two leads coming from the current

sensing toroid to the KW941 TS1 (# 14 and #

15) as shown in Figure 4.3 and described in

Table 4.1. If extension leads are needed, use 24

AWG or larger wire up to 30.5 m (100 ft.) long.

Table 4.2

KW941 Full Scale Power "FS" (Jp5 set to X10 Range)

Motor Power @ 1 turn Power @ 2 turns Power @ 3 Turns Power @ 4 turns Power @ 5 Turns

Volts KW HP KW HP KW HP KW HP KW HP

575 14.0 18.8 7.0 9.4 4.7 6.3 3.5 4.7 2.8 3.8

460 11.2 15.0 5.6 7.5 3.7 5.0 2.8 3.8 2.2 3.0

415 10.0 13.5 5.0 6.8 3.4 4.5 2.5 3.4 2.0 2.7

400 9.7 13.0 4.8 6.5 3.2 4.3 2.5 3.3 1.9 2.6

380 9.2 12.4 4.6 6.2 3.0 4.1 2.3 3.1 1.8 2.5

230 5.6 7.5 2.8 3.8 1.8 2.5 1.4 1.9 1.1 1.5

208 5.0 6.8 2.5 3.4 1.7 2.3 1.3 1.7 1.0 1.4

Table 4.3

KW941 Full Scale Power "FS" (Jp5 set to X1 Range -- Default)

Motor Power @ 1 turn Power @ 2 turns Power @ 3 turns

Volts KW HP KW HP KW HP

575 140 188 69.9 93.8 46.6 62.5

460 112 150 55.9 75.0 37.3 50.0

415 101 135 50.4 67.7 33.6 45.1

400 96.9 130 48.6 65.2 32.4 43.5

380 92.5 124 46.2 62.0 30.8 41.3

230 55.9 75.0 27.9 37.5 18.6 25.0

208 50.5 67.8 25.3 33.9 16.8 22.6

For motor voltages not listed in Table 4.2 or 4.3,

calculate Full Scale Power as follows:

a) For 110 VAC KW941 models

V

FSPFSP

M

12

V

××=4

C

b) For 220/240 VAC KW941 models

V

FSPFSP

M

12

V

××=2

C

FSP1 = FS Power @ 460 VAC from Table 4.2 or

4.3

KW941 VAC terminals (# 2 and # 3). This voltage

normally is the output voltage of the control

transformer in the motor starter and must be

110/115/120 or 220/230/240 VAC.

For applications with motor nameplates above 150

HP (112 KW) @ 460 VAC, if the motor lead does

not fit through the supplied current sensor, or if

custom full scale settings are desired, contact your

nearest Flowserve sales representative or

distributor.

Control voltage is the voltage to the

VM = motor voltage

VC = control voltage (110 or 220/240 VAC)

Page 11 of 24 flowserve.com

Page 12

KW941 Pump Power Monitor USER INSTRUCTIONS ENGLISH 71569285 02-12

Figure 4.5

4.2.3 Jumper Settings

By default, Jumper Jp5 connections are

pins # 1 to # 2 (see Figure 4.5 and Table 4.4) which

is the “X1” range. This range is used for motors over

11.2 KW (15 HP).

For smaller motors, the jumper Jp5 may need to be

moved to pins # 2 and # 3, which is the “X10” range.

Review Tables 4.2 and 4.3 for setting the ranges for

a given Full Scale Power (FS).

Never move jumpers when power is

on!

Table 4.4

Hz Selection (Jp3) Range Select (Jp5)

Hz Connect Pins Range Connect Pins

50 3 to 4 X1 1 to 2 (Default)

60 1 to 2 and 3 to 4 X10 2 to 3

4.2.4 Alarm Relays

Use of a surge suppressor is recommended when

switching highly inductive loads such as a magnetic

motor starter coil.

In case of an alarm condition, alarm relay contacts

can be connected into the pump start/stop control

circuit in order to shut down the pump. Refer to

Figure 4.3 and Table 4.1 for alarm relay connections.

Relays are shown powered up, not tripped. The

relays may also be used for audible or visual alarms.

4.2.5 4-20 Milliamp Output

The output provides 4-20 milliamps proportional to

the KW941 full scale power. An external load of up to

600 Ohms can provide remote indication or input to

another device. The load is connected across TS1 #

12 (4-20 mA +) and TS1 # 13 (4-20 mA -) as

identified in Figure 4.3.

