Page 1

FCD WCAIM2058-01

(Part 60130)

Worcester Actuation Systems

DataFlo Digital Electronic Remote Controller DRC-17

Installation, Operation and Maintenance Instructions

MODELS:

10 – For DataFlo Remote Controller and 10-23 75 Actuators

25 – For DataFlo Remote Controller and 25/30 75 Actuators

Setpoint Inputs:

DRC17-1K 1000 ohm Resistance Setpoint Input

DRC17-13 135 ohm Resistance Setpoint Input

DRC17-1 1 to 5 milliamp Setpoint Input

DRC17-4 4 to 20 milliamp Setpoint Input

DRC17-10 10 to 50 milliamp Setpoint Input

DRC17-5V 0 to 5 VDC Setpoint Input

DRC17-XV 0 to 10 VDC Setpoint Input

Voltages:

120A – 120 VAC Power Circuits

240A – 240 VAC Power Circuits

Page 2

2 DataFlo Digital Electronic Remote Controller DRC17 WCAIM2058

Flow Control

Worcester Actuation Systems

TABLE OF CONTENTS

1.0 GENERAL 3

1.1 Important Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.2 Operating Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1.3 Operating Humidity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2.0 FIELD INSTALLATION OF MOTOR DRIVER BOARD INTO SERIES 75 ACTUATOR 4

2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2.2 Mounting Potentiometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2.3 Mounting Circuit Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

3.0 WIRING OF THE DIGITAL CONTROLLER 7

3.1 Wiring the DRC Motor Driver Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.2 Wiring From the DRC to the Actuator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.3 Wiring the DRC Power Supply Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.3.1 Wiring for a Current Setpoint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.3.2 Wiring for a Potentiometer Setpoint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

3.3.3 Wiring for an Analog Current Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

3.3.4 Wiring for an RTD Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

3.3.5 Wiring for a Thermocouple Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

3.3.6 Serial Communications Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

3.3.7 Alarm Output Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

3.3.8 Position/Control Select Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

3.3.9 Position Feedback Output Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

3.3.10 Utility Voltage Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

3.3.11 Spare Connection Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4.0 OPERATION OF THE REMOTE CONTROLLER 14

4.1 General Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4.2 The DRC Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4.3 Changing Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

4.4 Tuning the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

4.5 The Run Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

4.5.1 The DRC Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

4.5.2 Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

4.6 Program Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

4.6.1 Entering the Program Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

4.6.2 Examining and Changing Parameter Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

4.6.3 Setting Default Factory Parameter Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

4.6.4 DRC Programmable Parameter Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

4.7 Manual Setpoint Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

4.7.1 Entering the Manual Setpoint Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

4.7.2 Enabling, Disabling, and Changing the Setpoint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

4.8 Manual Position Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

4.8.1 Entering the Manual Position Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

4.8.2 Changing Valve Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

4.8.3 Auto-Tune . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

4.8.3.1 Starting Auto-Tune . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

4.8.3.2 The Automated Auto-Tune Procedure and Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

4.9 Calibration Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

4.9.1 Entering the Calibration Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

4.9.2 Calibration of Valve Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

4.9.3 Calibration of Cycle Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

4.9.4 Calibration of 4-20 mA Setpoint Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

4.9.5 Calibration of a Potentiometer Setpoint Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

4.9.6 Calibration of an Analog (4-20 mA) Process Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

4.9.7 Calibration of an RTD Process Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

4.9.8 Calibration of a Thermocouple Process Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

5.0 TECHNICAL DATA 25

6.0 TROUBLESHOOTING 26

Page 3

1.0 General

The Worcester Actuation Systems Dataflo Remote Controller (DRC17)

was designed for use with the Worcester Series 75 electric actuators.

However, it may also be used with other actuators or electrically

operated rotary devices, provided the specified load parameters given

in Part 5.5 are not exceeded.

1.1 Important Items

PLEASE READ THIS SECTION

1.1.1 Sensitivity to Electrical Noise

The Dataflo Remote Controller (hereafter referred to as

the DRC) is sensitive to electrical noise on signal, process

and power supply lines. The DRC can also be affected by

radiated electrical noise. For maximum controller

sensitivity, the electrical noise level should be as low as

possible. Follow the installation and calibration guidelines

carefully and use shielded cable as noted in the paragraph

below.

Shielded wire should be used for all setpoint and process

signal input circuit wiring regardless of length. The

wiring from the feedback potentiometer and the control

signals between the actuator and the DRC enclosure

should be in a shielded cable as shown in section 3.0. If

multiple cables are used, their individual shields must be

attached together inside the actuator and connected as

shown for the one shield. A shield should never be used

as one of the signal wires. Shields for setpoint and

process signals should be grounded at their source and

not connected at the DRC.

NOTE: ALL WIRING TO TERMINAL STRIPS SHOULD BE

INSERTED ONLY TO MID-POINT OF TERMINAL STRIP.

For 240 VAC DRC only, limit switches do not directly

control the motor(s). Therefore, the actuator will not stop

when the limit switches trip. Use care not to drive the

actuator past its normal limits.

1.1.2 Fuses and Input Currents

The Setpoint input circuit is protected with a fuse (F1)

located on the microcontroller board inside the DRC

enclosure. The fuse is used to protect the input circuit

from excessively high current. The fuse is a ¹⁄₁₆ Amp

(about 62 mA) fast-acting fuse (Littlefuse PICO II or

equivalent). Although this fuse limits excessively high

currents, care should be taken to prevent current values

that are less than 62 mA but above 20 mA. High current

that would not cause the fuse to open might cause

excessive heating of the sense resistor. This fuse is

mounted in a socket holder for easy replacement.

The power supply circuit is protected with a fuse (F1)

located on the DRC Power Supply Board. This fuse is ¹⁄₄

Amp slow-acting fuse used to protect the power supply

from excessive current. If this fuse opens, the DRC

should be returned to Flowserve for service.

If the Analog Process Module is used, it also contains a

fuse for protection. The fuse (F1) is the same as that

described for the Setpoint circuit and is located on the

Analog Process Module. Although this fuse limits

excessively high currents, care should be taken to prevent

current values that are less than 62 mA but above 20 mA.

High current that would not cause the fuse to open might

cause excessive heating of the sense resistor. This fuse is

mounted in a socket holder for easy replacement.

1.1.3 Valve Actuator Configurations

The DRC electronics are designed to control the valve

actuator in 90° quadrants only, however with alternate

feedback potentiometer gearing, 180° of rotation is also

available. The number of quadrants over which the board

will control is determined by the number of teeth on the

feedback potentiometer pinion gear.

Quadrants of Operation

1.1.4 Position Feedback Potentiometer Calibration

Quite often, units received for repair are totally functional

except the feedback potentiometer (pot) is out of

calibration. It is very important that the feedback pot be

properly calibrated for correct operation of the DRC. It is

also very important that the actuator shaft not be rotated

out of the quadrant for which the feedback pot has been

calibrated. Always check the feedback pot calibration first

if calibration problems are encountered. See paragraph

6.5.6 in the troubleshooting section.

WCAIM2058 DataFlo Digital Electronic Remote Controller DRC17 3

Flow Control

Worcester Actuation Systems

Page 4

4 DataFlo Digital Electronic Remote Controller DRC17 WCAIM2058

1.1.5 Storage Conditions

Flowserve recommends that all products that must be

stored prior to installation be stored indoors, in an

environment suitable for human occupancy. Do not store

product in areas where exposure to relative humidity

above 85%, acid or alkali fumes, radiation above normal

background, ultraviolet light, or temperatures above

120°F or below 40°F may occur. Do not store within 50

feet of any source of ozone.

Temperature and humidity are the two most important

factors that determine the usefulness and life of electronic

equipment.

1.2 Operating Temperature

Operating solid state electronic equipment near or beyond its

high-temperature rating is the primary cause for most failures. It

is very important to be aware of and take into consideration

factors that affect the temperature at which the electronic circuits

will operate.

Operating an electronic device at or below its low-temperature

rating generally results in a unit operating poorly or not at all,

but it will usually resume normal operation as soon as rated

operating temperatures are reached. Low-temperature problems

can be easily cured by addition of a thermostatically controlled

heater to the actuator housing.

The DRC is rated for operation between –40°F (with heater and

thermostat) and 160°F. The Worcester Series 75 actuator and the

DRC enclosure both require a maximum ambient temperature of

115°F to insure the circuit boards maximum temperature of

160°F is not exceeded.

Temperature Ranging allows the user to specify the actual

process temperature conditions within the stipulated range of the

measuring element, i.e., RTD or thermocouple. The control range

can be as little as 50°C or 100°C respectively, or to the full range

of the measuring device. For temperatures above 600°C, consult

factory.

