Page 1

Series F39 Pneumatic Actuator - WCENIM2036-00 05/15

®

USER INSTRUCTIONS

Worcester Controls/McCANNA Series F39 Pneumatic Actuator

FCD WCENIM2036-00 05/15

Installation

Operation

Maintenance

1

Page 2

Series F39 Pneumatic Actuator - WCENIM2036-00 05/15

STOP!

STOP!

®

Contents

Page

1 Safety 2

2 Description 2

3 Installation 3

4 Air supply and electrical installation 5

5 Air Consumption 5

6 Electrical Supply (models with integral solenoid only) 6

7 Installation of accessories 6

8 Operation 6

8.1 Basic Actuator – (N Model) 6

8.2 Actuator With Factory-Supplied Solenoid 6

8.3 Standard Stroke Times 7

8.4 Manual Operation 7

9 Maintenance 8

10 Spare Parts 8

11 Troubleshooting 8

12 Rebuilding instructions 9

12.1 Actuator disassembly 9

12.2 Actuator reassembly 11

13 Spring-return actuator 13

14 Size 05 Exploded view/parts/materials 14

15 Size 10-50 Exploded view/parts/materials 15

1

SAFETY

The safety terms DANGER, WARNING, CAUTION and

NOTE are used in these instructions to highlight particular dangers and/or to provide additional information on

aspects that may not be readily apparent.

DANGER: indicates that death, severe personal injury and / or

substantial property damage will occur if proper precautions

are not taken.

WARNING: indicates that death, severe personal injury

and / or substantial property damage can occur if proper

precautions are not taken.

CAUTION: indicates that minor personal injury and / or

property damage can occur if proper precautions are not

taken.

NOTE: indicates and provides additional technical infor-

mation, which may not be very obvious even to qualified

personnel. Compliance with other, not particularly emphasised notes, with regard to transport, assembly, operation

and maintenance and with regard to technical documentation

(e.g. in the operating instruction, product documentation or

on the product itself) is essential, in order to avoid mistakes,

which, in themselves, might directly or indirectly cause

severe personal injury or property damage.

2

2 DESCRIPTION

Worcester Controls/McCANNA Series F39 actuators

are pneumatic quarter-turn valve actuators. The design

utilizes a double-rack, single pinion concept, with each

rack integrally cast to a piston. On sizes 10-50, both

pistons are supported and centered by large, stainless

steel guide rods that are also used to control the rotation

of actuator via externally mounted stroke adjustment

screws. In double-acting units, both pistons are pressurized on both strokes of the actuator.

Standard units feature an extended top shaft for manual

override capabilities and a completely modular design

which allows simple attachment of a variety of accessories. All units allow the direct mounting a solenoid control

block which properly directs supply air to the actuator.

On double-acting actuators, the solenoid control block

provides independently adjustable speed control for both

opening and closing strokes of the actuator. On spring-return actuators only the spring stroke is adjustable.

WARNING:

devices subject to normal wear and tear. Actuator life is

dependent upon application and environmental conditions. If applied in hazardous services such as, but not

limited to, media temperature extremes, toxins, flamma-

series F39 actuators are electro-mechanical

Page 3

Series F39 Pneumatic Actuator - WCENIM2036-00 05/15

®

bles, or other services where improper or incomplete

operation could produce a safety hazard, it is incumbent

upon the system designer and the user to provide proper

warning devices such as temperature sensors, oxygen

sensors and flow sensors. Flowserve also recommends

that the optional auxiliary limit switches be used for

monitoring and/or electrical interlock.

CAUTION: When actuator is installed in outdoor

conditions, water can enter the exhaust holes of the

double-acting solenoid block, and then freeze. Flowserve

suggests a cover be used, or mount the actuator such

that the solenoid block is upside down.

Do not install F39S (spring-return) models with air

connection in end cap or with integral solenoid vertical,

without proper precautions to eliminate the ingress of

water spray or rainfall. Exposed end cap or solenoid vent

port will allow water to accumulate in spring chambers.

Flowserve recommends that all products which must

be stored prior to installation be stored indoors, in an

environment suitable for human occupancy. Do not store

product in areas where exposure to relative humidity

above 85%, acid or alkali fumes, radiation above normal

background, ultraviolet light, or temperatures above 120

°F or below 40 °F may occur. Do not store within 50 feet

of any source of ozone.

3.3 Attach mounting bracket to actuator using four (4) cap

screws and lock washers provided in mounting kit. To

avoid any damage to the Series F39 actuator body, ONLY

the proper length screws supplied with the mounting kit

should be used. For small size top mount style valves,

attach bracket such that bracket nameplate will be to side

of valve.

3.4 For mounting to 818/828 Series valves, insert ISO locating

ring into groove on bottom of actuator before attaching

to bracket. Ring can be permanently held in groove by

applying Loctite® 638 to ring before inserting in groove.

NOTE:

Size 05F39, if furnished with factory solenoid, shall

be “cross-line” mounted (i.e. at 90 degrees to the pipe

run) to ensure adequate clearance for air connections.

3.5 Prepare valve for actuation:

CAUTION: Ball valves can trap pressurized media in the

cavity. If it is necessary to remove any valve body bolts,

stem nuts, or remove valve from the line, and if the valve

is or has been in operation, make sure there is NO pressure to or in the valve and operate valve one full cycle.

3.5.1 Valve models 45 (2½”–6”), 59 (2”–4”), 51/52 (½”–10”),

151/301 (3”–6”), 82/83 (½”–10”), 818/828 (2”–8”), 94

(½”–6”), 44 (¼”–2”), 59 (¼”–1½”), WK70/WK74 and

H71 (½”–2”):

NOTE:

included in all F39 actuator accessory and Repair

kits is a rebuild/accessory addition label, which is to be

marked with a permanent marker and then applied to the

actuator after an accessory kit has been installed or an

actuator has been repaired.

3 INSTALLATION

NOTE:

Sizes 10-35 Rev. R7 actuators may come with an ISO

Size 40-50 Rev. R7 actuators have an integral ISO loca-

3.1 Determine mode of operation desired (normally open or

3.2 Determine desired quadrant for bracket attachment and

The Series F39 actuator is normally installed with

its major axis parallel to the pipe line (this is mandatory

when mounting actuator to 90° V1 Diverter/Three-Way

(D44 and T44) valves and CPT valves. The actuator can

be oriented above, beside or beneath the valve without

affecting its operation.

locating ring, used for optional ISO mounting.

tion ring.

normally closed) of the valve.

direction of mounting of actuator (in-line or cross-line).

NOTE:

For above listed valves, it is not necessary to

remove any valve body bolts or remove valve from line in

order to mount actuator.

3.5.2 Rotate valve ball and stem to position necessary to

achieve desired operation. If any valve information is

marked on stop plate or handle, it will be necessary to

transfer this information to the bracket nameplate.

3.5.3 For ¼”–2” 44, ½”–2” WK70/WK74, ¼”–1½” 59, and

½”–1½” H71 series top-mount style valves, and ½”–2”

51/52, ½”–1½” 82/83 series valves with high-cycle stem

packing as standard, remove handle nut, lockwasher,

handle, separate stop plate (if any), retaining nut and

stop pin(s). Add the two additional Belleville washers with

their larger diameter sides touching each other. Add the

self-locking nut to the stem and tighten while holding the

stem flats with wrench. Tighten until Belleville washers

are flat — the nut will “bottom” — and then back nut off

1/3 of a turn. The two additional Belleville washers and

the self-locking nut are included in the mounting kit.

CAUTION: Due to the design of the self-locking stem

nut, resistance will be felt as it threads onto the stem

assembly. Ensure the Belleville washers are fully flattened

before backing off.

3

Page 4

Series F39 Pneumatic Actuator - WCENIM2036-00 05/15

®

3.5.4 For 2” 59, H71, 82/83, and 2½” 45, 82/83 valves, and

valves 3” and larger with square stem, remove handle

assembly, retaining nut, stop and stop screws. Replace

with valve stem spacer or, if valve has graphite stem

packing, with two Belleville washers (except 8”,10” 82/83

and 10” 51/52), and replace retaining nut.

NOTE:

Belleville washers are installed with their larger

diameter sides touching each other. Do not use stem

spacer when Belleville washers are used. Using a wrench

to prevent stem from turning, tighten retaining nut until

stem packing is fully compressed or Bellevilles, if used,

are fully flattened, then back off nut 1/6 turn. Excessive

tightening causes higher torque and shorter seal life.

