Page 1

Durco® G4 Full Area Plug Valves

Non-Lubricated Plug Valves

for Chemical Service

Page 2

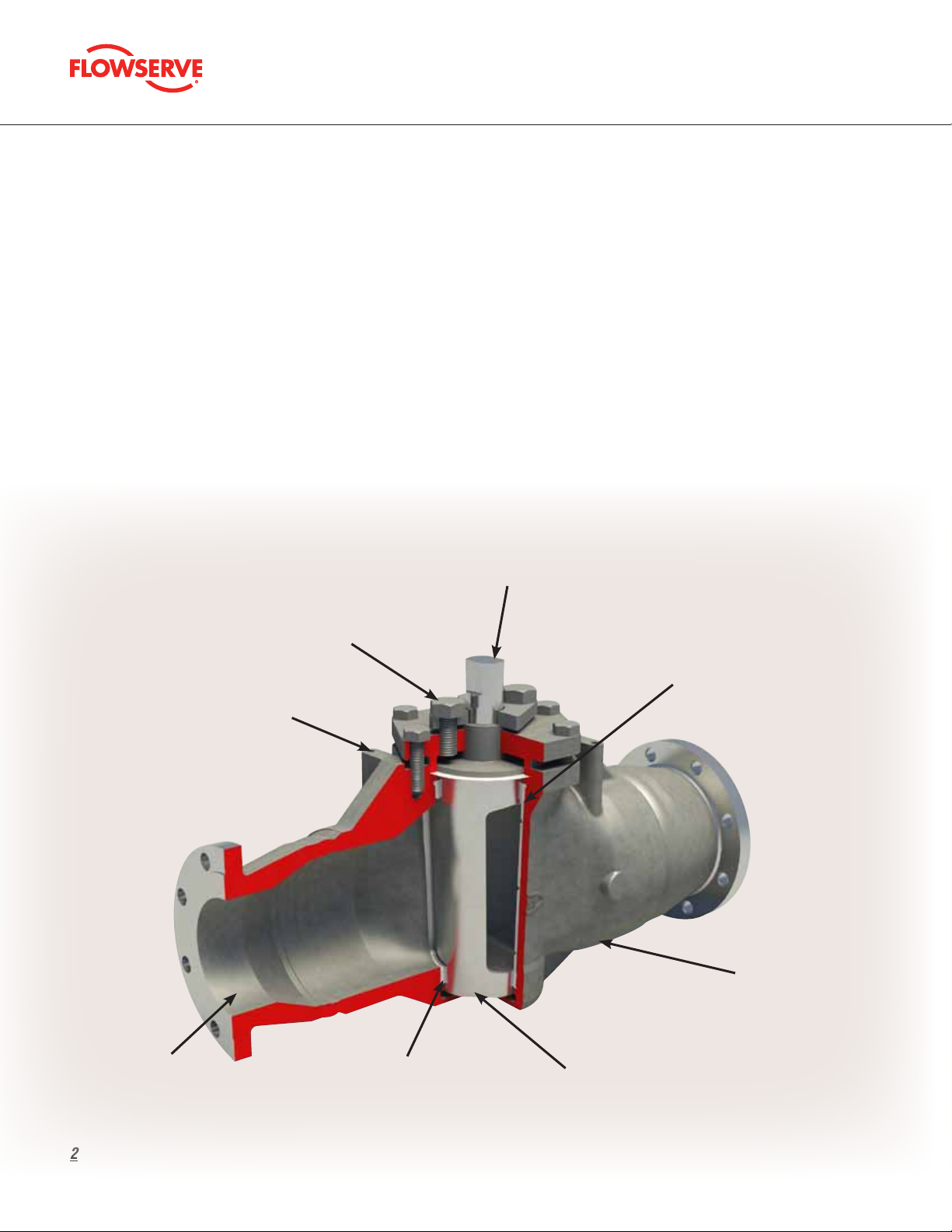

Durco® G4 Full Area Plug Valves

Flowserve, which has supplied the highest quality plug valves for the most corrosive and difficult chemical

services, is now pleased to offer the Durco G4 Full Area Sleeveline Plug Valves These valves offer greatly expanded

port areas to permit greatly increased flow of process fluid. All of the proven features of the standard G4 remain

with the full area model.

Special Configuration Valves

The G4 Full Area valve is available in a wide number of variations including designs for the following:

• Firesealed

• Chlorine service

• HF alkylation

• Weld end

• 3-way configurations

Double D Plug Stem

Accepts most standard

actuation equipment.

