Page 1

Gestra FPS 14

INSTALLATION

&

MAINTENANCE MANUAL

Page 2

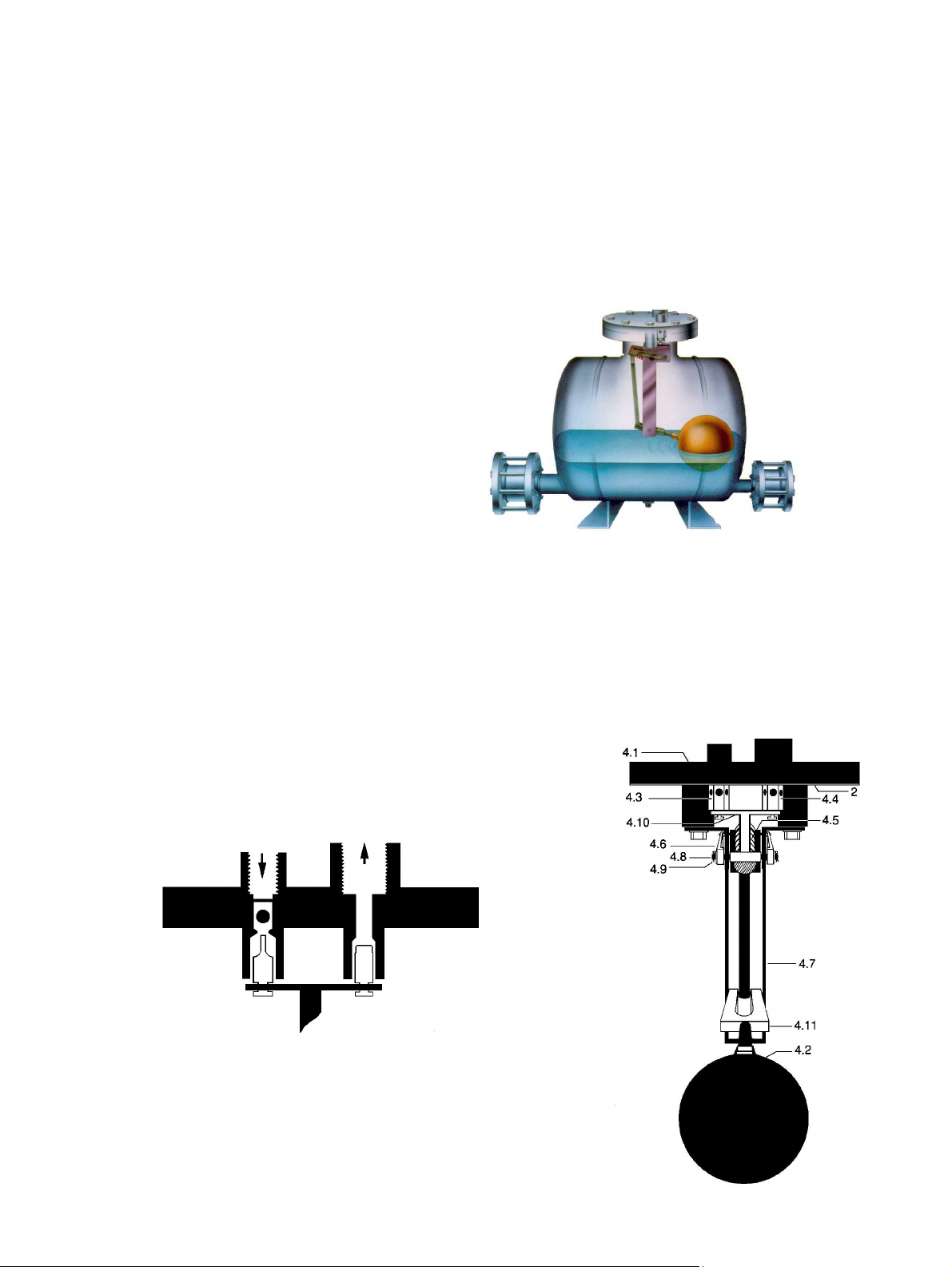

Operation

Maximum operating pressure: 150 psig

1. At the beginning of the cycle, the float ball

(4.2) is at its lowest position. The vent

valve (4.4) is open and the pressure valve

(4.3) is closed.

