Page 1

Valtek Auxiliary Handwheels

and Limit Stops

Table of Contents

Page

1 General information

2 Installation

2 Side-mounted handwheels, size 25 and 50

(linear actuators)

3 Side-mounted handwheels, size 100 and 200

(linear actuators)

6 Top-mounted, continuously connected hand-

wheels, Size 100 and 200 (linear actuators)

7 Top-mounted, push-only handwheels (linear

actuators)

9 Declutchable handwheels (rotary actuators)

11 Push-only limit stops (linear actuators)

11 Pull-only limit stops (linear actuators)

GENERAL INFORMATION

The following instructions are designed to assist in

installing, operating, performing maintenance and disassembling handwheels and limit stops mounted on

Valtek spring cylinder actuators. Product users and

maintenance personnel should thoroughly review this

bulletin in conjunction with the Valtek Installation, Operation, Maintenance Instructions for Cylinder Actuators (IOM 2), prior to working on the handwheels and

limit stops.

To avoid possible injury to personnel or damage

to valve parts, WARNING and CAUTION notes

must be strictly adhered to. Modifying this product, substituting non-factory parts, or using maintenance procedures other than outlined could

drastically affect performance, be hazardous to

personnel and equipment, and may void existing

warranties.

WARNING: Standard industry safety practices must

be adhered to when working on this, or any other,

process control product. Specifically, personal

protective and lifting devices must be used as

warranted.

Valtek control valves are often equipped with auxiliary

handwheels of the continuously connected or push-only

type, allowing for manual operation of the valve in case

of air failure. Continuously connected handwheels can

also be used as a limit stop to limit valve travel in either

the open or closed position. Push-only handwheels are

designed to close the valve or limit opening. Limit stops

limit the actuator stroke in one direction or the other.

INSTALLATION

Valtek control valves, equipped with auxiliary handwheels and limit stops, are installed as outlined in the

maintenance bulletin for each type of valve. Refer to the

sales catalog or certified dimensional drawing for estimated overhead clearance requirements. To allow for

manual operation and maintenance, adequate access

to the handwheel or limit stop must be provided.

SIDE-MOUNTED, CONTINUOUSLY

CONNECTED HANDWHEELS,

SIZE 25 AND 50 (Linear Actuators)

Operation

If air failure should occur, or if manual control of the

valve is desired, the side-mounted, continuously connected handwheel can be operated as follows:

1. Set the three-way bypass valve (located on the

supply line to the positioner) to 'manual' to vent the

air pressure from the actuator.

NOTE: Three-way valves are installed in the supply

line only when there is no lock-up system or volume

tank. On volume tank or lock-in-place systems, the

Rev. 6/93 Valtek No. 49015 © 1998 Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611 5-1

Page 2

bypass valve is located between the top and bottom

cylinder ports.

2. To open the valve, turn the handwheel counterclockwise to retract the plug.

3. To close the valve, turn the handwheel clockwise to

extend the plug.

4. To return the valve to automatic control, return the

handwheel nut to 'neutral' as shown by the handwheel position indicator and set the three-way

bypass valve to 'auto.'

5. Adjusting the handwheel nut to a position other than

neutral provides a limit stop function, either limiting

opening or closing.

Maintenance

For proper operation of the handwheel, maintain a coat

of multi-purpose lubricant on the bearings at all times.

To do this:

1. Locate the two zerk fittings on the handwheel

housing. One fitting lubricates both bearings

simultaneously.

NOTE: The screw and nut threads are permanently

Iubricated with a solid film lubricant, requiring no

additional Iubrication.

2. Check all pivot points for wear and replace worn or

damaged parts as necessary. Lubricate all pivot

points.

3. Keep screw, nut and bearings free from dirt at all

times. If dirt or grease builds up so that handwheel

operation is impaired, disassemble handwheel and

clean thoroughly.

