Page 1

USER INSTRUCTIONS

ESP3 Vertical Immersion Sump Pump

Mark 3 Standard, Lo-Flo and Recessed Impeller Hydraulics

PCN=26999943 – 08-11 (E)

Original Instructions

Installation

Operation

Maintenance

Page 2

ESP3 USER INSTRUCTIONS ENGLISH 26999943 08-11

of 64

CONTENTS

Page

1 INTRODUCTION AND SAFETY ...........................3

1.1 General ...........................................................3

1.2 CE marking and approvals..............................3

1.3 Disclaimer .......................................................3

1.4 Copyright.........................................................3

1.5 Duty conditions................................................3

1.6 Safety..............................................................4

1.7 Name plate and safety labels..........................7

1.8 Specific machine performance........................7

1.9 Noise level.......................................................7

2 TRANSPORT AND STORAGE.............................9

2.1 Consignment receipt and unpacking...............9

2.2 Handling..........................................................9

2.3 Lifting...............................................................9

2.4 Storage............................................................9

2.5 Recycling and end of product life..................10

3 DESCRIPTION ....................................................10

3.1 Configurations...............................................10

3.2 Nomenclature................................................10

3.3 Design of major parts.................................... 11

3.4 Performance and operation limits.................. 11

4 INSTALLATION ................................................... 17

4.1 Location.........................................................18

4.2 Part assemblies.............................................18

4.3 Foundation .................................................... 18

4.4 Pump Mounting.............................................18

4.5 Mechanical seals and packing......................18

4.6 Driver Mounting.............................................19

4.7 Piping ............................................................ 19

4.8 Final free rotation check................................23

4.9 Auxiliary piping..............................................23

4.10 Electrical connections .................................23

4.11 Level controls ..............................................23

4.12 Protection systems......................................31

6 MAINTENANCE ...................................................37

6.1 Maintenance schedule...................................37

6.2 Spare parts.....................................................38

6.3 Recommended spares and consumable items

7 FAULTS; CAUSES AND REMEDIES..................51

8 PARTS LIST AND DRAWINGS...........................53

9 CERTIFICATION..................................................62

10 OTHER RELEVANT DOCUMENTATION AND

.......................................................................38

6.4 Tools required................................................38

6.5 Fastener torques............................................39

6.6 Setting impeller clearance and impeller

replacement ...................................................40

6.7 Disassembly ..................................................41

6.8 Examination of parts......................................43

6.9 Assembly of pump and seal...........................46

8.1 General arrangement drawing.......................62

MANUALS...........................................................62

10.1 Supplementary User Instructions ................62

10.2 Change notes ..............................................62

10.3 Additional sources of information ................62

Page

5 COMMISSIONING, STARTUP, OPERATION AND

SHUTDOWN ......................................................31

5.1 Pre-commissioning procedure......................31

5.2 Bearing Lubrication ....................................... 31

5.3 Impeller clearance.........................................34

5.4 Direction of rotation.......................................34

5.5 Guarding .......................................................34

5.6 Priming and auxiliary supplies ......................34

5.7 Starting the pump..........................................34

5.8 Running or operation ....................................35

5.9 Stopping and shutdown.................................36

5.10 Hydraulic, mechanical and electrical duty...36

Page 2

Page 3

ESP3 USER INSTRUCTIONS ENGLISH 26999943 08-11

of 64

1 INTRODUCTION AND SAFETY

1.1 General

These instructions must always be kept

close to the product's operating location or

directly with the product.

Flowserve products are designed, developed and

manufactured with state-of-the-art technologies in

modern facilities. The unit is produced with great

care and commitment to continuous quality control,

utilizing sophisticated quality techniques, and safety

requirements.

Flowserve is committed to continuous quality

improvement and being at your service for any further

information about the product in its installation and

operation or about its support products, repair and

diagnostic services.

These instructions are intended to facilitate

familiarization with the product and its permitted use.

Operating the product in compliance with these

instructions is important to help ensure reliability in

service and avoid risks. The instructions may not

take into account local regulations; ensure such

regulations are observed by all, including those

installing the product. Always coordinate repair

activity with operations personnel, and follow all plant

safety requirements and applicable safety and health

laws/regulations.

These instructions must be read prior to

installing, operating, using and maintaining the

equipment in any region worldwide. The

equipment must not be put into service until all

the conditions relating to safety noted in the

instructions, have been met. Failure to follow and

apply the present user instructions is considered

to be misuse. Personal injury, damage, delay or

failure caused by misuse is not covered by the

Flowserve warranty.

1.2 CE marking and approvals

It is a legal requirement that machinery and equipment

put into service within certain regions of the world shall

conform with the applicable CE Marking Directives

covering Machinery and, where applicable, Low Voltage

Equipment, Electromagnetic Compatibility (EMC),

Pressure Equipment Directive (PED) and Equipment for

Potentially Explosive Atmospheres (ATEX).

Where applicable, the Directives and any additional

Approvals, cover important safety aspects relating to

machinery and equipment and the satisfactory provision

of technical documents and safety instructions. Where

applicable this document incorporates information

relevant to these Directives and Approvals.

To confirm the Approvals applying and if the product is

CE marked, check the serial number plate markings

and the Certification. (See section 9, Certification.)

1.3 Disclaimer

Information in these User Instructions is believed

to be complete and reliable. However, in spite of

all of the efforts of Flowserve Corporation to

provide comprehensive instructions, good

engineering and safety practice should always be

used.

Flowserve manufactures products to exacting

International Quality Management System Standards

as certified and audited by external Quality

Assurance organizations. Genuine parts and

accessories have been designed, tested and

incorporated into the products to help ensure their

continued product quality and performance in use.

As Flowserve cannot test parts and accessories

sourced from other vendors the incorrect

incorporation of such parts and accessories may

adversely affect the performance and safety features

of the products. The failure to properly select, install

or use authorized Flowserve parts and accessories is

considered to be misuse. Damage or failure caused

by misuse is not covered by the Flowserve warranty.

In addition, any modification of Flowserve products or

removal of original components may impair the safety

of these products in their use.

1.4 Copyright

All rights reserved. No part of these instructions may

be reproduced, stored in a retrieval system or

transmitted in any form or by any means without prior

permission of Flowserve.

1.5 Duty conditions

This product has been selected to meet the

specifications of your purchaser order. The

acknowledgement of these conditions has been sent

separately to the Purchaser. A copy should be kept

with these instructions.

The product must not be operated beyond

the parameters specified for the application. If

there is any doubt as to the suitability of the

product for the application intended, contact

Flowserve for advice, quoting the serial number.

If the conditions of service on your purchase order are

going to be changed (for example liquid pumped,

Page 3

Page 4

ESP3 USER INSTRUCTIONS ENGLISH 26999943 08-11

of 64

temperature or duty) it is requested that the user seeks

the written agreement of Flowserve before start up.

1.6 Safety

1.6.1 Summary of safety markings

These User Instructions contain specific safety

markings where non-observance of an instruction would

cause hazards. The specific safety markings are:

This symbol indicates electrical safety

instructions where non-compliance will involve a high

risk to personal safety or the loss of life.

This symbol indicates safety instructions where

non-compliance would affect personal safety and

could result in loss of life.

This symbol indicates “hazardous and toxic fluid”

safety instructions where non-compliance would affect

personal safety and could result in loss of life.

This symbol indicates safety

instructions where non-compliance will involve some

risk to safe operation and personal safety and would

damage the equipment or property.

This symbol indicates explosive atmosphere

zone marking according to ATEX. It is used in safety

instructions where non-compliance in the hazardous

area would cause the risk of an explosion.

1.6.3 Safety action

This is a summary of conditions and actions to

help prevent injury to personnel and damage to

the environment and to equipment. For products

used in potentially explosive atmospheres

section 1.6.4 also applies.

NEVER DO MAINTENANCE WORK

WHEN THE UNIT IS CONNECTED TO POWER

(Lock out.)

DRAIN THE PUMP AND ISOLATE PIPEWORK

BEFORE DISMANTLING THE PUMP

The appropriate safety precautions should be taken

where the pumped liquids are hazardous.

FLUOROELASTOMERS (When fitted.)

When a pump has experienced temperatures over

250 ºC (482 ºF), partial decomposition of

fluoroelastomers (example: Viton) will occur. In this

condition these are extremely dangerous and skin

contact must be avoided.

HANDLING COMPONENTS

Many precision parts have sharp corners and the

wearing of appropriate safety gloves and equipment

is required when handling these components. To lift

heavy pieces above 25 kg (55 lb) use a crane

appropriate for the mass and in accordance with

current local regulations.

This symbol is used in safety instructions to

remind not to rub non-metallic surfaces with a dry

cloth; ensure the cloth is damp. It is used in safety

instructions where non-compliance in the hazardous

area would cause the risk of an explosion.

This sign is not a safety symbol but indicates

an important instruction in the assembly process.

1.6.2 Personnel qualification and training

All personnel involved in the operation, installation,

inspection and maintenance of the unit must be

qualified to carry out the work involved. If the

personnel in question do not already possess the

necessary knowledge and skill, appropriate training

and instruction must be provided. If required the

operator may commission the manufacturer/supplier

to provide applicable training.

Always coordinate repair activity with operations and

health and safety personnel, and follow all plant

safety requirements and applicable safety and health

laws and regulations.

NEVER OPERATE THE PUMP WITHOUT THE

COUPLING GUARD AND ALL OTHER SAFETY

DEVICES CORRECTLY INSTALLED

GUARDS MUST NOT BE REMOVED WHILE

THE PUMP IS OPERATIONAL

THERMAL SHOCK

Rapid changes in the temperature of the liquid within

the pump can cause thermal shock, which can result

in damage or breakage of components and should be

avoided.

NEVER APPLY HEAT TO REMOVE IMPELLER

Trapped lubricant or vapor could cause an explosion.

HOT (and cold) PARTS

If hot or freezing components or auxiliary heating

equipment can present a danger to operators and

persons entering the immediate area, action must be

taken to avoid accidental contact (such as shielding). If

complete protection is not possible, the machine access

must be limited to maintenance staff only with clear

visual warnings and indicators to those entering the

Page 4

Page 5

ESP3 USER INSTRUCTIONS ENGLISH 26999943 08-11

of 64

immediate area. Note: bearing housings must not be

insulated and drive motors and bearings may be hot.

If the temperature is greater than 80 °C (176°F) or

below -5 °C (23 °F) in a restricted zone, or

exceeds local regulations, action as above shall

be taken.

HAZARDOUS LIQUIDS

When the pump is handling hazardous liquids care

must be taken to avoid exposure to the liquid by

appropriate pump placement, limiting personnel

access and by operator training. If the liquid is

flammable and/or explosive, strict safety procedures

must be applied.

Gland packing must not be used when pumping

hazardous liquids.

PREVENT EXCESSIVE EXTERNAL

PIPE LOAD

Do not use pump as a support for piping. Do not

mount expansion joints, unless allowed by Flowserve

in writing, so that their force, due to internal pressure,

acts on the pump flange.

ENSURE CORRECT LUBRICATION

(See section 5, Commissioning, startup, operation

and shutdown.)

NEVER EXCEED THE MAXIMUM

DESIGN PRESSURE (MDP) AT THE

TEMPERATURE SHOWN ON THE PUMP

NAMEPLATE

See section 3 for pressure versus temperature

ratings based on the material of construction.

NEVER OPERATE THE PUMP WITH

THE DISCHARGE VALVE CLOSED

(Unless otherwise instructed at a specific point in the

User Instructions)

(See section 5, Commissioning start-up, operation

and shutdown.)

NEVER RUN THE PUMP DRY OR

WITHOUT PROPER PRIME (Casing flooded)

NEVER OPERATE THE PUMP WITH

THE SUCTION VALVE CLOSED

It should be fully opened when the pump is running.

NEVER OPERATE THE PUMP AT

ZERO FLOW OR FOR EXTENDED PERIODS

BELOW THE MINIMUM CONTINUOUS FLOW

THE PUMP SHAFT MUST TURN

CLOCKWISE WHEN VIEWED FROM THE MOTOR

END

It is absolutely essential that the rotation of the motor

be checked before installation of the coupling drive

element and starting the pump. Incorrect rotation of

the pump for even a short period can unscrew the

impeller, which can cause significant damage.

1.6.4 Products used in potentially explosive

atmospheres

Measures are required to:

• Avoid excess temperature

• Prevent buildup of explosive mixtures

• Prevent the generation of sparks

• Prevent leakages

• Maintain the pump to avoid hazard

The following instructions for pumps and pump units

when installed in potentially explosive atmospheres

must be followed to help ensure explosion protection.

Both electrical and non-electrical equipment must meet

the requirements of European Directive 94/9/EC.

1.6.4.1 Scope of compliance

Use equipment only in the zone for which it is

appropriate. Always check that the driver, drive

coupling assembly, seal and pump equipment are

suitably rated and/or certified for the classification of

the specific atmosphere in which they are to be

installed.