Page 12 of 24 flowserve.com

Page 13

KW941 Pump Power Monitor USER INSTRUCTIONS ENGLISH 71569285 02-12

5 SETUP AND OPERATION

These operations must be carried

out by fully qualified personnel.

The normal startup/reset sequence begins when

power is supplied to the KW941. The display will

flash "888" and the front panel LEDs will also flash.

The software revision number will then be displayed

briefly before the display returns to "0". The display

and front panel LEDs should be constant when this

sequence is complete.

Once installed and powered, set the control values

for the KW941 using the front panel Function buttons

and the up and down (↕) SET buttons. A button is

activated by pressing the slightly raised front panel

label area containing the desired function. Setup

should be performed prior to start-up of the pump

with power applied to the KW941.

Setup is accomplished by performing the following

steps to set various control values:

1) Select the power display mode, i.e. HP or KW.

2) Set the Full Scale Adjust value.

3) Set the Start-Up Delay timer value.

4) Set the Low Power Trip Point value.

5) Set the Low Power Trip Delay timer.

6) Set the High Power Trip Point value.

7) Set the High Power Trip Delay timer

We recommend that the setup information be

recorded on the Installation/ Setup Configuration

Worksheet form.

Function Adjustments

Select the appropriate function button to adjust

functions. A red LED on the button will illuminate

indicating the function is active. The function can then

be adjusted by pressing the -↕ SET arrow buttons to

obtain the necessary display value.

Pressing the HP or KW display button after pressing

another function button will cause the function adjust

button LED to go out and return the KW941 to normal

operation.

If no button is pressed within 15 seconds after a

function button has been pressed, the function adjust

button LED will go out and the KW941 will return to

normal operation.

5.1 Display Mode – Power Units

Selection

The KW941 can display power in either HP

(horsepower) or KW (Kilowatts). Select the desired

display units by depressing the HP or KW button. The

red LED will illuminate for the selected units.

The KW941 can be set up and operated in either

mode. Conversion between units is automatic when

display units are changed.

5.2 Full Scale Adjust

The KW941 can be scaled to display power to the

motor or power to the pump. The preferred setup is

pump power.

5.2.1 To display PUMP POWER

1) Calculate the Full Scale Adjustment setting

(FSA) by multiplying the Full Scale (FS) Power

obtained from Table #4 or 4a, (HP or KW) times

the motor efficiency factor in decimal format.

Record the FSA on the installation/setup

worksheet.

Example: Motor Volts = 460 VAC, Full Scale

power from Table #4 = 3.8 HP, and motor

efficiency = .93 (93%).

FSA = 3.8 HP X 0.93 = 3.5 HP

or

FSA = 2.8 KW X 0.93 = 2.6 KW

2) Depress the Full Scale Adjust button. The LED

on the button will illuminate, indicating that the

Full Scale Adjust function is active.

3) Press the -↕ SET arrows to obtain the Full Scale

Adjust setting on the display.

4) Press the HP or KW display mode button to

return to normal operation or any other function

button to activate that function's adjustment

feature.

The display will now indicate power to the pump

in the selected units.

Page 13 of 24 flowserve.com

Page 14

KW941 Pump Power Monitor USER INSTRUCTIONS ENGLISH 71569285 02-12

5.2.2 To display MOTOR POWER

1) Obtain the Full Scale power (HP or KW) from

Table #4. This will be the Full Scale Adjust

setting (FSA).

Example: Full Scale power = 3.8 HP.

FSA = 3.8 HP

or

FSA = 2.8 KW

2) Depress the Full Scale Adjust button. The LED

on the button will illuminate, indicating that the

Full Scale Adjust function is active.

3) Press the ↕ SET arrows to obtain the Full Scale

Adjust setting on the display.

4) Press the HP or KW display mode button to

return to normal operation or any other function

button to activate that function's adjustment

feature.

The display will now indicate power to the motor in

the selected units.

Unbalanced power line load conditions will

affect power readings.

5.3 Alarms

The KW941 provides LOW POWER (UNDERLOAD)

and HIGH POWER (OVERLOAD) alarm relays.