1.3 Operating Humidity

Most electronic equipment has a reasonable degree of inherent

humidity protection and additional protection is supplied by the

manufacturer in the form of moisture proofing and fungicidal

coatings.

Such protection, and the 3 to 4 watts of heat generated by the

circuit board assemblies will generally suffice for environments

where the average relative humidity is in the area of 80% or less

and ambient temperatures are in the order of 70°F average.

Where relative humidity is consistently 80% to 90% and the

ambient temperature is subject to large variations, consideration

should be given to installing a heater and thermostat option in

the enclosures. The heater should not increase the enclosure

temperature to the point where a circuit board assembly’s

temperature exceeds 160°F.

In those instances where the internal heater would bring a circuit

board’s operating temperature near or above its maximum rating, the

user might consider purging the enclosures with a cool, dry gas. The

initial costs can usually be paid off quickly in the form of greatly

extended equipment life, low maintenance needs, and much less

process downtime.

2.0 Field Installation of Motor Driver

Board into Series 75 Actuator

2.1 General

If the DRC was purchased with the Motor Driver Board factory

installed, proceed to section 3.0.

2.1.1 Parts Listing

Qty Name

1 Circuit Board Subassembly

1 Insulating Board

4 Washer (Nylon)

4 Grommets (Rubber)

4 Mounting Screws (Circuit Board)

1 Nameplate – Base

1 Wiring Label – Cover

5 Cable Ties

1 Closed End Splice

1 Wire – White

1 Potentiometer Kit Subassembly

1 Bracket – Right (Long) (10-23 sizes only)

1 Bracket – Left (Short) (10-23 sizes only)

2 Spacer (Bracket) (10-2 sizes only)

2 Mounting Screws (Bracket/Spacer)

(10-23 sizes only)

1 Mounting Bracket (25-30 sizes only)

2 Mounting Screw (Bracket) (25-30 sizes only)

2.1.2 Tools Needed

¹⁄₄" Nut Driver, ¹⁄₈" screwdriver, needle nose pliers, ¹⁄₁₆"

Allen wrench (cams and spur gear).

2.1.3 Operation Check of Basic Actuator

Set cams for about 1° to 3° of over travel in each

direction (full-open and full-closed). That is, for 0° to 90°

operation set at minus 3° and plus 93°. Power terminals

1 and 3 for CCW rotation, terminals 1 and 4 for CW

rotation (reference part 6.2).

Flow Control

Worcester Actuation Systems

Page 5

WCAIM2058 DataFlo Digital Electronic Remote Controller DRC17 5

2.2 Mounting Potentiometer:

2.2.1 Mounting Single Potentiometer into Series 75 Actuator

(See Figure 1.)

A. With the potentiometer mounted to the potentiometer

bracket and the spur gear loosely fitted to the

potentiometer shaft, mount the potentiometer bracket

(if not already mounted) as follows:

10-23 75 Actuator: Remove the motor module

mounting screws on the side of the module furthest

away from the actuator shaft. Position potentiometer

assembly bracket holes over screw holes and line up

potentiometer shaft with center of actuator shaft,

replace and tighten screws.

25/30 75 Actuator: Attach potentiometer bracket to

motor support plate between the terminal strip and

actuator shaft with mounting screws as shown in

Figure 1.

2.2.2 Mounting Optional Dual Potentiometer Into Series 75

Electric Actuator

A dual potentiometer is also available when external

resistance indication is also desired. A dual pot consists

of an “A” & “B” pot. The “A” pot is at the front, closest to

the bracket. The “B” pot is at the rear, away from the

bracket. Each pot can serve only one function.

Note: Voltage limit of “B” pot is 30 volts maximum.

Mount potentiometer per paragraph A of 2.2.1.

2.2.3 Potentiometer Wiring

Connect the single or “A” potentiometer leads to the

terminal strip per wiring diagram. For dual pot, “B” pot

must be wired directly to external device.

2.2.4 Adjusting Potentiometer

A. Reference part 6.1 for moving the actuator shaft

electrically.

B. 10-30 75 Actuator

Place the large face gear (12) over the actuator shaft

with the gear teeth down and secure with snap ring

(16) provided.

NOTE: The face gear utilizes a friction fit to the shaft.

For best results, wipe off any lubricant that may be on

the shaft before sliding on the face gear.

CAUTION: Do not overstretch the snap ring; use the

minimum opening to allow it to slip over the gear.

C. Adjust the potentiometer spur gear until there is

approximately ¹⁄₁₆" engagement with the large face

gear. Ensure there is minimum backlash between the

gears. Tighten the spur gear set screw.

D. Rotate the face gear back and forth to ensure smooth

and easy operation of the potentiometer.

E. IMPORTANT: For 90° Valves:

See paragraph 4.9.2 for feedback potentiometer

calibration procedure.

F. The feedback potentiometer is now adjusted for use

in the 75 actuator. Add the potentiometer caution

label to the outside of the actuator cover.

CAUTION: If the actuator shaft is manually rotated a

multiple of 360° from its original position, the

feedback potentiometer will no longer be in

calibration. It must be recalibrated per paragraph

4.9.2, in order for the DRC to operate properly.

2.2.5 IMPORTANT

The feedback potentiometer is calibrated for only one 90

degree quadrant of valve operation.

If the valve and actuator output shaft is repositioned to

another 90 degree quadrant the feedback potentiometer

must be recalibrated as per paragraph 2.2.4.

The Series 75 actuators offer a manual override feature.

Whenever repositioning the valve using this manual

override capability on these actuators, move the valve

only within the 90 degrees for which the feedback

potentiometer has been calibrated.

2.3 Mounting Circuit Board

2.3.1 For 120/240 VAC 10-23 Size Electric Actuators

(See Figure 2.)

A. Mount the brackets to the actuator motors or spacers

as provided. The longer bracket is mounted to the

right side of the actuator (when facing the terminal

strip using the motor mounting screws).

B. Remove and replace motor screws carefully to avoid

stripping the threads of these self-tapping screws.

C. Once these motor screws and brackets are firmly

secured, firmly tap the motor stator to force

realignment of the top motor bearing.

D. Loosen all actuator terminal strip screws necessary to

connect the circuit board’s wiring to the terminal strip.

See manual section 3.0 for proper wiring of circuit

board to the actuator’s terminal strip. Wire routing is

important. Ensure that the wiring is not pinched and is

not near cams or mechanical brake (if installed).

E. Assemble circuit board into actuator. Slide rubber

grommets onto insulating board. Put nylon washer

under heads of self-tapping screws. (Four screws will

be used to install the circuit board onto the brackets).

F. Place circuit board over brackets. See Figure 2.

Loosely fasten board to brackets using mounting

screws.

G. The circuit board is wired to the terminal strip as

shown in section 3.0.

H. Snug down the circuit board and secure mounting

screws such that grommets are about half

compressed.

Flow Control

Worcester Actuation Systems

Page 6

6 DataFlo Digital Electronic Remote Controller DRC17 WCAIM2058

Flow Control

Worcester Actuation Systems

10-23 75

Plan View

25/30 75

Plan View

View A-A

View B-B

Figure 1

Item Description

1 LIMIT SWITCHES

2 MOTOR MODULE

3 MOTOR MODULE MOUNTING SCREWS (2)

4 TERMINAL STRIP

5 ACTUATOR SHAFT

6 POTENTIOMETER

7 POTENTIOMETER BRACKET

8 SPUR GEAR

9 SPUR GEAR SET SCREW

10 POTENTIOMETER LEADS

Item Description

11 POTENTIOMETER SHAFT

12 FACE GEAR

13 POTENTIOMETER BRACKET

14 MOUNTING SCREWS

15 MOTOR SUPPORT PLATE

16 SNAP RING

17 LOCKWASHERS (2)

18 NUT

NOTE: ILLUSTRATIONS SHOW SINGLE POTENTIOMETER ONLY.

