Page 1

ATEX E/F/D/N

ATEX Safety Manual for centrifugal and

positive displacement pumps

User instructions: to ensure compliance with

European Directive 94/9/EC. Original instructions.

English 3

Manuel de sécurité ATEX relatif aux pompes

centrifuges et volumétriques

Instructions utilisateur: assurer la conformite avec la Directive

Europeenne 94/9/CE. Notice originale.

ATEX-Sicherheitshandbuch für Kreisel- und

Verdängerpumpen

Anweisungen für den Benutzer: zur sicherstellung der einhaltung

der Europäischen Richtlinie 94/9/EG. Original-anweisungen.

ATEX Veiligheidshandleiding voor Centrifugale

en Verdringingspompen

Gebruikershandleiding: om overeenstemming te verzekeren

met Europese Richtlijn 94/9/EG. Oorspronkelijke

gebruiksaanwijzing.

Manual Part No: ATEX E/F/D/N 11-09

Français 7

Deutsch 11

Nederlands 16

Page 2

ATEX- E/F/D/N - 11-09

CONTENTS - ENGLISH

Page

1 GENERAL ..............................................................3

1.1 ATEX Directive 94/9/EC.................................3

1.2 Disclaimer.......................................................3

1.3 Personnel qualifications and training..............3

2 SAFETY..................................................................3

2.1 Summary of safety marking............................3

2.2 Products used in potentially explosive

atmospheres ..................................................3

2.3 Scope of compliance ......................................3

2.4 Marking...........................................................4

2.5 Avoiding excessive surface temperatures......4

2.6 Preventing the build up of explosive

mixtures..........................................................5

2.7 Preventing sparks...........................................5

2.8 Preventing leakage.........................................5

2.9 Maintenance to avoid the hazard ...................6

TABLE DES MATIERES - FRANCAIS

Page

1 GENERALITES ......................................................7

1.1 Directive ATEX 94/9/CE.................................7

1.2 Décharge de responsibilité.............................7

1.3 Qualification et formation du personnel..........7

2 SECURITE..............................................................7

2.1 Résumé des marquages de sécurité..............7

2.2 Produits utilisés dans des atmosphères

potentiellement explosibles............................7

2.3 Portée de la conformité ..................................8

2.4 Marquage........................................................8

2.5 Eviter les températures de surface

excessives .....................................................8

2.6 Empêcher la création de mélanges

explosifs.........................................................9

2.7 Empêcher les étincelles..................................9

2.8 Empêcher les fuites ......................................10

2.9 Entretien pour éviter tout danger..................10

INHALT - DEUTSCH

Seite

1 ALLGEMEINES ................................................... 11

1.1 ATEX-Richtlinie 94/9/EG.............................. 11

1.2 Haftungserklärung........................................ 11

1.3 Qualifikationen und Schulung des

Personals.....................................................11

2 SICHERHEIT........................................................11

2.1 Zusammenfassung der

Sicherheitskennzeichnungen...........................11

2.2 Geräte zur Verwendung in

explosionsgefährdeten Bereichen....................12

2.3 Konformitätsumfang...........................................12

2.4 Kennzeichnung...................................................12

2.5 Vermeidung übermäßiger

Oberflächentemperaturen.................................12

2.6 Vermeidung der Entstehung explosiver

Gemische .................................................... 14

2.7 Vermeidung von Funkenbildung .................. 14

2.8 Vermeidung von Undichtheiten....................14

2.9 Wartung zur Gefahrenvermeidung............... 14

INHOUD - NEDERLANDS

Pagina

1 ALGEMEEN......................................................... 16

1.1 ATEX Richtlijn 94/9/EG................................16

1.2 Disclaimer..................................................... 16

1.3 Bevoegdheid en training personeel ............. 16

2 VEILIGHEID......................................................... 16

2.1 Overzicht van Veiligheidsmarkeringen......... 16

2.2 Producten die gebruikt worden in potentieel

explosieve omstandigheden........................ 16

2.3 Omvang van de certificatie........................... 17

2.4 Markering ..................................................... 17

2.5 Voorkomen van excessieve

oppervlaktetemperaturen ............................ 17

2.6 Voorkomen van de opeenhoping van

explosieve mengsels ................................... 18

2.7 Voorkomen van vonken ............................... 19

2.8 Voorkomen van lekkage............................... 19

2.9 Onderhoud ter voorkoming van gevaar ....... 19

Page 2 of 20 flowserve.com

Page 3

ATEX- E/F/D/N - 11-09

English

1 GENERAL

These instructions must always be kept

close to the product's operating location or

directly with the product.

These instructions are intended to facilitate

familiarisation with the product and its permitted use

to help satisfy ATEX safety requirements. The

instructions may not have taken into account local

regulations; ensure such regulations are observed by

all, including those installing the product. Always

coordinate repair activity with operations personnel,

and follow all plant safety requirements and applicable

safety and health laws/regulations.

These instructions must be read prior

to installing, operating, using and maintaining the

equipment in any region worldwide and in

conjunction with the main user instructions

provided. The equipment must not be put into

service until all the conditions relating to safety

instructions have been met. Failure to follow and

apply the present User Instructions is considered

to be misuse. Personal injury, product damage,

delay or failure caused by misuse are not covered

by the Flowserve warranty.

1.1 ATEX Directive 94/9/EC

It is a legal requirement that machinery and

equipment put into service within certain regions of

the world shall conform with the applicable CE

Marking Directives for Equipment for Potentially

Explosive Atmospheres (ATEX).

Where applicable the Directive covers important

safety aspects relating to the equipment, its use and

the satisfactory provision of technical documents.

Where applicable this document incorporates

information relevant to these Directives. To establish

if the product itself is CE marked for a Potentially

Explosive Atmosphere check the nameplate and the

Certification provided.

1.2 Disclaimer

Information in these User Instructions is believed

to be reliable. In spite of all the efforts of

Flowserve Corporation to provide sound and all

necessary information the content of this manual

may appear insufficient and is not guaranteed by

Flowserve as to its completeness or accuracy.

1.3 Personnel qualification and training

All personnel involved in the operation, installation,

inspection and maintenance of the unit must be

qualified to carry out the work involved.

If the personnel in question do not already possess

the necessary knowledge and skill, appropriate

training and instruction must be provided. If required

the operator may commission the manufacturer/

supplier to provide applicable training.

2 SAFETY

2.1 Summary of safety marking

These instructions contain the following specific

ATEX safety marking where non-observance of the

instruction will cause a hazard.

This symbol indicates explosive atmosphere

marking according to ATEX. It is used in safety

instructions where non-compliance in the hazardous

area would cause the risk of an explosion.

This symbol is used in safety instructions to

remind not to rub non-metallic surfaces with a dry

cloth; ensure the cloth is damp. It is used in safety

instructions where non-compliance in the hazardous

area would cause the risk of an explosion.

2.2 Products used in potentially

explosive atmospheres

Measures are required to:

• Avoid excess temperature

• Prevent build up of explosive mixtures

• Prevent the generation of sparks

• Prevent leakages

• Maintain the pump to avoid hazard

The following instructions for pumps and pump units

when installed in potentially explosive atmospheres

must be followed to help ensure explosion protection.

Both electrical and non-electrical equipment must meet

the requirements of European Directive 94/9/EC.

2.3 Scope of compliance

Use equipment only in the zone for which it is

appropriate. Always check that the driver, drive

coupling assembly, seal and pump equipment are

suitably rated and/or certified for the classification of the

specific atmosphere in which they are to be installed.

Where Flowserve has supplied only the bare shaft

pump, the Ex rating applies only to the pump. The

party responsible for assembling the pump set shall

select the coupling, driver, seal and any additional

equipment, with the necessary CE Certificate/

Declaration of Conformity establishing it is suitable for

the area in which it is to be installed.

Page 3 of 20 flowserve.com

Page 4

ATEX- E/F/D/N - 11-09

rature

Temperature

The output from a variable frequency drive (VFD) can

cause additional heating affects in the motor and so, for

pump sets with a VFD, the ATEX Certification for the

motor must state that it covers the situation where

electrical supply is from the VFD. This is particular

requirement still applies even if the VFD is in a safe area.