When wired into the pump's motor starter circuit, the

alarm relays can trip out the pump motor during

UNDERLOAD or OVERLOAD conditions. The alarms

are disabled for an adjustable period of time during

motor start-up (Start-Up Delay) to permit the pump to

reach normal operation.

The following information describes how to set up the

Start-Up Delay timer and alarms.

5.3.1 Start-Up Delay

The start-up delay is the amount of time in seconds

(0-999) that must expire after the pump motor has

been started and before the High Power and Low

Power functions become active.

5.3.1.1 Operation

When the pump is started, the START-UP DELAY

LED will flash for the set period of time and then go

out.

5.3.1.2 Setting the START UP DELAY

1) Press the START-UP DELAY button. The StartUp Delay LED will illuminate and the display will

show the timer value in seconds.

2) Adjust the value by pressing the ↕ SET arrow

buttons to obtain the desired time (0-999

seconds) on the display. It is recommended that

the delay be set to the minimum time required to

obtain a normal pump start-up (usually less than

5 seconds). Excessive delays leave the pump

un-protected which may result in damage to the

pump or motor.

3) Press the desired display mode HP or KW

button to turn off the Start-Up Delay LED and

return to normal operation (or any other function

button to activate that function's adjustment

feature).

5.3.2 Low Power Alarm

The Low Power Trip Point is the minimum power

level necessary to prevent the Low Power Alarm

relay from tripping. The normal state of the Low

Power Trip Point LED is off.

5.3.2.1 Operation

If a low power trip has occurred, the Low Power Trip

Point LED will blink and the Low Power Alarm Relay

will trip if the Low Power Trip Delay timer has

expired.

The Low Power Trip Delay is the amount of time in

seconds (0-999) that must expire before the Low

Power Alarm Relay will trip. The timer is activated

when the power level has fallen below the Low Power

Trip Point setting. The normal state of the Low

Power Trip Delay LED is off.

When the power level has fallen below the Low

Power Trip Point setting, the Low Power Trip Delay

LED will blink. If the power level increases above the

trip point setting before the delay timer value times

out, the blinking LED will then go out and the unit

returns to normal operation. If the power level

remains below the trip point longer than the delay

timer setting, the Low Power Trip Relay is activated.

The blinking Trip Delay LED will go out and the Trip

Point LED will blink alerting the operator to the

problem.

Page 14 of 24 flowserve.com

Page 15

KW941 Pump Power Monitor USER INSTRUCTIONS ENGLISH 71569285 02-12

To reset, press the Low Power Trip Point function

button (or use the remote reset feature). This will

cause the Low Power Trip Point LED to go out and its

alarm relay to be reset. The pump may be restarted

after resetting the alarm, however, it is strongly

recommended that you investigate the cause of the

alarm.

5.3.2.2 Setting the Low Power Trip Point

1) Pressing this function button will cause its LED

to illuminate. The current setting for the Low

Power Trip Point is displayed.

2) Press the ↕ SET arrow buttons to adjust the

setting.

3) After the trip point is set, press the HP or KW

button to return to normal operation (or any

other function button to activate that function's

adjustment feature).

Flowserve recommends the Low Power

Trip Point be set at the pump's power level for its

minimum continuous flow. This power level is

provided by Flowserve via the PC based pump

selection program (PROS+). If the information is not

readily available, contact your Flowserve sales

representative or local distributor. You may also

obtain a copy of the PROS+ program for in-plant use.

5.3.2.3 Setting the Low Power Trip Delay

1) Press the Low Power Trip Delay button. The

Trip Delay LED will illuminate indicating the

function is active. The current delay value in

seconds (0 to 999) will be displayed.

2) Press the ↕ SET buttons to display the desired

value.

3) Press the HP or KW button to turn off the

function's LED and return to normal operation

(or any other function button to activate that

function's adjustment feature).

The delay time value should be set to

accommodate normal process fluctuations (usually 5

seconds or less). Excessive delays allow the pump

to operate at low power (low flow) conditions which

may result in damage to the pump.

5.3.3 High Power Alarm

The High Power Trip Point is the power level that, if

exceeded, will cause the High Power Alarm relay to

trip after the High Power Trip Delay has expired. The

normal state of the high power trip point LED is off.

5.3.3.1 Operation

If a high power trip has occurred, the High Power Trip

Point LED will blink and the High Power Alarm Relay

will trip if the High Power Trip Delay timer has

expired.