2. The liquid to be pumped enters the pump

tank by gravity through the inlet check

valve. As the pump fills, the float ball (4.2)

rises. The outlet check valve prevents back

flow of liquid into the pump tank from the

downstream side.

3. At the high trip point the mechanism

snaps over center. The compressed coil

spring (4.5) simultaneously closes the vent

valve (4.4) and opens the pressure valve (4.3). The motive gas flows through the pressure valve

(4.3) and pushes the liquid out of the pump tank though the outlet check valve. The inlet check

valve prevents liquid from flowing back into the upstream piping.

4. As the liquid falls, the float ball (4.2) drops. At the low trip point, the mechanism snaps over

center and the compressed coil spring (4.5) simultaneously opens the vent valve (4.4) and

closes the pressure valve (4.3). The pump tank depressurizes as the motive gas is relieved

through the vent valve.

5. After the pressure in the pump tank is relieved through the

vent valve (4.4), flow resumes through the inlet check valve

and a new cycle begins.

Page 3

Installation

Consult the Installation Drawings for the proper piping configuration for your application.

Please call GESTRA if you are not sure of the

proper configuration.

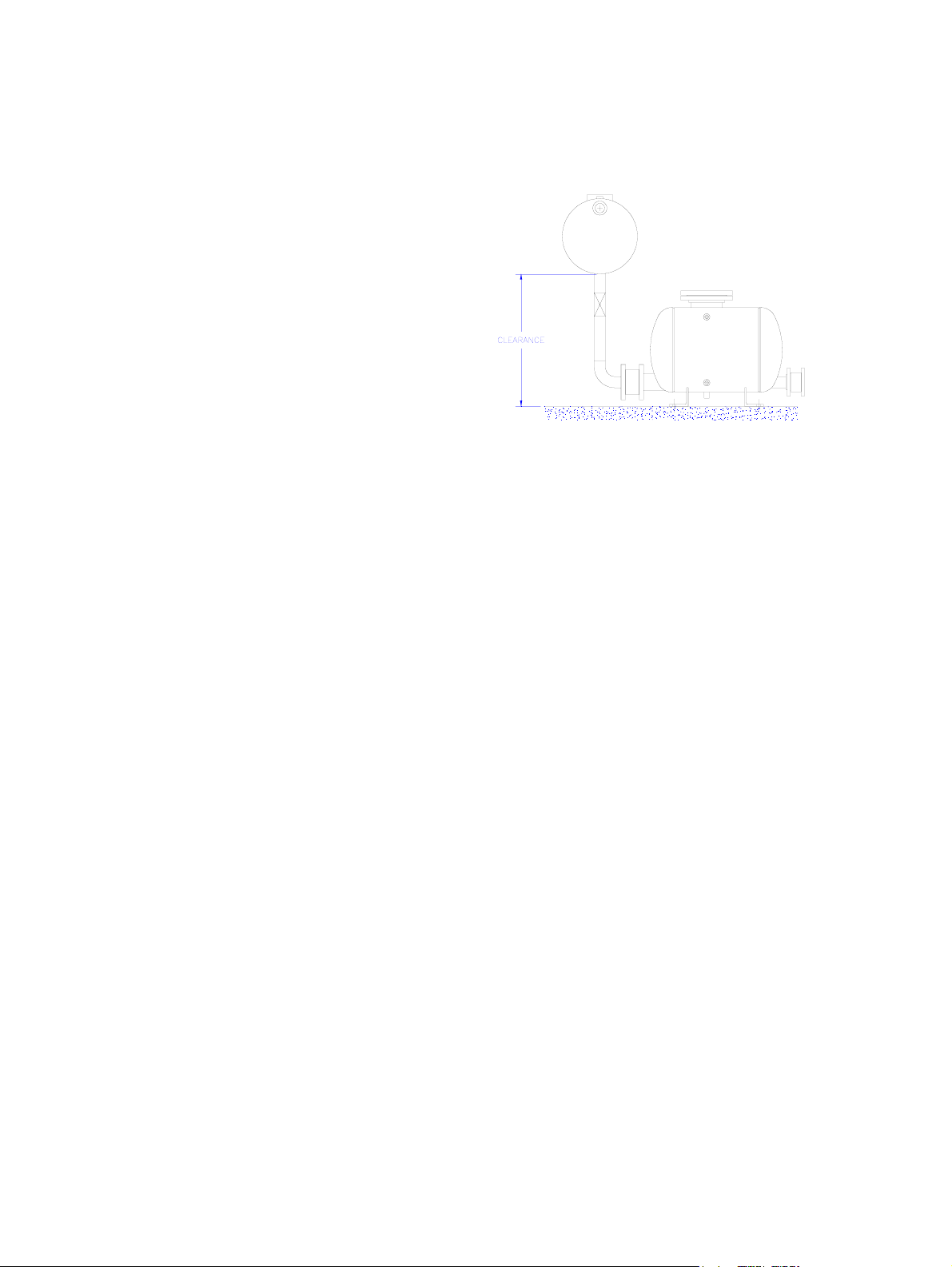

1. CLEARANCE: Install the pump below the

equipment to be drained. Proper clearance is

required for the pump to fill. The clearance is

the distance between the base of the pump

and the bottom of the equipment to be

drained. The FPS 14 and FPS 23 require a

minimum clearance of 36”.

2. CHECK VALVES: Install the check valves on

the pump tank, with gaskets, making sure the

check valves are installed in the same

direction. The flow direction has been stamped on each check valve and should match the flow

arrow on the front of the tank.

a. Install lower flange bolts and secure with nuts and lock washers.

b. Place the check valve between the flanges from above onto the bottom bolts. Verify the

flow arrows are pointing in the correct direction.

c. Install and center the gaskets on both sides of the check valves.

d. Install the remaining flange bolts, nuts, and lock washers. Tighten evenly in a star pattern.