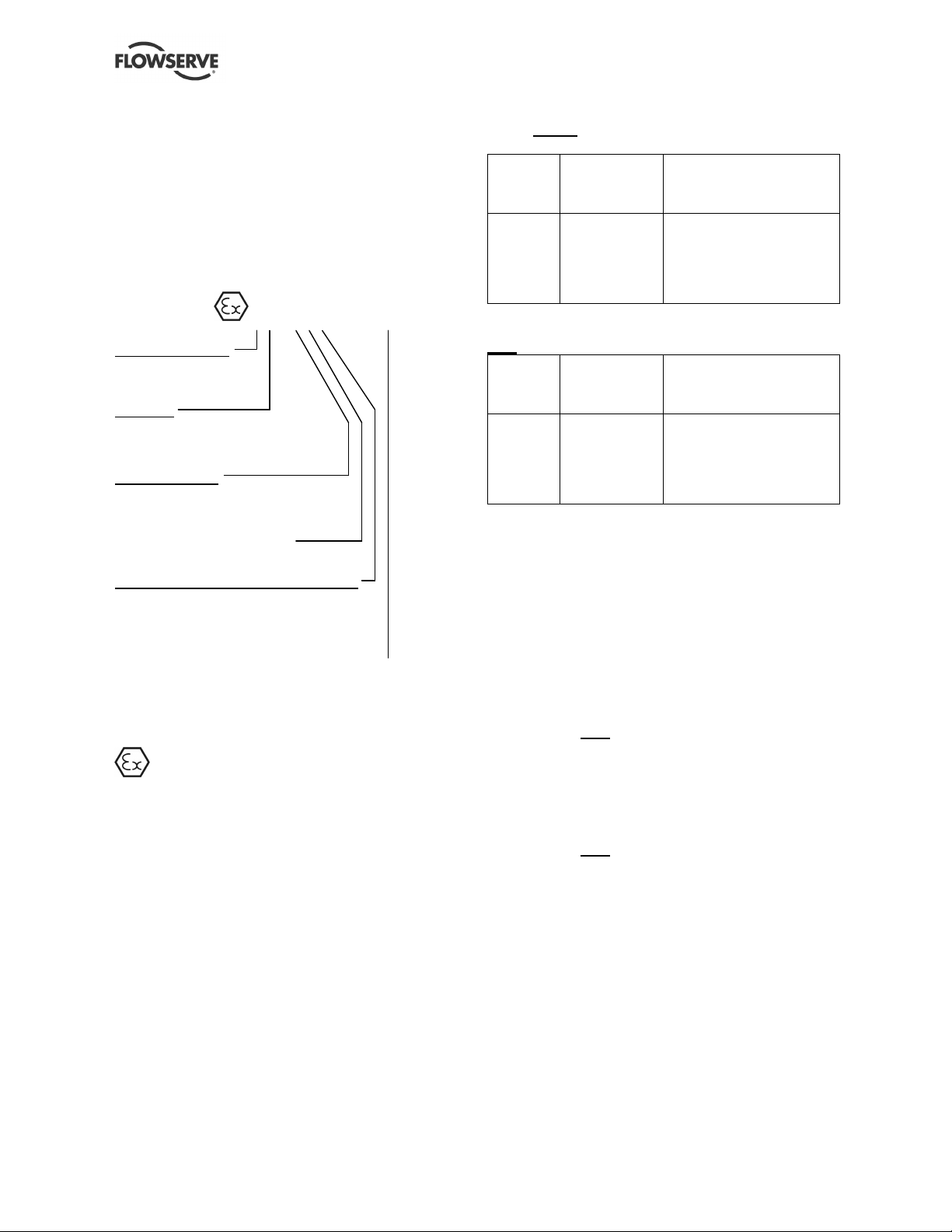

2.4 Marking

An example of ATEX equipment marking is shown

below. The actual classification of the pump will be

engraved on the nameplate.

II 2 GD c IIC 135 ºC (T4)

Equipment Group

I = Mining

II = Non-mining

Category

2 or M2 = high level protection

3 = normal level of protection

Gas and/or dust

G = Gas

D = Dust

c = Constructional safety

(in accordance with EN13463-5)

Gas Group (Equipment Category 2 only)

IIA – Propane (typical)

IIB – Ethylene (typical)

IIC – Hydrogen (typical)

Maximum surface temperature (Temperature Class)

(see section 2.5)

2.5 Avoiding excessive surface

temperatures

ENSURE THE EQUIPMENT TEMPERATURE

CLASS IS SUITABLE FOR THE HAZARD ZONE

2.5.1 Pump liquid temperature

Pumps have a temperature class as stated in the

ATEX Ex rating on the nameplate. These are based

on a maximum ambient of 40 °C (104 °F); refer to

Flowserve for higher ambient temperatures.

The surface temperature on the pump is influenced by

the temperature of the liquid handled. The maximum

permissible liquid temperature depends on the

temperature class and must not exceed the values in the

table applicable below.

The temperature rise at the seals and bearings and due

to the minimum permitted flow rate is taken into account

in the temperatures stated.

Maximum permitted liquid temperature for pumps

which do not have a magnetic drive or selfpriming casing:

Tempe

class to

EN13463-1

T6

T5

T4

T3

T2

T1

Maximum

surface

temperature

permitted

85 °C (185 °F)

100 °C (212 °F)

135 °C (275 °F)

200 °C (392 °F)

300 °C (572 °F)

450 °C (842 °F)

Temperature limit of liquid

handled (* depending on

material and construction

variant - check which is lower)

Consult Flowserve

Consult Flowserve

115 °C (239 °F) *

180 °C (356 °F) *

275 °C (527 °F) *

400 °C (752 °F) *

Maximum permitted liquid temperature for pumps

with magnetic drive or self priming casing:

class to

EN13463-1

T6

T5

T4

T3

T2

T1

Maximum

surface

temperature

permitted

85 °C (185 °F)

100 °C (212 °F)

135 °C (275 °F)

200 °C (392 °F)

300 °C (572 °F)

450 °C (842 °F)

Temperature limit of liquid

handled (* depending on

material and construction

variant - check which is lower)

Consult Flowserve

Consult Flowserve

110 °C (230 °F) *

175 °C (347 °F) *

270 °C (518 °F) *

350 °C (662 °F) *

The responsibility for compliance with the

specified maximum liquid temperature is with the

plant operator.

Temperature classification “Tx” is used when the

liquid temperature varies and when the pump is

required to be used in differently classified potentially

explosive atmospheres. In this case the user is

responsible for ensuring that the pump surface

temperature does not exceed that permitted in its

actual installed location.

2.5.2 Pumps with key driven impellers

If an explosive atmosphere exists during the

installation, do not attempt to check the direction of

rotation by starting the pump unfilled. Even a short

run time may give a high temperature resulting from

contact between rotating and stationary components.

2.5.3 Pumps with threaded on impellers

Do not attempt to check the direction of rotation with

the coupling element/pins fitted due to the risk of

severe contact between rotating and stationary

components.

2.5.4 Pumps with mechanical seal

Where there is any risk of the pump being run against a

closed valve generating high liquid and casing external

surface temperatures it is recommended that users fit an

external surface temperature protection device.

Avoid mechanical, hydraulic or electrical overload by

using motor overload trips or a power monitor and

make routine vibration monitoring.

Page 4 of 20 flowserve.com

Page 5

ATEX- E/F/D/N - 11-09

In dirty or dusty environments, regular checks must

be made and dirt removed from areas around close

clearances, bearing housings and motors.

2.5.5 Additional requirements for pumps with

magnetic drive

It is recommended for users to fit a temperature

monitor in the magnetic drive bearing/shell area when

pumping liquids with solids content or liquids that can

polymerize or freeze.

In unmanned locations where a magnetic drive is

used it is advisable to fit a vibration monitor.

2.5.6 Additional requirements for self-priming

casing pumps

Where the system operation does not ensure control of

priming, as defined in the User Instructions, and the

maximum permitted surface temperature of the T Class

could be exceeded it is recommended that users fit an

external surface temperature protection device.

2.5.7 Additional requirements for sump pumps

and vertical wet pit pumps with line shafts

Level control shall be fitted in the sump to prevent

liquid level dropping below minimum acceptable.

It is recommended that a Service Plan with vibration

monitoring is adopted. Alternatively the user should

fit external bearing housing surface temperature

protection device(s) to ensure the temperature class

(ie maximum surface temperature) is not exceeded.

For external flush the flow should be monitored.

2.6 Preventing the build up of explosive

mixtures

ENSURE PUMP IS PROPERLY FILLED AND

VENTED AND DOES NOT RUN DRY

Ensure the pump and relevant suction and discharge

pipeline system is totally filled with liquid at all times

during the pump operation, so that an explosive

atmosphere is prevented. In addition it is essential to

make sure that seal chambers, auxiliary shaft seal

systems and any heating and cooling systems are

properly filled.

If the operation of the system can not avoid this

condition it is recommended that you fit an

appropriate dry run protection device (eg liquid

detection or a power monitor).

To avoid potential hazards from fugitive emissions of

vapour or gas to atmosphere the surrounding area

must be well ventilated.

2.7 Preventing sparks

To prevent a potential hazard from mechanical

contact, the coupling guard must be non-sparking.

To avoid the potential hazard from random induced

current generating a spark, the earth contact on the

baseplate must be used.

Avoid electrostatic charge. Do not rub nonmetallic surfaces with a dry cloth; ensure the cloth is

damp.

The coupling must be selected to comply with

94/9/EC and correct alignment must be maintained.

2.7.1 Additional requirements for metallic pumps

on non-metallic baseplates

When metallic components are fitted on a nonmetallic baseplate they must be individually earthed.

2.8 Preventing leakage

2.8.1 Pumps with mechanical seal

The pump must only be used to handle liquids for

which it has been approved to have the correct

corrosion resistance.

Avoid entrapment of liquid in the pump and associated

piping due to closing of suction and discharge valves,

which could cause dangerous excessive pressures to

occur if there is heat input to the liquid. This can occur if

the pump is stationary or running.

Bursting of liquid containing parts due to freezing

must be avoided by draining or protecting the pump

and ancillary systems.

Where there is the potential hazard of a loss of a seal

barrier fluid or external flush, the fluid must be

monitored.

If leakage of liquid to atmosphere can result in a

hazard, the installation of a liquid detection device is

recommended.

2.8.2 Additional requirements for pumps with

magnetic drive

If protection greater than Categories 2 and M2 is

required, then liquid detection should be provided in

the bearing housing/support head.

Page 5 of 20 flowserve.com

Page 6

ATEX- E/F/D/N - 11-09

2.9 Maintenance to avoid the hazard

CORRECT MAINTENANCE IS REQUIRED TO

AVOID POTENTIAL HAZARDS WHICH GIVE A

RISK OF EXPLOSION

The responsibility for compliance with maintenance

instructions is with the plant operator.

To avoid potential explosion hazards during

maintenance, the tools, cleaning and painting

materials used must not give rise to sparking or

adversely affect the ambient conditions. Where there

is a risk from such tools or materials, maintenance

must be conducted in a safe area.

