Page 1

11444 Deerfield Road

Cincinnati, Ohio 45242

(513) 489-7800

FAX (513) 489-5243

ESP-DC Electronic Servo Positioner

Installation & Operating Instructions

Automax electric actuators with servo control are

factory adjusted for 90 degree operation and

shipped in the full clockwise position as viewed

from the motor side.

ESP-DC Configuration

The ESP-DC board provides a variety of options for

the user. These options are made available with the

configuration of the jumpers JP1-JP6. See the table

at the bottom of this page for a summary of the

available configurations.

Servo Control Input Options

1 Connect input signal to terminals marked +IN

and -IN on the junction block J3.

A 4-20mA Current Input (100 Ohm sink) - JP1

set to "A" (left) position. This is supplied as

standard.

B 2-10 Vdc Input - JP1 set to "B" (right)

position.

Direct or Reverse Acting

1 Standard units are direct acting:

Low input (e.g. 4 mA) = CW*

High input (e.g. 20 mA) = CCW*.

2 To make reverse acting, move jumper JP2 to

the 'R' (right) position.

Fault Detection and Action

1 FAULT conditions occur when the torque of the

DC motor exceeds a preset maximum value.

This feature is used to protect the valve

hardware, the actuator hardware, and alert the

user that there may be an obstruction in the

valve. When a fault occurs, the LED labeled

'FLT' will be lit, and the actuator will stop. The

actuator must receive a signal to drive in the

opposite direction in order to reset the FAULT

condition.

*

2 By running a wire to the FLT terminal strip

location on junction block J3, a signal can be

returned to indicate if a FAULT occurs. Jumper

JP3 can be used to set the FLT terminal output

to the following:

A High - Jumper JP3 set to "P" (left) connects

the FLT terminal to the Power Supply "+"

when a FAULT condition occurs.

B Low - Jumper JP3 set to "N" (right) shorts

the FLT terminal to the Power Ground "-"

when a FAULT condition occurs.

Low Power Operation

1 The factory configures the ESP-DC for full

functionality. If low power consumption is

required, the FLT output and the LED's may be

disabled.

A FLT - to disable the FLT output, move JP4

to the "N" (right) position.

B LED's - to disable the LED's, move JP5 to

the "N" (right ) position.

Loss of Input Signal

1 If the input signal to the actuator is lost, the

ESP-DC is configured to turn full CW* as a

safety precaution.

2 The Loss of Input action above can be disabled

by setting JP6 to the "S" (lower) position. In

this case the actuator will simply stop if the

Input Signal is lost.