NOTE:

Large valves with V51 high-cycle stem packing

option installed, identified by two Belleville washers

installed and handle assembly, stop and stop screws

removed, and 818/828 series valves, do not require stem

area disassembly.

3.5.5 For 2”–8” 818/828 valves, remove handle assembly,

locking plates and hardware, and stop screw (if any). Do

not remove stop plate (2”–6” sizes) or spacer (8” size).

3.5.6 For ½”–2” 94 valves, remove handle (if any). Do not

remove gland plate or gland bolts.

3.5.7 For 3”–6” 94 and 2”–8” E818/828 valves, remove handle

assembly, stop, and spacer (if any). Do not remove gland

plate or gland bolts.

• Fail Open or Fail Close - The normal method of mounting

is to have the actuator in line with the pipe line and the

valve and actuator in the “FAIL-CLOSED” (Clockwise to

close) position. “FAIL-OPEN” can be achieved using

the method above but the actuator will then work

as Clockwise to open).

• For “FAIL-OPEN” but with Clockwise to close opera tion, the pistons in the actuator will need to be removed

and reassembled from the opposite ends of the

actuator (keeping the guide rods the same sides

relative to the body). This will result in a slight offset

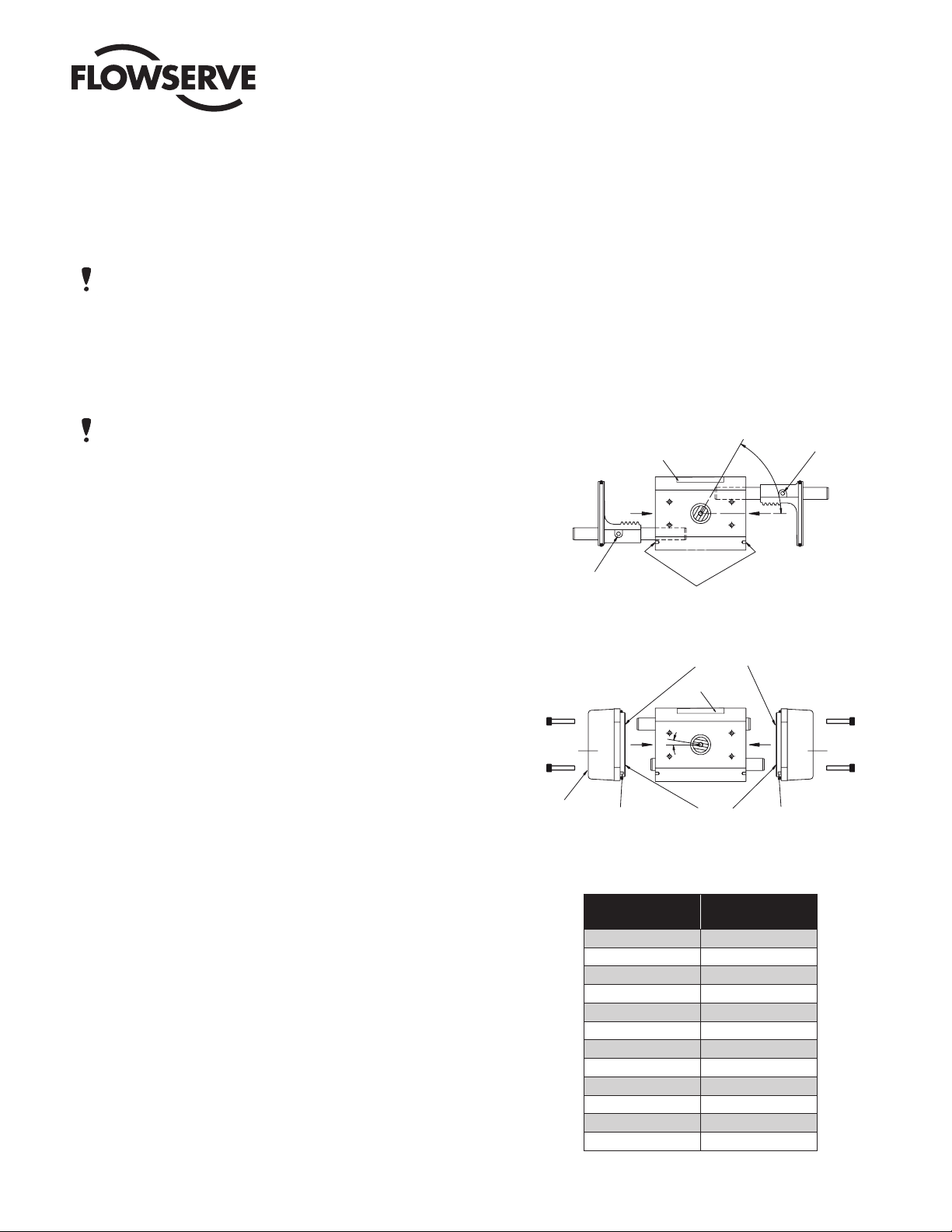

of pinion position on some sizes. See below:

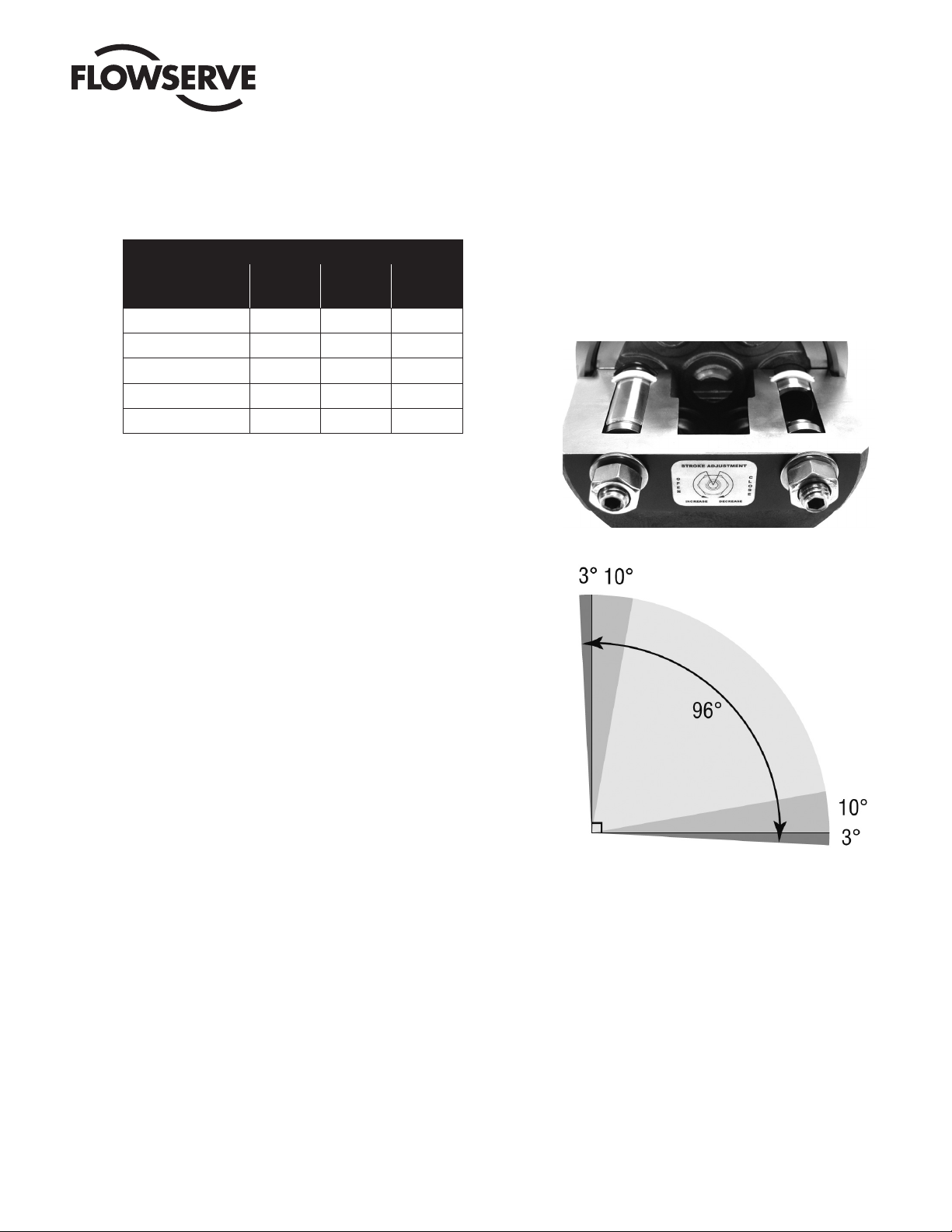

Position of pinion

Inlet support rod

(with cross hole)

Label

Label

flats and groove

(60º approx.)