It is recommended that a maintenance plan and

schedule is adopted, in line with the User Instructions

provided, to include the following:

a) Any auxiliary systems installed must be monitored,

if necessary, to ensure they function correctly.

b) Gland packings must be adjusted correctly to give

visible leakage and concentric alignment of the

gland follower to prevent excessive temperature of

the packing or follower.

c) Check for any leaks from gaskets and seals. The

correct functioning of the shaft seal must be

checked regularly.

d) Check bearing lubricant level, and if the hours run

show a lubricant change is required.

e) Check that the duty condition is in the safe

operating range for the pump.

f) Check vibration, noise level and surface

temperature at the bearings to confirm satisfactory

operation.

g) Check dirt and dust is removed from areas around

close clearances, bearing housings and motors.

h) Check coupling alignment and re-align if

necessary.

Page 6 of 20 flowserve.com

Page 7

ATEX- E/F/D/N - 11-09

Français

1 GENERALITES

1.3 Qualification et formation du

personnel

Ces instructions doivent toujours être

conservées à portée du lieu d'utilisation de ce

produit ou directement avec le produit.

Ces instructions ont pour objectif de faciliter la

familiarisation avec le produit et son utilisation

autorisée afin de répondre aux critères de sécurité

ATEX. Ces instructions peuvent ne pas avoir pris en

considération les réglementations locales. Assurezvous que de telles réglementations sont respectées

par tous, y compris les personnes installant le

produit. Coordonnez toujours les activités de

réparation avec le personnel chargé des opérations

et respectez tous les critères de sécurité de l'usine

ainsi que les réglementations/lois applicables

relatives à la santé et la sécurité.

Ces instructions doivent être lues

avant d'installer, d'actionner, d'utiliser et

d'assurer l'entretien du matériel dans n'importe

quelle région du monde. Ce matériel ne doit pas

être mis en service tant que toutes les conditions

relatives aux instructions de sécurité n'ont pas

été remplies. Ne pas appliquer, ni suivre les

recommandations du présent guide d'utilisateur

serait considéré comme une mauvaise utilisation.

Les blessures de personnes, les dégâts, retards,

défaillances causés par une mauvaise utilisation

ne seront pas couverts par la garantie Flowserve.

1.1 Directive ATEX 94/9/CE

C'est conformément à une requête légale que, dans

certaines régions du monde, tout dispositif et matériel

mis en service doivent être conformes aux directives de

marquage CE applicables relatives au matériel destiné

à être utilisé en atmosphère explosible (ATEX).

Lorsque cela s'applique, la directive couvre

d'importants aspects de sécurité relatifs au matériel,

à son utilisation et à la remise satisfaisante de

documents techniques. Lorsque cela s'applique, ce

document intègre des informations importantes pour

ces directives. Afin d'établir si le produit lui-même

porte la marque CE pour une utilisation en

atmosphère explosible, veuillez consulter la plaque

signalétique et la certification fournies.

1.2 Décharge de responsabilité

Les informations contenues dans ces

instructions utilisateur sont considérées comme

fiables. En dépit de tous les efforts déployés par

Flowserve Corporation afin de fournir des

informations sûres ainsi que tous les

renseignements nécessaires, le contenu de ce

manuel peut sembler insuffisant et Flowserve ne

garantit pas qu'il soit complet ou précis.

Tout le personnel impliqué dans le fonctionnement,

l'installation, l'inspection et l'entretien du groupe doit

être qualifié afin d'effectuer le travail concerné.

Si le personnel en question ne possède pas déjà les

connaissances et compétences nécessaires, une

formation et des instructions adéquates doivent lui être

dispensées. Si nécessaire, l'opérateur peut charger le

fabricant/fournisseur de fournir la formation applicable.

2 SECURITE

2.1 Résumé des marquages de sécurité

Ces instructions comprennent les marquages de

sécurité ATEX spécifiques suivants pour lesquels le

non-respect des instructions pourrait entraîner un

danger.

Ce symbole indique l'existence d'un marquage

de zone à atmosphère explosible conformément à ce

qui est indiqué dans ATEX les instructions de sécurité

spéciales qui, si elles ne sont pas respectées dans la

zone dangereuse, pourraient générer un risque

d'explosion.

Ce symbole est utilisé dans certaines instructions

de sécurité pour rappeler de ne pas frotter les surfaces

non métalliques avec un chiffon sec et de s’assurer que

le chiffon soit humide. Il est aussi utilisé dans les

instructions de sécurité spéciales qui, si elles ne sont

pas respectées dans la zone dangereuse, pourraient

générer un risque d'explosion.

2.2 Produits utilisés dans des

atmosphères potentiellement explosibles

Des mesures sont requises pour:

• Eviter toute température excessive

• Eviter la création de mélanges explosifs

• Empêcher les étincelles

• Empêcher les fuites

• Entretenir la pompe afin d'éviter tout danger

Les instructions suivantes relatives aux pompes et

groupes de pompe doivent être respectées lorsque

ces derniers sont installés dans des zones à risques

potentiels d'explosion afin d'assurer une protection

contre toute explosion. Tant le matériel électrique

que celui qui ne l'est pas doit répondre aux exigences

de la directive européenne 94/9/CE.

Page 7 of 20 flowserve.com

Page 8

ATEX- E/F/D/N - 11-09

vérifiez

vérifiez

2.3 Portée de la conformité

N'utilisez ce matériel que dans la zone qui lui

convient. Assurez-vous toujours que l'entraînement,

l'ensemble de raccord d'entraînement, les joints et

l'équipement de la pompe sont convenablement

évalués et/ou certifiés pour le marquage de

l'atmosphère spécifique dans laquelle ils vont être

installés.

Lorsque Flowserve a fourni uniquement la pompe à

axe, le marquage Ex ne s'applique qu'à la pompe. La

partie responsable de l'assemblage de la pompe doit

sélectionner le raccord, l'entraînement, le joint et tout

autre matériel supplémentaire, avec la déclaration de

conformité/le certificat CE nécessaires établissant qu'il

est adapté à la zone dans laquelle il va être installé.

La sortie d'un entraînement à fréquence variable

(VFD) peut engendrer un échauffement

supplémentaire dans le moteur. Pour les groupes

électropompes avec un VFD la certification ATEX

pour le moteur doit déclarer qu'elle est aussi

applicable pour les cas où l'alimentation est fournie

par un VFD. Ceci est obligatoire même si le VFD est

dans une zone sécurisée.

2.4 Marquage

Un exemple de la marque d'équipement ATEX est

donné ci-dessous. La classification réelle de la

pompe sera gravée sur sa plaque signalétique.

II 2 GD c IIC 135 ºC (T4)

Groupe d'équipement

I = Activité minière

II = Activité autre

que minière

Catégorie

2 ou M2 = protection haute

3 = protection normale

Gaz et/ou poussière

G = Gaz

D = Poussière

c = Sureté de construction

(suivant EN13463-5)

Groupe de gaz (équipement de

catégorie 2 uniquement)

IIA - Propane (typique)

IIB - Éthylène (typique)

IIC - Hydrogène (typique)

Température maximum de surface (classe de

température) (voir section 2.5)

2.5 Eviter les températures de surface

excessives

ASSUREZ-VOUS QUE LA CATEGORIE DE

TEMPERATURE DU MATERIEL EST ADAPTEE A

LA ZONE DE DANGER

2.5.1 Température du liquide de la pompe

Les pompes ont une classe de température telle

qu'indiquée dans le marquage ATEX sur la plaque

signalétique. Elles sont basées sur une température

ambiante maximum de 40 °C (104 °F). Veuillez

consulter Flowserve pour des températures

ambiantes supérieures.

La température de surface sur la pompe est influencée

par la température du liquide traité. La température de

liquide maximum acceptée dépend de la classe de

température et ne doit pas dépasser les valeurs

indiquées dans le tableau applicable ci-dessous.

L'augmentation de température au niveau des joints,

des paliers et due au débit minimum accepté est

prise en compte dans les températures indiquées.

Température de liquide maximale acceptée pour les

pompes n'étant pas équipées d'un entraînement

magnétique ou d'un boîtier à auto-amorçage:

Classe de

température

selon

EN13463-1

T6

T5

T4

T3

T2

T1

Température de liquide maximale acceptée pour

les pompes étant équipées d'un entraînement

magnétique ou d'un boîtier à auto-amorçage:

Classe de

température

selon

EN13463-1

T6

T5

T4

T3

T2

T1

C'est l'opérateur de l'usine qui est responsable de

la conformité avec la température maximum de

liquide spécifiée.

Classification de la température "Tx" est employée

quand la température du liquide varie et quand la

pompe est exigée pour être utilisée en atmosphères

explosif différemment classifiées. Dans ce cas-ci

l´utilisateur est résponsable de s´assurer que la

température de surface de pompe n´excéde pas,

celle autorisée dans son endroit réel installée.

Température

de surface

maximum

acceptée

85 °C (185 °F)

100 °C (212 °F)

135 °C (275 °F)

200 °C (392 °F)

300 °C (572 °F)

450 °C (842 °F)

Température

de surface

maximum

acceptée

85 °C (185 °F)

100 °C (212 °F)

135 °C (275 °F)

200 °C (392 °F)

300 °C (572 °F)

450 °C (842 °F)

Limite de température du liquide

traité (* selon le matériau et la

variante de construction -

laquelle est la plus basse)

Consulter Flowserve

Consulter Flowserve

115 °C (239 °F) *

180 °C (356 °F) *

275 °C (527 °F) *

400 °C (752 °F) *

Limite de température du liquide

traité (* selon le matériau et la

variante de construction -

laquelle est la plus basse)

Consulter Flowserve

Consulter Flowserve

110 °C (230 °F) *

175 °C (347 °F) *

270 °C (518 °F) *

350 °C (662 °F) *

Page 8 of 20 flowserve.com

Page 9

ATEX- E/F/D/N - 11-09

2.5.2 Pompes avec roues entraînées par

clavettes

S'il existe une atmosphère explosible pendant

l'installation, n'essayez pas de vérifier le sens de la

rotation en démarrant la pompe à vide. Un délai, même

court, de fonctionnement pourrait générer une

température élevée du fait du contact entre les

composants rotatifs et fixes.