Where Flowserve has supplied only the bare shaft

pump, the Ex rating applies only to the pump. The

party responsible for assembling the pump set shall

select the coupling, driver, seal and any additional

equipment, with the necessary CE Certificate/

Declaration of Conformity establishing it is suitable for

the area in which it is to be installed.

The output from a variable frequency drive (VFD) can

cause additional heating affects in the motor. On

pump installations controlled by a VFD, the ATEX

Certification for the motor must state that it covers the

situation where electrical supply is from the VFD.

This particular requirement still applies even if the

VFD is in a safe area.

Page 5

Page 6

ESP3 USER INSTRUCTIONS ENGLISH 26999943 08-11

of 64

Temperature

1.6.4.2 Marking

An example of ATEX equipment marking is shown

below. The actual classification of the pump will be

engraved on the nameplate.

II 2 GD c IIC 135ºC (T4)

Equipment Group

I = Mining

II = Non-mining

Category

2 or M2 = High level protection

3 = normal level of protection

Gas and/or dust

G = Gas

D = Dust

c = Constructional safety

(in accordance with En13463-5)

Gas Group

IIA – Propane (Typical)

IIB – Ethylene (Typical)

IIC – Hydrogen (Typical)

Maximum surface temperature (Temperature Class)

(see section 1.6.4.3)

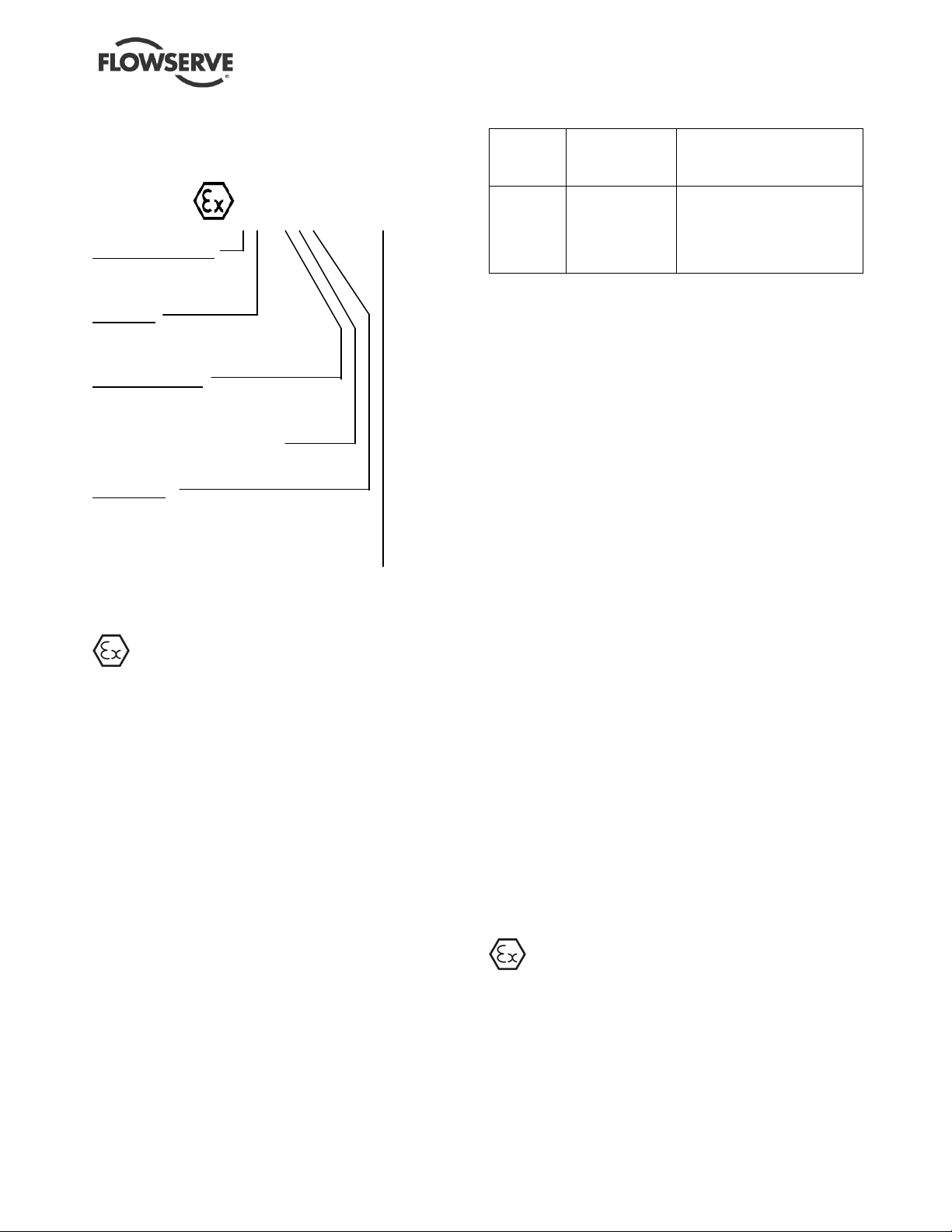

1.6.4.3 Avoiding excessive surface temperatures

ENSURE THE EQUIPMENT TEMPERATURE

CLASS IS SUITABLE FOR THE HAZARD ZONE

Pump liquid temperature

Pumps have a temperature class as stated in the ATEX

Ex rating on the nameplate. These are based on a

maximum ambient temperature of 40 ºC (104 ºF); refer

to Flowserve for higher ambient temperatures.

The surface temperature on the pump is influenced by

the temperature of the liquid handled. The maximum

permissible liquid temperature depends on the

temperature class and must not exceed the values in the

table applicable below.

Maximum permitted liquid temperature for pumps

Maximum

class to

EN 13463-1

T6

T5

T4

T3

T2

T1

* The table only takes the ATEX temperature class into consideration.

Pump design or material, as well as component design or material,

may further limit the maximum working temperature of the liquid.

surface

temperature

permitted

85 °C (185 °F)

100 °C (212 °F)

135 °C (275 °F)

200 °C (392 °F)

300 °C (572 °F)

450 °C (842 °F)

Temperature limit of liquid

handled (* depending on

material and construction

variant – check which is lower)

Consult Flowserve

Consult Flowserve

115 °C (239 °F) *

180 °C (356 °F) *

275 °C (527 °F) *

400 °C (752 °F) *

The temperature rise at the seals and bearings and due

to the minimum permitted flow rate is taken into account

in the temperatures stated.

The responsibility for compliance with the specified

maximum liquid temperature is with the plant

operator.

Temperature classification “Tx” is used when the

liquid temperature varies and the pump could be

installed in different hazardous atmospheres. In this

case the user is responsible for ensuring that the

pump surface temperature does not exceed that

permitted in the particular hazardous atmosphere.

Do not attempt to check the direction of rotation with the

coupling element/pins fitted due to the risk of severe

contact between rotating and stationary components.

Where there is any risk of the pump being run against a

closed valve generating high liquid, casing and

discharge pipe external surface temperatures, fit an

external surface temperature protection device.

Avoid mechanical, hydraulic or electrical overload by

using motor overload trips, temperature monitor or a

power monitor and perform routine vibration monitoring.

In dirty or dusty environments, make regular checks

and remove dirt from areas around close clearances,

bearing housings and motors.

1.6.4.4 Preventing the buildup of explosive

mixtures

Page 6

ENSURE PUMP IS PROPERLY FILLED AND

VENTED AND DOES NOT RUN DRY

Ensure that the pump and relevant suction and discharge

piping is totally filled with liquid at all times during the

pumps operation so that an explosive atmosphere is

prevented. In addition, it is essential to make sure that

seal chambers, auxiliary shaft seal systems and any

heating and cooling systems are properly filled.

Page 7

ESP3 USER INSTRUCTIONS ENGLISH 26999943 08-11

of 64

If the operation of the system cannot avoid this

condition, fit an appropriate dry run protection device

(for example liquid detection or a power monitor).

To avoid potential hazards from fugitive emissions of

vapor or gas to atmosphere, the surrounding area

must be well ventilated.

1.6.4.5 Preventing sparks

To prevent a potential hazard from mechanical

contact, the coupling guard must be non-sparking for

Category 2.

To avoid the potential hazard from random induced

current generating a spark, the baseplate must be

properly grounded.

Avoid electrostatic charge. Do not rub nonmetallic surfaces with a dry cloth; ensure the cloth is

damp.

The coupling must be selected to comply with

94/9/EC and correct alignment must be maintained.

Additional requirements for pumps on nonmetallic baseplates

When metallic components are fitted on a nonmetallic baseplate they must be individually earthed.

1.6.4.6 Preventing leakage

Pumps with mechanical seal: The pump must

only be used to handle liquids for which it has been

approved to have the correct corrosion resistance.

Avoid entrapment of liquid in the pump and associated

piping due to closing of suction and discharge valves,

which could cause dangerous excessive pressures to

occur if there is heat input to the liquid. This can occur if

the pump is stationary or running.

Bursting of liquid containing parts due to freezing

must be avoided by draining or protecting the pump

and auxiliary systems.

Where there is the potential hazard of a loss of a seal

barrier fluid or external flush, the fluid must be monitored.

If leakage of liquid to atmosphere can result in a

hazard, install a liquid detection device.

1.6.4.7 Maintenance of the centrifugal pump to

avoid a hazard

CORRECT MAINTENANCE IS REQUIRED TO

AVOID POTENTIAL HAZARDS WHICH GIVE A

RISK OF EXPLOSION

The responsibility for compliance with maintenance

instructions is with the plant operator.

To avoid potential explosion hazards during maintenance,

the tools, cleaning and painting materials used must not

give rise to sparking or adversely affect the ambient

conditions. Where there is a risk from such tools or

materials, maintenance must be conducted in a safe area.

It is recommended that a maintenance plan and schedule

is adopted. (See section 6, Maintenance.)

1.7 Name plate and safety labels

1.7.1 Nameplate

For details of nameplate, see the Declaration of

Conformity and section 3.

1.7.2 Safety labels

J218JZ250

ESSENTIAL PROCEEDURES BEFORE STARTING:

INSTALL AND OPERATE EQUIPMENT IN

ACCORDAND WITH THE INSTRUCTION

MANUAL SUPPLIED SEPARATELY.

ENSURE GUARDS ARE SECURELY IN

PLACE.

ENSURE CORRECT DIRECTION OF

ROTATION.

ENSURE CORRECT DRIVER DIRECTION

OR ROTATION WITH COUPLING

ELEMENT / PINS REMOVED: OTHERWISE

SERIOUS DAMAGE MAY RESULT.

VERIFIER LE SENS CORRECT DE

ROTATION DU MOTEUR. POMPE

DESACCOUPLEE / ENTRETOISE

DEMONTEE. NE PAS SUIVRE CETTE

RECOMMANDATION PEUT CONDUIRE A

DE GRAVES DOMMAGES POUR LA POMPE

CDC: 603 604 610 612 621 623 624

ENSURE ALL EXTERNAL CONNECTIONS TO

THE PUMP / SHAFT SEALING AND DRIVER

ARE CONNECTED AND OPERATIONAL

FULLY PRIME UNIT AND SYSTEM.

DO NOT RUN UNIT DRY

FAILURE TO FOLLOW THESE PR OCEEDURES

MAY RESULT IN PERSONAL INJURY

AND/ OR EQUIPMENT DAMAGE

J218JZ250

KONTROLLE VORGESCHRIEBENER

DREHRICHTUNG ! HIERZU

KUPPLUNGSZWISCHENSTÜCK /

KUPPLUNGSBOLZEN ENTFERNEN.

ANDERENFALLS ERNSTHAFTE SC HÄDEN !

ZORG VOOR JUISTE ROTATIERICHTING

VAN DRIJFAS WAARBIJ DE

KOPPELELELMENTEN / PENNEN

VERWIJDERD ZIJN: VERZUM KAN

ERNSTIGE SCHADE TOT GEVOLG HABBEN.

1.8 Specific machine performance

For performance parameters see section 1.5, Duty

conditions. Where performance data has been

supplied separately to the purchaser these should be

obtained and retained with these User Instructions if

required

.

