Page 1

USER INSTRUCTIONS

Limitorque ® B320 Series

FCD LMENIM3201-02 – 01/15

Installation

Operation

Maintenance

Experience In Motion

Page 2

This page is left intentionally blank.

Limitorque B320 Series FCD LMENIM3201-02 – 01/15

2

Page 3

Limitorque B320 Series FCD LMENIM3201-02 – 01/15

Contents

1 Introduction 5

1.1 Purpose 5

1.2 User Safety 5

2 Product Capabilities and Features 6

2.1 Initial Inspection and Storage Instructions 6

2.2 Product Identification 7

2.3 Inspection and Recording 7

2.4 Storage Procedure 8

3 Operator Weights 9

4 Installation Instructions 10

4.1 Safety Precautions 10

4.2 Safety Practices 11

4.3 Installation 11

4.3.1 Installing an Operator with a Threaded Stem Nut 11

4.3.2 Installing an Operator with a Blank Stem Nut (B320-10 through -90, one-piece) 11

4.3.3 Installing an Operator with a Blank Stem Nut (B320-90, two-piece) 12

5 Lubrication 13

5.1 Lubrication Inspection 13

5.2 Factory Lubricant 13

5.3 Minimum Lubricant Qualities Required 14

6 Disassembly and Reassembly 15

6.1 Disassembly and Reassembly of B320-10 through -80 16

6.1.1 Disassembly 16

6.1.2 Reassembly 16

6.2 Disassembly and Reassembly of B320-90 20

6.2.1 Disassembly 20

6.2.2 Reassembly 20

6.3 Disassembly and Reassembly of Spur Gear Attachments 21

6.3.1 Disassembly of 3:1 Spur Gear Attachment for B320-10 through -40 21

6.3.2 Reassembly of 3:1 Spur Gear Attachment for B320-10 through -40 22

6.3.3 Disassembly of 6.3:1, 10.3:1, and 10.8:1

Spur Gear Attachments for B320-50, -70, and -80 23

6.3.4 Reassembly of 6.3:1, 10.3:1, and 10.8:1

Spur Gear Attachments for B320-50, -70, and -80 23

6.3.5 Disassembly of 5:1 Spur Gear Attachment for B320-90 25

6.3.6 Reassembly of 5:1 Spur Gear Attachment for B320-90 25

6.3.7 Disassembly of 17.5:1 Spur Gear Attachment for B320-90 27

6.3.8 Reassembly of 17.5:1 Spur Gear Attachment for B320-90 27

7 How to Order Parts 30

3

flowserve.com

Page 4

Limitorque B320 Series FCD LMENIM3201-02 – 01/15

Figures

Figure 2.1 – B320 Bevel Gear Operator 7

Figure 2.2 – B320 Nameplate 8

Figure 6.1 – B320-10 and 20 Parts Diagram 17

Figure 6.2 – B320-30 and -40 Parts Diagram 17

Figure 6.3 – B320-50 and -70 Parts Diagram 18

Figure 6.4 – B320-80 Parts Diagram 18

Figure 6.5 – B320-90 Parts Diagram 20

Figure 6.6 – 3:1 SGA Parts Diagram for B320-10 through -40 22

Figure 6.7 – 6.3:1, 10.3:1, and 10.8:1 SGA Parts Diagram for B320-50 through 80 24

Figure 6.8 – 5:1 SGA Parts Diagram for B320-90 26

Figure 6.9 – 17.5:1 SGA Parts Diagram for B320-90 28

Tables

Table 3.1 – Operator Weights 9

Table 5.1 – Lubricant Quantities 14

Table 6.1 – Quantity of Ball Bearings 15

Table 6.2– Common Parts List 19

Table 6.3 – B320-90 Parts List 21

Table 6.4 – 3:1 SGA Parts List for B320-10 through -40 23

Table 6.5 – 6.3:1 , 10.3:1, and 10.8:1 SGA Parts List for B320-50 through 80 24

Table 6.6 – 5:1 SGA Parts List for B320-90 26

Table 6.7 – 17.5:1 SGA Parts List for B320-90 29

4

Page 5

1

Limitorque B320 Series FCD LMENIM3201-02 – 01/15

Introduction

1.1 Purpose

This Installation, Operation and Maintenance Manual (IOM) explains how to install and maintain the

B320 bevel gear operator. Information on installation, disassembly, lubrication, and spare parts is

provided.

1.2 User Safety

Safety notices in this manual detail precautions the user must take to reduce the risk of personal

injury and damage to the equipment. The user must read and be familiar with these instructions

before attempting installation, operation, or maintenance. Failure to observe these precautions could

result in serious bodily injury, damage to the equipment, void of the warranty, or operational difficulty.

Safety notices are presented in this manual in three forms:

c WARNING: Refers to personal safety. Alerts the user to potential danger. Failure to follow warning

notices could result in personal injury or death.

a CAUTION: Directs the user’s attention to general precautions that, if not followed, could result in

personal injury and/or equipment damage.

NOTE: Highlights information critical to the user’s understanding of the gear operator’s installation

and operation.

5

flowserve.com

Page 6

Product Capabilities

2

and Features

Limitorque B320 Series FCD LMENIM3201-02 – 01/15

Designed to make operation of multi-turn valves easier The B320 gear operator makes it easier to both

manually operate multi-turn valves and convert to a motorized service.

