Page 1

McCANNA/MARPAC Valves

MMAIM2003

Tri-Pac Three-Piece In-line Maintainable Ball Valves

Models E325/E525

Installation, Operation and Maintenance Instructions

1. Installation

These valves may be installed in any position

utilizing normal pipe fitting practices.

Socket-Weld End Valves

To keep from destroying soft parts of the

valve, loosen two bolts and remove six bolts

as shown in Figures 1A, 1B, and 1C and

swing out the body as for servicing. Take care

that the end seals are not damaged. Note that,

for the FIRE-GARD

®

valves with socket weld

ends, extra end seals are included with the

valve. Seals are to be replaced during the

reassembly after welding. Prior to removing

the bolts to allow the body to swing out, the

valve may be tack welded in the line to

facilitate line-up.

The base material of valve covered by this

procedure conforms to the following:

• Carbon Steel - ASTM A105 (Forged)

• 316 Stainless Steel - ASTM A182

• GRF316 (Forged)

Before welding, push pipe snugly into end

adapters and then back off approximately

1

/

16

". The socket and at least one inch of the

pipe (at the joint) must be free of all foreign

material which might prove detrimental to

the weld.

Use the smallest electrode and minimum

amperage consistent with efficient welding to

minimize warpage. Tacks should be ground

out before completing the root pass in that

area. Weld stringer beads with no weaving

and stagger all starts and stops.

Carbon steel ends should be allowed to cool

slowly. The valve ends may be covered with a

welding blanket to promote slow cooling.

2. Stem Packing

Adjustment

If leakage is evident in stem packing area,

tighten the adjusting nut (7)

1

/

8 turn. If leak

still persists, repeat above.

Replacement of the stem seals (5) is indicated

if leak is still apparent.

3. Seal Replacement

a WARNING: Begin with the valve partially

open in a depressurized line. Valve should

be cycled once to ensure there is no media

trapped behind the ball.