Page 7

WCAIM2058 DataFlo Digital Electronic Remote Controller DRC17 7

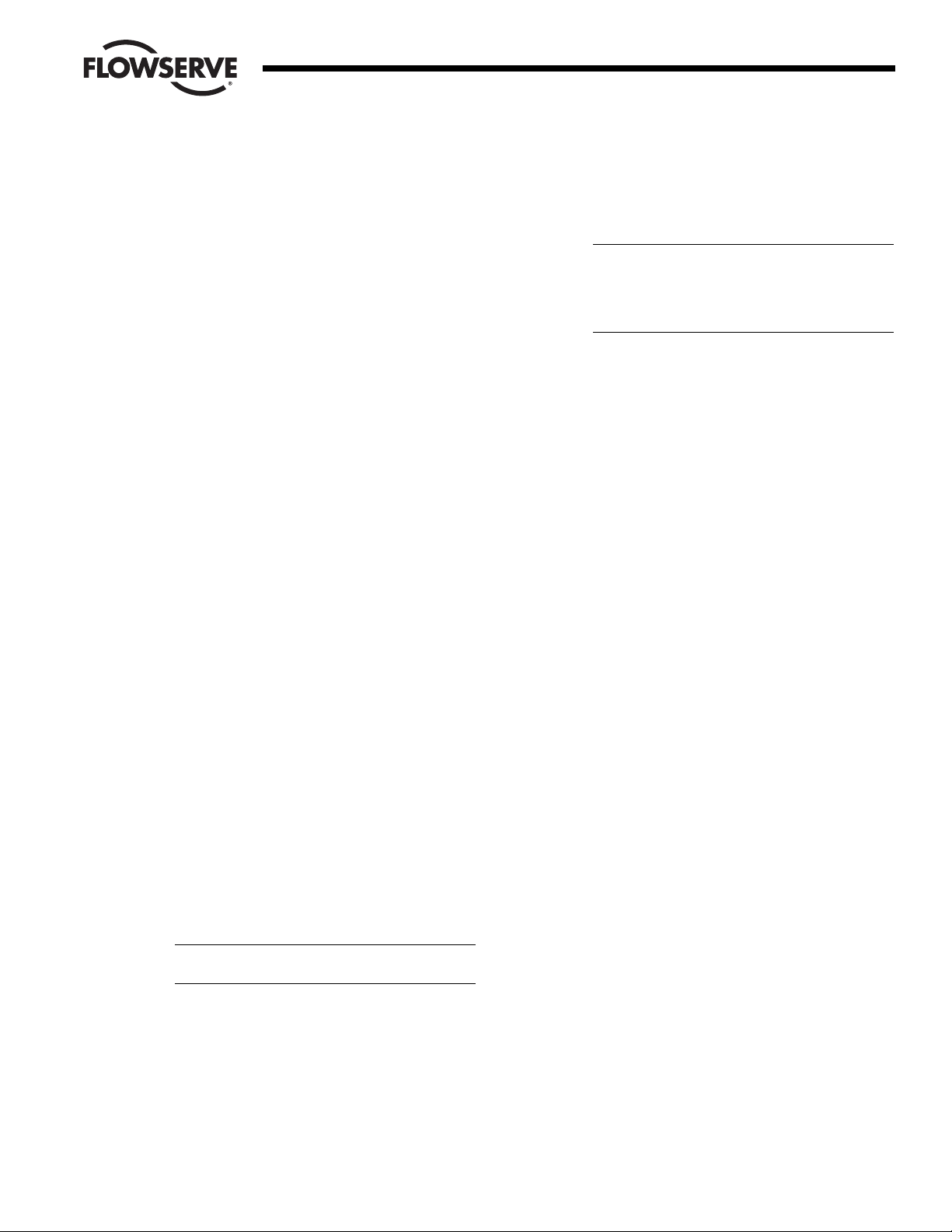

2.3.2 For 120/240 VAC 25 and 30 Size Electric Actuators:

(See Figure 3.)

A. Assemble circuit board to bracket as shown.

B. Place four rubber grommets onto the insulating

board. Put nylon washers on the self-tapping screws

and place screws through the circuit board and

insulating board. Start screws into the bracket.

C. If no insulating board is used, place a rubber

grommet between the board and the bracket. Tighten

all screws such that the grommets are about half

compressed.

D. Use two screws to fasten circuit board bracket to the

motor mounting plate (component side of the board

is facing out).

E. The circuit board is wired to the terminal strip as

shown in Section 3.0.

NOTE: Standard wiring for switches and capacitor as

shown in Figure 3 is the same for 10-23 75 actuators

and is for 120 VAC DRC only. For 240 VAC DRC, see

part 3.1.

2.3.3 Installation of Optional 4-20 Position Output Module

(if used and not factory installed)

A. The output of the position output option is suited for

a 4-20 mA DC meter with 0-100% scale (such as

General Electric type GE185) which is not part of the

package. If properly calibrated, it indicates actuator

shaft position from closed (0°, 0% to open (90°,

100%).

B. The module plugs into the upper left corner of the

Microcontroller Board located in the DRC enclosure.

Align pin 1 (soldered shut) on the module with the

lower right socket on the Microcontroller Board.

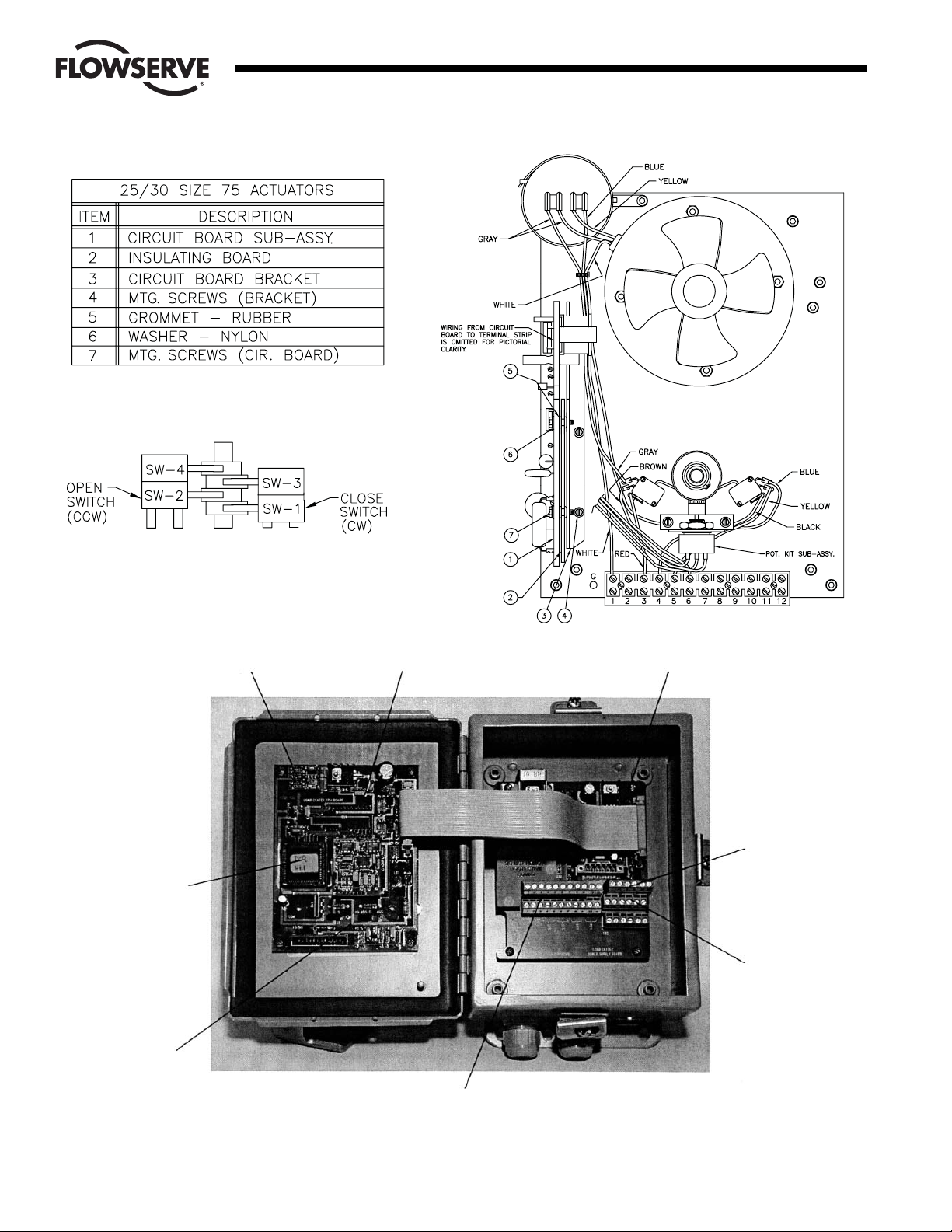

3.0 Wiring of the Digital Controller

The DRC consists of three circuit boards: 1) A motor driver board

inside the actuator housing; 2) A power supply board inside the DRC

enclosure; and 3) A microcontroller board inside the DRC enclosure.

The microcontroller board is prewired and installed to the cover of the

DRC enclosure. This wiring procedure discusses wiring for the motor

driver and power supply boards only.

Figure 4 shows the inside of the DRC enclosure. The following wiring

diagrams refer to connectors located inside the DRC enclosure and

the 75 actuator. The DRC enclosure connectors are located as

indicated in Figure 4.

For factory-installed motor driver board, wiring between board,

terminal strip and switches, and for feedback potentiometer has been

done.