NOTE: The correct bolts for the different check valves are as follows:

1” RK16A (S.S.) 1/2”-13x3-1/2” (FPS-366)

1” RK44 (Bronze) 1/2”-13x3” (FPS-193)

2” RK16A (S.S.) 5/8”-11x4-1/2” (FPS-313)

2” RK44 (Bronze) 5/8”-11x6” (FPS-034)

3” RK16A (S.S.) 5/8”-11x6” (FPS-034)

3” RK44 (Bronze) 5/8”-11x5” (FPS-071)

e. Connect piping from discharge check valve flange to the condensate return line or other

discharge point

Full Port Isolation Valves are recommended on the pump inlet and outlet to allow the pump to

be isolated for service.

Pressure Gauges are recommended upstream and downstream of the pump for accurate

measurement of actual operating conditions.

NOTE: All isolation valves must be full port in order to achieve rated pump capacity.

3. MOTIVE GAS SUPPLY: Connect the motive gas supply (steam, air, or gas) to the ½” NPT

connection “P” on the top of the cover flange. The motive gas supply line should have a

strainer and a steam trap (GESTRA MK series for steam service) or liquid drainer trap (GESTRA

UNA series for air or gas service) installed before the pump. See installation drawings for the

proper piping of the components for the motive supply.

A Pressure Gauge should be installed on the motive gas supply to verify that there is sufficient

motive gas pressure at the pump. If steam is being used, a siphon loop (pigtail) should be

installed before the pressure gauge.

Page 4

A Full Port Isolation Valve should be installed on the motive gas supply line to allow the pump

to be isolated for service.

A Union or Flange should be installed between the isolation valve and the pump mechanism to

allow for easy removal of the mechanism for service. This should be installed 14” or more

above the cover flange, or in a horizontal plane outside of the O.D. of the cover flange, for easy

removal.

NOTE: Motive gas pressure should be reduced to the minimum required to both overcome

back pressure and high enough to provide necessary pump capacity.

NOTE: If the motive gas pressure exceeds 200 psig, a pressure-reducing valve (PRV) must be

installed on the motive gas supply line to reduce the pressure to the pump. The PRV should be

installed as far upstream as possible for optimum performance.