Disassembly

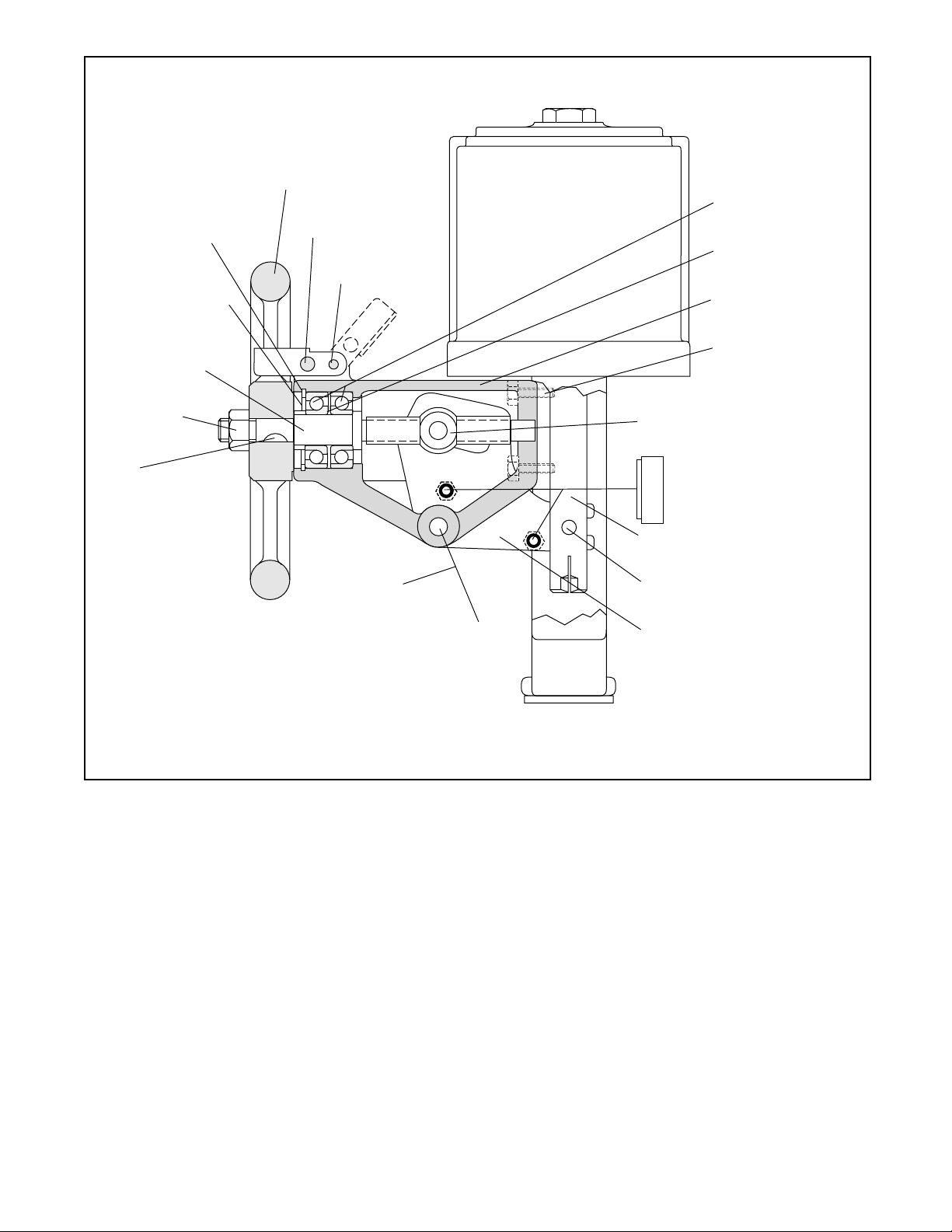

To disassemble the side-mounted handwheel assembly on size 25 and 50 linear actuators, refer to Figure 1.

NOTE: Because of the handwheel’s modular design,

the handwheel assembly can be removed from the

actuator without affecting the valve’s operation (unless

the handwheel is being used as a limit stop).

CAUTION: Prior to removing the handwheel unit,

ensure that the handwheel is not functioning as a

limit stop before removing the housing bolts. Failure to do so could cause serious personal injury. If

the actuator remains in service during handwheel

disassembly, keep hands and clothes away from

moving parts to avoid injury.

1. Remove four housing bolts and lift handwheel assembly off the yoke.

2. Loosen the crank levers by removing two sets of

spacers, bolts and nuts fastening the levers together. Remove one retaining ring from the pivot pin

and push the pin out.

3. Remove the lock nut, handwheel and Woodruff key

from the handwheel screw shaft.

4. Remove the internal retaining ring with a pair of

internal snap-ring pliers.

5. Remove the handwheel screw shaft from the handwheel nut by turning shaft clockwise (the screw has

left-hand threads). After the shaft is free from the

nut, pull the shaft and bearings straight out and

remove nut and crank levers from the housing.

6. After removing the support spacer, slide the two

bearings and support washer (sandwiched between

the bearings) off the handwheel screw shaft.

Reassembly

To reassemble the side-mounted handwheel on size 25

and 50 linear actuators:

1. Inspect all parts, especially the bearings, for damage or wear; clean all parts and lubricate each

bearing.

2. Replace the bearings on the shaft in the following

order: bearing, support washer, bearing, support

spacer.

NOTE: The bearings must be oriented with the

largest inside races (thrust supporting) facing each

other, with a support washer between them (refer to

Figure 1).

CAUTION: If the bearing orientation is incorrect,

the bearings will be damaged.

3. Position the handwheel nut between the two lever

cranks and reinstall the handwheel nut into the

housing. Make sure the position indicator pin on the

nut is inserted in the position indicator slot.

4. Lubricate the small tip on the handwheel shaft and

mating hole in the housing. Reinsert the handwheel

shaft into the housing and begin turning the screw

counter-clockwise into the handwheel nut. Continue to turn until the bearings are seated in the

housing and the nut is in the neutral position.

5. Install the internal retaining ring to hold the bearings

in the housing.

6. Replace the handwheel on the shaft, making sure

the Woodruff key is properly inserted in key slot.

7. Fasten the handwheel securely in position with the

lock nut.

NOTE: If there is excessive movement (1/8-inch or

more) when pulling on the handwheel screw, the

bearings are positioned backwards and must be

reversed (refer to Step 2) before bearing damage

occurs.

8. Lubricate and reinsert pivot pin and fasten with

retaining ring. Bolt the two sides of the crank levers

together, using two sets of spacers, bolts and nuts.

9. Reattach the handwheel assembly to the yoke

using four housing bolts. Make sure the slotted

ends of the lever cranks mate with the actuator

stem pin.

5-2 Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 3

Internal Retaining

Ring

(Item No. 393-9)

Support Spacer

(Item No. 393-6)

Handwheel

(Item No. 393-18)

Locking Bar

(Item No. 393-17)

Pin

(Item No. 393-1)

Bearings

(Item No. 393-8)

Support Washer

(Item No. 393-10)

Housing

(Item No. 393-14)

Handwheel

Screw Shaft

(Item No. 393-13)

Lock Nut

(Item No. 393-4)

Key

(Item No. 393-5)

Handwheel Nut

(Item No. 393-16)

Housing Bolt

(Item No. 333)

Spacer (Item No. 393-7)

Nut (Item No. 393-3)

Bolt (Item No. 393-2)

Not Shown:

Actuator Stem

(Item No. 211)

Grease Fittings

(Item No. 393-15)

Pivot Pin

(Item No. 393-19)

Actuator Pin

(Item No. 372)

Indicator Plate

(Item No. 393-12)

External Retaining Ring

(Item No. 393-20)

Crank Lever

(Item No. 393-11)

Indicator Plate Screws

(Item No. 401)

Figure 1: Size 25 and 50, Side-mounted, Continuously connected Handwheel

NOTE: Item numbers shown above correspond directly to valve’s bill of material. Refer to the bill of material for specific part numbers.