2.5.3 Pompes avec roues entraînées par filetages

N'essayez pas de vérifier le sens de la rotation avec

les éléments de raccord/broches installés du fait du

risque de contact grave entre les composants rotatifs

et fixes.

2.5.4 Pompes avec garniture mécanique

d'étanchéité

S'il existe un risque que la pompe soit mise en

fonctionnement sur une vanne fermée générant des

températures de surface externe du corps et de

liquide élevées, nous recommandons aux utilisateurs

d'installer un dispositif de protection de température

de surface externe.

Evitez toute surcharge mécanique, hydraulique ou

électrique en utilisant des bras de commande d'arrêt

automatique en cas de surcharge moteur ou un

contrôleur d'intensité puis effectuez un contrôle de

vibration de routine.

Dans des environnements sales ou poussiéreux, il

est nécessaire d'effectuer régulièrement des

contrôles et d'enlever la saleté des zones se trouvant

autour des écartements proches, des corps de palier

et des moteurs.

2.5.5 Exigences supplémentaires pour les

pompes dotées d'un entraînement magnétique

Nous recommandons aux utilisateurs d'installer un

contrôleur de température dans la zone du palier

d'entraînement magnétique/du revêtement lors du

pompage de liquides à contenu solide ou de liquides

pouvant se polymériser ou geler.

Dans les endroits non équipés où un entraînement

magnétique est utilisé, il est conseillé d'installer un

contrôleur de vibrations.

2.5.6 Exigences supplémentaires pour les

pompes dotées d'un boîtier à auto-amorçage

Lorsque le fonctionnement du système n'assure pas

un contrôle de l'amorçage, tel qu'il est défini dans les

instructions utilisateur, et que la température de

surface maximum acceptée de la classe T pourrait

être dépassée, il est recommandé aux utilisateurs

d'installer un dispositif de protection de température

de surface externe.

2.5.7 Exigences supplémentaires pour les

pompes à carter et les pompes à corps noyé

verticales à lignes d'arbre

Il convient d'installer un contrôle de niveau dans le

carter afin d'éviter que le niveau de liquide ne

devienne inférieur au minimum acceptable.

Il est recommandé d'adopter un plan d'entretien avec

contrôle des vibrations, l'utilisateur devra dans le cas

contraire installer un (des) dispositif(s) de protection de

température de surface du corps de palier externe afin

d'assurer que la classe de température, c'est à dire la

température de surface maximum, n'est pas dépassée.

Le débit de purge externe doit être contrôlé.

2.6 Empêcher la création de mélanges

explosifs

S'ASSURER QUE LA POMPE EST

CORRECTEMENT REMPLIE ET VENTILEE ET NE

FONCTIONNE PAS A SEC

Assurez-vous que la pompe et les conduits d'aspiration

et de refoulement concernés sont totalement remplis de

liquide en permanence au cours du fonctionnement de

la pompe afin d'empêcher la création d'une atmosphère

explosible. De plus, il est essentiel de s'assurer que les

chambres d'étanchéité, les systèmes d'étanchéité

d'arbre auxiliaire ainsi que tous les systèmes de

chauffage et de refroidissement sont correctement

remplis.

Si le fonctionnement du système ne peut pas éviter

cette condition, il est recommandé d'installer un

dispositif adéquat de protection contre le

fonctionnement à sec (par ex. une détection de

liquide ou un contrôleur d'intensité).

Afin d'éviter tous dangers potentiels dus à des

émissions fugitives de vapeur ou de gaz dans

l'atmosphère, la zone environnante doit être bien

ventilée.

2.7 Empêcher les étincelles

Pour éviter tout danger potentiel du fait d'un

contact mécanique, le dispositif de protection des

raccords doit être antiétiencelles.

Veuillez utiliser le contact de mise à la terre sur le

socle afin d'éviter tout danger potentiel du fait d'un

courant induit statistique générant une étincelle.

Eviter la création d'une charge électrostatique:

ne pas frotter des surfaces non-métalliques avec un

chiffon sec. S'assurer que le chiffon est humide.

L'accouplement doit être sélectionné conformément à

94/9/CE, et l'alignement correct doit être vérifié

périodiquement.

Page 9 of 20 flowserve.com

Page 10

ATEX- E/F/D/N - 11-09

2.7.1 Exigences supplémentaires pour les

pompes métalliques sur socles non-métalliques

Lorsque des composants métalliques sont installés

sur un socle non-métallique, ils doivent être

raccordés à la masse individuellement.

2.8 Empêcher les fuites

2.8.1 Pompes avec garniture d'étanchéité

mécanique

La pompe ne doit être utilisée que pour traiter des

liquides pour lesquels elle a été approuvée comme

ayant la bonne résistance à la corrosion.

Evitez que du liquide ne soit prisonnier dans la

pompe et la tuyauterie associée du fait de la

fermeture des vannes, à l'aspiration et au

refoulement, car cela pourrait entraîner des pressions

dangereuses excessives en cas d'entrée de chaleur

dans le liquide. Ceci peut se produire si la pompe est

à l'arrêt ou en fonctionnement.

Vous devez éviter que des pièces contenant du

liquide n'éclatent car ce dernier a gelé en vidangeant

ou en protégeant la pompe et les systèmes

accessoires.

Lorsqu'il existe un danger potentiel de perte d'un

liquide de barrière d'étanchéité ou d'arrosage

externe, le liquide de la barrière doit être contrôlé.

Si une fuite de ce liquide dans l'atmosphère peut être

source de danger, l'installation d'un dispositif de

détection de liquide est recommandée.

2.8.2 Exigences supplémentaires pour les

pompes dotées d'un entraînement magnétique

Si le niveau de protection requis est supérieur à celui

de catégories 2 et M2 il faut alors équiper le corps de

palier/la tête de support d'une détection de liquide.

2.9 Entretien pour éviter tout danger

Il est recommandé d'adopter un programme et un

plan d'entretien, conforme aux instructions utilisateur

fournies, afin d'inclure les éléments suivants:

a) Tous les systèmes accessoires installés doivent

être contrôlés, si nécessaire, afin de s'assurer

qu'ils fonctionnent correctement.

b) Les boutons d'étanchéité doivent être réglés

correctement afin de fournir une fuite visible et un

alignement concentrique du fouloir pour éviter une

température excessive de la garniture d'étanchéité

ou du fouloir.

c) Contrôler toute fuite possible au niveau des joints

plats et des joints. Il faut vérifier régulièrement

que la boîte d'étanchéité fonctionne correctement.

d) Contrôler le niveau de lubrifiant du palier et si la

durée de fonctionnement indique qu'il est

nécessaire de changer le lubrifiant.

e) S'assurer que la condition de rendement est dans

la plage de fonctionnement sûre pour la pompe.

f) Contrôler les vibrations, le niveau sonore et la

température de surface au niveau des paliers afin

de confirmer que le fonctionnement est

satisfaisant.

g) S'assurer que la poussière et la saleté sont

enlevées des zones situées à proximité des

écartements proches, des corps de palier et des

moteurs.

h) Contrôler l'alignement des raccords et les

réaligner si nécessaire.

UN ENTRETIEN CORRECT EST REQUIS

AFIN D'EVITER TOUT DANGER POTENTIEL

GENERANT UN RISQUE D'EXPLOSION

C'est l'opérateur de l'usine qui est responsable de

se conformer aux instructions d'entretien.

Pour éviter tout danger potentiel d'explosion au cours

de l'entretien, les outils ainsi que les matériaux de

nettoyage et de peinture utilisés ne doivent pas

générer des étincelles ni avoir un effet indésirable sur

les conditions ambiantes. Si de tels outils ou

matériaux sont susceptibles d'être utilisés, l'entretien

doit être effectué dans un lieu sûr.

Page 10 of 20 flowserve.com

Page 11

ATEX- E/F/D/N - 11-09

1 ALLGEMEINES

Diese Anweisungen sind stets in unmittelbarer

Nähe des Aufstellungsortes des Geräts, oder direkt

am Gerät selbst aufzubewahren

Diese Anweisungen sollen Ihnen dabei helfen, sich mit

dem Gerät und seinen zulässigen Anwendungsarten

vertraut zu machen, und dadurch zur Einhaltung der

ATEX-Sicherheitsanforderungen beitragen. Bei diesen

Anweisungen fanden lokale Verordnungen

möglicherweise keine Berücksichtigung. Bitte achten

Sie jedoch darauf, dass auch derartige Verordnungen

von allen Personen, einschließlich jenen, die mit der

Montage des Geräts betraut sind, eingehalten werden.

Koordinieren Sie allfällige Reparaturarbeiten stets mit

dem Bedienpersonal, erfüllen Sie alle

Anlagensicherheitsauflagen und befolgen Sie alle

geltenden sicherheits- und gesundheitsrelevanten

Gesetze/Verordnungen.

Diese Anweisungen sollten vor

Montage, Betrieb, Gebrauch und Wartung der

Geräte in allen Teilen der Welt zusammen mit den

mitgelieferten Haupt-Benutzeranweisungen

durchgelesen werden. Die Geräte dürfen erst

dann in Betrieb genommen werden, wenn alle

sich auf Sicherheitsanweisungen beziehenden

Bedingungen erfüllt worden sind. NichtBefolgung und -Anwendung der vorliegenden

Benutzeranweisungen gilt als Missbrauch.