The High Power Trip Delay is the amount of time in

seconds (0-999) that must expire before the high

power alarm relay will trip. The timer is activated

when the power level increases above the High

Power Trip Point setting. The normal state of the

High Power Trip Delay LED is off.

When the power level increases above the High

Power Trip Point setting, the High Power Trip Delay

LED will blink. If the power level decreases below

the trip point setting before the delay timer value

times out, the blinking LED will then go out and the

unit returns to normal operation. If the power level

remains above the trip point longer than the delay

timer setting, the high power relay trips. The blinking

Trip Delay LED will go out and the Trip Point LED will

blink.

To reset, press the High Power Trip Point function

button (or use the remote reset feature). This will

cause the High Power Trip Point LED to go out and

its alarm relay to be reset. The pump may be

restarted after resetting the alarm, however, it is

strongly recommended that you investigate the cause

of the alarm.

5.3.3.2 Setting the High Power Trip Point

1) Pressing this function button will cause its LED

to illuminate. The current setting for the High

Power Trip Point is displayed.

2) Press the ↕ SET arrow buttons to adjust the

setting.

3) After the trip point is set, press the HP or KW

button to return to normal operation (or any

other function button to activate that function's

adjustment feature).

Flowserve recommends the High Power

Trip Point be set at one of the following levels:

a) The end of curve power shown on the pump

performance curve.

b) The maximum rated power of the motor.

c) The power rating of the magnetic coupling of a

mag drive or canned motor pump motor.

Page 15 of 24 flowserve.com

Page 16

KW941 Pump Power Monitor USER INSTRUCTIONS ENGLISH 71569285 02-12

The High Power Trip Point setting is usually

determined by the lowest value of the above three

conditions, however, specific pumping applications

may benefit from lower setting. For additional

information, contact your Flowserve sales

representative or local distributor.

5.3.3.3 Setting the High Power Trip Delay

1) Press the High Power Trip Delay button. The

Trip Delay LED will illuminate indicating the

function is active. The current delay value in

seconds (0 to 999) will be displayed.

2) Press the ↕ SET buttons to display the desired

value.

3) Press the HP or KW button to turn off the

function's LED and return to normal operation

(or any other function button to activate that

function's adjustment feature).

The delay time value should be set to

accommodate normal process fluctuations (usually 2

seconds or less). Excessive delays allow the pump

to operate at high power conditions which may result

in damage to the pump or motor.

5.3.4 Resetting Alarms

Alarms, indicated by a blinking Low Power or High

Power Trip Point LED, can be reset by any of three

methods.

a) MANUAL: Press Trip Button with the flashing

LED.

b) REMOTE: Momentary contact closure between

Reset + and Reset - on TS1. See specifications

for contact requirements.

c) AUTOMATIC: In automatic reset mode, an alarm

condition will cause the selected alarm relay(s)

to remain in the tripped state for 10 seconds

before automatically resetting.

5.3.5 Activating Automatic Reset Mode

1) Press and hold the TRIP DELAY button until the

TRIP DELAY displayed value is flashing. This

indicates that the unit is now in automatic mode.

2) Press the HP or KW button to return to normal

operating mode.

5.3.6 De-activating Automatic Reset Mode

1) To return to manual alarm reset operation press

and hold the TRIP DELAY button until the TRIP

DELAY display value stops flashing.

2) Press the HP or KW button to return to normal

operating mode.

5.4 Demo Mode

Using the Demo Mode can be helpful in verifying

whether or not the alarm contacts are functional.

Varying the simulated input power in Demo Mode will

permit simulated alarm conditions causing the alarm

relay(s) to trip. This will enable verification of the

alarm contact wiring/wiring logic into the motor

start/stop circuit.

Changing time delays and setpoints, then

successfully causing alarm relays to trip while in

Demo Mode may indicate that a problem is due to

external causes such as wiring errors, misapplication,

or improper setup.

To enter the Demo Mode:

• press the "HP" button, and then the UP (↑)

setting arrow on the front panel consecutively.

The "HP" LED will blink indicating that the Demo

Mode is operational.

• Repeat this sequence to exit the Demo Mode.

• Use the UP (↑) and DOWN (↓) setting arrows to

change the readout to simulate a motor load.

