Page 1

GESTRA

GESTRA Steam Systems

BA 46

BA 47

BAE 46

BAE 47

Installation Instructions 818609-00

Continuous Blowdown Valve

BA 46, BA 47, BAE 46, BAE 47

1

Page 2

2

Contents

Page

Important Notes

Usage for the intended purpose .............................................................................................................5

Safety notes ...........................................................................................................................................5

Danger ...................................................................................................................................................5

Attention .................................................................................................................................................6

PED (Pressure Equipment Directive) ........................................................................................................6

ATEX (Atmosphère Explosible) .................................................................................................................6

Explanatory Notes

Scope of supply ...................................................................................................................................... 6

System description .................................................................................................................................7

Function .................................................................................................................................................7

Design .................................................................................................................................................... 8

Technical Data

Pressure ratings .....................................................................................................................................8

Materials ................................................................................................................................................8

Pressure/Temperature ratings .................................................................................................................8

Dimensions of end connections ..............................................................................................................9

Overall lengths ........................................................................................................................................9

Corrosion resistance ............................................................................................................................... 9

Sizing .....................................................................................................................................................9

Name plate / marking ...........................................................................................................................10

Dimensions BA 46, BA 47 ..................................................................................................................... 11

Dimensions BAE 46, BAE 47 ................................................................................................................. 12

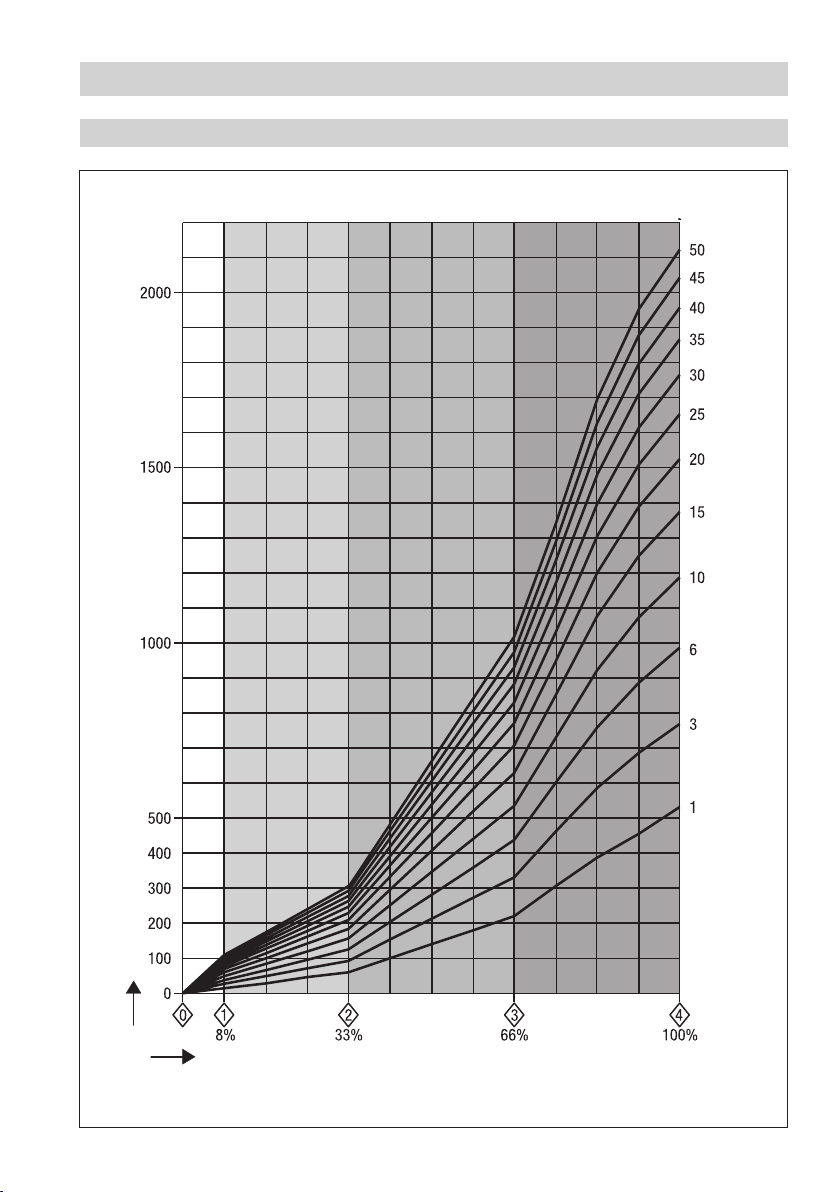

Capacity chart for DN 15 to 32, capacity ranges at a glance

Capacity chart for DN 15 to 32, capacity range up to 310 kg/h ..............................................................14

Capacity chart for DN 15 to 32, capacity range up to 1020 kg/h ............................................................15

Capacity chart for DN 15 to 32, capacity range up to 2120 kg/h ............................................................16

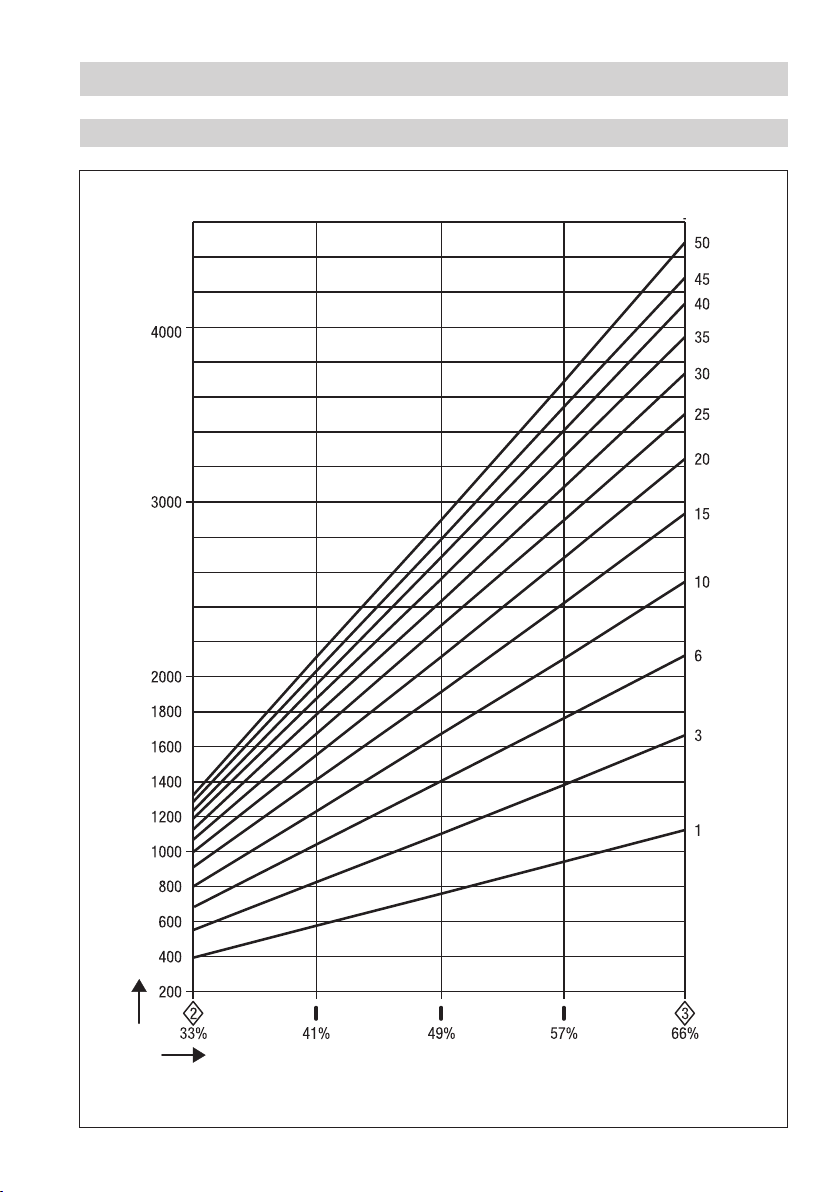

Capacity chart for DN 40 and 50, capacity ranges at a glance ...............................................................17

Capacity chart for DN 40 and 50, capacity range up to 1340 kg/h .........................................................18