Körperverletzungen, Produktschäden,

Verzögerungen oder Versagen, die durch

Missbrauch verursacht werden, fallen nicht unter

die Flowserve Garantie.

1.1 ATEX-Richtlinie 94/9/EG

Von Rechts wegen müssen Maschinen und Geräte,

welche in bestimmten Gebieten der Welt in Betrieb

genommen werden, die geltenden CEKennzeichnungs-Richtlinien für Geräte zur Verwendung

in explosionsgefährdeten Bereichen (ATEX) erfüllen.

Dort, wo sie Gültigkeit besitzt, deckt die Richtlinie

wichtige Sicherheitsaspekte hinsichtlich der Geräte,

deren Verwendung und der zufriedenstellenden

Bereitstellung technischer Unterlagen ab. Dieses

Dokument enthält Informationen, die für diese

Richtlinien von Relevanz sind. Um festzustellen, ob das

jeweilige Gerät mit einer CE-Kennzeichnung für eine

potenziell explosive Atmosphäre versehen ist, müssen

Sie das Typenschild und die bereitgestellte

Zertifizierung kontrollieren.

Deutsch

1.2 Haftungserklärung

Die in diesen Anweisungen für den Benutzer

enthaltenen Informationen gelten als zuverlässig.

Trotz aller Bemühungen der Flowserve

Corporation, korrekte und alle erforderlichen

Informationen bereitzustellen, kann der Inhalt

dieses Handbuchs unvollständig scheinen, und

Flowserve lehnt jegliche Garantie hinsichtlich

seiner Vollständigkeit und Genauigkeit ab.

1.3 Qualifikationen und Schulung des

Personals

Das gesamte an Betrieb, Montage, Prüfung und

Wartung des Aggregats beteiligte Personal hat

entsprechend qualifiziert zu sein, um die damit in

Verbindung stehenden Arbeiten auszuführen.

Wenn das betreffende Personal noch nicht über die

erforderlichen Kenntnisse und Fähigkeiten verfügt, ist

es entsprechend zu schulen und zu unterweisen.

Erforderlichenfalls kann der Betreiber den

Hersteller/Lieferanten damit beauftragen, die

entsprechende Schulung durchzuführen.

2 SICHERHEIT

2.1 Zusammenfassung der

Sicherheitskennzeichnungen

Diese Anweisungen enthalten die folgenden

spezifischen ATEX-Sicherheitskennzeichnungen, wobei

jegliche Nichtbeachtung der Anweisung eine Gefahr

nach sich zieht.

Dieses Symbol stellt die Kennzeichnung einer

Zone mit explosiver Atmosphäre gemäß ATEX dar. Es

wird in Sicherheitsanweisungen dargestellt, wobei die

Nichtbeachtung im Gefahrenbereich eine

Explosionsgefahr nach sich ziehen würde.

Dieses Symbol wird in den Sicherheitsvorschriften

verwendet und soll daran erinnern, dass nichtmetallische Oberflächen nicht mit einem trockenen

Tuch abgerieben werden dürfen; stellen Sie sicher,

dass das Tuch feucht ist. Es wird in den

Sicherheitsvorschriften verwendet, in denen bei

Zuwiderhandlung in einem gefährlichen Bereich die

Gefahr besteht eine Explosion auszulösen.

Page 11 of 20 flowserve.com

Page 12

ATEX- E/F/D/N - 11-09

2.2 Geräte zur Verwendung in

explosionsgefährdeten Bereichen

Maßnahmen sind erforderlich, um:

• Übertemperaturen zu vermeiden

• das Entstehen explosiver Gemische zu verhindern

• die Bildung von Funken zu verhindern

• Undichtheiten zu verhindern

• die Pumpe zu warten, um Gefahren zu vermeiden

Die folgenden Anweisungen für Pumpen und

Pumpenaggregate müssen, wenn diese in

explosionsgefährdeten Bereichen aufgestellt werden,

befolgt werden, um zur Gewährleistung des Schutzes

vor Explosionen beizutragen. Sowohl elektrische als

auch nichtelektrische Geräte müssen den

Anforderungen der Europäischen Richtlinie 94/9/EG

entsprechen.

2.3 Konformitätsumfang

Verwenden Sie Geräte nur in Bereichen, für die

sie geeignet sind. Überzeugen Sie sich stets davon,

dass der Antrieb, die Kupplung, die Dichtung und die

Pumpe auch wirklich entsprechend der Klassifizierung

des explosionsgefährdeten Bereichs, in dem sie

aufgestellt werden sollen, geeignet ausgelegt und/oder

zertifiziert sind.

In Fällen, in denen Flowserve nur die Pumpe ohne

Antrieb bereitgestellt hat, gilt die "Ex"- Kennzeichnung

nur für die Pumpe. Die für die Montage des kompletten

Aggregats zuständige Partei muss die Kupplung, den

Antrieb, die Dichtung und alle zusätzlichen

Ausstattungen auswählen, wobei anhand des/der

erforderlichen CE-Konformitätszertifikats/-erklärung

festgestellt wird, dass sie sich für den Bereich, in

welchem sie aufgestellt werden, eignen.

Bei Verwendung eines Frequenzumrichters (FU)

können Streuströme zu einer zusätzlichen

Erwärmung des Motors führen. Für Pumpen, die mit

frequenzgesteuerten Antrieben ausgestattet sind,

muß die ATEX Zertifizierung des Motors die

Anspeisung durch einen FU berücksichtigen. Dies

gilt auch dann, wenn der FU in einem sicheren

Bereich installiert ist.

2.4 Kennzeichnung

Ein Beispiel für die ATEX Geräteklassen

Kennzeichnung wird unten gezeigt. Die aktuelle

Klassifizierung ist dem Pumpenschild zu entnehmen.

II 2 GD c IIC 135 ºC (T4)

Gerätegruppe

I = Bergbau

II = kein Bergbau

Kategorie

2 oder M2 = Gelegentliches Auftreten

3 = Seltenes Auftreten

Gas oder Staub

G = Gas

D = Staub

c = Entzündungsschutz durch

Konstruktionssicherheit

(entsrechend EN13463-5)

Gasgruppe (nur Equipment-Kategorie 2)

IIA - Propan (normal)

IIB - Äthylen (normal)

IIC - Wasserstoff (normal

Zulässige Oberflächentemperatur (Temperatur Klasse)

(Siehe Kapitel 2.5)

2.5 Vermeidung übermäßiger

Oberflächentemperaturen

ÜBERZEUGEN SIE SICH DAVON, DASS SICH

DIE GERÄTETEMPERATURKLASSE FÜR DEN

GEFAHRENBEREICH EIGNET

2.5.1 Temperatur des Fördermediums

Pumpen weisen gemäß der "ATEX Ex"-Kennzeichnung

auf dem Typenschild eine Temperaturklasse auf. Diese

beruht auf einer maximalen Umgebungstemperatur von

40 °C (104 °C). Bezüglich höherer

Umgebungstemperaturen wenden Sie sich bitte an

Flowserve.

Die Oberflächentemperatur der Pumpe wird durch die

Temperatur der geförderten Flüssigkeit beeinflusst. Die

höchstzulässige Flüssigkeitstemperatur hängt von der

Temperaturklasse ab und darf die Werte in der

nachfolgenden Tabelle nicht überschreiten. Der

Temperaturanstieg an den Dichtungen, Lagern und bei

Mindestfördermenge wird bei der Temperaturangabe

berücksichtigt.

Page 12 of 20 flowserve.com

Page 13

ATEX- E/F/D/N - 11-09

zulässige

Höchstzulässige Flüssigkeitstemperatur für

Pumpen, die keinen Magnetantrieb haben bzw.

nicht selbstansaugend sind:

Temperatur-

klasse

gemäß

EN13463-1

T6

T5

T4

T3

T2

T1

Höchst-

zulässige

Oberflächen-

temperatur

85 °C (185 °F)

100 °C (212 °F)

135 °C (275 °F)

200 °C (392 °F)

300 °C (572 °F)

450 °C (842 °F)

Temperaturgrenzwert der

geförderten Flüssigkeit

(* abhängig von Material und

Konstruktionsvariante -

überprüfen, welcher der beiden

Werte niedriger ist)

Rückfrage bei Flowserve

Rückfrage bei Flowserve

115 °C (239 °F) *

180 °C (356 °F) *

275 °C (527 °F) *

400 °C (752 °F) *

Höchstzulässige Flüssigkeitstemperatur für

Pumpen mit Magnetantrieb bzw.

selbstansaugende Pumpen:

Temperatur-

klasse

gemäß

EN13463-1

T6

T5

T4

T3

T2

T1

Höchst-

Oberflächen-

temperatur

85 °C (185 °F)

100 °C (212 °F)

135 °C (275 °F)

200 °C (392 °F)

300 °C (572 °F)

450 °C (842 °F)

Temperaturgrenzwert der

geförderten Flüssigkeit

(* abhängig von Material und

Konstruktionsvariante -

überprüfen, welcher der beiden

Werte niedriger ist)

Rückfrage bei Flowserve

Rückfrage bei Flowserve

110 °C (230 °F) *

175 °C (347 °F) *

270 °C (518 °F) *

350 °C (662 °F) *

Die Verantwortung für die Einhaltung der

vorgegebenen höchstzulässigen

Flüssigkeitstemperatur liegt beim Anlagenbetreiber.

Temperaturklasse "Tx" wird verwendet, wenn sich die

Flüssigkeitstemperatur ändert und die Pumpe in einem

anderen explosionsgefährdeten Bereich betrieben wird.

In diesem Fall muss der Anwender sicherstellen, dass

die Oberflächentemperatur der Pumpe gemäß der

spezifizierten Temperaturklasse nicht überstiegen wird.