The display will increase or decrease as the

arrow buttons are pressed. Moving the load

above the High Power Trip Point or below the

Low Power Trip Point will activate the alarm

contacts (after Trip Delay has expired).

• The Startup Delay may need to be extended to

move the simulated load between the Trip

Points.

5.5 Current Sensor Field Replacement

The current sensor (toroid) can be replaced in the

field if required, but it must be calibrated to the

KW941 using the following procedure.

With the current sensor connected to the KW941 and

power to the unit but the motor not running (no

current through the lead going thru the sensor):

1. Press and hold in the “KW” button until the

display changes, a number will be displayed.

2. Release the “KW” button and immediately

press and release the up arrow “SET” button.

3. The display will return to zero and the sensor

will be calibrated for that unit. Select the

desired display units. The unit is now ready

for normal operation.

Page 16 of 24 flowserve.com

Page 17

KW941 Pump Power Monitor USER INSTRUCTIONS ENGLISH 71569285 02-12

6 MAINTENANCE

The KW941 Pump Power Monitor should not require

any routine maintenance outside of wiping down the

front cover occasionally.

It is the plant operator's responsibility to ensure

that all maintenance, inspection and assembly work

is carried out by authorized and qualified personnel

who have adequately familiarized themselves with

the subject matter by studying this manual in detail.

(See also section 1.6.2.)

Before restarting the machine, the relevant

instructions listed in section 5, Setup and Operation

must be observed.

Place a warning sign on the starting device:

"Machine under repair: do not start".

With electric drive equipment, lock the main switch

open and withdraw any fuses. Put a warning sign on

the fuse box or main switch:

"Machine under repair: do not connect".

6.1 Spare parts

No spare parts are needed. The internal fuse is not

meant to be accessed by the customer per CE

requirements. The current sensor (toroid) is robust,

but the leads can be broken off if handled roughly.

Contact your local Flowserve sales representative to

order a new toroid if the leads are damaged. Follow

the procedure in Section 5.5 to calibrate the new

toroid to the KW941 unit.

6.2 Tools required

A flat blade screwdriver, wire cutter, and wire stripper

are all that should be required to work on the wiring

going to the KW941 Pump Power Monitor once it is

installed.

7 FAULTS: CAUSES AND REMEDIES

Troubleshooting

The purpose of this guide is to supply general

information on how to troubleshoot problems related

to startup and operation of the KW941 Pump Power

Monitor. It is intended only as a guide and cannot

cover every situation. If a problem exists that is not

covered by one of the examples, then contact a

Flowserve Sales Engineer or

Distributor/Representative for assistance.

General Guidelines

• The KW941 Pump Power Monitor is intended for

use on fixed frequency, steady, non-pulsating

loads. The unit is not intended for use with

variable frequency drives.

• When troubleshooting, never swap electronics

from one unit to another. This will cause

operational problems and void any warranty

claim.

• It is often helpful to isolate the monitor to

determine if the cause of a problem is internal to

the KW941 or a part of the external wiring

system. By removing all connections except for

the voltage and current sensing toroid, the

problem can normally be isolated to either the

monitor itself or to the external wiring.

• Each KW941 has an internal "DEMO MODE"

which can be helpful in verifying the correct

function of the unit. See Section 5.4 for

instructions on how to use this mode.

• Typical writing configurations for utilizing alarm

relays are shown in Section 8 as Figures 8.1

and 8.2 for reference.

Page 17 of 24 flowserve.com

Page 18

KW941 Pump Power Monitor USER INSTRUCTIONS ENGLISH 71569285 02-12

FAULT SYMPTOM

Unit will not power up (i.e., no lights)

Display locks up or all LEDs continuously flashing

⇓⇓⇓⇓

Power readings higher than expected

⇓⇓⇓⇓

Power readings lower than expected

⇓⇓⇓⇓

Power readings drifting or inconsistent

⇓⇓⇓⇓

Non-zero reading when equipment not running

⇓⇓⇓⇓

Power reading flashing

⇓⇓⇓⇓

Unit repeats startup/reset cycle when motor is tripped due to alarm, or when the motor is started

⇓⇓⇓⇓

⇓⇓⇓⇓

Monitor will not shut off motor

Cannot start motor

⇓⇓⇓⇓

⇓⇓⇓⇓

No AC power to unit.