A Safety Relief Valve set at or below 200 psig, and a pressure gauge should be installed on the

motive gas supply line to protect the pump should the PRV fail. These items should be installed

downstream of the PRV, and upstream of the pump.

4. RESERVOIR / VENTED RECEIVER TANK: A reservoir or vented receiver tank is always required

ahead of the pump. This is to prevent equipment flooding while the pump is in the discharge

cycle. The actual requirement depends on the application and the type of installation. Please

consult GESTRA if a reservoir or vented receiver is not existing, or has not been specified.

5. VENT LINE: Connect the vent line to the 1” NPT vent connection “V”. This vent line should be

pipe to atmosphere, or back to the equipment to be drained. Application details will determine

how the vent must be piped.

A Tee and Ball Valve should be installed in the vent line for troubleshooting purposes (See

Installation Drawings). This is very important because it will allow troubleshooting of the vent

and pressure valves without removing the mechanism from the tank.

A full port isolation valve should be installed on the vent line to allow the pump to be isolated

for service.

A Union or Flange should be installed between the isolation valve and the pump mechanism to

allow for easy removal of the mechanism for service. This should be installed 14” or more

above the cover flange, or in a horizontal plane outside of the O.D. of the cover flange, for easy

removal.

If the vent line piping needs to be run more than 10 feet, the pipe size should be increased to

greater than 1” in order to prevent restrictions which could reduce the capacity of the pump.

If the vent line is run horizontally, the piping should be pitched so as to be self-draining to

prevent vapor lock.

NOTE: If condensate pressure from the equipment to be drained can exceed pump outlet

pressure under normal operating conditions, a steam trap must be installed after each pump.

This steam trap will prevent steam from blowing though the pump and entering the condensate

return line. Consult GESTRA for the proper steam trap sizing and selection.

Page 5

Maintenance

Turn off the motive gas pressure (steam, air, or gas). Close all isolation valves, and relieve the

pressure in the pump by opening the ½” NPT drain plug on the bottom of the tank, or one of the

two (2) ¼” NPT pipe plugs on the top of the cover flange. Remove the bolts from the mechanism

cover and lift the mechanism from the tank. A clearance of fourteen (14) inches is required to

remove the mechanism from the tank.

1. Be sure the mechanism is completely free of dirt and scale, and moves freely.

Remove any obstructions. Make sure the mechanism snaps at the top and the bottom of the

stroke. Check the integrity of the pivot and cotter pins.

2. Check the float ball for damage, pinholes, or water logging.

If the float ball is full of water, is cracked, or will not float it must be replaced.

If the float ball floats properly, it can be reinstalled on the mechanism.

3. With the float ball in the raised position (closest to the cover flange), check for an air gap

under the striking pin. There should be 1/16” or more clearance below the striking pin. If there

is no air gap under the pin, this is an indication that the valves may be worn.

4. Check the spring.

If the spring is broken or defective, it must be replaced.

To replace the spring, remove the float ball. Remove pivot pins #1 and #2 in that order. This

will free the spring for removal and replacement. After the new spring is in place, reinstall pivot

pin #2, using the float arm for leverage to compress the spring. After pivot pin #2 is in place,

reinstall pivot pin #1 and the float ball.

After the spring has been replaced it is important to recheck the air gap, as explained in step

#3 of the MAINTENANCE section. A proper air gap indicates that all of the components have

been reinstalled correctly.

PIN #2

AIR GAP

PIN #1

BOLT

Page 6

5. Check the vent and pressure valves for damage or blockage.

To check these valves the mechanism must be removed from the cover flange by unscrewing

the two (2) bolts from the sides of the support structure. Lift the entire mechanism until it

becomes free from the flange. Remove the valves and inspect them for damage.

If the valves are in good condition, clean and reinstall them on the cover flange.

If a blockage exists and can be removed without damaging the valves, clean the valves and

reinstall them on the cover flange. If the blockage was found in the pressure valve, inspect and

clean the strainer on the pressure supply line. If there is no strainer installed, install one

upstream of the pressure supply connection.

If any of the valve components are damaged the entire valve assembly must be replaced.

NOTE: when replacing the vent and pressure valves it is important that the valves are properly

matched. The vent has a flat head and the supply valve has a tapered head with a check ball

inside of the body.

