Page 1

11444 Deerfield Road

Cincinnati, Ohio 45242

(513) 489-7800

FAX (513) 489-5243

Heavy Duty Hydraulic Override

Nuclear Qualified Actuator

Installation, Operating, and Maintenance Instructions

Heavy Duty Hydraulic Overrides

Hydraulic manual overrides on Automax heavy-duty

actuators provide a compact, rugged method for

manually operating the actuator. The hydraulic

override consists of either a hydraulic piston or ram, a

hand pump, and a control valve. Double acting

actuators require a piston, and spring return actuators

utilize a ram. The piston or ram is an integral part of

the actuator, designed to override the full rated torque

of the actuator.

Installation

Automax standard hydraulic overrides are supplied

as a complete integral component of the heavy duty

actuator. Override units are shipped with required

accessories, tubing, and fluid installed on actuator,

ready to be used. No additional customer installation

is required. Oil level in hydraulic override should be

checked prior to installing actuator into service. See

maintenance instructions for checking oil level. See

Automax Nuclear Qaulified Heavy Duty Actuator

bulletin B00143 for instructions on installing Heavy

Duty actuator into service.

Note: Actuator orientation must be specified when

ordering, to allow for proper orientation of pump and

reservoir. Standard orientation is horizontal, as

shown below, under 'Manual Override Dimensional

Data'.

Special hydraulic override units may be supplied with

remote mounted pump and controls. Installation of

such units is as follows:

1. Run required hydraulic supply tubing from remote

pump and controls to appropriate ports on hydraulic override, per schematic supplied with unit.

2. Fill pump reservoir with a fire-resistant, nuclear

approved hydraulic fluid, such as Exxon Firexx

HS68. Consult factory for seal compatibility.

3. Use hand pump to circulate fluid into hydraulic

lines. Bleed air from lines by loosening cylinder

bleed plug or fitting on the hydraulic override.

Pump reservoir may have to be filled a few of

times to completely fill the hydraulic lines.