Built for reliable valve control — whether manual or motorized The B320 offers torque ranges up to

8,000 ft-lb (10,856 N m) and thrust capacities to 325,000 lb (1,445 kN) for any application

demanding superior strength and accuracy.

Easily adaptable for other applications The B320 is designed to be configured to each customer’s needs:

• Optional handwheel available for manual actuation

• Add a spur gear attachment for greater mechanical advantage

• Couple with an electric actuator from Limitorque for an economical, motorized, multi-turn package

2.1 Initial Inspection and Storage Instructions

c WARNING: Read this Installation, Operation and Maintenance Manual carefully and completely

before attempting to store the gear operator.

6

Page 7

2.2 Product Identification

Input Shaft Mounting Base Housing

Nameplate

Figure 2.1 – B320 Bevel Gear Operator

Limitorque B320 Series FCD LMENIM3201-02 – 01/15

2.3 Inspection and Recording

Upon receipt of the gear operator, inspect the condition of the equipment and record nameplate

information.

1. Carefully remove gear operator from shipping carton or skid. Thoroughly examine the equipment

for any physical damage that may have occurred during shipment. If damaged, immediately

report the damage to the transport company.

2. A nameplate is attached to each gear operator with the following information:

• Operator Size

• Limitorque Order Number

• Ratio

• Serial Number

Record this information for future reference, for ordering parts or obtaining further information.

7

flowserve.com

Page 8

Figure 2.2 – B320 Nameplate

Limitorque B320 Series FCD LMENIM3201-02 – 01/15

2.4 Storage Procedure

NOTE: The following is the recommended storage procedure to retain maximum product integrity

during storage. Failure to comply with recommended procedure will void the warranty.

Storage (Less Than One Year)

Operators should be stored in a clean, dry, protected warehouse and should be stored on wooden

skids to protect the machined mounting flange. If the operators must be stored outside, they must be

covered in polyethylene protection with silica gel crystals to absorb moisture. Input shafts should be

rotated every three months to mix lubricant.

8

Page 9

3

Limitorque B320 Series FCD LMENIM3201-02 – 01/15

Operator Weights

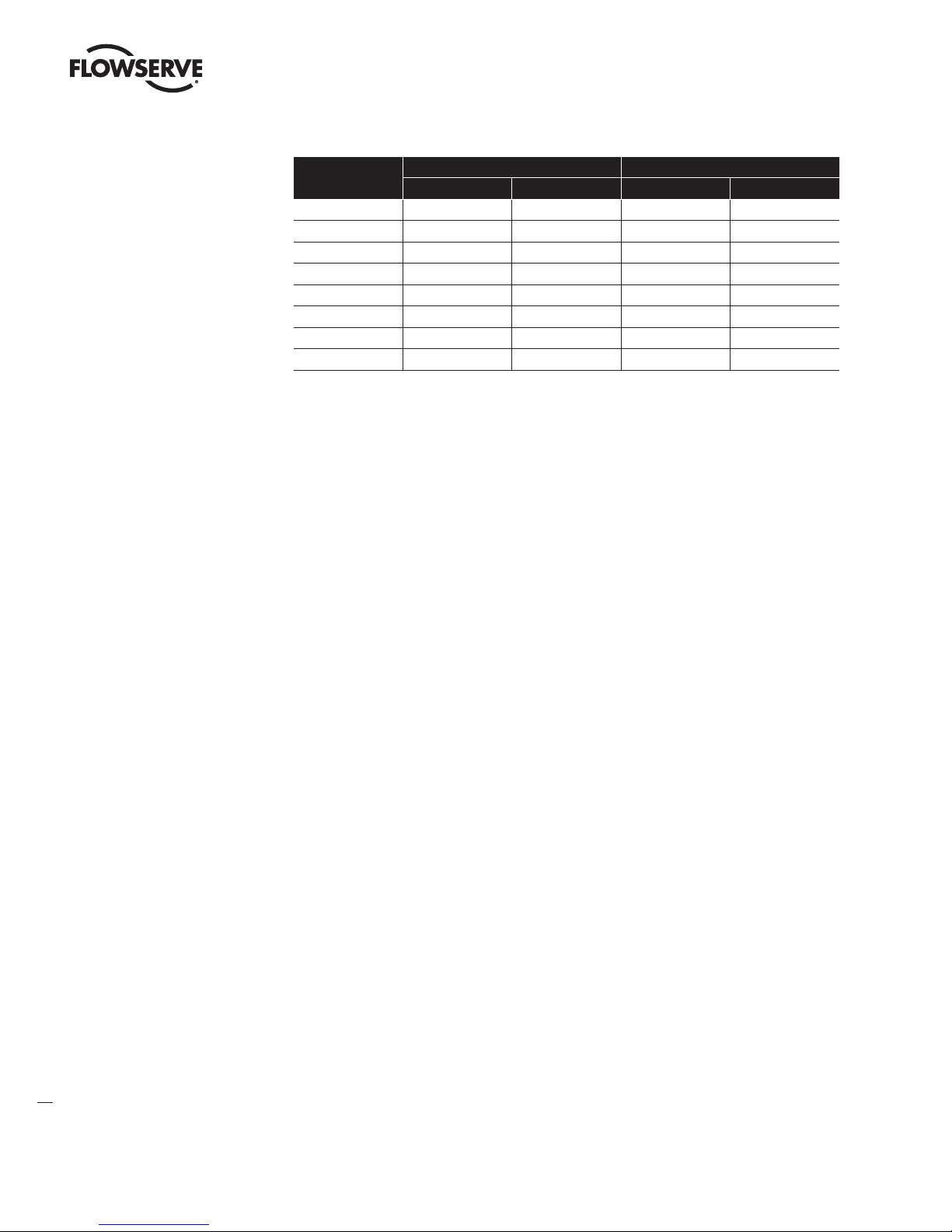

The approximate weights of the gear operators, with and without spur gear attachments, are provided

below:

Table 3.1 – Operator Weights

Operator Without SGA With SGA

lb kg lb kg

B320-10 45 21 75 34

B320-20 51 23 80 36

B320-30 57 26 86 39

B320-40 68 31 97 44

B320-50 143 65 198 90

B320-70 254 115 309 140

B320-80 418 190 474 215

B320-90 745 339 875 398

9

flowserve.com

Page 10

4

Limitorque B320 Series FCD LMENIM3201-02 – 01/15

Installation Instructions

4.1 Safety Precautions

c WARNING: Read this Installation, Operation and Maintenance Manual carefully and completely

before attempting to install, operate, or troubleshoot the Limitorque operator.

c WARNING: Potential HIGH PRESSURE vessel — be aware of high-pressure hazards associated

with the attached valve or other actuated device when installing or performing maintenance

on the operator. Do not remove the operator mounting bolts from the valve or actuated device

unless the valve or device stem is secured or there is no pressure in the line.

c WARNING: For maintenance and/or disassembly of the operator while installed on the valve,

ensure that the operator is not under thrust or torque load. If the valve must be left in service, the

valve stem must be locked in such a way as to prevent any movement of the valve stem.

c WARNING: Do not manually operate the operator with devices other than the installed hand-

wheel. Using force beyond the ratings of the operator and/or using additive force devices such as

cheater bars, wheel wrenches, pipe wrenches, or other devices on the operator handwheel may

cause serious personal injury and/or damage to the operator and valve.

c WARNING: Do not exceed any design limitations or make modifications to this equipment

without first consulting Limitorque.

c WARNING: Use of the product must be suspended any time it fails to operate properly.

a CAUTION: If a motor actuator is driving the manual operator, do not operate the valve under

motor operation without first checking and setting the limit switch setting and checking for

correct motor rotation.

a CAUTION: Do not use replacement parts that are not genuine Flowserve Limitorque parts, as

10

serious personal injury and/or damage to the operator and valve may result.

Page 11

Limitorque B320 Series FCD LMENIM3201-02 – 01/15

4.2 Safety Practices

The following check points should be performed to maintain safe operation of the B320 gear

operator:

• Set up a periodic operating schedule on infrequently used valves.

• Ensure that the limit and/or torque switches on any electric actuator fitted to the bevel gear

operator are correctly and appropriately adjusted.

4.3 Installation

The B320 series of gear operators has been designed to transmit torque as well as thrust. The gear

operator can be supplied with a threaded stem nut, keyed stem nut, or a blank stem nut.

4.3.1 Installing an Operator with a Threaded Stem Nut

1. Position operator above the valve stem.

2. Rotate the operator handwheel or wrench nut several turns until there is positive engagement

between the valve stem and the operator stem nut.

3. Rotate the handwheel to lower the operator onto the valve until contact has been made with the

valve flange.

4. Bolt the gear operator securely to the valve mounting flange.

4.3.2 Installing an Operator with a Blank Stem Nut

(B320-10 through -90, one-piece)

1. Remove the thrust ring from the base of the operator.

a CAUTION: Care must be taken to ensure that the O-ring seals located on the ring are not

damaged.

2. Remove the stem nut assembly consisting of a bronze nut and two needle roller bearings with

washers.

3. Remove bearings and washers. Place them in a clean and dry area until reassembly.

4. Machine the stem nut to suit the valve stem.

a CAUTION: Care should be taken to ensure that the clamping devices used during machining do

not damage surfaces of the stem nut.

5. Reassemble the operator, reversing steps 1, 2, and 3.

a. Install bearings and washers onto the bronze stem nut.

b. Install the assembly into the thrust base.

c. Bolt the thrust base assembly to the main housing.

a CAUTION: Ensure that no dirt or foreign material enters the operator.

11

flowserve.com

Page 12

Limitorque B320 Series FCD LMENIM3201-02 – 01/15

6. Using the specified lubricant, grease the thrust base assembly through the grease fitting. See

Section 5 Lubrication, and Figure 6.1, 6.2, 6.3, 6.4 and 6.5 for grease fitting location.

7. Mount the operator on the valve as detailed in Section 4.3.1, Installing an Operator with a Threaded

Stem Nut.

4.3.3 Installing an Operator with a Blank Stem Nut

(B320-90, two-piece)

(Piece numbers refer to Figure 6.5 and Table 6.3).

1. Remove the key from the bottom of the operator. The key is located between the Thrust Drive

Sleeve (piece #117) and the Stem Nut (piece #392). The key is tapped (¼-20) to provide for

removal.

2. Remove the Stem Nut by rotating in the proper direction. The Stem Nut is threaded into the Thrust

Drive Sleeve (piece #394). A slot is provided on the end of the Stem Nut to aid in its removal.

