Page 1

EV 30

Installation Instructions 810496-00

Bottom Loading and Unloading System EV 30

1

Page 2

2

Page 3

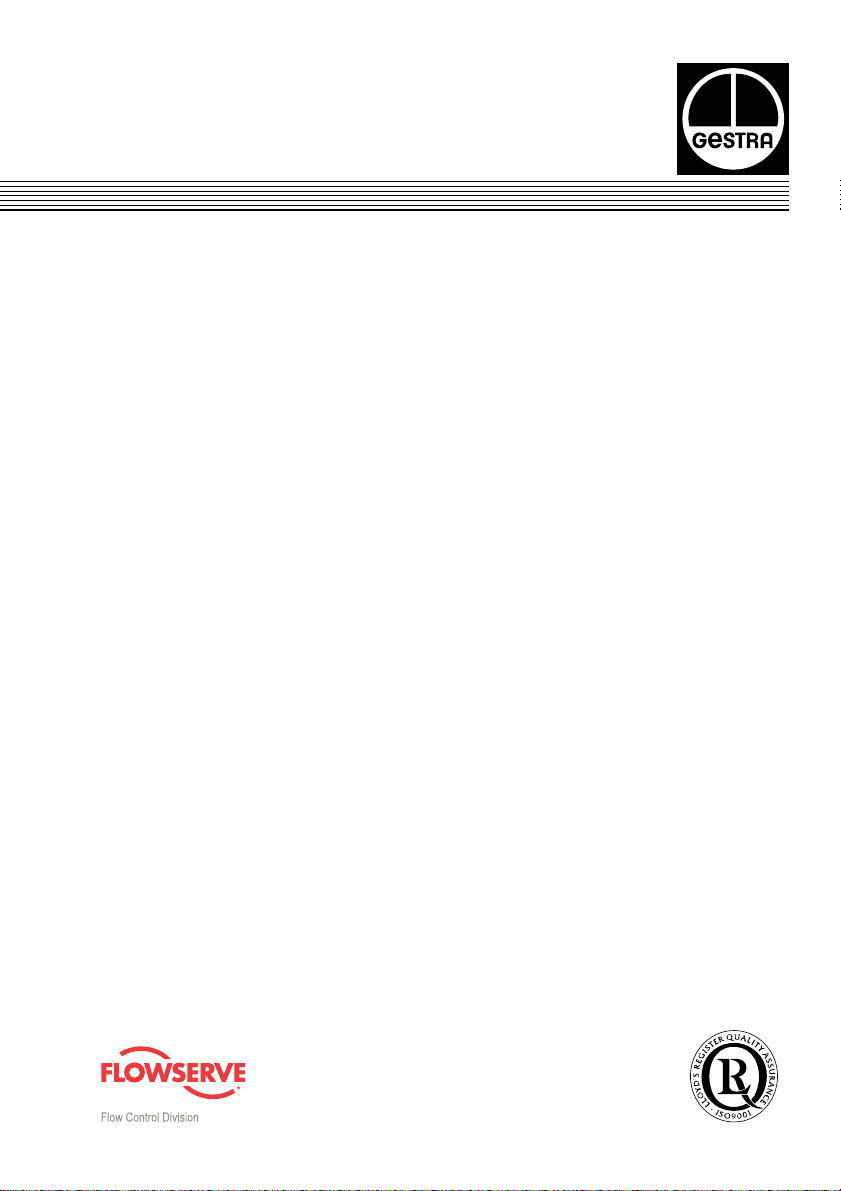

Dimensions

Fig. 1

3

Page 4

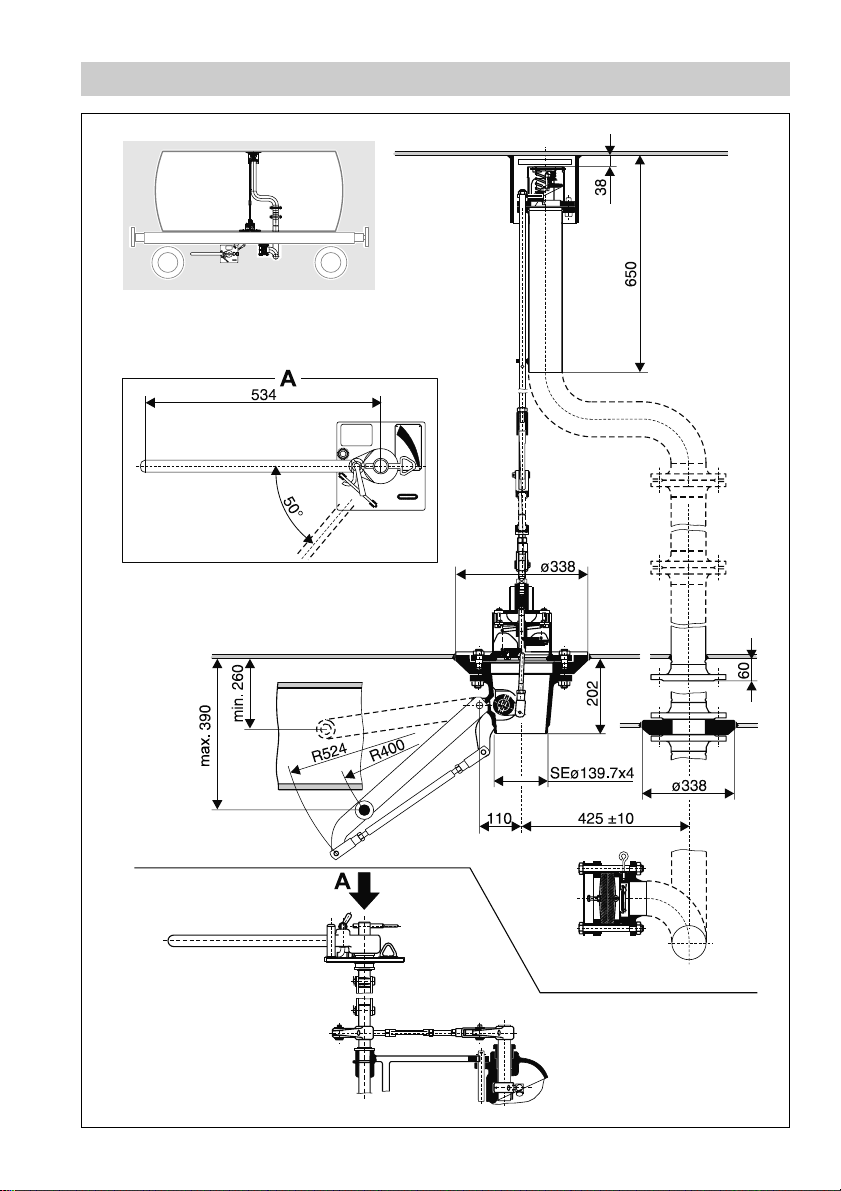

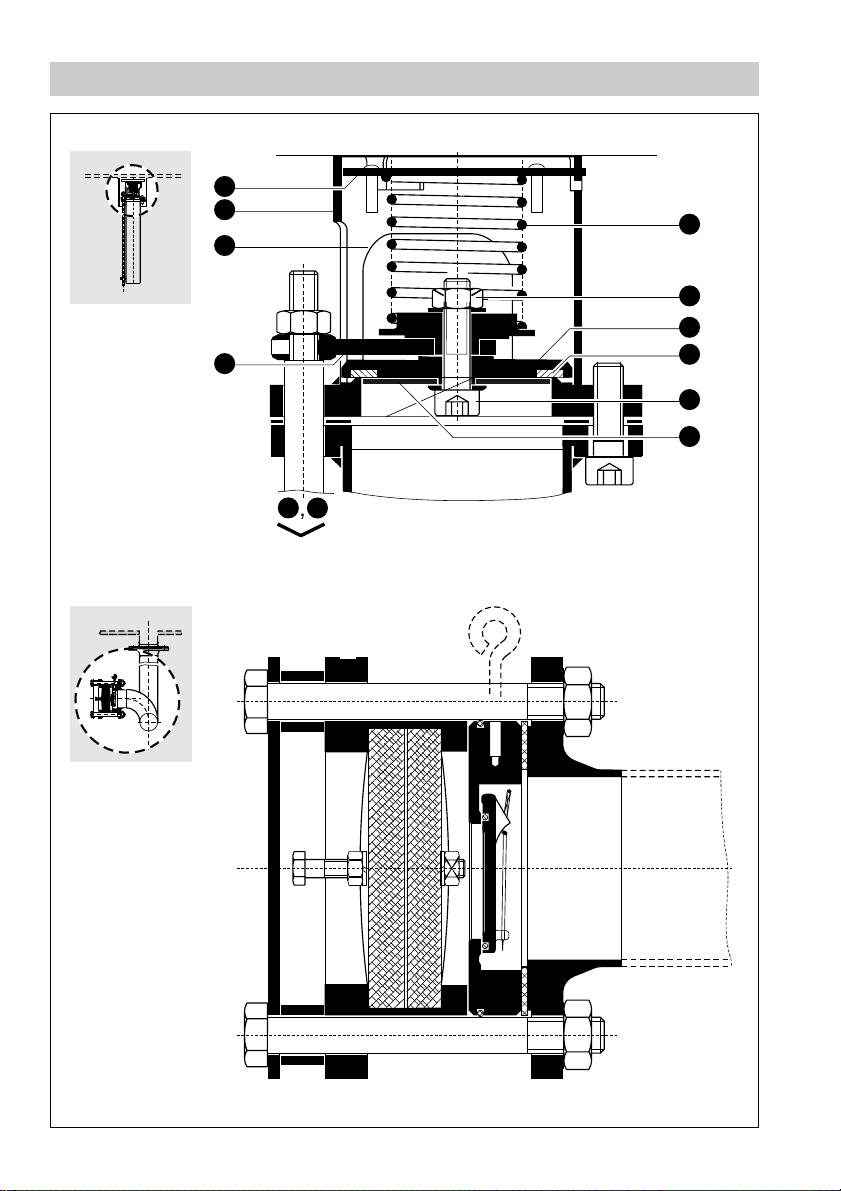

Functional elements

G

F

E

4

B

3

B

D

C

B

1

B

A

H

I

* welded directly into

tank shell

** boiler port with

valve-mounting flange

J

Fig. 2

Fig. 3

4

Lever at limit stop

1

B

K

R

L

M

N

1

N

Page 5

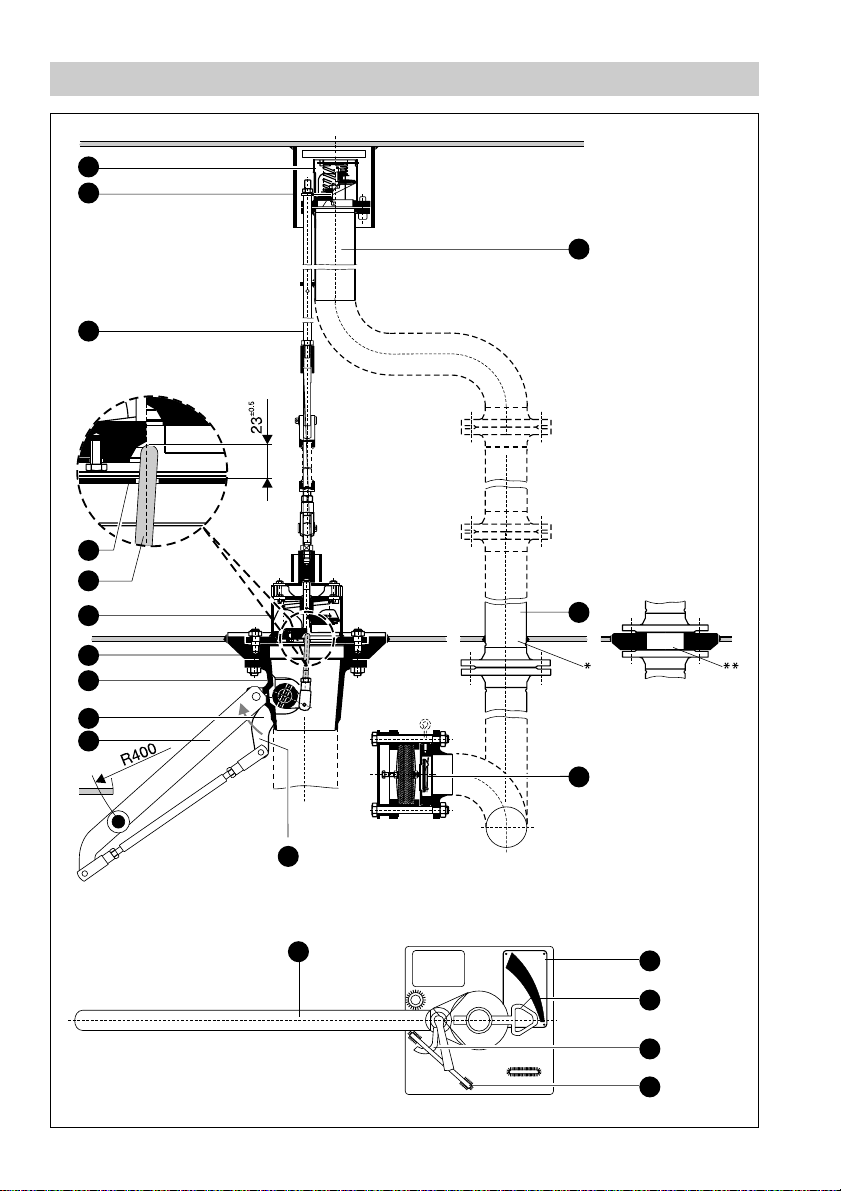

Installation

G

F

X

W

V

U

T

S

R

Q

P

O

Fig. 4

Not part of the

GESTRA consignment

5

Page 6

Installation

2

A

Pipe 42.4 x 5.6 to DIN 2448,

carbon steel

L

L

L1

L

4

A

A

Pipe 42.4 x 5.6 to DIN 2448,

carbon steel

7

A1A5L

R1

R

L

B

1

B

Fig. 5

6

M

N1N K

6

A

1

A

2

A

Page 7

Maintenance

Fig. 6

1

D

1

R

O

Y

Z

3

D

2

D

Fig. 7

2

B

7

Page 8

Maintenance

Fig. 8

3

G

4

G

5

G

G

6

G

10

G

9

2

G

T

U

G

7

G

8

G

Fig. 9

8

Page 9

Key

A

Manual operating mechanism EV 30

B

Operating mechanism BV 50, DN 150 mm

C

Valve mounting flange, DN 125/150 mm

D

Bottom valve UV 70, DN 125 mm

E

Actuating rod assembly with threaded bush for adjustment

F

Support for gas balance pipe (not included in the GESTRA consignment)

G

Vent valve LV 50, DN 80 mm

H

Connecting pipe LV 50 with rod assembly guide

I

Standpipe for gas balance pipe (not included in the GESTRA consignment),

– optional valve mounting flange not represented –