In-Line Adjustment

Prevents thru-line leakage.

Actuator Mounting Pads

Mounts directly on flanges

for solid support.

PTFE Sleeve

Large seal area offers

positive shutoff and

extended service life.

Expanded ports

offer low pressure drop

and high CV.

2

Raised Locking Ribs

Along with grooves and recesses positively

lock sleeve in body.

Rugged, Heavy-Duty Body

Limited lifetime casting

guarantee. ANSI (ASA) or

DIN flanges standard. N.P.T.

screwed, socket and butt weld

available.

Rated to ANSI Class 150

lb and 300 lb designs at

pressures to 740 psi (5102

kPa) and vacuum

to 1 micron (0.133 kPa).

Tapered Plug

Assures reduced turning torque and in-line seal adjustment

and wear. Adjustment is independent of stem seals. With ± 3⁄16

in (± 5 mm) adjustment, plug cannot bottom out.

Page 3

Marathon Option offers High Cycle Positive Stem Sealing

G4B Marathon Valve

PPM

flowserve.com

3-Year Performance Guarantee

Unprecedented limited warranty. The valve will be repaired

or replaced if stem seal fails within 3 years after installation.

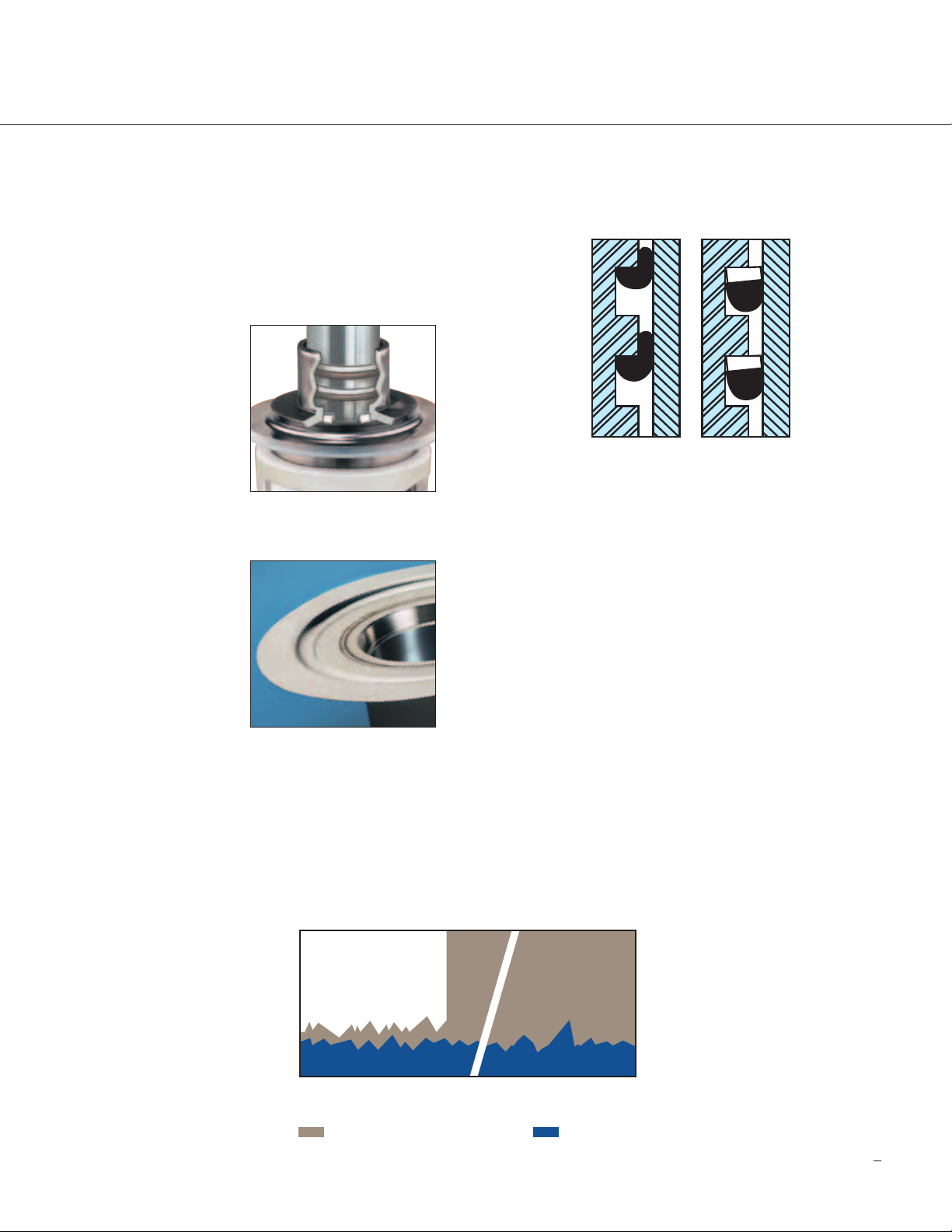

Unique Stem-Sealing Design

The G4B Marathon

valve can be used with

confidence in chemical

processing applications

where tight shutoff and

emissions containment

are priority requirements.

As a bonus, its very

design assures long-lived,

high cycle performance.

New Welded Diaphragm

The integral thrust

collar/alloy diaphragm

is a third line of defense

against leakage to

the atmosphere. The

underside of the metal

bellows-like diaphragm

acts as an expansion

joint by allowing the PFA

diaphragm to adjust to

plug movement and pressure changes. The Hastelloy C

diaphragm provides an impermeable barrier to chlorine as

well as many other services.

Available for G4Z, MG4, FJG and other models.

Viton O-Rings

A pair of Viton

O-rings prevents

stem leakage while

containing line

pressure. They also

protect the thrust

collar against attack

from atmospheric

corrosion. PTFE

back-up rings firmly

lock the Viton

O-rings in the stem

grooves and serve

as anti-extrusion

devices.

Optional Kalrez O-rings are available for special services.

Without

back-up rings

With back-up

rings

Proven High Cyclability

Lab and field tests have proven that the G4B Marathon can

cycle as many as three-to-five times more than a standard

PTFE sleeved quarter-turn valve before it begins to show

stem seal wear.

Passing The Test

Lab technicians defeated the PTFE sleeve and PFA