Grounding wires should be connected to green colored grounding

screw (if present) on actuator base or to any baseplate mounting

screw in the actuator.

Minimum Fuse Ratings

See table below for minimum fuse rating when overcurrent protection

is used in motor power circuit.

Minimum Fuse Rating for Overcurrent Protection

Actuator Size Voltage Fuse Rating

10-23 120 VAC 5 A

25/30 120 VAC 10 A

10-23 240 VAC 3 A

25/30 240 VAC 5 A

NOTE: This table shows the minimum rating to prevent inrush current

from blowing the fuse.

Flow Control

Worcester Actuation Systems

Figure 2

Page 8

8 DataFlo Digital Electronic Remote Controller DRC17 WCAIM2058

Flow Control

Worcester Actuation Systems

Limit Switch Locations

(SW-3 and SW-4 are optional.)

Figure 3

Figure 4

Location for

optional position

feedback module

Microcontroller

Board

Power Supply

Board

Process

Module

Alarm

LED

TB1

Top and bottom tiers are

connected together

P1

TB2

Page 9

WCAIM2058 DataFlo Digital Electronic Remote Controller DRC17 9

Flow Control

Worcester Actuation Systems

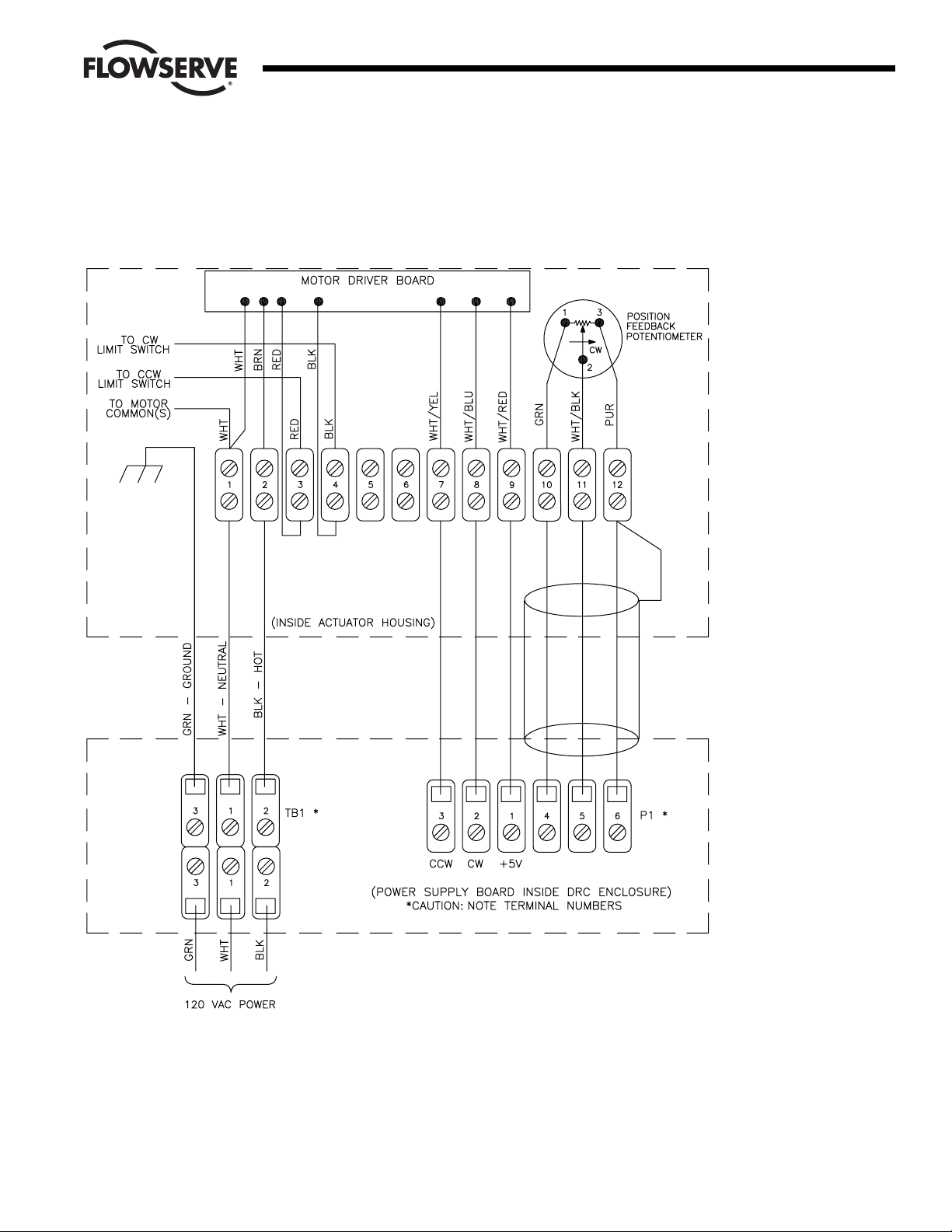

Power and Control Signal Wiring

120 VAC Models

Figure 5

Page 10

10 DataFlo Digital Electronic Remote Controller DRC17 WCAIM2058

Flow Control

Worcester Actuation Systems

Power and Control Signal Wiring

240 VAC Models

Figure 6

Page 11

WCAIM2058 DataFlo Digital Electronic Remote Controller DRC17 11

3.1 Wiring the DRC Motor Driver Board

In the following instructions, the “rear” side of the terminal strip

refers to the side that faces toward the center of the actuator; the

“front” side faces toward the outside of the actuator. Wire color

descriptions show the dominant color first and the stripe last

(e.g., WHT/YEL is a white wire with yellow stripe).

If not factory-installed, locate the motor driver board and mount

the board to the actuator brackets inside the actuator housing

per part 2.3.

Insert the WHITE wire from the board along with the WHITE motor

common wire to the rear side of location 1 on the terminal strip.

NOTE: When there are multiple wires going to terminal location

1, use short white wire provided. Connect it to terminal location

1 and then splice it to the other white wires (common) using the

closed-end splice provided.

Attach the BROWN wire to the rear side of location 2 on the

terminal strip.

Attach the RED wire to the front side of location 3 on the

terminal strip. The RED wire from the rear of this terminal should

go to the counterclockwise limit switch.

Attach the BLACK wire to the front side of location 4 on the

terminal strip. The BLACK wire from the rear of this terminal

should go to the clockwise limit switch.

For 120 VAC only, remove the yellow wire from terminal 5 and

the brown wire from terminal 6, disconnect them from the N.O.

contacts of switches 1 and 2 and discard them.

NOTE: For 240 VAC Controller Wiring:

For this voltage only, the two limit switches do not directly

switch off the motor.

Replace the original gray and blue actuator wires (make a note of

which color wire is on which capacitor terminal and then discard

them) with those provided. Connect them to the capacitor as

originally wired and to terminals 3 and 4 (gray to 3, blue to 4)

(reference 240 VAC wiring diagram).

The two black wires (#20 gauge) from the motor driver board

connect to the common and normally closed contacts of switch

1 (lower right hand switch), and the two red wires (#20 gauge)

from the motor driver board connect to the common and

normally closed contacts of switch 2 (lower left-hand switch).

Route the wires so they will not interfere with switch or feedback

pot operation.

The cams which operate these switches are adjusted as

referenced in paragraph 2.1.3.

Attach the WHT/YEL wire to the rear side of location 7 on the

terminal strip.

Attach the WHT/BLU wire to the rear side of location 8 on the

terminal strip.

Attach the WHT/RED wire to the rear side of location 9 on the

terminal strip.

Attach the feedback pot GREEN wire to the rear side of location

10 on the terminal strip.

Attach the feedback pot WHT/BLK wire to the rear side of

location 11 on the terminal strip.

Attach the feedback pot PURPLE wire to the rear side of location

12 on the terminal strip.

3.2 Wiring From the DRC to the Actuator

A shielded 20 AWG multi-conductor cable should be used to

connect the potentiometer lines between the DRC and the

actuator. The potentiometer lines are those at the actuator

terminal strip in locations 10 through 12. The power supply

cable should be 16 AWG.

Attach a signal wire between DRC P1 location 3 and the Actuator

terminal strip location 7.

Attach a signal wire between DRC P1 location 2 and the Actuator

terminal strip location 8.

Attach a signal wire between DRC P1 location 1 and the Actuator

terminal strip location 9.

Attach a signal wire between DRC P1 location 4 and the Actuator

terminal strip location 10.

Attach a signal wire between DRC P1 location 5 and the Actuator

terminal strip location 11.

Attach a signal wire between DRC P1 location 6 and the Actuator

terminal strip location 12. This location is shared with the drain

wire of the signal cable.