2.5.2 Pumpen mit auf der Welle geschraubten

Laufrädern

Wenn bei der Inbetriebnahme eine explosive

Atmosphäre vorherrscht, dürfen Sie nicht versuchen,

die Drehrichtung zu überprüfen, indem Sie die

Pumpe im nicht befüllten Zustand starten.

Andernfalls kann selbst eine kurze Laufzeit durch den

Kontakt zwischen sich drehenden und feststehenden

Komponenten zu hohen Temperaturen führen.

2.5.3 Pumpen mit auf der Welle aufgeschobenen

Laufrädern

Versuchen Sie auf Grund der Gefahr des Verreibens

zwischen sich drehenden und feststehenden

Komponenten nicht, die Drehrichtung mit montierten

Kupplungselementen/Stiften zu überprüfen.

2.5.4 Pumpen mit Gleitringdichtung

In Fällen, in denen die Gefahr besteht, dass die

Pumpe gegen ein geschlossenes Ventil betrieben

wird, was hohe Flüssigkeits- und

Gehäuseoberflächen-temperaturen nach sich zieht,

wird empfohlen, eine externe Oberflächentemperaturüberwachung anzubringen.

Vermeiden Sie mechanische, hydraulische oder

elektrische Überlastzustände, indem Sie einen

Motorüberlastschalter oder eine

Leistungsüberwachung vorsehen, und führen Sie

eine routine-mäßige Vibrationsüberwachung durch.

In schmutziger oder staubiger Umgebung sind

regelmäßige Kontrollen durchzuführen, und Schmutz

ist aus Bereichen rund um enge Zwischenräume,

Lager-gehäuse und Motoren zu entfernen.

2.5.5 Zusätzliche Anforderungen für Pumpen mit

Magnetantrieb

Benutzern wird empfohlen, eine Temperaturüberwachung im Bereich des Magnetantriebs-lagers

bzw. des Spalttopfes zu montieren, wenn

Flüssigkeiten mit Feststoffgehalt oder Flüssigkeiten,

welche polymerisieren oder gefrieren können,

gefördert werden.

An unbemannten Orten, an denen ein Magnetantrieb

verwendet wird, ist es ratsam, eine Vibrationsüberwachung zu installieren.

2.5.6 Zusätzliche Anforderungen für

selbstansaugende Pumpen

In Fällen, in denen die Ansaugung der Flüssigkeit nicht

entsprechend der Benutzeranweisung durch den

Betrieb der Anlage gewährleistet werden kann, und in

denen die höchstzulässige Oberflächentemperatur der

T-Klasse überschritten werden könnte, empfiehlt es

sich, eine externe Oberflächentemperaturschutzvorrichtung anzubringen.

2.5.7 Zusätzliche Anforderungen für

Sumpfpumpen und vertikale Gestängepumpen

Es ist eine Pegelregelung im Sumpf zu montieren,

um zu verhindern, dass der Flüssigkeitspegel unter

den zulässigen Mindestwert fällt.

Es empfiehlt sich, einen Wartungsplan aufgrund von

Vibrationsmessungen zu erstellen. Zusätzlich sollte der

Benutzer eine externe Überwachung der

Oberflächentemperatur des Lagergehäuses vorsehen,

um zu gewährleisten, dass die Temperaturklasse, d.h.

die maximale Oberflächentemperatur, nicht

überschritten wird. Bei externer Spülung der Lager

sollte der Durchfluss überwacht werden.

Page 13 of 20 flowserve.com

Page 14

ATEX- E/F/D/N - 11-09

2.6 Vermeidung der Entstehung

explosiver Gemische

ÜBERZEUGEN SIE SICH, DASS DIE PUMPE

KOMPLETT GEFÜLLT UND ENTLÜFTET IST UND

NICHT TROCKEN LÄUFT

Vergewissern Sie sich, dass die Pumpe und das

zugehörige Rohrleitungssystem jederzeit während

des Pumpenbetriebs völlig mit Flüssigkeit gefüllt ist,

so dass die Entstehung eines explosiven Gemisches

verhindert wird. Zudem ist es von wesentlicher

Bedeutung sicherzustellen, dass Dichtungsräume,

Dichtungssysteme und jegliche Heiz- und

Kühlsysteme entsprechend befüllt sind.

Wenn beim Betrieb der Anlage Trockenlauf nicht

auszuschließen ist, wird empfohlen, eine

entsprechende Trockenlauf-Schutzvorrichtung zu

montieren (z.B. Durchfluß- oder Leistungsüberwachung)

Um mögliche Gefahren durch in die Atmosphäre

entweichende Dampf- oder Gasemissionen zu

vermeiden, ist der umliegende Bereich gut zu belüften.

2.7 Vermeidung von Funkenbildung

Der Kupplungsschutz muss aus

nichtfunkendem Material sein, um die Bildung von

Funken infolge von mechanischem Kontakt zu

unterbinden.

Der Erdungskontakt auf der Grundplatte muss

verwendet werden, um die Funkenbildung durch

Fehlerströme zu vermeiden.

Vermeiden Sie elektrostatische Ladungen: Reiben

Sie nichtmetallische Oberflächen nicht mit einem

trockenen Tuch ab; stellen Sie sicher, dass das Tuch

feucht ist.

Die Kupplung muss entsprechend 94/9/EG

ausgewählt werden.

2.7.1 Zusätzliche Anforderungen für metallische

Pumpen auf nichtmetallischen Grundplatten

Wenn metallische Komponenten auf einer

nichtmetallischen Grundplatte montiert werden,

müssen diese einzeln geerdet werden.

2.8 Vermeidung von Undichtheiten

2.8.1 Pumpen mit mechanischer Dichtung

Die Pumpe darf nur zur Förderung von Flüssigkeiten

verwendet werden, für welche sie aufgrund der

Korrosionsbeständigkeit zugelassen wurde.

Vermeiden Sie einen Betrieb der Pumpe gegen ein

geschlossenes Saug- und/oder

Druckrohrleitungssystem. Die damit verbundene

Wärmeentwicklung kann gefährliche Überdrücke

verursachen. Das kann sowohl laufende als auch

stillstehende Pumpen betreffen.

Bei Frostgefahr muss die Pumpe samt zugehörigen

Leitungen entleert werden.

Sperrsysteme für Gleitringdichtungen müssen

hinsichtlich Leckage des Fördermediums und des

Sperrmediums überwacht werden.

Wenn das Austreten von Fördermedium und/oder

Sperrmedium in die Atmosphäre eine Gefahr nach

sich ziehen kann, wird die Montage eines

Leckagewächters empfohlen.

2.8.2 Zusätzliche Anforderungen für Pumpen mit

Magnetantrieb

Wenn eine höhere Schutzklasse als Kategorie 2 und

M2 erforderlich ist, sollte ein Leckagewächter im

Lagergehäuse/Lagerlaterne vorgesehen werden.

2.9 Wartung zur Gefahrenvermeidung

EINE ORDNUNGSGEMÄSSE WARTUNG IST

ERFORDERLICH, UM MÖGLICHE GEFAHREN, DIE

EIN EXPLOSIONSRISIKO NACH SICH ZIEHEN, ZU

VERMEIDEN

Die Verantwortung für das Einhalten der

Wartungsanweisungen liegt beim Anlagenbetreiber.

Um möglichen Explosionsgefahren bei der Wartung

vorzubeugen, dürfen die Werkzeuge, die Reinigungsund die Lackiermaterialien weder Funken erzeugen

noch die Umgebungsbedingungen auf andere Weise

nachteilig beeinflussen. Falls auf Grund derartiger

Werkzeuge oder Materialien eine Gefahr besteht, ist

die Wartung in einem sicheren Bereich

durchzuführen.

Page 14 of 20 flowserve.com

Page 15

ATEX- E/F/D/N - 11-09

Es wird empfohlen, einen terminisierten

Wartungsplan entsprechend den mitgelieferten

Benutzeranweisungen zu erstellen, welcher folgende

Punkte abdecken soll:

a) Jedwede installierten Hilfssysteme müssen

gegebenenfalls überwacht werden, um

sicherzustellen, dass sie einwandfrei

funktionieren.

b) Stopfbüchspackungen müssen so eingestellt

werden, dass sich eine sichtbare Leckage ergibt.

Dadurch werden zu hohe Temperaturen in der

Stopfbüchse vermieden.

c) Überprüfen Sie Dichtungen auf Leckage. Die

einwandfreie Funktion der Wellenabdichtung ist

regelmäßig zu überprüfen.

d) Überprüfen Sie den Lagerschmiermittelpegel, und

ob die bereits verstrichenen Betriebsstunden

einen Schmiermittelwechsel erfordern.

e) Überzeugen Sie sich davon, dass der

Betriebszustand innerhalb des sicheren

Betriebsbereichs für die Pumpe liegt.

f) Kontrollieren Sie Vibrationen, Lärmpegel und

Oberflächentemperatur der Lagergehäuse, um

einen zufriedenstellenden Betriebszustand der

Lager zu bestätigen.

g) Überzeugen Sie sich, dass enge Zwischenräume,

Lagergehäuse und Motoren von Schmutz und

Staub befreit sind.

h) Überprüfen Sie die Kupplungsausrichtung und,

falls erforderlich, korrigieren Sie diese.

Page 15 of 20 flowserve.com

Page 16

ATEX- E/F/D/N - 11-09

1 ALGEMEEN

Deze instructies dienen altijd in de buurt van

de werkplek van het product of samen met het

product bewaard te worden

Deze instructies zijn bedoeld voor de kennismaking met

het product en het toegestane gebruik om te voldoen

aan de ATEX veiligheidsvereisten. De instructies

houden niet noodzakelijk rekening met de plaatselijke

voorschriften; zorg ervoor dat dergelijke voorschriften

door iedereen worden opgevolgd, inclusief die personen

die het product installeren. Coördineer

reparatiewerkzaamheden altijd met het bedienend

personeel en volg alle veiligheidsvoorschriften van de

fabriek en de van toepassing zijnde voorschriften voor

arbeidsveiligheid en hygiëne.