Start-Up

1. Slowly open the motive gas (stem, air, or gas) supply valve to the pump. Make sure that there is

adequate pressure to the pump, and that the steam trap (steam) or liquid drainer (air or

pressurized gas) is working properly.

2. Open any isolation valves on the vent, condensate outlet and inlet, in that order. This should

allow liquid to begin flowing into the pump. The pump will discharge when the tank is nearly

full.

NOTE: For low liquid flow rates, the pump may take several minutes before it cycles.

3. If the pump does not seem to be operating properly, recheck the installation and restart the

start-up procedure. If the pump is still not working correctly, follow the Troubleshooting

procedures in this manual.

Page 7

Troubleshooting

PROBLEM – Pump will not fill or is slow to fill

1. Are all of the isolation valves open?

Check the isolation valves on the pump inlet and vent. If these are closed, open the valves and

check for proper pump operation. Check all strainer screens for obstruction. Clean the strainers

if necessary and check for proper pump operation.

2. Is there sufficient clearance?

The clearance is the distance between the base of the pump

and the bottom of the equipment to be drained. The FPS 14

and FPS 23 require a minimum clearance of 36” to fill properly.

Verify the clearance, lower the pump or raise the equipment if

there is insufficient clearance. Consult GESTRA if this is not

possible.

3. Are the check valves installed in the proper direction?

Make sure the flow arrows on both of the check valves are in the same direction and match the

flow arrow on the pump tank. If the check valves are installed incorrectly, reinstall properly and

check for proper pump operation.

4. Are the check valves working properly?

There are two possible problems:

a.) The inlet check valve is stuck closed.

b.) The outlet check valve is stuck open.

i.) If the inlet check valve is stuck closed, condensate will not be able to fill the tank.

To check the inlet check valve it must be removed from the line.

ii.) If the outlet check valve is stuck open, the condensate from the down stream side

will re-enter the pump tank. To verify this, close the outlet isolation valve. If the

pump begins to fill properly the outlet check valve could be stuck partially or

completely open.

If there appears to be a check valve problem, remove them from the pump. Check for any

debris or foreign matter blocking the check valve. Make sure that the check valve disc is not

canted or cocked. Push the disc with your finger, it should move freely and return to the closed

position. You will feel some resistance from the check valve spring when pushing the disc.

If the check valve(s) are good reinstall them and check for proper pump operation.

If the check valve(s) are damaged they must be replaced or repaired.

5. Is the pump cycling?

Listen to the pump. During the proper operation of the pump, each complete cycle should be

noted by two (2) audible sounds. If a Gauge Glass is installed, check to see if the liquid level is

rising and falling. A Cycle Counter or Pressure Gauge will also indicate whether or not the

pump is cycling.

NOTE: If the condensate load is very low when the pump is being check, it would not be

unusual to have to wait for several minutes to verify proper pump operation.

If it is determined that the pump is not cycling, the mechanism must be removed from the tank

and inspected. See MAINTENANCE Instructions.

Page 8

6. Check the operation of the Vent and Pressure valves.

CAUTION: At the end of each pumping cycle, when the vent valve first opens, there will be a

puff of motive gas (Steam, air, or gas) as the tank is depressurizing. This is normal and should

not be mistaken for a leaking pressure valve. Be careful when troubleshooting, and only put

your hand near the vent after the initial puff disappears.

a.) Close the isolation valve on the vent line. If a ball valve has been installed on a tee in the

vent line, open the valve. If not, detach the vent line so that it is open to atmosphere.

b.) When the pump is in the filling cycle, the vent valve should be open and there should be a

flow of gas from the vent. This is the pump contents being evacuated as the liquid fills the

pump tank. If there is no flow of gas from the vent then the vent valve either has not

opened or has a blockage. The mechanism will have to be removed from the tank and

inspected to resolve this problem. See MAINTENANCE Instructions.

c.) If the full motive gas pressure is found at the vent, this indicated either that the pressure

valve is not closed, or that there is a leak in the pressure valve. If this is the case, close and

re-open the isolation valve on the pressure supply line. This may dislodge any debris. If

there is still full motive gas pressure at the vent or the pump still will not fill properly, the

mechanism must be removed from the tank and inspected. See MAINTENANCE

Instructions.

d.) Closed System: If the pump begins to fill when the vent valve is open to atmosphere and

stops when the vent line is reconnected to the return tank, then the pump is vapor locked.