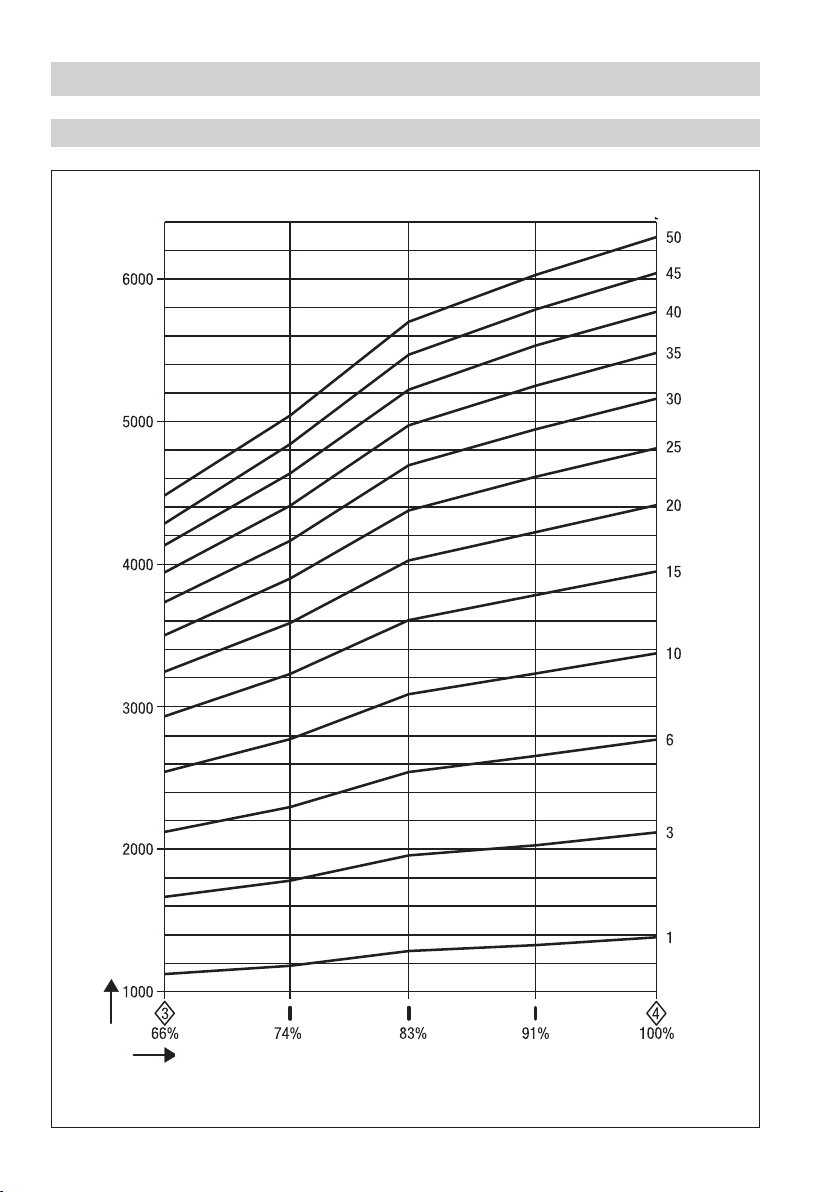

Capacity chart for DN 40 and 50, capacity range up to 4500 kg/h .........................................................19

Capacity chart for DN 40 and 50, capacity range up to 6300 kg/h .........................................................20

..................................................................13

Design

BA 46, BA 47 ........................................................................................................................................ 21

BAE 46, BAE 47 ....................................................................................................................................22

Key ....................................................................................................................................................... 23

Page 3

Contents – continued –

Page

Installation

BA 46, BA 47, BAE 46, BAE 47 ..............................................................................................................24

Attention ...............................................................................................................................................24

Valve with flanged ends ........................................................................................................................ 24

Valve with socket-weld ends .................................................................................................................24

Valve with butt-weld ends ....................................................................................................................24

Attention ...............................................................................................................................................25

Heat treatment of welds........................................................................................................................25

Reposition control lever by 180 ° (if position of installation is unfavourable) .......................................... 25

Install sample valve ..............................................................................................................................25

Wiring

Danger ...............................................................................................................................................26

Continuous blowdown valves BAE 46, BAE 47 with actuator .................................................................26

Factory settings of BAE 46, BAE 47 .......................................................................................................26

Commissioning

Danger ...............................................................................................................................................26

BA 46, BA 47, BAE 46, BAE 47 ..............................................................................................................26

Attention ...............................................................................................................................................27

Continuous blowdown valves BA 46, BA 47 without actuator ................................................................27

Continuous blowdown valves BAE 46, BAE 47 with actuator .................................................................27

Operation

Danger ...............................................................................................................................................27

BA 46, BA 47, BAE 46, BAE 47 ..............................................................................................................27

Attention ...............................................................................................................................................27

Calculating the amount of boiler blowdown ...........................................................................................28

Emergency Operation

BAE 46, BAE 47 ....................................................................................................................................28

Maintenance

Changing packing and internals of BA 46, BA 47 ........................................................................... 28 - 29

Changing packing and internals of BAE 46, BAE 47 ....................................................................... 29 - 30

Torques ................................................................................................................................................30

Tools .....................................................................................................................................................30

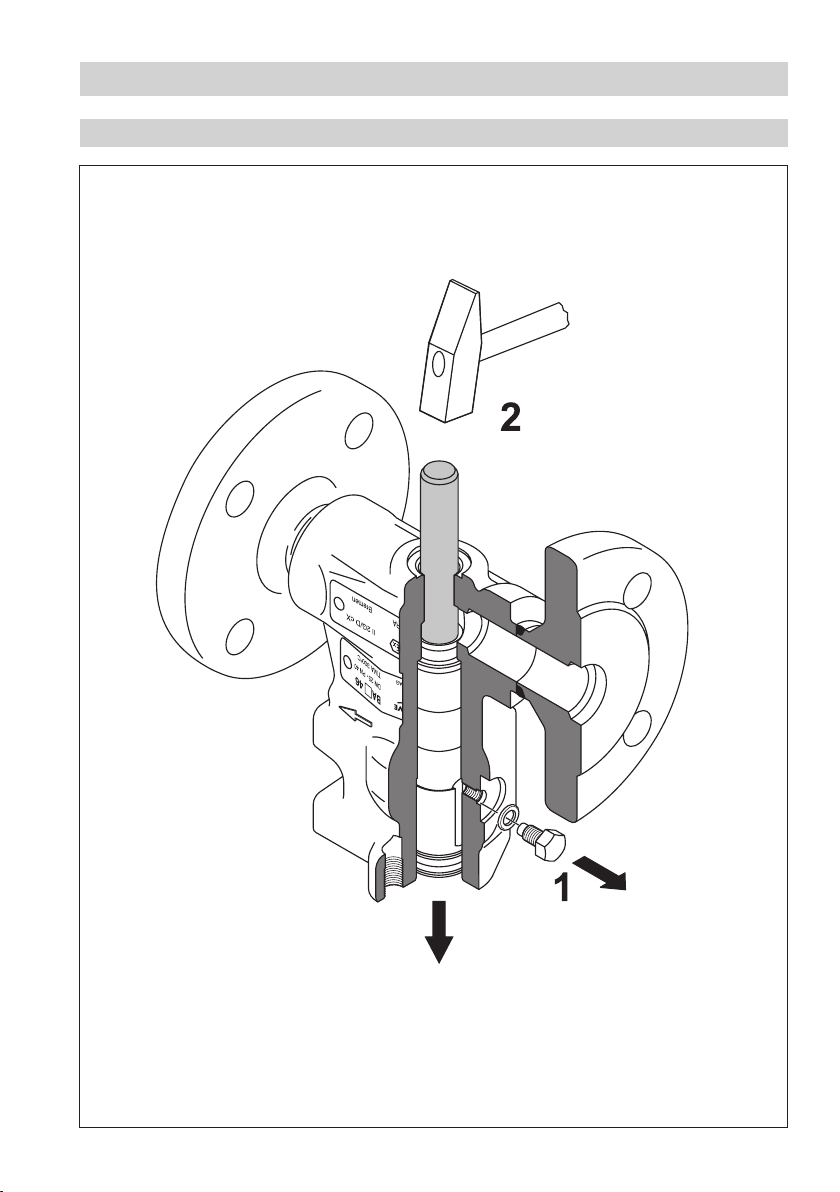

Removing internals ............................................................................................................................... 31

3

Page 4

4

Contents – continued –

Page

Retrofitting

Danger ...............................................................................................................................................32

Mounting the actuator ........................................................................................................................... 32

Toques ..................................................................................................................................................32

Tools .....................................................................................................................................................32

Spare Parts

Spare parts list ....................................................................................................................................33

Retrofitting Parts

Retrofitting parts list ............................................................................................................................34

Decommissioning

Danger .................................................................................................................................................34

Disposal................................................................................................................................................34

Annex

Declaration of Conformity ....................................................................................................................35

Page 5

Important Notes

Usage for the intended purpose

BA 46, BA 47:

Use the continuous blowdown valves BA 46, BA 47 only for discharging water from steam boilers to

ensure the correct water conditions in the boiler. Application in pipes within the admissible pressure/

temperature ratings, taking the chemical and corrosive effects on the pressure equipment into account.