Deze gebruiksaanwijzing moet gelezen

worden voordat de apparaatuur geïnstalleerd,

bestuurt, gebruikt en onderhouden wordt, waar ook

ter wereld en in overeenstemming met de

meegeleverde hoofdgebruiksaanwijzing. De

apparatuur mag niet gebruikt worden totdat aan alle

voorwaarden met betrekking tot veiligheid voldaan

is. Het negeren en niet toepassen van de huidige

gebruiksaanwijzing wordt als misbruik gezien.

Lichamelijk letsel, productschade, vertraging of

storingen veroorzaakt door misbruik vallen niet

onder de garantie van Flowserve.

1.1 ATEX Richtlijn 94/9/EG

Het is een wettelijke verplichting dat machines en

apparatuur die gebruikt worden in bepaalde regio's in

de wereld voldoen aan de van toepassing zijnde CE

Merkteken Richtlijnen voor Apparatuur voor

Potentieel Explosieve Atmosferen (ATEX).

Waar van toepassing behandelt de Richtlijn

belangrijke veiligheidsaspecten met betrekking tot de

apparatuur, het gebruik daarvan en het in

toereikende mate ter beschikking stellen van

technische documenten. Waar van toepassing bevat

dit document relevante informatie met betrekking tot

deze Richtlijn. Om vast te stellen of het product zelf

CE gecertificeerd is voor Potentieel Explosieve

Atmosferen controleer het naamplaatje en de

bijgeleverde Certificaten.

1.2 Disclaimer

De informatie in deze Gebruikershandleiding wordt

betrouwbaar geacht. Ondanks alle inspanningen

van de Flowserve Corporation om de juiste en alle

noodzakelijke informatie te verstrekken kan de

inhoud van deze handleiding onvoldoende blijken

en de compleetheid en accuratesse kan niet door

Flowserve worden gegarandeerd.

Nederlands

1.3 Bevoegdheid en training personeel

Al het personeel dat betrokken is bij de bediening,

installatie en onderhoud van de machine dient

bevoegd te zijn om dit werk uit te voeren.

Indien het betrokken personeel de noodzakelijke

kennis en vakkundigheid niet al bezit, dan dient

gezorgd te worden voor geschikte training en

instructie. Indien gewenst kan de gebruiker de

fabrikant/leverancier opdracht geven de van

toepassing zijnde training te leveren.

2 VEILIGHEID

2.1 Overzicht van Veiligheidsmarkeringen

Deze instructies bevatten de volgende specifieke

ATEX veiligheidsmarkeringen waarbij het niet

opvolgen van de instructies gevaar oplevert.

Dit symbool duidt op een zonemerkteken voor

een explosieve atmosfeer in overeenstemming met

ATEX en de speciale veiligheidsinstructies, waarvan

het niet opvolgen in de gevarenzone het risico van

een explosie teweegbrengt.

Dit symbool in de veiligheidsinstructies geeft

aan dat niet metalen delen niet met een droge doek

gewreven mogen worden. Een doek moet altijd

vochtig zijn. Het niet opvolgen van deze

veiligheidsinstructie in de gevarenzone leidt tot het

risico van een explosie.

2.2 Producten die gebruikt worden in

potentieel explosieve omstandigheden

Maatregelen zijn vereist om:

• Excessieve temperaturen te vermijden

• De opeenhoping van explosieve mengsels te

voorkomen

• Vonken te voorkomen

• Lekkage te voorkomen

• Onderhoud te plegen aan de pomp ter

voorkoming van gevaar

De volgende instructies voor pompen en

pompeenheden die geïnstalleerd worden in een

gevaarlijke omgeving dienen te worden opgevolgd om

het gevaar van explosies te helpen voorkomen. Zowel

elektrische als niet-elektrische apparatuur moet voldoen

aan de vereisten van de Europese Richtlijn 94/9/EG.

Page 16 of 20 flowserve.com

Page 17

ATEX- E/F/D/N - 11-09

2.3 Omvang van de certificatie

Gebruik apparatuur alleen in een omgeving

waarvoor deze geschikt is. Controleer altijd of de

aandrijving, de constructie van de aandrijfkoppeling,

de afdichting en de pompapparatuur de juiste

specificaties en/of certificatie hebben voor de

omgeving waar zij geïnstalleerd worden.

Waar Flowserve enkel de pomp heeft geleverd is de

"Ex"-certificering alleen van toepassing op de pomp.

De partij verantwoordelijk voor de montage van de

pompinstallatie dient de koppeling, aandrijving,

afdichting en alle eventueel bijkomende apparatuur te

selecteren met het vereiste EG Certificaat/

Overeenkomstigheidsverklaring die vaststelt dat de

apparatuur geschikt is voor de omgeving waar deze

geïnstalleerd wordt.

Het vermogen van een aandrijving met variabele

frequentie regeling (VFD) kan extra verhitting van de

motor veroorzaken. Daarom dient voor pompen met

een VFD de ATEX certificatie voor de motor te

vermelden dat deze geschikt is voor situaties waar de

elektrische stroomverzorging geleverd wordt door de

VFD. Dit speciale vereiste is ook van toepassing

wanneer de VFD in een veilige omgeving gebruikt

wordt.

2.4 Markering

Een voorbeeld van een ATEX-markering voor

apparatuur wordt hieronder getoond. De werkelijke

klassificatie van de pomp is gegraveerd op het

naamplaatje.

II 2 GD c IIC 135 ºC (T4)

Apparatuur Groep

I = Mijnbouw

II = Niet-mijnbouw

Categorie

2 of M2 = Hoog beschermingsniveau

3 = Normaal beschermingsniveau

Gas en/of stof

G = Gas

D = Stof

c = Constructieveiligheid

(in overeenstemming met EN13463-5)

Gasgroep

(alleen installatiecategorie 2)

IIA - Propaan (typisch)

IIB - Ethyleen (typisch)

IIC - Waterstof (typisch)

Maximum oppervlaktetemperatuur

(Temperatuurklasse) (zie hoofdstuk 2.5)

2.5 Voorkomen van excessieve

oppervlaktetemperaturen

ZORG ER VOOR DAT DE

TEMPERATUURKLASSE VAN DE APPARATUUR

GESCHIKT IS VOOR DE GEVARENZONE

2.5.1 Temperatuur pompvloeistof

Pompen hebben een temperatuurklasse als

aangegeven in de ATEX Ex specificatie op het

naamplaatje. Deze zijn gebaseerd op een maximum

omgevingstemperatuur van 40 °C (104 °F); raadpleeg

Flowserve voor hogere omgevingstemperaturen.

De oppervlaktetemperatuur van de pomp wordt

beïnvloed door de temperatuur van de gebruikte

vloeistof. De maximum toelaatbare

vloeistoftemperatuur is afhankelijk van de

temperatuurklasse en dient de voorgeschreven

waarden in de onderstaande van toepassing zijnde

tabel niet te overschrijden.

De voorgeschreven temperaturen houden rekening

met temperatuurstijging aan de afdichtingen, lagers

en als gevolg van de minimum doorstroomsnelheid.

Maximum toegestane vloeistoftemperatuur voor

pompen die geen Magnetische Aandrijving of

Automatische Ontstekingsmantel hebben:

Temperatuur-

klasse tot

EN13463-1

T6

T5

T4

T3

T2

T1

Maximum

toegestane

oppervlaktetemperatuur

85 °C (185 °F)

100 °C (212 °F)

135 °C (275 °F)

200 °C (392 °F)

300 °C (572 °F)

450 °C (842 °F)

Maximum toegestane vloeistoftemperatuur voor

pompen met Magnetische Aandrijving of

Automatische Ontstekingsmantel:

Temperatuur-

klasse tot

EN13463-1

T6

T5

T4

T3

T2

T1

Maximum

toegestane

oppervlaktetemperatuur

85 °C (185 °F)

100 °C (212 °F)

135 °C (275 °F)

200 °C (392 °F)

300 °C (572 °F)

450 °C (842 °F)

De verantwoordelijkheid voor het aanhouden van

de voorgeschreven maximumtemperatuur berust

bij het bedieningspersoneel.

Temperatuurlimiet van de gebruikte

vloeistof (* afhankelijk van materiaal

en constructievariant - controleer

welke lager is)

Raadpleeg Flowserve

Raadpleeg Flowserve

115 °C (239 °F) *

180 °C (356 °F) *

275 °C (527 °F) *

400 °C (752 °F) *

Temperatuurlimiet van de gebruikte

vloeistof (* afhankelijk van materiaal

en constructievariant - controleer

welke lager is)

Raadpleeg Flowserve

Raadpleeg Flowserve

110 °C (230 °F) *

175 °C (347 °F) *

270 °C (518 °F) *

350 °C (662 °F) *

Page 17 of 20 flowserve.com

Page 18

ATEX- E/F/D/N - 11-09

De Temperatuur klassificatie “Tx” wordt gebruikt als

de vloeistof temperatuur varieerd en indien vereist is

dat de pomp in verschillende Potentieel Explosieve

Atmosferen gebruikt wordt c.q. kan worden. In deze

gevallen is de gebruiker er verantwoordelijk voor zorg

te dragen dat de pomp oppervlakte temperatuur de

toegestane temperatuur van de actuele locatie niet

overschrijd

2.5.2 Pompen met spie geborgde waaiers

Indien er sprake is van een explosieve atmosfeer

tijdens de installatie probeer dan niet om de

draairichting te controleren door de pomp ongevuld te

starten. Zelfs een korte looptijd kan een hoge

temperatuur veroorzaken als gevolg van contact

tussen de draaiende en stilstaande onderdelen.