Page 7

Page 8

ESP3 USER INSTRUCTIONS ENGLISH 26999943 08-11

of 64

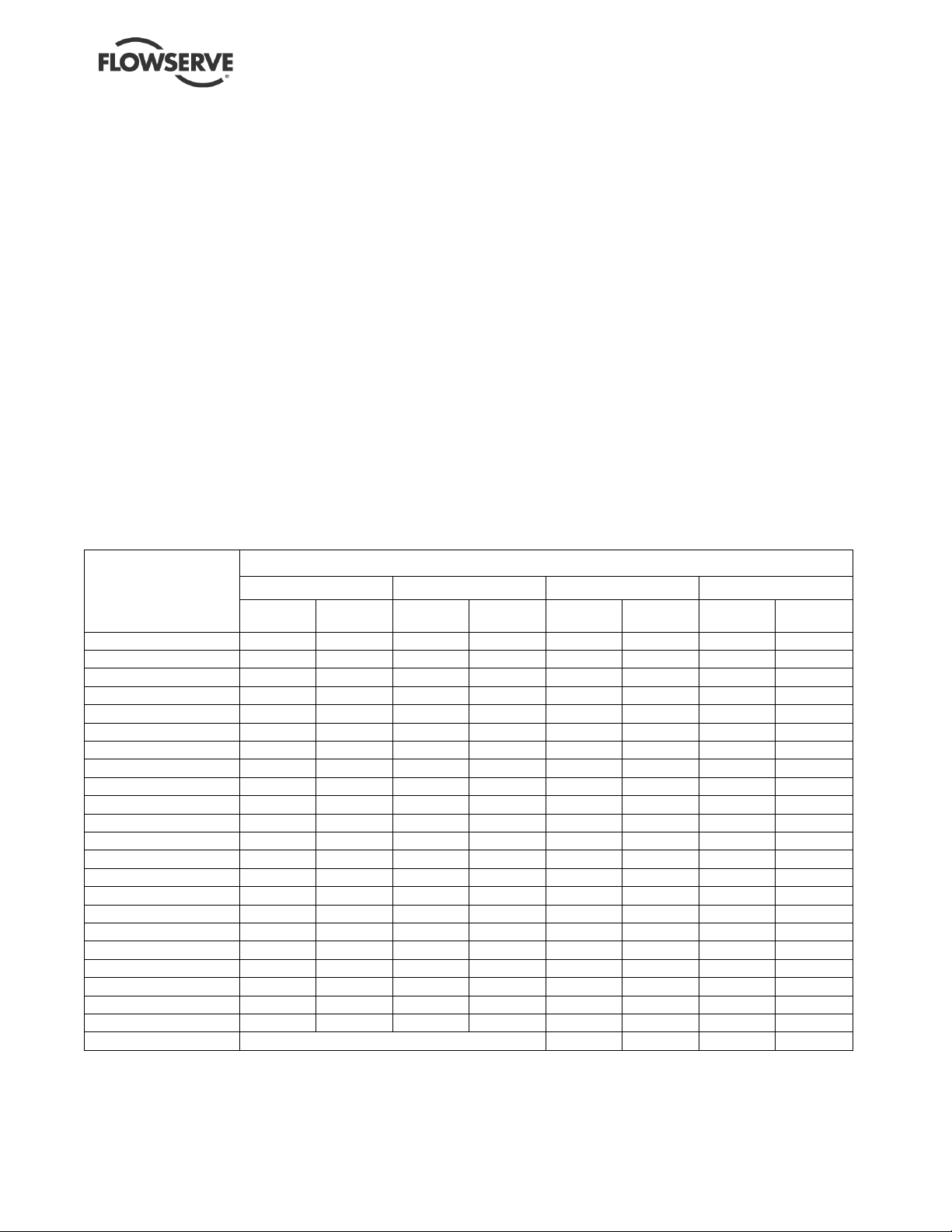

1.9 Noise level

Attention must be given to the exposure of personnel

to the noise, and local legislation will define when

guidance to personnel on noise limitation is required,

and when noise exposure reduction is mandatory.

This is typically 80 to 85 dBA.

The usual approach is to control the exposure time to

the noise or to enclose the machine to reduce emitted

sound. You may have already specified a limiting

noise level when the equipment was ordered,

however if no noise requirements were defined, then

attention is drawn to the following table to give an

indication of equipment noise level so that you can

take the appropriate action in your plant.

Pump noise level is dependent on a number of

operational factors, flow rate, pipe work design and

acoustic characteristics of the building, and so the

values given are subject to a 3 dBA tolerance and

cannot be guaranteed.

Similarly the motor noise assumed in the “pump and

and high efficiency motors when on load directly

driving the pump. Note that a motor driven by an

inverter may show an increased noise at some

speeds.

If a pump unit only has been purchased for fitting with

your own driver then the “pump only” noise levels in

the table should be combined with the level for the

driver obtained from the supplier. Consult Flowserve

or a noise specialist if assistance is required in

combining the values.

It is recommended that where exposure approaches

the prescribed limit, then site noise measurements

should be made.

The values are in sound pressure level LpA at 1 m

(3.3 ft) from the machine, for “free field conditions

over a reflecting plane”. The values are

representative of a non-submerged wet end.

For estimating sound power level LWA (re 1 pW) then

add 14 dBA to the sound pressure value.

motor” noise is that typically expected from standard

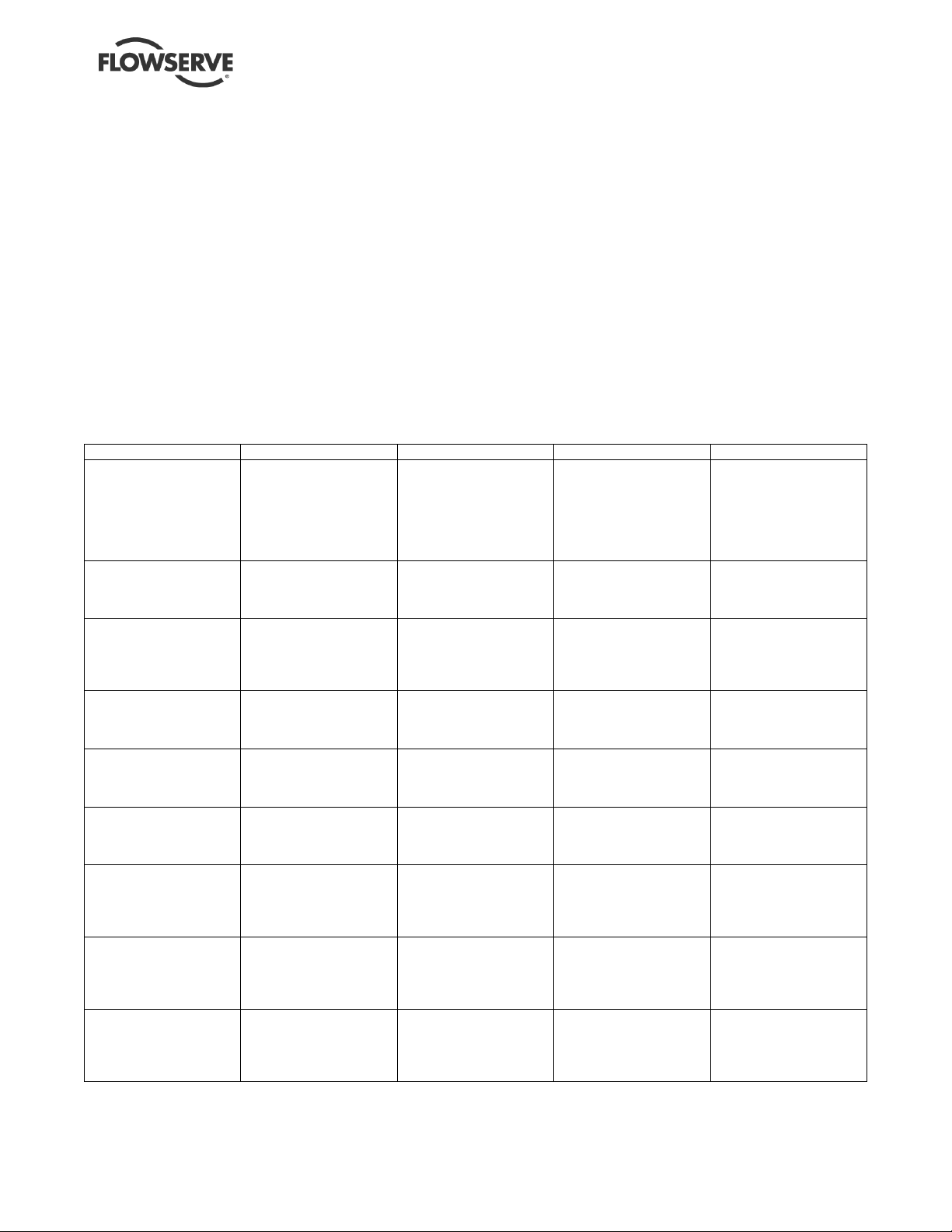

Motor size

and speed

kW (hp)

<0.55(<0.75) 72 72 64 65 62 64 62 64

0.75 (1) 72 72 64 66 62 64 62 64

1.1 (1.5) 74 74 66 67 64 64 62 63

1.5 (2) 74 74 66 71 64 64 62 63

2.2 (3) 75 76 68 72 65 66 63 64

3 (4) 75 76 70 73 65 66 63 64

4 (5) 75 76 71 73 65 66 63 64

5.5 (7.5) 76 77 72 75 66 67 64 65

7.5 (10) 76 77 72 75 66 67 64 65

11(15) 80 81 76 78 70 71 68 69

15 (20) 80 81 76 78 70 71 68 69

18.5 (25) 81 81 77 78 71 71 69 71

22 (30) 81 81 77 79 71 71 69 71

30 (40) 83 83 79 81 73 73 71 73

37 (50) 83 83 79 81 73 73 71 73

45 (60) 86 86 82 84 76 76 74 76

55 (75) 86 86 82 84 76 76 74 76

75 (100) 87 87 83 85 77 77 75 77

90 (120) 87 88 83 85 77 78 75 78

110 (150) 89 90 85 87 79 80 77 80

150 (200) 89 90 85 87 79 80 77 80

200 (270)

300 (400) 87 90 85 86

`1 The noise level of machines in this range will most likely be of values which require noise exposure control, but typical values are

inappropriate.

Note: for 1 180 and 960 r/min reduce 1 450 r/min values by 2 dBA. For 880 and 720 r/min reduce 1 450 r/min values by 3 dBA.

Pump

only

1 1 1 1

Typical sound pressure level LpA at 1 m reference 20 µPa, dBA

3 550 r/min 2 900 r/min 1 750 r/min 1 450 r/min

Pump and

motor

Pump

only

Pump and

motor

Pump

only

85 87 83 85

Pump and

motor

Pump

only

Pump and

motor

Page 8

Page 9

ESP3 USER INSTRUCTIONS ENGLISH 26999943 08-11

of 64

2 TRANSPORT AND STORAGE

2.1 Consignment receipt and unpacking

Immediately after receipt of the equipment it must be

checked against the delivery/shipping documents for

its completeness and that there has been no damage

in transportation. Any shortage and/or damage must

be reported immediately to Flowserve Pump Division

and must be received within ten days of receipt of the

equipment. Later claims cannot be accepted.

Check any crate, boxes or wrappings for any

accessories or spare parts that may be packed

separately with the equipment or attached to

sidewalls of the box or equipment.

Each product has a unique serial number. Check

that this number corresponds with that advised and

always quote this number in correspondence as well

as when ordering spare parts or further accessories.

2.2 Handling

Boxes, crates, pallets or cartons may be unloaded

using forklift vehicles or slings dependent on their

size and construction.

2.3 Lifting

Pumps and motors often have integral

lifting lugs or eye bolts. These are intended for use in

only lifting the individual piece of equipment.

Do not use or cast-in lifting lugs to lift

pump, motor and mounting plate assemblies.

Care must be taken to lift components

or assemblies above the center of gravity to prevent

the unit from flipping.

Carefully sling ESP pumps so that

bearing lubrication lines [3840.1] will not be bent or

damaged when lifting.

It is advisable to raise the pump into the vertical

position before uncrating. If this isn't possible, pumps

over eight feet long must be supported at more than

one place when raising to the vertical position. Use a

support strap around the bottom column [1341.2] and

on the motor support [3160]. Or lift use optionally

supplied lifting eyes [6820] installed on mounting

plate [6130].

2.4 Storage

Store the pump in a clean, dry location

away from vibration. Leave flange covers in place to

keep dirt and other foreign material out of pump

casing. Turn the pump shaft at regular intervals to

prevent brinelling of the bearings and the seal faces,

if fitted, from sticking.

The pump may be stored as above for up to 6

months. Consult Flowserve for preservative actions

when a longer storage period is needed.

2.4.1 Short term storage and packaging

Normal packaging is designed to protect the pump

and parts during shipment and for dry, indoor storage

for up to six months or less. The following is an

overview of our normal packaging:

• All loose un-mounted items are packaged in a

water proof plastic bag and secured to the pallet.

• Inner surfaces of the bearing housing, shaft (area

through bearing housing) and bearings are coated

with Cortec VCI-329 rust inhibitor, or equal.

Bearing housings are not filled with oil

prior to shipment

• Regreasable bearings are packed with grease

• The internal surfaces of ferrous casings, covers,

flange faces, and the impeller surface are

sprayed with Cortec VCI-389, or equal

• Exposed shafts are taped with Polywrap

• Flange covers are secured to both the suction

and discharge flanges

• In some cases with assemblies ordered with

external piping, components may be

disassembled for shipment

• The pump must be stored in a covered, dry

location

2.4.2 Long term storage and packaging

Long term storage is defined as more than six

months, but less than 12 months. The procedure

Flowserve follows for long term storage of pumps is

given below. These procedures are in addition to the

short term procedure.