Voltage supply different than unit rating. Verify supply voltage is the same as unit rating (110V or 220V).

Unit held in reset mode (closed

switch/contact at remote reset terminals

# 10 and # 11).

Internal fault.

Corrupted memory or internal fault. Reset unit (power off/on) to clear the fault. If normal operation

Equipment operating at higher than

expected load.

Incorrect KW941 installation/setup. 1. Verify correct number of turns of motor power lead through

Current sensing toroid on wrong motor

lead.

Incorrect voltage sample. Verify voltage sample taken from two phases supplying a three-

Equipment operating at lower than

expected load.

Incorrect KW941 installation/setup. 1. Verify correct number of turns of motor power lead through

Current sensing toroid on wrong motor

lead.

Incorrect voltage sample. Verify voltage sample taken from two phases supplying a three-

Current sensing toroid leads too long. Limit lead length to 30.5 m (100 ft.).

Equipment load fluctuating. Verify equipment operating conditions are at designed levels.

Current sensing toroid on wrong motor

lead.

PROBABLE CAUSES POSSIBLE REMEDIES

Check for proper voltage supply to terminals # 2 and # 3.

Use normally open switch/contact for remote reset.

Return unit through the sales representative to supplier for

evaluation and repair.

is not seen, return the unit through the sales representative to

supplier for evaluation and repair.

1. Verify equipment operating conditions are at designed levels.

2. Check equipment for abnormal operation (e.g., excessive

mechanical rubbing).

current sensing toroid.

2. Verify correct Full Scale Adjustment setting.

3. Verify correct Full Scale Range is selected (X1 or X10).

4. Verify correct frequency is selected (50 Hz or 60 Hz).

Verify current sample is not taken from either of the lead from

which the voltage sample is taken.

phase motor.

1. Verify equipment operating conditions are at designed levels.

2. On mag drive pumps, check for magnet decoupling.

3. Check for closed valve or other flow restriction.

4. Check motor to pump coupling.

current sensing toroid.

2. Verify correct Full Scale Adjustment setting.

3. Verify correct Full Scale Range is selected (X1 or X10).

4. Verify correct frequency is selected (50 Hz or 60 Hz).

Verify current sample is not taken from either of the lead from

which the voltage sample is taken.

phase motor.

Verify current sample is not taken from either of the lead from

which the voltage sample is taken.

Page 18 of 24 flowserve.com

Page 19

KW941 Pump Power Monitor USER INSTRUCTIONS ENGLISH 71569285 02-12

FAULT SYMPTOM

Unit will not power up (i.e., no lights)

Display locks up or all LEDs continuously flashing

⇓⇓⇓⇓

Power readings higher than expected

⇓⇓⇓⇓

Power readings lower than expected

⇓⇓⇓⇓

Power readings drifting or inconsistent

⇓⇓⇓⇓

Non-zero reading when equipment not running

⇓⇓⇓⇓

Power reading flashing

⇓⇓⇓⇓

Unit repeats startup/reset cycle when motor is tripped due to alarm, or when the motor is started

⇓⇓⇓⇓

⇓⇓⇓⇓

⇓⇓⇓⇓

Monitor will not shut off motor

Cannot start motor

⇓⇓⇓⇓

Incorrect voltage sample. Verify voltage sample taken from two phases supplying a three-

Poor or open connection from current

sensing toroid leads to terminals # 14

and # 15.

Current input circuit damaged because

of overload from selecting the wrong Full

Scale Range (X10 instead of X1) or

having too many turns through the toroid.

Wrong input voltage frequency setting. Verify correct frequency is selected (50 Hz or 60 Hz) per

Wrong current sensing toroid used with

unit.

Other load exists on terminal # 14 and #

15 or on the leads of the toroid.

Over-range condition. 1. Verify equipment operating conditions are at designed levels.

Electrical interference caused by KW941

relay contacts switching too large or

unsuppressed load.

Nearby equipment causing interference. Relocate the KW941 unit.

Improper application of remote reset. Use normally open switch/contact for remote reset.

Interference picked up by reset leads. 1. Relocate the leads.

Incorrect alarm inputs. Check equipment performance characteristics to determine

Alarm contact not wired, or improperly

wired into motor start/stop circuit.

