Page 1

Flowserve Corporation 765 South 100 East Phone: 801 373 3028

Flow Control Division Provo, Utah 84606 Facsimile:801 489 2228

www.flowserve.com Email: actuators@flowserve.com

Automax Valve Automation Systems

Installation, Operation and Maintenance Instructions

B00101-1 03/00 Page 1 of 2

© 2000, Flowserve Corporation, Provo, UT

Heavy Duty Gear Overrides

Gear overrides on Automax heavy duty actuators provide

an easy, durable method for manually operating the actuator. The gear overrides are declutchable for efficient,

automatic operation. The gear override consists of a

declutchable gear mounted to the accessory side of the

actuator. Any accessories, such as limit switches and

positioners, may be offset mounted.The gear override is

designed for the full rated torque of the actuator.

Installation

Automax standard gear ov errides are provided as a complete integral component of the heavy duty actuator .Gear

override units are shipped with the gear mounted

to the

actuator and shut-off & vent valves installed on the pressure cylinder. No additional customer installation is

required. See Automax Heavy Duty IOM (B00032) for

instructions on installing Heavy Duty actuator into service.

To retrofit gear o verride onto e xisting heavy duty actuator,

existing torque shaft must be replaced with override

torque shaft.

1. Disconnect air pressure and electrical power from

actuator. Remove all accessories from actuator and

dismount from valve.

2. Loosen stop bolt jam nut and back off clockwise stop

bolt to remove spring cartridge preload. Refer to

Heavy Duty IOM (B00032) for cross-sectional vie w of

parts.

3. Remove the bearing retainer screws from the valve

mounting side and slide the retainer plate off the

shaft.

4. The torque shaft may now be tapped out using a soft

faced hammer. Use care not to drop the shaft or the

bearing when they come out.

5. Reverse steps 3 and 4 with manual override torque

shaft. Orientation of the torque shaft is unimportant,

since it is symmetrical.

To install gear override to heavy duty actuator with

manual override torque shaft:

1. Assemble bracket and coupler provided with gear

override field mounting kit to the accessory side of

the actuator.

2. Mount gear override to actuator in orientation shown

below. Gear override should be declutched. To

declutch, lift declutching handle out of slot and

rotate 90 degrees.

3. Add shut-off and vent valves to actuator per operating schematic (see back).

4. Mount any accessories to actuator and test in automatic mode.

Note: After mounting actuator to valve, the gear override

travel stops must be set.Make sure that the actuator

travel stops are set correctly.Then set the gear override travel stops at the same position.

