Page 1

Automax Valve Automation Systems

3-Position Control/Dribble Control

Installation, Operation and Maintenance Instructions

Flowserve Corporation 765 South 100 East Phone: 801 373 3028

Flow Control Division Provo, Utah 84606 Facsimile: 801 489 2228

www.flowserve.com Email: actuators@flowserve.com

SR Limit Switch Method

Centura CE Extra-Switch & Heater & Thermostat Installation

Caution: To prevent ignition of hazardous atmospheres, keep unit tight while circuits are alive. Disconnect supply circuit

before opening.

SWITCHES

Adding extra switches to the CENTURA CE series actuator requires a Single Switch Kit (P/N 108474) or a Dual Switch Kit

(P/N 108475).

1) Disconnect all power to the actuator.

2) Remove the actuator cover.

3) The accessory mounting bracket must first be removed. Remove the bolts that fasten the bracket to the motor and the

base plate. Remove potentiometer gear (if installed) and any switch wires. Lift the bracket away from the base.

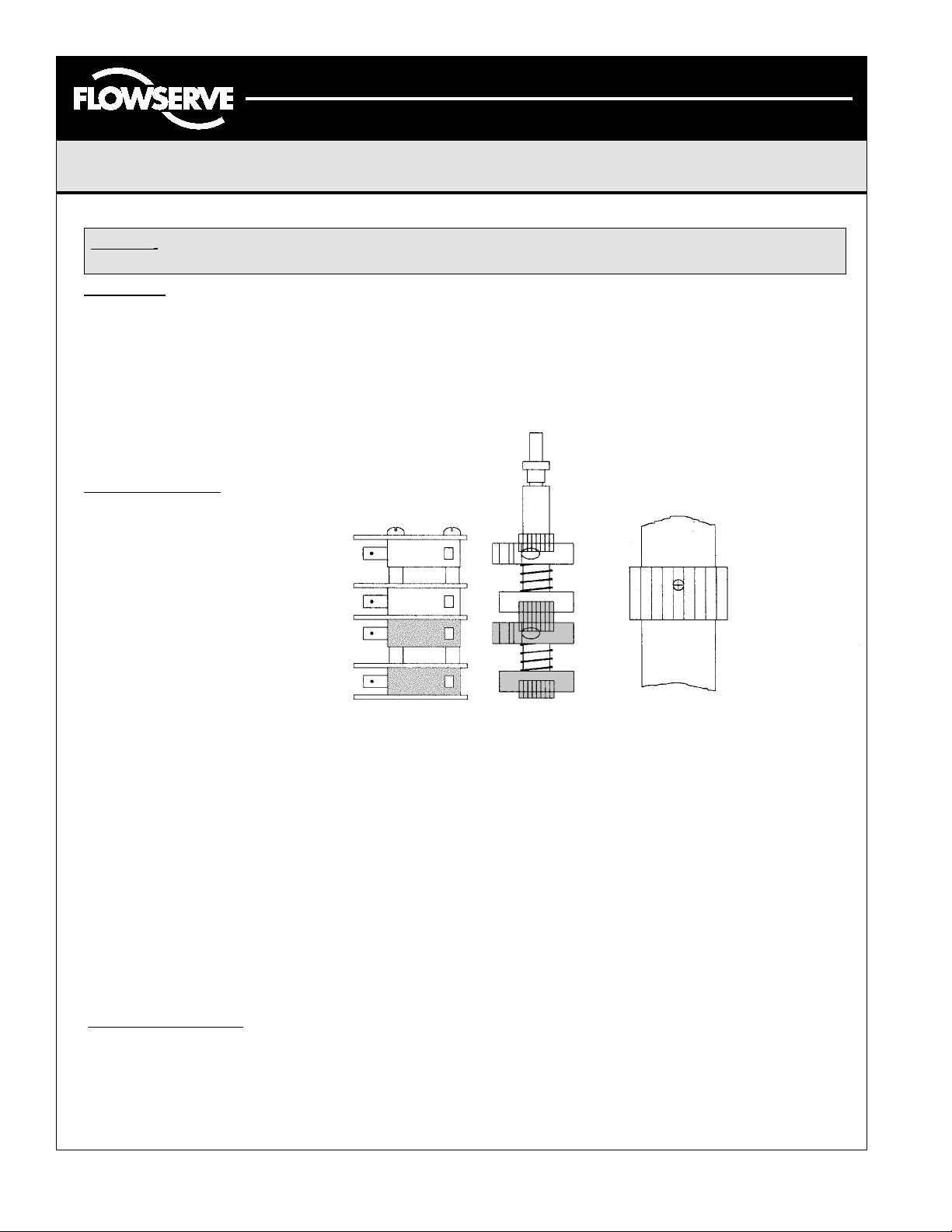

4) After the accessory mounting is removed, remove existing switches. Note the orientation of the switch stack. Here is an

example of proper switch stacking:

FROM TOP DOWN

1. Insulator

2. Switch

3. Nylon Spacer

4. Insulator

5. Switch

6. Insulator

7. Switch

8. Nylon Spacer

9. Insulator

10. Switch

11. Insulator

5) After stacking the proper amount of desired switches, extra cams will need to be installed. The first extra cam is simply

slid over the end of the cam shaft. Make sure the female side of the cam faces toward the actuator base, and slides

securely over the male splines. Next slide the supplied spring over the camshaft. Now, if two extra switches are being

installed, slide the second extra cam over the camshaft with the female side facing upward. While compressing the

spring, slide the male spline over the camshaft as pictured above (with longer end of the spline facing downward

towards the base) and insert the supplied roll pin to hold in place.

6) Re-install the accessory mounting bracket and re-connect the wires as per the schematic located inside the cover.

7) Attach the supplied terminal strip to the leg of the accessory bracket. The mounting holes are located near the “right”

conduit entry (as shown in the drawing).

8) Wire the extra switches per the supplied schematic.

9) Attach the supplied schematic sticker to the inside of the actuator cover for future reference.

10) When replacing the cover, the machined joints must be clean and clear of any obstructions. The integrity of the

explosion-proof rating depends on the care of these joints.

* Refer to Installation Instructions for proper cam adjustment. (The micro adjust set screws in the cams are set as follows:

Auxiliary 2

Auxiliary 1

CW Switch

CCW Switch

Aux. Switch 1 is for CCW adjustment Aux. Switch 2 is for CW adjustment.)

Stack

Orientation

Switch

Cam

Stack

Orientation

Note: Roll pin

hole is not

centered to the

length of the

spline. Install

as shown.