Attach the drain wire (shield) of the signal cable to location 12 of

the actuator terminal strip. This location is shared with a signal

wire. Cut off the drain wire at the other end inside the DRC

enclosure. Be sure the drain wire is cut as close to the insulation

as possible to avoid contact with any other terminals.

Attach a GREEN (ground) power supply wire from DRC TB1

location 3 to a metal ground location on the actuator.

Attach a WHITE (neutral) power supply wire from DRC TB1

location 1 to the front side of location 1 on the actuator terminal

strip.

Attach a BLACK (hot) power supply wire from DRC TB1 location

2 to the front side of location 2 on the actuator terminal strip.

3.3 Wiring the DRC Power Supply Board

Wiring the DRC power supply board involves wiring the setpoint

input signal, the process input, and power. These are necessary

for operation of the unit. Optionally, the DRC can be wired for

serial communications, an alarm output, a positioner control

selector, a position feedback current output, and spare locations.

Each area of wiring is discussed in this section.

3.3.1 Wiring for a Current Setpoint (DRC17 – 4 – x – x – xxx)

Refer to Figure 7 and connect the positive current signal

lead to TB2 location 7 in the DRC enclosure.

Connect the negative current signal lead to TB2 location 6

in the DRC enclosure.

Location 8 has no connection.

Flow Control

Worcester Actuation Systems

Page 12

12 DataFlo Digital Electronic Remote Controller DRC17 WCAIM2058

3.3.2 Wiring for a Potentiometer Setpoint

(DRC17 – K – x – x – xxx)

Refer to Figure 8 and connect one side of a potentiometer

to TB2 location 6 in the DRC enclosure. The side chosen

should be the direction the wiper will move to decrease

the setpoint (generally counterclockwise).

Connect the other side of the potentiometer to TB2

location 7 in the DRC enclosure. This side should be the

direction the wiper will move to increase the setpoint

(generally clockwise).

Connect the wiper of the potentiometer to TB2 location 8

in the DRC enclosure.

3.3.3 Wiring for an Analog Current Process

(DRC17 – x – 4 – x – xxx)

Refer to Figure 9 and connect the process positive current

lead to TB2 location 4 in the DRC enclosure.

Connect the process negative current lead to TB2 location

3 in the DRC enclosure.

Location 5 has no connection.

3.3.4 Wiring for an RTD Process (DRC17 – x – R – x – xxx)

Refer to Figure 10 and connect the BLACK return lead of a

100-ohm platinum RTD to TB2 location 3.

Connect the BLACK sense lead of the RTD to TB2

location 4.

Connect the RED source lead of the RTD to TB2

location 5.

3.3.5 Wiring for a Thermocouple Process

(DRC17 – x – J (K,T, or E) – x – xxx)

The wiring of the thermocouple to the process module

must be done as shown below for the type of

thermocouple selected. The polarity of the wires is critical

for proper operation. The thermocouple module is located

on the component side of the microcontroller board

mounted to the front door of the DRC.

Type Term 1 (+) Term 2 (–)

JFeC

K Ni-Cr Ni-Al

E Ni-Cr C

TCuC

Where: FE = Iron

C = Constantan

Ni-Cr = Nickel-Chromium (Chromel)

Ni-Al = Nickel-Aluminum (Alumel)

Cu = Copper

Using the table and illustrations above, connect the

positive thermocouple lead directly to the thermocouple

process module connector TB3 at location 1. Do not

make copper wire splices or extensions to this wire — it

must be directly attached.

Similarly, connect the negative thermocouple lead directly

to the thermocouple process module connector TB3 at

location 2.

There are no connections to TB2 in locations 3 through 5.

Flow Control

Worcester Actuation Systems

Figure 7

Current Setpoint Connection

Figure 9

Analog Current Process

Connection

Figure 10

RTD Process Connection

Figure 8

Potentiometer Setpoint

Connection

Figure 11

Page 13

WCAIM2058 DataFlo Digital Electronic Remote Controller DRC17 13

3.3.6 Serial Communications Wiring

In these steps, the DRC is shown attached to an RS-485

serial communications bus with another DRC and a host

controller. The last DRC on the communications bus must

have a terminating resistor installed as shown.

Attach the RED positive communications wire to P1 at

location 3. If another DRC is on the bus, its positive

communication wire should also be attached here. If this

is the last DRC on the bus, attach one side of a 120-ohm

resistor at this location as shown below.

Attach the BLACK negative communications wire to P1 at

location 2. If another DRC is on the bus, its negative

communication wire should also be attached here. If this

is the last DRC on the bus, attach the other side of the

120-ohm resistor at this location as shown.

Attach the drain wire shield(s) to P1 at location 5. This

location provides a high resistance and capacitive

reactance to chassis ground.

P1 location 1 provides +12 VDC at 100 mA (maximum)

power supply for a data converter. P1 location 4 is the

common for this power supply. A likely device would be

an RS-232 to RS-485 converter.

3.3.7 Alarm Output Wiring

The alarm output of the DRC consists of an opticallyisolated NPN transistor that can be used to close the

circuit for an light, buzzer, or other alarm. This circuit can

also be used to signal other equipment. The isolated

transistor can handle voltages up to 25 volts and a

maximum continuous current of 100 mA. The output

circuit is shown below connected to a power source and

load.

Connect the negative lead of a power source to TB2

location 9 (transistor emitter).

Connect the positive lead of the power source to one side

of a load.

Connect the other side of the load to TB2 location 10

(transistor collector).

3.3.8 Position/Control Select Wiring

This wiring allows the DRC to become a simple valve

positioner controlled by the setpoint input. Activating this

input will cause the DRC to discontinue controlling and

begin positioning. The input is an optically-isolated

transistor designed to receive a 12 to 24-volt signal to

activate positioning as shown in Figure 14.

Attach the positive lead from a 24-volt signal to TB2

location 12.

Attach the common lead from the signal to TB2

location 11.

Flow Control

Worcester Actuation Systems

Figure 12

INTERNAL DRIVER

REPRESENTATION

LOAD

+V POWER

SUPPLY

(5–24VDC)

TB2

INTERNAL CIRCUIT

REPRESENTATION

+12 TO +24 VOLT

COM (GND)

TB2

Figure 14

Figure 13

Page 14

3.3.9 Position Feedback Output Wiring (applies to optional

module #19226 only)

This output provides a current proportional to the position

of the valve shaft. Depending on the output current

parameter setting, the output will be either 4 mA or 0 mA

at 0% position. The output will be 20 mA at 100%. The

voltage for this current source is provided by the DRC

circuitry. The load resistance should be less than 350

ohms. A typical monitoring circuit is shown in Figure 15.

Attach the positive monitoring lead to TB2 location 13.

Attach the negative monitoring lead to TB2 location 14.

3.3.10 Utility Voltage Source

The DRC provides a 5-volt power source to be used by

external devices. This output is +5 volts and can supply

up to 50 mA. Connect to the supply as shown in

Figure 16.

3.3.11 Spare Connection Locations

The DRC provides 8 uncommitted connection points

labeled in pairs as “LS1” through “LS4”. These locations

provide a convenient way of connecting to actuator

signals. These locations may be defined by the customer

and do not have any connection to DRC electronics.

4.0 Operation of the Digital Controller

4.1 General Operation

When power is applied to the DRC, it enters the Run Mode and

begins controlling the process. The DRC achieves control by

comparing the setpoint to the process. As the setpoint changes,

or as outside factors change the process value, the DRC will

adjust valve position to maintain control. Several parameters can

be set to specify the behavior of the controller — the way it

controls the process. The front-panel display and keypad are

used to enter and view data. Using the keypad, the operator can

also change the mode of operation.

The DRC controls the process according to the setting of various

parameters. Parameters are changed in the Program Mode,

described in this section.

The DRC circuitry is calibrated from the factory for accurate

operation. If it becomes necessary to recalibrate the circuitry it

can be done in the Calibration Mode, described in this section.

The DRC normally receives the setpoint signal from an external

source. However, the DRC can also operate with an operatorentered setpoint by using the Manual Setpoint Mode, described

in this section.

Sometimes it is desirable to suspend controlling and move the

valve to a known position. This can be achieved in the Manual

Position Mode, described in this section. Positioning can also be

achieved by activating a special input that causes the DRC to

become a positioner, using the analog setpoint input to specify

valve position (see External Positioning in this section).

As the DRC controls the process, various alarm conditions can

occur. The DRC contains a circuit that will provide an opticallyisolated alarm output that will activate when any alarm occurs.

This output can be used simply for notification or as a signal to

other processes. Parameters can be programmed to take an

action when certain alarms occur. The alarm state can be viewed

on the DRC display.

An optional current output module can be used to indicate shaft

position. A programmable parameter can be set to specify the

current range (4 to 20 mA or 0 to 20 mA).