3. Thread the Stem Nut to suit the valve stem.

a CAUTION: Do not clamp the splined area of the Stem Nut during the tapping operation.

4. Reassemble the operator, reversing steps 1 and 2. Stem Nuts should be positioned flush with the

Thrust Drive Sleeve but can be recessed inward approximately ¼ inch, if so desired. Stem Nuts

can also be positioned to extend below the Thrust Drive Sleeve approximately ¼ inch without

jeopardizing the thrust rating of the operator. All Stem Nuts are threaded on the outside diameter

using eight threads per inch.

5. Mount the operator on the valve as detailed in Section 4.3.1, Installing an Operator with a Threaded

Stem Nut.

12

Page 13

5

Limitorque B320 Series FCD LMENIM3201-02 – 01/15

Lubrication

The B320 bevel gear operators have a sealed gear case, factory-lubricated with grease. No seal

can remain absolutely tight at all times. Therefore, it is not unusual to find a very small amount of

weeping around shaft seals — especially during long periods of idleness such as storage. Using

grease minimizes this condition as much as possible. If a small amount is weeping at start-up,

remove it with a clean cloth. Once the equipment is operating on a regular basis, the weeping should

stop.

5.1 Lubrication Inspection

Inspect the B320 bevel gear operators for correct lubrication prior to operating — particularly

following a storage period. We recommend the operators be checked during an overhaul program.

5.2 Factory Lubricant

The B320 series operator gear case is factory-lubricated with EP-0 lithium soap, mineral base grease,

suitable for temperatures from -20˚F (-29˚C) to 225˚F (107˚C).

a CAUTION: Do not mix lubricants of dissimilar bases.

13

flowserve.com

Page 14

Limitorque B320 Series FCD LMENIM3201-02 – 01/15

Table 5.1 – Lubricant Quantities

Operator Without SGA With SGA

lb kg lb kg

B320-10 0.7 0.3 1.2 0.6

B320-20 0.7 0.3 1.2 0.6

B320-30 1.2 0.6 1.7 0.8

B320-40 1.2 0.6 1.7 0.8

B320-50 2.2 1.0 2.7 1.2

B320-70 4.0 1.8 4.5 2.0

B320-80 4.0 1.8 4.5 2.0

B320-90 4.2 1.9 6.7 3.1

5.3 Minimum Lubricant Qualities Required

The standard lubricants used by Limitorque have been proven to be extremely reliable over years of

service. Lubricant substitute may be used; however, Limitorque does require the following lubricant

qualities as a minimum.

The lubricant must

• contain an “EP” additive.

• be suitable for the temperature range intended.

• be water- and heat-resistant and non-separating.

• not create more than 8% swell in Buna N or Viton.

• not contain any grit, abrasive, or fillers.

• be slump-prefer NLGI-0 grade.

• not be corrosive to steel gears, balls, or roller bearings.

• have a dropping point above 316°F (158°C) for temperature ranges of -20°F to 150°F (-28°C to

65°C).

14

Page 15

6

Limitorque B320 Series FCD LMENIM3201-02 – 01/15

Disassembly and Reassembly

No special tools are required for assembly/disassembly of the B320 series bevel gear operators.

c WARNING: Valve must be in fully opened position with no pressure in the line to perform work

on the gear operator.

a CAUTION: During disassembly and reassembly, all removed components should be cleaned and

placed in an area free of dirt, water, or other foreign material.

a CAUTION: Care should be taken in removing the ball bearings located between the bevel gear and

thrust housing. These bearings are non-caged, hardened ground balls.

The table below indicates the number of ball bearings utilized by each B320 size.

Table 6.1 – Quantity of Ball Bearings

Operator Quantity

B320-10 42

B320-20 42

B320-30 57

B320-40 57

B320-50 53

B320-70 74

B320-80 80

B320-90 66

15

flowserve.com

Page 16

Limitorque B320 Series FCD LMENIM3201-02 – 01/15

6.1 Disassembly and Reassembly of B320-10

through -80

6.1.1 Disassembly

(Piece numbers refer to Figures 6.1, 6.2, 6.3, and 6.4).

1. Remove Thrust Ring (piece #5). Pull out Stem Nut (piece #4), Washers (piece #7) and Bearings

(piece #6).

2. Remove Endcover (piece #20).

3. Slide out Bevel Pinion Shaft/Bearing Subassembly (piece #21, 22, and 23) together with Shims

(piece #25).

4. Remove Housing (piece #1) from Base (piece #2).

5. Remove Bevel Gear (piece #3) and Ball Bearings (piece #8).

NOTE: Please note the number and position of each shim.

6.1.2 Reassembly

(Piece numbers refer to Figures 6.1, 6.2, 6.3, and 6.4).

1. Install Ball Bearings (piece #8) and Bevel Gear (piece #3) on Base (piece #2).

2. Attach Housing (piece #1) to Base (piece #2).

3. Slide in Bevel Pinion Shaft/Bearing Subassembly (piece #21, 22, and 23) together with Shims

(piece #25).

4. Attach Endcover (piece #20).

5. Insert Thrust Washer (piece #7), Needle Bearing (piece #6) and another Thrust Washer (piece #7).

6. Insert Stem Nut (piece #4)

7. Insert Thrust Washer (piece #7), Needle Bearing (piece #6) and another Thrust Washer (piece #7).

8. Attach Thrust Ring (piece #5).

NOTE: Gasket compound is to be used on all metal/metal faces.