BAE 46, BAE 47:

Use the continuous blowdown valves BAE 46, BAE 47 only in conjunction with the control equipment

KS 90, LRR 1-40 or LRR 1-5, LRR 1-6 for discharging water from steam boilers to ensure the correct

water conditions in the boiler. Application in pipes within the admissible pressure/temperature ratings,

taking the chemical and corrosive effects on the pressure equipment into account.

To ensure the safe operation of the BAE 46, BAE 47 mount only actuators that are explicitly specified by

GESTRA onto the control valve. Specified and approved actuators are:

ARIS EF 0.5, ARIS EF 1, ARIS EF 1-1 and ARIS EF 1-40.

Safety note

The equipment must only be installed and commissioned by qualified and competent staff.

Retrofitting and maintenance work must only be performed by qualified staff who – through adequate

training – have achieved a recognised level of competence.

Danger

The valve is under pressure during operation.

When loosening flanged connections, sealing plugs or stuffing boxes, hot water and

steam may escape.

The valve becomes hot during operation.

This presents the risk of severe burns to hands and arms.

Before servicing the valve or loosening flanges, stuffing box connections or sealing plugs

make sure that all connected lines are depressurised (0 bar) and cooled down to room

temperature (20 °C).

During operation moving internals can pinch one‘s hands or fingers. Do not touch

moving parts! The continuous blowdown valves BAE 46, BAE 47 are remote controlled

and can open and close very abruptly.

The terminal strips of the actuator EF ... are live during operation.

This presents the danger of electric shock.

Cut off power supply before fixing or removing the equipment.

Sharp edges on internals present a danger of cuts to hands. Always wear industrial

gloves when replacing the packing, valve seat or valve plug.

5

Page 6

6

Important Notes – continued –

Attention

The name plate specifies the technical features of the equipment. Note that any piece of

equipment without its specific name plate must neither be commissioned nor operated.

PED (Pressure Equipment Directive)

The equipment meets the requirements of the Pressure Equipment Directive 97/23/EC.

Application in fluids of group 2. With CE marking, except equipment according to section 3.3.

ATEX ( Atmosphère Explosible)

The valves BA 46, BA 47 can be used in potentially explosive areas, provided that the following notes

are observed:

The operating fluid must not generate excessively high temperatures. Electrostatic charges that may

be generated during operation must be discharged. Make sure that the stuffing box is tight and that

the valve spindle can run smoothly. The equipment can be used in Ex zones 1, 2, 21, 22 (1999/92/EC)

II 2 G/D c X.

According to the European Directive 94/9/EC the valves BAE 46, BAE 47 must not be used in

potentially explosive areas. For more information refer to our ATEX Declaration of Conformity.

Explanatory Notes

Scope of supply

BA 46

1 Continuous blowdown valve BA 46

1 Sample valve (not mounted)

1 Gasket A17 x 23 x 1.5

1 Installation manual

BA 47

1 Continuous blowdown valve BA 47

1 Sample valve (not mounted)

1 Gasket A17 x 23 x 1.5

1 Installation manual

Retrofitting kit for BA 46, BA 47

1 Electric actuator

EF 0.5, EF 1, EF 1-1 or EF 1-40

1 Mounting kit for coupling / mounting bracket

1 Installation manual for ARIS actuator EF...

Spare parts

1 Kit according to spare parts list, page 33

BAE 46

1 Continuous blowdown valve BAE 46

1 Sample valve (not mounted)

1 Gasket A17 x 23 x 1.5

1 Installation manual

1 Installation manual of the ARIS actuator EF...

1 Declaration of manufacturer

BAE 47

1 Continuous blowdown valve BAE 47

1 Sample valve (not mounted)

1 Gasket A17 x 23 x 1.5

1 Installation manual

1 Installation manual for ARIS actuator EF...

1 Declaration of manufacturer

Page 7

Explanatory Notes – continued –

System description

Due to the continuous evaporation process in the steam boiler the density and hence the TDS

(= Total Dissolved Solids) concentration of the boiler water is increased. The TDS level must remain

within the limits specified by the boiler manufacturer and applicable guidelines. For this purpose a

certain amount of boiler water (= boiler blowdown) is discharged continuously or periodically. The

continuous blowdown valves BA... and BAE... feature specially designed and wear resistant nozzle stems

that enter concentrically into a system of expansion chambers which are arranged one after the other,

making the valve well suited for the continuous discharge of boiler blowdown at very high differential

pressures. The continuous blowdown valves BA... and BAE ... are suitable for operation in steam boiler

plants according to TRD 604, EN 12952 and EN 12953

n BA 46 PN 40, manually operated

n BA 47 PN 63, manually operated

n BAE 46 PN 40, operated by the electric actuator EF...*)

n BAE 47 PN 63, operated by the electric actuator EF...*)

*) Explosion-proof actuators or actuators powered by d. c. or three-phase current are available

on request.

Function

The continuous blowdown valve BA 46/BA 47 is moved to its control position by means of the control

lever. Use the scale on the control lever to adjust the required amount of boiler blowdown.The required

amount of boiler blowdown is calculated with the aid of a formula or read off on a nomogram. The

continuous blowdown valve BAE 46/BAE 47 is motored to its control position by means of the actuator EF... The actuator is activated by the GESTRA conductivity controller KS 90 working in conjunction

with the GESTRA conductivity electrode LRGT 1...-1 or the conductivity controller LRR 1-5, LRR 1-6 in

combination with the GESTRA conductivity electrode LRG 16... or the conductivity controller LRR 1-40 in

conjunction with the conductivity electrode LRG 1..-40.

The actuator opens or closes the continuous blowdown valve as a function of the required amount of

boiler blowdown and the desired operating position, at which – independent of the actual electrical

conductivity of the boiler water – a freely selectable fundamental amount can be discharged by the BAE

46/BAE 47. The valve positions “OPEN” and “CLOSED” are limited by the cam-operated switch located in

the actuator, the “OPERATING POSITION” is variably adjustable by means of an operating cam. The power

flow towards the closing direction is transmitted via a rigid coupling with integrated torsion spring. The

coupling permits the actuator to travel a little bit further when the nozzle stem is pressed into the valve

seat.

The conductivity of the boiler water is monitored by the equipment combination consisting of a

conductivity electrode and a conductivity controller. The continuous evaporation process in the steam

boiler increases the boiler water density and, consequently, the TDS level, causing the conductivity of

the boiler water to rise. Once the set limit value is reached, the actuator receives an opening pulse from

the conductivity controller according to the deviation from the conductivity setpoint. When the adjusted

conductivity setpoint is attained, the actuator closes the continuous blowdown valve or returns to the

adjusted operating position. The valve positions “CLOSED” and “OPEN” are limited by the cam-operated

switch in the actuator, the “OPERATING POSITION” is variably adjustable by means of an operating cam

or a feedback potentiometer.

.