4.2 The DRC Keypad

The keypad is used to enter data and move between displays.

The layout of the keypad is shown below.

This key is used to return to the process value

display of the Run Mode from any of the other modes.

While editing a parameter in other modes, this key will

abort editing (and not exit the mode).

14 DataFlo Digital Electronic Remote Controller DRC17 WCAIM2058

Flow Control

Worcester Actuation Systems

SENSING RESISTOR

SHOULD BE LESS

THAN 250 OHMS

221 OHMS 1%

TB2

+5 VDC

COMMON

TB

Figure 15

Figure 16

ENT

Page 15

WCAIM2058 DataFlo Digital Electronic Remote Controller DRC17 15

This is the ENTER key. This key is used to accept an edited

value. While viewing alarms in the Run Mode, pressing this key

will attempt to clear the alarm condition. In the Calibration Mode,

pressing this key while setting viewing a voltage or option will

record the displayed value.

When editing parameters, pressing this key causes the

value to increase. When in either the Run Mode or

Calibration Mode, this key will move to the previous

display item. When a parameter is alternating with its value in

the Program Mode, pressing this key will move to the previous

parameter.

When editing parameters, pressing this key causes the

value to decrease. When in either the Run Mode or

Calibration Mode, this key will move to the next display

item. When a parameter is alternating with its value in the

Program Mode, pressing this key will move to the next

parameter.

4.3 Changing Modes

When the DRC has power first applied, it enters the Run Mode

and will stay in that mode to control the process. To run other

modes, use the keypad as described below:

Press either the key or the key until the mode display

appears.

Press ENT to edit the value. It will start blinking the current

mode.

Press either or until the new mode is visible.

With the correct new mode blinking, press the ENT key to

change to the new mode.

To return back to the Run Mode, press the key.

4.4 Tuning the Controller

Proper performance of the DRC controller depends on proper

tuning of controller parameters. The DRC is shipped from the

factory with preset variables that may provide good process

control. However, optimal performance can be obtained by

tuning the system parameters.

The DRC controller provides an automated tuning procedure

(called Auto-Tune) that can help establish a starting point for

tuning the control parameters. Auto-Tune is performed as an

option in the Manual Position Mode. See paragraph 4.8.3. for

more information.

Auto-Tune can determine proper control parameter settings,

however it may be necessary to manually tune the system

further for optimum control. Several methods exist for tuning

controllers. Some methods use an open-loop approach where

the process is examined as valve position is manually changed.

Other approaches use a closed-loop method where the controller

is actively performing its function and the process is examined.

The DRC Auto-Tune procedure uses the open-loop method.

Closed-loop tuning can tell the period of cycling which is also

useful in determining the dead (or lag) time and the Motor Cycle

Interval. J. G. Ziegler and N. B. Nichols have done a great deal in

the area of control systems and have established a set of tuning

rules that can be followed for closed-loop tuning. Refer to their

work for further information.

4.5 The Run Mode

The Run Mode is the state of the DRC when it is controlling the

process. In this mode, the operator can view the process and

setpoint values, and other data. The DRC is attempting to control

the process by making it track the setpoint while in this mode.

As described above, other modes can be entered from the Run

Mode to set parameters, perform calibration, manually set the

valve position, or to manually set the operating setpoint.

4.5.1 The DRC Display

The display on the front panel of the DRC enclosure

shows operating data, parameters, alarms and other

messages. The table below shows the Run Mode displays

and their meaning. The displays are in the order they will

appear when the key is pressed. Pressing the key

simply reverses the order in which the displays appear.

From any data display in the Run Mode pressing the

key will return to the process variable display.

Table 1

Run Mode

Display Definition

PV: 0 Process Variable.

SV: 0 Setpoint Variable.

AL: NONE Alarm conditions that are active

as shown below:

AL: HiPr Process is above high-process limit.

AL: LoPr Process is below low-process limit.

AL: HiPo Valve shaft is above high-position limit.

AL: LoPo Valve shaft is below low-position limit.

AL: NoFB No shaft position feedback signal.

AL: NoPr Invalid process signal.

AL: HiSp Invalid setpoint signal.

AL: Ther Thermal warning (DC motors only).

AL: NONE No active alarms.

PH: 0 Process highest tracked value.

PL: 0 Process lowest tracked value.

Md: RUN Mode of operation.

4.5.2 Alarms

If an alarm condition occurs, the condition is viewed with

the alarm display as shown above. If more than one alarm

condition is active, the highest priority alarm will be shown.

The priority of alarms is the order shown in the table. So if

the process has gone above the programmed high limit

and the shaft position is lower than the programmed limit,

the display will show the high-process alarm.

Flow Control

Worcester Actuation Systems

Page 16

16 DataFlo Digital Electronic Remote Controller DRC17 WCAIM2058

Alarm conditions may be cleared by pressing the ENT key.

However, if the condition that caused the alarm is still

present after the ENT key is pressed, the alarm will reappear and will not be cleared. While any alarm condition

is present, the Alarm LED on the DRC circuit card will

also be activated.

4.6 Program Mode

The Program Mode of operation is used to examine and change

parameter values. Instructions are given in this section for using

this mode. Table 2 shows all programmable parameters, their

display name, and data range.

4.6.1 Entering the Program Mode

1. In the Run Mode, press either the key or the key

until the mode display appears.

2. Press ENT to edit the value. It will start blinking the

current mode.

3. Press either or until PROG is visible.

4. With PROG blinking, press the ENT key to change to

the Program Mode.

4.6.2 Examining and Changing Parameter Values

1. Press either the or key until the parameter name

appears on the display. It will alternate with its value.

2. Examine the value as it alternates with the parameter

name.

3. To change the value, press the ENT key and the value

will begin blinking.

4. Press the or keys to increase or decrease the

value respectively. If the variable has selections made

from a list, pressing the keys will access each item in

the list. If the variable has both list and numeric

possibilities, the list choices will be shown when the

maximum numeric value is reached and is pressed

or when the lowest numeric value is reached and

is pressed.

5. To save a new value, press the ENT key. The

parameter name will then alternate with its new value.

6. To not use the new value, press the key to abort

editing. The parameter name will then alternate with

its original value.

Flow Control

Worcester Actuation Systems

Page 17

WCAIM2058 DataFlo Digital Electronic Remote Controller DRC17 17

Table 2

Parameter Minimum Maximum

Name Numeric Numeric List

Display Value Value Values Description Notes

Sec Code 0000 9999 Security code

Unit Adr 1 255 Communications address

Curr Rng 4-20 mA, 0-20 mA Optional current output module range

P-term 0 9999 Proportional term for controlling algorithm

I-term 0 999 Integral term for controlling algorithm

D-term 0 8000 Derivative term for controlling algorithm

Cyc Intr 1.0 s 999.9 s Cycle interval

Flt Time 0.8 s 60.0 s Filtering time window

Bkl Time 0 ms 9999 ms Gear backlash time

Trq Time 0 ms 9999 ms Torque time

Dead Bnd 0.1 20.0 Dead band

Action RISE, FALL Controller direct (RISE)/reverse (FALL) action

Cyc Res ON, OFF Cycle interval reset option

PrLo Alr -999 999 Process low alarm point

PrHi Alr -999 999 Process high alarm point

SigErPos 0.0 % 100.0 % HOLD, IGNORE Invalid signal position or action

FBErrAct IGNORE, FULL CW, Invalid shaft position reading action

FULL CCW

Pon Posn 0.0 % 100.0 % HOLD Power-on actuator shaft position

Pon Time 0 s 9999 s Power-on position dwell time

LoPosLim 0.0 % 100.0 % Lowest position valve is allowed to reach 2

HiPosLim 0.0 % 100.0 % Highest position valve is allowed to reach 2

Brk Time 0.10 s 0.99 s Time motor brake is applied when stopping

CyCount Valve cycle counter 1

HiPosAlr 0.0 % 100.0 % Valve shaft high position alarm point

LoPosAlr 0.0 % 100.0 % Valve shaft low position alarm point

Com Rate 1200, 2400, 4800, Serial communications bit rate

9600, 19200, 38400

PrLo Eng -999 999 Process lower value in engineering units 4

PrHi Eng -999 999 Process upper value in engineering units. 4

SpLo Eng -999 999 Setpoint lower value in engineering units 3

SpHi Eng -999 999 Setpoint upper value in engineering units 3

Dflt Val YES, NO Option to default all programmable parameters

NOTES

1. The cycle counter cannot be programmed. It can be cleared in the Program Mode by editing the value and pressing both the and keys

simultaneously. 2. This parameter restricts valve movement to between the two values. The lower shaft limit must be less than the upper shaft

limit. 3. The setpoint limit must lie within the range of the Process Engineering Units. 4. When the process lower and upper value are edited,

pressing both the and keys simultaneously will change the system decimal point. The possibilities for decimal point location are xxx, xx.x,

x.xx, and 0.xxx.