CAUTION: Avoid reattaching the handwheel assembly to the yoke while the actuator remains in

service. If the actuator remains in service during

handwheel reassembIy, ensure that the

handwheel is in the neutral position and that

hands and clothes are kept away from moving

parts to avoid injury.

SIDE-MOUNTED, CONTINUOUSLY

CONNECTED HANDWHEELS, SIZE 100

AND 200 (Linear Actuators only)

Operation

See 'Operation' under Size 25 and 50 Side-mounted

Handwheels section.

necessary; however, periodically examine the handwheel assembly:

1. Check bearing wear by pulling on the handwheel. If

movement more than 1/8-inch in any one direction is

present disassemble and inspect bearings.

2. Keep the handwheel mechanism free from dirt. If

dirt begins to impair handwheel operation, disassemble and clean thoroughly.

Disassembly

To disassemble the side-mounted handwheel on size

100 and 200 linear actuators, refer to Figure 2:

1. Depressurize the process line and actuator to atmospheric pressure. Remove the actuator from

valve (see valve’s maintenance bulletin for instruc-

Maintenance

Because the screw threads are permanently lubricated

with a solid film lubricant, periodical lubrication is not

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611 5-3

tions). Disassemble cylinder by following steps 1-6

under 'Disassembling Actuator' instructions found

in IOM 2 (Cylinder Actuators).

Page 4

WARNING: Failure to repressurize process line

and actuator to atmospheric pressure could

result in serious personaI injury.

2. Slide the stem clamp and bellows off the actuator

stem.

2. Insert upper actuator stem O-ring and replace

O-ring retaining washer and retaining ring.

3. If the pinion shaft bearings have been removed,

press in two new bearings with a dowel of the same

diameter, using a suitable press.

3. Remove the bolt holding the handwheel to the

pinion shaft. Slide handwheel off pinion shaft.

4. Remove the housing set screw at the base of the

handwheel housing and the retaining ring Iock

screw which releases the compression on the

handwheel housing retaining ring.

5. Using two screwdrivers, remove the handwheel

housing retaining ring.

6. Pull the handwheel assembly off the yoke, taking

care not to gall the actuator stem O-ring as it is

pulled from yoke.

7. With the cylinder and piston removed (Step 1), pull

actuator stem straight out of the housing.

8. Remove the bearing spacer, lower bearing and

handwheel nut from the actuator stem.

9. To remove the pinion gear and shaft, remove the

pin retaining ring, rotate the pinion shaft so the pin

will not hit the indicator gear bearing, and push the

pin out. Slide the pinion shaft out of the pinion gear

and housing.

10. Remove the bevel gear, wave spring and the upper

thrust bearing.

11. If the pinion shaft bearings are worn or damaged,

push them out with a suitable press and a dowel the

same size as the bearing’s outside diameter.

12. Remove the upper actuator stem O-ring. (It is not

necessary to remove the O-ring retaining ring and

O-ring retaining washer).

13. The indicator cover plate is attached to the housing

with an adhesive gasket. Gently pry it off.

14. With a screwdriver, remove the two carriage screws

holding the position indicator assembly to the housing. Remove assembly from housing.

15. Normally the position indicator assembly does not

require disassembly. If disassembly is required,

remove the inside stem retaining ring located on the

lower end on the indicator stem. Screw the stem out

of the indicator nut.

Reassembly

To reassemble the side-mounted handwheel on Size

100 and 200 Iinear actuators:

1. Replace and lubricate all O-rings with a silicone

lubricant (Dow Corning® 55M or equivalent). Clean

all internal parts thoroughly before beginning

assembly.

4. To install the bevel gear and bearings, place the

handwheel housing upside down. Lubricate the

upper ball thrust bearing and place it in the housing,

squarely on the machined shoulder.

5. Lubricate the bevel gear thoroughly on the teeth

and the outer surface where it makes contact with

the housing. Lubricate the inside of the square drive

tube. Position the bevel gear assembly into the

housing.

6. Lubricate the pinion gear, shaft and thrust bearings.

Reposition the pinion gear and thrust bearings.

Slide the pinion shaft through the outside of the

housing until it mates with the pinion gear. Rotate

the shaft until the hole in the pinion gear aligns with

the shaft. Insert pin and replace pin retaining ring.

7. Screw the handwheel nut midway onto the actuator

stem and insert the stem through the center of the

bevel gear. Be careful not to score the polished

surfaces of the actuator stem.

8. Position the wave spring on the shoulder of the

bevel gear. Lubricate the lower ball thrust bearing

and place it on the wave spring. Make sure the

bearing fits into the step in the bevel gear with the

wave spring sandwiched in between. Replace the

bearing spacer with the bearing fitting inside the

spacer’s lip.

9. After replacing the lower actuator stem O-ring in the

yoke, insert the yoke into the housing, taking care

not to gall the actuator stem on the stem bushings

or damage the O-ring.

10. Using two screwdrivers, replace the housing retaining ring.

11. Rotate the housing to the desired orientation and

screw-in the retaining ring Iockscrew and reinstall

the housing setscrew until the retaining ring and

housing are locked securely in place.

12. Reinstall the handwheel and handwheel bolt onto

the pinion shaft. Fasten securely with nut.

13. Reassemble the position indicator assembly by

inserting the indicator stem onto the carriage. Screw

the indicator nut into the stem. Replace the stem

retaining ring. Turn the stem until the indicator nut

is centered between the two neutral marks stamped

on the carriage.

14. Turn the handwheel counter-clockwise until the

actuator stem begins to retract. Turn the handwheel

clockwise for two complete turns, so that the handwheel nut is in the neutral position.