7

Page 8

8

Explanatory Notes – continued –

Design

Type Standard Special version

BA(E) 46

BA(E) 47

Flanged to

EN 1092-1, PN 40

Flanged to

EN 1092-1, PN 63

Flanged to ASME, Class 150, 300

Butt-weld ends for pipes to DIN or ASME

Socket-weld ends for pipes to DIN or ASME

Flanged to ASME, Class 400

Butt-weld ends for pipes to DIN or ASME

Socket-weld ends for pipes to DIN or ASME

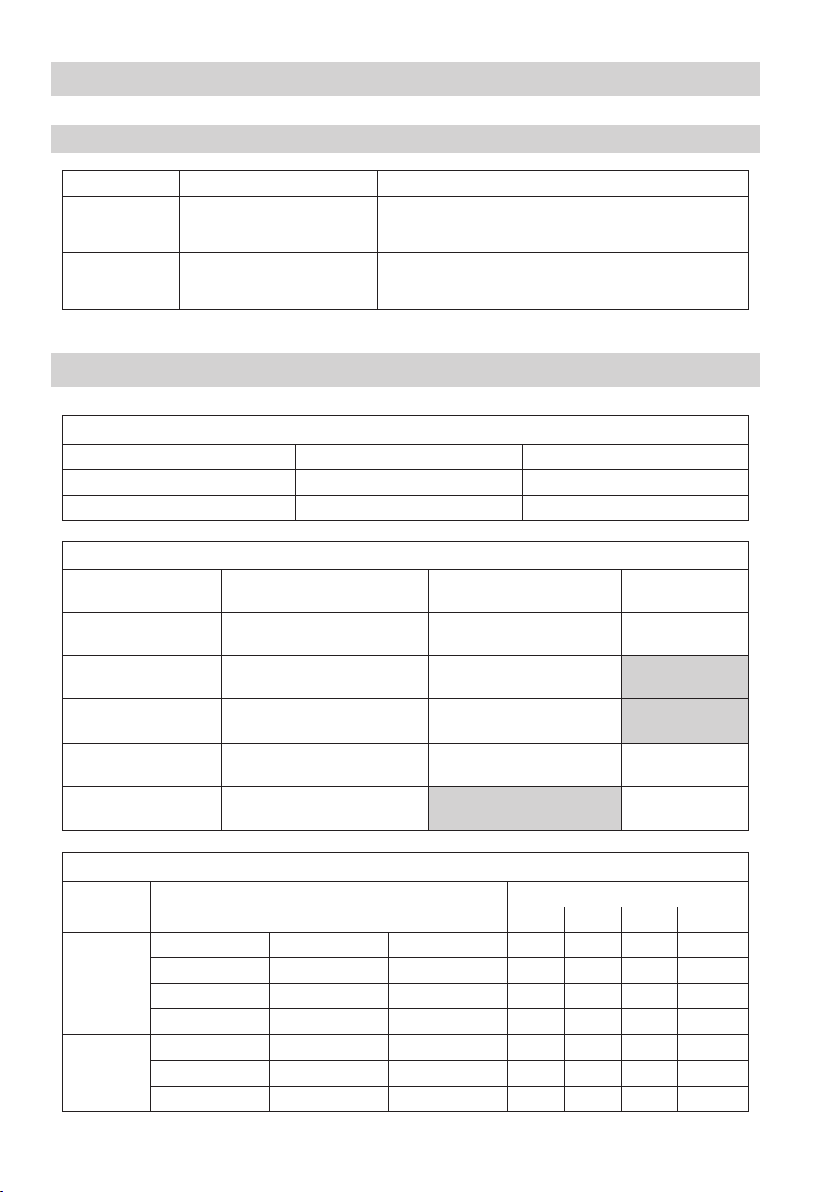

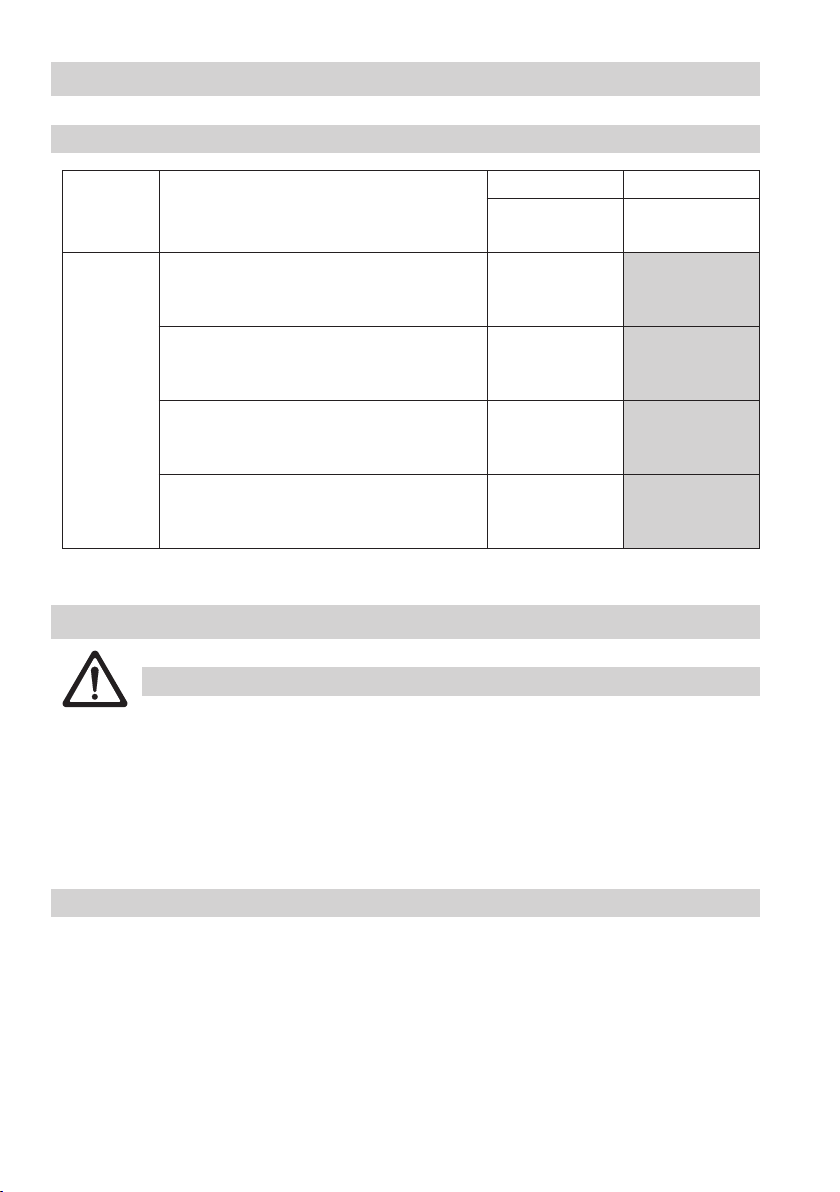

Technical Data

Pressure ratings

Type EN ASME

BA(E) 46 PN 40 Class 150, 300

BA(E) 47 PN 63 Class 400

Materials

Designation EN DIN ASTM

Valve body

BA..., BAE...

Nozzle stem X20Cr13 (1.4021) X20Cr13 (1.4021)

Seat and stage sleeves X14CrMoS17 (1.4104) X14CrMoS17 (1.4104)

Locking screw A2-70 A2-70 A193 CL 2B-B8

Sealing plug 42CrMo4 (1.7225) A193 B7

P250GH (1.0460) C 22.8 (1.0460) A 105

Pressure/Temperature ratings

Type Ratings according to

EN 1092-1 1.0460*)

BA(E) 46

BA(E) 47

*) Material according to AD 2000

EN 1092-1 A105

ASME B16-34 A105 Class 150 17.7 13.8 10.2 198 / 14

ASME B16-34 A105

EN 1092-1 1.0460*)

EN 1092-1 A105

ASME B16-34 A105

PN 40 37.3 30.2 25.8 234 / 29

PN 40 40 37.9 33.5 246 / 36

Class 300 46.6 43.8 39.8 254 / 42

PN 63 58.8 47.6 40.6 257 / 44

PN 63 63 59.6 52.7 271 / 55

Class 400 62.1 58.4 53.1 270 / 55

max. pressure [bar] at

100 °C 200 °C 300 °C ts / p

max

Page 9

Technical Data – continued –

Dimensions of end connections

Outside diameter of pipe x wall thickness

Butt-weld ends for pipe*) [DN] 15 20 25 32 40 50

EN PN 40 21.3 x 2 26.9 x 2.3 33.7 x 3.4 42.4 x 2.6 48.3 x 2.6 60.3 x 2.9

EN PN 63 21.3 x 2 26.9 x 2.6 33.7 x 2.6 42.4 x 2.9 48.3 x 2.9 60.3 x 2.9

ASME Schedule 40 CL150/300 21.3 x 2.8 26.7 x 2.9

ASME Schedule 80 CL400/300 21.3 x 3.7 26.7 x 3.9 33.4 x 4.5 42.2 x 4.8 48.3 x 5.1 60.3 x 5.5

Inside diameter x depth

Socket-weld ends EN/ASME**) [DN] 15 20 25 32 40 50

EN/ASME 21.8 x 10 27.3 x 13 34.1 x 13 42.8 x 13 48.8 x 13 61.3 x 16

*) The dimensions (outside diameter of pipe x wall thickness) refer to the connecting pipe, not to the dimensions

of the butt-weld end!

**) The dimensions (inside diamter x depth) refer to the socket-weld ends.

Overall lengths

End connection [mm]

[inch]

Flange Class 150 L 150 150 160 180 230 230

Flange Class 300 L 150 150 160 180 230 230

Flange Class 400 L 216 216 250

Butt-weld ends L 200 200 200 200 250 250

Socket-weld ends L 200 200 200 200 250 250

Flange PN 40 L 150 150 160 180 200 230

Flange PN 63 L 190 220 250

Weight BA 4... [kg] 4.7 5.3 5.8 7.1 10.7 12.5

Weight BAE 4... [kg] 8.8 9.4 9.9 11.2 14.8 16.6

15

½

33.4 x 3.4 42.2 x 3.6 48.3 x 3.7 60.3 x 3.9

20

¾

25

1

32

1¼

40

1½

50

2

Corrosion resistance

When used for its intended purpose, the safe functioning of the equipment will not be impaired by

corrosion.

Sizing

The valve body must not be subjected to sharp increases in pressure. The sizing and dimensional

allowances for corrosion reflect the latest state of technology.