Foolproof pin

location holes

Bores containing

bearings only

Label

Blank support rod

(without cross hole)

3.6 Attach bracket/actuator assembly to valve as follows:

3.6.1 Center coupling on valve stem.

3.6.2 Lower mounting bracket/actuator assembly over coupling

and onto valve, making sure that female star drive actuator shaft engages in the correct orientation with the

coupling.

3.6.3 Secure bracket to valve using cap screws and lockwashers, or bolts and nuts provided in mounting kit.

Tighten securely. For small size top-mount style valves,

bracket nameplate will be to side of valve.

3.6.4 Install set screws (if any) in coupling and tighten securely.

3.6.5 Determine if mode of operation (air to open or close/fail

open or closed) is as desired; if not:

• Air to Open or Close - On all sizes of F39 double-acting

and spring-return actuators, the female drive shaft

is a star drive. This allows selection of either mode of

operation by indexing the coupling (including valve ball

and stem) 90° to the actuator shaft, while keeping the

actuator in an in-line orientation.

Actuator

Size

#

Bores containing

bearings and

0-rings

Foolproof pin

Pinion Offset

Angle #

Inlet

End Cap End Cap

Inlet port

Foolproof pin

Limit Stop

05 0°

10 10°

15 2°

20 2°

25 2°

30 2°

33 2°

35 2°

40 0°

42 0°

45 0°

50 12°

4

Page 5

Series F39 Pneumatic Actuator - WCENIM2036-00 05/15

STOP!

®

3.6.6 Determine position indication. Buttons on position indicator are set up to show valve closed on in-line mounting,

i.e., pistons together on actuator. If different indication is

required:

• Check which visual indication is required.

• Check that indicator, when located on actuator shaft,

will show correct indication.

• To change indication, on size 10 to 20 push out

(remove) red and white buttons and reassemble in

opposite positions. For sizes 25 and above remove the

complete indicator and orientate to the correct position.

• Locate indicator on actuator shaft flats. Press firmly

until location nibs snap into recess on actuator shaft.

4 AIR SUPPLY AND ELECTRICAL

INSTALLATION

4.1 Air Supply:

The Series F39 Actuator is factory lubricated. For optimum

operation, the use of filtered and lubricated air is recommended.

4.2 Air Supply Pressure:

Standard double-acting actuators require 40–120 psig

supply air. Spring-return actuators require 80–120 psig

supply air. Spring-return actuators can also be set up

to operate on supply air pressures ranging from 40–80

psig by using fewer springs. See “Rebuilding Instructions”, Spring-Return Actuator, paragraph 1 on page 13

for proper number and location of springs for reduced

supply air pressures.

WARNING: Air pressure greater than 120 psi must not be

applied.

4.3 Air Supply Connections:

4.3.1 No Integral Solenoid:

Double-Acting (N Models) – Connect air supply lines to

both NPT (1/8” on size 05, ¼” on sizes 10–50) ports.

Spring-Return (SN Models) – Connect air supply line to

the outboard NPT (1/8” on size 05, ¼” on sizes 10–50)

port.

For sizes 10–50, the ports are on the solenoid end cap.

The solenoid end cap is the one on the right end of the

actuator when looking at the nameplate. For 05 size only,

the ports are on the solenoid block interface plate on back

of actuator when looking at the nameplate. For size 05

spring-return it is on the back and near center of actuator.

4.3.2 With Integral Solenoid:

Connect air supply line to the NPT (1/8” on four-way

double-acting blocks, ½” on threeway spring-return

blocks) port on the solenoid block.

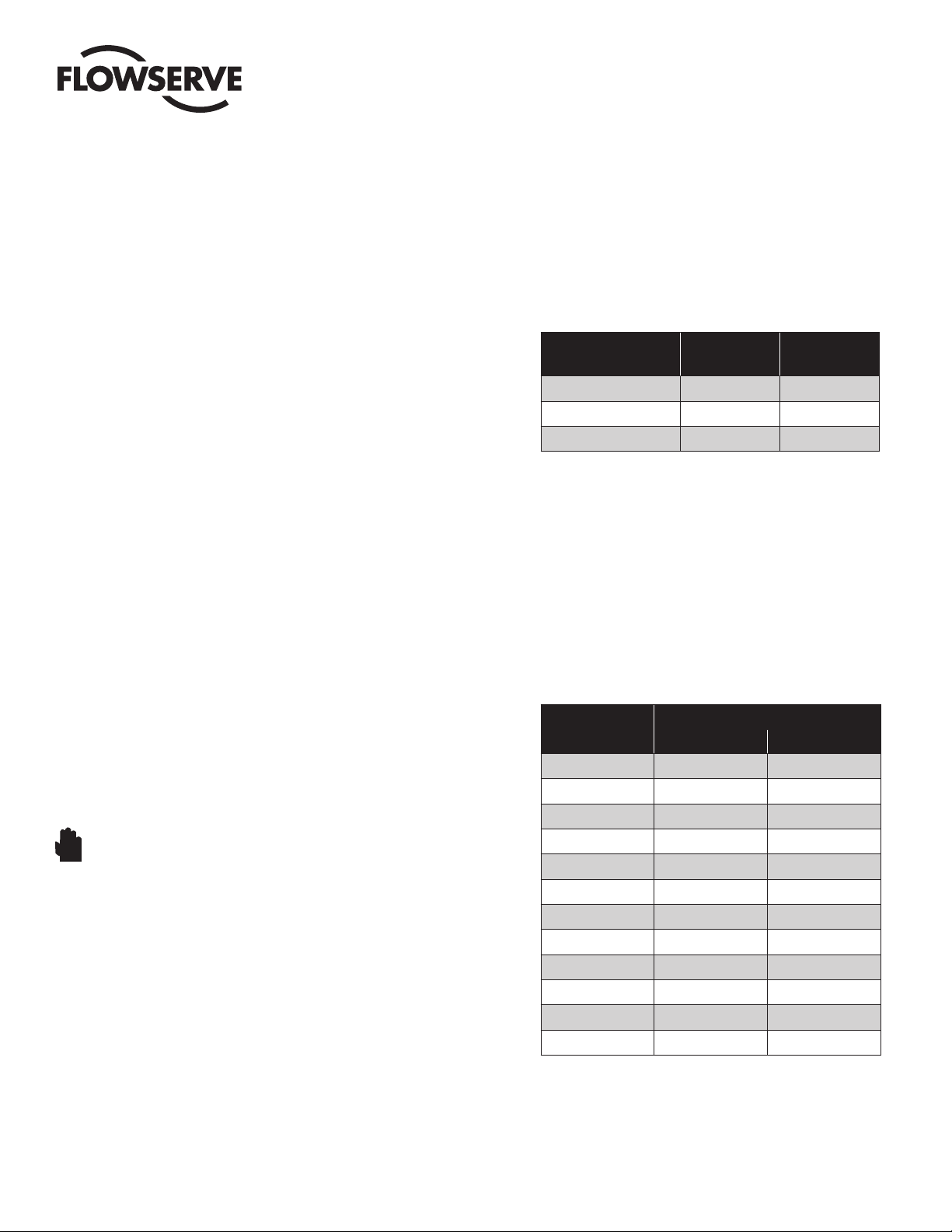

4.4 Recommended Tubing Sizes:

In order to provide sufficient flow of supply air to the

Series F39 actuator, the following tubing sizes are recommended:

Actuator Size

Runs Up To

4 Ft. Long

05, 10, 15, 20, 25

30, 33, 35, 40, 42, 45 ¼

1

8

/

Runs Over

4 Ft. Long

¼

3

8

/

50 ¼ ½

5. Air Consumption

The following chart shows the amount of pressurized (80

psig) air consumed per stroke in cubic feet. To determine

the total amount of air consumed per complete cycle

for double-acting actuators, simply add the volumes for

both the opening and closing strokes together; for spring

return units, the total volume of air consumed is the

volume shown for the opening stroke.