5-4 Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 5

Retaining Ring

O-ring Retaining Washer

Upper Actuator Stem

O-ring

Stem Bushing

Upper Ball Thrust Bearing

Housing O-ring

Cylinder Retaining Ring

Carriage Screw

Indicator Carriage

Indicator Cover Plate

Indicator

Stem

Handwheel Housing

Square Drive Tube

Handwheel Nut

Bevel Gear

Wave Spring

Lower Ball

Thrust Bearing

Housing Setscrew

Handwheel Housing

Retaining Ring

Bearing Spacer

Stem Bushing

Actuator Stem

Bellows

Stem Clamp

Indicator Nut

Stem Retaining Ring

Indicator Gear

Thrust Bearing

Pinion Shaft Bearing

Handwheel

Bolt

Pinion Shaft

Nut

Pin Retaining Ring

Retaining Ring Lockscrew

Pinion Gear

Lower Actuator Stem O-ring

Figure 2: Size 100 and 200, Side-mounted, Continuously connected Handwheel

NOTE: Refer to factory for valve’s bill of material item numbers.

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611 5-5

Page 6

NOTE: For correct neutral indication, it is important

to have the handwheel assembly in the neutral

position and the indicator nut between the neutral

marks before installing the indicator assembly in

the housing.

15. With two carriage screws, reinstall the position

indicator assembly, making sure the indicator gear

properly meshes with the pinion gear. Turn the

handwheel to the full open or closed position and

check for correct orientation; readjust if necessary.

With the new adhesive gasket, reattach indicator

cover plate.

16. Replace the housing O-ring.

17. Reattach the bellows and stem clamp to the yoke

and actuator stem.

18. Reassemble the cylinder according to instructions

found in IOM 2.

TOP-MOUNTED, CONTINUOUSLY

CONNECTED HANDWHEELS

Size 100 and 200 (Linear Actuators)

Operation

If air failure occurs, or if manual control of the valve is

desired, the top-mounted, continuously connected handwheel can be operated as follows:

1. Set the three-way bypass valve (located on the

supply line to the positioner) to 'manual' to vent the

air pressure from the actuator.

NOTE: three-way valves are installed in the supply

line only when there is no lock-up system or volume

tank. On volume tank or lock-in-place systems, the

bypass valve is Iocated between the top and bottom

cylinder ports.

2. To open the valve, turn the handwheel counterclockwise to retract the plug.

3. To close the valve, turn the handwheel clockwise to

extend the plug.

4. To return the valve to automatic control, return the

handwheel nut to 'neutral' as shown by the handwheel position indicator and set the three-way

bypass valve to 'auto.' The neutral position is indicated when the top of the screw aligns with the red

line on the cap liner.

5. Adjusting the handwheel nut to a position other than

neutral provides a limit stop function, either limiting

opening or closing.

Maintenance

Since the top-mounted, continuously connected handwheel is totally enclosed, there is generally no need for

periodic maintenance; however, disassembly may be

necessary if the mechanism fails. When reassembling

the handwheel, be sure to thoroughly clean and lubricate the handwheel screw and drive nut with a multipurpose lubricant.

Cap

(Item No. 381)

Gear Operator

(Item No. 393)

Stem Key

(Item No. 373)

Bolt Gasket

(Item No. 379)

Pedestal

(Item No. 389)

Spacer

(Item No. 383)

Bushing

(Item No. 390)

Handwheel Stem

(Item No. 380)

Spring

(Item No. 229)

Piston

(Item No. 225)

Actuator Spacer

(Item No. 228)

Stem Lock Nut

(Item No. 350)

Cap Liner

(Item No. 374)

Cap Extension

(Item No. 387)

Handwheel Screw

(Item No. 388)

Gear Operator Bolts

(Item No. 334)

Pedestal Bolts

(Item No. 333)

Pedestal Gasket

(Item No. 378)

Spring Button

(Item No. 227)

Handwheel O-ring

(Item No. 276)

Stem Pin

(Item No. 372)

Piston Stem O-ring

(Item No. 272)

Actuator Stem

(Item No. 211)

Figure 3: Top-mounted, Continuously

connected Handwheel

NOTE: Item numbers shown above correspond directly to the valve’s

bill of material. Refer to the bill of material for specific part numbers.

Disassembly

Refer to Figure 3:

WARNING: Repressurize line and actuator to atmospheric pressure before disassembling the handwheel or removing the actuator from the valve. Also,

make sure the handwheel screw is in the neutral

position before disassembly. Failure to do so can

cause serious personal injury to occur.

NOTE: These instructions are for air-to-open only.

Instructions for the air-to-close design is the same with

one exception: Pedestal bolts are not used to compress

the spring for air-to-close action; therefore, no spring

tension is released.

1. The handwheel may be disassembled while mounted

on the valve, or the actuator can be removed and

disassembled separately. If a change in the failure

action is required, the entire actuator subassembly

must be removed before proceeding (See 'Disassembling Actuator' in Maintenance Bulletin 1). The

recommended procedure is to remove the actuator

subassembly from the valve.

5-6 Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 7

2. Remove the handwheel cap and the handwheel cap

extension.

3. Loosen stem clamp and slide it off actuator stem.

4. Use a wrench on the actuator stem flats to secure

the position of the stem so it cannot rotate. Remove

the stem locknut.

CAUTION: Damage to the seating surfaces of

the plug and seat can result if the plug is allowed

to rotate during removal of the stem locknut.

5. Unbolt gear operator from pedestal.

NOTE: Bolts are located on the pedestal underneath the gear operator. They are not the bolts

located at the top portion of the gear operator itself.

6. Lift off the gear operator, drive nut assembly and

handwheel screw.

7. Unbolt pedestal from the cylinder actuator. This will

relieve spring tension in the actuator (air-to-open

only).