Vacuum breaker FV 10

J

K

Hand lever EV 30

Base plate EV 30

L

Indicator EV 30

M

Locking lever with hook for positions

N

1

Guide for hand lever

N

OPEN and CLOSED

All other items will be explained in the following pages and are therefore not listed here.

9

Page 10

Contents

Page

Important Notes

Safety note .................................................................................................................... 11

Danger ..........................................................................................................................11

Explanatory Notes

System description .......................................................................................................12

Function ........................................................................................................................12

Design ...........................................................................................................................12

General technical data ..................................................................................................13

Technical data of bottom valve UV 70 ..........................................................................13

Technical data of vent valve LV 50 DN 80 mm.............................................................1 3

Technical data of swing check valve fitted in FV 10.................................................... 1 3

Technical data of hand lever ....................................................................................... 1 3

Installation

Tools.............................................................................................................................. 15

Installation materials ..................................................................................................... 15

Bottom valve with operating mechanism ......................................................................1 5

Vent valve and standpipe (internal gas balance pipe)..................................................17

Maintenance

Tools.............................................................................................................................. 19

Bottom valve: Exchanging gasket .................................................................................19

Operating mechanism: Re-tightening stuffing box .......................................................20

Vent valve: Exchanging gasket.....................................................................................20

Operation

Open loading and unloading system EV 30 .................................................................22

Close loading and unloading system EV 30.................................................................22

10

Page 11

Important Notes

Safety Note

Use bottom loading system EV 30 only for loading and unloading tanks designed

for transporting products which are liquid at normal outside temperatures

(cf. temperature ratings on page 13). The system may only be installed by

qualified staff.