diaphragm, the G4B’s primary and secondary stem seals, by

cutting both of them in four places. They operated the valve

to 160,000 cycles. Rather than using the standard Method

21 methane emissions test, they chose the more demanding

helium emissions test. The results were impressive.

Viton O-Rings and welded metal diaphragm stem seals

Sleeve and diaphragm cut in four places

20

10

0

10 20

Cycles (x 1000)

Conventional Plug Valve > 2000 PPM

140 160

G4EB Valve

3

Page 4

Automated Systems

FLOWSERVE offers Automax, Norbro and Worcester Actuators and I

complete automated on-off or modulating

packages to meet exacting technical requirements.

nstrumentation allowing us to supply

Durco Sleeveline valves are readily adaptable for automatic operation because the torque is relatively constant and lubrication is not required.

Flowserve, a specialist in complete automation systems, produces a broad line of rack and pinion, heavy

duty, electric and linear actuators. In addition, a comprehensive line of engineered special control circuits,

solenoid valves, limit switches positioners and actuator mounting kits is offered.

Our wide range of electrical and pneumatic instrumentation

incorporates:

•Digital network communication

•Superior diagnostics

•Intelligent valve controllers

•Comprehensive user-friendly software

•

On-line accessible automated drawing system

• Control sizing software

• Actuator sizing software

For complete tables of torque and

Cv (Kv) values, please refer to the

Instrument Engineers Handbook for

Durco Quarter-Turn Control Valves

4

Page 5

Parts and Materials

G4 Valve

Stem Configuration

½ in (15 mm) to

6 in (150 mm) flats

G4B

Exclusive

Parts

flowserve.com

G4 & G4B

Item No. Description Material of Construction No. Req.

1 Body * 1

11 •

20 •

21 •

2 •

2 Plug * 1

2 • Plug * 1

3 Top Cap

3A Top Cap Fastener

5 Sleeve PTFE*** 1

6 Diaphragm PFA or TM*** 1

11 Thrust Collar Durcomet 100 1

Thrust Collar/

11 •

Diaphragm

12 Adjuster Durcomet 100 1

12A Adjuster Fastener

13 Wrench Ductile Iron 1

17 Grounding Spring 304 SS 1

+

19

Stop Collar Zinc Plated Carbon Steel 1

19A Stop Collar Retainer 302 SS 1

20 • Back-up Ring PTFE 2

21 • O-ring Viton (Kalrez optional) 2

* Body (Item No. 1) and Plug (Item No. 2) available in the following cast

materials: Ductile Iron; Carbon Steel; CF-8 SS; Durcomet 100; Durimet 20;

Chlorimet 2 and 3; Nickel; Monel; Inconel; Titanium and Zirconium.