9

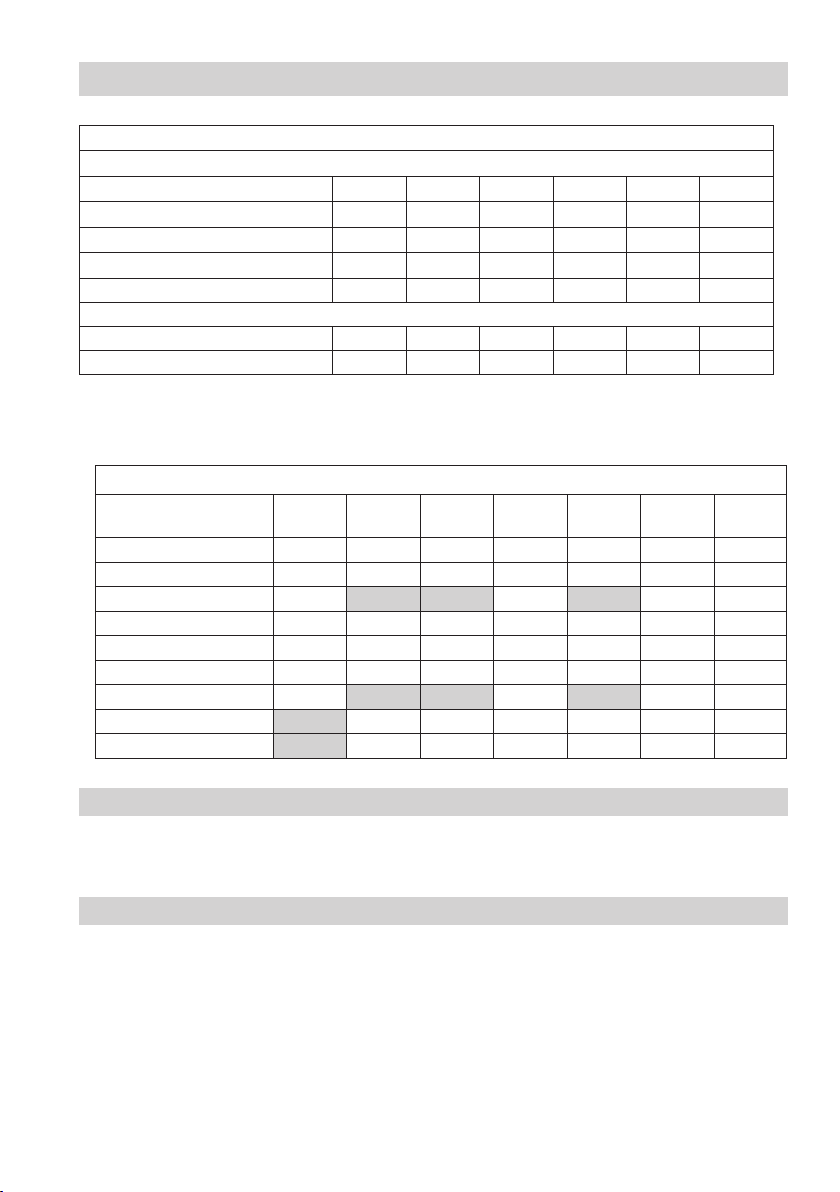

Page 10

10

Technical Data – continued –

MADE BY GESTRA AG

BA 47

0525

TMA 300°C

PN 63

DN

MADE BY GESTRA AG

BA 46

0525

TMA 572°F

B16.34 CL300

DN

MADE BY GESTRA AG

BA 47

0525

TMA 572°F

B16.34 CL400

DN

MADE BY GESTRA AG

BA 46

TMA 300°C

DN 25 PN 40

Name plate / marking

For pressure and temperature ratings see the designation on the valve body or the data given on the

name plate. Further details are given in various GESTRA publications, such as datasheets and technical

information.

In accordance with EN 19, the following type and design data are indicated on the name plate or body:

n Manufacturer

n Type designation

n Pressure class PN or Class

n Material number

n Maximum temperature

n Maximum pressure

n Direction of flow

n Stamp on valve body, e. g. specificies the manufacturing quarter and year

(in this case the 4

th

Nominal size

4

05

quarter of 2005)

max. admissible temperature

Nominal pressure

Letter “E”

Fig. 1

Page 11

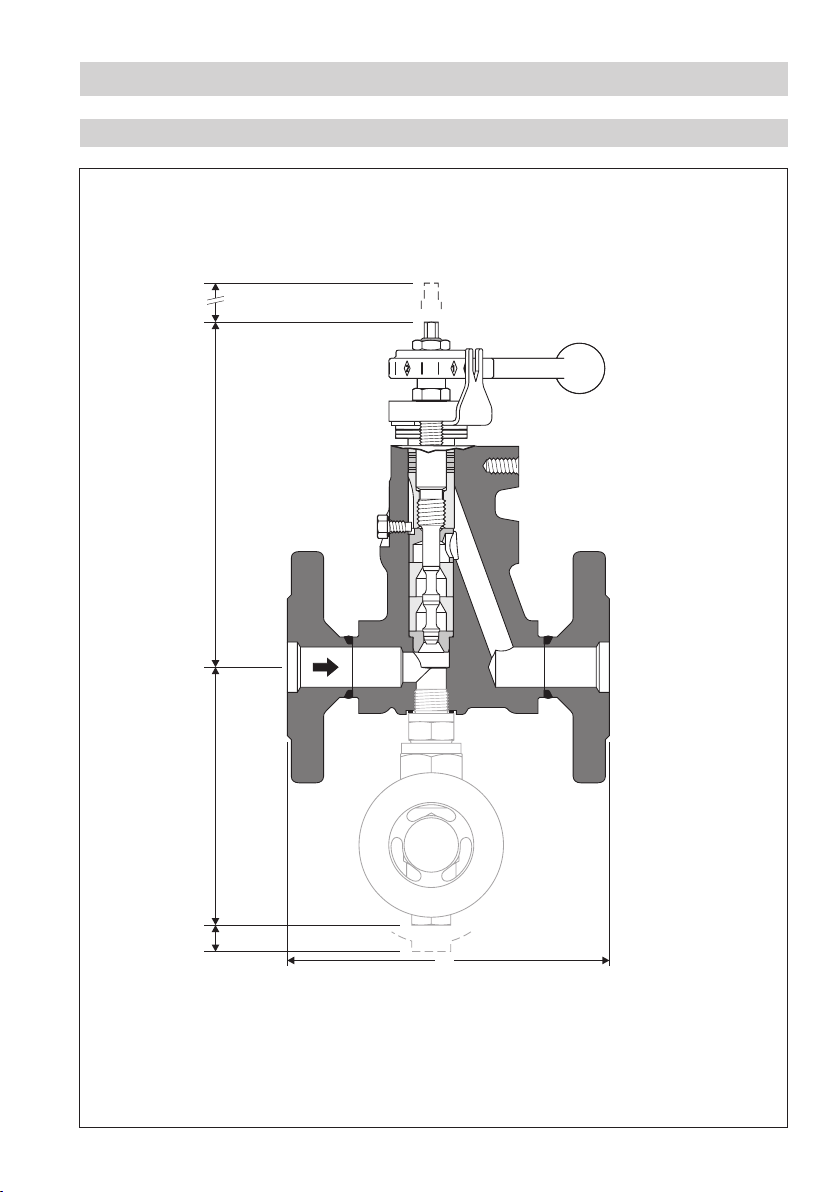

Technical Data – continued –

Dimensions BA 46, BA 47

180

DN 15-32: 172

DN 40, 50: 213DN 40, 50: 132

Fig. 2

DN 15-32: 126

20

L

11

Page 12

12

Technical Data – continued –

Dimensions BAE 46, BAE 47

100

DN 15-32: 388

DN 40, 50: 428DN 40, 50: 132

Fig. 3

DN 15-32: 126

20

L

Page 13

Technical Data – continued –

Capacity chart for DN 15 to 32, capacity ranges at a glance

Boiler pressure [bar]

Fig. 4

Hot water capacity [kg/h]

Position of control lever

13

Page 14

14

Technical Data – continued –

Capacity chart for DN 15 to 32, capacity range up to 310 kg/h

Boiler pressure [bar]

Fig. 5

Hot water capacity [kg/h]

Position of control lever

Page 15

Technical Data – continued –

Capacity chart for DN 15 to 32, capacity range up to 1020 kg/h

Boiler pressure [bar]

Fig. 6

Hot water capacity [kg/h]

Position of control lever

15

Page 16

16

Technical Data – continued –

Capacity chart for DN 15 to 32, capacity range up to 2120 kg/h

Boiler pressure [bar]

Fig. 7

Hot water capacity [kg/h]

Position of control lever

Page 17

Technical Data – continued –

Capacity chart for DN 40 and 50, capacity ranges at a glance

Boiler pressure [bar]

Fig. 8

Hot water capacity [kg/h]

Position of control lever

17

Page 18

18

Technical Data – continued –

Capacity chart for DN 40 and 50, capacity range up to 1340 kg/h

Boiler pressure [bar]

Fig. 9

Hot water capacity [kg/h]

Position of control lever

Page 19

Technical Data – continued –

Capacity chart for DN 40 and 50, capacity range up to 4500 kg/h

Boiler pressure [bar]