Qualified staff are those persons who have achieved a recognised level of

competence appropriate to the installation and commissioning of this equipment.

Danger

Do not undertake any installation or maintenance work unless the mobile

tank is completely empty and free of gas. Escaping vapours or gases

can endanger the life and health of the person entrusted with the

installation or maintenance and cause damage to property.

11

Page 12

Explanatory Notes

Scope of Supply

EV 30 DN 125 mm type F for liquid phase consisting of:

1 Valve mounting flange DN 125/150 mm (on request)

1 Bottom valve UV 70 DN 125 mm

1 Operating mechanism BV 50 DN 150 mm

1 Manual operating mechanism for EV 30

EV 30 DN 80 mm type G for gas phase consisting of:

1 Valve mounting flange LV 50 DN 80 mm (on request)

1 Vent valve LV 50 DN 80 mm with operating rod

1 Vacuum breaker FV 10

EV 30 DN 125 mm type F and EV 30 DN 80 mm type G can also be used singly.

System Description

The bottom loading system EV 30 consists of EV 30 DN 125 mm type F for liquid

phase and EV 30 DN 80 mm type G for gas phase (gas balance pipe) and is used in

mobile tanks, e.g. rail tank cars.

The system meets the requirements of the following rules:

■

GGVE/RID Appendix XI

■

TRT 024, TRT 006, TRT 30

Function

The bottom valve UV 70 DN 125 mm serves as first internal shut-off according to

GGVE/RID. The opening mechanism for the bottom valve UV 70 is incorporated in

the operating mechanism BV 50 on to which the corresponding manifold for loading/

unloading tank cars can be welded.

The valves for liquid and gas phases can be operated independently of each other

with the aid of hand levers. When the valve is in the open position the hand lever is

automatically locked. Visual position indication is provided by indicators on both sides

of the tank car.

The vent valve and the bottom valve are interlinked by means of a connecting rod,

which means that the vent valve is opened when the bottom valve is being opened.

The connecting rod also prevents the vent valve from opening when the fluid is

sloshing about in the tank.

The vacuum breaker FV 10 fitted in the gas balance pipe of the tank car opens if

negative pressure builds up when the gas balance pipe is not connected to the

tank car.

12

Page 13

Design

EV 30 DN 125 mm type F

■

Bottom valve UV 70 for DN 125 and 150 mm

■

Valve mounting flange EV 30 for DN 150 mm

■

Operating mechanism BV 50 DN 125/150 mm

EV 30 DN 80 mm type G

■

Vent valve LV 50 DN 80 mm

■

Flanged pipe socket for mounting LV 50

■

Vacuum breaker fitted with swing check valve and flame arrestor

Materials

■

Carbon steel or austenitic steel for corrosive fluids

General Technical Data

Type approval no.

EV 30 type F TÜ.AGG.276.97

LV 50 TÜ.AGG.277.97

Temperature/pressure ratings

Max. service pressure: 3 barg (43.5 psig)

Max. service temperature: + 150 °C (302 °F)

Min. service temperature: –10 °C (14°F) as defined by the German Technical

Directives for Tanks TRT 024

Technical Data of Bottom Valve UV 70

Spring forces

Position OPEN 1150 N

Position

CLOSED 700 N

Valve lift

Completely open: 37 mm, limited by stop

Safety distance between tappet and valve

2 mm

Technical Data of Vent Valve LV 50 DN 80 mm

Closing force: 140 N

Technical Data of Swing Check Valve Fitted in FV 10

Opens at a negative pressure of 0.07 barg (2.17 psig)

Technical Data of Hand Lever

Manual force required for opening

Without pressure: 56 N

At test pressure 4.5 barg (65 psig): 180 N

13

Page 14

Materials

EV 30 DN 125 mm type F

Standard design Austenitic design

Valve mounting flange 1.0425 H II 1.4571 X6CrNiMoTi 17 12 2

UV 70, DN 125 mm

Valve disc 1.0460 C22.8 1.4571 X6CrNiMoTi 17122

Seat ring 1.4301 X5CrNi 1810 1.4301 X5CrNi 1810

Bayonet socket pipe 1.0038 RSt 37-2 1.4541 X6CrNiTi 1810

Bayonet base cap 1.0308 St 35 1.4301 X5CrNi 1810

Spring 1.1200 Carbon spring 1.4310 X12CrNi 177

BV 50, DN 150 mm

Body 1.0619 GS-C 25 1.4308 G-X6CrNi 1 89

Shaft 1.4021 X20Cr 13 1.4301 X50CrNi 1 815

Screwed union 1.4301 X5CrNi 1810 1.4301 X5CrNi 1810

Other parts 1.0305 + St 35.8 + 1.4571 + X6CrNiMoTi 17122

0.7040 GGG-40 1.4308 A2 G-X6CrNi 1 89

Manual operating mechanism

Base plate 1.0038 RSt 37-2 Valves made of austenitic

Hand lever 0.7040 GGG-40 materials have the operating

Operating shaft 1.4104 X12CrMoS 17 mechanisms also made of

Lever 0.7040 GGG-40 carbon steel (= standard

Supporting arm 1.0110 St 37 design)

steel wire

EV 30 DN 80 mm type G

Standard design Austenitic design

Valve mounting flange 1.0425 H II 1.4571 X6CrNiMoTi 17 12 2

LV 50, DN 80 mm

Internals 1.4301 X5CrNi 1810 1.4301 X5CrNi 1810

Flanges 1.4301 X5CrNi 1 81 0 1.4571 X6CrNiMoTi 1 7122

Bayonet socket pipe 1.0038 RSt 37-2 1.4541 X6CrNiTi 18 10

Bayonet base cap 1.0308 St 35 1.4301 X5CrNi 1810

Spring 1.4310 X12CrNi 1 77 1.4310 X12CrNi 1 77

Connecting pipe L V 50

Flange 1.0038 RSt 37 -2 1.4301 X5CrNi 18 10

Pipe 1.0305 St 35.8 1.4301 X5CrNi 18 10

Bayonet base cap UV 70 (welded part)