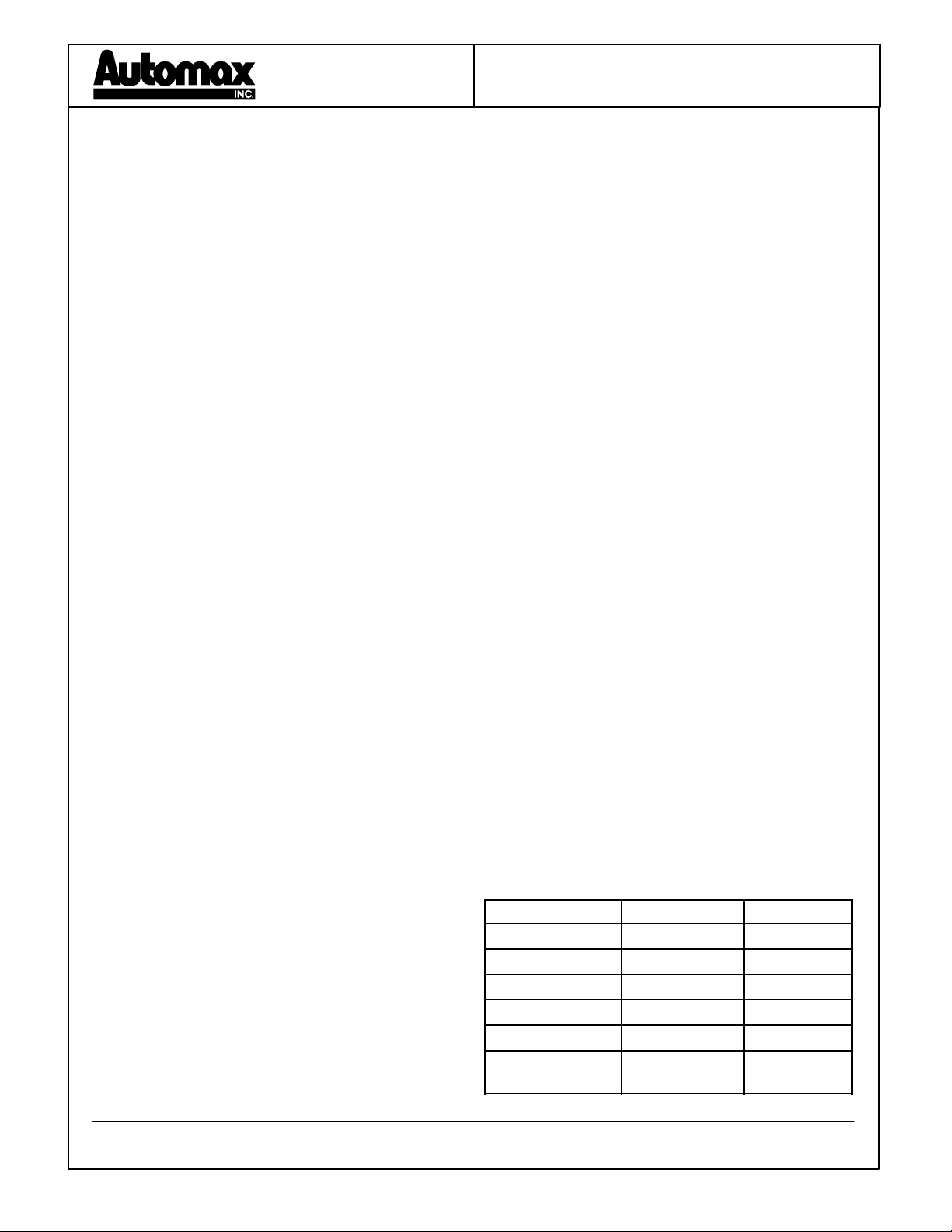

ESP-DC Jumper Configuration

JUMPER Factory Setting Option

JP1 - INPUT A : 4-20mA B : 2-10 Vdc

JP2 - ACTION D : Direct R : Reverse

JP3 - FLT output P : +Vcc N : GND

JP4 - FLT enable Y : Enable N : Disable

JP5 - LED enable Y : Enable N : Disable

JP6 - Loss of

Input

R : Full CW* S : Stop

* For Reverse Acting, the CW and CCW directions marked with a * are reversed.

B00156-0 Page: 1 of 4

Page 2

11444 Deerfield Road

Cincinnati, Ohio 45242

(513) 489-7800

FAX (513) 489-5243

ESP-DC Electronic Servo Positioner

Valve Alignment and Servo Calibration

1 Connect DC power to terminals marked '+' and

'-' to junction block J3. The DC power supply

should be the same voltage as the actuating

motor (12 or 24 Vdc).

2 Safety overtravel switches disconnect the

motor if the actuator overtravels approximately

5 degrees past the full CW or CCW position.

On valves with mechanical stops, the safety

overtravel switches need to be set so that the

motor will disconnect prior to hitting a

mechanical valve stop. See note 3 under

"Trouble Shooting" on page 3 before

adjustment.

3 Minimum Position Adjustment:

Apply minimum input signal to ESP-DC terminals

+IN and -IN and adjust zero 'Z' potentiometer

until actuator stops at full CW* position and

CW** LED turns off. Turn the 'Z' adjustment CW

to move actuator CW* .

4 At the minimum signal position, the voltage from

test point TP1 to TP5 should be approximately

0.15 Vdc. If not, see note 4 under "Trouble

Shooting".