WARNING: Cylinder is spring loaded. Do not

attempt to remove the handwheel pedestal bolts

without following Step 8 exactly. Failure to do

so can cause serious injury.

8. Remove the six pedestal bolts gradually to relieve

spring tension. This can be done by loosening the

first bolt approximately one-quarter turn, then loosening the bolt directly opposite one-quarter turn

until all bolts have been loosened and the spring

tension is relieved.

NOTE: The bolts are long enough to relieve all

spring tension prior to removing the pedestal.

9. Remove the pedestal.

10. Lift out the spring button and spacer if provided (airto-open only).

11. Remove cylinder retaining ring.

12. Disassemble cylinder from yoke.

13. Remove spring and spring button.

14. Lift out piston, actuator stem and handwheel stem

assembly.

CAUTION: Unless the piston stem O-ring (sealing the two cylinder air chambers) is leaking, do

not remove the handwheel stem from the actuator stem. It may be difficult to realign the stem

pin hole while reassembling the handwheel stem.

15. Remove piston, yoke, and pedestal O-rings.

Reassembly

Refer to Figure 3:

1. Make sure all internal parts are thoroughly cleaned

and lubricated before beginning assembly. Use

new O-rings and gaskets. (O-rings should be lubricated with a silicone lubricant such as Dow Corning

55M or equivalent).

2. Reassemble the cylinder actuator using the appropriate actuator maintenance bulletin.

3. Place the gasket on the cylinder. Place the pedestal

on top of the cylinder. Pedestal should align with

spring button or spring button spacer if used.

NOTE: Check bolting alignment for proper handwheel orientation.

4. Replace aluminum flat washers.

NOTE: To prevent air leaks, lightly coat the washers with a standard pipe sealant.

5. Reassemble pedestal bolts. Begin tightening the

bolting in a manner that will keep the pedestal

square with the cylinder.

WARNING: Failure to keep the pedestal square

with the cylinder may result in damage to the

pedestal O-ring and bushing.

6. Tighten the first bolt approximately one-quarter turn,

then tighten the bolt directly opposite one-quarter

turn. Continue tightening until sufficient gasket compression is applied to seal cylinder and pedestal

tightly. This is necessary to prevent air leakage.

7. Before applying air to the cylinder, make sure the

cylinder retaining ring is installed properly. Feed air

to bottom of cylinder to raise handwheel stem (airto-open only).

8. Insert round end key into slot in handwheel stem.

Remove air. Handwheel stem will retract (air-toopen only).

9. Place gear operator on flat surface with top of the

operator facing down. Insert key in gear operator

drive nut. Install one set of roller thrust bearings in

gear operator.

10. Align the key to the bevel gear key way and install

drive nut. Install second set of roller thrust bearings.

11. Lubricate handwheel screw, and then screw (screw

is left-hand threaded) into the drive nut until screw

bottoms out.

CAUTION: Before completing the next step, be

sure not to allow assembled portion of the

handwheel to drop out of the gear operator.

Failure to do so will cause the drive nut key to

drop out of place. Steps 9 and 10 will then have

to be repeated.

12. Install pedestal gasket.

13. Take the gear operator and handwheel screw assembly and insert it on handwheel stem while

aligning stem key with slot in handwheel screw.

Make sure gear operator is flush with pedestal top.

14. Once the gear operator is flush with the pedestal,

replace bolts and tighten. Tighten the first bolt onequarter turn, then tighten the bolt directly opposite

one-quarter turn. Continue tightening all bolting

until gear operator and pedestal are firmly seated.

15. Install lock nut on handwheel stem, and screw on

handwheel cap extension.

16. Insert gaskets and cap liner (sight glass) into handwheel cap.

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611 5-7

Page 8

17. Screw on handwheel cap until no movement can be

felt in the cap liner.

18. Tighten handwheel cap assembly.

CAUTION: Excessive tightening is not required.

This is not a pressure retaining seal.

Reversing Spring Action

After following the disassembly of the actuator as

outlined, the spring action can be reversed as follows:

1. Remove cylinder retaining ring, cylinder and spring.

2. Drive out the stem pin locking the handwheel stem

to the actuator stem.

3. Screw the handwheel stem off the actuator stem.

Make sure a wrench is used to prevent the actuator

stem from rotating.

CAUTION: Damage to the seating surfaces of

the plug and seat can result if the plug is allowed

to rotate during removal of the handwheel stem.

4. Reinstall the actuator spacer on the opposite side of

the piston. Replace the piston stem O-ring during

this step.

5. Screw the handwheel stem back into the actuator

stem. Realign stem pin hole and reinsert stem pin.

6. Reassemble actuator with spring under the piston

for air-to-open (spring-to-retract). The spring should

be installed over the piston for air-to-close (springto-extend). Make sure the actuator spacer is on the

same side of the piston as the spring.

7. Reassemble by following the instructions in the

'Reassembly' section.

NOTE: The spring button and spring button guide

are not used in the air-to-open configuration and

should be removed and set aside. When changing

to the air-to-close configuration, a spring button and

spring button guide must be obtained from Flowserve

or from existing supply.

TOP-MOUNTED, PUSH-ONLY

HANDWHEELS (Rotary Actuators Only)

Operation

The push-only handwheel can be used to close the

valve or as a limit stop to limit valve opening:

1. If provided, set the three-way bypass valve on

'manual' to vent air pressure to the actuator.

2. Turn handwheel in a clockwise direction to extend

the actuator stem and to lower the valve plug.

3. To return the valve to automatic control, turn the

handwheel counter-clockwise until the handwheel

runs out of threads and stops (neutral position), and

set the three-way valve on 'auto.'