Fig. 10

Hot water capacity [kg/h]

Position of control lever

19

Page 20

20

Technical Data – continued –

Capacity chart for DN 40 and 50, capacity range up to 6300 kg/h

Boiler pressure [bar]

Fig. 11

Hot water capacity [kg/h]

Position of control lever

Page 21

Design

BA 46, BA 47

U

T

S

R

A

B

C

D

E

F

G

H

I

I

J

K

Q

P

Fig. 12

L

M

N

O

21

Page 22

22

Design – continued –

BAE 46, BAE 47

1

2

3

4

5

Fig. 13

K

8

6

Open Close

7

Page 23

Key

A Stuffing box screw

B Scale plate

C Stuffing box gland

D Disk spring (3 pieces)

E Spring sleeve

Packing with 4 wiper rings

F

G Guide sleeve

H Wearing bushing

I Stage bushing

J Seat bushing

K Valve body

L Nameplate

M ATEX marking

N Gasket A17 x 23 x 1.5

O Sealing plug (connection for a sample valve)

P Locking screw

Q Gasket C6 x 10 x 1.5 (DN 15-32) C10 x 16 x1.5 (DN 40, 50)

R Nozzle stem

S Scale

T Hexagon nut

U Control lever

1 Actuator

2 Compression spring

3 Thrust washer

4 Grooved dowel pin ISO 8742

5 Mounting bracket

6 Checking pin

7 Hexagon screw with washer

8 Coupling

23

Page 24

24

Installation

BA 46, BA 47, BAE 46, BAE 47

Mount the continuous blowdown valve, taking the direction of the flow arrow into account. The

blowdown take-off point must be located in the steam boiler underneath the low level mark and close

to the steam outlet. The continuous blowdown valve can be installed in horizontal and vertical

pipes. The continuous blowdown valve is delivered ready for installation, with the actuator mounted

or supplied separately. Before commissioning read the technical documentation provided by the

manufacturer of the actuator and store the document together with the installation manual “BA 46, BA

47, BAE 46, BAE 47” in a sheltered place. The continuous blowdown valve is delivered with a sample

valve (not installed). This sample valve must only be attached to the continuous blowdown valve at the

intended point. Before commissioning read the technical documentation provided by the manufacturer

of the sample valve and store the document together with the installation manual “BA 46, BA 47, BAE

46, BAE 47” in a sheltered place.

Attention

n Note that the inclination of the actuator when installed must not exceed 90

Valve with flanged ends

1. Ensure correct position of installation. The control lever

2. Observe direction of flow. The flow arrow is on the valve body.

3. Consider space required for servicing the valve. When the continuous blowdown valve is installed a

minimum space of at least 180 mm is required for removing the equipment or for the subsequent

installation of the actuator.

4. Remove plastic plugs. They are only used as transit protection.

Clean seating surfaces of both flanges.

5.

6. Install the continuous blowdown valve.

Valve with socket-weld ends

1. Ensure correct position of installation. The control lever

2. Observe direction of flow. The flow arrow is on the valve body

Consider space required for servicing the valve. When the continuous blowdown valve is installed a

3.

minimum space of at least 180 mm is required for removing the equipment or for the subsequent

installation of the actuator.

Remove plastic plugs. They are only used as transit protection.

4.

5. Clean socket-weld ends

6. Arc-weld trap only manually (welding process 111 and 141 to ISO 4063) or apply gas-welding

process (welding process 3 in accordance with ISO 4063).

Valve with butt-weld ends

1. Ensure correct position of installation. The control lever

2. Observe direction of flow. The flow arrow is on the valve body.

3. Consider space required for servicing the valve. When the continuous blowdown valve is installed

a minimum space of at least 180 mm is required for removing the equipment or for the subsequent

installation of the actuator.

4. Remove plastic plugs. They are only used as transit protection.

5. Clean butt-weld ends.

6. Arc-weld trap only manually (welding process 111 and 141 to ISO 4063) or apply gas-welding

process (welding process 3 in accordance with ISO 4063)

U must be freely movable.

U must be freely movable.

.

U must be freely movable.

°!

Page 25

Installation – continued –

Attention

n Only qualified welders certified according to EN 287-1 may weld continuous

blowdown valves in pressurised lines.

Heat treatment of welds

After welding the continuous blowdown valve in place the welds might require a subsequent heat

treatment (stress-relief annealing process to DIN EN 100529). Note that the heat treatment must be

limited to the area close to the welds. The internal parts of the continuous blowdown valve do not have

to be removed before performing the heat treatment.

Reposition control lever by 180 ° (if position of installation is unfavourable)

If the position of installation is unfavourable (flow from right to left), it may be necessary to reposition the

control lever by 180

1. Take heed of the danger note on page 5.

2. Unscrew the hexagon nut

3. Undo stuffing box screws

by 180

4. Screw out nozzle stem

7 Nm (DN 15 – 32) or 11 Nm (DN 40, 50).

5. Turn nozzle stem

and align scale S with the scale plate B such that the diamond-shaped marker “0” is in the

middle of the scale plate.

6. Screw hexagon nut

20 Nm while holding the control lever.

° so that the scale plate can be seen.

T and detach control lever U with the aid of a pulling device.

A, remove stuffing box gland C and scale plate B. Turn scale plate

° and put it back in place.

R by half a turn and tighten stuffing box screws A with a torque of

R into the closed position, applying a torque of 7 Nm. Put control lever U in place

T onto the threaded part of the nozzle stem R and tighten with a torque of

Install sample valve

1. Unscrew sealing plug

2. Observe installation instructions of the sample valve.

3. Install the sample valve, applying rules of good practice.

O and remove gasket N.

25

Page 26

26

Wiring

Danger

During operation moving internals can pinch one‘s hands or fingers. Do not touch moving

parts! The continuous blowdown valves BAE 46, BAE 47 are remote controlled and can

open and close very abruptly.

The terminal strips of the actuator EF ... are live during operation.

This presents the danger of electric shock.

Cut off power supply before fixing or removing the equipment.

Continuous blowdown valves BAE 46, BAE 47 with actuator

Apart from the positions OPEN and CLOSED you can select an OPERATING POSITION for the actuators

EF 0.5 and EF 1. The OPERATING POSITION allows the continuous discharge of a definded amount

of boiler water. The OPERATING POSITION can be adjusted in the actuator via the switching cam. For

more information refer to the attached installation manual “Actuators EF...”. The actuator EF 1-1 has a

feedback potentiometer ( 0 – 1000 ohm) but no switching cam for setting an OPERATING POSITION. For

more information on the setting refer to the attached installation manual “Actuators EF...”. The actuator

EF 1-40 sends at regular intervals a data telegram to the controller LRR 1-40. The data are transferred

via CAN bus in accordance with DIN ISO 11898, using the CANopen protocol. For more information refer

to the installation manual of the actuator EF 1-40.

Wire the actuator EF... in accordance with the attached installation manual “Actuators EF...”.

Factory settings of BAE 46, BAE 47

The default settings of the actuators EF 0.5 and EF 1 are: CLOSED (scale position “0”), OPERATING

POSITION (scale position “1”) and OPEN (scale position “4”),

In the OPERATING POSITION a predefined amount of boiler water is continuously discharged. The

OPERATING POSITION can be set in the actuator via the switching cam. For more information on the

adjustment refer to the installation manual “Actuators EF...”. The default settings of the actuators EF 1-1

and EF 1-40 are: CLOSED (scale position “0”) and OPEN (scale position “4”).

Fig. 4, Fig. 5

Commissioning

Danger

The control lever of the continuous blowdown valve and the coupling of the actuator

become hot during operation. This presents the risk of severe burns to hands and arms

when touching the control lever or the coupling. Do not operate the equipment unless you

are wearing thermally insulated and temperature resistant safety gloves.

BA 46, BA 47, BAE 46, BAE 47

Make sure that the flanged connections of the BA 46, BA 47, BAE 46, BAE 47 are securely tightened and

not leaking. Retighten the stuffing box C if there is a leak in this area.

Page 27

Commissioning – continued –

Attention

n As the stuffing box screws are tightened the break-out force and the frictional forces

of the nozzle steam are increased.

n The break-out force and the frictional forces of the nozzle steam must not exceed the

max. allowable operating forces of the actuator.

n Excessive fastening of the stuffing box screws impairs the correct functioning of the

continuous blowdown valve and can cause jamming of the nozzle stem.

n If the nozzle stem is jammed, the continuous blowdown valve can no longer open,

control or close.

Continuous blowdown valves BA 46, BA 47 without actuator

The amount of boiler blowdown dictated by the operating conditions can be adjusted by means of the

control lever on the continuous blowdown valve. For more information please refer to the capacity charts

on pages 13 to 20.