4. See maintenance instructions to check oil level.

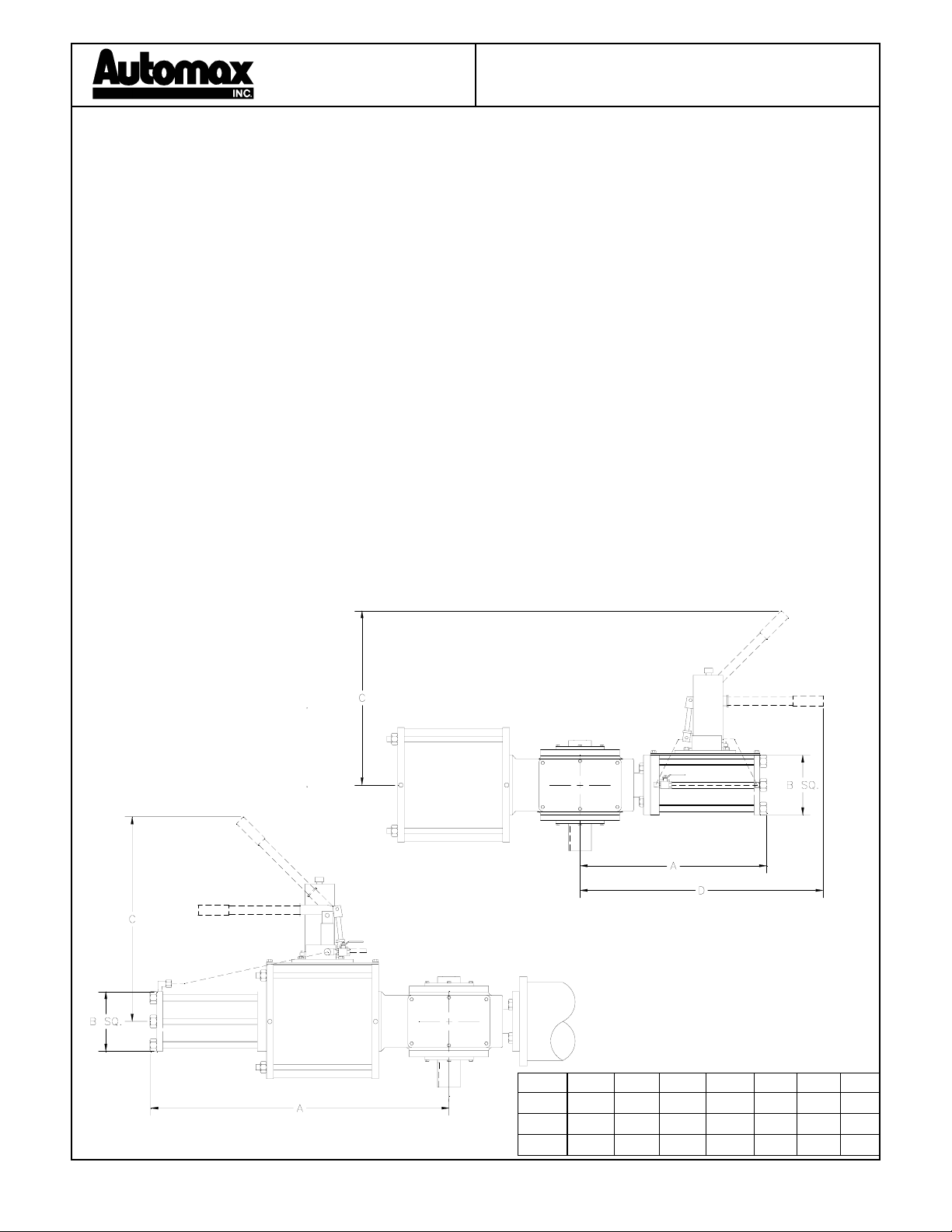

MANUAL OVERRIDE

DIMENSIONAL DATA

Note: Other actuator dimensions may

be found in Heavy Duty Catalog

Double Acting Hydraulic

Manual Override

Spring Return Hydraulic

Manual Override

SR and DA Hydraulic Manual

Override Overall and Pump

Handle Dimensions

Model A(DA) A(SR) B(DA) B(SR) C(DA) C(SR) D

RN2 18.31 28.95 5.50 4.00 30.53 32.18 36.75

RN3 22.44 33.75 7.13 5.13 31.35 36.24 39.31

RN4 29.13 45.93 9.82 6.75 32.69 39.70 44.34

B00151-0 Page 1 of 4

Page 2

11444 Deerfield Road

Cincinnati, Ohio 45242

(513) 489-7800

FAX (513) 489-5243

Heavy Duty Hydraulic Override

Nuclear Qualified Actuator

Operation

Operation of hydraulic overrides requires shifting a

manual valve and operating a hand pump. Standard

operation for DA or SR actuators is described below.

Operation of special hydraulic override designs is per

hydraulic schematics supplied with actuator.