4. To limit the opening of the valve, move the handwheel from neutral to the desired limiting position.

Maintenance

For proper operation of the handwheel, it is important to

Handwheel Stem Nut

(Item No. 348)

Bolt Gasket

(Item No. 379)

Flange

(Item No. 389)

Handwheel

Stem O-ring

(Item No. 276)

Bushing

(Item No. 390)

Handwheel

Stem

(Item No. 380)

Handwheel

(Item No. 393)

Handwheel Key

(Item No. 370)

Flange Gasket

(Item No. 378)

Flange Bolt

(Item No. 333)

Figure 4: Top-mounted,

Push-only Handwheel

NOTE: Item numbers shown above correspond directly to the

valve’s bill of material. Refer to the bill of material for specific part

numbers.

maintain a coat of multi-purpose lubricant on the screw

at all times. To do this:

1. Turn the handwheel counter-clockwise until the

handwheel runs out of threads and stops, exposing

the full length of the screw.

2. Clean and lubricate the exposed threads.

Disassembly

Refer to Figure 4:

1. The handwheel assembly can be disassembled

while mounted on the valve, or the actuator can be

removed and disassembled separately (see the

valve’s maintenance bulletins for instructions).

WARNING: Repressurize line and actuator to

atmospheric pressure before removing the actuator from the valve, or serious personal injury

could result.

2. Rotate the handwheel counter-clockwise until the

handwheel runs out of threads and stops (neutral

position). This releases some of the spring compression.

WARNING: Cylinder is spring loaded. Do not

attempt to remove flange bolts without following Steps 3 and 4 exactly or serious injury can

occur.

3. Remove four of the six handwheel flange bolts,

leaving two opposing bolts.

4. Remove two remaining handwheel flange bolts

5-8 Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 9

slowly and simultaneously, relieving the remaining

spring compression. The bolts are long enough to

relieve all spring compression prior to removing the

flange (as long as the handwheel is in the full

counter-clockwise position).

WARNING: Make sure handwheel is in full

counter-clockwise position. Otherwise, serious

injury may result when removing the flange

bolts.

5. Lift the handwheel/flange assembly from the actuator. Remove the flange gasket.

6. The actuator may now be disassembled according

to the valve’s or actuator’s maintenance bulletin.

7. If it is necessary to replace the handwheel stem Oring, remove handwheel nut and handwheel.

8. Screw the handwheel stem off flange and replace

O-ring. There is no need to replace the bushing.

Reassembly

Refer to Figure 4:

1. Make sure all internal parts are thoroughly cleaned

and lubricated before beginning reassembly. Use

new O-rings and gaskets (O-rings should be lubricated with a silicone lubricant, such as Dow Corning

55 M).

2. Insert new handwheel stem O-ring. Reassemble

handwheel assembly (if disassembled) by screwing the handwheel stem into the flange. Replace the

handwheel, handwheel key and lock nut.

Worm

(Item No. 397-10)

Stem Pin

(Item No. 397-14)

Thrust Roller

(Item No. 397-12)

Thrust Race

(Item No. 397-13)

Stem Bushing

(Item No. 397-7)

Handwheel Key

(Item No. 397-17)

Handwheel

(Item No. 397-1)

Handwheel Locknut

(Item No. 397-18)

Clutch Indicator

(Item No. 397-20-7)

Cover Plate

(Item No. 397-5)

Clutch Shaft

(Item No. 397-20-1)

Small External

Retaining Ring

(Item No. 397-20-4)

Coupling

(Item No. 397-4)

Transfer Case

(Item No. 204)

Clutch Handle

(Item No. 397-1)

Shaft

(Item No. 50)

Handwheel Gear

(Item No. 397-3)

Handwheel Stem

(Item No. 397-2)

External

Retaining Ring

(Item No. 397-16)vva

Large External

Retaining Ring

(Item No. 397-20-3)

Screw

(Item No. 397-20-5)

Cover Plate Bolt

(Item No. 397-8)

Compression

Spring

(Item No. 397-20-2)

Clutch Key

(Item No. 397-6)

Housing

(Item No. 397-9)

Flanged

Bushing

(Item No. 397-15)

3.Reassemble the actuator using the valve’s or

actuator’s maintenance bulletin.

4. Install a new flange gasket.

5. Position the handwheel/flange assembly on the

actuator.

6. Using new bolt gaskets, install two opposing flange

bolts and tighten evenly to compress spring.

7. Remount and tighten four remaining flange bolts.

DECLUTCHABLE HANDWHEELS

(Rotary Actuators Only)

Operation

The declutchable handwheel used on rotary actuators

can be operated as follows:

1. Set the three-way bypass valve to 'manual' to vent

the air pressure from the actuator.

2. Engage the handwheel mechanism by rotating the

clutch handle 90° and allowing it to be fully seated

in the clutch indicator’s deep slot.

3. Rotate the handwheel until the spring loaded clutch

key engages the handwheel gear. At this point the

handwheel mechanism is fully engaged.

Figure 5: Declutchable Handwheel

NOTE: Item numbers shown above correspond directly to the valve’s

bill of material. Refer to the bill of

material for specific part numbers.

4. To open, turn the handwheel counter-clockwise.

5. To close, turn the handwheel clockwise.

6. To declutch the handwheel, rotate the handwheel

until there is little or no load on it. Pull the clutch

handle out and index it 90° until it seats in the clutch

indicator’s shallow slot.

NOTE: It will be difficult to pull out the clutch

handle if the handwheel mechanism is transmitting torque.

Maintenance

Because the handwheel gearbox is packed with grease,

periodic maintenance is not required; however, periodically examine the handwheel:

1. Check for bearing and gear wear by pulling on the

handwheel. If it gives more than 1/8-inch in any one

direction, disassemble and inspect the bearings

and gears.

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611 5-9

Page 10

2. Keep the handwheel mechanism free from dirt. If

dirt begins to impair handwheel operation, disassemble and clean thoroughly.