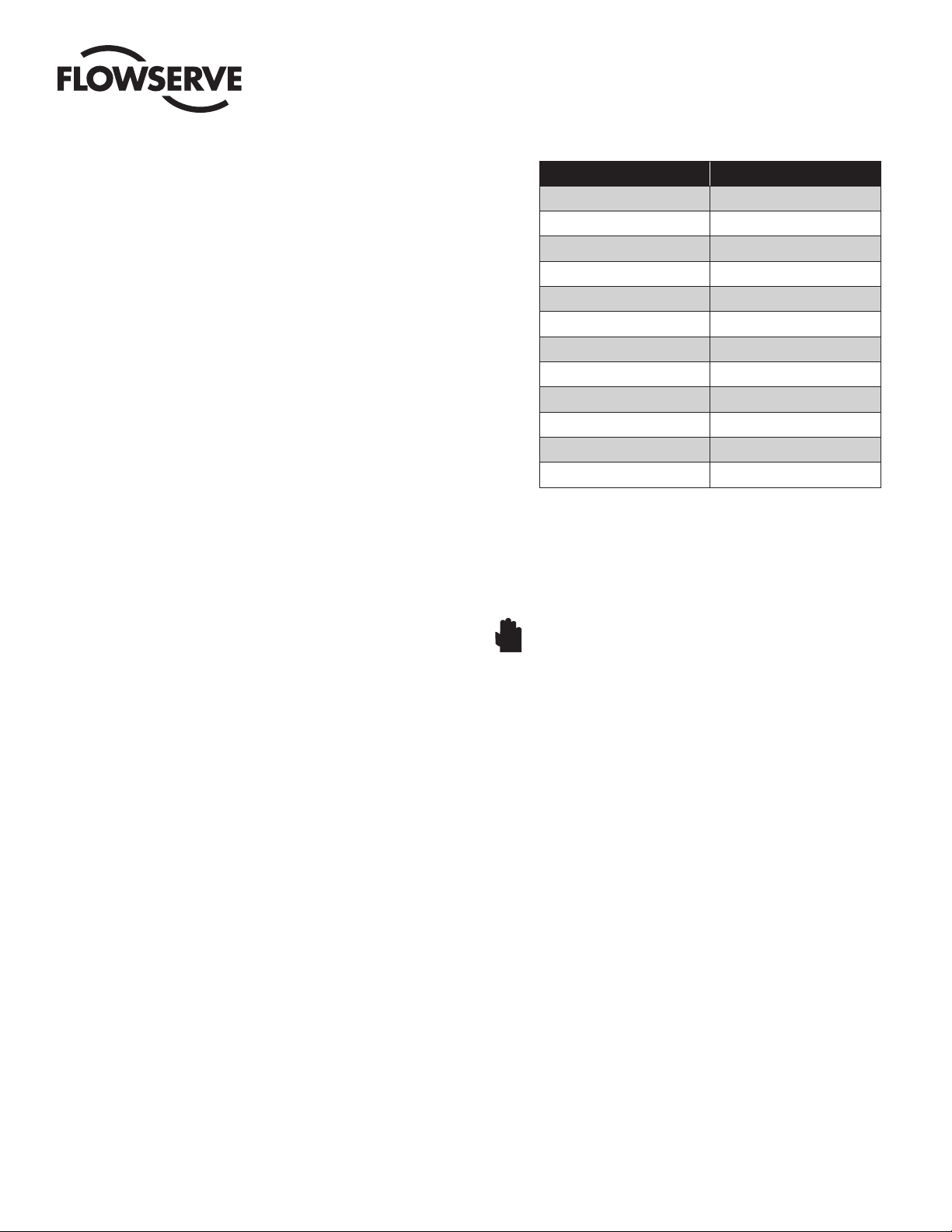

Actuator Size

05F39 .01 .01

10F39 .04 .05

15F39 .08 .09

20F39 .16 .17

25F39 .28 .30

30F39 .43 .47

33F39 .65 1.1

35F39 .90 1.3

40F39 1.3 1.4

42F39 1.7 3.3

45F39 3.1 4.6

50F39 5.5 7.0

Air consumption cu. ft.

Opening Stroke Closing Stroke

5

Page 6

Series F39 Pneumatic Actuator - WCENIM2036-00 05/15

®

6. Electrical Supply

(models with integral solenoid only)

The solenoid coil wattage and required amperage are as

follows:

Watertight and Hazardous Location Solenoids

Voltage

24 VAC 50/60 Hz .71 1.13 11

120 VAC 50/60 Hz .14 .23 10

240 VAC 50/60 Hz .07 .11 10

12 VDC .81 — 10

24 VDC .41 — 10

7

For details of installation of accessories refer to the instal-

INSTALLATION OF ACCESSORIES

lation instructions contained in respective accessory kit

Holding

Amps

Inrush

Amps

Watts

the lock nut will need to be backed off, the adjustment

screw rotated to provide correct positioning and the lock

nut retightened. For size 10 to 35 turn screw clockwise

to decrease rotation and counterclockwise to increase

rotation. For size 40 to 50 the reverse applies. It is critical

to retighten to ensure an effective seal of the washer.

Care should be taken to secure travel stop setting when

tightening lock nut.

8 OPERATION

8.1 Basic Actuator – (N Model)

The Series F39 actuator drive shaft rotates through a full

90° segment with approximately 3° overtravel at each

end of travel. Rotation is accomplished by feeding supply

air into the center chamber, forcing the two opposing

pistons apart, resulting in a counter-clockwise rotation of

the drive shaft to the “open” position. For double-acting

actuators, closure is obtained by feeding supply air into

the end cap chambers, which forces the pistons together,

resulting in a clockwise rotation of the drive pinion. For

spring-return actuators, closure is accomplished by

means of springs contained within the end caps which

force the pistons together when the supply air to the

center chamber has been interrupted.

If rotation opposite to that described above is required,

refer to the section on Installation for the proper procedure to reverse the rotation.

The accurate rotation of the actuator pinion is controlled

through the adjustment of two hexagon headed bolts

on the end cap. Each bolt will control either the open

or closing stroke (based on how the actuator has been

orientated on the valve). The adjustment of each bolt

is shown on the end cap. Actuators are factory set to

provide a 90˚ operation. If adjustment needs to be made

8.2 Actuator With Factory-Supplied Solenoid

Double-Acting – Air is supplied to the one NPT port on the

bottom of the block. When the solenoid is energized, the

spring-loaded plunger is withdrawn, allowing the supply

air to shift the spool within the block, which opens the

supply path to the center chamber of the actuator. Air

from the end chambers of the actuator is allowed to pass

through the block and exhaust to atmosphere.

When the solenoid is de-energized, the spring-loaded

plunger blocks the flow of air to the center chamber of the

actuator. The supply air now shifts the spool within the

6

Page 7

®

STOP!

block to a position which opens the supply path to the end

chambers of the actuator. Air from the center chamber

of the actuator is allowed to pass through the block and

exhaust to atmosphere.

The double-acting solenoid assembly is electrically fail-

safe. That is, it will return to its de-energized position

upon electrical failure and cycle the actuator to the closed

position provided the air supply is not interrupted.

Double-acting solenoid assemblies have two inde-

pendently adjustable speed control screws which can be

used to adjust the speed of operation for the opening and/

or closing stroke. If the speed control screws are too tight,

the unit will fail to operate. NOTE: Speed control screws

are shipped from the factory in the full open position.

Spring-Return – Air is supplied to the one NPT port on

the bottom of the block. When the solenoid is energized,

the spring-loaded plunger is withdrawn, which opens the

supply path to the center chamber of the actuator. Air

from the end chambers of the actuator is allowed to pass

directly through the block and exhaust to atmosphere.

When the solenoid is de-energized, the spring-loaded

plunger blocks the flow of air to the center chamber of

the actuator. The springs in the end cap of the actuator,

which were compressed on the opening stroke, now

relax, forcing the air contained in the center chamber

of the actuator to exhaust through its supply port in the

solenoid block. The exhaust air passes through the block

and the solenoid where it exhausts to atmosphere.

When using a spring-return solenoid assembly, only

the speed of the spring stroke is adjustable. This is

accomplished by tightening the set screw contained in

the exhaust nut (shipped separately in envelope) which

mounts directly to the end of the solenoid.

8.3 Standard Stroke Times

Series F39 Pneumatic Actuator - WCENIM2036-00 05/15

Actuator Size Stroke Time (sec.)