KW941 not powered. Check voltage supply to unit.

KW941 tripped due to previous alarm

condition.

Internal fault not allowing contacts to

close.

Alarm contacts wired improperly into

motor start/stop circuit.

PROBABLE CAUSES POSSIBLE REMEDIES

phase motor.

Check connections.

Return unit through the sales representative to supplier for

evaluation and repair.

jumper Jp3.

Verify that the sensor being used is the same one shipped with

the unit. If it is not, see section 5.5 for the calibration

procedure.

Eliminate all connection except those for the KW941.

2. Verify correct installation/setup (see “power readings higher

or lower than expected”).

1. Verify load is within relay ratings.

2. Add arc suppression device to motor starting coil.

3. Use interposing relay (a separate relay switched by the

KW941 relay) to switch load. See schematic in Figure 8.2.

2. Use twisted shielded pair for reset leads.

appropriate set points.

Verify proper wiring of alarm contacts into motor start/stop

circuit.

Check equipment for cause of alarm. Reset unit using manual,

remote, or auto reset features.

Reset unit (power off/on) to clear the fault. If normal operation

is not seen, return the unit through the sales representative to

supplier for evaluation and repair.

Verify proper wiring of alarm contacts into motor start/stop

circuit.

Page 19 of 24 flowserve.com

Page 20

KW941 Pump Power Monitor USER INSTRUCTIONS ENGLISH 71569285 02-12

100

8 PARTS LIST AND DRAWINGS

Installation / Setup Configuration Worksheet

Pump/Equipment Identification ______________________________

Location KW941 ______________________________

Model / Part Number ______________________________

Serial Number ______________________________

Motor Data

Motor Nameplate Full Load Power ________ KW HP

Motor Nameplate Voltage ________ Volts

Motor Nameplate Frequency ________ Hertz (HZ)

Control Voltage from Transformer ________ 110 V or 220/240 V

Motor Efficiency =

Calculate: Input Power =

%__ EfficiencyMotor

________

PowerLoadFull __

________

iencyMotorEffic

Current Sensor

Full Scale Power (FS) [Table 4.2 or 4.3] ________ KW HP

Number of Turns through Toroid [Table 4.2 or 4.3] ________ Turns

Display Settings

Units ________ KW or HP

Full Scale Power (FS) [from Table 4.2 or 4.3] ________ KW HP

Calculate: Full Scale Adjust =

Full Scale (FS) x Motor Efficiency ________ KW HP

Start-up Delay ________ Seconds

Low Power Trip Point ________ KW HP

Low Power Trip Delay ________ Seconds

High Power Trip Point ________ KW HP

High Power Trip Delay ________ Seconds

Fault Reset Method

Local (from keypad) ________

Remote (TS1) ________

Automatic ________

Page 20 of 24 flowserve.com

Page 21

KW941 Pump Power Monitor USER INSTRUCTIONS ENGLISH 71569285 02-12

Figure 8.1

Schematic showing wiring arrangement used to shut off motor in case of HIGH or LOW Alarm and

provide 120 VAC to alarm indicators or other devices.

Page 21 of 24 flowserve.com

Page 22

KW941 Pump Power Monitor USER INSTRUCTIONS ENGLISH 71569285 02-12

Figure 8.2:

Schematic showing wiring arrangement used to shut off motor in case of HIGH or LOW Alarm and

provide 120 VAC to alarm indicators or other devices (interposed relay).

Page 22 of 24 flowserve.com

Page 23

KW941 Pump Power Monitor USER INSTRUCTIONS ENGLISH 71569285 02-12

9 CERTIFICATION

Certificates, determined from the contract

requirements, are provided with these instructions

where applicable. Examples are certificates for CE

marking and ATEX marking etc. If required, copies of

other certificates sent separately to the Purchaser

should be obtained from Purchaser for retention with

these User Instructions.

Statement on ATEX Compliance

The KW941 Pump Power Monitor must not be

installed in a potentially explosive atmosphere, but is

compliant with Ignition Prevention Level 1 in EN

13463-6 and so it can provide protection, by control

of ignition source ‘b’, of equipment of classification

Category 2 and 3, which is operating in a potentially

explosive atmosphere, (Zones -- 1, 21, 2 and 22).

The KW941 is not ATEX marked as an independent

device.