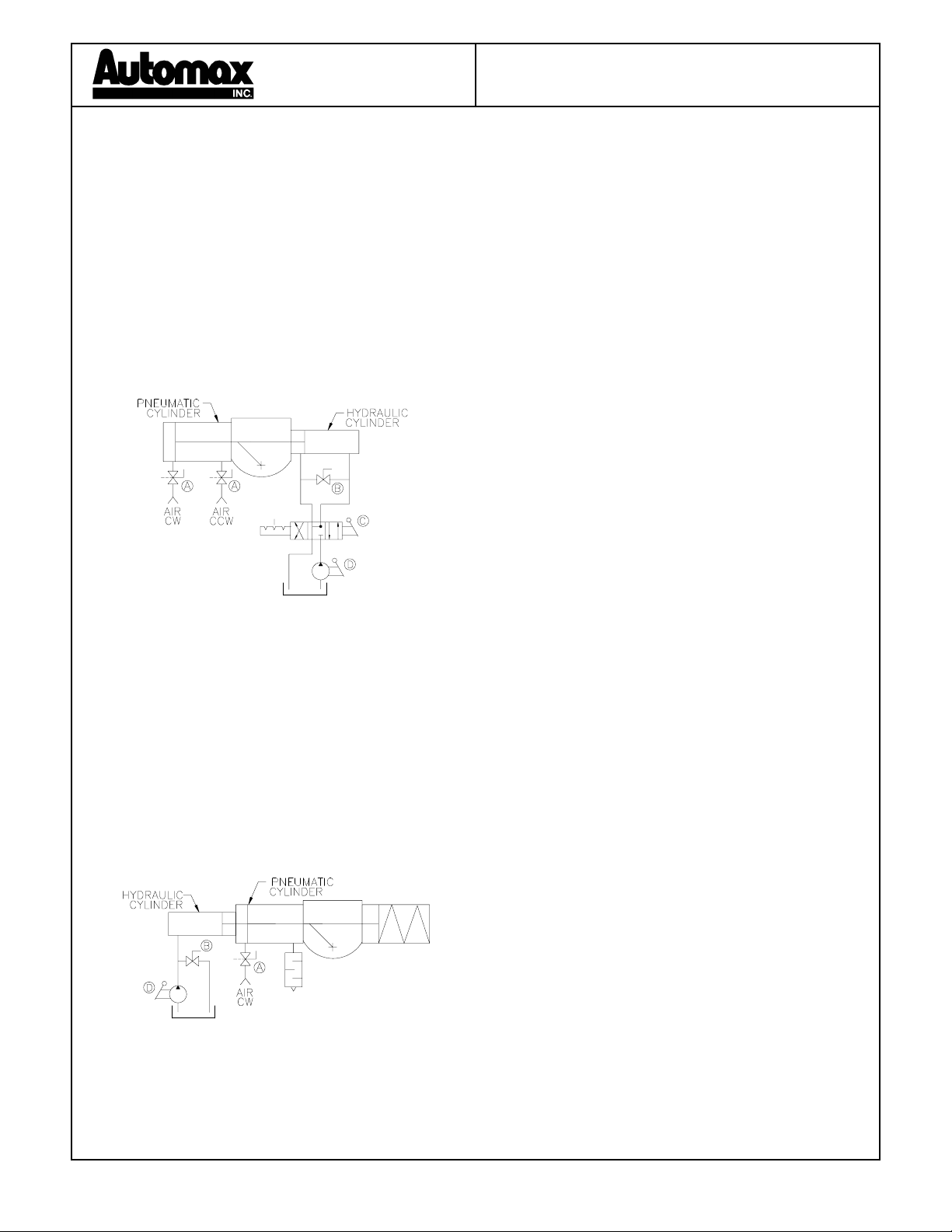

Double Acting

Pneumatic Operation:

1. Open ball valve 'B' on hydraulic override.

2. Place directional valve 'C' in mid position.

3. Open dump valves 'A' on pneumatic cylinder.

4. Connect air supply pressure and operate.

Manual Override:

1. Close both dump valves 'A' clockwise to block air

pressure and vent cylinder.

2. Close ball valve 'B' clockwise.

3. Rotate directional valve 'C' handle full clockwise

to manual override actuator counter-clockwise.

4. Rotate directional valve 'C' handle full counterclockwise to manual override actuator clockwise.

5. Operate manual pump 'D' to override actuator.

Spring Return

Pneumatic Operation:

1. Open ball valve 'B' on hydraulic override.

2. Open dump valve 'A' on pneumatic cylinder.

3. Connect air supply pressure and operate.

Manual Override:

1. Close dump valve 'A' clockwise to block air pressure and vent cylinder.

2. Close valve 'B' clockwise.

3. Operate pump to open actuator against spring.

4. Open valve 'B' to allow actuator to spring return.

Maintenance

Disassembly Procedures

1. Disconnect all air and electric supplies from

actuator.

2. Remove all accessories from actuator and dismount actuator from valve.

Note: See Heavy Duty Nuclear Qualified Actuator

Bulletin B00143 for complete instructions on actuator

disassembly.

Hydraulic Pressure Group

1. Drain hydraulic fluid from cylinder.

2. Remove Tie Rod Nuts (8), Tie Rods (7), and the

Endcap (9).

3. Slide Cylinder (1) over Piston (2) or Ram (2). DA

Cylinder is honed and chromed; care should be

taken not to scratch inner cylinder walls.

4. DA: Remove Piston Bolt (3), and Piston Bolt

Lockwasher (4). Remove Piston (2) and Piston

Face Seal (5).

5. DA: Remove Adapter Nuts (12) and Lockwashers

(13), and carefully slide Adapter (11) over Piston

Rod. Remove High Pressure Rod Seal (14).

SR: Remove Hydraulic Adapter (11), High Pressure Rod Seal (14), Rod Bearing (15), and Low

Pressure Rod Seal (16).

Reassembly Procedures

1. Inspect all parts for wear and replace any worn

parts as needed. Normally, all seals and gaskets should be replaced when reassembling an

actuator.

2. Clean all components and lubricate seals with the

hydraulic fluid.

3. Reverse the disassembly procedures to

reassemble. Tie Rod Locknuts (8), Adapter Nuts

(12), and Piston Bolts (3) should be tightened to

torque listed on Bolt Torque chart. All threads

should be lubricated with Locktite Nuclear Grade

Pipe Sealant 580 prior to assembly.

4. Recommended spare parts are shown in Parts

and Materials section below.