05F39 1

10F39 1

15F39 1

20F39 1

25F39 2–3

30F39 3–4

33F39 4–5

35F39 4–5

40F39 5–6

42F39 6–7

45F39 10–12

50F39 12–14

8.4. Manual Operation

In the event of air failure, the Series F39 actuator can

be cycled manually. This is accomplished by applying

a wrench to the exposed top shaft of the actuator and

turning it in the desired direction.

WARNING: Care must be taken to ensure that the actuator

is not operated automatically while manual operation is

being performed.

If a routine cycle check is to be performed on a double-

acting actuator equipped with the proper Worcester/

McCANNA solenoid control block, the actuator can be

cycled manually by shifting the spool valve within the

block. This can be done by pushing the red momentary

override button located on the coil housing. The actuator

will cycle to its original position as soon as the manually

applied pressure on the red button is released.

Standard stroke times of the Series F39 actuator are

shown in the following table. Times shown are in seconds

and represent average times under 50% load conditions

with an air supply pressure of 80 psig. Times shown are

per stroke for double acting actuators. For spring-return

actuators, the opening stroke times may be slightly

longer; stroke times for the closing (spring) stroke are

dependent upon the number of springs used.

The figures shown below are meant as an indication

of obtainable speeds only. Faster or slower speeds are

obtainable, if required, by using additional control equipment.

7

Page 8

Series F39 Pneumatic Actuator - WCENIM2036-00 05/15

STOP!

®

9 MAINTENANCE

CAUTION: The actuator must be isolated both pneumat-

ically and electrically before any maintenance activity is

begun.

Periodic checks should be performed to make certain

that all fasteners remain tight.

All actuators are supplied with sufficient lubrication for

Depending upon the conditions under which the actu-

On spring-return actuators, the springs may need replace-

Actuator

size

05F39 M5 4Nm

10F39 M6 9Nm

15F39 M6 9Nm

20F39 M8 19Nm

25F39 M8 19Nm

30F39 M10 35Nm

33F39 M10 35Nm

35F39 M12 49Nm

40F39 M12 49Nm

42F39 M16 98NM

45F39 M16 98Nm

45F39 M20 216Nm

their normal working life. If required, recommended lubrication for all standard actuators is a #1 grease. Consult

Flowserve for lubricants used for high or low temperature

applications.

ator must work, such as extended duty, non-compatible

operating media or abnormal operating conditions,

periodic replacement of internal seals is recommended.

Repair kits containing all necessary seals can be obtained

through any authorized Worcester/McCANNA distributor.

ment after extended duty since springs may fatigue and

break. SPRINGS SHOULD ALWAYS BE REPLACED IN

COMPLETE SETS. Spring kits are available through any

authorized Worcester/McCANNA distributor.

Fastening size Torque

11 TROUBLESHOOTING

For solenoid controlled actuators (with Worcester/

11.1 If actuator does not function, check to ascertain:

11.1.1 That valve is free to rotate. This can be done as described

11.1.2 That actuator is the correct size.

11.1 3 That speed control screws are loose (if screws are tight-

11.1.4 That correct voltage is supplied to solenoid.

11.1.5 That sufficient air supply is available at inlet to control

11.2 If proper voltage and air pressure have been verified and

11.2.1 Turn on signal voltage. Check solenoid for clicking sound.

11.2.2 If no sound is detected, remove air pressure and turn off

• Carefully unscrew solenoid and solenoid stem from

• Reapply signal voltage and observe solenoid plunger. If

11.2.3 If solenoid functions, remove solenoid valve block and

WARNING:

ANY REASON, CONSULT REBUILDING INSTRUCTIONS

CONTAINED IN FOLLOWING SECTION.

McCANNA solenoid control block)

above in Manual Operation (Section 8.4).

ened all the way, actuator will not operate).

block. Inlet pressure to control block should be at least 40

psig for double-acting, 80 psig for spring-return (unless a

reduced spring complement is installed (fewer springs)).

When checking supply pressure, place gauge in line at

control block inlet and monitor gauge for unexpected

pressure drops.

valve is free, proceed as follows:

signal voltage.

block.

it does not retract, replace solenoid.

place on bench. Connect to reduced air supply (50 psig)

and correct voltage. Switch signal voltage and check air

flow. Air should flow out only one output port when solenoid is energized. The flow should occur only at the other

port when de-energized. (Slight back pressure may be

required to shift the valve spool. This may be generated

by obstructing the outlet ports.)

BEFORE DISASSEMBLING ACTUATOR FOR

10 SPARE PARTS

The following are recommended spare parts which should

be kept on hand for Series F39 pneumatic actuators:

Repair Kit(s) – Kits contain all necessary seals, bearings

and instructions.

Spring Kit(s) – For Spring-Return Actuators.

8

11.2.4 If control block and solenoid are operating correctly,

proceed to Section 11 below.

11.3 If the actuator functions but exhibits leakage, or power

loss accompanied by leakage, proceed as follows:

11.3 .1 Check voltage. Voltage must be within 10% of the specified voltage (low voltage will cause leakage out of the

back of the solenoid and burn out the coil).

Page 9

Series F39 Pneumatic Actuator - WCENIM2036-00 05/15

®

11.3.2 Check air supply. Be certain that no sharp air pressure

drops occur as unit is cycled. Loss of air pressure can

cause incomplete shifting of the spool valves used in all

double-acting units, which results in bypass leakage and

substantial actuator torque losses.

11.4 If air supply and voltage are adequate, proceed as follows:

11.4.1 If leak is at solenoid exhaust port, replace the solenoid.

11.4.2 If leak occurs at exhaust ports in the block itself, the

trouble will be in either the spool valves in the block, or

at one of the piston seals of the actuator. A leaking piston

seal will usually leak on either cycle.

On spring-return actuators, piston seal leakage will show

at the breather port of the end cap, or for 05F39, the solenoid block interface plate.

The recommended procedure in the cases above is to

replace the spool valve O-rings. If the leakage persists,

rebuild the actuator using a factory-supplied repair kit.

11.5 For actuators without the Worcester/McCANNA solenoid

control block, or if block and solenoid are operating

correctly, remove the actuator from the valve, disassemble (per Rebuilding Instructions) and check the

following:

11.5.1 Make sure that all internal porting is free and clear of any

obstructions. End caps, guide rods and pistons are air

transporting components.

NOTE: The most common problem encountered on F39

actuators is the improper replacement of the piston guide

rod assembly with the hole in it, relative to the nameplate

on the body (see section 12.2.6 on page 11).

11.5.2 Make certain that the actuator has lubrication, and that

there is no solidified grease between the pinion and the

piston racks:

• If actuator has no lubrication, apply generous amount

of a #1 grease. If actuator is prepared for high or low

temperature operation, consult Flowserve for proper

lubricants.

• If solidified grease between the pinion and the piston

racks is present, clean, dry, re-grease and reassemble.

11.5.3 Verify that actuator pinion shaft and/or pistons are not

bound. If bound, reassemble per Rebuilding Instructions.

11.5.4 If unit exhibits excessive amounts of backlash, check

teeth on piston racks for wear. If worn, replace piston

assemblies.

11.5.5 In spring-return actuators, check for misplaced or broken

springs. If springs are broken, check body bore for

scoring:

• If springs are broken, replace springs. SPRINGS

SHOULD ALWAYS BE REPLACED IN COMPLETE SETS.

• If body bore is scored, replace it. Also, replace piston

O rings (contained in repair kit).

11.5.6 If actuator is free, valve is free and control block (if used)

is shifting air properly, reassemble the actuator and

retest. If unit still fails to operate, consult Flowserve.

12 REBUILDING INSTRUCTIONS

NOTE: For identification of all numbered parts discussed

below, consult exploded view of actuator (see pages

14/15)

After actuator has been repaired, mark rebuild label

accordingly and apply to actuator.

12.1 Actuator disassembly

12.1.1 Disconnect the air supply and electrical service to the

actuator.

12.1.2 Remove the actuator and its mounting bracket from the

valve. If the actuator uses a positioner, loosen the set

screws in the coupling between the valve and actuator.

(See Caution note below.)

CAUTION: Ball valves can trap pressurized media in the

cavity. Isolate the piping system in which the actuator/

valve assembly is mounted and relieve any pressure on

the valve. To remove the actuator bracket from a threepiece non-top-mount style “Miser” valve, the two top

valve body bolts must be removed. For all the valves

listed in Section 3.5, the actuator bracket can be removed

without loosening or removing any valve body bolts.