A thermostatic air vent must be installed on the vent line at the highest point, and the vent

line must be self-draining.

PROBLEM – Pump will not properly discharge the condensate after filling

1. Are all of the isolation valves open?

Check the isolation valves on the pump outlet and motive supply line. If these are closed, open

the valves and check for proper pump operation. Check all strainer screens for obstruction.

Clean the strainers if necessary and check for proper pump operation.

2. Is there motive gas pressure (steam, air, or gas) to the pump?

Verify that all pressure supply valves are open, and that there is pressure at the motive gas

supply inlet.

If there is no motive gas pressure, check the motive gas supply system and pressure valve for

clogging.

3. Is the motive gas pressure (steam, air, or gas) high enough for proper operation?

The motive gas pressure must be high enough to overcome the backpressure after the pump

and high enough to provide the required pumping capacity. If there is not a pressure gauge

installed on the outlet of the pump, the backpressure can be measured during the pumping

cycle by installing a pressure gauge in the ¼” NPT connection on the top of the cover flange.

The pressure in the tank during the pumping cycle is approximately 2 – 3 psig higher than the

backpressure. If the pump tank pressure equals the motive gas pressure, the motive gas

pressure is not high enough to overcome the backpressure on the pump.

If the motive gas pressure is not high enough to overcome the backpressure then increase the

motive gas pressure.

Page 9

4. Are the check valves installed in the proper direction?

Make sure the flow arrows on both of the check valves are in the same direction and match the

flow arrow on the pump tank. If the check valves are installed incorrectly, reinstall properly and

check for proper pump operation.

5. Are the check valves working properly?

There are two possible problems:

c.) The inlet check valve is stuck closed.

d.) The outlet check valve is stuck open.

iii.) If the inlet check valve is stuck closed, condensate will not be able to fill the tank.

To check the inlet check valve it must be removed from the line.

iv.) If the outlet check valve is stuck open, the condensate from the down stream side

will re-enter the pump tank. To verify this, close the outlet isolation valve. If the

pump begins to fill properly the outlet check valve could be stuck partially or

completely open.

If there appears to be a check valve problem, remove them from the pump. Check for any

debris or foreign matter blocking the check valve. Make sure that the check valve disc is not

canted or cocked. Push the disc with your finger, it should move freely and return to the closed

position. You will feel some resistance from the check valve spring when pushing the disc.

If the check valve(s) are good reinstall them and check for proper pump operation.

If the check valve(s) are damaged they must be replaced or repaired.

6. Is there water in the vent line?

A small amount of water is caused by the condensation of the venting motive gas and is not an

indication of a problem.

If a large amount of water is present in the vent line, there are two (2) possible problems:

a.) The mechanism has “hung up”.

b.) The float ball has collapsed.

Either problem would keep the mechanism from snapping at the top trip point, preventing the

pump from discharging condensate. If this is the case the mechanism will have to be removed

from the pump tank and inspected. See Maintenance Instructions.

7. Is the pump cycling?

Listen to the pump. During the proper operation of the pump, each complete cycle should be

noted by two (2) audible sounds. If a Gauge Glass is installed, check to see if the liquid level is

rising and falling. A Cycle Counter or Pressure Gauge will also indicate whether or not the

pump is cycling.

NOTE: If the condensate load is very low when the pump is being check, it would not be

unusual to have to wait for several minutes to verify proper pump operation.

If it is determined that the pump is not cycling, the mechanism must be removed from the tank

and inspected. See MAINTENANCE Instructions.

8. Check the operation of the vent and Pressure valves.

CAUTION: At the end of each pumping cycle, when the vent valve first opens, there will be a

puff of motive gas (Steam, air, or gas) as the tank is depressurizing. This is normal and should

not be mistaken for a leaking pressure valve. Be careful when troubleshooting, and only put

your hand near the vent after the initial puff disappears.