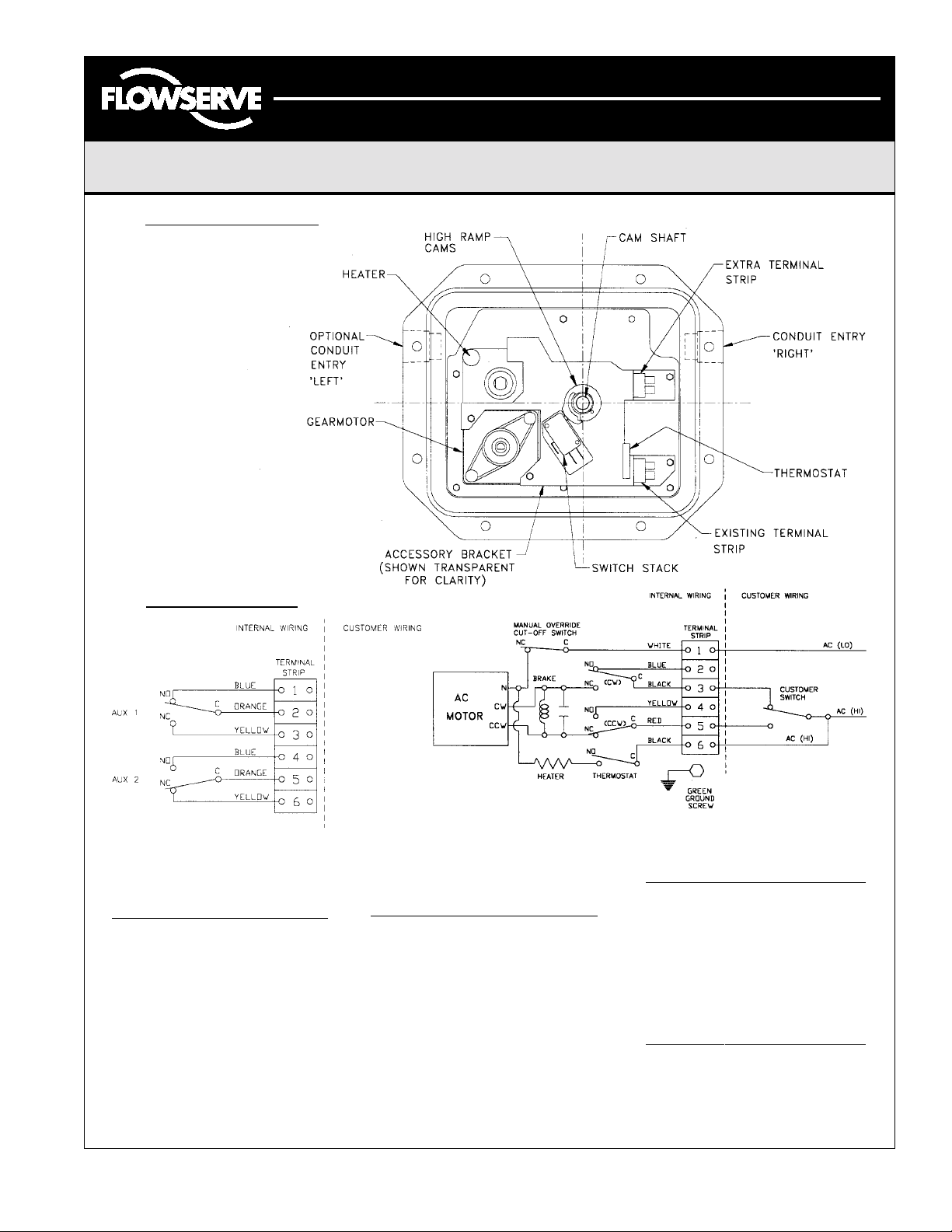

HEATER & THERMOSTAT

* Disconnect power to the actuator before installing heater and thermostat.*

1 ) The heater & thermostat come in a kit, with the wires already spliced together.

2) The heater is simply screwed into the left, front mounting hole on the gearmotor (as shown in the drawing).

3) The thermostat is then wire tied to the existing wire bundle near the leg of the accessory bracket.

4) The white wire is twisted to the motor common wire and both are inserted into the #1 terminal strip location.

5) The black lead of the thermostat is then inserted into the #6 terminal strip location.

LML0008-1 (AUTO-44) 12/00 Page 1 of 2

©

2000, Flowserve Corporation, Provo, Utah

Page 2

Automax Valve Automation Systems

3-Position Control/Dribble Control

Installation, Operation and Maintenance Instructions

Flowserve Corporation 765 South 100 East Phone: 801 373 3028

Flow Control Division Provo, Utah 84606 Facsimile: 801 489 2228

www.flowserve.com Email: actuators@flowserve.com

SR Limit Switch Method

TOP VIEW OF ACTUATOR

Some components are not

shown for clarity.

WIRING SCHEMATICS

PARTS LIST FOR

108474 - 1 EXTRA SWITCH KIT

QTY. PART # DESCRIPTION

1 108096 SWITCH

1 103675 INSULATOR

2 104307 440x1.75" SCREW

1 107622 Hl-RAMP CAM

1 103714 SPRING

1 103572 SPLINE

1 103621 ROLL PIN

1 103687 MARKER STRIP

1 103683 TERMINAL STRIP

5 106574 CABLE TIE

2 X00318 3-48x50" SCREW

* TYPICAL HEATER & THERMOSTAT WIRING

LOCATION MAY VARY DEPENDING ON UNIT.

PARTS LIST FOR

108475 - 2 EXTRA SWITCH KIT

QTY. PART # DESCRIPTION

2 108096 SWITCH

2 103675 INSULATOR

2 103991 4-40X2.50” SCREW

2 107622 HI-RAMP CAM

1 103714 SPRING

1 103572 SPLINE

1 103621 ROLL PIN

1 103687 MARKER STRIP

1 103683 TERMINAL STRIP

1 815188 SCHEMATIC STICKER

2 X00318 3-48X.50” SCREW

5 106574 CABLE TIE

2 105679 NYLON SPACERS

PARTS LIST FOR 120V

106857-HEATER & STAT

QTY. PART # DESCRIPTION

1 100871 THERMOSTAT

1 105973 HEATER

1 100591 WHITE WIRE

2 100697 BUTT SPLICE

5 106574 CABLE TIE

PARTS LIST FOR 230V

108977-HEATER & STAT

QTY. PART # DESCRIPTION

1 100871 THERMOSTAT

1 108881 HEATER

1 100591 WHITE WIRE

2 100697 BUTT SPLICE

5 106574 CABLE TIE

LML0008-1 (AUTO-44) 12/00 Page 2 of 2

©

2000, Flowserve Corporation, Provo, Utah

Loading...

Loading...