• Each assembly is hermetically (heat) sealed from

the atmosphere by means of tack wrap sheeting

and rubber bushings (mounting holes)

• Desiccant bags are placed inside the tack

wrapped packaging

• A solid wood box is used to cover the assembly

This packaging will provide protection for up to twelve

months from humidity, salt laden air, dust etc.

Page 9

Page 10

ESP3 USER INSTRUCTIONS ENGLISH 26999943 08-11

of 64

After unpacking, protection will be the responsibility of

the user. If units are to be idle for extended periods

after addition of lubricants, inhibitor oils and greases

should be used. Every three months, the pump shaft

should be rotated approximately 10 revolutions.

2.5 Recycling and end of product life

At the end of the service life of the product or its

parts, the relevant materials and parts should be

recycled or disposed of using an environmentally

acceptable method and in accordance with local

regulations. If the product contains substances that

are harmful to the environment, these should be

removed and disposed of in accordance with current

local regulations. This also includes the liquids

and/or gases that may be used in the "seal system"

or other utilities.

Make sure that hazardous substances are

disposed of safely and that the correct personal

protective equipment is used. The safety

specifications must be in accordance with the current

local regulations at all times.

3 DESCRIPTION

3.1 Configurations

The ESP3 vertical immersion sump pumps are

separately coupled metallic construction single stage

centrifugal pumps for wet pit applications. The ESP3

wetted parts are available in a wide range of

materials to handle most fluids. Vapor-tight, vaporproof, and pressurized construction options are

available. The hydraulics utilized are from Mark 3

chemical process pumps.

Figure 3-1: Nameplate mounted to housing

3.2 Nomenclature

The pump size will be engraved on the nameplate

typically as below:

2 E 6 X 4 SP - 13 A /12.5 RV

• Frame size

“2" indicates a medium size pump frame (in this

example, a Group 2)

1 = Group 1 (small frame)

2 = Group 2 (medium frame)

3 = Group 3 (large frame)

• Power end

E = ESP3 Pump

• “6” = nominal suction port size (in.)

• “4” = Nominal discharge port size (in.)

• Modifier for “specialty pumps”

SP = standard sump pump

RSP = recessed impeller pump

LFSP = Lo-Flo pump

• Nominal maximum impeller diameter. “13” = 13 in.

• Pump design variation

A = This pump has been redesigned from an earlier

version. The impeller and casing are no longer

interchangeable with the earlier version.

H = This pump is designed for a higher flow capacity

than another pump with the same basic

designation. (Examples: 4X3-10 and 4X3-10H;

6X4-10 and 6X4-10H; 10X8-16 and 10X8-16H.

HH = This pump is designed for a higher head than

another pump with the same basic designation.

(Example: 4X3-13 and 4X3-13HH.)

• Actual impeller size

“12.5” = 12 ½ in. diameter; 8.13 = 8 ⅛ in.;

10.75 = 10 ¾ in.

(Previous annotation: 124 = 12 4/8 or 12 ½ in.

diameter; 83 = 8 ⅜ in.)

• Impeller style

RV = reverse vane impeller; OP = Open impeller

Serial No.

Equipment No.

Purchase Order

Material

Date DD/MMM/YY

Page 10

Model

Size

MDP

2E6X4 SP-13A/12.5 RV

Page 11

ESP3 USER INSTRUCTIONS ENGLISH 26999943 08-11

of 64

3.3 Design of major parts

3.3.1 Pump casing

As used by the Mark 3 Product Line. Depending upon

the installation, the casing feet may have been

removed. Axial bolting retains the casing to the cover

and compresses the sealing gasket.

3.3.2 Impeller

Depending on the product, the impeller is either reverse

vane or open. The impeller is threaded to the end of the

shaft

3.3.3 Shaft/sleeve

Solid and sleeved shafts are available. The shaft is

threaded on the impeller end and keyed on the drive

end.

3.3.4 Pump bearings and lubrication

The external thrust bearing is a grease-lubricated

duplex angular contact ball bearing. The radial load

line bearings are sleeve plain bearings lubricated by

product, external flush or grease.

3.3.5 Bearing housing

The external housing contains grease ports and is

sealed with lip seals.

3.3.6 Cover plate

The cover plate has a spigot (rabbet) fit between the

pump casing and adapter for optimum concentricity.

The cover plate holds the throttle bushing at the back

of the impeller.

3.3.7 Shaft seal

There is no shaft seal required near the impeller

since the pump is submerged. Only a small amount

of pressurized fluid escapes through controlled leak

paths from the backside of the impeller. Packing or a

mechanical seal can be fitted above the sump level to

provide vapor proof or pressurized options for the

application.

3.3.8 Driver

The standard driver is a NEMA C-Face vertical electric

motor. The motor must be equipped with a drip-cap

when installed outdoors.

3.3.9 Accessories

Accessories may be fitted when specified by the

customer.

3.4 Performance and operation limits

This product has been selected to meet the

specification of your purchase order. See section 1.5.

The following data is included as additional information

to help with your installation. It is typical, and factors

such as liquid being pumped, temperature, material of

construction, and seal type may influence this data. If

required, a definitive statement for your application can

be obtained from Flowserve.

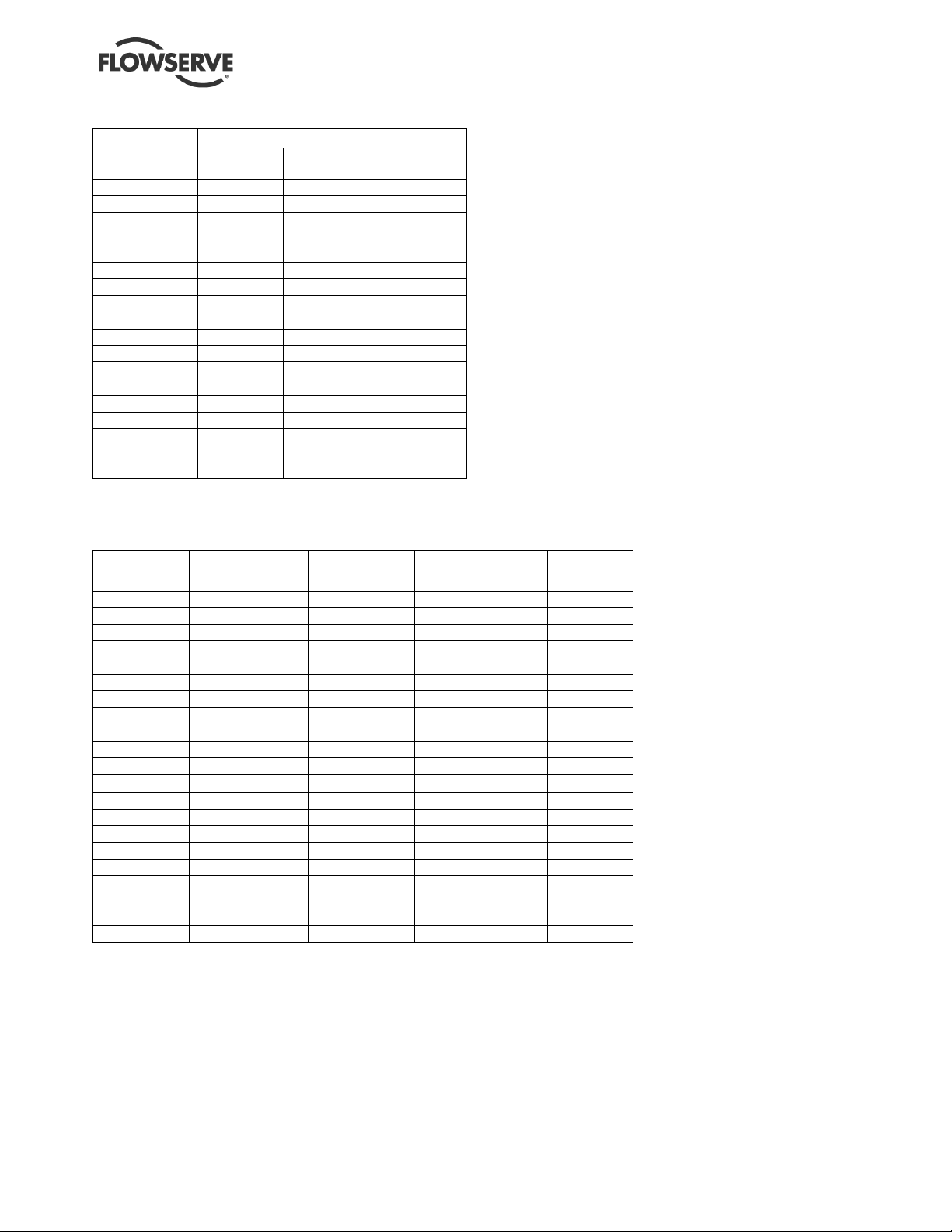

3.4.1 Alloy cross reference chart

Figure 3-3 is the Alloy cross-reference chart. The

chart is used to material group number which can be

used to establish the pressure-temperature rating as

discussed below. Not all materials may be available

3.4.2 Pressure-temperature ratings

The pressure–temperature (P-T) ratings for ESP3

pumps are shown in figures 3-4 and 3-5. Determine

the appropriate casing “Material Group No.” in Figure

3-3. Interpolation may be used to find the pressure

rating for a specific temperature.

Example:

The pressure temperature rating for a standard GP210” pump with Class 150 flanges and CF8M

construction at an operating temperature of 149˚C is

found as follows:

a) The correct pressure-temperature chart is Figure

3-4.

b) From Figure 3-3, the correct material group for

CF8M is 2.2

c) From Figure 3-4, the pressure-temperature rating

is 14.8 bar.

The maximum discharge pressure must be less

than or equal to the P-T rating. Discharge pressure

may be approximated by adding the suction pressure

and the differential head developed by the pump.

3.4.3 Suction pressure limits

Pump suction pressure is limited by the maximum pump

length and the maximum sump pressure of 3.45 bar (50

psi).

3.4.4 Minimum continuous flow

The minimum continuous flow (MCF) is based on a

percentage of the best efficiency point (BEP).

Figure 3-2 identifies the MCF for all ESP3 pump

models with the exception of the Lo-Flo pump line;

there is no MCF associated with this product line.