Bayonet base cap 1.0308 St 35 1.4301 X5CrNi 1810

Pipe 1.0305 St 35.8 1.4571 X6CrNiTi 18 10

T appet 1.4301 X5CrNi 1810 1.4301 X5CrNi 1810

Parts for assembly LV 50

Socket-head cap screw A2 A2

Operating rod 1.0711.07 9 S 20 1.4301 X5CrNi 18 10

FV 10, DN 80 mm

Adaptor 1.0254... ST 37.0 – –

CB 26

Body 1.0460... C 22.8 – –

Flap 1.4581... G-X7CrNiMoNb 1810 – –

O-ring FKM – – –

Bow spring 1.4571K X10CrNiMoTi 1 81 0 – –

Backfire grid assembly

Body Ms 64 – – –

Backfire grid 1.4541... X10CrNiTi 189

14

Page 15

Installation

Dimensions and component parts see Fig. 1 – 4

Tools

For installation and maintenance work use tools commonly used by fitters and

mechanics.

Installation Materials

The following items are to be provided on site:

■

Standpipe for gas balance pipe

■

Support for gas balance pipe

■

Guide for gas phase valve

■

Connecting rod between gas and liquid phase valve

■

Valve mounting flange (unless supplied by GESTRA)

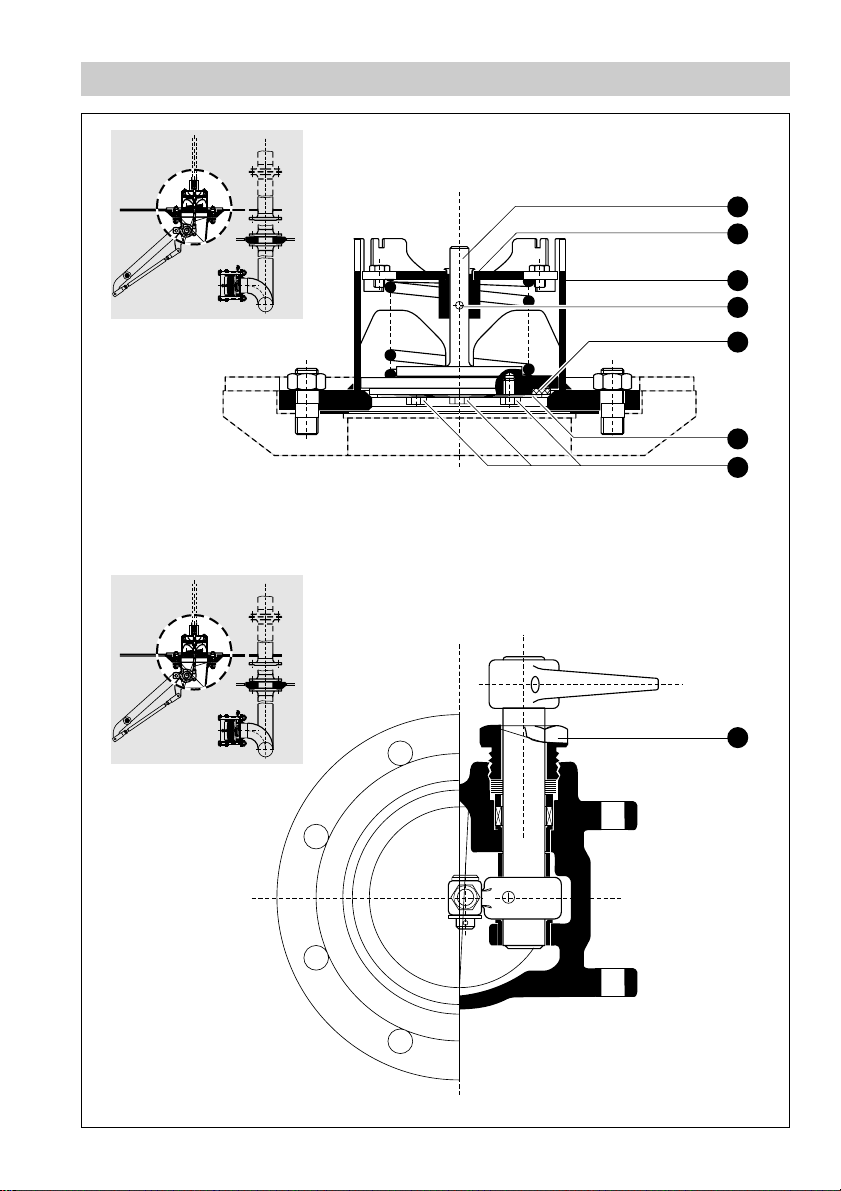

Bottom Valve with Operating Mechanism

see Fig. 2, 3 and 5

1. Weld valve mounting flange on to tank bottom.

2. Weld manifold to operating mechanism .

3. Screw fixing studs for operating mechanism from below into the valve mounting

C

flange . Put gasket onto the sealing face of the operating mechanism. Attach

gasket and operating mechanism to valve mounting flange by fastening the nuts of

the fixing studs, torque required for tightening 90 Nm.