16

Page 17

Figure 6.1 – B320-10 and -20 Parts Diagram

2

25

17

18

1

11

21

18

17

22

23

20

26

25229 24

27

28

8

19

12

13

14

15 16

59

6

7

10

4

3

61

Limitorque B320 Series FCD LMENIM3201-02 – 01/15

1

11

3

8

12

13

61

10

Figure 6.2 – B320-30 and -40 Parts Diagram

6

7

27

28

19

14

15

16

4

5

9

29

22

20

23

24

21

26

17

flowserve.com

Page 18

Figure 6.3 – B320-50 and -70 Parts Diagram

1

11

3

8

17

13

2106 7495 16 15

14

19

18

25

20

24

28

27

21

26

29

49

27

53

23 22

43

52

23A

11

1

3

8

Limitorque B320 Series FCD LMENIM3201-02 – 01/15

18

17

23

29

25

24

20

27

28

21

26

53

54

13

2

61

10

6

7

Figure 6.4 – B320-80 Parts Diagram

19

14

9

4

5

16

15

22

22A

52

18

Page 19

Table 6.2– Common Parts List

Piece Quantity Description

1 1 Housing

2 1 Base

3 1 Bevel Gear

4 1 Stem Nut

5 1 Thrust Ring

6 2 Needle Bearing

7 4 Thrust Washer

8 A/R Ball Bearings

9 1 O-ring

10 1 O-ring

11 1 O-ring

12 A/R Lockwasher

13 A/R Hex Head Cap Screw

14 1 Grease Fitting

15 1 Plain Washer

16 1 Flat Head Mach. Screw

17 1 Nameplate

18 2 Drive Screw

19 1 Grease Fitting Cap

20 1 Endcover

21 1 Bevel Pinion

22 (B320-20) 2 Spacer

23 (B320-20) 2 Ball Bearing

22 (B320-40) 2 Spacer

23 (B320-40) 3 Ball Bearing

22 (B320-50) 2 Spacer

23 (B320-50) 2 Ball Bearing

22 (B320-70) 1 Spacer

22A (B320-70) 1 Spacer

23 (B320-70) 2 Spacer

22 (B320-80) 1 Spacer

23 (B320-80) 2 Ball Bearing

23A (B320-80) 1 Ball Bearing

24 1 O-ring

25 A/R Shim

26 1 Key

27 4 Lockwasher

28 4 Hex Head Cap Screw

29 1 Circlip

43 (B320-80) 1 Washer

52 1 Motorized Adapter

53 1 Lockwasher

54 1 Hex Head Cap Screw

56 (B320-50) 1 Spacer Ring (not shown)

61 (B320-20, -40, -50, -70) 1 O-ring

Limitorque B320 Series FCD LMENIM3201-02 – 01/15

19

Note: A/R–as required

flowserve.com

Page 20

Limitorque B320 Series FCD LMENIM3201-02 – 01/15

6.2 Disassembly and Reassembly of B320-90

6.2.1 Disassembly

(Piece numbers refer to Figure 6.5).

1. Remove Thrust Plate (piece #118) followed by Stem Nut (piece #392, two-piece) and Drive Sleeve

(piece #117, 2-piece; piece #394, one-piece) and Roller Bearings (piece #115 and 116).

2. Remove Bevel Cap (piece #94) and withdraw Bevel Pinion/Bearing Subassembly (piece

#95, #103 and #104).

3. Remove Bevel Housing (piece #91) from Thrust Housing (piece #114).

4. Remove Bevel Gear/Torque Drive Sleeve subassembly (piece #93 and 96) and Ball Bearings (piece

#102).

6.2.2 Reassembly

(Piece numbers refer to Figure 6.5).

1. Install Ball Bearings (piece #102) and Bevel Gear/Torque Drive Sleeve subassembly (piece #93 and 96).

2. Attach Bevel Housing (piece #91) to Thrust Base (piece #114).

3. Attach Bevel Cap (piece #94) and Bevel Pinion/Bearing Subassembly (piece

#95, #103 and #104).

4. Install Roller Bearings (piece #115 and 116) and Stem Nut (piece #392, two-piece) and Drive

Sleeve (piece #117, two-piece; piece #394, one-piece), followed by Thrust Plate (piece #118).

Figure 6.5 – B320-90 Parts Diagram

105

124

94

107

108

97

95

99

100

96

93

336

115

116

106

114

113

111

121

347

110

109

105

104

103

102

91

122

20

395

119

117 393 392 394

Tw o-Piece Stem Nut Design

118

120

One-Piece Stem Nut Design

Page 21

Table 6.3 – B320-90 Parts List

Piece Quantity Description

91 1 Bevel Housing

93 1 Torque Drive Sleeve

94 1 Bevel Cap

95 1 Input Shaft/Pinion

96 1 Bevel Gear

97 1 Threaded Collar

99 1 Quad Ring

100 1 O-ring

102 66 Ball Bearing

103 2 Roller Bearing Cone

104 2 Roller Bearing Cup

105 2 Spacer-Pinion

106 1 Spacer-Input Bearing

107 6 Hex Head Cap Screw

108 6 Lockwasher

109 12 Soc Head Cap Screw

110 12 Lockwasher

111 6 Hex Head Cap Screw

113 6 Lockwasher

114 1 Thrust Housing

115 2 Roller Bearing Cone

116 2 Roller Bearing Cup

117 1 Thrust Drive Sleeve (2-pc)