Continuous blowdown valves BAE 46, BAE 47 with actuator

Use the control equipment KS 90, LRR 1-40, LRR 1-5 or LRR 1-6 to set the required TDS level of the

boiler water. Please compare the resulting valve positions (see scale on the control lever) with the values

indicated in the capacity charts on page 13 to 20.

Operation

Danger

The control lever of the continuous blowdown valve and the coupling of the actuator

become hot during operation. This presents the risk of severe burns to hands and arms

when touching the control lever or the coupling. Do not operate the equipment unless you

are wearing thermally insulated and temperature resistant safety gloves.

BA 46, BA 47, BAE 46, BAE 47

Make sure that the flanged connections of the BA 46, BA 47, BAE 46, BAE 47 are securely tightened and

not leaking. Retighten the stuffing box C if there is a leak in this area.

Attention

n As the stuffing box screws are tightened the break-out force and the frictional forces

of the nozzle steam are increased.

n The break-out force and the frictional forces of the nozzle steam must not exceed the

max. allowable operating forces of the actuator.

n Excessive fastening of the stuffing box screws impairs the correct functioning of the

continuous blowdown valve and can cause jamming of the nozzle stem.

n If the nozzle stem is jammed, the continuous blowdown valve can no longer open,

control or close.

27

Page 28

28

Operation – continued –

Calculating the amount of boiler blowdown

Amount of boiler water to be discharged

Q · S

A =

K – S

A = Amount of boiler

blowdown [kg/h]

Q = Boiler capacity [kg/h]

S = Conductivity of feedwater

[

µs/cm]

K = Admissible conductivity of

boiler water [

µs/cm]

Example

Boiler pressure: 15 bar

Nominal size of the continuous blowdown valve: DN 20

Boiler capacity: Q = 10000 kg/h

Conductivity of feedwater: S = 100 µs/cm

Admissible conductivity of the boiler water: K = 3000 µs/cm

Amount of boiler water to be discharged: A ≈ 345 kg/h

10 % of which is intermittently blown out:

Amount of continuous blowdown: A1 ≈ 310 kg/h

Set control lever according to scale to an opening of 41 %,

≈ 35 kg/h

Fig. 6

Emergency Operation

BAE 46, BAE 47

Cut off power supply to the actuator and lift the coupling 8 approx. 1 cm by hand. Fig. 13

1.

Use the scale S on the control lever U to set the desired blowdown rate, Fig. 13

2.

Maintenance

The continuous blowdown valves BA 46, BA 47, BAE 46, BAE 47 do not require any special maintenance.

Depending on the quality of the boiler water it might be necessary to service the valve every one or two

years.

Changing packing and internals of BA 46, BA 47

1 Take heed of the danger note on page 5.

2. Unscrew the hexagon nut

3. Undo stuffing box screws

and spring sleeve

4. Unscrew nozzle stem

5. Unscrew locking screw

6. Unscrew sealing plug

7. Use a brass drift punch d = 14.8 mm to force out the internals

8. Clean and, if required, exchange valve body

9. Apply glue “Loctite

10. Align wearing bushing

screw

11. Screw in the locking screw

5 Nm (DN 15 – 32) or 11 Nm (DN 40, 50) when cold.

12. Align and insert the guide sleeve

on the locking screw

13. Insert new wiper rings and packing rings

14. Apply lubricant (type WINIX

P.

T and detach control lever U with the aid of a pulling device.

A, remove stuffing box gland C, scale plate B, disk springs D

E.

R and pull is out of the valve body.

P and remove gasket Q.

O and remove gasket N.

K and internals.

® 620” to seat bushing J and put it in place. Insert stage bushing I.

H in such a way that the groove is on the longitudinal axis of the locking

P together with gasket Q and tighten it with a torque of

G in such a way that the groove on the longitudinal axis is

P, Fig. 12.

F as shown, Fig. 12.

® 2010) to the thread and sealing surface of the nozzle stem.

F to J, Fig. 14

Page 29

Maintenance – continued –

Changing packing and internals of BA 46, BA 47 – continued –

15. Insert nozzle stem R and screw it into the guide sleeve G by two turns.

16. Insert spring sleeve

17. Put scale plate

18. Screw out nozzle stem

7 Nm (DN 15 – 32) or 11 Nm (DN 40, 50).

19. Turn nozzle stem

place and align scale

middle of the scale plate.

20. Screw hexagon nut

20 Nm while holding the control lever.

21. Screw sealing plug

130 Nm or screw in the sample valve with the gasket according to the instructions given by the

manufacturer.

Changing packing and internals of BAE 46, BAE 47

1. Take heed of the danger note on page 5.

2. Cut off power supply to actuator

3. Undo hexagon screws

4. Unscrew the hexagon nut

5. Undo stuffing box screws

spring sleeve

6. Unscrew nozzle stem

7. Unscrew locking screw

8. Unscrew sealing plug

9. Use a brass drift punch d = 14.8 mm to force out the internals

10. Clean and, if required, exchange valve body

11. Apply glue type “Loctite

12. Align wearing bushing

screw

13. Screw in the locking screw

5 Nm (DN 15 – 32) or 11 Nm (DN 40, 50) when cold.

14. Align and insert the guide sleeve

is on the locking screw

15. Insert new wiper rings and packing rings

16. Apply lubricant (type WINIX

17. Insert nozzle stem

18. Insert spring sleeve

19. Put scale plate

20. Screw out nozzle stem

7 Nm (DN 15 – 32) or 11 Nm (DN 40, 50).

21. Turn nozzle stem

P.

place and align scale S with the scale plate B such that the diamond-shaped marker “0” is in the

middle of the scale plate.

E and disk springs D in the shown sequence.

B and stuffing box gland C in place and tighten stuffing box screws A slightly.

R by half a turn and fasten stuffing box screws A with a torque of

R into the closed position, applying a torque of 7 Nm. Put control lever U in

S with the scale plate B such that the diamond-shaped marker “0” is in the

T onto the threaded part of the nozzle stem R and tighten with a torque of

O together with gasket N into the valve body and tighten with a torque of

1.

7 and remove actuator and coupling 8.

T and detach control lever U with the aid of a pulling device.

A, remove stuffing box gland C, scale plate B, disk springs D and

E.

R and pull is out of the valve body.

P and remove gasket Q.

O and remove gasket N.

F to J, Fig. 14

K and internals.

® 620” to seat bushing J and put it in place. Insert stage bushing I.

H in such a way that the groove is on the longitudinal axis of the locking

P together with gasket Q and tighten it with a torque of

G in such a way that the groove on the longitudinal axis

P, Fig. 12.

F as shown, Fig. 12.

® 2010) to the thread and sealing surface of the nozzle stem.

R and screw it into the guide sleeve G by two turns.

E and disk springs D in the shown sequence.

B and stuffing box gland C in place and tighten stuffing box screws A slightly.

R by half a turn and fasten stuffing box screws A with a torque of

R into the closed position, applying a torque of 7 Nm. Put control lever U in

WINIX® 2010 is a registered trademark of WINIX GmbH, Norderstedt

LOCTITE® is a registered trademark of HENKEL KgaA, Düsseldorf

29

Page 30

30

Maintenance – continued –

Changing packing and internals of BAE 46, BAE 47 – continued –

22. Screw hexagon nut T onto the threaded part of the nozzle stem R and tighten with a torque

of 20 Nm while holding the control lever.

Screw sealing plug O together with gasket N into the valve body and tighten with a torque of

23.

130 Nm or screw in the sample valve with the gasket according to the instructions given by the

manufacturer.

Put coupling 8 onto control lever U and fix the mounting bracket 5 and actuator 1 to the valve

24.

body using the hexagon screws 7. Adjust control lever until the coupling makes contact.

Align the actuator, making sure that the coupling 8 is level on the control lever. Fasten hexagon

25.

screws 7 with a torque of 7 Nm.

Adjust the switching cams for OPEN, CLOSED and OPERATING POSITION or, if fitted, the feedback

26.

potentiometer according to the attached installation manual “Actuators EF...”.

Set the switching cam for CLOSED in the actuator such that the torque checking pin 6 is to the

27.

right but does not touch the checking hole.The closing torque in this position is 10 Nm. Fig. 13

Torques

Torque required

Item

A

O

P

R

T

7

All torques indicated in the table are based on a room temperature of 20 °C.