Page 11

Page 12

ESP3 USER INSTRUCTIONS ENGLISH 26999943 08-11

of 64

Figure 3-2: Minimum continuous flow

Pump size

1E3x2SP-62 20% 10% 10%

2E3x2SP-82 20% 10% 10%

2E4x3SP-82 20% 10% 10%

2E3x2SP-10A 30% 10% 10%

2E4x3SP-10 30% 10% 10%

2E6x4SP-10 40% 10% 10%

2E6x4SP-10H n.a. 20% 10%

2E3x1.5SP-13 30% 10% 10%

2E3x2SP-13 40% 10% 10%

2E4x3SP-13 40% 20% 10%

2E4x3SP-13HH n.a. 50% 30%

2E6x4SP-13A 60% 40% 10%

3E8x6SP-14A n.a. 40% 15%

3E10x8SP-14 n.a. 40% 10%

3E6x4SP-16 n.a. 50% 10%

3E8x6SP-16 n.a. 50% 10%

3E10x8SP-16 n.a. 50% 10%

All other sizes 10% 10% 10%

3500/2900

r/min

MCF % of BEP

1750/1450

r/min

1180/960

r/min

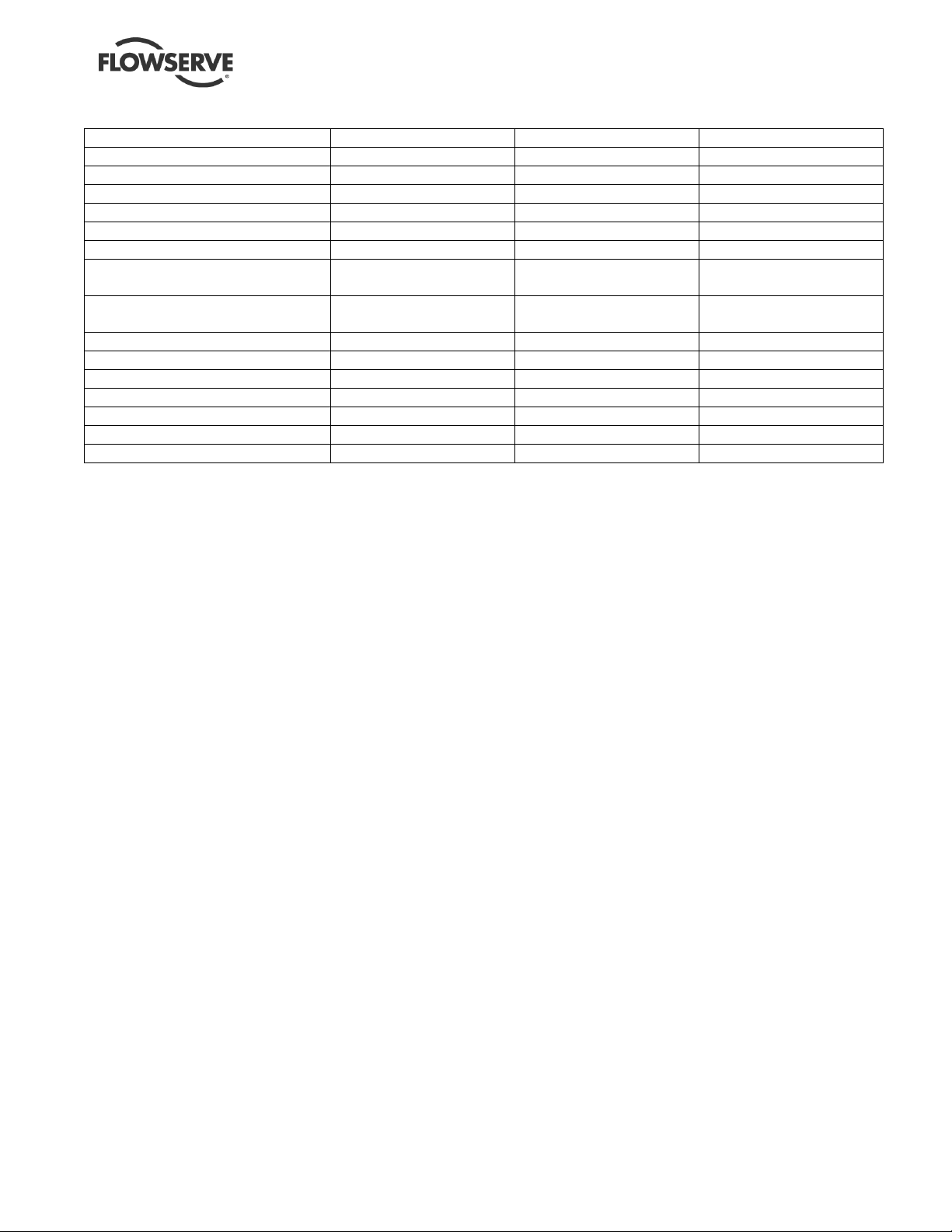

Figure 3-3: Alloy cross-reference chart

Flowserve

Material Code

E3020 Ductile iron DCI A395, Gr. 60-40-18 1.0

C3009 Carbon steel DS A216 Gr. WCB 1.1

C3062 304 D2 A744, Gr. CF8 2.1

C3069 304L D2L A744, Gr. CF3 2.1

C3063 316 D4 A744, Gr. CF8M 2.2

C3067 316L D4L A744, Gr. CF3M 2.2

C4029 Durcomet 5 DV None 2.2

C3107 Duplex Stainless CD4M A995, Gr. CD4MCuN 2.8

C4028 Alloy 20 D20 A744, Gr. CN7M 3.17

K3008 Nickel DNI A494, Gr. CZ100 3.2

K3007

K3005

K4007

K4008

D4036 Durco DC8 DC8 None H3004 Titanium Ti B367, Gr. C3 Ti

H3005 Titanium-Pd TiP B367, Gr. C8A Ti

H3007 Zirconium Zr B752, Gr. 702C Ti

E3033 High chrome iron CR28 A532 class 3 Cr

E4027 High chrome iron CR29 None Cr

E4028 High chrome iron CR35 None Cr

Duriron, Durichlor 51 and Superchlor are registered trademarks of Flowserve Corporation.

Hastelloy is a registered trademark of Haynes International, Inc.

Inconel and Monel are registered trademarks of International Nickel Co. Inc.

Generic

Designation

Monel400

Inconel600

HastelloyB

HastelloyC

Durco Legacy

DMM A494, Gr. M35-1 3.4

DINC A494, Gr. CY40 3.5

DC2 A494, Gr. N7M 3.7

DC3 A494, Gr. CW6M 3.8

Codes

ASTM

Specifications

Material

Group No.

Page 12

Page 13

ESP3 USER INSTRUCTIONS ENGLISH 26999943 08-11

of 64

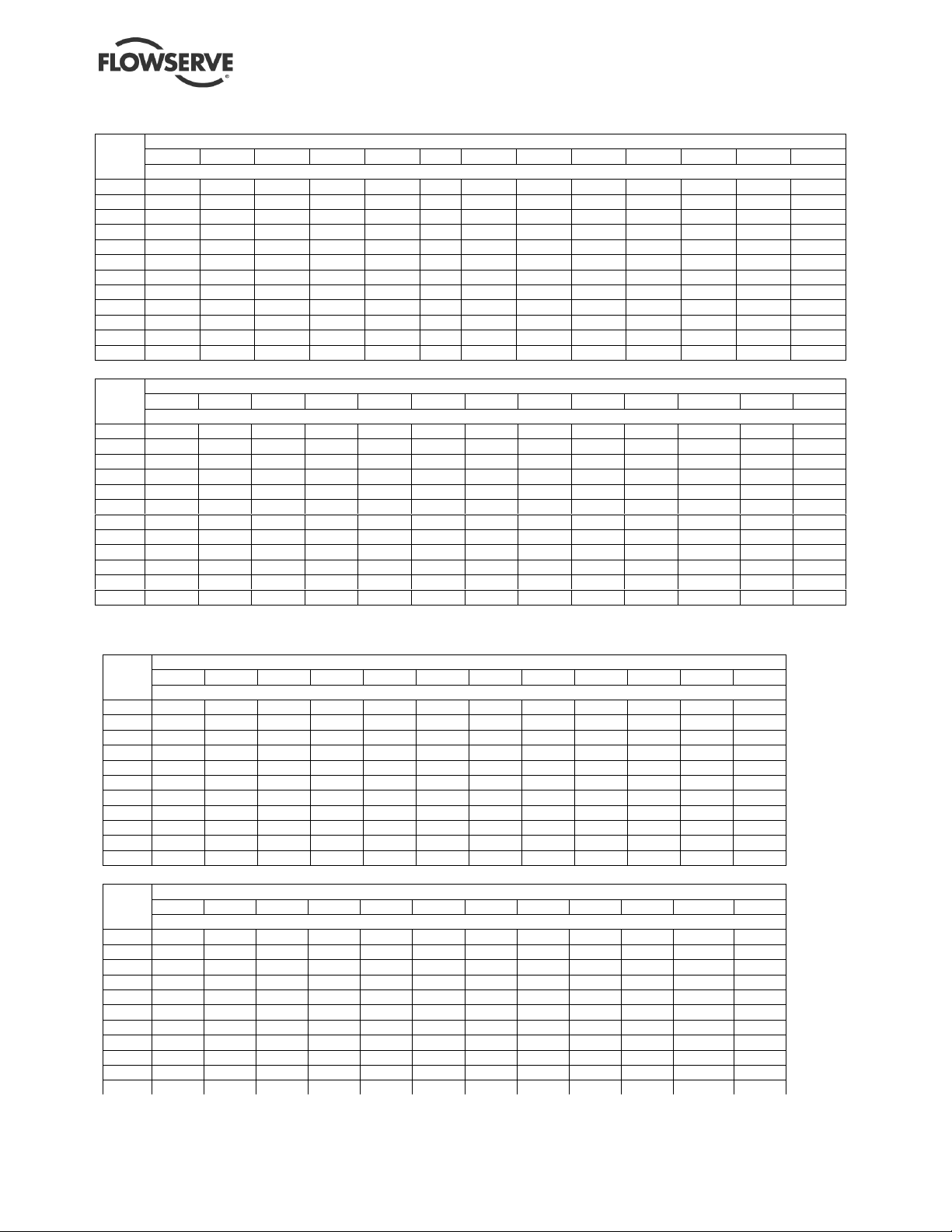

700 325 266 269

277 313 342 342 144

Figure 3-4 Class 150 Flanges

Material Group No.

˚C

-73 19.0 19.0 19.7 15.9 9.7 15.9 15.2 20.0 20.0 20.0

-29 17.2 19.7 19.0 19.0 19.7 15.9 9.7 15.9 15.2 20.0 20.0 20.0

-18 17.2 19.7 19.0 19.0 19.7 15.9 9.7 15.9 15.2 20.0 20.0 20.0 12.6

38 17.2 19.7 19.0 19.0 19.7 15.9 9.7 15.9 15.2 20.0 20.0 20.0 12.6

93 16.2 17.9 15.9 16.2 17.9 13.8 9.7 13.8 13.8 17.9 17.9 17.9 12.6

149 14.8 15.9 14.1 14.8 15.9 12.4 9.7 13.1 12.4 15.9 15.9 15.9 12.6

171 14.4 15.0 13.7 14.3 15.0 11.9 9.7 13.0 12.1 15.0 15.0 15.0 12.6

204 13.8 13.8 13.1 13.4 13.8 11.0 9.7 12.8 11.7 13.8 13.8 13.8

260 11.7 11.7 11.7 11.7 11.7 10.3 9.7 11.7 11.0 11.7 11.7 11.7

316 9.7 9.7 9.7 9.7 9.7 9.7 9.7 9.7 9.7 9.7 9.7 9.7

343 8.6 8.6 8.6 8.6 8.6 8.6 8.6 8.6 8.6

371 7.6 7.6 7.6 7.6 7.6 7.6 7.6 7.6

1.0 1.1 2.1 2.2 2.8 3.17 3.2 3.4 3.5 3.7 3.8 Ti Cr Temp

bar

Material Group No.

˚F

-100 275 275 285 230 140 230 220 290 290 290

-20 250 285 275 275 285 230 140 230 220 290 290 290

100 250 285 275 275 285 230 140 230 220 290 290 290 183

200 235 260 230 235 260 200 140 200 200 260 260 260 183

300 215 230 205 215 230 180 140 190 180 230 230 230 183

340 209 218 199 207 218 172 140 188 176 218 218 218 183

400 200 200 190 195 200 160 140 185 170 200 200 200

500 170 170 170 170 170 150 140 170 160 170 170 170

600 140 140 140 140 140 140 140 140 140 140 140 140

650 125 125 125 125 125 125 125 125 125

700 110 110 110 110 110 110 110 110

1.0 1.1 2.1 2.2 2.8 3.17 3.2 3.4 3.5 3.7 3.8 Ti Cr Temp

psi

0 250 285 275 275 285 230 140 230 220 290 290 290 183

Figure 3-5 Group2-13” Lo-Flo Pumps with Class 300 Flanges

Material Group No.

˚C

-73 31.0 31.0 31.0 24.1 17.4 24.1 27.6 31.0 31.0 31.0

-29 31.0 31.0 31.0 31.0 31.0 24.1 17.4 24.1 27.6 31.0 31.0 31.0

-18 31.0 31.0 31.0 31.0 31.0 24.1 17.4 24.1 27.6 31.0 31.0 31.0

38 31.0 31.0 31.0 31.0 31.0 24.1 17.4 24.1 27.6 31.0 31.0 31.0

93 29.1 28.3 25.9 26.7 29.8 20.9 17.4 21.3 26.1 31.0 31.0 27.5

149 27.4 27.5 23.3 24.1 27.5 18.7 17.4 19.9 24.4 30.2 30.2 24.0

204 25.5 26.6 21.3 22.2 25.4 16.9 17.4 19.3 22.7 29.2 29.2 20.5

260 24.0 25.2 19.7 20.7 23.8 15.7 17.4 19.1 22.1 27.5 27.5 17.0

316 22.5 23.1 18.7 19.4 23.0 14.5 17.4 19.1 21.9 25.0 25.0 13.4

343 21.8 22.4 18.5 19.2 19.1 21.8 24.4 24.4 11.7

371 22.4 18.3 18.5 19.1 21.6 23.6 23.6 9.9

1.0 1.1 2.1 2.2 2.8 3.17 3.2 3.4 3.5 3.7 3.8 Ti Temp

bar

Material Group No.