118 1 Thrust Plate

119 8 Hex Head Cap Screw

120 1 Quad Ring

121 1 Bushing

122 1 Quad Ring

336 1 Grease Fitting

347 1 Pipe Plug

392 1 Stem Nut

393 1 Key

394 1 Thrust Drive Sleeve (1-pc)

395 1 Lockwasher

Limitorque B320 Series FCD LMENIM3201-02 – 01/15

6.3 Disassembly and Reassembly of Spur Gear

Attachments

6.3.1 Disassembly of 3:1 Spur Gear Attachment for B320-10

through -40

(Piece numbers refer to Figure 6.6 and Table 6.4).

1. Remove Hex Head Cap Screws(piece #34) and Lockwashers (piece #35).

2. Remove the Spur Gear Cover (piece #31) and O-ring (piece #46), followed by the Input Shaft and

Pinion (piece #37), Idler Gear (piece #38), and Output Gear (piece #40).

21

flowserve.com

Page 22

Limitorque B320 Series FCD LMENIM3201-02 – 01/15

38

37

39

32

30

33

40

29

36

26A

31

34

35

37

46

28

27

3. Remove the Snap Ring (piece #29).

4. Remove the Hex Head Cap Screw (piece #28) and Lockwasher (piece #27).

5. Remove the Spur Gear Housing (piece #30).

6. Continue disassembly as detailed in Section 6.1. Disassembly and Reassembly – 320-10 through -80.

6.3.2 Reassembly of 3:1 Spur Gear Attachment for B320-10

through -40

(Piece numbers refer to Figure 6.6 and Table 6.4).

1. Install the Spur Gear Housing (piece #30), using the Hex Head Cap Screw (piece #28) and

Lockwashers (piece #27).

2. Install the Snap Ring (piece #29).

3. Install the Output Gear (piece #40), Idler Gear (piece #38), and Input Shaft and Pinion (piece #37).

4. Install the O-ring (piece #46) and Spur Gear (piece #31), using the Hex Head Cap Screws (piece #34)

and Lockwashers (piece #35)

Figure 6.6 – 3:1 SGA Parts Diagram for B320-10 through -40

22

Page 23

Limitorque B320 Series FCD LMENIM3201-02 – 01/15

Table 6.4 – 3:1 SGA Parts List for B320-10 through -40

Piece Quantity Description

26A 1 Key

27 4 Lockwasher

28 4 Hex Head Cap Screw

29 1 Snap Ring

30 1 Spur Gear Housing

31 1 Spur Gear Cover

32 5 Bushing

33 2 Dowel Pin

34 4 Hex Head Cap Screw

35 4 Lockwasher

36 2 Expansion Plug

37 1 Input Shaft and Pinion

38 1 Idler Gear

39 1 Key

40 1 Output Gear

46 1 O-ring

6.3.3 Disassembly of 6.3:1, 10.3:1, and 10.8:1 Spur Gear

Attachments for B320-50, -70, and -80

(Piece numbers refer to Figure 6.7 and Table 6.5).

1. Remove the Hex Head Cap Screws (piece #47) and Lockwashers (piece #35).

2. Remove the End Cover (piece #44) and O-ring (piece #46), followed by the Input Shaft and Pinion

(piece #37) and outer Ball Bearing (piece #45).

3. Remove the Hex Head Cap Screw (piece #34) and Lockwasher (piece #35).

4. Remove the Spur Gear Cover (piece #31), followed by the Idler Shaft subassembly (piece #48),

inner Ball Bearing (piece #45), and Final Gear (piece #40).

5. Remove the Socket Head Cap Screws (piece #53) and Lockwashers (piece #54).

6. Remove the Spur Gear Housing (piece #30).

7. Continue disassembly as detailed in Section 6.1, Disassembly and Reassembly of B320-10 through -80.

6.3.4 Reassembly of 6.3:1, 10.3:1, and 10.8:1 Spur Gear

Attachments for B320-50, -70, and -80

(Piece numbers refer to Figure 6.7 and Table 6.5).

1. Install the Spur Gear Housing (piece #30), using the Socket Head Cap Screws (piece #53) and

Lockwashers (piece #54).

2. Install the Final Gear (piece #40), inner Ball Bearings (piece #45), Idler Shaft subassembly (piece

#48), and the Spur Gear Cover (piece #31).

3. Install the Spur Gear Cover (piece #31), using the Hex Head Cap Screws (piece #34) and

Lockwashers (piece #35).

4. Install the outer Ball Bearing (piece #45) and Input Shaft and Pinion (piece #37).

5. Install the O-ring (piece #46) and End Cover (piece #44), using the Hex Head Cap Screws (piece

#47) and Lockwashers (piece #35).