4. Place tappet guide onto valve mounting flange and pass tappet through

B

guide.

5. Check correct position of tappet (specified setting 23 ± 0.5 mm) from inside of

tank. When checking, make sure that the lever of the operating mechanism is

at the limit stop.

Limit stop: With the tappet guide inser ted it should not be possible to turn the

lever any further in direction of arrow.

If required re-adjust position of tappet by pushing in or pulling out the tappet

until the specified setting is attained.

C

B

B

4

3

B

C B

3

B

Attention

After adjusting the tappet fix it firmly to the clevis by fastening the nut on

the tappet (see Fig. 3)

6. Screw fixing studs for the bottom valve inside the tank into the valve mounting

C

flange . Put gasket and guide onto the seating for the bottom valve and then fit

bottom valve . When putting bottom valve in place make sure that the tappet

D

D

extends into the central recess in the valve disc. Tighten nuts in steps to a torque

of 90 Nm.

15

Page 16

Bottom Valve with Operating Mechanism – continued –

See Fig. 5

6

7. Attach suppor t to operating mechanism by using a pin.

8. Position base plates and with shaft and as specified on page 6

(for dimensions refer to Fig. 5 B) to the tank car.

Size connecting sleeves and (not included in GESTRA consignment)

A

L

L

R

L

4

A

5

A

according to the formulae for length X =

ends with holes as specified in Fig. 5 (∅ 10

1

9. Put lever onto shaft . The linear size of the connecting rod should be

420 – 450 mm (cf. Fig. 5 B) for basic adjustment. Attach connecting rod to

levers and . Put connecting sleeves and between base plates

and and shaft .

A

1

A

R

L

1

B

7

A

7

A

B

L1

L

L

– 168 and Y =

2

H11

mm).

4

A

R1

L

L

– 230 and provide their

2

2

A

5

A

2

A

Attention

1

Make sure that lever is at the limit stop.

B

L

L

7

Mark position of hole on shaft for pin of lever . Withdraw connecting sleeves

4

A

and . Remove shaft from support and connecting rod from

lever . Drill a hole ∅ 10

5

A

1

A

A

7

A

H11

mm at the marking in the shaft using a

1

A

6

A

7

A

2

A

pillar drilling machine.

7

10.Mount shaft in support . Put lever onto shaft and secure with a pin.

Place connecting sleeves and between shafts and . Attach

connecting rod to levers and . If the connecting rod does not fit

A

2

A

properly turn the setting screws to adjust the correct linear size.

6

A

4

A

A

1

A

3

A

1

A

5

1

B

7

A

L1

L

R1

L

2

A

Attention

2

After the adjustment re-tighten firmly all nuts of the connecting rod .

Note that one of the two threaded rods fitted in the connecting rod

A

2

A

features a left-hand thread.

11.The two indicators must point to the position CLOSED (see Fig. 5 A). Attach

connecting sleeves and to shafts and using a pin and a split pin.

Drill a hole ∅ 10

5

A

and by means of a pin and split pin.

12.Turn the locking hook clockwise. Pull the hand lever towards the indicator

and connect the hand lever with the indicator. Press down the hand lever to

open the bottom valve. When the valve is open the locking hook engages

into the locking guide , keeping the bottom valve in the open position.

When the valve is open the lift of the valve disc must be 37

N

hook does not engage at the rear of the locking guide grind off the bottom

M

4

A

H11

mm in shaft . Attach shaft to connecting sleeves

N K M

N

5

A

7

A

1

L1

L

R1

L

Y

N

-2

mm. If the locking

1

N

4

A

K

edge of the locking guide until the locking hook engages.

16

Page 17

Vent valve and standpipe (internal gas balance pipe)

see Fig. 4

1. Weld support from inside into the tank top, taking spacing specifications

F

(59 ± 2) into account. The support is not par t of the GESTRA consignment. We

recommend using a pipe (168.3x4.5 mm) as suppor t.

Attention

The grooves (145x18 mm – cf. Fig. 4) of the support have to be crosswise

to the longitudinal axis of the tank.

2. Weld valve mounting flange or socket for standpipe according to Fig. 4 a and

I

4b into the tank bottom.

3. Weld pipe end with flange for mounting the vent valve to the internal standpipe.

Attention

X

Guide has to be in alignment with the centre line of the bottom valve.

4. Mount vent valve with operating rod onto the flange before fitting the

G W

standpipe in the tank. To do that, put the gasket onto the seating surface of the

flange and then tighten the four cheese-head screws to fix the vent valve firmly in

place. Tightening torque 50 Nm

5. Attach the standpipe with the vent valve to support . Put a gasket onto the valve

F

mounting flange or tank socket and secure the standpipe with the vent valve by

using bolts.

6. Screw operating rod to vent valve using washers and nuts (see Fig. 4).

Screw lock nut onto operating rod up to the end of thread.

Screw connecting sleeve onto operating rod , taking specified setting

GW

WV

WU

(30 ± 1 mm) into account.

7. Put bayonet base cap onto bayonet socket pipe and insert square connecting

piece into bayonet base cap .

RS

OR

8. The length of the connecting rod (not part of the GESTRA consignment) is found

by adding the linear size Z (distance between connecting sleeve and square

connecting piece ) to the depth of insertion (2x15 mm). From this it follows that

S

U

the length of the connecting rod = linear size Z + 30 mm.