** Durcomet 100 is a high alloy stainless steel, CD4M Cu.

*** Other materials available on request.

• Parts exclusive to G4B.

+

locking stop collar is standard for valves ½ - 3”

Du rco met 10 0**/

Ductile Iron

B8M3 SS/B7 (CR-MO)

Steel

Durcomet 100/Hastelloy

B8-40 SS/B7 (CR-MO)

Steel

1

4

®

1

2

Applicable Valve Standards

Specification Title

ASM E B16.10 Face-to-face dimension

ASME B16.34 Steel valves, flanged &

buttweld

ASME B16.5 Flange & flange fitting

ASME B1.20.1 Screwed ends

API 607 Fire safe valve testing

API 598 Valve inspection & test

ASM E B16.11 Forged fittings, socket

weld and threaded

M.S.S. SP-54 Radiographic

M.S.S. SP-55 Visual quality

M.S.S. SP-61 Hydrostatic testing

Standard Materials Selection Chart A

ASTM A395 Ductile Cast Iron

Ductile Cast Iron Nickel Plated (Plug Only)

ASTM A216 Gr. WCB (Cast Steel)

Cast Steel Nickel Plated (Plug Only 3" or larger)

ASTM A351/A744 Gr. CF8 (304 S.S.)

ASTM A351/A744 Gr. CF3 (304L S.S.)

ASTM A351/A744 Gr. CF8M (316 S.S.)

ASTM A351/A744 Gr. CF3M (316L S.S.)

Durcomet 5 (Durco’s High Silicon S.S.)

ASTM A351/A744 Gr. CD4MCuN (Duplex S.S.)

ASTM A351/A744 Gr. CN-7M (Alloy 20)

1. Registered trademark of Avesta AB

2. Registered trademark of the International Nickel Company, Inc.

This list shows several of our common materials; however, any of the wide range of Flowserve

materials is available.

ASTM A351/A744 Gr. CK-3MCuN (254 SMO)

ASTM A494 Gr. CY-40 (Inconel 600)

ASTM A494 Gr. M35-2 (Monel 400)

ASTM A494 Gr. M35-1 (Monel 400)

ASTM A494 Gr. CZ-100 (Nickel 200)

ASTM A494 Gr. N-7M (Chlorimet 2)

STM A494 Gr. CW-6M (Chlorimet 3)

ASTM B367 Gr. C-3 ( Titanium)

ASTM B752 Gr. 702C (Zirconium)

ASTM B752 Gr. 705C (Zirconium)

ASTM A995 Gr. 5A (CE3MN) Super Duplex SS

2

2

2

1

5

Page 6

Dimensions (in.)

Size

1

1.5

2 ¾ 4 ¾ 4 ¾ 5 8 17

3 ¾ 6 4

4 ¾ 7 ½ 8

6

8 7/8 11 ¾ 8 1 13 12 39 ¼ 16 18 18 3/16 1 5/16

10

Cv Values

C/F contact Factory

150# Drilling 300# Drilling

Hole B.C. No. Hole B.C. No.

5

/8 3 1/8 4 ¾ 3 ½ 4 11 ½

5

/8 3 7/8 4 7/8 4 ½ 4 12 ¾

7

/8 6 5/8 8 22 ¼ 12 1/16 12 8 3/8 3

7

/8 7 7/8 8 24 12 1/16 12 10 3/8 3

7

/8 9 ½ 8 7/8 10 5/8 12 31 ½ 16 18 14 5/8 5/16

A M N P X

Sizing Torques (inch-pounds)

Size Cv

1 61

1.5 96

2 223

3 300

4 644

6 1096

8 1677

10 C/F

For values with PTFE sleeve

C/F-contact factory

Size Clean service Slurry

1 497 671

1,5 675 911

2 118 0 1458

3 2400 3240

4 6000 8100

6 9300 12555

8 39900 42000

10 60000 C/F

6

Page 7

Testing and Pressure/Temperature Ratings

flowserve.com

G4 valves have been extensively tested to ensure the highest level

of reliability possible.