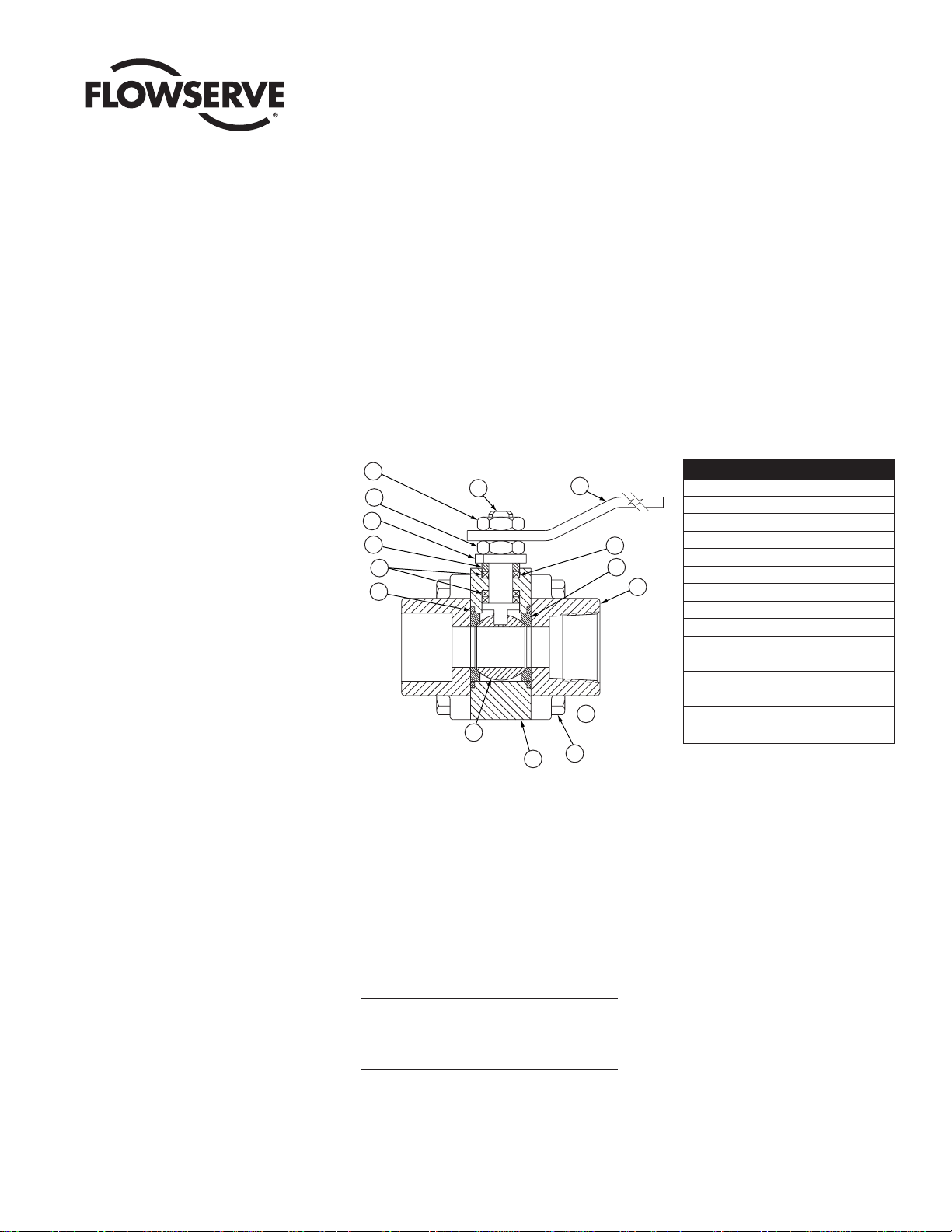

A. Turn ball (3) to open position and remove

handle nut (9), handle (8), adjusting nut (7),

travel stop (13), (part of the handle on sizes

1

/

4" –

3

/

4") and gland ring (6).

B. Loosen two bolts (14) (one per side in line

with each other) and remove remaining six

bolts (Figures 1A and 1B). The center body

section of the valve will swing out (Figure 1C)

for access to the ball (3), stem (4), seats (10)

and body seals (11).

NOTE: Valve must be in open position in

order to swing out body section.

C. Remove body seals (11) by using a sharp

instrument such as pocket knife. Care should

be taken to avoid damage to the surfaces of

the seal groove.

D. To take out one seat (10) and the ball (3),

rotate the stem (4) so ball (3) is in fully

closed position and insert wooden dowel (not

metal) in port and tap gently on ball (3)

thereby forcing it out of body (1).

NOTE: Extreme caution should be taken to

avoid damage to the ball (3).

E. Take out other seat (10).

13

9

4

14

2

10

8

1

3

11

5

6

7

12

15

NOT

SHOWN

Part No. Description

1 Body

2 End Adapters

3 Ball

4 Stem

5 Stem Seal Set

6 Gland Ring

7 Adjusting Nut

8 Handle

9 Handle Nut

10 Seat

11 Body Seals

12 Stop Pins (not shown)

13 Travel Stop

14 Bolts

15 Grounding Washer

Page 2

F. Push the stem (4) down thru the body (1)

and out the open end of the body (1). Remove

the upper and lower stem seals (5) and the

grounding washer (15). Grounding washer is

not used with the FIRE-GARD valves. Save the

grounding washer (15) for reassembly.

Flowserve recommends replacement of all soft

parts whenever the valve is disassembled for

reconditioning. Replacement parts can be

ordered in kit form.

4. Reassembly

A. Put one seat (10) in body (1).

NOTE: Seats (10) are to be installed with

concave surfaces positioned against the ball (3).

B. Lightly grease the stem seals (5) and the

seal area and the threads of the stem (4).

Insert stem seal(s) (5) into the lower stem

seal cavity with the raised outer edge facing

into the counterbore (FIRE-GARD seals are

square cut seals). Insert stem (4) through the

installed stem seals (5) and the body (1).

Place travel stop (13) on the stem (4) so that

it rests on the top surface of the body (1).

Thread the adjusting nut (7) on the stem (4)

and torque to

3

/

4 of the final torque value for

the adjusting nut (7) (see Table 1).

Table 1: Adjusting Nut Torques

(lb-ft) Number of Seals

SIZE TORQUE UPPER LOWER

1

/

4

" to

1

/

2

"5 1 1

3

/

4" to 2" 10 1 2

Remove the adjusting nut (7) and the travel

stop (13) without moving the stem. Place the

grounding washer (15) into the upper seal

cavity with the raised fingers pointing up.

Push the upper stem seal(s) (5) into the

counterbore with raised outer edge pointing

into the valve. Add the gland ring (6), the

travel stop (13) and the adjusting nut (7).