5 Maximum Position Adjustment:

Apply maximum input signal to ESP-DC and

adjust span 'S' potentiometer until actuator

stops at full CCW* position and CCW* LED

turns off. Turn the 'S' adjustment CCW to

move the actuator CCW.

6 Due to zero-span interaction, repeat steps 3

and 5 until actuator positions repeat at both

ends of travel (usually 2 to 3 times).

ESP-DC Transmitter (optional)

Note: If the ESP-DC Transmitter is used, the valve

alignment and servo calibration must be completed

with the 4-20mA transmitter installed. Servo

calibration should be performed before transmitter

calibration.

1 Connect 4-20mAdc output leads to transmitter

terminals marked '+' and '-'.

2 For 90` operation, the two jumpers on the

transmitter should be set to connect pins 1 and

3 , and pins 2 and 4. For 180` rotation, the

jumpers should connect pins 1 and 2, and pins

3 and 4.

3 Drive actuator to the full CCW position and

adjust 'S' span adjustment of the ESP-DC

Transmitter for 20mA output.

4 Drive actuator to the CW position and adjust 'Z'

zero adjustment of the ESP-DC Transmitter for

4mA output.

5 Repeat steps 3 and 4 until the desired output is

achieved at both positions. If there is difficulty

achieving the desired range, see note 4 under

Trouble Shooting on page 3.

6 Standard ESP-DC Transmitters are direct

acting.

Important Notes About Reverse Acting

ESP-DC with Transmitter

Note: Reverse acting transmitter means a 4mA

output for full CCW, and a 20mA output for full

CW position.

7 If you are using a positioner that is not factory

calibrated for reverse acting with a transmitter,

you will need to order an Adapter Kit #108921.

SPEED and TORQUE adjustments

1 The SPEED potentiometer can be adjusted to

increase (CW) or decrease (CCW) the Speed

of the actuator.

2 The TORQUE potentiometer can be adjusted to

Lower (CCW) or Raise (CW) the maximum

torque output of the actuator before a FAULT

condition occurs. The factory setting is full CW

(maximum Torque).

8 If you have specified a reverse acting ESP-DC

with a transmitter, JP2 is to be set on the 'D'

right position.

A The feedback potentiometer voltages as

measured from test points TP1 to TP5 on

the ESP-DC card are as follows:

FULL CCW ~ 0.15 Vdc

FULL CW ~ 1.42 Vdc

The drive LED's will now indicate the opposite of

the actual drive travel.

* For Reverse acting, the CW and CCW directions marked with a * are reversed.

B00156-0 Page: 2 of 4

Page 3

11444 Deerfield Road

Cincinnati, Ohio 45242

(513) 489-7800

FAX (513) 489-5243

ESP-DC Electronic Servo Positioner

Trouble Shooting

Note: All of the Test Point voltage

measurements are taken in reference to test

point TP5 labeled "REF."

1 Actuator does not respond to the input signal.

A Verify proper input configuration and signal

polarity connections. Measure voltage at

TP4 and verify it's in the range .4 to 2.0 Vdc.

B Verify the proper power connections. Refer

to the schematic on page 4.

2 Actuator does not travel when CW or CCW

LED is lighted.

A Check the safety overtravel cams and

overtravel switches, and adjust as needed

(see note 3).

B If actuator exceeds full CW or CCW

positions, check the feedback potentiometer

voltage (see note 4).

3 Safety overtravel switches need adjustment.

Note: On valves with mechanical stops, the

safety overtravel switches must be set so that

the motor will disconnect prior to hitting the

mechanical valve stops.

A Disconnect the actuator power connector J1

from the ESP-DC.

B Drive the motor to 5 degrees past full CW by

placing DC power directly on the terminal of

the actuator electric motor. To drive the

motor CW, place +DC on the terminal with

the red wire. Be careful not to drive the

actuator into any mechanical stops. This

may damage the actuator and the valve.

Set the CW cam so the overtravel switch

trips.

C While setting CW safety overtravel switch,

ensure a voltage between 0.10Vdc and

0.20Vdc is measured at test point TP1

when switch is tripped. Otherwise see note

4 in this section.

from B. Adjust CCW cam (bottom) until

switch trips.