12.1.3 Remove the actuator bracket (and actuator positioner)

from the actuator to begin repair. (Note mounting of

removed bracket and positioner for easy reassembly.)

12.1.4 It is not necessary to remove solenoid control block (7A)

or (7B) (if so equipped) to rebuild actuator. However,

if it becomes necessary to remove the block, begin by

removing the solenoid block bolts (8E). Use care to retain

the solenoid block gasket (9).

For 05 size only, also remove the solenoid block interface

plate (20) and the interface gasket (19) by removing the

three screws (21).

9

Page 10

Series F39 Pneumatic Actuator - WCENIM2036-00 05/15

STOP!

®

For sizes 10 to 35 it is not necessary to remove the limit

stop bolts from the end cap.

CAUTION: For sizes 40 to 50 the limit stop bolts will need

to be removed to facilitate disassembly. On these sizes

remove the air inlet end cap. Then remove the limit stop

lock nuts and unscrew the limit stop bolts through the

guide rods. This should be done in conjunction with the

instructions below.

12.1.5 For sizes 10–50, each end cap (5A and 5B) is aligned onto

the body (1) over a “foolproof pin”. This ensures that the

end caps can only be assembled to their respective end

of the actuator. Remove all four metric screws (5C) from,

and remove, both end caps. For Rev. R2 and R3 through

R7 actuators, remove the two bearings (6A) and O-rings

(15A and 15B) from each end cap. Note that for Rev. R2

models with top-hat style (6C) bearings, the bearings and

particularly the retaining washers (16) in each end cap

should not be disturbed during O-ring seal replacement,

as they are not included in the rebuilding kit. For size 05,

remove all four metric screws (5C) from both end caps

(5). Remove O-ring (15A) from each end cap.

WARNING: Spring return actuators contain energized

springs. The following section must be followed to ensure

safe disassembly of the actuator.

If the actuator is a spring-return model, first remove

two end cap screws diagonally opposite each other,

then lubricate the threads and under the head. Replace

the screws and repeat the procedure for the other two

screws. Do this for each end cap as this will aid reassembly. Now uniformly loosen all four end cap screws on

each end cap two to three turns at a time, in sequence,

to relieve preload of the springs. On larger actuators with

springs use caution when removing end caps. End cap

screws are long enough to allow springs to relieve before

disengaging.

After the screws are removed, gently pry off each end

cap, being careful not to damage the end cap O-Rings.

12.1.6 The two piston guide rod (4) assemblies can now be

removed from each end of the body. Do not disassemble

the piston from the guide rod. (To assist reassembly, mark

the body with a line on the side from which the guide rod

using the thru-hole is removed). Remove all O-rings (15B

and 15C) and bearings (6B) from pistons (3). For size 05,

the two pistons (3) can now be removed from each end

of the body. Remove O-rings (15C) from pistons (3).

12.1.7 The shaft (2A) on Rev. R2 and sizes 05–20 Rev. R3

through R7 models can only be removed after the piston

assemblies are taken out. Remove the position indicator

(17) (if any), the shaft clip (15F) (not a reusable part!)

(see Note below) and the stainless steel washer from the

top of shaft. Then remove the shaft through the larger

opening in the bottom of the body. The top bearing (15G)

and the O-ring (15D) can now be removed. Remove the

two stainless steel washers (10–35 sizes only) and thrust

bearing (10) from the top of the shaft, the O-ring (15E),

and the bearing (15H) (10–42 sizes only) from the bottom

end.

NOTE: For sizes 40 and 42 Rev. R3 through R6 models

and sizes 10 to 50 Rev R7, only a single stainless steel

washer is used and thrust bearing (10) is not used.

NOTE: Some actuators may

be using a spiral-ring type

shaft clip as shown at right.

To remove this clip, engage the lower end of the ring

with a flat blade screwdriver. Using another flat blade

screwdriver push the top end of the clip in the opposite

direction. As the clip I.D. expands, lift the clip from the

shaft. The installation of a new clip would be the above

steps in reverse and ensuring that the edges of the clip

are properly seated in the shaft groove.

The Rev. R2 model, all sizes and the Rev. R3 through

R7 models, sizes 25 through 42, have an anti-ejection

ring (15J). The anti-ejection ring on Rev. 1, sizes 45–50

consists of a flat washer with a shaft clip. All others are

a one-piece spiral wound ring. This ring does not have

to be removed and may or may not be included in repair

kits.

For Rev. R2 models, remove shaft clip (15F) (not a

reusable part!) (see Note above) and the stainless steel

washer from the shaft. Then remove the top shaft bearing

(15G) and the bottom shaft bearing (15H) by carefully

prying them away from the body.

CAUTION: Both of these bearings may have a projecting

“nib” which locates the bearings to the actuator body. Be

careful not to break off these nibs inside the body when

removing the top and bottom bearings. Note: Top bearing

is marked “Top”. Bottom bearing has a larger ID than the

top bearing.

Next, slide the shaft out through the bottom of the body

and remove the top O-Ring (15D) and the bottom O-Ring

(15E) from the body.

10

Page 11

Series F39 Pneumatic Actuator - WCENIM2036-00 05/15

®

12.2 Actuator reassembly

12.2.1 Be sure the actuator surfaces are clean and free of grit

and scratches. If the inside walls of the body are scored,

or the guide rod surfaces are scratched, the actuator will

leak after rebuilding. New parts should be obtained from

the factory. Light tracking, barely detectable to touch, is

acceptable.

12.2.2 All rebuilding kit O-Rings and bearings may now be

installed. Lubricate the standard actuator thoroughly with

a #1 grease. Apply a light film of grease to all O-Rings.

12.2.3 If converting over to a “high-temperature” actuator, or

rebuilding an existing one, lubricate thoroughly with Dow

Corning #7 or other equivalent high temperature silicone

or graphite base grease.

12.2.4 Some Rev. R2 actuators, sizes 10–35, use flanged bearings in the end caps. They resemble a “top hat” (6C), and

are installed with the brim of the hat facing out, and are

retained by “star washers” (16). These bearings and star

washers should not be removed for O-Ring seal replacement. On sizes 10 and 15 only, there is one star washer,

or retainer, per bearing. On sizes 20–35, there are two

star washers per bearing. They are installed one on top

of the other, with the “points” of the “star” overlapping

each other (as opposed to being on top of each other). All

the washers must be pressed in firmly and straight. The

points of the star are bent slightly. When installed, they

bear back, away from the hole.

For Rev. R3 through R7, sizes 25 through 42 actuators,

replace anti-ejection ring (15J) in its groove on the shaft

(2B), if removed.

For Rev. R2 Models:

• Locate the shaft O-Rings into the actuator body. O-ring

(15D) is the top O-ring while (15E) is the bottom O-Ring.

• Replace the top bearing (15G) and bottom bearing

(15H).

• If the anti-ejection ring (15J) was removed, replace

it in its groove on the shaft (2B). Check that the ring is

properly seated in its groove.

• Replace the shaft in the body through the larger opening

in the bottom of the actuator body.

12.2.6 Replace the stainless steel washer over the top shaft

extension.

12.2.7 For sizes 10–50, very carefully align the piston guide rod

assemblies inside the body. Keep the pistons square to

the body. (This is very important in the 30 F39 actuator

where steel set screws can cause internal body damage if

the piston assemblies “cock” inside the actuator body.)

IMPORTANT:

One piston guide rod assembly has a through

hole drilled in it. It can be easily located by looking down

the ends of both guide rods. This piston assembly must

be reassembled, with its respective guide rod, opposite

the nameplate on the body, as it was removed.

For sizes 10–50 Rev. R2 and 10–42 Rev. R3 through R7

actuators, replace the two split-ring style bearings (6A)

and one guide rod O-ring (15B) in each end cap.

Replace the split-ring style bearing (6B) and guide rod

O-ring(s) (15B) into I.D. groove(s) in each piston (3).

Install O-Rings (15C) onto pistons.

For size 05 actuators, install O-rings (15C) onto the

pistons.

12.2.5 Replace O-ring (15E) and bearing (15H) (10–42 sizes

only) on the bottom of shaft. On the top of the shaft add

the two stainless steel washers (10–35 sizes only) with

the thrust bearing (10) between them. NOTE: For sizes

40 and 42 Rev. R3 through R6 and sizes 10 to 50 Rev.