˚F

-100 450 450 450 350 252 350 400 450 450 450

-20 450 450 450 450 450 350 252 350 400 450 450 450

100 450 450 450 450 450 350 252 350 400 450 450 450

200 422 410 375 388 432 303 252 309 379 450 450 399

300 397 398 338 350 399 271 252 289 354 438 438 348

400 369 386 309 322 369 245 252 280 330 423 423 297

500 348 365 285 300 345 228 252 277 320 399 399 246

600 327 334 272 281 333 210 252 277 318 363 363 195

650 316 325 269 278 277 316 354 354 170

1.0 1.1 2.1 2.2 2.8 3.17 3.2 3.4 3.5 3.7 3.8 Ti Temp

psi

0 450 450 450 450 450 350 252 350 400 450 450 450

Page 13

Page 14

ESP3 USER INSTRUCTIONS ENGLISH 26999943 08-11

of 64

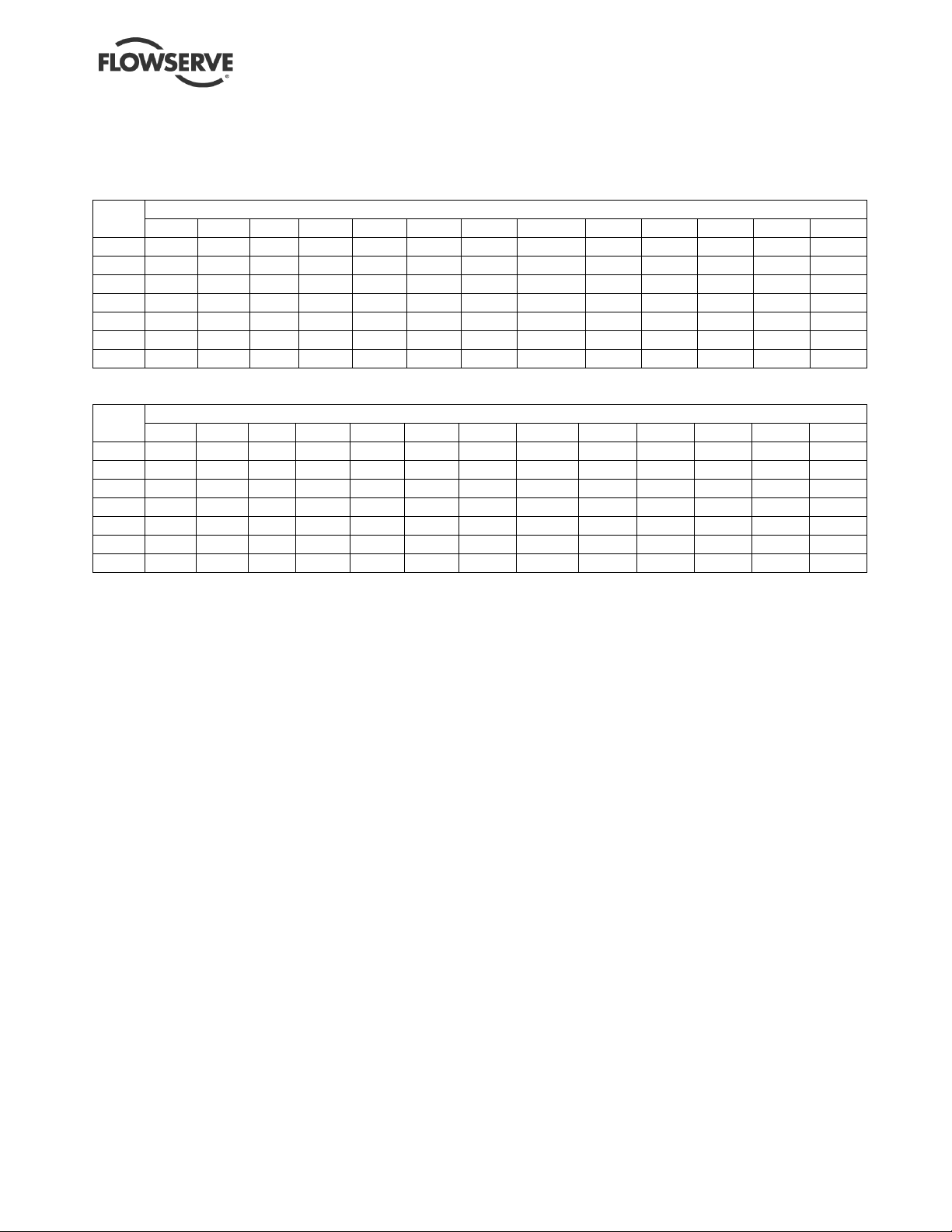

3.4.5 Minimum suction pipe submergence

The minimum submergence is shown in Figure 3-6.

Figure 3-6

Minimum submergence (meters)

Flow (m3/hr.) Suct.

Size

1.5 0.30 0.55 1.07 2.65

2 0.30 0.58 1.40 2.74

3 0.30 0.79 1.52 2.38

4 0.30 0.55 1.07 2.13

6 0.43 .076 1.19 1.83

8 0.55 0.94 1.19 1.65

10 0.64 0.85 1.22 1.52

Minimum submergence (feet)

Size

1.5 1.0 1.8 3.5 8.7

2 1.0 1.9 4.6 9.0

3 1.0 2.6 5.0 7.8

4 1.0 1.8 3.5 7.0

6 1.4 2.5 3.9 6.0

8 1.8 3.1 3.9 5.4

10 2.1 2.8 4.0 5.0

6.8 11.4 20.5 45.5 79.5 136 273 341 500 568 727 1023 1250

Flow (USgpm) Suct.

30 50 90 200 350 600 1200 1500 2200 2500 3200 4500 5500

Page 14

Page 15

ESP3 USER INSTRUCTIONS ENGLISH 26999943 08-11

of 64

3.4.6 ESP3 Bearing Materials

• CARBON - Carbon graphite, especially developed

for sump pump applications, is chemically inert. The

self-lubricating properties of graphite present in

the carbon bearings enhance its dry running

capabilities.

• BRONZE - SAE 660 Bronze (grooved when

grease lubricated).

• CAST IRON - ASTM A48 Class 30 iron (grooved

when grease lubricated).

• RUBBER - Resilient compounded rubber, fluted to

allow abrasives to wash away.

• TEFLON - Fiberglass & molybdenum disulphide

filled, with low cold flow, high tensile and

elongation characteristics.

• ARHT - Chemical and wear resistant bearing

material developed by Greene, Tween & Co.

(grooved when grease lubricated).

All bearing materials are enclosed in an AISI-316

shell (ex. Bronze, Cast Iron & ARHT). Higher

alloys are available (grooved when grease

lubricated).

• VITON - Resilient Viton, fluted to allow handling of

dirty corrosive liquids not able to be handled by

carbon or rubber.

Figure 3-7: ESP3 Bearing selection

Bearing Material Max Temp Liquid Pumped Lubricant Shaft Material

Most clean acids,

Carbon

Bronze

Cast Iron

Rubber

Teflon

Teflon

Viton

ARHT

ARHT

177˚C

350˚F

82˚C

180˚F

82˚C

180˚F

71˚C

160˚F

177˚C

350˚F

Liquid Lube

82˚C

180˚F

Grease Lube

149˚C

300˚F

121˚C

250˚F

Liquid Lube

82˚C

180˚F

Grease Lube

general chemicals,

water, cleaning fluids,

gasoline, kerosene, jet

Water and compatible

Water and compatible

liquids including alkaline

General abrasive liquids

compatible with rubber

compatible with carbon

compatible with carbon

compatible with carbon

Dirty acids, hot water

compatible with PEEK

chemicals compatible

fuels

liquids

caustics

Clean acids not

Clean acids not

Dirty acids not

or rubber

and chemicals

Dirty acids and

with PEEK

External flush

Product Lube

External flush

Product Lube

Grease Lube

External flush

Product Lube

Grease Lube

External flush

Product Lube

External flush

Product Lube

Grease SS only

External flush

Product Lube

External flush

Product Lube

Grease SS only

Steel or SS

Steel or SS

Steel only

Steel only

Steel only

Steel

Steel

Steel

SS only

SS only

SS only

SS only

SS only

SS only

SS only

SS only

Page 15

Page 16

ESP3 USER INSTRUCTIONS ENGLISH 26999943 08-11

of 64

Figure 3-8: Engineering information

Pump Group Size GP1 – 1E GP2 – 2E GP3 – 3E

Ball Bearing Size

1st Critical Speed @ 3550 span

1st Critical Speed @ 1750 span

1st Critical Speed @ 1180 span

Std. Bearing Span @ 3550 rpm

Std, Bearing Span @ 1750 rpm

Standard Bearing Span @

1180 rpm

Shaft Diameter @ Sleeve

Bearing

Shaft Diameter @ Stuffing Box

Shaft Diameter @ Coupling

Keyway Size mm (in)

Nominal Impeller Clearance

Corrosion Allowance

Minimum Pit Depth

Maximum Pit Depth

28.58 mm (1.125 in.) 38.10 mm (1.500 in.) 53.98 mm (2.125 in.)

28.58 mm (1.125 in.) 38.10 mm (1.500 in.) 47.63 mm (1.875 in.)

25.4 mm (1.000 in.) 34.93 mm (1.375 in.) 41.28 mm (1.625 in.)

6.4 x 3.2 (1/4 x 1/8) 7.9 x 4.0 (5/16 x 5/32) 15.9 x 7.9 (5/8 x 5/16)

7308 7310 7313

6000 5555 n.a.

2344 2469 2833

2344 2469 2833

760 mm (30 in.) 915 mm (36 in.) n.a.

1220 mm (48 in.) 1220 mm (48 in.) 1520 mm (60 in.)

1220 mm (48 in.) 1220 mm (48 in.) 1520 mm (60 in.)

.46 mm (0.018 in.) .46 mm (0.018 in.) .64 mm (0.025 in.)

3.2 mm (0.125 in.) 3.2 mm (0.125 in.) 3.2 mm (0.125 in.)

.61 m (2.0 ft) .61 m (2.0 ft) .91 m (3.0 ft)

6.10m (20.0 ft) 6.10 m (20.0 ft) 6.10 m (20.0 ft)

Page 16

Page 17

ESP3 USER INSTRUCTIONS ENGLISH 26999943 08-11

of 64

4 INSTALLATION

INSTALLATION AND START-UP CHECKLIST

1. Check that the sump design will keep the

liquid level within the proper range.

2. Check that the pump location is accessible and

has adequate ventilation.

3. Verify that the pump and motor are suitable for

the pump environment.

4. Check the sump design to be sure it is adequate

to support the complete pumping assembly.

5. Verify the discharge piping meets Hydraulic

Institute Standards for design and is properly

supported.

6. Install the suction strainer

7. Install the liquid level controls.

8. If pump was ordered for vapor proof or

pressurized design, install sealing device.

9. Lift the pump into place and tighten the mounting

plate bolts.

10. Install the motor on the pump, but do not connect

the coupling or electric power.

11. Connect the wiring to the liquid level

indicators and pump controls, as required.

12. Connect the discharge piping,

13. Check that all auxiliary piping is connected

14. Verify the pump is free of pipe strain by

turning the shaft by hand.

15. Verify the impeller setting.

16. Lubricate the driver and pump as required

using approved lubricants.

1 _________ __________

2 _________ __________

3 _________ __________

4 _________ __________

5 _________ __________

6 _________ __________

7 _________ __________

8 _________ __________

9 _________ __________

10 _________ __________

11 _________ __________

12 _________ __________

13 _________ __________

14 _________ __________

15 _________ __________

16 _________ __________

17 _________ __________

17. Connect the wiring for the motor.

18. Turn power ON and jog the driver to verify proper

rotation; clockwise looking down.

19. Turn power OFF and install the coupling element

and coupling guard. Then turn power ON, but do

not start the driver.

Page 17

18 _________ __________

19_________ __________

Page 18

ESP3 USER INSTRUCTIONS ENGLISH 26999943 08-11

of 64

4.1 Location

The pump should be located to allow room for

installation, access, ventilation, maintenance, and

inspection with ample headroom for lifting. Refer to

the general arrangement drawing for the pump set.

If pump is furnished with external flush-lubricated

bearings, the fluid lines must be accessible from

the pump location.

Also important, especially in the larger flow units, is

proper sump design. Liquid velocity approaching

the pump should be one foot per second or less.

When more than one pump is installed and used at

the same time in the same sump, the location and

spacing of the pumps are important. The

guidelines for sump design and pump placement as

outlined in the "Hydraulic Institute Standards" are

recommended.

4.2 Part assemblies

• Pumps are shipped completely assembled

except for driver, strainer [6531], float controls

(if furnished), pit cover, and the mechanical

seal [4200] or packing [4130] for the stuffing

box on a vapor proof or pressurized design

pump.

• When mechanical seals are furnished, they

should be installed before the motor is put in

place. Refer to seal installation instructions in

section 6.9.5.

• Vapor Proof and Pressurized design pumps

are furnished with an upper stuffing box

[4110]. If the stuffing box doesn't already have

the packing [4130] or seal [4200] installed,

then they should be installed before the motor

is mounted. See section 6.

• The driver will be mounted after the pump is

installed.

• When the pump is shipped, all threads and all

openings are covered. This protection should

not be removed until installation. If the pump

is removed from service, this protection should

be reinstalled.

4.3 Foundation

There should be adequate space for workers to

install, operate, and maintain the pump. The

foundation should be sufficient to absorb any

vibration and should provide a rigid support for the

pump and motor. Recommended mass of a

concrete foundation should be three times that of

the pump, motor and mounting plate. Supporting

members must be sufficiently strong to prevent

spring action and/or lateral movement.