2.5.3 Pompen met opgeschroefde waaiers

Probeer niet om de draairichting te controleren met

behulp van de roterende koppelingselementen/

borgpennen vanwege het risico van heftig contact

tussen de bewegende en niet-bewegende

onderdelen.

2.5.4 Pompen met mechanische afdichting

Indien er enig gevaar bestaat dat de pomp tijdens

bedrijf tegen een gesloten klep kan draaien,

waardoor hoge vloeistoftemperaturen en hoge

temperaturen van het pompoppervlak kunnen

ontstaan, wordt aangeraden dat gebruikers een

temperatuurbeveiliging monteren tegen hoge externe

oppervlaktetemperaturen.

Vermijdt mechanische, hydraulische of elektrische

overbelasting door gebruikmaking van

overbelastingsbeveiligingen of een vermogenmonitor

en voer routinematig trilling controles uit.

In een vuile of stoffige omgevingen dient men

regelmatig controles uit te voeren en de omgeving van

openingen, lagerbehuizingen en motoren te reinigen.

2.5.5 Aanvullende vereisten voor pompen met

een magnetische aandrijving

Gebruikers wordt aangeraden om een

temperatuurbeveiliging te monteren in de magnetische

aandrijflager/mantelomgeving bij het pompen van

vloeistoffen met vaste bestanddelen of stoffen die

kunnen polymeriseren of bevriezen. Op locaties zonder

bedieningspersoneel en waar een magnetische

aandrijving gebruikt wordt verdient het aanbeveling om

een trilling detectie apparatuur te monteren.

2.5.6 Aanvullende vereisten voor Pompen met

een Automatische Ontstekingsmantel

Wanneer de systeemwerking de controle van de

ontsteking niet garandeert, als gedefinieerd in de

gebruikshandleiding, en de maximum toegestane

oppervlaktetemperatuur van de T-klasse kan worden

overschreden, wordt de gebruiker aangeraden om

een temperatuurbeveiliging voor

oppervlaktetemperatuur te monteren.

Er dient een niveauregeling in de pompput te worden

geïnstalleerd om te vermijden dat het vloeistofniveau

onder het minimum toegestane niveau komt.

2.5.7 Aanvullende vereisten voor

vuilwaterpompen en verticale natte

schachtpompen met assen, voorzien van een

asbeschermpijp

De gebruiker wordt aangeraden om een

onderhoudsplan met trilling detectie apparatuur op te

zetten, of, als alternatief, dient de gebruiker een

temperatuurbeveiliging voor de

oppervlaktetemperatuur van de lagerbehuizing te

monteren om ervoor te zorgen dat de

temperatuurklasse, d.w.z. de maximum toegestane

oppervlaktetemperatuur, niet wordt overschreden.

Voor externe spoeling dient de doorstroming te

worden gecontroleerd.

2.6 Voorkomen van de opeenhoping van

explosieve mengsels

ZORG ERVOOR DAT DE POMP

VOLDOENDE GEVULD IS EN NIET DROOGLOOPT

Zorg ervoor dat de pomp en het relevante aanzuig-

en afvoerleidingsysteem geheel en voortdurend met

vloeistof gevuld is tijdens de werking van de pomp,

zodat een explosieve atmosfeer vermeden wordt.

Bovendien is het essentieel om ervoor te zorgen dat

de afdichtingskamers, reserve asafdichtingssystemen

en alle eventuele verwarming- en koelsystemen naar

behoren gevuld zijn.

Indien de werking van het systeem deze toestand

niet kan voorkomen dient men een geschikte

droogloopbeveiliging te installeren (bv. een

vloeistofdetector of een vermogenmonitor).

Om mogelijke gevaren als gevolg van de uitstoot van

vluchtige dampen of gassen in de atmosfeer te

voorkomen dient de omgeving goed geventileerd te

worden.

Page 18 of 20 flowserve.com

Page 19

ATEX- E/F/D/N - 11-09

2.7 Voorkomen van vonken

Ter voorkoming van gevaren als gevolg van

mechanisch contact dient de koppelingbescherming

vonkvrij te zijn.

Om de mogelijke gevaren te voorkomen van een

willekeurig opgewekte spanning die een vonk

veroorzaakt, dient men de aardkabel die aan de

fundatieplaat bevestigd is te gebruiken.

Vermijdt elektrostatische spanning: wrijf niet

over metaalvrije oppervlakken met een droge doek.

De koppeling dient te voldoen aan Richtlijn 94/9/EG.

2.7.1 Aanvullende vereisten voor metalen

pompen op non-metalen grondplaten

Wanneer metalen onderdelen worden gemonteerd op

een non-metalen fundatieplaat dienen ze apart

geaard te worden.

2.8 Voorkomen van lekkage

2.8.1 Pompen met mechanische afdichting

De pomp mag alleen gebruikt worden voor het

verwerken van die vloeistoffen waaraan de juiste

corrosiebestendigheid is toegekend.

Vermijdt het ophopen van vloeistof in de pomp of

daarmee verbonden leidingen door het afsluiten van

kleppen dat het optreden van gevaarlijke excessieve

druk kan veroorzaken wanneer de vloeistof verwarmd

wordt.

Het barsten van vloeistof bevattende onderdelen als

gevolg van bevriezing dient vermeden te worden door

het aftappen of beschermen van de pomp en

aanvullende systemen.

Indien er een mogelijk gevaar is voor het verlies van

een afdichtings/spervloeistof, dient de

afdichtings/spervloeistof gecontroleerd te worden.

Indien lekkage van vloeistof in de atmosfeer gevaar

op kan leveren wordt de installatie van een

vloeistofdetectiebeveiliging aangeraden.

2.8.2 Aanvullende vereisten voor een pomp met

magnetische aandrijving

Indien een bescherming groter dan Categorie 2 en

M2 vereist is dan dient voorzien te worden in een

vloeistofdetector in de lagerbehuizing/steunkop.

2.9 Onderhoud ter voorkoming van

gevaar

CORRECT ONDERHOUD IS VEREIST TER

VOORKOMING VAN POTENTIËLE GEVAREN DIE

HET RISICO VAN EEN EXLOSIE MET ZICH MEE

BRENGEN

De verantwoordelijkheid voor het opvolgen van

de onderhoudsinstructies ligt bij het

bedieningspersoneel.

Om tijdens het onderhoud potentieel explosiegevaar

te voorkomen dienen de gereedschappen en

reiniging- en schildermaterialen vonkvrij te zijn en

geen negatieve invloed te hebben op de

omgevingscondities. Indien er een risico bestaat als

gevolg van dergelijke gereedschappen of materialen,

dient het onderhoud te worden uitgevoerd in een

veilige ruimte.

Aangeraden wordt om een onderhoudsplan en

schema op te stellen dat, overeenkomstig de

bijgeleverde gebruikershandleiding, onder meer uit

de volgende werkzaamheden bestaat:

a) Alle geïnstalleerde aanvullende systemen dienen

te worden gecontroleerd om te zorgen voor een

correcte werking.

b) Pakkingbussen dienen correct te worden

afgesteld om zichtbare lekkage te geven en het

drukstuk dient concentrisch te worden uitgelijnd

ter voorkoming van excessieve temperaturen van

de pakkingbus of de pakkingdrukker.

c) Controleer pakkingen en afdichtingen op lekkage.

Het correct functioneren van de asafdichting dient

regelmatig gecontroleerd te worden.

d) Controleer het niveau van de smering van de

lager(s) en ververs de olie wanneer de bedrijfsurenteller aangeeft dat dit nodig is.

e) Controleer dat het werkgebied binnen het veilige

werkgebied van de pomp ligt.

f) Controleer op trilling, geluidsniveau en

oppervlaktetemperatuur van de lagers om de

geode werking te bevestigen.

g) Controleer of vuil en stof verwijderd is van de

omgeving van openingen, lagerbehuizingen en

motoren.

h) Controleer de uitlijning van de koppeling en lijn

deze opnieuw uit indien nodig.

Page 19 of 20 flowserve.com

Page 20

ATEX- E/F/D/N - 11-09

Your Flowserve factory contacts:

In Europe:

Flowserve Pumps

Flowserve GB Limited

Lowfield Works, Balderton

Newark, Notts NG24 3BU

United Kingdom

Telephone (24 hours) +44 1636 494 600

Sales & Admin Fax +44 1636 705 991

Repair & Service Fax +44 1636 494 833

Email newarksales@flowserve.com

In North America:

Flowserve Pump Division

15 Worthington Drive

PO Box 40, Brantford

Ontario, Canada N3T 5M5

Telephone +1 (519) 753 7381

Fax +1 (519) 753 0845

Your local Flowserve representative:

To find your local Flowserve representative please

use the Sales Support Locator System found at

www.flowserve.com

FLOWSERVE REGIONAL

SALES OFFICES:

USA and Canada

Flowserve Corporation

5215 North O’Connor Blvd.,

Suite 2300

Irving, Texas 75039-5421, USA

Telephone +1 972 443 6500

Fax +1 972 443 6800

Europe, Middle East, Africa

Worthing S.P.A.

Flowserve Corporation

Via Rossini 90/92

20033 Desio (Milan), Italy

Telephone +39 0362 6121

Fax +39 0362 303 396

Latin America and Caribbean

Flowserve Corporation

6840 Wynnwood Lane

Houston, Texas 77008, USA

Telephone +1 713 803 4434

Fax +1 713 803 4497

Asia Pacific

Flowserve Pte. Ltd

10 Tuas Loop

Singapore 637345

Telephone +65 6771 0600

Fax +65 6779 4607

Loading...

Loading...