R7, only a single stainless steel washer is used and thrust

bearing (10) is not used. Locate the top bearing (15G)

and O-ring (15D) into the body. NOTE: For sizes 10–35

Rev. R7 and size 05 actuators, top bearing (15G) is flat

and the same as, and interchangeable with, thrust bearing

(10). Insert the shaft through the larger opening in the

bottom of the body.

°

Nameplate

Figure 1

Pistons at End of Body

IMPORTANT: Note the relative location of the shaft teeth

and the piston assembly's rack teeth. The above figure is

viewed when looking at the top of the actuator.

For size 05, align the pistons inside the body. Keep the

pistons square to the body.

12.2.8 Align the shaft so that the teeth on the shaft will “pickup” the piston assembly’s rack teeth when turning the top

extension of the shaft clockwise (CW). (See Figure 1.)

IMPORTANT: Proper 90°rotation can only be ensured if

the shaft teeth begin to mesh with the piston assembly’s

teeth at the “proper tooth” between these meshing gear

pairs. (See Figure 1.)

11

Page 12

Series F39 Pneumatic Actuator - WCENIM2036-00 05/15

®

12.2.9 To ensure proper meshing of teeth, move the shaft 15

to 20 degrees counter-clockwise (CCW) from its normal

position when the piston assemblies are located at the

body ends. (See Figure 2.) NOTE: The “normal position”

of the shaft on the 05–20 sizes is when the top flats are

parallel to the main axis of the actuator body. On the 25–

50 sizes the teeth of the shaft will be on the left side of

the actuator when viewed from the ends of actuator. (See

Figure 1.)

12.2.10 With the piston assemblies in the body, gently push each

piston into the body. Turn the top shaft extension clockwise (CW). Do not allow the pistons to “cock”.

At the proper point of engagement between the shaft

and piston assemblies, both piston assemblies will move

toward the center of the body when turning the top shaft

extension of the actuator clockwise (CW).

12.2.11 Once the shaft and pistons are properly engaged, ensure

that smooth movement and 90 degree operation can

occur without moving the pistons out of the actuator

body. This is important!

12.2.12 Install O-Ring (15A) into and replace the actuator end

caps, (5 or 5A and 5B), noting that the “foolproof” pin

between the body and end cap mates properly (10–50

sizes only). For sizes 40 to 50 the limit stop end cap must

be assembled first. Once assembled feed the limit stop

bolts through the guide rod and screw into the end cap.

Add the sealing washer and lock nut and then attach the

air inlet end cap.

12.2.13 VERY IMPORTANT: Install the NEW shaft clip (15F)

into its mating groove on the top shaft extension. (The

removed shaft clip is not to be reused.)

Place the numbered side up on the shaft clip and be

certain the clip is fully seated in its groove. See Note at

bottom of page 10 for installation of spiral-ring type shaft

clip (which newer rebuilding kits will contain).

12.2.14 If solenoid control block was removed:

For size 05 only, place interface gasket (19) onto solenoid

block interface plate (20) and attach securely to body with

three screws (21). Do not apply any grease to gasket.

Place gasket (9) on solenoid control block (7A) or (7B)

(if used) and attach block securely to end cap, or for size

05, the solenoid block interface plate, to obtain a seal at

gasket. NOTE: If fiber gasket is used, work a generous

amount of assembly grease or petroleum jelly into the

gasket prior to assembly (wipe off excess grease). If a

rubber gasket is used, do not apply any grease, it must

be installed dry.

12.2.15 Replace position indicator (17) (if any). See Section 3.6.6.

12.2.16 Mark Rebuild/Accessory Addition Label, if included in

repair kit, and apply to actuator.

NOTE: For spring return actuators, see spring installa-

tion section on page 13 before installing end caps.

NOTE: When installing the end cap O-Rings, use a small

amount of a general purpose lubricant, such as petroleum jelly, to hold them in place for ease of assembly and

to avoid having them drop down and get pinched.

On Rev. R2 and earlier actuators, be sure O-Ring is

installed in groove on end cap.

15˚ - 20˚

15˚ - 20˚

05 - 20 F39 Actuator 25 - 50 F39 Actuator

Figure 2

Alignment of Shaft at Reassembly

IMPORTANT:

12

Align gear teeth on the shaft as per Figure 1.

Page 13

Series F39 Pneumatic Actuator - WCENIM2036-00 05/15

®

13 SPRING-RETURN ACTUATOR

13.1 When replacing springs in a spring-return actuator,

ensure that the springs are replaced in their identical

position in the end cap from where they were removed.

IMPORTANT: When less than the standard number of

springs are used in each end cap, these springs should

be positioned according to the air supply figures below.

The values listed below are for standard and less than the

standard air pressure as required per the ordering code.

NOTE: Maximum operating pressure does not change.

Sizes 10–35 Rev. R2 through R7 and Sizes 40 and 42 Rev. R 2

70 psi - 8 springs - 4 per end cap. Remove center spring.

60 psi - 8 springs - 4 per end cap. Remove center spring.

50 psi - 6 springs - 3 per end cap. Use three on a diagonal.

40 psi - 4 springs - 2 per end cap. Use two in opposite corners.

Sizes 10–50 Rev. R2 (Except Size 40 and 42)

70 psi - 20 springs - 10 per end cap.

60 psi - 20 springs - 10 per end cap.

50 psi - 16 springs - 8 per end cap.

40 psi - 12 springs - 6 per end cap.

The size 05 spring-return actuator operating at 80 psi has four springs

(two per end cap). For air supplies of 70, 60 or 50, remove inner spring

of each end cap.

Remove required number of

springs starting in the center.

Remaining springs should be

evenly spaced as possible.

13.2 If a spring-return actuator is being repaired due to a failed

spring, REPLACE all the springs in this actuator, as well

as any other parts which may have been damaged.

13.3 When replacing the springs in a spring-return actuator,

place the springs in the end cap pocket after thoroughly

lubricating each spring. Be generous with lubricant!

13.4 With the springs pointing up and the end cap on a solid

surface, place the actuator body over the springs and the

proper end cap. (Each end cap can only be mounted to

just one end of the actuator body, as there is a “foolproof”

pin in the end cap, which aligns with a hole in the body.)

13.5 Force the body down and begin by engaging two end cap

screws (5C) by hand through the end cap. Take each end

cap screw up in SMALL and EQUAL turns. Once the end

cap is temporarily secured to the body, turn the actuator

over to its normal position and uniformly take up the four

end cap screws. Uniformly load all the springs to prevent

any spring from buckling.

IMPORTANT: Locating nibs are cast into the Rev. R2 (all

sizes) and the Rev. R3 through R7 (sizes 25 through 42)

actuator piston face. The actuator springs must fit over

these locating nibs on the piston face. Care in following

the above instructions will ensure the proper alignment of

the spring in the actuator body — proper contact with the

piston face and end cap.

13.6 In a similar manner, as written in the previous steps,

replace the springs in the other end of the actuator body.

Ordering Code

Supply Pressure (psi)

05 32 32 32 41

Ordering Code 4 5 6 7 ( )

Supply Pressure (psi)

Actuator Size and

Current Rev.

10 R7

15 R7

20 R7

25 R7

30 R7

33 R7

35 R7

40 R7

42 R7

45 R2

50 R2

1 1 1 ( )

50 60 70 80

40 50 60 70 80

End of Spring Torque (in Lbs)

42 63 84 84 104

74 112 149 149 186

135 212 272 272 339

232 348 465 465 581

372 558 744 744 929

804 1204 1611 1611 2009

929 1398 1859 1859 2328

1496 2239 2982 2982 3735

2593 3885 5177 5177 6469

4735 6319 7849 7849 9478

7319 9762 12204 12204 14638

13.7 On sizes 40 to 50 Rev. R7 only encapsulated springs (pre

compressed) can be used with this design.