If the KW941 is used to monitor and alarm but not

automatically shut down, it shall still not be used in a

potentially explosive atmosphere, but there is no

restriction on its use with equipment in the potentially

explosive atmosphere.

If the KW941 is purchased separately to a Flowserve

pump/motor set, the user is responsible for the risk

assessment of the complete equipment.

The Flowserve KW941 Pump Power Monitor has

the following approvals:

The KW941 carries a CSA Certificate of Compliance

to Canadian and U.S. standards, Certificate Number:

LR 108009-1, dated 2007/08/09. Details are as

follows:

Products:

Class 3211 07 - Industrial Control Equipment Miscellaneous Apparatus

Class 3211 87 - Industrial Control equipment Miscellaneous Apparatus - CERTIFIED TO U.S.

STANDARDS

Applicable requirements:

CAN/CSA-C22.2 No. 14-05 - Industrial Control

Equipment

CAN/CSA-C22.2 No. 94-M91 - Special Purpose

Enclosures

UL Std No. 508 - Industrial Control Equipment

The "C" and "US" indicators next to the CSA Mark

signifies that the product was tested to applicable

ANSI/UL and CSA Standards, for use in the U.S. and

Canada.

In addition to the CSA Certification, theKW941 also

carries an EC-Declaration of Conformity:

Article 10.1 of the Directive 89/336/EEC (EMCDirective) in accordance with the following standards

or standardized documents:

EN 55 011:1991 Gr. 1 Kl.A Emission EMA

EN 61 000-3-2:1995 EMA Harmonics

EN 61 000-3-3:1995 EMA, Voltage Fluctuations

EN 50 082-2:1995 Immunity EMB

Appendix III of the Directive 73/23/EEC (Low Voltage

Directive)

IEC 1010-1:90 +A1:92 +A2:95

Test Reports of TUV Rheinland, Product Safety

GmbH, 51101 Cologne, Germany

No. P9612 781 E01 (EMC Test report)

No. E 9712536 E02 (Low Voltage Directive test

report)

10 OTHER RELEVANT

DOCUMENTATION AND MANUALS

10.1 Supplementary user instructions

Supplementary instructions such as for using the

KW941 Power Monitor for applications over 112 KW

(150 hp) or further clarification on how to use the 4-20

mA output are available. Have your local sales

representative contact Flowserve Engineering to

discuss your needs and get copies of the

supplementary instructions.

10.2 Change Notes

If any changes, agreed with Flowserve Pump

Division, are made to the product after it is supplied,

a record of the details should be maintained with

these User Instructions.

Page 23 of 24 flowserve.com

Page 24

KW941 Pump Power Monitor USER INSTRUCTIONS ENGLISH 71569285 02-12

Your Flowserve factory contact:

Flowserve Pump Division

3900 Cook Boulevard

Chesapeake, VA 23323-1626 USA

Telephone +1 757 485 8000

Fax +1 757 485 8149

Flowserve Pumps

Flowserve GB Limited

Lowfield Works, Balderton

Newark, Notts NG24 3BU

United Kingdom

Telephone (24 hours): +44 1636 494 600

Sales & Admin Fax: +44 1636 705 991

Repair & Service Fax: +44 1636 494 833

Email: newarksales@flowserve.com

Your local Flowserve representative:

To find your local Flowserve representative please

use the Sales Support Locator System found at

www.flowserve.com

FLOWSERVE REGIONAL

SALES OFFICES:

USA and Canada

Flowserve Corporation

5215 North O’Connor Blvd.,

Suite 2300

Irving, Texas 75039-5421, USA

Telephone +1 972 443 6500

Fax +1 972 443 6800

Europe, Middle East, Africa

Flowserve FSG – Italy

Worthing S.r.l.

Via Rossini 90/92

20033 Desio (Milan), Italy

Telephone +39 0362 6121

Fax +39 0362 628 882

Latin America and Caribbean

Flowserve Corporation

6840 Wynnwood Lane

Houston, Texas 77008, USA

Telephone +1 713 803 4434

Fax +1 713 803 4497

Asia Pacific

Flowserve Pte. Ltd

10 Tuas Loop

Singapore 637345

Telephone +65 6771 0600

Fax +65 6862 2329

Page 24 of 24 flowserve.com

Loading...

Loading...