(Rule of thumb for determining the size of the connecting rod: Inside diameter of

tank minus 650 mm; the exact sizing should be effected when fitting the

connecting rod.)

9. Remove connecting sleeve and square piece .

SU

Cut the connecting rod (∅ 22 mm, made of carbon steel or, in case of austenitic

design, of DIN material 1.4305 or equivalent) to the respective length and weld it

to the connecting sleeve and square piece .

Connecting sleeve and square piece (at weld area) are made of:

SU

SU

Standard design: Forged steel C22.8 (DIN no. 1.0460)

Austenitic design: S. S. type X6CrNiTi 1810 (DIN no. 1.4541)

17

Page 18

Vent valve and standpipe (internal gas balance pipe) – continued –

10.Use operating rod to open the vent valve . Fix it in place by inserting a

suitable fixing pin (∅ 4 mm) into the hole above the guide .

Pass connecting rod into the guide pipe of the bayonet base cap and

screw it into the connecting sleeve by turning it to the r ight until the

T R

U

adjustment setting 30±1 mm is attained. Tighten lock nut , remove fixing

pin and close the vent valve .

G

GW

X

V

Checking the adjustment

The square piece has to protrude 15 +2 mm from the guide pipe.

S

It must be easily possible to push the complete operating rod assembly

(connecting rod and operating rod weigh approx. 8 kg) smoothly approx.

6 mm upwards (vent valve does not open yet, i.e. idle lift).

If this is not possible modify the adjustment setting in such a way that the

specified setting (15

(6±0.5 mm) is also taken into account. Secure the bayonet base cap by

using hexagon-head bolts M8x40 and nuts M8 .

T W

G

+2

mm) is maintained and the idle lift of the valve

PQ

R

18

Page 19

Maintenance

Attention

Before carrying out any maintenance work inside the tank make sure that

the latter is accessible and sufficiently aearated.

After servicing check the adjustments as specified in the section

“Installation”.

We recommend to replace the gaskets of the bottom valve and the vent valve after

every tank inspection.

Tools

For installation and maintenance work use tools commonly used by fitters and

mechanics.

Bottom Valve: Replacing Gasket

See Fig. 2, 4, 6

1. Loosen connecting rod (linked with and ) from bottom valve.

2. Unscrew fixing bolts of bayonet base cap . Pull bayonet base cap out of the

bayonet socket pipe .

3. Use manual operating mechanism to open the bottom valve.

1

4. Fix valve disc by inserting a pin ∅ 5 mm into the hole .

D

5. Use manual operating mechanism to close the bottom valve. The valve disc is

kept in the open position by virtue of the fixing pin.

6. Remove valve disc with guide and spring from bayonet socket pipe.

7. Check adjustment setting 23±0.5 mm at tappet of the operating mechanism

(see Fig. 2) and, if necessary, adjust the tappet as described in the section

“Installation”.

8. Undo the three hexagon-head screws fastening the mounting base to the

valve disc . Remove the mounting base and gasket .

1

D

9. Put new gasket into the valve disc, place mounting base onto the valve disc

and fasten the three hexagon-head screws; torque required for tightening:

18 Nm.

10.Put valve disc with guide and spring into the bayonet socket pipe and guide

into the bayonet base cap.

11.Push hand lever in the opening position.

T S U

O

1

D

1

R

R

Y

3

B

2

D

3

D

Z

3

D

3

D

R

Attention

3

Make sure that the tappet extends into the recess in the valve disc.

B

19

Page 20

Bottom Valve: Replacing Gasket – continued –

12.Remove fixing pin from the hole and close the bottom valve.

13.Put bayonet base cap into bayonet socket pipe and secure with bolts.

R O

Y

14.Attach connecting rod to bottom valve.

Required spare parts:

Designation Material Ref. no.

Gasket FPM 049230

Gasket PTFE 048571

Please state the reference number when ordering these parts at GESTRA.

Operating Mechanism: Retightening Stuffing Box

See Fig. 7

Normally it is not necessary to re-tighten the stuffing box between tank car

inspections.The stuffing box is, to a certain degree, self-tightening.

Inserting additional packing ring:

2

1. Undo screwed union , six-point socket of spanner: 55 A. F

B

2. Take disk springs and pressure pad off the stuffing box.

3. Insert additional packing ring.

4. Put gland and disk springs onto the stuffing box.

2

5. Fasten screwed union to stuffing box and preload disk springs.

B

Required spare parts:

Designation Material Ref. no.

Packing PTFE 048648

Please state the reference number when ordering these parts at GESTRA.

Vent Valve: Exchanging Gasket

See Fig. 4, 8

1. Loosen connecting rod (linked with and ) from the bottom valve.

T S U

2. Detach internal gas balance pipe from valve mounting flange or pipe socket.

3. Undo the four fixing screws of the vent valve.

2

4. Detach the connecting rod from the driving pin of the vent valve.

3

5. Remove bayonet base cap by pulling it down and turning it anticlockwise out

of the bayonet socket pipe .

G

4

G

G

20

Page 21

Vent Valve: Exchanging Gasket – continued –

Attention

3

Note that the bayonet base cap is spring loaded.

– Spring force when spring is mounted: 140 N

– Length of unloaded spring : 157 mm

6

6. Unscrew nut , using a hexagon socket spanner for holding the cheese head

G

bolt .

7. Remove retaining plate and gasket from valve disc .

8. Insert new gasket in valve disc . Attach retaining plate and spring disk

G

7

8

G

G

to valve disc using cheese head bolts and nuts. Torque required for

G

5

G

9

G

10

7

G

10

G

8

G

tightening: 30 Nm.