Disassembly

To disassemble the declutchable handwheel on rotary

actuators, refer to Figure 5:

1. It is not necessary to remove the valve from line to

disassemble handwheel, although it is important to

repressurize the line to atmospheric pressure.

WARNING: Failure to repressurize the line and

actuator to atmospheric pressure could result

in serious personal injury.

2. Remove the four cover-plate bolts and slide the

handwheel assembly off the transfer case and

shaft.

3. Remove the two sockethead screws holding the

clutch indicator to the coupling and remove the

cover plate from the assembly.

4. If disassembly of clutch assembly is necessary,

remove large external retaining ring (use snap-ring

pliers) located on the clutch shaft by the clutch

handle. Slide the clutch handle and clutch indicator

off the shaft. Remove clutch shaft from the cover

plate and slide compression spring off of the shaft.

Remove the small external retaining ring and the

clutch key from the shaft.

5. If it is necessary to remove the handwheel from the

handwheel stem, remove the handwheel lock nut

and slide the handwheel and handwheel key off the

handwheel stem.

NOTE: All stems use either an external retaining

ring or a shoulder on the stem to hold the handwheel

in place. The retaining ring does not require removal

except for replacement.

6. Drive the stem pin through the stem and worm gear

until it nearly touches the housing wall. Rotate the

stem 180° and pull out the pin with a pair of vice

grips or similar tool.

7. Slide the stem out of the assembly. Simultaneously

slide the handwheel gear off the coupling and

remove the worm. Remove the two sets of thrust

rollers and races. The two stem bearings should be

visually inspected for damage or wear. If removal of

the stem bushings is necessary, push them out

using a dowel of the same diameter and a suitable

press.

8. Pull the coupling out of the housing. Inspect the

flanged bushing for wear. If necessary, remove with

an appropriate press and dowel.

Reassembly

To reassemble the declutchable handwheel on rotary

actuators, refer to Figure 5:

1. Clean all parts thoroughly before reassembling the

declutchable handwheel.

2.To reassemble the clutch assembly (if disassembled), slide the clutch key onto the small end of

the clutch shaft and secure with the small external

retaining ring. Install the compression spring over

the shaft. Position the clutch indicator on the outside of the cover plate. Slide the large end of the

clutch shaft through the clutch indicator from the

inside of the cover. Install the clutch handle and

large external retaining ring.

3. Using a press, install new stem bushings (if removed).

4. Using a press, install a new flanged bushing (if

removed). Lubricate and reinstall the coupling. Note

that the coupling rotates inside the flanged bushing.

5. Thoroughly lubricate the worm and handwheel gear.

Holding the worm engaged in the gear (as shown in

Figure 5), slide the handwheel gear onto the

coupling.

6. Install a thrust bearing at each end of worm, making

sure roller is sandwiched between the two races.

7. Slide the handwheel stem through the stem bearings and worm gear. Align pin holes in the worm

gear and stem, and drive pin into place.

8. If the handwheel was removed from the stem, insert

the handwheel key into its slot in the handwheel

stem. Slide the handwheel on and secure it with the

handwheel locknut.

9. Pack the entire inside volume of the handwheel

housing with a multi-purpose grease.

10. Rotate the coupling until its slot aligns with the slot

in the handwheel gear. Replace the cover plate,

making sure the clutch key slides into the slots.

Rotate the clutch handle until it fits into the bottom

of the deep slot in the indicator and allows the clutch

key to engage the gear and coupling. If the key does

not engage, rotate the handwheel back and forth

until it does. Rotate the clutch indicator until the two

screw holes line up and the pointer points to the

stroke indicator scale. Fasten in place with the two

screws.

CAUTION: Since the gear has limited rotation,

the splines on the shaft and coupling must be

correctly oriented. Incorrect alignment will result in limited handwheel rotation.

11. To correctly orient the splined shaft and coupling,

check to see if the valve is open or closed. If closed,

rotate the handwheel clockwise with the clutch

engaged until the gear hits the stop. Next, slide the

handwheel assembly onto the splined shaft, making sure the line on the end of the shaft lines up

exactly with the closest line on the coupling. Reinstall the four cover plate bolts.

12. If the handwheel does not stroke the valve fully, the

splined shaft and coupling are not aligned correctly.

Repeat Step 11.

5-10 Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 11

Jam Nut

(Item No. 350)

Limit Stop Bolt

(Item No. 380)

Limit Stop Hub

(Item No. 391)

Hub Gasket

(Item No. 248)

O-ring

(Item No. 376)

Spring Button

(Item No. 227)

Cylinder

(Item No. 202)

6. Tighten the limit stop jam nut firmly against the

locking stop hub.

Disassembly

Refer to Figure 6:

WARNING: Repressurize line and actuator to atmospheric pressure before disassembling the handwheel or removing the actuator from the valve, or

serious personal injury could result.

1. The limit stop may be disassembled while mounted

on the valve, or the actuator can be removed and

disassembled separately (see the valve’s maintenance bulletins for instructions).

2. Vent air pressure on both sides of the piston.

Loosen the limit stop jam nut and screw the limit

stop bolt counter-clockwise until it can be removed

from the limit stop hub. Remove the O-ring and jam

nut from the limit stop bolt.

3. Screw the limit stop hub off the cylinder. Larger

sizes are designed with an internal flanged hub. If

this is the case, remove the flange bolts. Remove

the gasket from the limit stop hub.

4. Actuator may now be disassembled according to

Maintenance Bulletin 2.

Figure 6: Push-only Limit stop

NOTE: Item numbers shown above correspond directly to the valve’s

bill of material. Refer to the bill of material

for specific part numbers.

PUSH-ONLY LIMIT STOPS

(Linear Actuators Only)

Operation

The push-only limit stop is used to limit valve opening.