13

Page 14

Series F39 Pneumatic Actuator - WCENIM2036-00 05/15

®

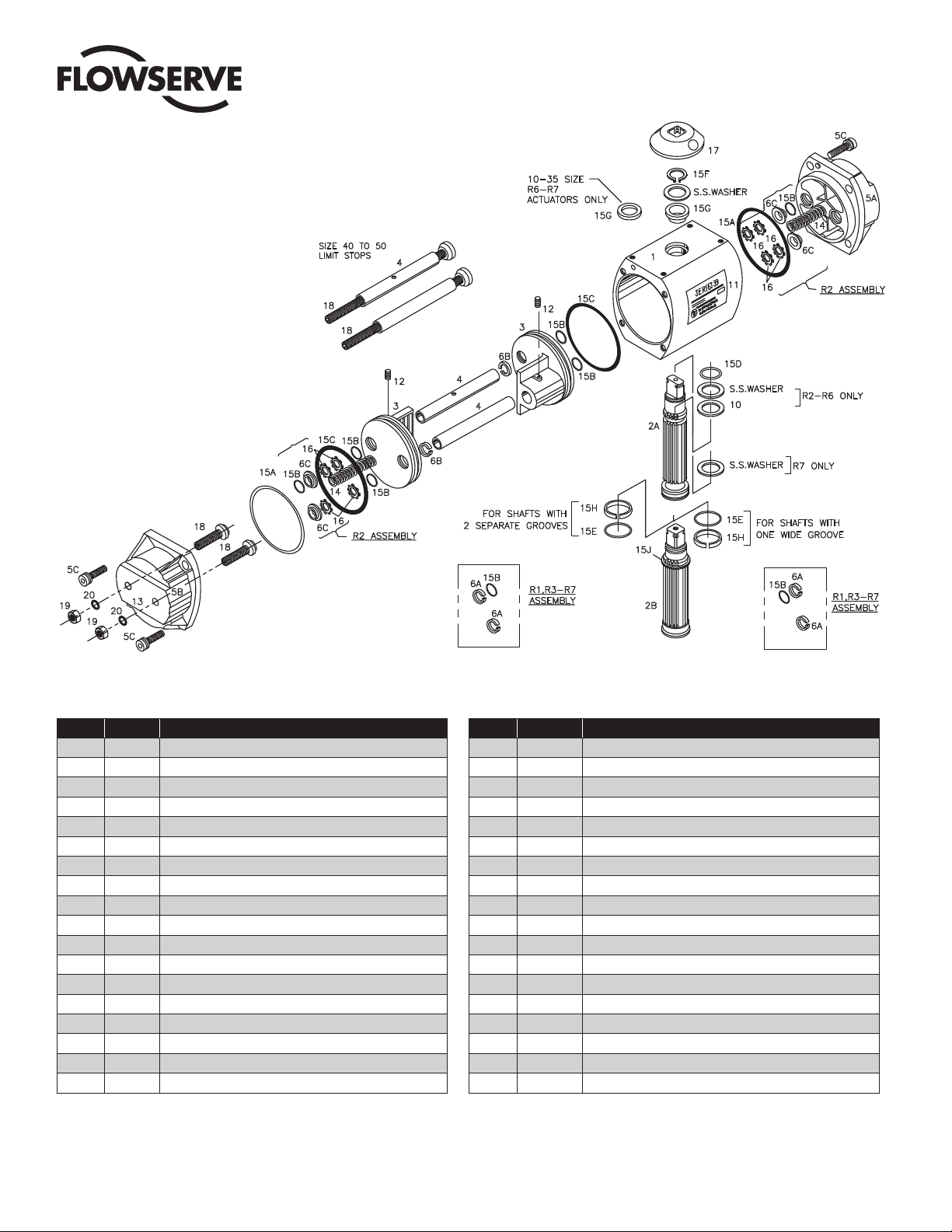

14 Size 05 Exploded view/parts/materials

(Spring return)

(Double acting)

14A

14A

18

17

14A

5

14B

15F

S. S. Washer

15G

20

15C

3

9

19

5

21

5

(Spring return)

5C

5

(Double acting)

15A

Optional "Rebreather" gasket

(spring return actuators only)

7B

5C

15A

15C

1

3

15D

10

2

15E

9

8E

8D

7A

8E

8B

18C

8A

Item Qty. Description Item Qty. Description

1 1 Body 11 1 Nameplate (Not Shown)

2 1 Shaft

3 2 Pistons

4 2 Guide Rods

12 2 Piston Set Screws

13 2 Pipe Plugs

14A 2 Inner Springs (See Table Page 9)

5 2 End Caps 14B 2 Outer Springs (See Table Page 9)

5A 1 Solenoid Block (Inlet) End Cap

5B 1 Limit Switch End Cap

15A 2 End Cap O-Rings

15C 2 Piston O-Rings

5C 8 End Cap Screws (Metric) 15D 1 Top Shaft O-Ring

7A 1 Solenoid Block (Double-Acting) 15E 1 Bottom Shaft O-Ring

7B 1 Solenoid Block (Spring-Return) 15F 1 Shaft Clip

8A 1 Solenoid 15G 1 Top Pinion Bearing

8B 1 Solenoid O-Ring 17 1 Position Indicator

8C 1 Solenoid Plunger 18 1 Indicator Mounting Screw

8D 1 Solenoid Spring 19 1 Interface Gasket

8E 2 Solenoid Block Bolts 20 1 Solenoid Block Interface Plate

9 1 Solenoid Block Gasket 21 3 Plate Mounting Screws (Metric)

10 1 Thrust Bearing

To order proper parts, please specify the actuator size, model and revision number. Use the standard nomenclature listed above.

The rebuilding kits include Items 15A, 15C through 15G, 10, 19 and stainless steel washer. Color of some replacement parts, such

as bearings, may vary from the parts removed.

14

Page 15

Series F39 Pneumatic Actuator - WCENIM2036-00 05/15

®

15 Size 10-50 Exploded view/parts/materials

The rebuilding kit includes items

15A through 15H, 6A and 6B, 10,

and stainless steel washers. Color

of some replacement parts, such as

bearings, may vary from the parts

removed. Item 15J may or may not

be included in repair kits.

Rebuild kit labled R6 is for Rev. R2

through R6 actuators.

Item Qty. Description Item Qty. Description

1 1 Body 8E 2 Solenoid Block Bolts

2A 1 Shaft (10-2039) 9 1 Soleniod Block Gasket

2B 1 Shaft (25-50F39) 10 1 Thrust bearing (R7 RK Only)

3 2 Pistons 11 1 Nameplate

4 2 Guide Rods 12 2 Piston Set Screws

5A 1 Solenoid Block (Inlet) End Cap 13 2 Pipe Plugs

5B 1 Limit Switch End Cap 15A 2 End Cap O-Rings

5C 8 End Cap Screws (Metric) 15B 6 or 12 Guide Rod O-Rings (See Note Below)

*6 - Bearings (Guide Rod) 15C 2 Piston O-Rings

6C 4 End Cap Bearing (Top-Hat Style) 15D 1 Top Shaft O-Ring

6A 4 End Cap Bearing (Split-Ring Style) 15E 1 Bottom Shaft O-Ring

6B 2 Piston Bearing (Split-Ring Style) 15F 1 Shaft Clip

7A 1 Solenoid Block (Double-Acting) 15G 1 Top Pinion Bearing

7B 1 Solenoid Block (Spring-Return) 15H 1 Bottom Pinion Bearing

8A 1 Solenoid 15J 1 Anti-Ejection Ring (R2 and Sizes 25-42 R3-R7)

8B 1 Solenoid O-Ring 16 4 or 8 Bearing Retainer (R2 Only)

8C 1 Solenoid Plunger 17 1 Position Indicator

8D 1 Solenoid Spring

NOTE: Size 15 Rev. R7 rebuilding kits include twelve Guide Rod O-rings. The six larger diameter O-rings are for Rev. R3 through R7 actuators.

*End cap bearings (6C) illustrated are for Rev. R2 actuators only. All other revision end caps use split-ring style (6A), same as piston bearing

(6B). Only split-ring style bearings are included in R7 rebuilding kits, and normally all styles of bearings do not need replacement during a rebuild.

To order proper parts, please specify the actuator size, model and revision number. Use the standard nomenclature listed above.

15

Page 16

Series F39 Pneumatic Actuator - WCENIM2036-00 05/15

®

FLOWSERVE Flow Control

1978 Foreman Drive

Cookeville, Tennessee 38501

USA

Phone: 931 432 4021

Fax: 931 432 5518

FCD WCENIM2036-00-AQ 05/15

To find your local Flowserve representative:

For more information about Flowserve Corporation.

visit www.flowserve.com

© 2015 Flowserve Corporation. Flowserve a trademark of Flowserve Corporation

Due to continuous development of our product range. we reserve the

right to alter the dimensions and information contained in this leaflet as

required. Information given in this leaflet is made in good faith and based

upon specific testing but does not, however, constitute a guarantee

flowserve.com

16

Loading...

Loading...