4 With the actuator in full CW position, the

feedback potentiometer voltage should read

approximately 0.15 Vdc at TP1. If the feedback

potentiometer is not set correctly, the "dead

spot" at the end of the pot's rotation may cause

over/under travel or a lack of transmitter range.

A Loosen potentiometer drive gear and rotate

potentiometer until approximately 0.15 Vdc

is measured at TP1, and then re-tighten

drive gear.

B Recalibrate ESP-DC Zero and Span

adjustments, starting with Step 3 on page 2.

5 Actuator is oscillating or is not responsive to

small input changes, the Dead Band 'DB'

potentiometer may need adjusting.

A Drive actuator to mid position and turn DB

CCW until both LED's energize, then

immediately turn CW until both LED's

de-energize. Turn adjustment CW an

additional 1/4 turn and operate actuator over

full range in small increments to check

operation. Voltage from test point TP2

should measure approximately 0.10 Vdc.

6 The FLT LED is lit and the actuator won't move:

The FLT LED indicates a FAULT condition,

where the actuator is drawing too much current.

Check the TORQUE potentiometer setting,

turning CW to increase the FAULT current limit,

Drive the actuator in the reverse direction to

reset . If this doesn't work, there may be an

obstruction in the valve.

7 Special precautions for operating the ESP-DC.

A It is always necessary to limit actuator from

repeated safety overtravel switch trippage.

B Always remove DC power to actuator, prior

to removing input signal, and apply signal

prior to applying DC power to actuator.

D Drive the actuator CCW until approximately

5 degrees past the standard full CCW

position by applying power to the motor

terminals, this time with the opposite polarity

B00156-0 Page: 3 of 4

Page 4

Performance Data

LINEARITY 1%

RESOLUTION 1.0 `

DEADBAND 1%

HYSTERESIS 0.5 %

11444 Deerfield Road

Cincinnati, Ohio 45242

(513) 489-7800

FAX (513) 489-5243

ESP-DC Electronic Servo Positioner

INPUT 4-20 mA

+

POWER SUPPLY

12/24 Vdc

TP1

FB

TP2

DB

TP3

OUT

TP4

IN

TP5

REF

DB

Z

S

JP1

Is

+IN

-IN

FLT

+

-

ESP-DC TRANSMITTER

+

-

JP4

Y N

P

JP3

J4

TORQUE

N

SPAREFUSE

JP2

R D

A

B

J5

JP6 R

S

Z S

JP5 Y

N

CW CCW FLT

SPEED

GREEN

YELLOW

BLUE

TO FEEDBACK POT.

TO MOTOR

Fig. 1 ESP-DC wiring diagram

11444 Deerfield Road

Cincinnati, Ohio 45242

(513) 489-7800

Fax (513) 489-5243

B00156-0 Page: 4 of 4

Service Center

4214 Bluebonnet Drive

Stafford, Texas 77477

(713) 240-7484

Fax (713) 240-7097

Service Center

7445 Whitepine Road

Richmond Virginia 23237

(804) 271-7800

Fax (804) 271-0155

Automax Controls, Inc.

120 Vinyl Court

Woodbridge, Ontario L4L 4A3

(905) 856-8568

Fax (905) 856-7905

Page 5

11444 Deerfield Road

Cincinnati, Ohio 45242

(513) 489-7800

FAX (513) 489-5243

Calibration Voltages

Actuator Angle TP1 Voltage

-10` Mechanical Stop

-5` Safety Overtravel Switch 0.10

0` CW Position

(4mA Direct)

(20mA Reverse)

90` CCW Position

(20mA Direct)

(4mA Reverse)

95` Safety Overtravel Switch 1.50

100` Mechanical Stop

180` Positioning Option 2.70

0.05

0.15

1.42

1.57

ESP-DC Electronic Servo Positioner

Technical Assistance

If technical assistance is required, please

have the following information ready

before calling:

A) Actuator model number.

B) Actuator serial number.

C) Actuator sales order number.

D) Input signal configuration used.

B00156-0 Page: 5 of 4

Loading...

Loading...