23

flowserve.com

Page 24

Limitorque B320 Series FCD LMENIM3201-02 – 01/15

48

40

30

31

34

35

32

36

44

47

35

37

21A

26A

45

46

51

39

32A

Figure 6.7 – 6.3:1, 10.3:1, and 10.8:1 SGA Parts Diagram for B320-50 through -80

24

Table 6.5 – 6.3:1 , 10.3:1, and 10.8:1 SGA Parts List for B320-50 through -80

Piece Quantity Description

21A 1 Spur Pinion

26A 2 Key

30 1 Spur Gear Housing

31 1 Spur Gear Cover

32 1 Bushing

32A 1 Bushing

33 2 Dowel Pin (not shown)

34 8 Hex Head Cap Screw

35 12 Lockwasher

36 2 Plug

37 1 Input Shaft & Pinion

39 1 Key

40 1 Final Gear

44 1 Endcover

45 2 Ball Bearing

46 1 O-ring

47 4 Hex Head Cap Screw

48 1 Idler Shaft Subassembly

51 1 Motorized Adapter (if required)

53 8 Socket Head Cap Screw (internal, not shown)

54 8 Lockwasher (Hi Collar) (internal, not shown)

Page 25

Limitorque B320 Series FCD LMENIM3201-02 – 01/15

6.3.5 Disassembly of 5:1 Spur Gear Attachment for B320-90

(Piece numbers refer to Figure 6.8 and Table 6.6).

1. Remove the Socket Head Cap Screws (piece #217) and Lockwashers (piece #216) to remove the

Housing (piece #201).

2. Remove the Housing complete with the Input Shaft and Pinion (piece #202) and Idler Gear (piece

#203).

3. Remove the Hex Head Cap Screw (piece #215), Lockwasher (piece #214), and Flat Washer (piece

#213).

4. Remove the Output Gear (piece #204).

5. Remove the Hex Head Cap Screw (piece #218) and Lockwasher (piece #216).

6. Remove the Adapter Plate (piece #200) and O-ring (piece #211).

7. Continue disassembly as detailed in Section 6.1, Disassembly and Reassembly of B320-90.

6.3.6 Reassembly of 5:1 Spur Gear Attachment for B320-90

(Piece numbers refer to Figure 6.8 and Table 6.6).

1. Install the O-ring (piece #211) and Adapter Plate (piece #200), using the Hex Head Cap Screws

(piece #218) and Lockwashers (piece #216).

2. Install the Output Gear (piece #204).

3. Install the Flat Washer (piece #213), Lockwasher (piece #214), and Hex Head Cap Screw (piece

#215).

4. Install the Idler Gear (piece #203) and the Input Shaft and Pinion (piece #202) into the Housing

(piece #201).

5. Apply liquid gasket to the Adapter Plate flange and install the Housing assembly (piece #210, #202,

and #203), using the Socket Head Cap Screws (piece #217) and Lockwashers (piece #216).

25

flowserve.com

Page 26

Limitorque B320 Series FCD LMENIM3201-02 – 01/15

202

210

206

201

212

216

217

200

206

208

218

216

213

214

215

209

204

211

205

219

Section "A-A"

208

206

203

206

Section "B-B"

Thru Idler Gear

Figure 6.8 – 5:1 SGA Parts Diagram for B320-90

26

Table 6.6 – 5:1 SGA Parts List for B320-90

Piece Quantity Description

200 1 Adapter Plate

201 1 Housing

202 1 Input Shaft and Pinion

203 1 Idler Gear

204 1 Output Gear

205 1 Spacer

206 4 Teflon Bearing

208 2 Expansion Plug

209 1 Expansion Plug

210 1 Quad Ring

211 1 O-ring

212 1 Gasket

213 1 Flat Washer

214 1 Lockwasher

215 1 Hex Head Cap Screw

216 13 Lockwasher

217 7 Socket Head Cap Screw

218 6 Hex Head Cap Screw

219 2 Dowel Pin

347 1 Pipe Plug (not shown)

Page 27

Limitorque B320 Series FCD LMENIM3201-02 – 01/15

6.3.7 Disassembly of 17.5:1 Spur Gear Attachment for B320-90

(Piece numbers refer to Figure 6.9 and Table 6.7).

1. Remove Socket Head Cap Screws (piece #220) and Lockwashers (piece #221) to remove the

Housing Cover (piece #201). The Input Shaft and Pinion (piece #202, 207, 208 ad 211) are

removed with the Housing Cover (piece #201).

NOTE: If the Input Shaft is horizontal, exercise caution when removing the Housing Cover.

Prepare to support the 2nd Set Input Shaft Assembly (piece# 204, #205, and #206)

2. Remove the 1st Set Output Gear (piece #203), the 2nd Set Input Shaft (piece #204), and the 2nd

Set Input Gear (piece #205).

3. Remove the Socket Head Screw (piece #218), Lockwasher (piece #217), and the Flat Washer

(piece #216).

4. Remove the 2nd Set Output Gear (piece #206).

5. Remove the Hex Head Cap Screw (piece #222) and Lockwashers (piece #223), and remove the

Housing (piece #200) and O-ring (piece #212).

6. Continue disassembly as detailed in Section 6.2, Disassembly & Reassembly – B320-90.

6.3.8 Reassembly of 17.5:1 Spur Gear Attachment for B320-90

(Piece numbers refer to Figure 6.9 and Table 6.7).

1. Install O-ring (piece #212) and Housing (piece #200) using the Hex Head Cap Screws (piece

#222) and Lockwashers (piece #223).

2. Install the 2nd Set Output Gear (piece #206).

3. Install the Flat Washer (piece #216), Lockwasher (piece #217), and Socket Head Cap Screws

(piece #218).