Make sure the travel stop (13) is installed so

that the valve can close in a clockwise

direction and open counterclockwise. If the

rotation is not correct, the travel stop (13)

must be inverted. Torque the adjusting nut to

the value shown in Table 1. Cycle several

times and check the adjusting nut torque.

C. Turn the stem (4) to a position with the

stem tang flats parallel to the cavity. (Ball will

be in closed position and stay in this position

through steps D and C).

D. Install the ball (3). NOTE: Ball should be

carefully examined for nicks, scratches, pitting

or corrosion and replaced as necessary.

E. Put other seat (10) into body, being certain

that spherical surface of the seat is positioned

against the ball.

F. Press body seals (11) into grooves on face

of body.

G. Turn ball to open position and swing valve

body section back into position

H. Turn ball back to full closed position.

External stem flats positioned perpendicular

to run of valve.

I. Install and tighten all bolts (14) finger tight.

J. Evenly tighten bolts (14) going around

three or four times, alternating sides and in

sequence shown in Figure 2. Bolts should be

tightened until body (1) and end adapter (2)

mating surfaces are metal to metal, but do

not exceed torque values listed in Table 2. Do

not substitute for original bolts. Replacements

may be ordered if necessary.

K. Install handle (8) and handle nut (9).

Table 2

Valve Size Bolt Torque (ft-lbs.)

1

/

4",

3

/

8",

1

/

2"9

3

/

4"17

1" 31

11/

4", 1

1

/

2"48

2" 1

Flow Control Division

McCANNA/MARPAC Valves

Flowserve Corporation has established industry leadership in the design and manufacture of its products. When properly selected, this Flowserve product is designed to perform its intended function

safely during its useful life. However, the purchaser or user of Flowserve products should be aware that Flowserve products might be used in numerous applications under a wide variety of industrial

service conditions. Although Flowserve can (and often does) provide general guidelines, it cannot provide specific data and warnings for all possible applications. The purchaser/user must therefore

assume the ultimate responsibility for the proper sizing and selection, installation, operation, and maintenance of Flowserve products. The purchaser/user should read and understand the Installation

Operation Maintenance (IOM) instructions included with the product, and train its employees and contractors in the safe use of Flowserve products in connection with the specific application.

While the information and specifications contained in this literature are believed to be accurate, they are supplied for informative purposes only and should not be considered certified or as a guarantee of

satisfactory results by reliance thereon. Nothing contained herein is to be construed as a warranty or guarantee, express or implied, regarding any matter with respect to this product. Because Flowserve

is continually improving and upgrading its product design, the specifications, dimensions and information contained herein are subject to change without notice. Should any question arise concerning

these provisions, the purchaser/user should contact Flowserve Corporation at any one of its worldwide operations or offices.

For more information about Flowserve Corporation, contact www.flowserve.com or call USA 1-800-225-6989.

FLOWSERVE CORPORATION

FLOW CONTROL DIVISION

1978 Foreman Drive

Cookeville, Tennessee 38501 USA

Phone: 931 432 4021

Facsimile: 931 432 3105

www.flowserve.com

© 2003 Flowserve Corporation, Irving, Texas, USA. Flowserve and McCANNA/MARPAC Valves are registered trademarks of Flowserve Corporation. MMAIM2003 9/03 Printed in USA

Figure 1A: Loosen two bolts

Figure 1B: Remove remaining six bolts

Figure 1C: Swing body section and service

Figure 2

NOTICE: McCANNA Valves are designed and manufactured using good workmanship and materials, and they meet all applicable industry standards. Flowserve Corp. is anxious to avoid

injuries and property damage which could result from misapplication of the product. Proper valve selection is imperative. Examples of the misapplications or misuse of a valve include

but are not limited to use in a service in which the pressure/temperature rating is exceeded or in a chemical service incompatible with the valve materials; use of undersized valve

actuators; use of extremely fast valve actuation and/or continuous valve cycling on standard valves; making modifications of the product of any kind; failure to use caution in operating

valves in high temperature, high pressure, or highly hazardous services; and the failure to maintain valves as recommended. The right is reserved to change or modify product design or

construction without prior notice and without incurring any obligation to make such changes and modification on products previously or subsequently sold.

Marpac

®

is a registered trademark of M&FC Holding Co. Inc. • FIRE-GARD®is a registered trademark of M&FC Holding Co. Inc.

1

3

4

2

Loading...

Loading...