5

9. Put spring onto spring disk and press bayonet base cap against the spring

until the pins engage in the corresponding J-shaped slots of the bayonet socket

pipe . Then rotate the bayonet base cap clockwise until its pins are seated

G

4

G

3

G

firmly in the slots.

2

10.Attach operating rod and driving pin to the vent valve.

G

11.Put a new gasket on the vent valve and fix it to the gas balance pipe with four

socket-head cap screws, torque required for tightening: 50 Nm.

12.Mount gas balance pipe with vent valve to the valve mounting flange or pipe

socket of the tank.

13.Attach connecting rod to bottom valve.

Required spare parts:

Designation Material Ref. no.

Gasket FPM 008372

Gasket PTFE 008860

Gasket Centellen 048597

Please state the reference number when ordering these parts at GESTRA.

21

Page 22

Operation

Opening the loading and unloading system EV 30

See Fig. 1, 3, 5

1. Turn locking hook clockwise upwards to unlock the hand lever .

2. After unlocking the hand lever pull the latter with both hands towards the

indicator until they are firmly interlocked.

M

3. Release the locking hook and open the bottom valve with the interlocking vent

valve by pulling down the hand lever. In this position the locking hook will

automatically engage at the rear of the locking guide , thereby keeping the

valves open.

4. The indicator visually indicates on both sides of the tank car that the valves

are open.

Closing the loading and unloading system EV 30

See Fig. 1, 3, 5

Attention

N K

K

N

N

M

1

N

Note that hand lever is spring-loaded. In case of improper handling the

K

lever may spring upwards.

1. Push hand lever in the opening position. Turn the locking hook clockwise

upwards until the hook disengages from the locking guide .

2. Move the hand lever slowly upwards to close the valve system.

3. Push back hand lever with both hands (disengaging indicator ) until the

locking hook engages.

4. The indicator visually indicates on both sides of the tank car that the valves

K N

K

K M

N

M

1

N

are closed.

22

Page 23

23

Page 24

GESTRA Gesellschaften · GESTRA Companies · Sociétés GESTRA · Sociedades Gestra · Società GESTRA

GESTRA Gesellschaften · GESTRA Companies · Sociétés GESTRA · Sociedades Gestra · Società GESTRA

Vertretungen weltweit · Agencies all over the world · Représentations dans le monde entier · Representaciones en todo el mundo · Agenzie in tutto il mondo

Vertretungen weltweit · Agencies all over the world · Représentations dans le monde entier · Representaciones en todo el mundo · Agenzie in tutto il mondo

España

España

GESTRA ESPAÑOLA S.A.

GESTRA ESPAÑOLA S.A.

Luis Cabrera, 86-88

Luis Cabrera, 86-88

E-28002 Madrid

E-28002 Madrid

Tel. 003491/5 152032

Tel. (091) 5 152032

Fax0 03491/413 6747; 515 2036

Fax (091) 4 136 747; (091) 5152036

E-mail: gestra@gestra.es

France

France Portugal

GESTRA S.A.R.L.

10 Avenue du Centaure, BP 8263

Flowserve Flow Control S.A.S.

F-95801 CERGY PONTOISE

10 Avenue du Centaure, BP 8263

Tél. (01) 34.43.26.60

F-95801 CERGY PONTOISE CEDEX

Fax (01) 34.43.26.87

Tél. 0 0331/34432660

Fax 00331/34432687

Italia

E-mail: gnation@flowserve.com

Polska

Polska

GESTRA POLONIA Spolka zo.o.

GESTRA POLONIA Spolka z o. o.

Ul. Schuberta 104, P.O. Box 71

Ul. Schuberta 104

PL-80-172 Gdansk

PL-80-172 Gdansk

Tel. 004858/ 30610 02 oder 30610 10

Tel. (058) 306 10 02

Fax 00 4858 /3061003 oder 3063300

Fax (058) 306 10 03

E-mail: gestra@gestra.pl

Portugal

GESTRA PORTUGUESA VALVULAS LDA.

Av. Dr. Antunes Guimarães, 1159

GESTRA PORTUGUESA VALVULAS LDA.

P-4100 Porto

Av. Dr. Antunes Guimarães, 1159

Tel. (02) 6 10 75 51

Porto 4100-082

Fax (02) 6 10 75 75

Tel. 0035122/ 619 87 70

Fax 0035122/6107575

E-mail: gestra@gestra.pt

ITALGESTRA S.r.l.

Via Carducci 125

Italia

l-20099 S.S. Giovanni (MI)

Tel. (02) 2 62 97-0

Italgestra S.r.l.

Fax (02) 26 2974 60

Via Carducci 125

l-20099 Sesto San Giovanni (MI)

Tel. 003902/ 241012.1

Fax 00 3902 /241012.460

E-mail: info@italgestra.it

®

®

GESTRA GmbH

GESTRA GmbH

Postfach 10 5 460

Postfach 10 54 60

D-28054 Bremen

D-28054 Bremen

Hemmstraße 130

Münchener Str. 77

D-28215 Bremen

D-28215 Bremen

Tel. + 49 (0) 421 35 03- 0

Tel. +49 (0) 421 3503-0

Fax +49 (0) 421 35 03-393

Fax+49 (0) 421 35 03-393

Internet www.gestra.de

E-mail

gestra.gmbh@gestra.de

E-mail

gestra.gmbh@gestra.de

Internet www.gestra.de

A Unit of Flowserve Corporation

An Invensys company

810496-00/1299c · ©1997 GESTRA GmbH · Bremen · Printed in Germany

24

Loading...

Loading...