Continuous blowdown valve

BA 46, BA 47, BAE 46, BAE 47 7 11

BA 46, BA 47, BAE 46, BAE 47 130

BA 46, BA 47, BAE 46, BAE 47 5 11

BA 46, BA 47, BAE 46, BAE 47 7

BA 46, BA 47, BAE 46, BAE 47 20

BAE 46, BAE 47 7

for tightening [Nm]

DN 15-32 DN 40,50

Tools

n Combination spanner 7 mm A. F., DIN 3113, form B

n Combination spanner 10 mm A. F., DIN 3113, form B

n Combination spanner 13 mm A. F., DIN 3113, form B

n Combination spanner 16 mm A. F., DIN 3113, form B

n Combination spanner 17 mm A. F., DIN 3113, form B

n Torque spanner 1 – 12 Nm, ISO 6789

n Torque spanner 8 – 40 Nm, ISO 6789

n Torque spanner 80 – 400 Nm, ISO 6789

n Punch 14.8 x 220 CuZn (brass)

n Hammer 300 g, Din 1041

n Self-centering pulling device, size 0

Page 31

Maintenance – continued –

Removing internals

Fig. 14

31

Page 32

32

Retrofitting

GESTRA continuous blowdown valves BA 46 and BA 47 can be retrofitted with a GESTRA actuator EF...

(BAE 46, BAE 47).

Danger

During operation moving internals can pinch one‘s hands or fingers. Do not touch moving

parts! The continuous blowdown valves BAE 46, BAE 47 are remote controlled and can

open and close very abruptly.

The terminal strips of the actuator EF ... are live during operation.

This presents the danger of electric shock.

Cut off power supply before fixing or removing the equipment.

Mounting the actuator

1. Observe the installation instructions of the actuator manufacturer.

2. Attach compression spring 2, thrust washer 3 and grooved dowel pin 4 to actuator 1

EF... , Fig. 13

Put coupling 8 onto control lever U and fix the mounting bracket 5 and actuator 1 with hexagon

3.

screws 7 to the valve body. Align control lever until the coupling makes contact.

Align the actuator, making sure that the coupling 8 is level on the control lever. Fasten hexagon

4.

screws 7 with a torque of 7 Nm.

Adjust the switching cams for OPEN, CLOSED and OPERATING POSITION or, if fitted, the feedback

5.

potentiometer according to the attached installation manual “Actuators EF...”.

Set the switching cam for CLOSED in the actuator such that the torque checking pin 6 is to the

6.

right but does not touch the checking hole.The closing torque in this position is 10 Nm. Fig. 13

7. Remove

ATEX marking M from the valve body K. BAE 46, BAE 47 must not be used in potentially

explosive areas.

Torques

Item

7

All torques indicated in the table are based on a room temperature of 20 °C.

Continuous blowdown valve

BAE 46, BAE 47 7

Tools

n Combination spanner 13 mm A. F., DIN 3113, form B

n Torque spanner 1 – 12 Nm, ISO 6789

n Hammer 300 g, DIN 1041

Torque required

for tightening [Nm]

Page 33

Spare Parts

Spare parts list

Item

Designation

Stock code Stock code

BA 46

BA 47

BAE 46

BAE 47

F N

Q 5

F N

Q 5

R J

I H

G F

N Q

R J

I H

G F

N Q

1

1

1

Packing/gasket kit, DN 15 to DN 32:

2 packing rings 15 x 23 x 4, 4 wiper rings,

1 gasket C 6 x 10 x 1.5,

1 gasket A 17 x 23 x 1.5

Packing/gasket kit, DN 40 and DN 50:

2 packing rings 18 x 28 x 5, 4 wiper rings,

1 gasket C 10 x 16 x 1.5,

1 gasket A 17 x 23 x 1.5

Complete spare parts kit, DN 15 to DN 32:

1 nozzle stem, 1 seat bushing, 2 stage bushings,

1 wearing bushing, 1 guide sleeve,

2 packing rings 15 x 23 x 4, 4 wiper rings,

1 gasket C 6 x 10 x 1.5,

1 gasket A 17 x 23 x 1.5

Complete spare parts kit, DN 40 and DN 50:

1 nozzle stem, 1 seat bushing, 2 stage bushings,

1 wearing bushing, 1 guide sleeve,

2 packing rings 18 x 28 x 5, 4 wiper rings,

1 gasket C 10 x 16 x 1.5,

1 gasket A 17 x 23 x 1.5

Actuator EF 0.5, 230 V, 50/60 Hz 332754

Actuator EF 1, 230 V, 50/60 Hz 333312

Actuator EF 1-1, 230 V, 50/60 Hz 333311

335702 335702

335704 335704

335703 335703

335705 335705

1

Explosion-proof actuators or actuators powered with d. c. or three-phase current are available on request.

Actuator EF 1-40, 230 V, 50/60 Hz 335664

33

Page 34

34

Retrofitting Parts

Retrofitting parts list

Item

1

2

3

4

5

7

8

Designation

1 actuator EF 0.5, 230 V, 50/60 Hz

1 mounting bracket, 1 assembly set for coupling

3 hexagon screws

1 actuator EF 1, 230 V, 50/60 Hz

1 mounting bracket, 1 assembly set for coupling

3 hexagon screws

1 actuator EF 1-1, 230 V, 50/60 Hz

1 mounting bracket, 1 assembly set for coupling

3 hexagon screws

1 actuator EF 1-40, 230 V, 50/60 Hz

1 mounting bracket, 1 assembly set for coupling

3 hexagon screws

Decommissioning

Stock code Stock code

BA 46

BA 47

335658

335659

335660

335661

BAE 46

BAE 47

Danger

The equipment becomes hot during operation.

This presents the risk of severe burns and scalds to the whole body.

Before loosening flanged connections or sealing plugs make sure that all connected lines

are depressurised (0 bar) and cooled down to room temperature (20 °C).

The terminal strips of the actuator EF ... are live during operation.

This presents the danger of electric shock.

Cut off power supply before fixing or removing the equipment.

Disposal

Dismantle the equipment and separate the waste materials.

For the disposal of the equipment observe the pertinent legal regulations concerning waste disposal.

Page 35

Annex

Declaration of Conformity

We hereby declare that the equipment BA 46, BA 47 conforms to the following European Directives:

n ATEX Directive 94/9/EC of 23 March 1994

n Pressure Equipment Directive 97/23/EC of 29 May 1998 (unless the equipment is excluded from the

scope of the Directive according to section 3.3).

Applied conformity assessment procedure: Annex III, Module H, verified by the Notified Body 0525.

This declaration is no longer valid if modifications are made to the equipment without consultation

with us.

We hereby declare that the equipment BAE 46, BAE 47 conforms to the following European Directives:

n Pressure Equipment Directive 97/23/EC of 29 May 1998 (unless the equipment is excluded from the

scope of the Directive according to section 3.3).

Applied conformity assessment procedure: Annex III, Module H, verified by the Notified Body 0525.

This declaration is no longer valid if modifications are made to the equipment without consultation

with us.

Bremen, 5th October 2005

GESTRA AG

Dipl.-Ing. Uwe Bledschun

(Academically qualified engineer)

Head of the Design Dept.

Dipl.-Ing. Lars Bohl

(Academically qualified engineer)

Quality Assurance Manager

35

Page 36

Agencies all over the world:

www.gestra.de

GESTRA

España

GESTRA ESPAÑOLA S.A.

Luis Cabrera, 86-88

E-28002 Madrid

Tel. 00 34 91 / 5 15 20 32

Fax 00 34 91 / 4 13 67 47; 5 15 20 36

E-mail: aromero@flowserve.com

Great Britain

Flowserve Flow Control (UK) Ltd.

Burrel Road, Haywards Heath

West Sussex RH 16 1TL

Tel. 00 44 14 44 / 31 44 00

Fax 00 44 14 44 / 31 45 57

E-mail: gestraukinfo@flowserve.com

Italia

Flowserve S.p.A.

Flow Control Division

Via Prealpi, 30

l-20032 Cormano (MI)

Tel. 00 39 02 / 66 32 51

Fax 00 39 02 / 66 32 55 60

E-mail: infoitaly@flowserve.com

Polska

GESTRA POLONIA Spolka z.o.o.

Ul. Schuberta 104

PL - 80-172 Gdansk

Tel. 00 48 58 / 3 06 10 -02 od 10

Fax 00 48 58 / 3 06 33 00

E-mail: gestra@gestra.pl

Portugal

Flowserve Portuguesa, Lda.

Av. Dr. Antunes Guimarães, 1159

Porto 4100-082

Tel. 0 03 51 22 / 6 19 87 70

Fax 0 03 51 22 / 6 10 75 75

E-mail: jtavares@flowserve.com

USA

Flowserve DALCO Steam Products

2601 Grassland Drive

Louisville, KY 40299

Tel.: 00 15 02 / 4 95 01 54, 4 95 17 88

Fax: 00 15 02 / 4 95 16 08

E-mail: dgoodwin@flowserve.com

GESTRA AG

P. O. Box 10 54 60, D-28054 Bremen

Münchener Str. 77, D-28215 Bremen

Telephone +49 (0) 421 35 03- 0

Fax +49 (0) 421 35 03 -393

E-Mail gestra.ag@flowserve.com

Internet www.gestra.de

818609-00/106cm · © 2005 GESTRA AG · Bremen · Printed in Germany

36

Loading...

Loading...