4. Install the 2nd Set Input Gear (piece #205), 2nd Set Input Shaft (piece #204), and 1st Set Output

Gear (piece #203).

5. Apply liquid gasket to the flange surface of the Housing (piece #200), and install the Housing

Cover (piece #201) using Lockwashers (piece #221) and Socket Head Cap Screws (piece #220).

27

flowserve.com

Page 28

Limitorque B320 Series FCD LMENIM3201-02 – 01/15

Figure 6.9 – 17.5:1 SGA Parts Diagram for B320-90

212

200

223

222

206

220

221 201

216

217

218

215

28

214

204

209

210

205

213

209

219

203

202

210

207

209

214

208

211

Page 29

Table 6.7 – 17.5:1 SGA Parts List for B320-90

Piece Quantity Description

200 1 Housing

201 1 Housing Cover

202 1 1st Set Input Shaft/Pinion

203 1 1st Set Output Gear

204 1 2nd Set Input Shaft

205 1 2nd Set Input Gear

206 1 2nd Set Output Gear

207 1 Spacer

208 1 Bushing

209 3 Bushing

210 2 Thrust Washer

211 1 Quad Ring

212 1 O-ring

213 1 Gasket

214 2 Expansion Plug

215 1 Expansion Plug

216 1 Flatwasher

217 1 Lockwasher

218 1 Socket Head Cap Screw

219 2 Dowel Pin

220 8 Socket Head Cap Screw

221 8 Lockwasher

222 6 Hex Head Cap Screw

223 6 Lockwasher

347 1 Pipe Plug (not shown)

Limitorque B320 Series FCD LMENIM3201-02 – 01/15

29

flowserve.com

Page 30

7

Limitorque B320 Series FCD LMENIM3201-02 – 01/15

How to Order Parts

To order parts or obtain further information for your Limitorque B320 gear operators, contact your

local Limitorque distributor sales office, or:

Flowserve Flow Control

Limitorque Actuation Systems

5114 Woodall Road

P.O. Box 11318

Lynchburg, VA 24506-1318

Telephone 434 528 4400

Fax 434 845 9736

www.flowserve.com/valves

All inquiries or orders must be accompanied by the following information:

1. Actuator Size

2. Limitorque Order Number

3. Limitorque Serial Number

30

Page 31

This page is left intentionally blank.

Limitorque B320 Series FCD LMENIM3201-02 – 01/15

31

flowserve.com

Page 32

FCD LMENIM3201-02-AQ Printed in USA. January 2015

Flowserve Corporation

Flow Control

United States

Flowserve Limitorque

5114 Woodall Road

P.O. Box 11318

Lynchburg, VA 24506-1318

Phone: 434-528-4400

Fax: 434-845-9736

England

Flowserve Limitorque

Euro House

Abex Road

Newbury

Berkshire, RG14 5EY

United Kingdom

Phone: 44-1-635-46999

Fax: 44-1-635-36034

Singapore

Limitorque Asia, Pte., Ltd.

12, Tuas Avenue 20

Singapore 638824

Phone: 65-6868-4628

Fax: 65-6862-4940

To find your local Flowserve representative,

visit www.flowserve.com or call USA 1 800 225 6989

Flowserve Corporation has established industry leadership in the design and manufacture of its products. When properly selected, this Flowserve product is designed to perform its intended

function safely during its useful life. However, the purchaser or user of Flowserve products should be aware that Flowserve products might be used in numerous applications under a wide

variety of industrial service conditions. Although Flowserve can (and often does) provide general guidelines, it cannot provide specific data and warnings for all possible applications. The

purchaser/user must therefore assume the ultimate responsibility for the proper sizing and selection, installation, operation, and maintenance of Flowserve products. The purchaser/user

should read and understand the Installation Operation Maintenance (IOM) instructions included with the product, and train its employees and contractors in the safe use of Flowserve

products in connection with the specific application.

While the information and specifications contained in this literature are believed to be accurate, they are supplied for informative purposes only and should not be considered certified or as

a guarantee of satisfactory results by reliance thereon. Nothing contained herein is to be construed as a warranty or guarantee, express or implied, regarding any matter with respect to this

product. Because Flowserve is continually improving and upgrading its product design, the specifications, dimensions and information contained herein are subject to change without notice.

Should any question arise concerning these provisions, the purchaser/user should contact Flowserve Corporation at any one of its worldwide operations or offices.

© 2015 Flowserve Corporation, Irving, Texas, USA. Flowserve is a registered trademark of Flowserve Corporation.

China

Limitorque Beijing, Pte., Ltd.

RM A1/A2

22/F, East Area, Hanwei Plaza

No. 7 Guanghua Road, Chaoyang

District

Beijing 100004, Peoples Republic

of China

Phone: 86-10-5921-0606

Fax: 86-10-6561-2702

India

Flowserve Limitorque

Plot No. #4, 1 A, Road No. 8, EPIP

Whitefield, Bangalore – 560066

Karnataka

India

Phone: 91-80-40146200

Fax: 91-80-28410286

Italy

Flowserve Limitorque

Fluid Power Systems

Via Rio Vallone 17

20883 Mezzago MB

Italy

Phone: 39-039-620601

Fax: 39-039-62060 213

flowserve.com

Loading...

Loading...