Page 10

a.) Close the isolation valve on the vent line. If a ball valve has been installed on a tee in the

vent line, open the valve. If not, detach the vent line so that it is open to atmosphere.

b.) When the pump is in the filling cycle, the vent valve should be open and there should be a

flow of gas from the vent. This is the pump contents being evacuated as the liquid fills the

pump tank. If there is no flow of gas from the vent then the vent valve either has not

opened or has a blockage. The mechanism will have to be removed from the tank and

inspected to resolve this problem. See MAINTENANCE Instructions.

c.) If the full motive gas pressure is found at the vent, this indicated either that the pressure

valve is not closed, or that there is a leak in the pressure valve. If this is the case, close and

re-open the isolation valve on the pressure supply line. This may dislodge any debris. If

there is still full motive gas pressure at the vent or the pump still will not fill properly, the

mechanism must be removed from the tank and inspected. See MAINTENANCE

Instructions.

d.) Closed System: If the pump begins to fill when the vent valve is open to atmosphere and

stops when the vent line is reconnected to the return tank, then the pump is vapor locked.

A thermostatic air vent must be installed on the vent line at the highest point, and the vent

line must be self-draining.

PROBLEM – Chattering or Banging in condensate return line after pump has discharged

1. Are the multiple rises and drops after the pump discharge?

If so, install a vacuum breaker on the highest point in the return line. For a closed system install

an air vent downstream of the vacuum breaker.

2. Does the condensate inlet pressure to the pump exceed the condensate return line pressure?

If so, this indicates the probability that live steam is blowing through the pump.

Page 11

Installation of Optional Accessories

Cycle Counter

The cycle counter is installed by screwing the pneumatic cylinder into one of the ¼” NPT

connections on top of the cover flange. The force of the pressurizing gas lifts the counter

arm for each cycle.

Freeze Protection Drain Valve

If the pump is to be installed outside, or anywhere that freezing is a threat, a Freeze

Protection Drain Valve should be installed on the ½” NPT drain connection on the bottom

of the tank. A pipe should be installed after the drain valve so that the discharge is visible.

See the instructions provided with the valve for more detailed installation directions.

Gauge Glass Assembly

2 Valves, 2 Rods, 1 Glass, 2 ¾” NPT Short Nipples, and 2 ¾” NPT Unions

This assembly is installed on the two (2) ¾” NPT connections on the front of the tank. The

valve with the drain connection must be installed in the bottom connection. The ¾” short

nipples and unions are threaded into the top and bottom tank connections. The valve is

threaded into the mating part of the ¾” union. It is very important that the top and bottom

valves line up before the glass is installed, or else the glass will break. The glass is installed

into the bottom valve, and the top valve is fitted over the top of the glass, and the union is

tightened. Tighten the two (2) fittings that hold the glass and install the guard rods.

Insulation Blanket

Wrap the main blanket piece around the pump tank so that the opening is on the same

side as the two (2) ¾” NPT couplings on the front of the tank. Fasten the front seam and

the two (2) end pieces, (if required) using the supplied stainless steel wire.

Pressure Gauge

Install the pressure gauge, with the syphon loop (pigtail), in one of the ¼” NPT connections

on the top of the cover flange.

Pressure Reducing Valve

The PRV must be installed upstream of the pump mechanism on the motive gas supply line.

The pressure must be regulated below 200 psig, unless a special tank has been ordered. See

the instructions provided with the valve for more detailed installation instructions.

Safety Relief Valve

A safety relief valve set at or below 200 psig, and a pressure gauge should also be installed

between the PRV and the pressure valve connection on to of the cover flange. This will

protect the pump in case the PRV fails. See the instructions provided with the valve for

more detailed installation instructions.

®

GESTRA GmbH

Postfach 10 54 60

D-28054 Bremen

Hemmstraße 130

D-28215 Bremen

Tel. +49 (0) 421 35 03 - 0

Fax +49 (0) 421 35 03- 393

E-mail

gestra.gmbh@gestra.de

Internet www.gestra.de

An Invensys company

A Unit of Flowserve Corporation

Loading...

Loading...