5. Test the actuator for smooth operation and absence of hydraulic leakage before re-installing.

B00151-0 Page 2 of 4

Page 3

11444 Deerfield Road

Cincinnati, Ohio 45242

(513) 489-7800

FAX (513) 489-5243

Heavy Duty Hydraulic Override

Nuclear Qualified Actuator

Checking Oil Level

1. Actuator should be in full CW position for DA actuator or failed position for SR actuator.

2. Remove cap from oil reservoir and check oil

level.

3. Oil level should be 2-3 inches from top of reservoir. If required, add hydraulic fluid to reservoir to

reach this level.

Pump/Oil Specifications

Temperature: 0°F to 300°F

Oil Type: Fire resistant, Nuclear Approved hydraulic

fluid, such as Exxon Firexx HS68. Consult

factory for seal compatibility and temperature

ranges of other fluids.

Oil Volume:

Actuator SR/DA Volume (gal)

RN2 SR 1/2

DA 1/2

RN3 SR 1/2

DA 3/4

RN4 SR 1

DA 1 1/2

Pump Pressure: DA 1500 psi

SR 3500 psi

Number of strokes to override:

Actuator SR/DA # Pumps

RN2 SR 17

DA 9

RN3 SR 45

DA 25

RN4 SR 132

DA 74

Bolt Torques

Piston Bolt (3) (SAE Grade 8 Bolt)*

Actuator Size Bolt Size Torque Range

RN2 3/4"-10 UNC 271-320 ft.lb.

RN3 1 1/4"-7 UNC 537-591 ft.lb.

RN4 1 1/4"-7 UNC 1014-1116 ft.lb.

* Not present in SR overrides

Tie Rod (7) (A311 Stressproof Rod)

Actuator Size Bolt Size Torque Range

RN2 5/8"-11 UNC 117-130 ft.lb.

RN3 3/4"-10 UNC 207-229 ft.lb.

RN4 1"-8 UNC 249-270 ft.lb.

Adapter Nut (12) and Stud (ASTM A193 Gr. B7)*

Actuator Size Bolt Size Torque Range

RN2 1/2"-13 UNC 64-71 ft.lb.

RN3 3/4"-10 UNC 226-249 ft.lb.

RN4 1"-8 UNC 546-603 ft.lb.

*Not present in SR Overrides

B00151-0 Page 3 of 4

Page 4

11444 Deerfield Road

Cincinnati, Ohio 45242

(513) 489-7800

FAX (513) 489-5243

Heavy Duty Hydraulic Override

Nuclear Qualified Actuator

Parts and Materials

Note: Other components are shown in Heavy Duty

Nuclear Qualified Actuator bulletin, B00143.

DA Hydraulic Override

SR Hydraulic Override

Item Description Material Qty

1 Cylinder Steel/Chrome Pl. 1

2 Piston(DA)/Ram(SR) Steel

3 Piston Bolt Steel

4 Piston Bolt Lockwasher Steel

5 Piston Face Seal Viton

6 Piston Seal Viton/Nylon

7 Tie Rod Steel 4

8 Tie Rod Locknut Steel/Nylon 4

9 Endcap Steel 1

10 Cylinder Seals Viton 2

11 Adapter Steel

12 Adapter Nuts Steel

13 Adapter Stud Locknuts Steel

14 High Pressure Rod Seal Flouromyte/Viton 1*

15 Rod Bearing Bronze

16 Snap Ring Steel

17 Low Pressure Rod Seal Viton

11444 Deerfield Road

Cincinnati, Ohio 45242

(513) 489-7800

Fax (513) 489-5243

Service Center

4214 Bluebonnet Drive

Stafford, Texas 77477

(713) 240-7484

Fax (713) 240-7097

Seal Kits

Viton/Flouromyte- RN(Actuator Base Model)-SKV

i.e.: Buna Seal kit for RN316SR80HV is:

†

1

†

1

†

1

†

1*

1*

Replacement hand pumps, manual directional control

†

valves, and manual ball valves are also available.

Consult factory.

*

†

1

†

4

†

4

*Recommended Spare Parts

‡

1

1

1*

†

Not present in SR Actuator Override

‡

‡

Not present in DA Actuator Override

‡

Service Center

7445 Whitepine Road

Richmond Virginia 23237

(804) 271-7800

Fax (804) 271-0155

RN316SRHSKV

Automax Controls, Inc.

120 Vinyl Court

Woodbridge,Ontario L4L 4A3

(905) 856-8568

Fax (905) 856-7905

B00151-0 Page 4 of 4

Loading...

Loading...