Flow Control

Worcester Actuation Systems

Page 18

18 DataFlo Digital Electronic Remote Controller DRC17 WCAIM2058

4.6.3 Setting Default Factory Parameter Values

Press either the or key until the parameter name

Dflt appears on the display.

Press the ENT key and the value will begin blinking.

Change the value to YES.

Press the ENT key. The display will show Loading as the

default parameters are being set.

Factory Default Parameters

Parameter

Name Factory

Parameter Display Default

Communications address Unit Adr 1

Optional current output module range Curr Rng 4-20

Proportional term for controlling algorithm P-term 1000

Integral term for controlling algorithm I-term 60

Derivative term for controlling algorithm D-term 10

Cycle interval Cyc Intr 1.5

Filtering time window Flt Time 0.8

Gear backlash time Bkl Time 600

Torque time Trq Time 0

Deadband Dead Bnd 0.5

Controller direct action Action RISE

Cycle interval reset option Cyc Res ON

Invalid signal position or action SigErPos NON

Invalid shaft position reading action FBErrAct NONE

Power-On Position Pon Posn 0.0

Power-On Position Time Pon Time 0

Lowest position valve is allowed to reach LoPosLim 0.0

Highest position valve is allowed to reach HiPosLim 100.0

Time motor brake is applied Brk Time 0.25

Valve cycle counter CyCount Unaffected

Valve shaft high position alarm point HiPosAlr 100.0

Valve shaft low position alarm point LoPosAlr 0.0

Serial communications bit rate Com Rate 38400

Manual Setpoint Disabled

System Decimal Point (none)

NOTE: The following default values are determined based on the type

of element used (in the case of a thermocouple) and the degree units

used. MIN will be 0°C or 32°F for thermocouples and –200°C or

–300°F for RTDs. MAX can be found in the table at the bottom of

the column.

Factory Default Parameters

Parameter Analog

Name Module Factory

Parameter Display Default Default

Process low alarm point PrLo Alr 0 MIN

Process high alarm point PrHi Alr 100 MAX

Process lower value PrLo Eng 0 MIN

in engineering units

Process upper value PrHi Eng 100 MAX

in engineering units

Setpoint lower value SpLo Eng 0 MIN

in engineering units

Setpoint upper value SpHi Eng 100 MAX

in engineering units

Type J K E T RTD

°F 900 999 650 750 999

°C 500 550 350 400 800

Flow Control

Worcester Actuation Systems

Page 19

WCAIM2058 DataFlo Digital Electronic Remote Controller DRC17 19

4.6.4 DRC Programmable Parameter Definitions

Parameter Display Definition

Security Code Sec Code The security code is used to prevent unauthorized access to other modes. A security

code of 0000 disables security checking. All other code numbers will require an

operator to enter the correct code to change to other modes.

Unit Address Unit Adr Communications address.

Output Current Range Curr Rng Defines the range of the position feedback output current module.

Proportional Term P-term Coefficient used in computing the proportional part of the PID algorithm. This term

determines the effect of the (process - setpoint) error. The higher the proportional

term, the greater the correction or valve movement for a given error.

Integral Term I-term Coefficient used in computing the integral part of the PID algorithm. This term

determines the effect of a prolonged difference (process - setpoint) error. The higher

the integral term, the greater the correction or valve movement with a prolonged

error condition.

Derivative Term D-term Coefficient used in computing the derivative part of the PID algorithm. This term

determines the effect of a change in the present process value and the process value

8 seconds ago. This change is important in controlling systems that respond quickly

or that have a significant lag. The effect of the rate of change can be amplified or

ignored using the derivative term.

Motor Cycle Interval Cyc Intr The time interval at which the motor will make a correction (e.g., once every 1.5 sec).

Filter Time Flt Time The length of time over which process readings are averaged. This time should never

be greater than the motor cycle interval.

Backlash Time Bkl Time The extra amount of time the motor will run when the direction is reversed to

compensate for gear backlash in the gear drive train.

Torque Time Trq Time The extra amount of time the motor will run to overcome the torque needed to move

the valve. In valves with a high torque, this parameter is important to overcome the

imposed stress on the gears when they try to move the shaft.

Deadband Dead Bnd This parameter is used to prevent oscillations about a setpoint because of small

fluctuations in either the setpoint signal or the feedback process signal. It is an area

in which the process is in control and the valve will not move.

Action Action Describes which direction the valve will move to correct the process. RISE means

that if the process is greater than the setpoint, the actuator shaft will travel in the CW

direction. FALL means that if the process is greater than the setpoint, the actuator

shaft will travel in the CCW direction.

Cycle Interval Reset Cyc Res Determines whether to reset the Motor Cycle Interval timer when the process is

within the deadband.

Process Low Alarm Value PrLo Alr Process value below which an alarm condition will be issued.

Process High Alarm Value PrHi Alr Process value above which an alarm condition will be issued.

Invalid Reading Position SigErPos Valve position to go to if an invalid setpoint or process value is read. If the DRC

should attempt to keep controlling in the event of an invalid reading, set this

parameter to IGNORE. It can also be set to the value of HOLD to hold the position.

Invalid Shaft Position Reading Action FBErrAct Valve movement action to perform if an invalid shaft position is read. The valve can

be set to drive full CW (Full CW), drive full CCW (Full CCW), HOLD its position, or

IGNORE to keep controlling in the event of an invalid reading.

Flow Control

Worcester Actuation Systems

Page 20

20 DataFlo Digital Electronic Remote Controller DRC17 WCAIM2058

Parameter Display Definition

Power-On Position Pon Posn Position the shaft will be driven to when power is first applied. A value of NONE will

hold the current shaft position. The position specified will be held for the time

specified in the Pon Time parameter.

Power-On Position Time Pon Time Time to hold the valve position specified by the Pon Posn parameter. A time value of

0 will bypass the power-on position feature.

Lower Shaft Limit LoPosLim Lowest position percentage the shaft can move to while controlling.

Upper Shaft Limit HiPosLim Highest position percentage the shaft can move to while controlling.

Brake Time Brk Time Amount of time the brake is applied to stop motor movement.

Cycle Count Cy Count The count of the number of complete valve cycles.

Upper Shaft Alarm Limit HiPosAlr Shaft position above which an alarm condition will be issued.

Lower Shaft Alarm Limit LoPosAlr Shaft position below which an alarm condition will be issued.

DRC Communications Rate Com Rate The serial communications rate on the DRC bus

Process Lower Engineering Units PrLo Eng Lower range value for the process transducer being used.

Process Upper Engineering Units PrHi Eng Upper range value for the process transducer being used.

Setpoint Lower Engineering Units SpLo Eng This is the lowest setpoint value. It must be within the limits of the process range.

Setpoint Upper Engineering Units SpHi Eng This is the highest setpoint value. It must be within the limits of the process range.

Default Parameters Dflt Val This variable allows the operator to set all parameters to their factory default values.

See paragraph 4.6.3 for more details.

Flow Control

Worcester Actuation Systems

4.7 Manual Setpoint Mode

Manual Setpoint Mode is used to override the electrical setpoint

input signal and establish a new setpoint. The mode is useful in

testing the controller at various setpoints without having external

equipment generate them. When the manual setpoint is set, it

will remain in effect until disabled or changed by an operator.

The setpoint state will be preserved even if power is removed.

So if the DRC is operating with a manual setpoint and power is

removed and reapplied, it will continue to control using the

manual setpoint.

4.7.1 Entering the Manual Setpoint Mode

In the Run Mode, press either the key or the key

until the mode display appears.

Press ENT to edit the value. It will start blinking the

current mode.

Press either or until MSET is visible.

With MSET blinking, press the ENT key to change to the

Manual Setpoint Mode.

If the security code is zero, no security code is needed to

enter the mode.

Otherwise, when prompted for the security code, press

ENT.

Press and to enter the correct security code then

press ENT to enter the mode.

If the incorrect security code is entered, the Manual

Setpoint Mode cannot be entered.

The Manual Setpoint Mode is exited by pressing the

key to return to the Run Mode.

4.7.2 Enabling, Disabling, and Changing the Setpoint

When the mode is entered, the display will alternate

between Man Setp and the setpoint value. If the manual

setpoint is disabled, the display will show Disabled as the

value.

To disable manual setpoint, simultaneously press both the

and keys while the display is alternating Man Setp

and the setpoint value. The display will then indicate

Disabled as a value.