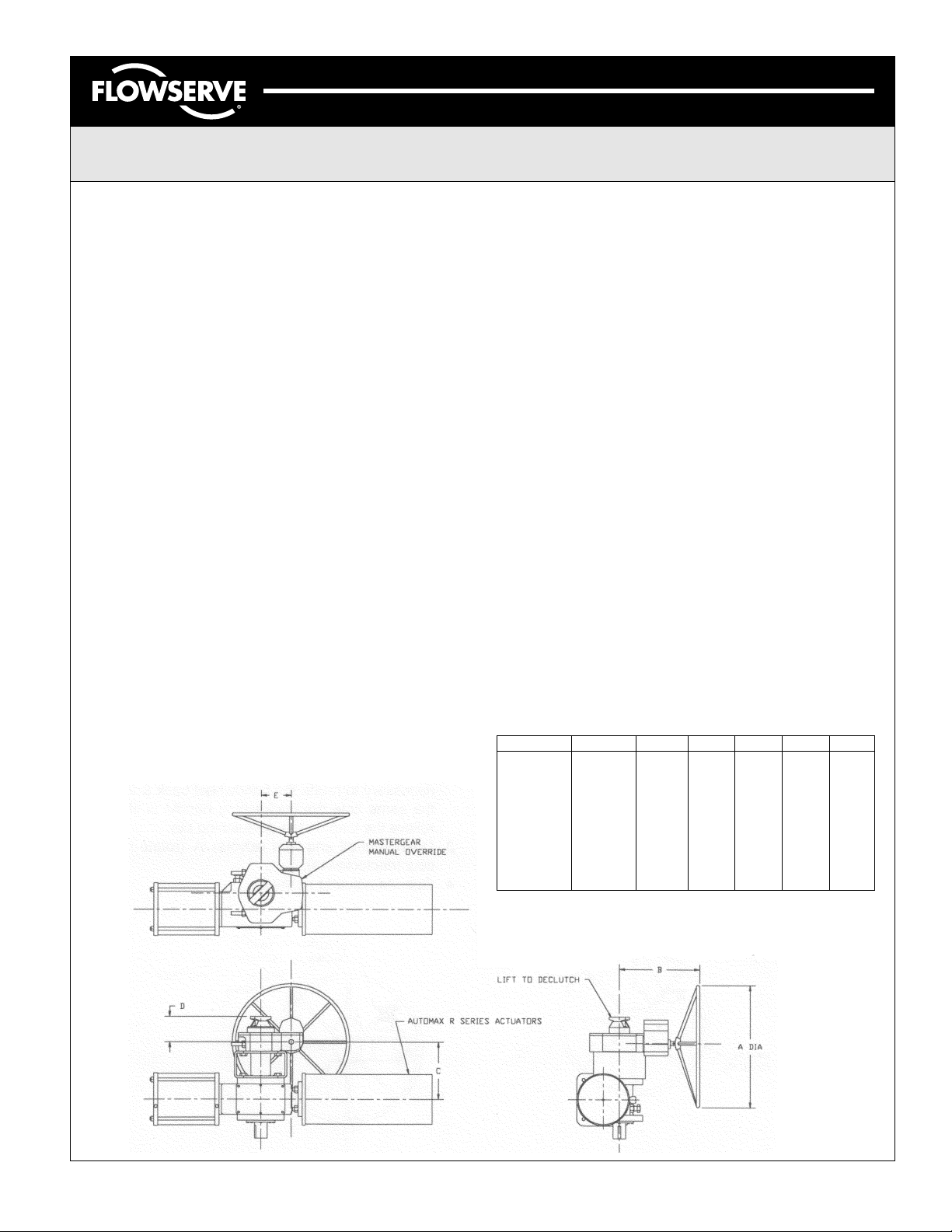

GEAR MANUAL OVERRIDE DIMENSIONAL DATA

NOTES:

1) ACTUATOR IS SHOWN IN THE FULL CLOCKWISE POSITION AS VIEWED FROM

THE ACCESSORY SIDE.

2) FOR COMPLETE ACTUATOR MOUNTING DIMENSIONS SEE PNEUMATIC

ACTUATORS CATALOG.