The unique reverse lip stem seal has been tested from -50°F

(-46°C) to 450°F (232°C) maximum, and with pressures up to 720

psig (4960 kPa).

High temperature throttling tests at 450°F (232°C) with pressure

drops of 175 psig (1205 kPa) have proven the superiority of G4

valves over other soft-seated valves. Ask your Durco Valve Sales

Representative for specific test results.

The valves have been temperature cycled to 450°F (232°C), and

have provided performance superior to any other soft-seated valve

available for cyclical temperature situations.

We believe the G4 valve is the best soft-seated valve on the market

today, and will outlast and outperform all competitive valves.

Pressure-Temperature Ratings

The pressure-temperature ratings of all the materials below are

based on mechanical property requirements cited in the latest

ASME specifications.

The pressure-temperature rating for ductile iron is in agreement

with ASME B16.42, 1998.

Valves may require adjustment to remain drop tight at the lower end

of temperature range when operating below 0°F (-17°C) or during

extreme temperature cycles.

G4 Pressure/Temperature Ratings

Class 150 Valves Class 300 Valves

D-20 = Durimet 20 (CN-7M), CD4M = Durcomet 100 (CD-4MCu), D4 = Cast 316 SS (CF-8M), D4L = Cast 316L SS (CF-3M), D2 = Cast 304

SS (CF-8), D2L = Cast 304L SS (CF-3), DC2 = Chlorimet 2 (N-7M), DC3 = Chlorimet 3 (CW-6M), DINC = Cast Inconel (CY-40), DS = Cast

Carbon Steel (WCB), DCI = Ductile Cast Iron (60-40-18), DNI = Cast Nickel (CZ-100), DM-1 = Cast Monel (M-35-1), Zr-705C = Zirconium

705C, Zr-702C = Zirconium 702C, Ti = Titanium, CK-3MCuN = 254 SMO

7

Page 8

FCD DVENBR0025-00 08/12 Printed in USA.

To find your local Flowserve representative:

For more information about Flowserve Corporation, visit

www.flowserve.com or call USA 1 800 225 6989

United States

Flowserve Corporation

Flow Control Division

1978 Foreman Drive

Cookeville, Tennessee 38501

Phone: 931 432 4021

Fax: 931 432 3105

www.flowserve.com

Germany

Flowserve Ahaus GmbH

Von Braun Straße 19a

D-48683 Ahaus

Germany

Phone: +49 2561 686-0

Fax: +49 2561 686-39

Singapore

Flowserve Pte. Ltd.

12 Tuas Avenue 20

Republic of Singapore 638824

Phone: +65 6879 8900

Fax: +65 6862 4940

Brazil

Av. Tocantins 128

Sao Caetano do Sul

SP 09580-130

Brazil

Tel 55 11 2169 6300

Fax 55 11 2169 6313

China

Flowserve Corporation Beijing Office

Room 22A1&A2.HanWei Plaza

No.7 GuangHua Road

Chaoyang District

Beijing. China 100004

Tel: +86-10-59210600

+86-10-59210601

Fax: +86-10-65611899

Flowserve Corporation has established industry leadership in the design and manufacture of its products. When properly selected, this Flowserve product is designed to perform its

intended function safely during its useful life. However, the purchaser or user of Flowserve products should be aware that Flowserve products might be used in numerous applications

under a wide variety of industrial service conditions. Although Flowserve can (and often does) provide general guidelines, it cannot provide specific data and warnings for all possible

applications. The purchaser/user must therefore assume the ultimate responsibility for the proper sizing and selection, installation, operation, and maintenance of Flowserve products.

The purchaser/user should read and understand the Installation Operation Maintenance (IOM) instructions included with the product, and train its employees and contractors in the safe

use of Flowserve products in connection with the specific application.

While the information and specifications contained in this literature are believed to be accurate, they are supplied for informative purposes only and should not be considered certified or

as a guarantee of satisfactory results by reliance thereon. Nothing contained herein is to be construed as a warranty or guarantee, express or implied, regarding any matter with respect

to this product. Because Flowserve is continually improving and upgrading its product design, the specifications, dimensions and information contained herein are subject to change

without notice. Should any question arise concerning these provisions, the purchaser/user should contact Flowserve Corporation at any one of its worldwide operations or offices.

© 2005 Flowserve Corporation, Irving, Texas, USA. Flowserve is a registered trademark of Flowserve Corporation.

flowserve.com

flowserve.com

Loading...

Loading...