To enable manual setpoint or to change the value, press

ENT while the display is alternating Man Setp and the

setpoint value. The current setpoint value will begin

blinking. Press the and keys to change the setpoint

to the desired value. Note that the setpoint can only be

set in the range of the lower and upper setpoint values

Page 21

WCAIM2058 DataFlo Digital Electronic Remote Controller DRC17 21

established in Program Mode (paragraph 4.6.2). When

the correct manual setpoint is displayed, press the ENT

key to lock the value.

The display will alternate Man Setp and the setpoint value.

Press to return to the Run Mode and use the manual

setpoint specified.

4.8 Manual Position Mode

Manual Position Mode is used to manually position the valve. All

control ceases while in this mode and the valve position is

shown. This mode is also used to access the Auto-Tune feature

of the DRC

4.8.1 Entering the Manual Position Mode

In the Run Mode, press either the key or the key

until the mode display appears.

Press ENT to edit the value. It will start blinking the

current mode.

Press either or until MPOS is visible.

With MPOS blinking, press the ENT key to change to the

Manual Position Mode. The name Shft Pos will alternate

with the valve shaft position. 0% is the full clockwise

position; 100% is the full counterclockwise position.

The Manual Setpoint Mode is exited by pressing the

key to return to the Run Mode.

4.8.2 Changing Valve Position

When the mode is entered, the display will alternate

between Shft Pos and the valve shaft position. Press and

hold the key to rotate the valve in a clockwise (CW)

direction; press and hold the key to rotate the valve in

the counterclockwise (CCW) direction. The valve will

rotate as long as the key is pressed.

Note: It is possible to exceed the calibrated CW and CCW

position limits in this mode. Care should be taken when

rotating the valve when its position is close to the limit of

travel in either direction.

The valve position expressed as a percentage of travel will

be displayed as the valve rotates. When the valve is not

commanded, the display will alternate between Shft Pos

and the valve shaft position.

4.8.3 Auto-Tune

Auto-Tune is a feature of the DRC that allows an operator

to determine a starting point for PID control parameters.

Once the necessary data is entered, the Auto-Tune

procedure is performed automatically. Before Auto-Tune

is performed, the valve shaft should not be at either end

of valve travel. A shaft position close to 50% would be a

good starting point.

Remember that Auto-Tune results are only suggestions

for the PID terms. Automatic tuning does not always

determine optimum terms. The operator should closely

examine the results before installing them.

4.8.3.1 Starting Auto-Tune

NOTE: At any point in the Auto-Tune procedure, the

procedure can be aborted by pressing the key

which will return control back to the Manual Position

Mode.

Using the and keys, set the valve position to the

desired starting point. This is a center point about

which the tuning will be performed. The shaft should

not be located close to either travel limit (i.e., full CW

or full CCW).

When ready to start the tuning, press the ENT key.

The display will show the Autotune name followed by

Shaft dS alternating with a default valve increment.

The valve increment is the amount the valve will move

during the Auto-Tune procedure.

If the valve increment displayed is already correct,

this step can be skipped by pressing the key.

Otherwise, press ENT to edit the valve increment

amount. Use the the and keys to adjust the

amount to the correct increment. The value will not

be able to be set less than 1% nor greater than either

40% or the distance to the nearest travel limit,

whichever is smaller. When valve position is changed,

it is important to allow the process to settle with the

new position. When the value is correctly displayed

and the process has stabilized, press the ENT key and

the automated procedure will begin.

4.8.3.2 The Automated Auto-Tune Procedure and Results

NOTE: At any point in the automated procedure, the

procedure can be aborted by pressing the key

which will return control back to the Manual Position

Mode.

The automated procedure begins by measuring

fluctuations in the process. The display will alternate

between Fluct and a measure of tenths of a unit of

process variation. This measurement will continue for

one minute.

When the fluctuation measurement has completed,

the shaft will be moved clockwise by the specified

valve increment. The display will show Step #1 while

the valve is moving.

When step 1 valve movement has completed, the

display will alternate between Step #1 and the number

of seconds the step has taken. Step 1 is waiting for

the process to stabilize at the new valve position. If

the process does not stabilize within 30 minutes, the

tuning procedure will be aborted and the TIMEOUT

message will be displayed. The error message will

remain until the ENT key is pressed.

When step 1 has completed, the shaft will be moved

counterclockwise by twice the specified valve

increment. The display will show Step #2 while the

valve is moving.

Flow Control

Worcester Actuation Systems

Page 22

22 DataFlo Digital Electronic Remote Controller DRC17 WCAIM2058

When step 2 valve movement has completed, the

display will alternate between Step #2 and the number

of seconds the step has taken. Step 2 is waiting for

the process to stabilize at the new valve position. If

the process does not stabilize within 30 minutes, the

tuning procedure will be aborted and the TIMEOUT

message will be displayed. The error message will

remain until the ENT key is pressed.

When step 2 has completed, the shaft will be moved

clockwise by the specified valve increment, returning

it to the original starting position. The display will

show Step #3 while the valve is moving.

When step 3 valve movement has completed, the

display will alternate between Step #3 and the number

of seconds the step has taken. Step 3 is waiting for

the process to stabilize at the new valve position. If

the process does not stabilize within 30 minutes, the

tuning procedure will be aborted and the TIMEOUT

message will be displayed. The error message will

remain until the ENT key is pressed.

When step 3 completes, a set of PID parameters will

be computed. Those parameters include the P-term,

I-term, D-term, and the cycle time. The display will

alternate between P-term and the proposed valve. The

operator can examine the other values by pressing

the and keys.

At this point, the operator can either accept all of the

proposed values, or reject them. If the values are

accepted, they will be programmed and will be in use

when the Run Mode is re-entered. If the values are

rejected, the original PID terms will remain in effect.

To accept all of the proposed values, press the ENT

key. To reject the values, press the key. After either

ENT or is pressed, control will return to the

Manual Position Mode.

It may be desirable to run the Auto-Tune procedure

several times using different valve starting points and

different valve increments, writing down the proposed

PID terms for each procedure. In that way, an

operator can determine PID terms from the

intermediate results and install them in the Program

Mode. See section 4.4 for other notes on tuning.

4.9 Calibration Mode

The Calibration Mode is used to adjust electrical components for

accuracy and for the proper range. The DRC is calibrated from

the factory for the process module selected. For the best

accuracy the DRC can be calibrated in the system where it will

be used.

4.9.1 Entering the Calibration Mode

In the Run Mode, press either the key or the key

until the mode display appears.

Press ENT to edit the value. It will start blinking the

current mode.

Press either or until CAL is visible.

With CAL blinking, press the ENT key to change to the

Program Mode.

If the security code is zero, no security code is needed to

enter the mode.

Otherwise, when prompted for the security code, press

ENT.

Press and to enter the correct security code then

press ENT to enter the mode.

If the incorrect security code is entered, the Calibration

Mode cannot be entered.

Calibration is performed by displaying the item to be

calibrated, then executing the procedure for that item. The

steps in the calibration procedure will depend on the type

of setpoint input signal used and the process module

used. The calibration of valve position and cycle time is

the same for all models of DRC used. The steps below

assume the Calibration Mode has successfully been

entered.

4.9.2 Calibration of Valve Position

Press the or key until MaxCW is displayed

alternating with its voltage value.

Press ENT to calibrate the clockwise position, the display

will continuously show a voltage value.

Press the or key to adjust the valve position to the

correct full clockwise position. Adjust the feedback pot by

rotating the face gear, located on the actuator shaft, with

your fingers for a reading between .200 and .400 volts.

NOTE: It is not necessary to loosen or remove face gear

snap ring (if present) to rotate gear — it is a friction fit.

For gears that do have a snap ring and if for any reason

the snap ring must be removed, do not overstretch it. Use

the minimum opening to allow the ring to slip over the

gear.

With the valve in the proper full-clockwise position, press

the ENT key to record the position. The display will then

alternate MaxCW with its voltage value.

Press the key once to display MaxCCW alternating with

its voltage value.

Press ENT to calibrate the counterclockwise position, the

display will continuously show a voltage value.

Press the or key to adjust the valve position to the

correct full-counterclockwise position.

With the valve in the proper full-counterclockwise

position, press the ENT key to record the position. The

display will then alternate MaxCCW with its voltage value.

The valve position is now calibrated.

Upon successful completion of this procedure, the cycle

time calibration procedure should also be performed.

Flow Control

Worcester Actuation Systems

Page 23

WCAIM2058 DataFlo Digital Electronic Remote Controller DRC17 23

4.9.3 Calibration of Cycle Time

NOTE: This procedure should only be performed if the

clockwise and counterclockwise valve positions are

correctly calibrated. This procedure should also be

performed following any valve position calibration.