Heavy Duty Gear Override

ACTUATORS OVERRIDE A B C D E

R2 C24 24.00 10.44 7.80 4.69 3.02

R2 D30 30.00 12.94 8.00 5.69 3.38

R2 E30 30.00 12.94 8.13 5.88 4.38

R2 F24 24.00 16.21 8.13 5.88 1.31

R3 G30 30.00 18.33 12.00 6.03 2.31

R3 H30 30.00 18.71 13.08 6.19 2.11

R3 J30 30.00 19.33 12.63 10.37 2.68

R4 H30 30.00 18.71 15.77 6.19 2.11

R4 J30 30.00 19.33 15.32 10.37 2.68

R4 K36 36.00 19.96 15.32 10.75 3.81

R4 L36 36.00 23.33 15.57 10.65 9.33

Page 2

Automax Valve Automation Systems

Installation, Operation and Maintenance Instructions

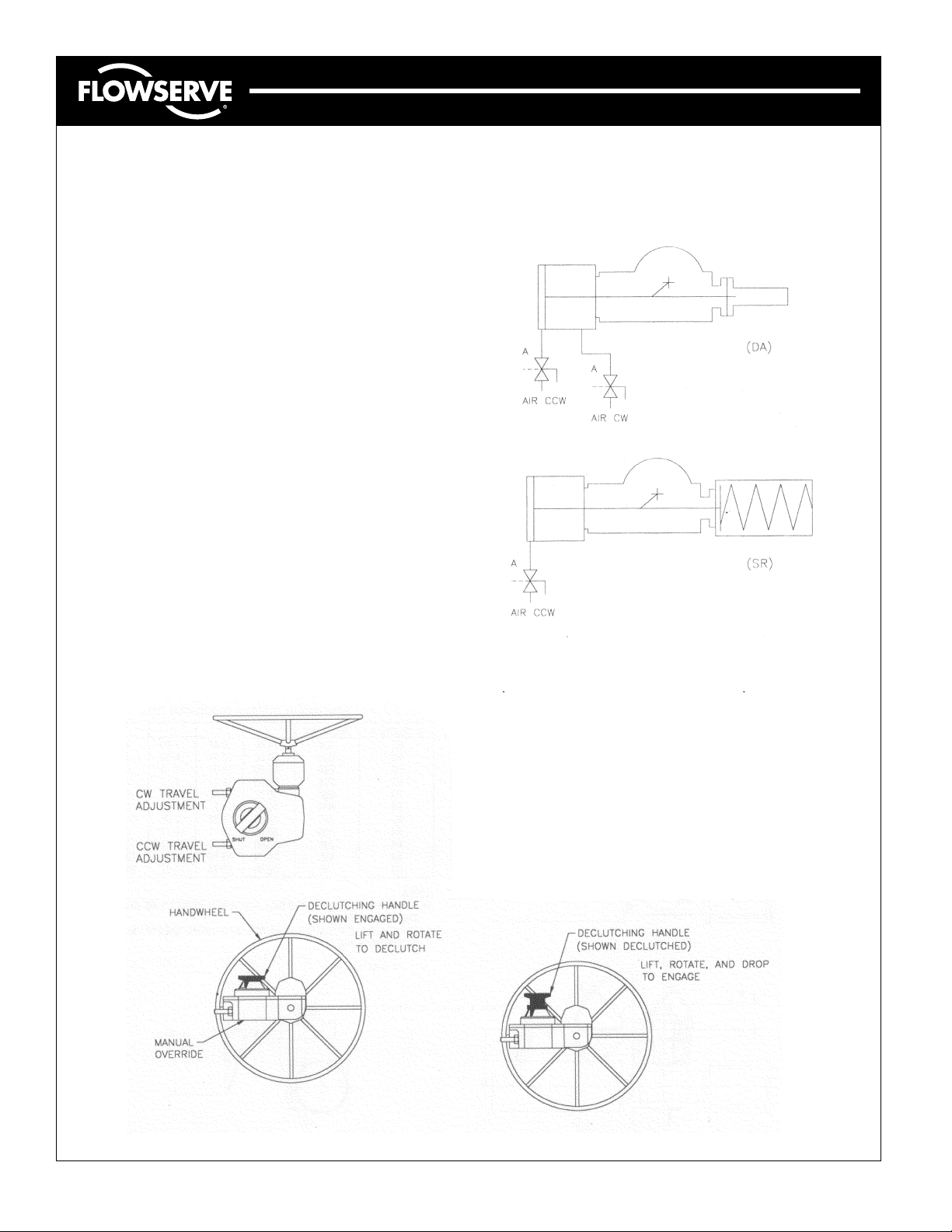

Operation:

Manual Operation

1. Rotate the handwheel on the manual override until

the position indicator on the manual override

agrees with the valve position.

Note: The position indicator on the manual override

indicates actuator/valve position only when the

handwheel is engaged. (Position indicator shows

‘SHUT’ in full CW position and ‘OPEN’ in full CCW

position.)

2. Engage handwheel by lifting the declutching handle from the shallow slot and rotating handle 90

degrees. Handle is spring loaded to drop into the

deep slot. Operate handwheel until the handle

drops fully into the deep slot.

Note: Occasionally it may be necessary to back the

gear override trav el stops out slightly to engage the

declutch mechanism.

3. Turn the shut-off and vent valve(s) ‘A’, located

on the supply port(s) of the actuator, to the full

clockwise position, to vent air pressure from the

cylinder.

4. Manually operate the actuator/valve by turning the

handwheel. Turning handwheel clockwise will

rotate actuator/valve clockwise.

Operating Schematic

Automatic Operation

1. Operate handwheel to desired valve position. This

should be full failed position for a spring return

actuator.

2. Lift the declutching handle out of deep slot. Rotate

90 degrees and drop into shallow slot. It may be

necessary to rotate the handwheel back & forth at

the same time the declutching handle is lifted to

relieve the load on the declutching pin.

3. Open shut-off and vent valve(s) ‘A’ (rotate handle

counter-clockwise).

4. Operate actuator nor mally.

B00101-1 03/00 Page 2 of 2

© 2000, Flowserve Corporation, Provo, UT

Loading...

Loading...