4.4 Pump Mounting

The pump may be mounted directly on the pit

using the pump mounting plate [6130] or in

conjunction with a pit cover.

a) The pump was checked during assembly at

the factory to make sure the pump shaft [2100]

rotated freely by hand. Handling during

shipment, storage, or preparation for

installation could have caused distortions

resulting in pump shaft binding. Check the

shaft to make sure that it will rotate freely by

hand.

b) Check all bolts and nuts for tightness, then

carefully lower the assembled pump into the

pit, taking care not to damage lube lines or float

control equipment. Make sure that any

equipment used to lift the pump or any of

its components is capable of supporting the

weights encountered. Make sure that all parts

are properly rigged before attempting to lift.

c) Pump mounting plate and/or pit cover must

maintain level within 1/8in/ft. from one side of

the plate to the other, and be supported evenly

at all points before being bolted down.

d) If the sump doesn't provide a level mounting

surface for the pump, drive wedges under

the mounting plate/pit cover until pump levels

out. The wedges must be able to support the

weight of the entire pumping assembly and

hold the assembly steady enough that no

excess vibration occurs.

e) Do not bolt the discharge flange of the pump

to the piping until the baseplate foundation is

completely installed.

f) Run piping to the discharge of the pump.

There should be no piping loads transmitted to

the pump after connection is made.

4.5 Mechanical seals and packing

Pumps supplied with vapor proof construction or

pressurized designs are furnished with an upper

stuffing box [4110] equipped to take mechanical

seals or packing (see vapor proof and pressurized

design cross-sections in section 8). Gas seals are

typically of a canister design, thus the stuffing box

is omitted. The canister seals are mounted directly

to the upper column [1341.1]. Installation

instructions can be found in section 6.9.5

4.5.1 Mechanical seal

Mechanical seals [4200] are typically installed prior

to shipment. Specific order requirements may

specify that the seal be shipped separately, or none

be supplied. It is the pump installer’s responsibility

to determine if a seal was installed. Installation

instruction can be found in section 6

Page 18

Page 19

of 64

Failure to ensure that a seal is installed may

result in serious leakage of vapor and of the pumped

fluid.

Seal and seal support system must be installed and

operational as specified by the seal manufacturer.

The stuffing box/seal chamber/gland may have

ports that have been temporarily plugged at the

factory to keep out foreign matter. It is the

installer’s responsibility to determine if these plugs

should be removed and external piping connected.

Refer to the seal drawings and or the local

Flowserve representative for the proper

connections.

4.5.2 Packing

When the pump is intended to be equipped with

shaft packing, it is NOT Flowserve standard

practice to install the packing in the stuffing box

prior to shipment. The packing is shipped with the

pump. It is the pump installer’s responsibility to

install the packing in the stuffing box. Installation

instructions can be found in section 6.

Failure to ensure that the packing is installed

may result in serious leakage of vapor and of the

pumped fluid.

4.6 Driver Mounting

a) Before the motor is installed, be sure to

connect the motor half coupling hub and the

pump half coupling hub onto their respective

shafts.

b) Carefully lift the motor and place it on the

support head [3160] of the pump.

c) Turn the motor frame to one of the four

positions where the motor bolt holes line up to

the support head [3160]. Select the position of

the motor to suit the desired conduit box

location. Install the motor hold down bolts

[6570.1]. In some instances a motor adapter

[1340.3] may be furnished. In this case the

adapter must be installed before the motor can

be mounted.

d) Motor to pump alignment is controlled by fits

within the adapter and cannot be adjusted.

e) Locate the coupling and source of electrical

power but DO NOT INSTALL THE COUPLING

DRIVE ELEMENT AT THIS TIME.

f) Connect the motor terminals to the leads from

the starter panel. Make sure the motor shaft

and/or coupling is not touching any part of the

pump shaft or pump half coupling. Rotate the

ESP3 USER INSTRUCTIONS ENGLISH 26999943 08-11

motor shaft by hand to make sure it is free to

rotate when energized.

Never check driver rotation unless the

pump and driver shafts are disconnected and

physically separated. Failure to follow this

instruction can result in serious damage to the

pump and driver if rotation is in the wrong

direction.

g) Jog the motor and check for proper rotation

which should be clockwise when looking

down on top of the motor. If rotation is wrong,

interchange any two motor connections on

three-phase motors. On single-phase motors,

follow the motor manufacturer’s instructions. After

changing the connections, again check the rotation

to ensure that the direction is correct.

h) Disconnect and lockout the power supply to the

driver.

i) The coupling can now be fully installed and

join the driver and pump shafts together (see

section 5.4.2).

j) Install the coupling guarding [7450.1-.2] (see

section 5.5).

4.7 Piping

Protective covers are fitted to both the

suction and discharge flanges of the casing and must

be removed prior to connecting the pump to any

pipes.

4.7.1 General piping

If the pump flange(s) have tapped holes, select flange

fasteners with thread engagement at least equal to

the fastener diameter but that do not bottom out in the

tapped holes before the joint is tight.

4.7.2 Suction piping

ESP pumps typically only have strainers attached to

the suction flange of the pump casing. An option for

an extension from the suction flange is available and

is called a tailpipe (see section 8 for cross-sectional

drawing). A tailpipe is useful for applications where

there is adequate NPSH at the lowest sump level but

the discharge pressure is critical and must be

maintained at a maximum value compared to using a

longer column and shaft. Pumps may air-bind if air is

allowed to leak into the piping

Page 19

Page 20

ESP3 USER INSTRUCTIONS ENGLISH 26999943 08-11

of 64

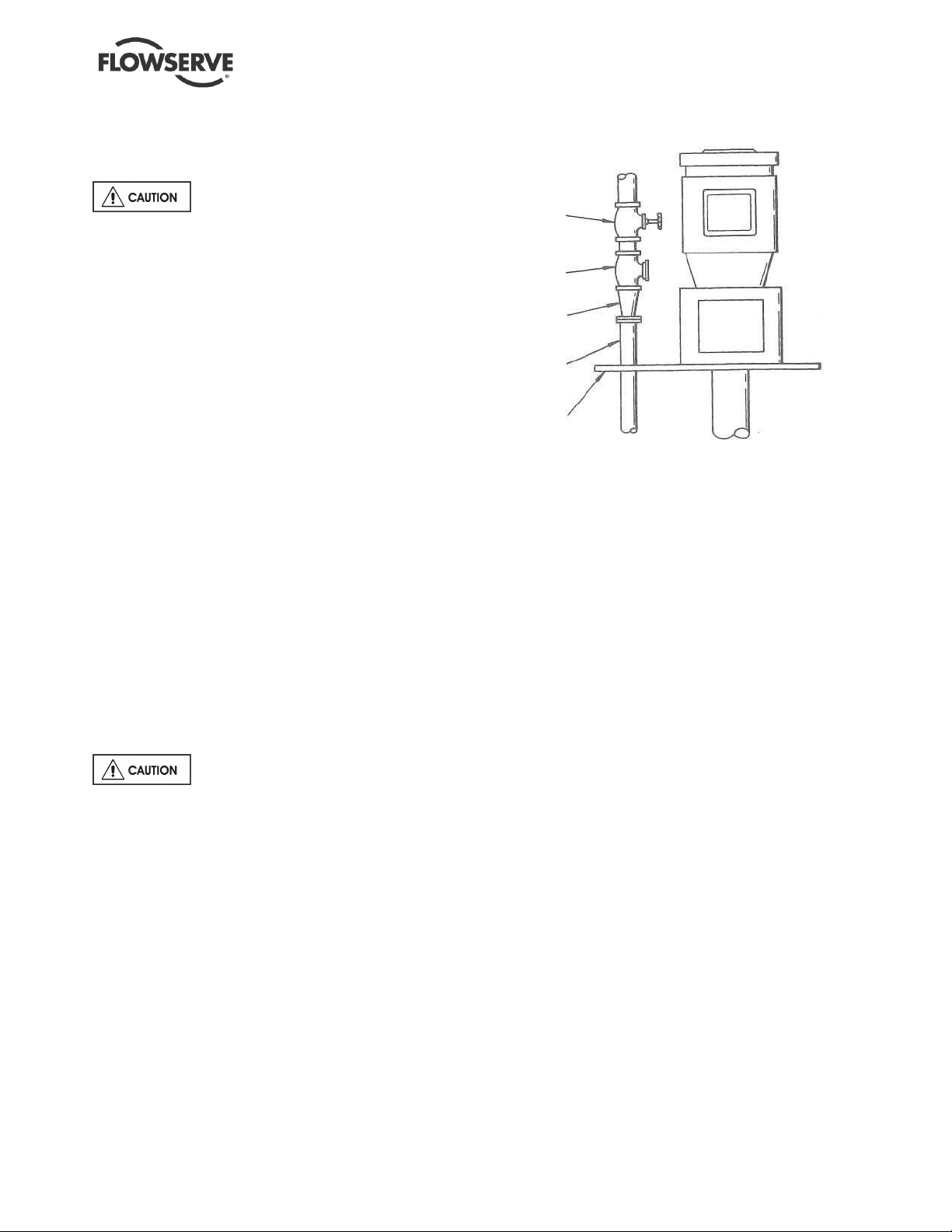

4.7.3 Discharge piping

Install a valve in the discharge line. This valve is

required for regulating flow and/or to isolate the

pump for inspection and maintenance.

When fluid velocity in the pipe is

high, for example, 3 m/s (10 ft/sec) or higher, a

rapidly closing discharge valve can cause a

damaging pressure surge. A dampening

arrangement should be provided in the piping.

All piping must be independently supported,

accurately aligned and preferably connected to the

pump by a short length of flexible piping. The pump

should not have to support the weight of the pipe. It

should be possible to install discharge bolts through

mating flanges without pulling or prying either of the

flanges. All piping must be tight.

a) Use discharge piping one size larger than the

pump discharge.

b) Discharge piping should be well supported

and connected to the pump such that no strain

or weight of the piping is carried by the pump.

c) Check pump shaft for freedom of rotation by

hand to make sure any discharge piping strain

is not causing binding.

d) After the pump discharge, the increaser

should be the first item in the discharge line,

followed by the check valve and gate valve,

respectively. See Figure 4-1.

e) It is recommended that pressure indicating

devices be installed before and after the

valves in the discharge line to verify the pump

is not being run dry and that the discharge

valves are not closed.

Figure 4-1

GATE

VALVE

CHECK

VALVE

CONCENTRIC

INCREASER

PUMP.

DISCHARGE

MOUNTING,

PLATE

The check valve is required to

prevent back-flow through the pump on shut-down.

This flow can reverse rotation of the pump,

potentially damaging the pump, motor and

associated equipment.

Page 20

Page 21

ESP3 USER INSTRUCTIONS ENGLISH 26999943 08-11

of 64

4.7.4 Allowable Nozzle Loads

Discharge piping should be constructed to fit to the

ESP3 discharge piping flange. The ESP3 design

can accommodate large piping loads without

installation should not impose unnecessary loads to

the discharge flange. The allowable piping loads

are shown in Figure 4.2.