To set the limit stop:

1. Loosen the limit stop jam nut (see Figure 6).

2. To lengthen the stroke, screw the limit stop bolt

counter-clockwise from the locking stop hub until

the desired position is reached. To shorten the

stroke, screw the limit stop bolt clockwise into the

locking stop hub until the desired position is reached.

3. Tighten the limit stop jam nut firmly against the

locking stop hub.

Maintenance

For proper maintenance of the limit stop, it is important

to maintain a coat of multi-purpose Iubricant on the limit

stop bolt threads at all times. To do this:

1. Vent air pressure on both sides of piston.

2. Loosen the limit stop jam nut.

3. Extend the limit stop bolt until the entire length of the

threaded portion is exposed.

4. Clean and lubricate the threads.

5. Return the limit stop bolt to desired position.

Reassembly

Refer to Figure 6 and proceed as follows:

1. Make sure all internal parts are thoroughly cleaned

and lubricated before beginning reassembly. Use

only new O-rings and gaskets (O-rings should be

lubricated with a silicone lubricant, such as Dow

Corning 55 M). Reassemble the actuator according

to Maintenance Bulletin 2.

2. Install a new O-ring on the limit stop bolt and a new

gasket on the limit stop hub.

3. Screw the limit stop hub into the cylinder or on larger

sizes, reinstall hub and flange bolts.

4. Make sure the end of the hub seats properly with the

spring button. Tighten the limit stop hub (or flange

bolts) only enough to make an adequate air seal

with the gasket.

5. After installing the jam nut on the limit stop bolt,

screw the limit stop bolt into the limit stop hub until

the desired position is reached.

6. Tighten the jam nut against the limit stop hub.

PULL-ONLY LIMIT STOPS

(Linear Actuators Only)

Operation

WARNING: The limit stop bolt and jam nuts are

moving parts. Keep hands, hair or clothing clear

during operation or serious injury can result.

The pull-only limit stop is used to limit valve closing. To

set the limit stop:

1. Loosen the limit stop jam nuts (see Figure 7).

2. Apply air under the piston until the limit position is

reached.

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611 5-11

Page 12

3. Readjust the jam nuts until they are seated next to

the limit stop flange. Tighten jam nuts securely

against each other.

Maintenance

For proper maintenance, maintain a coat of multipurpose lubricant on the limit stop bolt threads at all

times. To do this:

1. Apply air under the piston until the actuator is fully

retracted, exposing the bolt threads.

2. Remove the limit stop jam nuts.

3. Clean and lubricate the threads.

4. Return limit stop jam nuts to the desired position.

5. Securely tighten the jam nuts against each other.

Jam Nut

(Item No. 350)

Bolt Gasket

(Item No. 379)

Flange

Gasket

(Item No. 378)

WARNING:

MOVING PARTS!

KEEP HANDS CLEAR

Flange Bolts

(Item No. 333)

Limit Stop

Flange

(Item No. 389)

Limit Stop Bolt

(Item No. 380)

Limit Stop

Flange O-ring

(Item No. 276)

Disassembly

Refer to figure 7:

WARNING: Repressurize the line and actuator to

atmospheric pressure before disassembling the

limit stop or removing the actuator from the valve,

or serious personal injury could result.

1. The limit stop may be disassembled while mounted

on the valve, or the actuator can be removed and

disassembled separately (see the valve’s maintenance bulletin for instructions).

2. Vent air on both sides of the piston.

3. Loosen and remove the limit stop jam nuts.

WARNING: Cylinder is spring loaded. Do not

attempt to remove the flange bolts without following Steps 4 and 5 exactly or serious injury

could occur.

4. Remove all but two opposing flange bolts and bolt

gaskets.

5. Remove the two remaining bolts slowly and simultaneously, relieving the remaining spring compression. The bolts are of sufficient length to relieve all

spring compression prior to releasing the flange.

6. Lift the limit stop flange off the cylinder, taking care

not to damage the limit stop bolt threads and

bushing. Remove flange gasket from top of cylinder.

7. Remove the limit stop flange O-ring.

8. The actuator may now be disassembled according

to Maintenance Bulletin 2.

9. Unless the limit stop bolt is to be replaced, do not

remove the pin from the actuator stem, since realigning the pin hole in both pieces is difficult.

However, if it is necessary to replace the piston

stem O-ring, drive the stem pin out and screw the

limit stop bolt off the actuator stem.

Reassembly

Refer to Figure 7:

1. Make sure all internal parts are thoroughly cleaned

and lubricated before beginning reassembly. Use

Bushing

(Item No. 390)

O

C

Cylinder

(Item No. 202)

Pin

(Item No. 372)

Piston Stem

O-ring

(Item NO. 272)

Figure 7: Pull-only Limit Stop

NOTE: Item numbers shown above correspond directly to the valve’s

bill of material. Refer to the bill of material

only new O-rings and gaskets (O-rings should be

lubricated with a silicone lubricant such as Dow

Corning 55 M).

2. Reassemble the actuator according to Maintenance

Bulletin 2. If the limit stop bolt is being replaced,

replace the piston stem O-ring and screw the limit

stop bolt and the actuator stem together. Realign

the pin hole and drive the stem pin firmly in place.

Reassemble the cylinder and retaining ring according to Maintenance Bulletin 2.

3. Replace the limit stop flange O-ring. Install the

flange and a new flange gasket on the cylinder.

4. Using new bolt gaskets, install two opposing boltsand tighten evenly to compress the spring.

5. Reassemble the four remaining bolts and bolt gaskets. Tighten sufficiently to form a proper seal with

the flange gasket and bolt gasket.

6. Apply air under the piston until the desired limit

position is reached.

7. Reinstall the limit stop jam nuts until they are seated

against the limit stop flange. Tighten both jam nuts

firmly against each other.

or specific part numbers.

5-12 Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Loading...

Loading...