affecting the operation of the pump, but the

Figure 4-2 ESP3 Nozzle Loading

Mz

Mz

1

≤+++++

maxmaxmaxmaxmaxmax

Fx

Fx

Fy

Fy

Fz

Fz

Mx

Mx

My

My

Force N Moments Nm

Group Size Fx Fy Fz Mx My Mz

1E 1.5x1LFSP-4 760 1270 760

1E 1.5x1SP-62 760 1270 760

1E 3x1.5SP-62 930 1560 930

1E 3x2SP-62 1110 1870 1110

1E 1.5x1SP-8 760 1270 760

1E 1.5x1LFSP-8 760 1270 760

1E 3x1.5SP-82 930 1560 930

1E 3x2SP-82 1110 1870 1110

2E 3x1.5SP-82 930 1560 930 515 542 515

2E 3x2SP-82 1110 1870 1110

2E 4x3SP-82 1380 2310 1380

2E 2x1SP-10A 760 1270 760

2E 2x1LFSP-10 760 1270 760

2E 3x1.5SP-10 930 1560 930

2E 2x2RSP-10 1110 1870 1110

2E 3x2SP-10 1110 1870 1110

2E 3x3RSP-10 1380 2310 1380

2E 4x3SP-10 1380 2310 1380

2E 4x3SP-10H 1380 2310 1380

2E 6x4SP-10\H 1780 2980 1780

2E 3x1.5SP-13 930 1560 930

2E 3x1.5LFSP-13 930 1560 930

2E 3x2SP-13 1110 1870 1110

2E 4x3SP-13\HH 1380 2310 1380

2E 4x3RSP-13 1380 2310 1380

3E 6x4SP-13A 1780 2980 1780 976 1030 976

3E 6x4RSP-13 1780 2980 1780

3E 8x6SP-14A 2340 3890 2340

3E 10x8SP-14 2800 4670 2800

3E 6x4SP-16\A 1780 2980 1780

3E 8x6SP-16 2340 3890 2340

3E 10x8SP-16\H 2800 4670 2800

414 441 414

414 441 414

515 542 515

610 644 610

414 441 414

414 441 414

515 542 515

610 644 610

610 644 610

759 800 759

414 441 414

414 441 414

515 542 515

610 644 610

610 644 610

759 800 759

759 800 759

759 800 759

976 1030 976

515 542 515

515 542 515

610 644 610

759 800 759

759 800 759

976 1030 976

1281 1356 1281

1539 1620 1539

976 1030 976

1281 1356 1281

1539 1620 1539

Page 21

Page 22

ESP3 USER INSTRUCTIONS ENGLISH 26999943 08-11

of 64

Fx

Fx

Force lbf Moments lbf▪ft

Group Size Fx Fy Fz Mx My Mz

1E 1.5x1LFSP-4 170 285 170 305 325 305

1E 1.5x1SP-62 170 285 170 305 325 305

1E 3x1.5SP-62 210 350 210 380 400 380

1E 3x2SP-62 250 420 250 450 475 450

1E 1.5x1SP-8 170 285 170 305 325 305

1E 1.5x1LFSP-8 170 285 170 305 325 305

1E 3x1.5SP-82 210 350 210 380 400 380

1E 3x2SP-82 250 420 250 450 475 450

2E 3x1.5SP-82 210 350 210 380 400 380

2E 3x2SP-82 250 420 250 450 475 450

2E 4x3SP-82 310 520 310 560 590 560

2E 2x1SP-10A 170 285 170 305 325 305

2E 2x1LFSP-10 170 285 170 305 325 305

2E 3x1.5SP-10 210 350 210 380 400 380

2E 2x2RSP-10 250 420 250 450 475 450

2E 3x2SP-10 250 420 250 450 475 450

2E 3x3RSP-10 310 520 310 560 590 560

2E 4x3SP-10 310 520 310 560 590 560

2E 4x3SP-10H 310 520 310 560 590 560

2E 6x4SP-10\H 400 670 400 720 760 720

2E 3x1.5SP-13 210 350 210 380 400 380

2E 3x1.5LFSP-13 210 350 210 380 400 380

2E 3x2SP-13 250 420 250 450 475 450

2E 4x3SP-13\HH 310 520 310 560 590 560

2E 4x3RSP-13 310 520 310 560 590 560

3E 6x4SP-13A 400 670 400 720 760 720

3E 6x4RSP-13 400 670 400 720 760 720

3E 8x6SP-14A 525 875 525 945 1000 945

3E 10x8SP-14 630 1050 630 1135 1195 1135

3E 6x4SP-16\A 400 670 400 720 760 720

3E 8x6SP-16 525 875 525 945 1000 945

3E 10x8SP-16\H 630 1050 630 1135 1195 1135

Fy

Fy

Fz

Fz

Mx

Mx

My

My

Mz

Mz

1

≤+++++

maxmaxmaxmaxmaxmax

Page 22

Page 23

ESP3 USER INSTRUCTIONS ENGLISH 26999943 08-11

of 64

4.8 Final free rotation check

After connecting the piping, rotate the pump drive

shaft clockwise (viewed from motor end) by hand

several complete revolutions to be sure there is no

binding and that all parts are free. If piping caused

unit to be in a bind, correct piping to relieve strain

on the pump.

4.9 Auxiliary piping

Check to see if any other connections need to be

made to pump, such as fluid injection to stuffing

box for seal or packing lubrication (when furnished)

and make the required connections.

Check to see that connections are made to the

lubrication fittings at pump manifold [3869] on

mounting plate [6130]

4.10 Electrical connections

Electrical connections must be made

by a qualified Electrician in accordance with

relevant local national and international regulations.

It is important to be aware of the EUROPEAN

DIRECTIVE on potentially explosive areas where

compliance with IEC60079-14 is an additional

requirement for making electrical connections.

4.11 Level controls

Assemble float control equipment per Figure 4-3

below. Wire the float controls following the

diagrams on the next several pages. The stops

should be set in accordance with maximum and

minimum liquid levels desired and required. Float

rods are furnished in kits of a standard length. The

rod might have to be cut off to fit the particular

installation.

Figure 4-3

It is important to be aware of the EUROPEAN

DIRECTIVE on electromagnetic compatibility when

wiring up and installing equipment on site.

Attention must be paid to ensure that the techniques

used during wiring/installation do not increase

electromagnetic emissions or decrease the

electromagnetic immunity of the equipment, wiring or

any connected devices. If in any doubt contact

Flowserve for advice.

The motor must be wired up in

accordance with the motor manufacturer's

instructions (normally supplied within the terminal

box) including any temperature, earth leakage,

current and other protective devices as appropriate.

The identification nameplate should be checked to

ensure the power supply is appropriate.

See section 5.4, Direction of rotation

before connecting the motor to the electrical supply.

Some of the wiring diagrams are included on the

following pages. If the wiring diagram needed is not

included, contact control manufacturer for wiring

instructions.

Page 23

Page 24

ESP3 USER INSTRUCTIONS ENGLISH 26999943 08-11

of 64

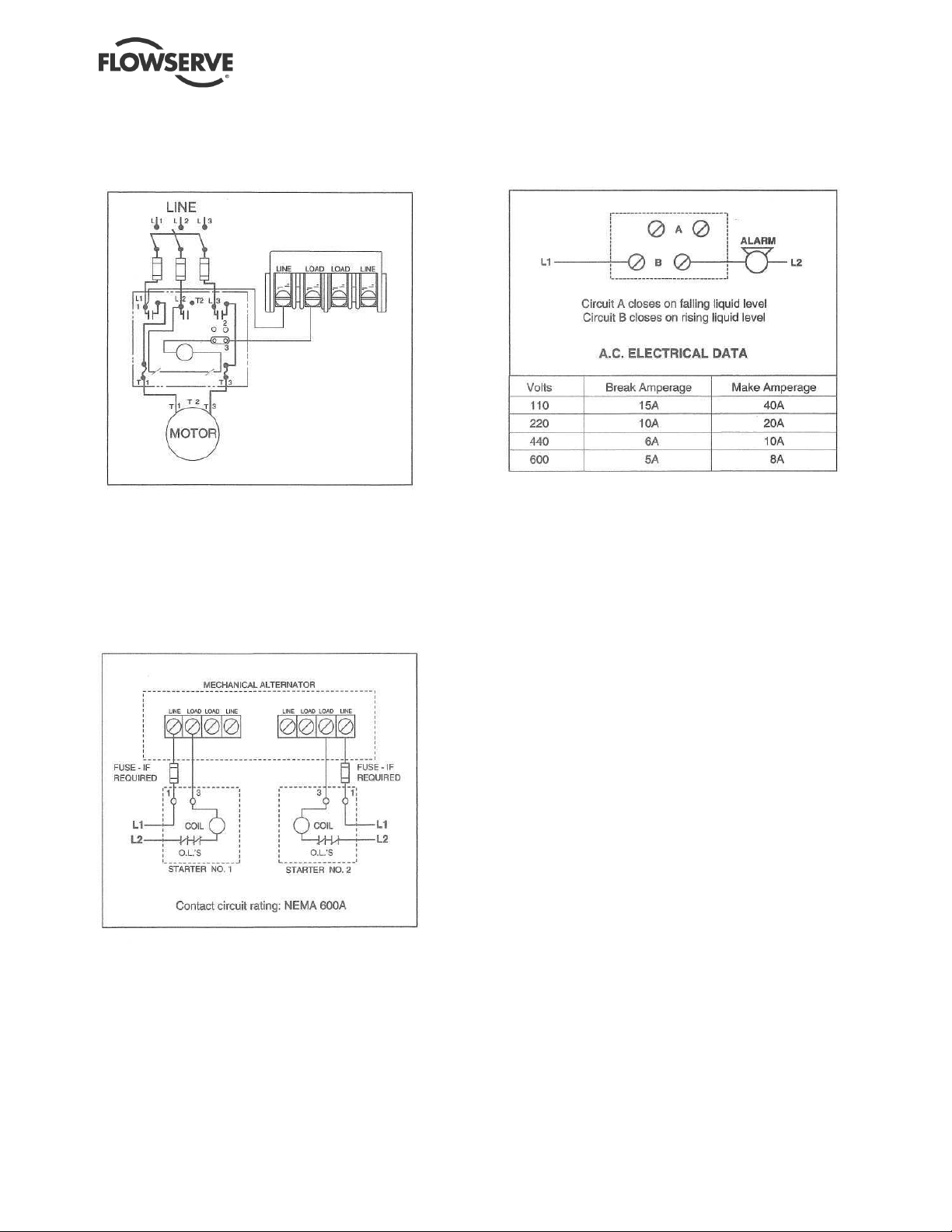

SQUARE "D" CLASS 9036

TYPE GG, DR, DW, GR AND GW - FLOAT SWITCH

(Typical Only)

SQUARE "D" CLASS 9038

TYPE AG, AW, AR - MECHANICAL

ALTERNATOR (Typical Only)

OPTIONAL SQUARE "D" FORM N5

HIGH LEVEL ALARM FOR USE WITH CLASS

9038 MECHANICAL ALTERNATOR (Typical Only)

Page 24

Page 25

ESP3 USER INSTRUCTIONS ENGLISH 26999943 08-11

of 64

MAGNATROL®

FOR SINGLE FUNCTION (A10) SWITCHES

(Typical Only)

MAGNATROL®

FOR DOUBLE FUNCTION (B10) SWITCHES

(Typical Only)

Page 25

Page 26

ESP3 USER INSTRUCTIONS ENGLISH 26999943 08-11

of 64

MAGNATROL®

FOR DOUBLE FUNCTION (B10) SWITCHES

(Typical Only)

Page 26

Page 27

ESP3 USER INSTRUCTIONS ENGLISH 26999943 08-11

of 64

MAGNATROL®

FOR DOUBLE FUNCTION (B10) SWITCHES

(Typical Only)

Page 27

Page 28

ESP3 USER INSTRUCTIONS ENGLISH 26999943 08-11

of 64

MAGNATROL®

FOR TRIPLE FUNCTION (C10) SWITCHES

(Typical Only)

Page 28

Page 29

ESP3 USER INSTRUCTIONS ENGLISH 26999943 08-11

of 64

MAGNATROL®

FOR TRIPLE FUNCTION (C10) SWITCHES

(Typical Only)

Page 29

Page 30

ESP3 USER INSTRUCTIONS ENGLISH 26999943 08-11

of 64

APEX SWITCH

(Typical Only)

Page 30

Page 31

ESP3 USER INSTRUCTIONS ENGLISH 26999943 08-11

of 64

4.12 Protection systems

The following protection systems are

recommended particularly if the pump is installed in a

potentially explosive area or is handling a hazardous

liquid. If in doubt consult Flowserve.

If there is any possibility of the system allowing the

pump to run against a closed valve or below

minimum continuous safe flow a protection device

should be installed to ensure the temperature of the

liquid does not rise to an unsafe level.

If there are any circumstances in which the system

can allow the pump to run dry, or start up empty, a

power monitor should be fitted to stop the pump or

prevent it from being started. This is particularly

relevant if the pump is handling a flammable liquid.

If leakage of product from the pump or its associated

sealing system can cause a hazard it is

recommended that an appropriate leakage detection

system is installed.

To prevent excessive surface temperatures at

bearings it is recommended that temperature or

vibration monitoring is carried out.

5 COMMISSIONING, STARTUP,

OPERATION AND SHUTDOWN

These operations must be carried

out by fully qualified personnel.

5.1 Pre-commissioning procedure

5.1.1 Pre start-up checks

Prior to starting the pump it is essential that the

following checks be made. These checks are all

described in detail in the Maintenance section of this

manual.

• Motor properly secured to the support head

• All fasteners tightened to the correct torque

• Coupling guard in place and not rubbing

• Rotation check, see section 5.4.

This is absolutely essential

• Impeller clearance setting

• Shaft seal properly installed

• Seal support system operational

• Bearing lubrication

• Pump instrumentation is operational

• Rotation of shaft by hand

As a final step in preparation for operation, it is

important to rotate the shaft by hand to be certain that

all rotating parts move freely, and that there are no

foreign objects in the pump casing.

5.2 Bearing Lubrication

Two types of bearings are used in the ESP3. Line

shaft bearings are used to support pump shaft within

the column. These plain bearings are lubricated by

external flush, product lubrication or grease. Duplex

angular contact bearings are used to support the

coupling end of the shaft. These ball bearings

support coupling loads and pump thrust. They are

lubricated by bearing grease. See (5.2.3)

Operation of the unit without proper

lubrication can result in bearing failures, pump

seizures and pump failure.

5.2.1 Line Shaft Bearings

Check to see that no damage has occurred to any

lubrication lines above the mounting plate [6130]

during shipment or installation. For number of

bearings, refer to Figure 5-6. Check to see that

connections are made to lubrication fittings at pump

manifold [3869] on mounting plate [6130].

5.2.1.1 External Flush Lubrication

a) Clean liquid from an external source must be

used when pumps are furnished with external

flush lubrication connections. Liquid is typically

supplied continuously during operation. Some

bearings (such as carbon) can run without